Assessment of Appropriate Experimental Parameters for Studying the Kaiser Effect of Rock

Abstract

1. Introduction

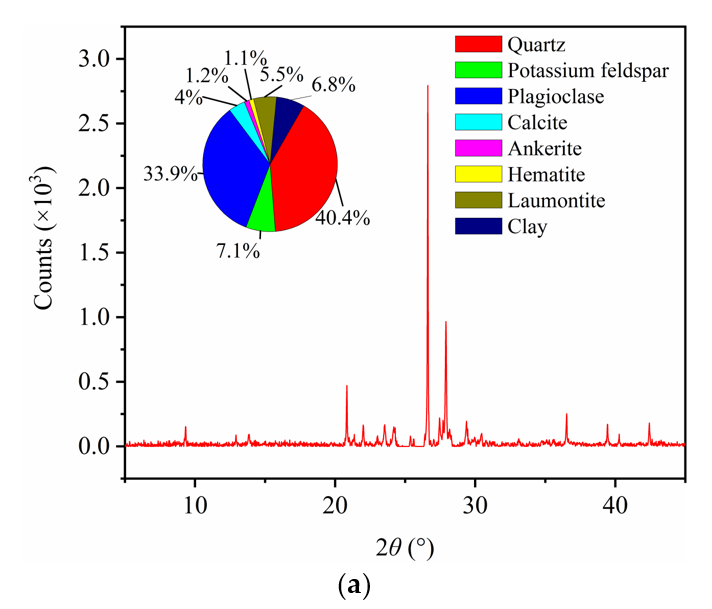

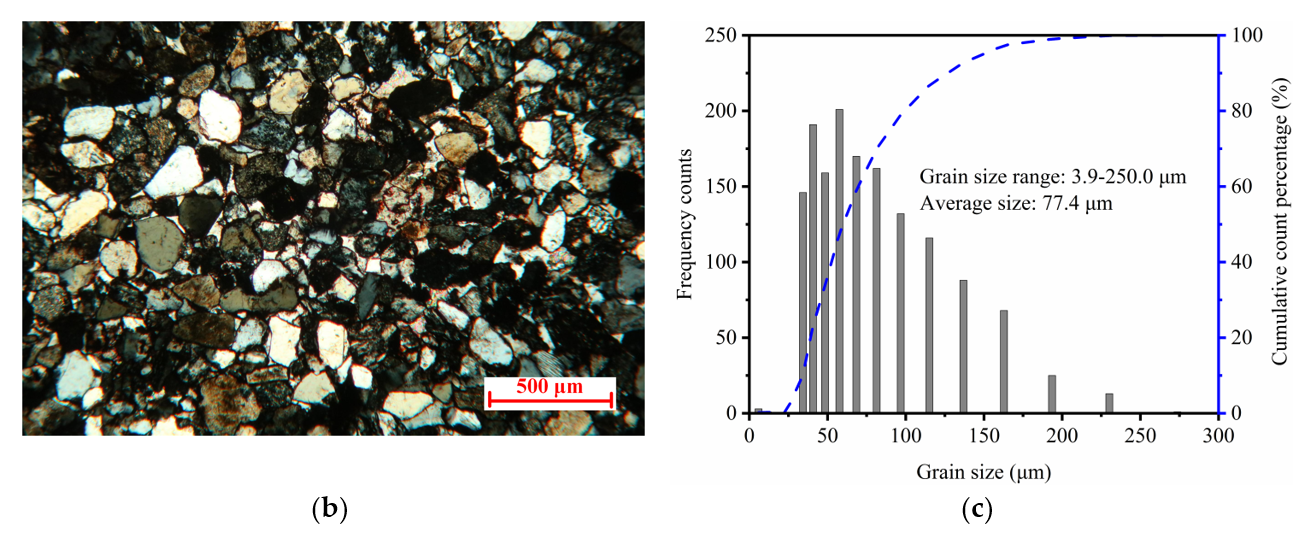

2. Experiments

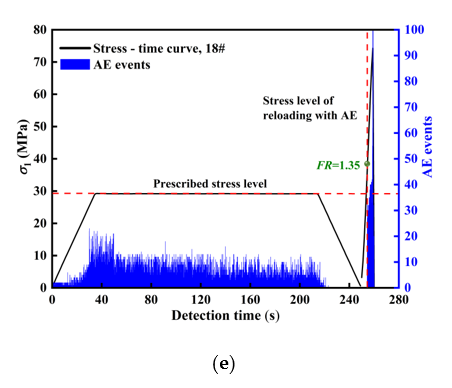

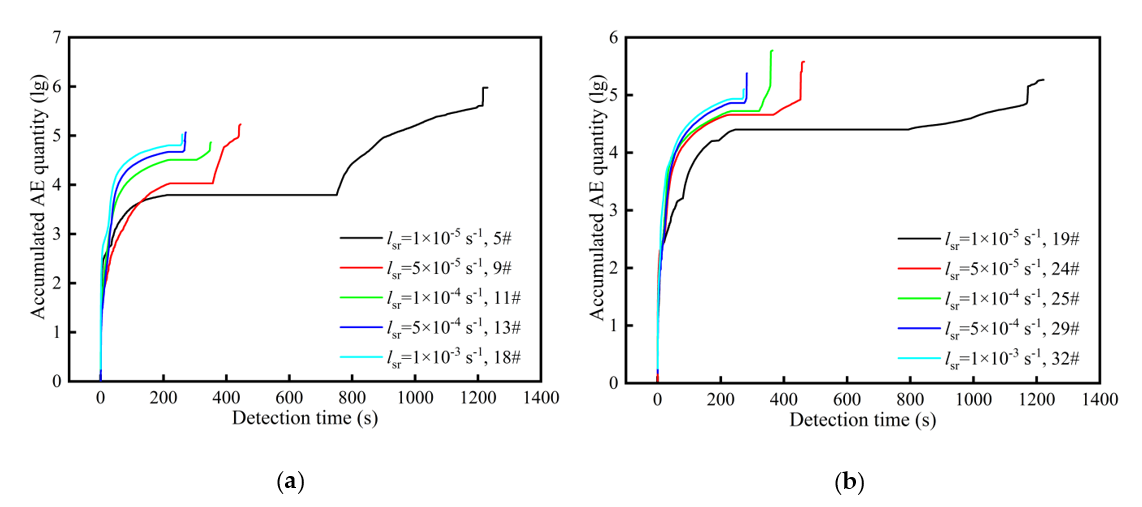

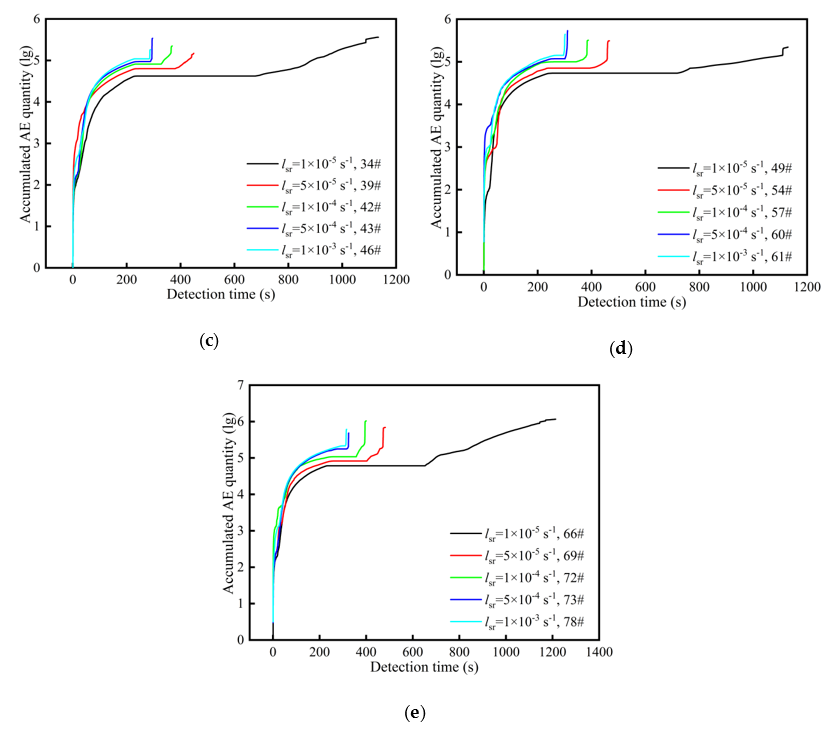

3. Results

4. Discussion

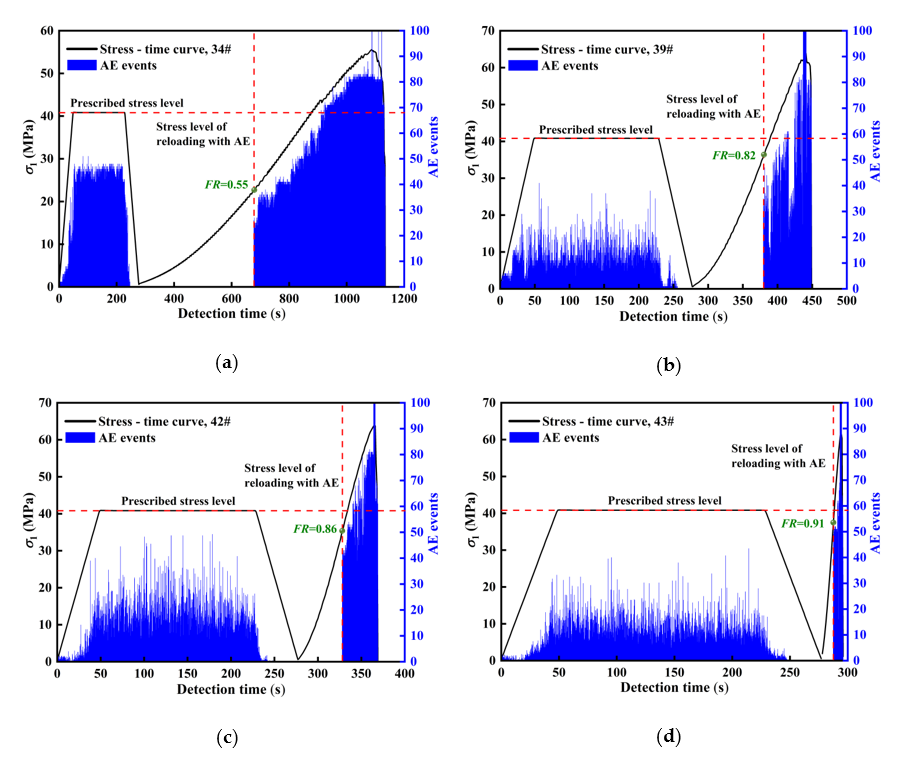

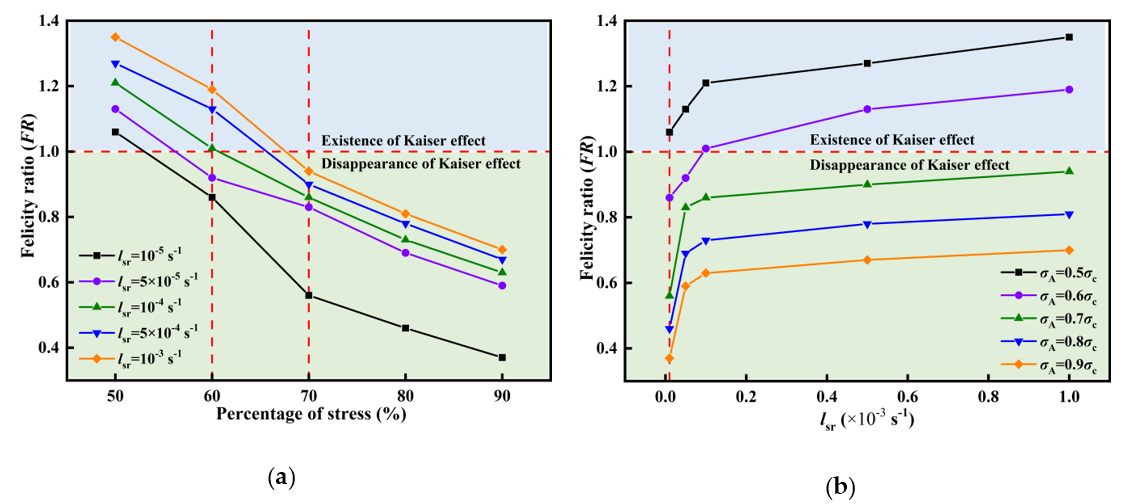

4.1. Dependence of the Kaiser Effect on the Prescribed Stress

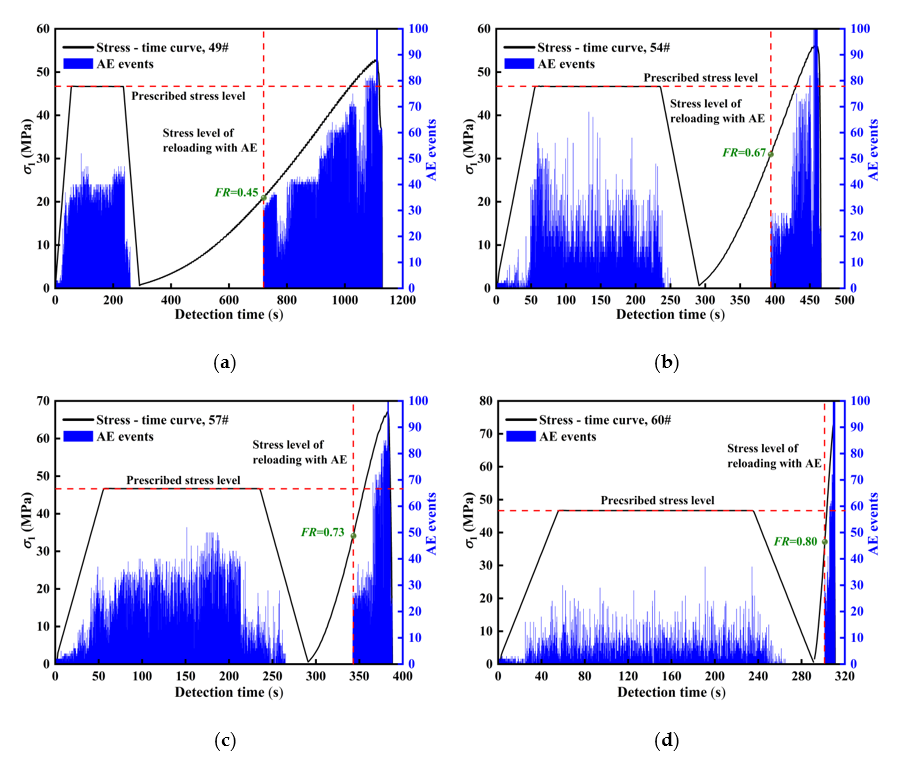

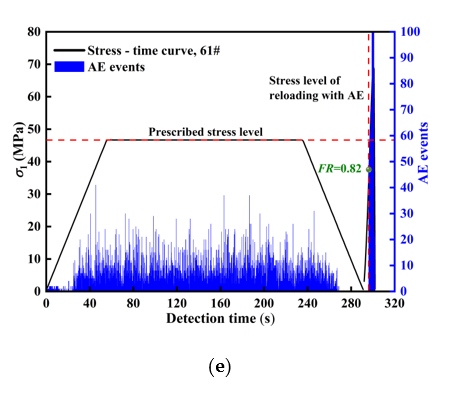

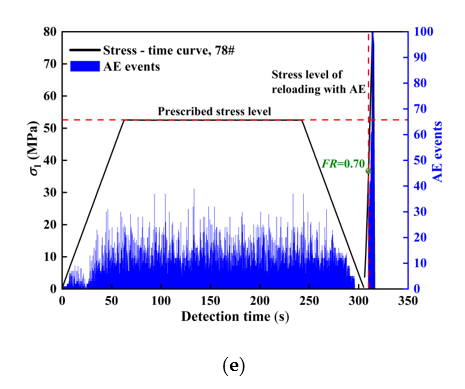

4.2. Dependence of the Kaiser Effect on the Loading Strain Rate

5. Conclusions

- (1)

- The Kaiser effect is greatly influenced by σA. Internal damage of the rock was gradually intensified as σA grows. Consequently, the Felicity ratio (FR) reduces and the Kaiser effect slowly vanishes, followed by appearance of the Felicity effect. The FR increases as the loading strain rate increases, and this, in turn, increases the possible appearance of the Kaiser effect.

- (2)

- For the red sandstone specimen, the Kaiser effect is always observed when σA is between 0.5σc to 0.7σc, corresponding to the stable crack grow stage in the stress-strain relationship.

- (3)

- When σA ≤ 0.5σc, a large number of AEs appear in the rock specimen during the re-loading stage only after σA is exceeded, suggesting an apparent Kaiser effect. When σA = 0.6σc, the appearance of the Kaiser effect is closely related to the loading strain rate. For lsr < 10−4 s−1, the Felicity effect appears in the re-loading stage, whereas the Kaiser effect appears in the re-loading process if lsr ≥ 10−4 s−1. When σA ≥ 0.7σc, remarkable AEs are generated in the initial re-loading stage, indicating that the Kaiser effect vanishes and the Felicity effect occurs.

- (4)

- The FR ascends and the Kaiser effect appears readily as lsr is increased. The FR grows quickly when lsr increases, but is no larger than 10−4 s−1, whereas the increase rate of the FR becomes less remarkable after lsr exceeds 10−4 s−1. Therefore, a relative high loading strain higher than 10−4 s−1 possibly favors the determination of the stress level of the Kaiser effect.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, H.Q.; Miao, X.X.; Zhang, G.M.; Wu, Y.; Chen, Y.L. Non-destructive testing and pre-warning analysis on the quality of bolt support in deep roadways of mining districts. Int. J. Min. Sci. Tech. 2017, 27, 989–998. [Google Scholar] [CrossRef]

- Liu, D.; Li, J.; Zou, C.N.; Cui, H.Y.; Ni, Y.Y.; Liu, J.Q.; Wu, W.; Zhang, L.; Coyte, R.; Kondash, A.; et al. Recycling flowback water for hydraulic fracturing in Sichuan basin, China: Implications for gas production, water footprint, and water quality of regenerated flowback water. Fuel 2020, 272, 117621. [Google Scholar] [CrossRef]

- Wang, H.Y.; Sharma, M.M. A rapid injection flowback test (rift) to estimate in-situ stress and pore pressure. J. Petrol. Sci. Eng. 2020, 190, 107108. [Google Scholar] [CrossRef]

- He, Q.Y.; Li, Y.C.; Xu, J.H.; Zhang, C.G. Prediction of mechanical properties of igneous rocks under combined compression and shear loading through statistical analysis. Rock Mech. Rock Eng. 2020, 53, 841–859. [Google Scholar] [CrossRef]

- Li, P.; Ren, F.H.; Cai, M.F.; Guo, Q.F.; Miao, S.J. Present-day stress state and fault stability analysis in the capital area of china constrained by in situ stress measurements and focal mechanism solutions. J. Asian Earth Sci. 2019, 185, 104007. [Google Scholar] [CrossRef]

- Zhang, N.; Zeng, W.T.; Wang, Y.H.; Sun, Q. Beyond multiple-continuum modeling for the simulation of complex flow mechanisms in multiscale shale porous media. J. Comput. Appl. Math. 2020, 378, 112854. [Google Scholar] [CrossRef]

- Li, Y.; Fu, S.S.; Qiao, L.; Liu, Z.B.; Zhang, Y.H. Development of twin temperature compensation and high-level biaxial pressurization calibration techniques for csiro in-situ stress measurement in depth. Rock Mech. Rock Eng. 2019, 52, 1115–1131. [Google Scholar] [CrossRef]

- Yan, P.; He, Q.; Lu, W.B.; He, Y.L.; Zhou, W.; Chen, M. Coring damage extent of rock cores retrieved from high in-situ stress condition: A case study. KSCE J. Civ. Eng. 2017, 21, 2946–2957. [Google Scholar] [CrossRef]

- Figueiredo, B.; Cornet, F.H.; Lamas, L.; Muralha, J. Determination of the stress field in a mountainous granite rock mass. Int. J. Rock Mech. Min. 2014, 72, 37–48. [Google Scholar] [CrossRef]

- Liu, B.; Song, C.J.; Tian, N.; Zhong, H.; Cao, B. In-situ stress measurement and acoustic emission instrumentation for rock burst control in a deep tunnel. In Rock Stress and Earthquakes; Proceedings of the 5th International Symposium on In-Situ Rock Stress, Beijing, China, 25–27 August 2010; Xie, F., Ed.; Taylor & Fransis Group: London, UK, 2010; pp. 407–411. [Google Scholar]

- Srinivasan, V.; Gupta, T.; Ansari, T.A.; Singh, T.N. An experimental study on rock damage and its influence in rock stress memory in a metamorphic rock. Bull. Eng. Geol. Environ. 2020, 79, 4335–4348. [Google Scholar] [CrossRef]

- Chong, Z.H.; Li, X.H.; Hou, P.; Chen, X.Y.; Wu, Y.C. Moment tensor analysis of transversely isotropic shale based on the discrete element method. Int. J. Min. Sci. Tech. 2017, 27, 507–515. [Google Scholar] [CrossRef]

- Elizarov, S.; Barat, V.; Terentyev, D.; Kostenko, P.; Bardakov, V.; Alyakritsky, A.; Koltsov, V.; Trofimov, P. Acoustic emission monitoring of industrial facilities under static and cyclic loading. Appl. Sci. 2018, 8, 1228. [Google Scholar] [CrossRef]

- Esola, S.; Wisner, B.; Vanniamparambil, P.; Geriguis, J.; Kontsos, A. Part qualification methodology for composite aircraft components using acoustic emission monitoring. Appl. Sci. 2018, 8, 1490. [Google Scholar] [CrossRef]

- Liu, R.; Hao, F.; Engelder, T.; Shu, Z.G.; Yi, J.Z.; Xu, S.; Teng, C.Y. Stress memory extracted from shale in the vicinity of a fault zone: Implications for shale-gas retention. Mar. Petrol. Geol. 2019, 102, 340–349. [Google Scholar] [CrossRef]

- Tang, J.H.; Chen, X.D.; Dai, F.; Wei, M.D. Experimental investigation of fracture damage of notched granite beams under cyclic loading using dic and ae techniques. Fatigue Fract. Eng. M. 2020, 43, 1583–1589. [Google Scholar] [CrossRef]

- Zang, A.; Oye, V.; Jousset, P.; Deichmann, N.; Gritto, R.; McGarr, A.; Majer, E.; Bruhn, D. Analysis of induced seismicity in geothermal reservoirs—An overview. Geothermics 2014, 52, 6–21. [Google Scholar] [CrossRef]

- Meng, Q.B.; Chen, Y.L.; Zhang, M.W.; Han, L.J.; Pu, H.; Liu, J.F. On the kaiser effect of rock under cyclic loading and unloading conditions: Insights from acoustic emission monitoring. Energies 2019, 12, 3255. [Google Scholar] [CrossRef]

- Meng, Q.B.; Zhang, M.W.; Han, L.J.; Pu, H.; Chen, Y.L. Acoustic emission characteristics of red sandstone specimens under uniaxial cyclic loading and unloading compression. Rock Mech. Rock Eng. 2018, 51, 969–988. [Google Scholar] [CrossRef]

- Chen, Y.L.; Irfan, M. Experimental study of kaiser effect under cyclic compression and tension tests. Geomech. Eng. 2018, 14, 203–209. [Google Scholar]

- Li, C.; Nordlund, E. Experimental verification of the kaiser effect in rocks. Rock Mech. Rock Eng. 1993, 26, 333–351. [Google Scholar] [CrossRef]

- Lavrov, A. Kaiser effect observation in brittle rock cyclically loaded with different loading rates. Mech. Mater. 2001, 33, 669–677. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.L.; Yu, R.G.; Hu, L.Q.; Irfan, M. Effect of loading rate on the felicity effect of three rock types. Rock Mech. Rock Eng. 2017, 50, 1673–1681. [Google Scholar] [CrossRef]

- Li, D.X.; Wang, E.Y.; Kong, X.G.; Jia, H.S.; Wang, D.M.; Muhammad, A. Damage precursor of construction rocks under uniaxial cyclic loading tests analyzed by acoustic emission. Constr. Build. Mater. 2019, 206, 169–178. [Google Scholar]

- Mayr, S.I.; Stanchits, S.; Langenbruch, C.; Dresen, G.; Shapiro, S.A. Acoustic emission induced by pore-pressure changes in sandstone samples. Geophysics 2011, 76, MA21–MA32. [Google Scholar] [CrossRef]

- Chen, Y.L.; Irfan, M.; Song, C.P. Verification of the kaiser effect in rocks under tensile stress: Experiment using the brazilian test. Int. J. Geomech. 2018, 18, 04018059. [Google Scholar] [CrossRef]

- Wu, J.H.; Chang, C.F. Studying on influences of anisotropy of rock mass on determining the pre-stress using kaiser effect. In Proceedings of the International Offshore and Polar Engineering Conference 17th International Offshore and Polar Engineering Conference (ISOPE 2007), Lisbon, Portugal, 1–6 July 2007; p. 1607. [Google Scholar]

- Chen, C.F.; Xu, T.; Heap, M.J.; Baud, P. Influence of unloading and loading stress cycles on the creep behavior of darley dale sandstone. Int. J. Rock Mech. Min. 2018, 112, 55–63. [Google Scholar] [CrossRef]

- Yoshikawa, S.; Mogi, K. A new method for estimation of the crustal stress from cored rock samples: Laboratory study in the case of uniaxial compression. Tectonophysics 1981, 74, 323–339. [Google Scholar] [CrossRef]

- Kurita, K.; Fujii, N. Stress memory of crystalline rocks in acoustic emission. Geophys. Res. Lett. 1979, 6, 9–12. [Google Scholar] [CrossRef]

- Chen, Y.L.; Wu, H.S.; Pu, H.; Zhang, K.; Ju, F.; Wu, Y.; Liu, J.F. Investigations of damage characteristics in rock material subjected to the joint effect of cyclic loading and impact. Energies 2020, 13, 2154. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.K.; Suorineni, F.; Su, K. A study on the dynamic behavior of the meuse/haute-marne argillite. Phys. Chem. Earth 2007, 32, 907–916. [Google Scholar] [CrossRef]

- Zhang, Q.B.; Zhao, J. A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech. Rock Eng. 2014, 47, 1411–1478. [Google Scholar] [CrossRef]

- Rao, M.V.M.S.; Ramana, Y.V. A study of progressive failure of rock under cyclic loading by ultrasonic and ae monitoring techniques. Rock Mech. Rock Eng. 1992, 25, 237–251. [Google Scholar] [CrossRef]

- Meng, Q.B.; Zhang, M.W.; Han, L.J.; Pu, H.; Li, H. Effects of size and strain rate on the mechanical behaviors of rock specimens under uniaxial compression. Arab. J. Geosci. 2016, 9, 1–14. [Google Scholar] [CrossRef]

- Peng, S.; Podnieks, E.R. Relaxation and the behavior of failed rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1972, 9, 699–700. [Google Scholar] [CrossRef]

- Blanton, T.L. Effect of strain rates from 10−2 to 10 sec-1 in triaxial compression tests on three rocks. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1981, 18, 47–62. [Google Scholar] [CrossRef]

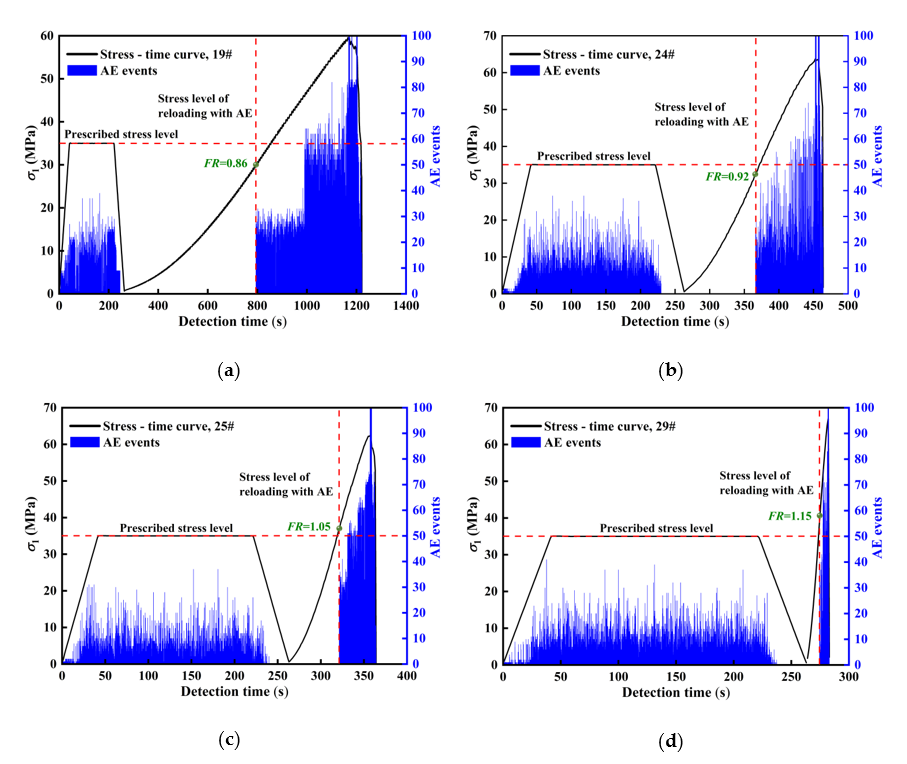

| Serial Number of Rock Specimens | Loading Strain Rate (lsr, s−1) | |||||

|---|---|---|---|---|---|---|

| 1 × 10−5 | 5 × 10−5 | 1 × 10−4 | 5 × 10−4 | 1 × 10−3 | ||

| σA (MPa) | 0.5σc | 4#, 5#, 6# | 7#, 8#, 9# | 10#, 11#, 12# | 13#, 14#, 15# | 16#, 17#, 18# |

| 0.6σc | 19#, 20#, 21# | 22#, 23#, 24# | 25#, 26# 27# | 28#, 29#, 30# | 31#, 32#, 33# | |

| 0.7σc | 34#, 35#, 36# | 37#, 38#, 39# | 40#, 41#, 42# | 43#, 44#, 45# | 46#, 47#, 48# | |

| 0.8σc | 49#, 50#, 51# | 52#, 53#, 54# | 55#, 56#, 57# | 58#, 59#, 60# | 61#, 62#, 63# | |

| 0.9σc | 64#, 65#, 66# | 67#, 68#, 69# | 70#, 71#, 72# | 73#, 74#, 75# | 76#, 77#, 78# | |

| Felicity Ratio (FR) | Loading Strain Rate (lsr, s−1) | |||||

|---|---|---|---|---|---|---|

| 1 × 10−5 | 5 × 10−5 | 1 × 10−4 | 5 × 10−4 | 1 × 10−3 | ||

| σA (MPa) | 0.5σc | 1.08, 1.03, 1.07 | 1.14, 1.11, 1.13 | 1.21, 1.23, 1.19 | 1.29, 1.27, 1.25 | 1.32, 1.38, 1.35 |

| 0.6σc | 0.86, 0.88, 0.85 | 0.95, 0.90, 0.92 | 1.05, 1.00, 0.99 | 1.10, 1.15, 1.14 | 1.19, 1.18, 1.21 | |

| 0.7σc | 0.55, 0.61, 0.53 | 0.83, 0.84, 0.82 | 0.87, 0.86, 0.86 | 0.91, 0.88, 0.91 | 0.95, 0.94, 0.93 | |

| 0.8σc | 0.45, 0.46, 0.46 | 0.71, 0.69, 0.67 | 0.73, 0.74, 0.73 | 0.78, 0.77, 0.80 | 0.82, 0.80, 0.81 | |

| 0.9σc | 0.37, 0.39, 0.36 | 0.60, 0.59, 0.57 | 0.64, 0.63, 0.63 | 0.67, 0.66, 0.67 | 0.70, 0.69, 0.70 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Meng, Q.; Li, Y.; Pu, H.; Zhang, K. Assessment of Appropriate Experimental Parameters for Studying the Kaiser Effect of Rock. Appl. Sci. 2020, 10, 7324. https://doi.org/10.3390/app10207324

Chen Y, Meng Q, Li Y, Pu H, Zhang K. Assessment of Appropriate Experimental Parameters for Studying the Kaiser Effect of Rock. Applied Sciences. 2020; 10(20):7324. https://doi.org/10.3390/app10207324

Chicago/Turabian StyleChen, Yanlong, Qingbin Meng, Yingchun Li, Hai Pu, and Kai Zhang. 2020. "Assessment of Appropriate Experimental Parameters for Studying the Kaiser Effect of Rock" Applied Sciences 10, no. 20: 7324. https://doi.org/10.3390/app10207324

APA StyleChen, Y., Meng, Q., Li, Y., Pu, H., & Zhang, K. (2020). Assessment of Appropriate Experimental Parameters for Studying the Kaiser Effect of Rock. Applied Sciences, 10(20), 7324. https://doi.org/10.3390/app10207324