Multi-Agent Simulation Environment for Logistics Warehouse Design Based on Self-Contained Agents

Abstract

1. Introduction

2. Related Work

- Prototypical and modifiable implementation of inter-subsystems: Current simulation environments focus on individual material-handling equipment behavior, the logistics warehouse’s inter-subsystem simulation in detail, or prototypical multi-agent simulation of partial logistics warehouse. We focused on prototypical (low development costs) and modifiable implementation of a simulation model with multiple subsystems and material-handling equipment by incorporating pre-defined messages and data structure.

- Not necessary to learn new syntax and interfaces: We only used the Python programming language’s syntax for rule and data description. In practice, developers often choose a programming language to model the target logistics warehouse from scratch. From a survey of simulation modeling [21], the largest portion of users choose this approach. One of the most significant reasons is that developers do not want to learn the new programming language’s syntax.

- Third party functions (APIs, software development kits (SDKs)) can be easily integrated into the simulation model: As long as the desired API library or SDK is usable with the Python programming language, our simulation environment can use the library without developing a designated wrapper.

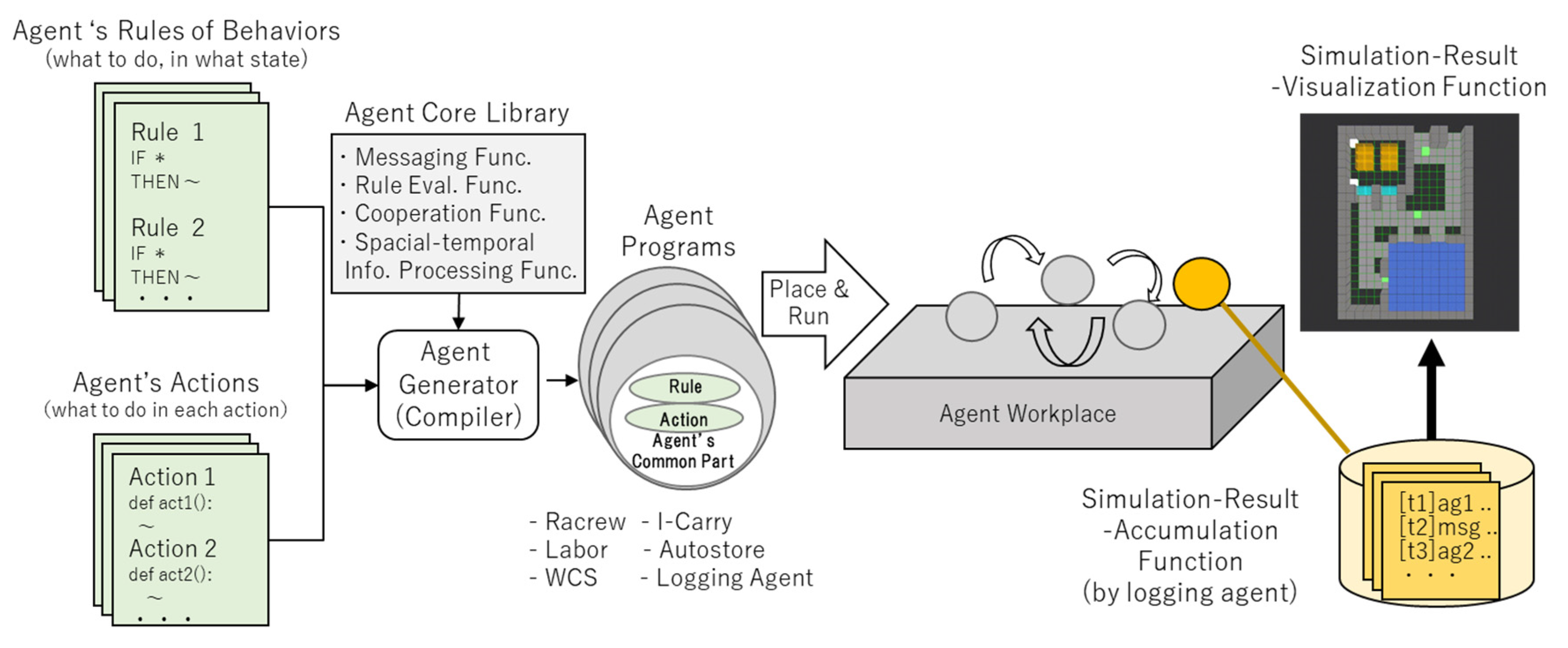

3. Proposed Multi-Agent Simulation Modeling Environment for Logistics Warehouses

3.1. Strategy of Proposed Simulation Environment

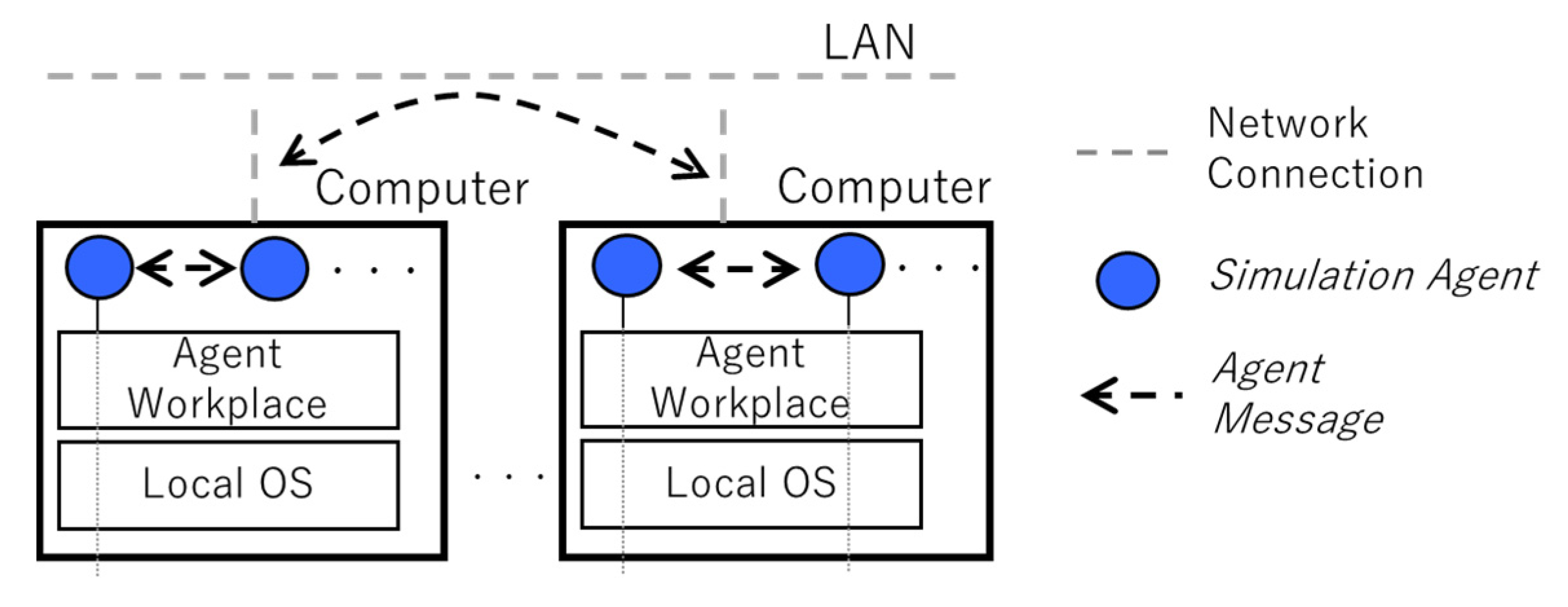

- Self-contained architecture of agents representing entities in a logistics warehouse: This architecture makes it easy for the model developer to add, replace, and modify the agents in the environment. We made each agent self-contained and individually executable without the need of installing a specific software development kit (SDK) and sharing information only with messages.

- Unified message architecture and message primitives for a logistics warehouse: To reduce the development costs of a logistics warehouse simulation model, we designed a unified architecture of agent messages and pre-defined primitives to make the description of message easier. Our simulation environment has a template of agents that has basic functionalities to process messages with the pre-defined primitives, which reduces the development costs.

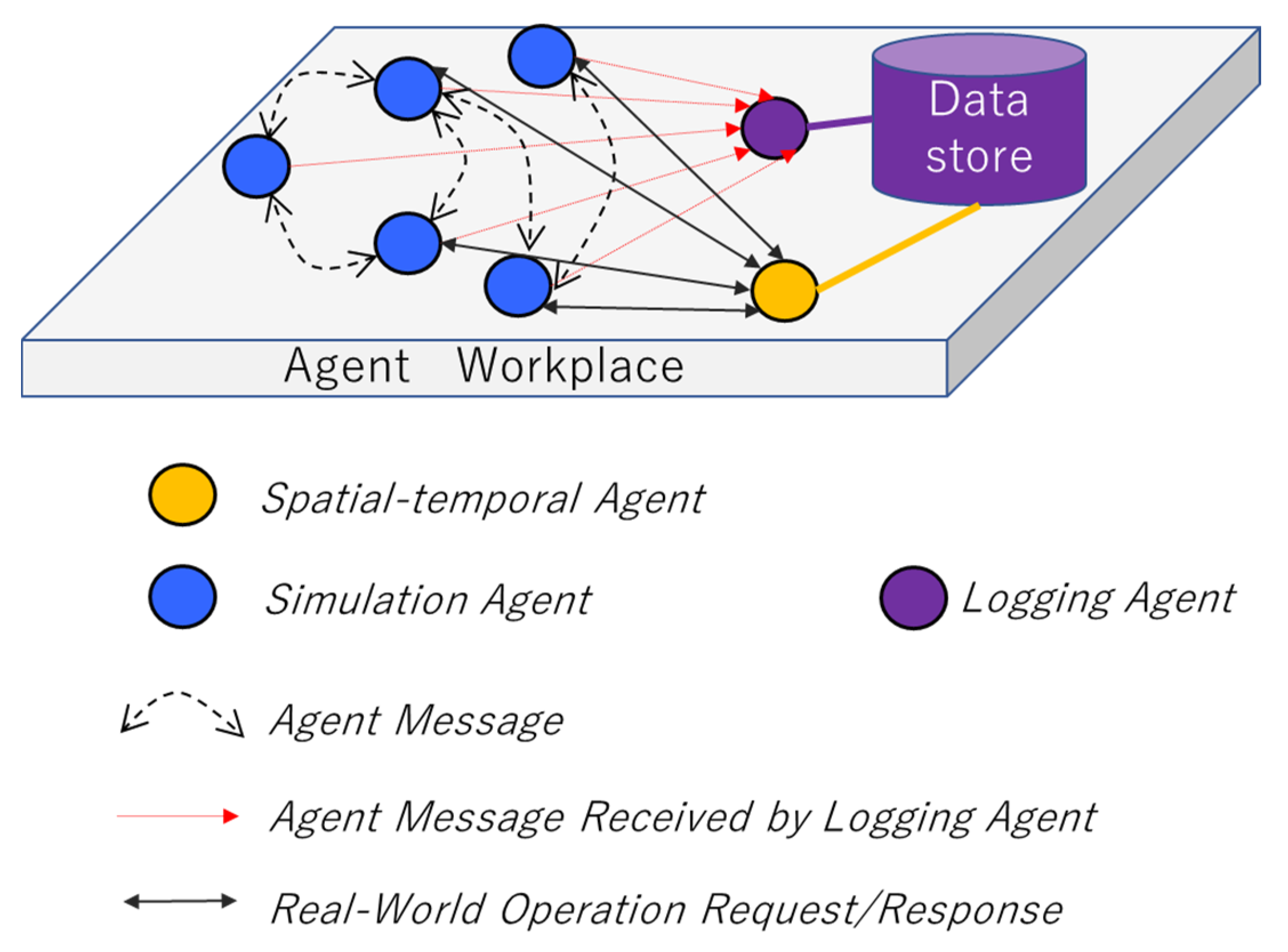

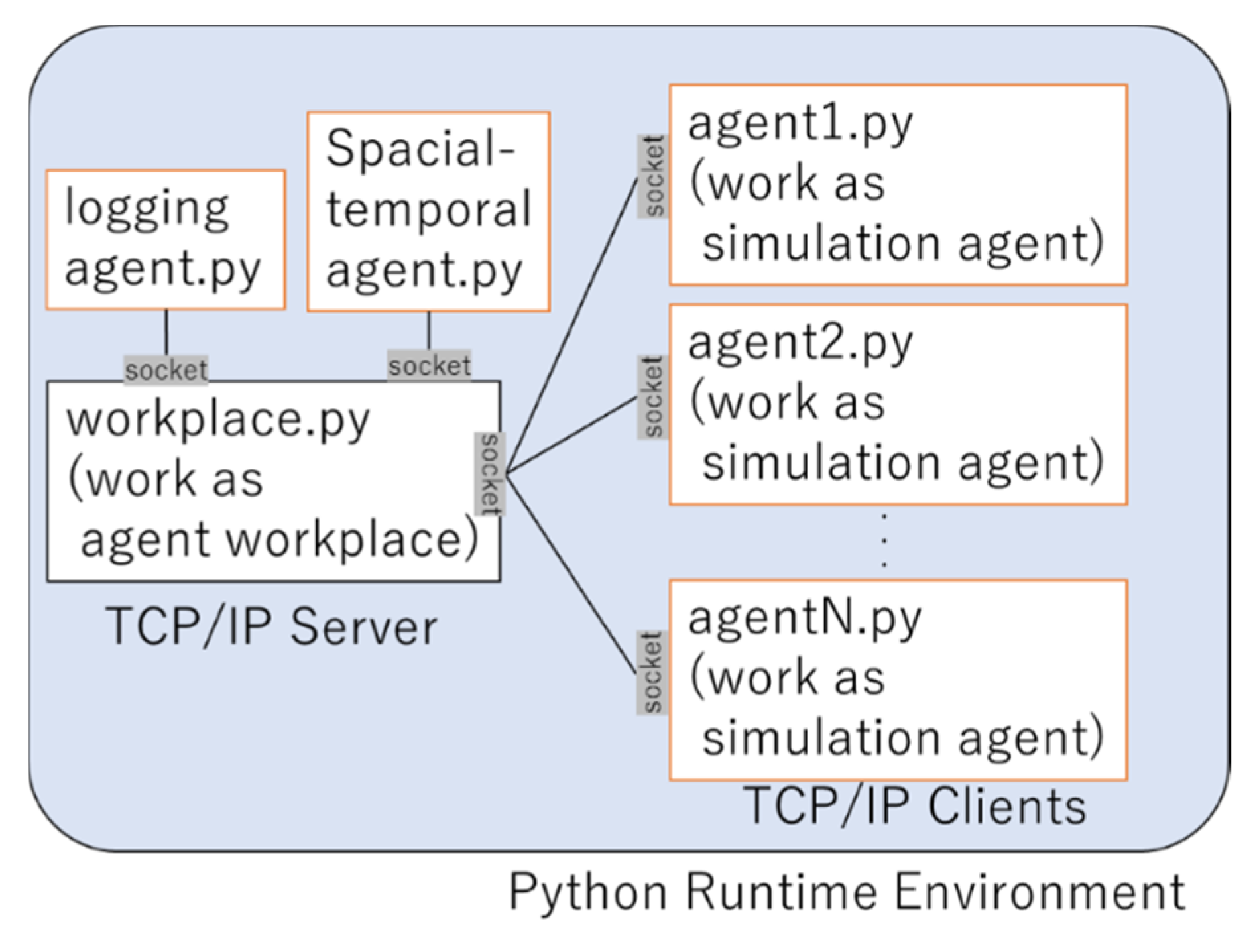

3.2. Multi-Agent Simulation Environment Architecture

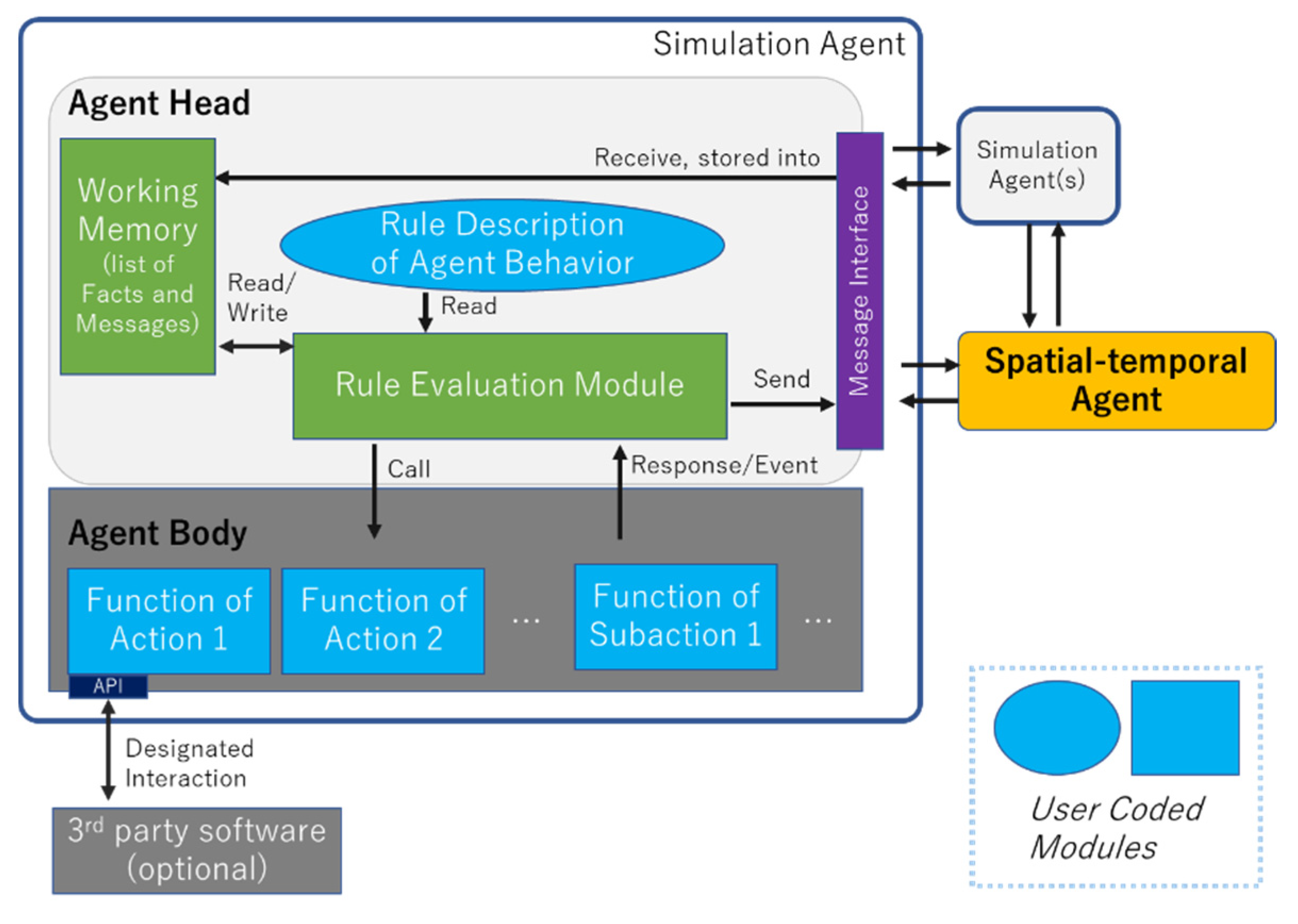

3.3. Agent Architecture

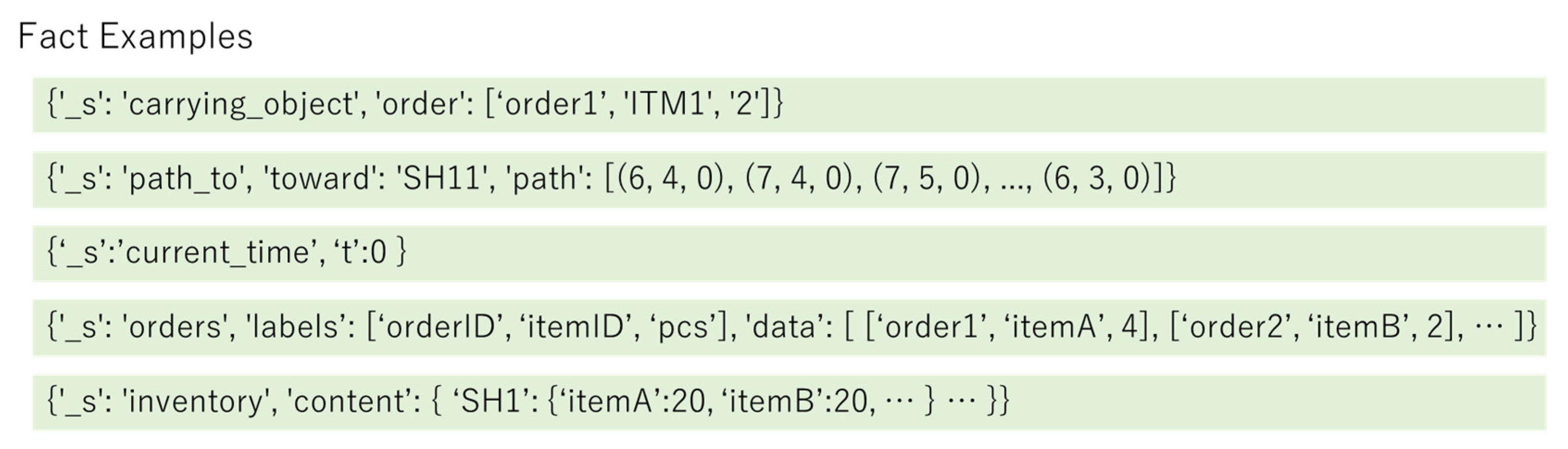

3.4. Message and Fact Architecture

- MSG1: sent from a simulation agent of the Racrew (Racrew is a registered Japanese trademark owned by Hitachi Industrial Products, Ltd.) AGV to iCarry AGV (Racrew and iCarry are AGVs for logistics warehouses, explained in detail later) to transfer the data value of the “object”. This handover primitive triggers the sender to automatically update the fact representing the carrying object in its working memory. The primitive also triggers the receiver to update the fact of carrying an object to add the handed over object data.

- MSG2: sent from the WMS to an agent of the Racrew AGV to order the AGV to carry the shelf with the ID “SH11” at the node location [6, 4, 0] to one of the available picking stations.

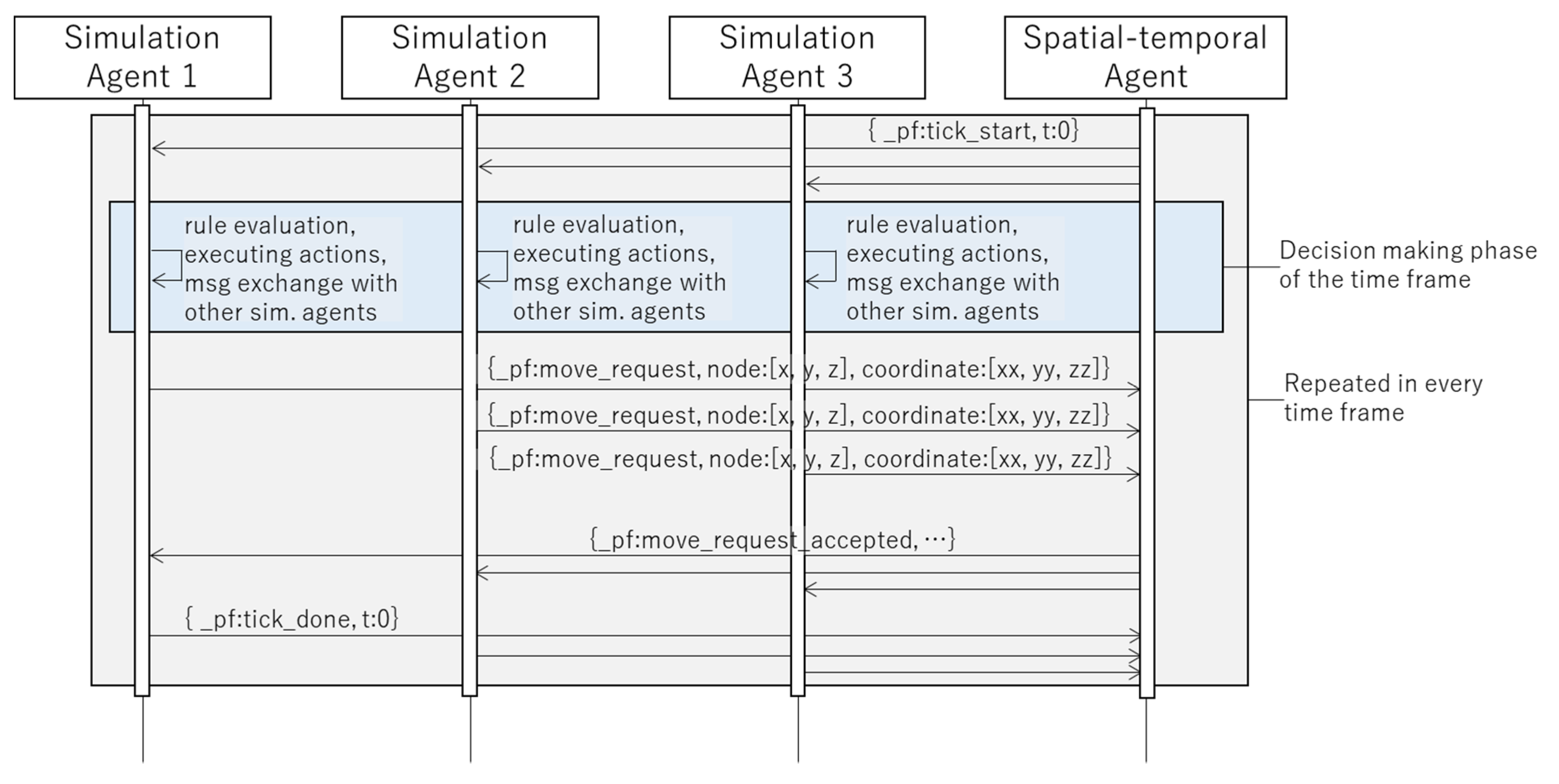

- MSG3: sent from the spatial-temporal agent to all the simulation agents to start the interaction of the next time frame (t = 10).

- MSG4: sent from a simulation agent of the Racrew AGV to the spatial-temporal agent to notify the spatial-temporal agent that there is no more information to send in this time frame (t = 10).

- MSG5: sent from a simulation agent of the iCarry AGV to the spatial-temporal agent to move to the coordinate of the values “node” and “coordinate”.

- MSG6: sent from a simulation agent of the iCarry AGV to the spatial-temporal agent to notify the spatial-temporal agent that the previously sent move_request is accepted. When this primitive is sent from the spatial-temporal agent to a simulation agent, the fact representing map information is automatically updated both in the spatial-temporal agent and simulation agent.

- MSG7: sent from a simulation agent of the iCarry AGV to the spatial-temporal agent to notify the spatial-temporal agent that the previously sent move_request is rejected. When this primitive is sent from the spatial-temporal agent to a simulation agent, the fact representing map information is automatically updated both in the spatial-temporal agent and simulation agent.

4. Prototypical Implementation of Proposed Simulation Environment

5. Experiment to Compare Development Costs

5.1. Purpose of Experiment

- (i)

- A GUI with a simulation space visualization function. Basically, there is no need to add visualization descriptions to the code.

- (ii)

- Default primitives for manipulating simulation space and objects in the grid world, which is highly compatible with warehouse simulations.

- (iii)

- A function to output graphic charts of the simulation model’s values without additional descriptions.

- First, when we outsourced the simulation model development, we only provided a description of the simulated system and the requirements of the simulation model, as well as the specifications of the inputs and outputs.

- Second, based on the requirements, we asked the software developing company to design how to implement the agents using NetLogo, i.e., how to implement the internal states and how to make them cooperate with each other.

- Third, we reviewed the presented design by the software developing company and asked them to modify the functional discrepancies to the developed model using our modeling environment, so that the functions of the material-handling equipment can be the same. We did not specify how to write the code. We ensured the validity of the experiment by asking them to write the code based on their standard method so that we did not tamper with the experimental results. In addition, we did not disclose our intention to use the outsourced model for development cost comparison.

- Finally, we checked the delivered source codes to see if there was any unfairness in comparing the development cost.

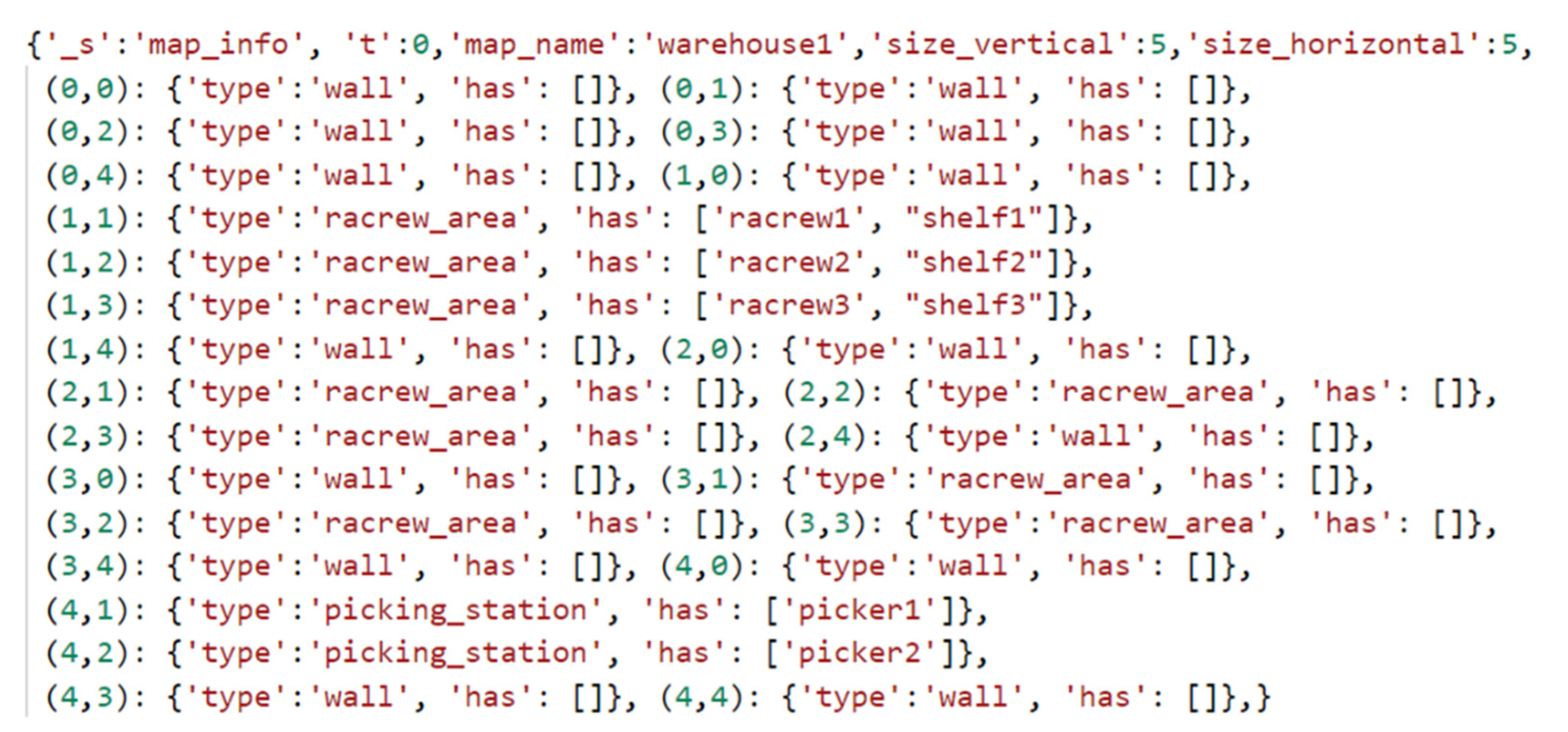

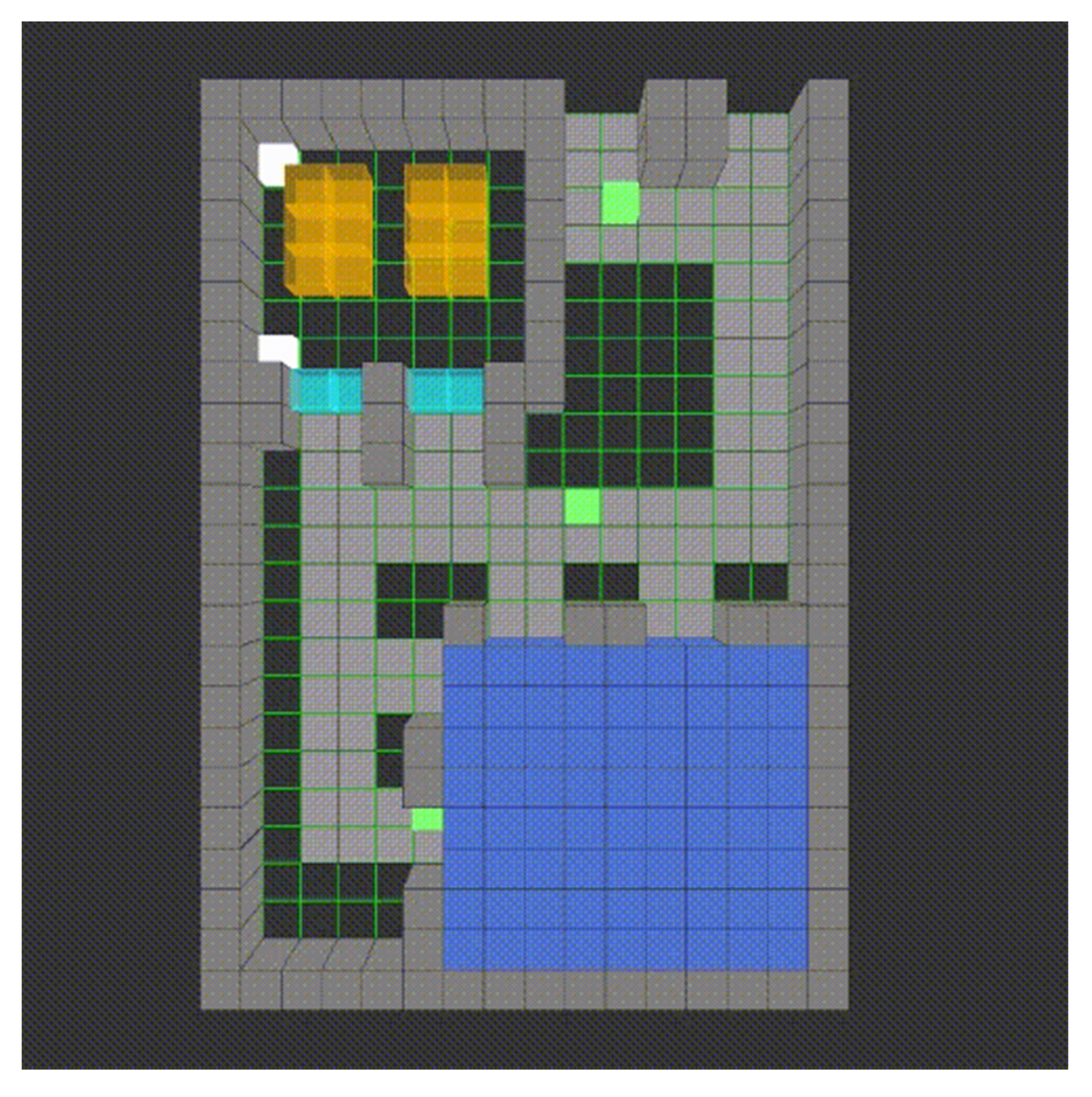

5.2. Developed Simulation Model of Logistics Warehouse with Various Robots and Material-Handling Equipment

- Racrew AGV Picking System: At the beginning of the shipping process, it is necessary to pick items specified by the customer orders from the inventory shelves. The classic configuration to pick items is that people carry a cart with them, walk to the shelf storing the desired items, pick the items from the shelf, then put the items into the sorting bucket in the cart. Finally, the cart goes through the rest of the shipping process, such as item inspection and packing. However, this way of picking is not efficient because people need to walk long distances to finish their picking tasks. Therefore, a novel automated logistics warehouse uses an AGV picking system. Instead of people walking to the shelves, AGVs carry the shelves to the people, and the people pick items from the shelves then put the items into the sorting bucket near them.

- iCarry AGV Transport System: In a logistics warehouse, it is necessary to carry items from area to area to process the logistics tasks. This AGV transport system can carry objects by having AGVs move in a pre-defined path.

- Automatic Storage System: In a logistics warehouse, storing items in a buffer is sometimes efficient because the picking task does not always finish right before the shipping time. This system stores items so that the items can be retrieved when the rest of the shipping process is ready.

- WMS: In a logistics warehouse, there is almost always a WMS that has the information of customer’s orders and record of inventory. It is also in charge of controlling the picking system regarding which items to pick, when to pick, etc.

- Racrew Agent: represents an AGV in the Racrew AGV Picking System.

- iCarry Agent: represents an AGV in the iCarry AGV Transport System.

- Picker Agent: represents a human picker in the Racrew AGV Picking System.

- AutoStorage Agent: represents an auto storage system in the simulated logistics warehouse.

- WMS Agent: represents a WMS in the simulated logistics warehouse.

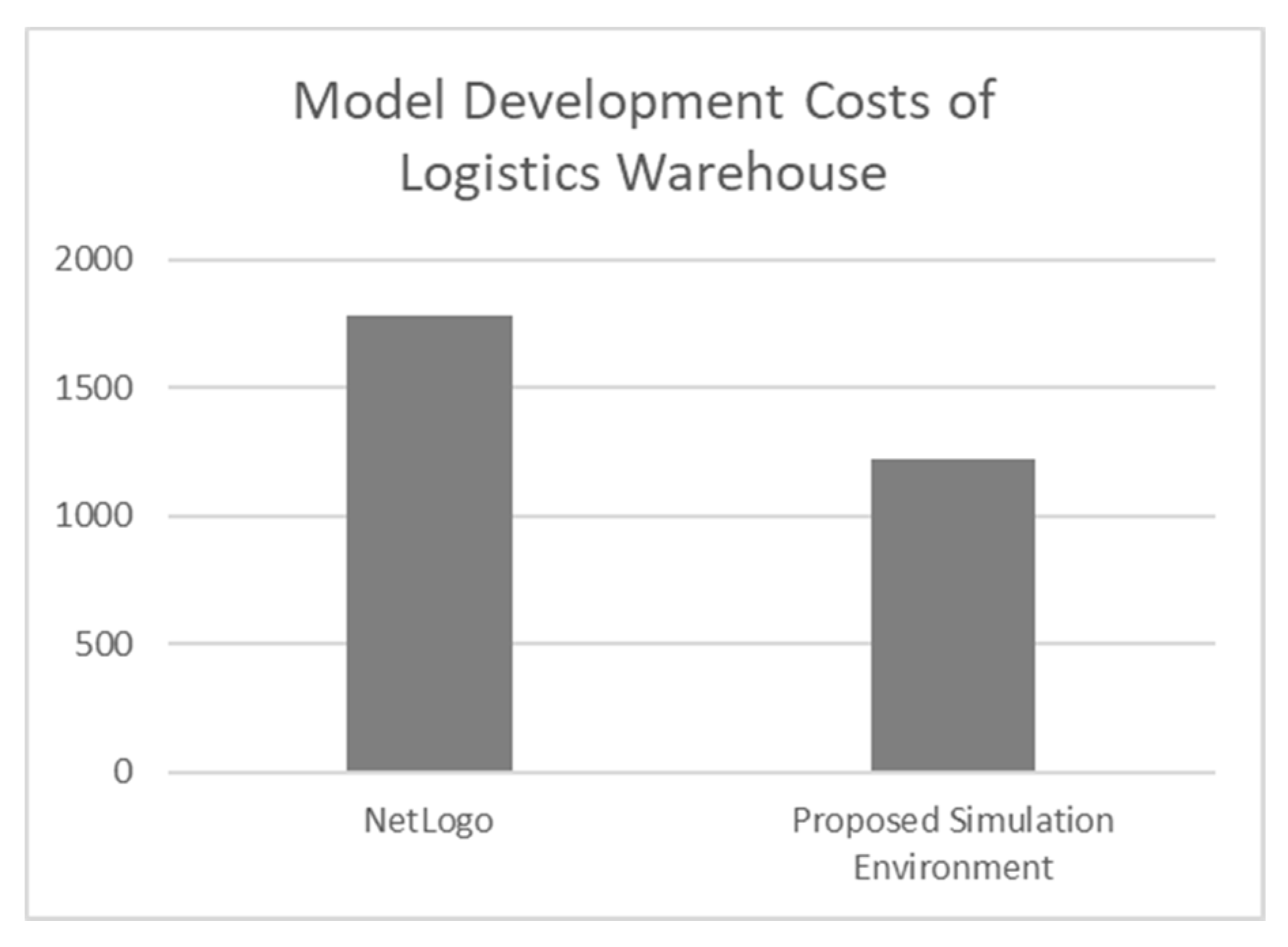

5.3. Comparison of Development Costs

6. Conclusions

- (i)

- Designed self-contained architecture of agents representing entities in a logistics warehouse.

- (ii)

- Designed unified message architecture and message primitives for logistics warehouses.

- (iii)

- Empirically compared the model development costs of logistics warehouses with a current multi-agent simulation environment and confirmed that the proposed environment reduces such costs while maintaining architectural modifiability.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Case ID | Modification Case Description | Conventional Simulation Environment | Proposed Simulation Environment | ||

|---|---|---|---|---|---|

| Required Modification Procedures | Reviewed and Modified Parts | Required Modification Procedures | Reviewed and Modified Parts | ||

| C5 | Changing the route of iCarry AGVs |

| N/A |

| N/A |

| C6 | Changing the route of Racrew AGVs |

| N/A |

| N/A |

| C7 | Changing the area of Racrew picking system |

| N/A |

| Spatial-temporal agent |

| C8 | Changing the items stored in shelves |

| N/A |

| N/A |

| C9 | Changing the area of iCarry transport system |

| N/A |

| Spatial-temporal agent |

| Case ID | Modification Case Description | Conventional Simulation Environment | Proposed Simulation Environment | ||

|---|---|---|---|---|---|

| Required Modification Procedures | Reviewed and Modified Parts | Required Modification Procedures | Reviewed and Modified Parts | ||

| C10 | Changing the number of AGVs in the iCarry transport system |

| N/A |

| N/A |

| C11 | Changing the speed of iCarry AGVs |

| N/A |

| N/A |

| C12 | Changing the number of AGVs in the Racrew picking system |

| N/A |

| N/A |

| C13 | Changing the battery charging threshold of the AGVs in Racrew picking system |

| N/A |

| N/A |

| C14 | Changing the speed of AGVs in Racrew picking system. |

| N/A |

| N/A |

| C15 | Changing the box import speed of Auto Storage System. |

| N/A |

| N/A |

References

- Hofmann, E.; Rusch, M. Industry 4.0 and the Current Status as well as Future Prospects on Logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Pokahr, A.; Braubach, L.; Sudeikat, J.; Renz, W.; Lamersdorf, W. Simulation and Implementation of Logistics Systems based on Agent Technology. In Proceedings of the Hamburg International Conference on Logistics 2008: Logistics Networks and Nodes, Hamburg, Germany, 4–5 September 2008; pp. 1–18. [Google Scholar]

- Barbosa, J.; Leitão, P. Simulation of Multi-agent Manufacturing Systems using Agent-Based Modelling Platforms. In Proceedings of the 9th IEEE International Conference on Industrial Informatics, Lisbon, Portugal, 26–29 July 2011; pp. 477–482. [Google Scholar]

- NetLogo. Available online: https://ccl.northwestern.edu/netlogo/references.shtml (accessed on 1 April 2020).

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The Industrial Internet of Things (IIoT): An Analysis Framework. Comput. Ind. 2018, 101, 1–12. [Google Scholar] [CrossRef]

- Merschformann, M.; Xie, L.; Li, H. RAWSim-O: A Simulation Framework for Robotic Mobile Fulfillment Systems. Logist. Res. 2018, 11, 1–11. [Google Scholar]

- Hazard, C.J.; Wurman, P.R.; D’Andrea, R. Alphabet Soup: A Testbed for Studying Resource Allocation in Multi-vehicle Systems. In Proceedings of the AAAI Workshop on Auction Mechanism for Robot Coordination, Boston, MA, USA, 16–17 July 2006; pp. 1–8. [Google Scholar]

- World Population Prospects 2019, United Nations. Available online: https://population.un.org/wpp/ (accessed on 24 July 2020).

- Ståhl, I. Simulation prototyping. In Proceedings of the Winter Simulation Conference, San Diego, CA, USA, 8–11 December 2002; pp. 572–579. [Google Scholar]

- Bengtsson, P.; Lassing, N.; Bosch, J.; Vliet, H. Architecture-level modifiability analysis (ALMA). J. Syst. Softw. 2004, 69, 129–147. [Google Scholar] [CrossRef]

- Luke, S.; Cioffi-Revilla, C.; Panait, L.; Sullivan, K.; Balan, G. MASON: A Multi-Agent Simulation Environment. Simul. Trans. Soc. Modeling Simul. Int. 2005, 81, 517–527. [Google Scholar] [CrossRef]

- GAMA Platform. Available online: https://www.media.mit.edu/tools/gama-platform/ (accessed on 1 July 2020).

- Artisoc4. Available online: https://mas.kke.co.jp/en/ (accessed on 1 July 2020).

- Brooks, R.J.; Tobias, A.M. Choosing the best model: Level of detail, complexity, and model performance. Math. Comput. Model. 1996, 24, 1–14. [Google Scholar] [CrossRef]

- RaLC. Available online: http://ralc.cec-ltd.co.jp/ (accessed on 1 April 2020).

- Xie, L.; Li, H.; Thieme, N. From Simulation to Real-World Robotic Mobile Fulfillment Systems. Logist. Res. 2019, 12, 9. [Google Scholar]

- Cossentino, M.; Lodato, C.; Lopes, S.; Ribino, P. Multi Agent Simulation for Decision Making in Warehouse Management. In Proceedings of the Federated Conference on Computer Science and Information Systems, Szczecin, Poland, 18–21 September 2011; pp. 611–618. [Google Scholar]

- Maka, A.; Cupek, R.; Wierzchanowski, M. Agent-based Modeling for Warehouse Logistics Systems. In Proceedings of the UKSim 13th International Conference on Modelling and Simulation, Cambridge, UK, 30 March–1 April 2011; pp. 151–155. [Google Scholar]

- Wang, Y.; Ye, S.; Yan, G. Multi-agent System Developed for the Logistics Supply Chain Coordination and Risk Management. In Proceedings of the International Conference on E-Business and E-Government, Guangzhou, China, 7–9 May 2010; pp. 3243–3246. [Google Scholar]

- Wang, Y. Flexible and Responsive Multi-agent Based Logistics Coordination Management. In Proceedings of the 2nd IEEE International Conference on Information Management and Engineering, Chengdu, China, 16–18 April 2010; pp. 43–47. [Google Scholar]

- Heath, B.; Hill, R.; Ciarallo, F. A Survey of Agent-Based Modeling Practices (January 1998 to July 2008). J. Artif. Soc. Soc. Simul. 2009, 12, 1–9. [Google Scholar]

- Bordini, R.; Hubner, J.; Wooldridge, M. Programming Multi-Agent Systems in AgentSpeak Using Jason; John Wiley & Sons, Inc.: West Sussex, UK, 2 October 2007; pp. 1–294. [Google Scholar]

- Finin, T.; Fritzson, R.; McKay, D.; McEntire, R. KQML as an Agent Communication Language. In Proceedings of the Third International Conference on Information and Knowledge Management, Gaithersburg, MD, USA, 29 November–2 December 1994; pp. 456–463. [Google Scholar]

- FIPA ACL Message Structure Specification. Available online: http://www.fipa.org/specs/fipa00061/SC00061G.html (accessed on 23 September 2020).

- Kato, T.; Takahashi, H.; Kinoshita, T. Multiagent-based Autonomic and Resilient Service Provisioning Architecture for the Internet of Things. Int. J. Comput. Sci. Netw. Secur. 2017, 17, 36–58. [Google Scholar]

| Performative. | Argument | Description |

|---|---|---|

| tick_start | ‘t’:int | Spatial-temporal agent sends this performative to start an interaction for a designated time frame. |

| tick_done | ‘from’:<AgentID> | Simulation agent sends this performative to notify spatial-temporal agent that there is no more messages to send regarding the current time frame. |

| move_request | ‘from’:<AgentID>, ‘node’: [int, int, int], ‘coordinate’: [float, float, float] | Simulation agent sends this performative to notify spatial-temporal agent where the simulation agent is assigned to move in the next time frame. |

| move_request_accepted | ‘to’:<AgentID> | Spatial-temporal agent sends this performative to notify a simulation agent that the previously sent move_request is accepted. |

| move_request_rejected | ‘to’:<AgentID> | Spatial-temporal agent sends this performative to notify a simulation agent that the previously sent move_request is rejected and it needs to stay where it is. |

| handover | ‘to’:<AgentID>, ‘object’: <ObjectData> | Simulation agent 1 sends this performative to anther simulation agent 2 to handover the object carried by agent 1 to agent 2. |

| order_carry_shelf | ‘to’:<AgentID>, ‘content’: <ShelfData> | Simulation agent 1 (WMS agent) sends this performative to another simulation agent 2 that can carry a shelf to a picking station in the AGV picking system. |

| ready | ‘to’:<AgentID> | Simulation agent 1 (agents of AGVs) sends this performative to another simulation agent 2 (WMS agent) to notify that the agent 1 is waiting for some commands. |

| pick | ‘to’:<AgentID>, ‘content’: <OrderData> | Simulation agent 1 (WMS agent) sends this performative to another simulation agent 2 (a human/robot for picking) to pick the designated items from near objects. |

| Case ID | Modification Case Description | Conventional Simulation Environment | Proposed Simulation Environment | ||||

|---|---|---|---|---|---|---|---|

| Required Modification Procedures | Reviewed and Modified Parts | LoC | Required Modification Procedures | Reviewed and Modified Parts | LoC | ||

| C1 | Replacing iCarry with another transport system |

|

| 501 |

|

| 351 |

| C2 | Replacing Racrew with another picking system |

|

| 630 |

|

| 421 |

| C3 | Replacing automatic storage with another storage system |

|

| 358 |

|

| 241 |

| C4 | Introducing a picking system in addition to Racrew picking system |

|

| 681 |

|

| 486 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kato, T.; Kamoshida, R. Multi-Agent Simulation Environment for Logistics Warehouse Design Based on Self-Contained Agents. Appl. Sci. 2020, 10, 7552. https://doi.org/10.3390/app10217552

Kato T, Kamoshida R. Multi-Agent Simulation Environment for Logistics Warehouse Design Based on Self-Contained Agents. Applied Sciences. 2020; 10(21):7552. https://doi.org/10.3390/app10217552

Chicago/Turabian StyleKato, Takumi, and Ryota Kamoshida. 2020. "Multi-Agent Simulation Environment for Logistics Warehouse Design Based on Self-Contained Agents" Applied Sciences 10, no. 21: 7552. https://doi.org/10.3390/app10217552

APA StyleKato, T., & Kamoshida, R. (2020). Multi-Agent Simulation Environment for Logistics Warehouse Design Based on Self-Contained Agents. Applied Sciences, 10(21), 7552. https://doi.org/10.3390/app10217552