Special Equipment Safety Supervision System Architecture Based on Blockchain Technology

Abstract

Featured Application

Abstract

1. Introduction

- 1.

- Different from other research in this field that focuses on safety factor analysis, this article focuses on improving the supervision efficiency by optimizing the supervision system and changing the supervision mechanism.

- 2.

- Taking “transaction” as “information update”, we use the smart contract of blockchain to record the work information of supervision participants. In this way, we can ensure that there is sufficient and authentic data to be relied on when tracing accident responsibility.

- 3.

- The expansibility of the system is considered in the design, and the overall design idea of the system architecture can be used for reference by other safety supervision fields.

2. Requirement Analysis

2.1. Role Analysis

2.1.1. Equipment Users

2.1.2. Inspection Agencies

2.1.3. Primary Supervisors

2.1.4. Supervisory Agencies

2.2. Current Requirements

2.2.1. Efficient Accident Responsibility Tracing

- The equipment users collude with the inspection agency to conceal the safety risks of the equipment.

- In order to reduce maintenance costs, potential safety risks are covered by equipment users in safety management.

- The inspection agencies are slack in inspection work.

- Corruption between the primary supervisors and those they supervise.

2.2.2. More Efficient Data Sharing

2.2.3. More Transparent Supervision Information

2.2.4. Integrating More Functions into the Safety Supervision System

3. Methods

3.1. Using Blockchain Technology

3.2. Blockchain Platform Selection

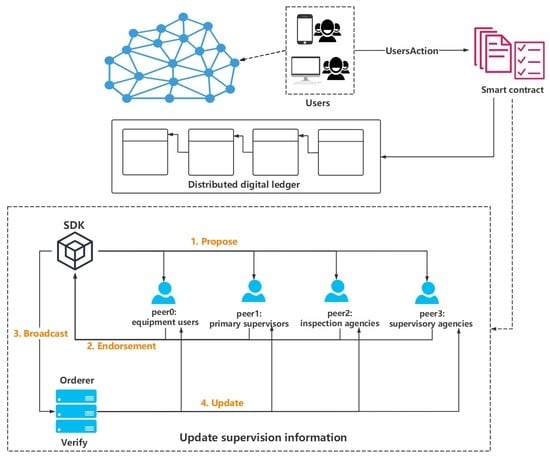

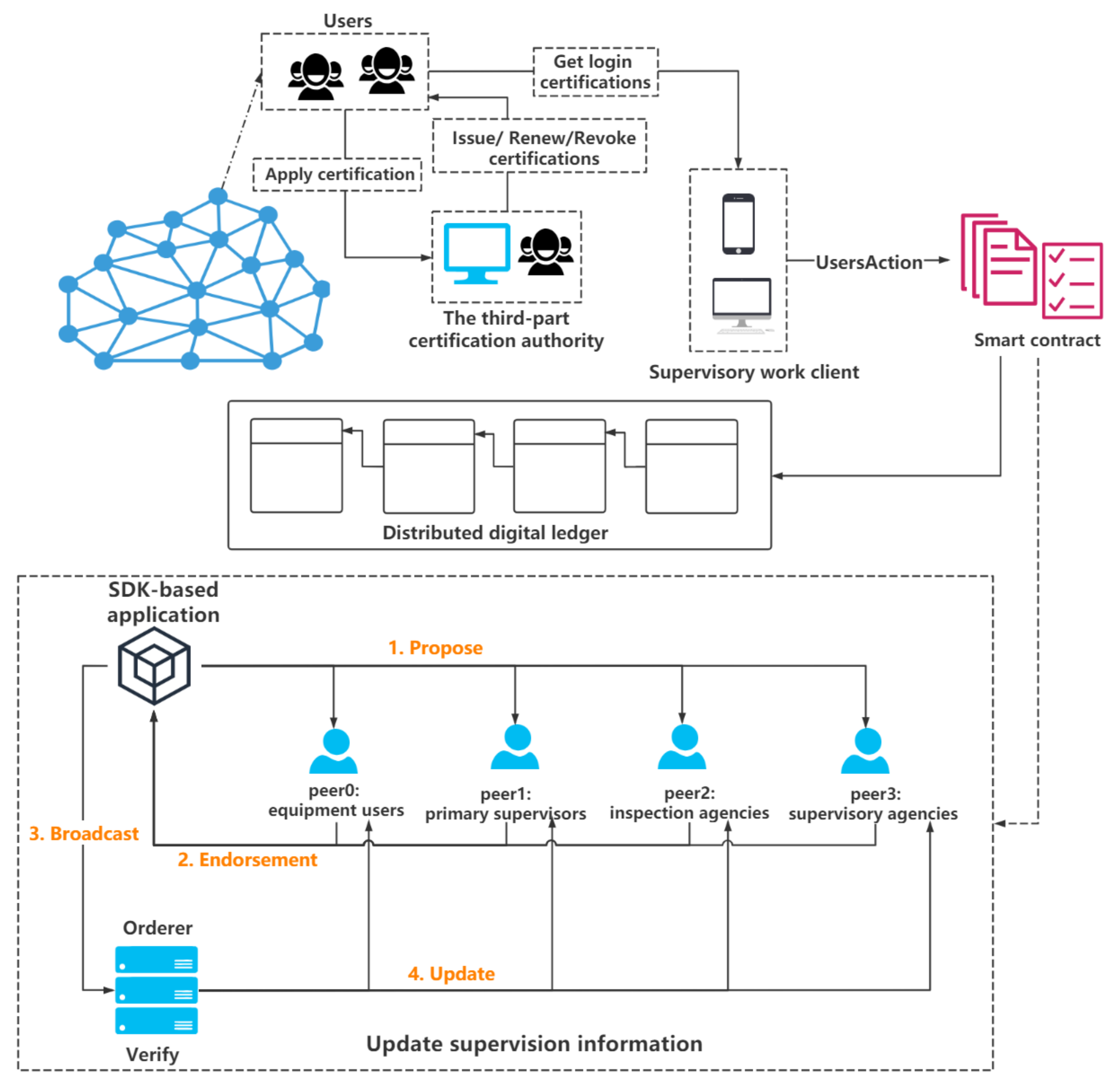

4. Blockchain System Architecture for Safety Supervision of Special Equipment

4.1. System Users

4.2. System Design

4.3. System Function

4.3.1. Recording Safety Management Information

4.3.2. Recording Inspection Information

4.3.3. Recording Sampling Check Information

4.3.4. Accident Responsibility Tracing

5. Discussion

5.1. The Ability to Complete the Task Objectives

5.2. The Feasibility of System Application and Promotion

5.3. The Expansibility of the System Function

- Add the information, before the equipment is put into use, to the traceability system, including the information of primary material supply, product processing, transportation, and installation.

- For elevator, amusement facilities, and other public service equipment, public supervision interface should be developed so that the public can query the maintenance information and safe condition of the equipment through QR code.

5.4. The Shortcomings and Solutions

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ding, R.; Zhang, Y. Analysis on safety risk and structure relations of special equipment based on the perspective of supervision. In Proceedings of the 2017 International Conference on Service Systems and Service Management, Dalian, China, 16–18 June 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Lan, Q.; Xiao, Y.; Wang, P. The Current Situation and Development Countermeasure for China Special Equipment Safety Supervision. J. US-China Public Adm. 2017, 14, 46–56. [Google Scholar]

- State Administration for Market Regulation. The Report about Safety Situation of Special Equipment in China in 2019; State Administration for Market Regulation: Beijing, China, 2020. Available online: http://www.samr.gov.cn/tzsbj/tzgg/zjwh/202004/t20200416_314295.html (accessed on 16 April 2020).

- Jiang, S. Study on Safety Classification Supervision of Special Equipment Users Based on Risk. Ph.D. Thesis, Department of Management Science and Engineering, China University of Mining and Technology, Beijing, China, 2013. [Google Scholar]

- State Administration for Market Regulation. The Report about Safety Situation of Special Equipment in China in 2018; State Administration for Market Regulation: Beijing, China, 2019. Available online: http://www.samr.gov.cn/tzsbj/gzdt/201904/t20190404_292592.html (accessed on 19 November 2019).

- State Administration for Market Regulation. The Report about Safety Situation of Special Equipment in China in 2017; State Administration for Market Regulation: Beijing, China, 2018. Available online: https://www.sohu.com/a/229317479_468648 (accessed on 24 April 2018).

- State Administration for Market Regulation. The Report about Safety Situation of Special Equipment in China in 2016; State Administration for Market Regulation: Beijing, China, 2017. Available online: http://www.samr.gov.cn/tzsbj/tzgg/zjwh/201704/P020190216455423723930.doc (accessed on 10 April 2017).

- State Administration for Market Regulation. The Report about Safety Situation of Special Equipment in China in 2015; State Administration for Market Regulation: Beijing, China, 2016. Available online: http://www.samr.gov.cn/tzsbj/tzgg/zjwh/201604/t20160405_283556.html (accessed on 5 April 2016).

- Shao, L. Research on Safety Supervision of Special Equipment in China. Master’s Thesis, Department of Public Administration, Jilin University, Changchun, China, 2014. [Google Scholar]

- Ølnes, S.; Ubacht, J.; Janssen, M. Blockchain in government: Benefits and implications of distributed ledger technology for information sharing. Gov. Inf. Q. 2017, 34, 355–364. [Google Scholar] [CrossRef]

- Natarajan, H.; Krause, S.; Gradstein, H. Distributed Ledger Technology and Blockchain; World Bank Group: Washington, DC, USA, 2017; Note No. 1; Available online: https://elibrary.worldbank.org/doi/abs/10.1596/29053 (accessed on 15 March 2018).

- Mao, D.; Wang, F.; Hao, Z.; Li, H. Credit Evaluation System Based on Blockchain for Multiple Stakeholders in the Food Supply Chain. Int. J. Environ. Res. Public Health 2018, 15, 1627. [Google Scholar] [CrossRef] [PubMed]

- Adriaan, L.; Shila, D.M. Blockchain for Distributed Systems Security: Private Blockchain Configurations for Improved IoT Security; John Wiley & Sons: Hoboken, NJ, USA, 2019; pp. 253–274. [Google Scholar]

- Zhang, G.-M.; Qiu, C.-L.; Li, X.-D.; Zhu, W. The Risk Assessment Model of Special Equipment Based on F-AHP and ANN. In Proceedings of the 2008 Fourth International Conference on Natural Computation, Jinan, China, 18–20 October 2008; IEEE: Piscataway, NJ, USA, 2008. [Google Scholar]

- Men, Z.; Zhang, Y. Risk assessment of special equipment. J. Saf. Sci. Technol. 2006, 2, 92–94. [Google Scholar]

- Zeng, Z.; Luo, Y.; Yang, Y.; Zhang, Y. Identification and analysis of special equipment’s use-related key risk factors suitable for supervision. J. China. Saf. Sci. 2014, 24, 157–163. [Google Scholar]

- Zhang, J.; Li, H.; Liang, X. The Analysis of Special Equipment Accident Factor Based on Rough Set. In Proceedings of the 21st International Conference on Industrial Engineering and Engineering Management 2014; Atlantis Press: Paris, France, 2015. [Google Scholar]

- Yao, X.; Lan, Q.; Wang, P. Initial Analysis on the Construction of Smart Governance System for Special Equipment Safety. In Proceedings of the 2017 International Conference on Smart City and Systems Engineering (ICSCSE), Changsha, China, 11–12 November 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Christian, C. Architecture of the hyperledger blockchain fabric. Workshop Distrib. Cryptocurrencies Consens. Ledgers 2016, 310, 15718952. [Google Scholar]

- Ge, L.; Brewster, C.; Spek, J.; Smeenk, A.; Top, J.; Van Diepen, F.; Klaase, B.; Graumans, C.; De Wildt, M.D.R. Blockchain for Agriculture and Food: Findings from the Pilot Study; Wageningen Economic Research, Wageningen University & Research: Wageningen, The Netherlands, 2017. [Google Scholar]

- Bumblauskas, D.; Mann, A.; Dugan, B.; Rittmer, J. A blockchain use case in food distribution: Do you know where your food has been? Int. J. Inf. Manag. 2020, 52, 102008. [Google Scholar] [CrossRef]

- Lucena, P.; Binotto, A.P.D.; Momo, F.D.S.; Kim, H. A case study for grain quality assurance tracking based on a Blockchain business network. arXiv 2018, arXiv:1803.07877. [Google Scholar]

- Liu, Q.; Guan, Q.; Yang, X.; Zhu, H.; Green, G.; Yin, S. Education-Industry Cooperative System Based on Blockchain. In Proceedings of the 2018 1st IEEE International Conference on Hot Information-Centric Networking (HotICN), Shenzhen, China, 15–17 August 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Wang, S.; Taha, A.F.; Wang, J.; Kvaternik, K.; Hahn, A. Energy crowdsourcing and peer-to-peer energy trading in blockchain-enabled smart grids. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 1612–1623. [Google Scholar] [CrossRef]

- Kodali, R.K.; Yerroju, S.; Yogi, B.Y.K. Blockchain Based Energy Trading. In Proceedings of the TENCON 2018–2018 IEEE Region 10 Conference, Jeju, Korea, 28–31 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1778–1783. [Google Scholar]

- Seungeun, K.; Kim, D. Design of an innovative blood cold chain management system using blockchain technologies. ICIC Express Lett. B Appl. Int. J. Res. Surv. 2018, 9, 1067–1073. [Google Scholar]

- Bryatov, S.R.; Borodinov, A.A. Blockchain technology in the pharmaceutical supply chain: Researching a business model based on Hyperledger Fabric. In Proceedings of the International Conference on Information Technology and Nanotechnology (ITNT), Samara, Russia, 21–24 May 2019. [Google Scholar]

- Ariffin, N.; Ismail, A.Z. The Design and Implementation of Trade Finance Application based on Hyperledger Fabric Permissioned Blockchain Platform. In Proceedings of the 2019 International Seminar on Research of Information Technology and Intelligent Systems (ISRITI), Yogyakarta, Indonesia, 5–6 December 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Ma, C.; Kong, X.; Lan, Q.; Zhou, Z. The privacy protection mechanism of Hyperledger Fabric and its application in supply chain finance. Cybersecurity 2019, 2, 1–9. [Google Scholar] [CrossRef]

- Lidong, N.; Kai, W. Research on Safety Supervision Model of Shanxi Group Coal Enterprises. Procedia Eng. 2012, 43, 499–505. [Google Scholar] [CrossRef]

- Liu, Q.; Dou, F.; Meng, X. Building risk precontrol management systems for safety in China’s underground coal mines. Resour. Policy 2020, 101631. [Google Scholar] [CrossRef]

- Chen, H.; Chen, F.; Zhu, D.; Qi, H.; Long, R. Burnout in Chinese coal mine safety supervision. Energy Policy 2015, 85, 22–31. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, G.; Zhao, Z.; Huang, Z.; Li, H.; Yang, J. Discussion on application of IOT technology in coal mine safety supervision. Procedia Eng. 2012, 43, 233–237. [Google Scholar]

- Reniers, G.; Ale, B.; Dullaert, W.E.; Soudan, K. Designing continuous safety improvement within chemical industrial areas. Saf. Sci. 2009, 47, 578–590. [Google Scholar] [CrossRef]

- Bellamy, L.J.; Geyer, T.; Wilkinson, J. Development of a functional model which integrates human factors, safety management systems and wider organisational issues. Saf. Sci. 2008, 46, 461–492. [Google Scholar] [CrossRef]

- McDonald, N.; Corrigan, S.; Daly, C.; Cromie, S. Safety management systems and safety culture in aircraft maintenance organisations. Saf. Sci. 2000, 34, 151–176. [Google Scholar] [CrossRef]

- Kong, J. Discussion on Safety Management Mode of Special Equipment. Master’s Thesis, Department of Public Administration, Nanchang University, Nanchang, China, 2010. [Google Scholar]

- Liu, S. Analysis on the Reform of Special Equipment Inspection System. J. Macro Qual. Res. 2013, 2, 29–35. [Google Scholar]

- Liang, X.; Wang, X.; Wang, F.; Zhang, J. Graded and Classified Safety Management for Elevator Users Based on the Coordination Theory. In Proceedings of the Eighth International Conference on Management Science and Engineering Management; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Hao, S.; Jiang, S.; Ding, R. Research on Classified Regulations of Risk-oriented Special Equipment Users. Ind. Saf. Environ. Prot. 2013, 39, 31–33. [Google Scholar]

- China Quality Daily. Special Equipment Accident Report and Investigation Regulation. 20 November 2019. Available online: http://m.cqn.com.cn/zj/content/2019-11/20/content_7800031.htm (accessed on 19 October 2020).

- Yao, J.; Hu, L.; Wu, S. Application design of special equipment traceability system. China Equip. Eng. 2019, 21, 167–168. [Google Scholar]

- Xu, P. Research on supervision issues under the background of socialization of special equipment inspection. Master’s Thesis, Department of Public Administration, Shandong Normal University, Jinan, Shandong, China, 2018. [Google Scholar]

- State Administration for Market Regulation. Report on the Management Regulation of Special Equipment Inspection Agencies; State Administration for Market Regulation: Beijing, China, 2003. Available online: http://www.chinalawedu.com/falvfagui/fg22016/42137.shtml (accessed on 8 August 2003).

- Wang, R. Building a comprehensive information management system for special equipment inspection institutions. China Spec. Equip. Saf. 2006, 22, 2–6. [Google Scholar]

- Ruan, H. Study on the Government Supervision of Special Equipment Safety in M City. Master’s Thesis, Department of Public Administration, South China University of Technology, Guangzhou, China, 2014. [Google Scholar]

- Cheng, X.; Zhou, S. Data management of special equipment safety supervision system. Qual. Technol. Superv. Res. 2019, 64, 55–57. [Google Scholar]

- Farshidi, S.; Jansen, S.; Espana, S.; Verkleij, J. Decision Support for Blockchain Platform Selection: Three Industry Case Studies. IEEE Trans. Eng. Manag. 2020, 76, 1109–1128. [Google Scholar] [CrossRef]

- Verkleij, J.R.Q. A Decision Support System for Blockchain Platform Selection. Master’s Thesis, Department of Information and Communication Sciences, Utrecht University, Utrecht, The Netherlands, 2018. [Google Scholar]

- Androulaki, E.; Barger, A.; Bortnikov, V.; Cachin, C.; Christidis, K.; De Caro, A.; Enyeart, D.; Ferris, C.; Laventman, G.; Manevich, Y.; et al. Hyperledger fabric: A distributed operating system for permissioned blockchains. In Proceedings of the Thirteenth EuroSys Conference, Porto, Portugal, 23–26 April 2018. [Google Scholar]

- State Administration for Market Regulation. Special Equipment Safety Supervision Regulations; State Administration for Market Regulation: Beijing, China, 2008. Available online: http://www.gov.cn/zhengce/content/2008-03/28/content_4470.htm (accessed on 3 August 2008).

| Requirements | Related Supervision Problems | Reference Source |

|---|---|---|

| Efficient accident responsibility tracing | The primary supervisors become scapegoats after the accident; The primary supervisor’s fatigue and inefficiency; The trust crisis among various roles in the supervision system; The equipment users collude with the inspection agency to conceal safety risks of the equipment; Potential safety risks are covered by equipment users in safety management; The inspection agencies are slack in inspection work; The corruption between the primary supervisor and those they supervise | [43] |

| More efficient data sharing | Delayed and high technical requirements of data sharing Equipment user’s distrust about inspection results | [45] |

| More transparent supervision information | The supervision information is seriously interfered with by interpersonal relationships, resulting in low supervision efficiency | [46] |

| Integrating more functions into the safety supervision system | The work of license approval is inefficient | [47] |

| Features of Hyperledger Fabric | Corresponding Requirements and Technical Features of Safety Supervision of Special Equipment |

|---|---|

| Permissioned and modular architecture | Authorization for participants in supervision work, integrating more functions into the safety supervision system |

| Queryable data—supporting multiple query methods, and event hooks to integrate data into your preferred database or analytics engine. | Efficient accident responsibility tracing |

| Lower latency of confirmation | More efficient supervision and data sharing |

| Supporting rolling upgrades and asymmetric version | Expansibility, new requirements in the future |

| Open smart contract model—flexibility to support various solution and data models (account model, UTXO model, structured data, unstructured data, etc.) | Supporting diversified supervision information records |

| Data privacy—complete transaction isolation using “channels”, or share private data on a need-to-know basis using private data “collections” | Keeping data safe, supporting the independent supervision of each equipment and the classified supervision |

| Multi-language smart contract support: Go, Java, Javascript | More suitable developers, lower development threshold |

| Governance and versioning of smart contracts | Flexible and efficient supervision information records |

| Inspection Items | Results | Remarks |

|---|---|---|

| Technical files | Pass/Fail | Describe the reason, if Fail |

| Operator certificates | Pass/Fail | Describe the reason, if Fail |

| Infrastructure | Pass/Fail | Describe the reason, if Fail |

| Cabs | Pass/Fail | Describe the reason, if Fail |

| Cages | Pass/Fail | Describe the reason, if Fail |

| Metal structures | Pass/Fail | Describe the reason, if Fail |

| Wire ropes and pulleys | Pass/Fail | Describe the reason, if Fail |

| Transmission systems | Pass/Fail | Describe the reason, if Fail |

| Electrical system | Pass/Fail | Describe the reason, if Fail |

| Safety system | Pass/Fail | Describe the reason, if Fail |

| Load tests | Pass/Fail | Describe the reason, if Fail |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Z.; Zhou, K.; Gao, R.; Gao, K. Special Equipment Safety Supervision System Architecture Based on Blockchain Technology. Appl. Sci. 2020, 10, 7344. https://doi.org/10.3390/app10207344

Liang Z, Zhou K, Gao R, Gao K. Special Equipment Safety Supervision System Architecture Based on Blockchain Technology. Applied Sciences. 2020; 10(20):7344. https://doi.org/10.3390/app10207344

Chicago/Turabian StyleLiang, Zhipeng, Keping Zhou, Rugao Gao, and Kaixin Gao. 2020. "Special Equipment Safety Supervision System Architecture Based on Blockchain Technology" Applied Sciences 10, no. 20: 7344. https://doi.org/10.3390/app10207344

APA StyleLiang, Z., Zhou, K., Gao, R., & Gao, K. (2020). Special Equipment Safety Supervision System Architecture Based on Blockchain Technology. Applied Sciences, 10(20), 7344. https://doi.org/10.3390/app10207344