Experimental Investigation on Mechanics and Seepage Characteristics of Tectonic and Intact Coal Containing Gas

Abstract

1. Introduction

2. Experimental Method

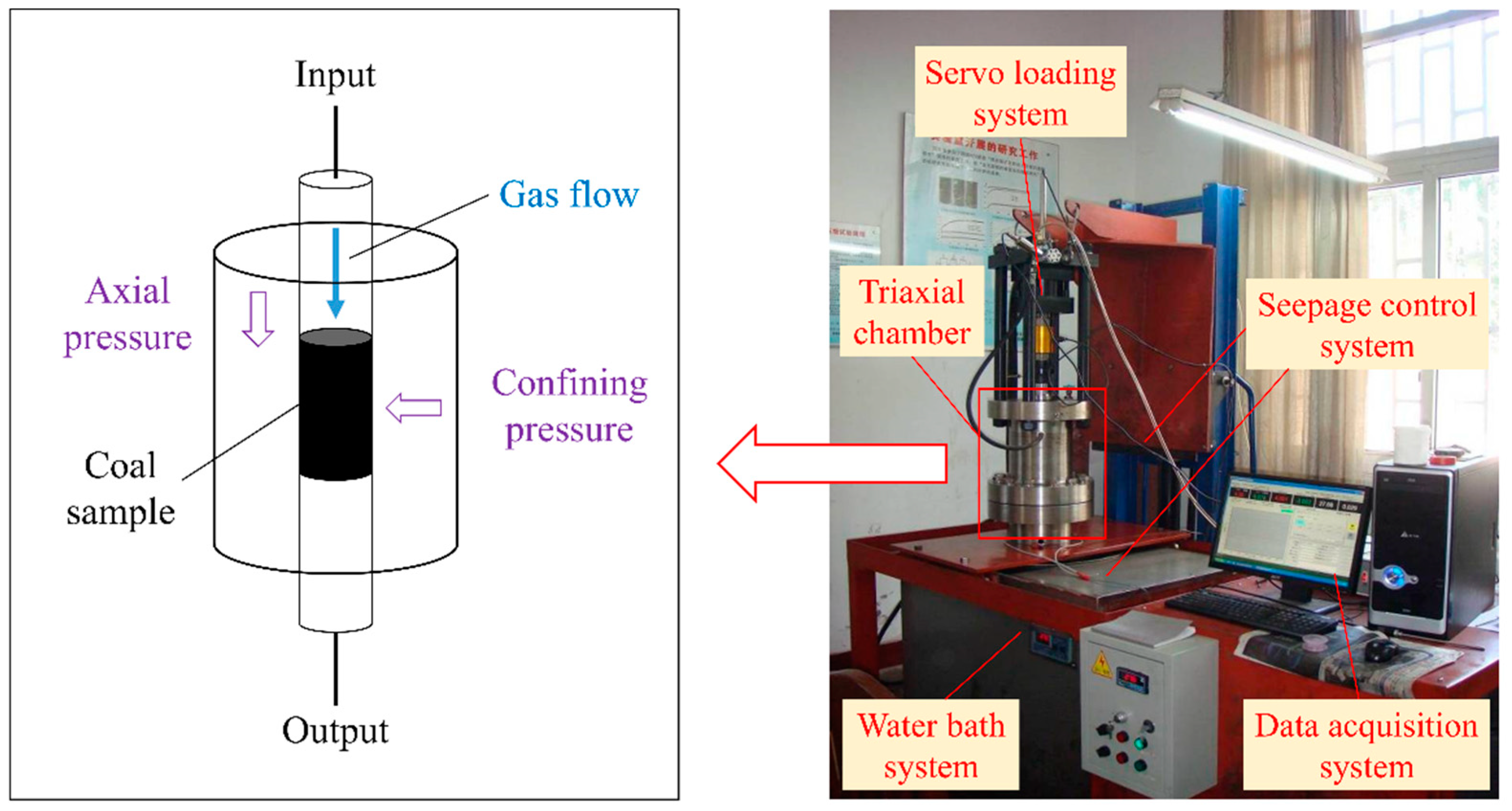

2.1. Experimental Apparatus

2.2. Experimental Samples

2.3. Experimental Procedures

- Triaxial compression tests.

- The coal sample surface was coated with a layer of 704 silica gel except for both ends and covered by a thermoplastic tube. Then the coal sample was placed into the triaxial chamber and the environmental temperature was set as 25 ℃.

- After the sealing of the coal sample, the triaxial chamber was vacuumed for 12 h to remove the residual air.

- Applied the axial pressure of 8 MPa, the confining pressure of 4 MPa, and the gas (using pure CH4) pressure of 1 MPa to the coal sample.

- The axial stress was continuously loaded by a displacement control at a speed of 0.2 mm/min until the coal sample failure while the confining pressure and the gas pressure were fixed. Monitored the axial pressure, displacement, and gas flow rate during the entire test process.

- Gas depletion tests. Steps (1) and (2) were the same as the triaxial compression tests.

- 3

- Applied the axial pressure of 12 MPa, the confining pressure of 4 MPa, and the gas (using pure CH4) pressure of 4 MPa to the coal sample, then recorded the displacement and gas flow rate.

- 4

- Closed the gas input valve and opened the gas output valve while the axial pressure and the confining pressure were fixed. When the gas pressure was balanced at 3.5 MPa, recorded the displacement and gas flow rate. Then tested the relative data when the gas pressure was balanced at 3 MPa, 2.5 MPa, 2 MPa, 1.5 MPa, 1 MPa, and 0.5 MPa in turn.

3. Results and Discussion

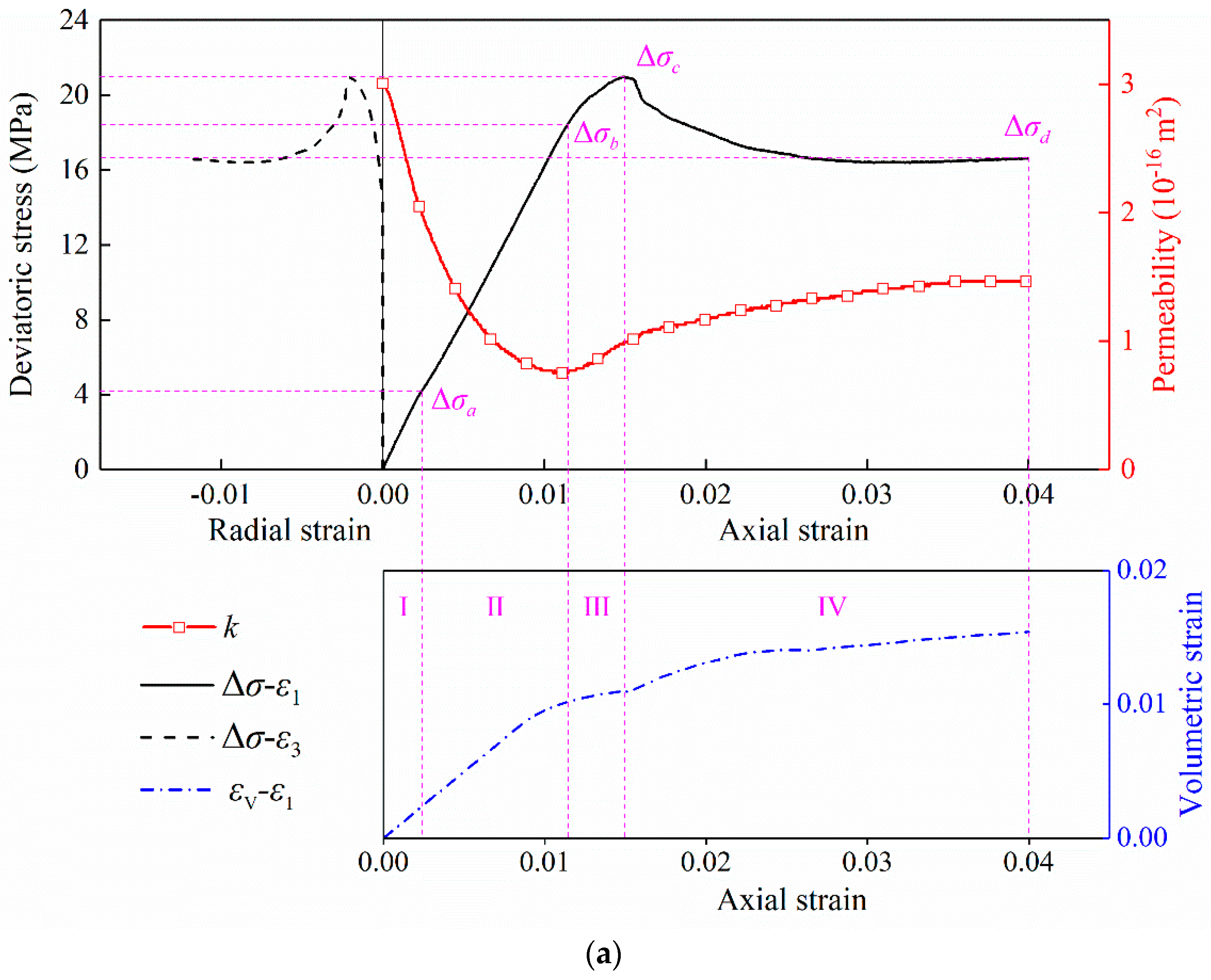

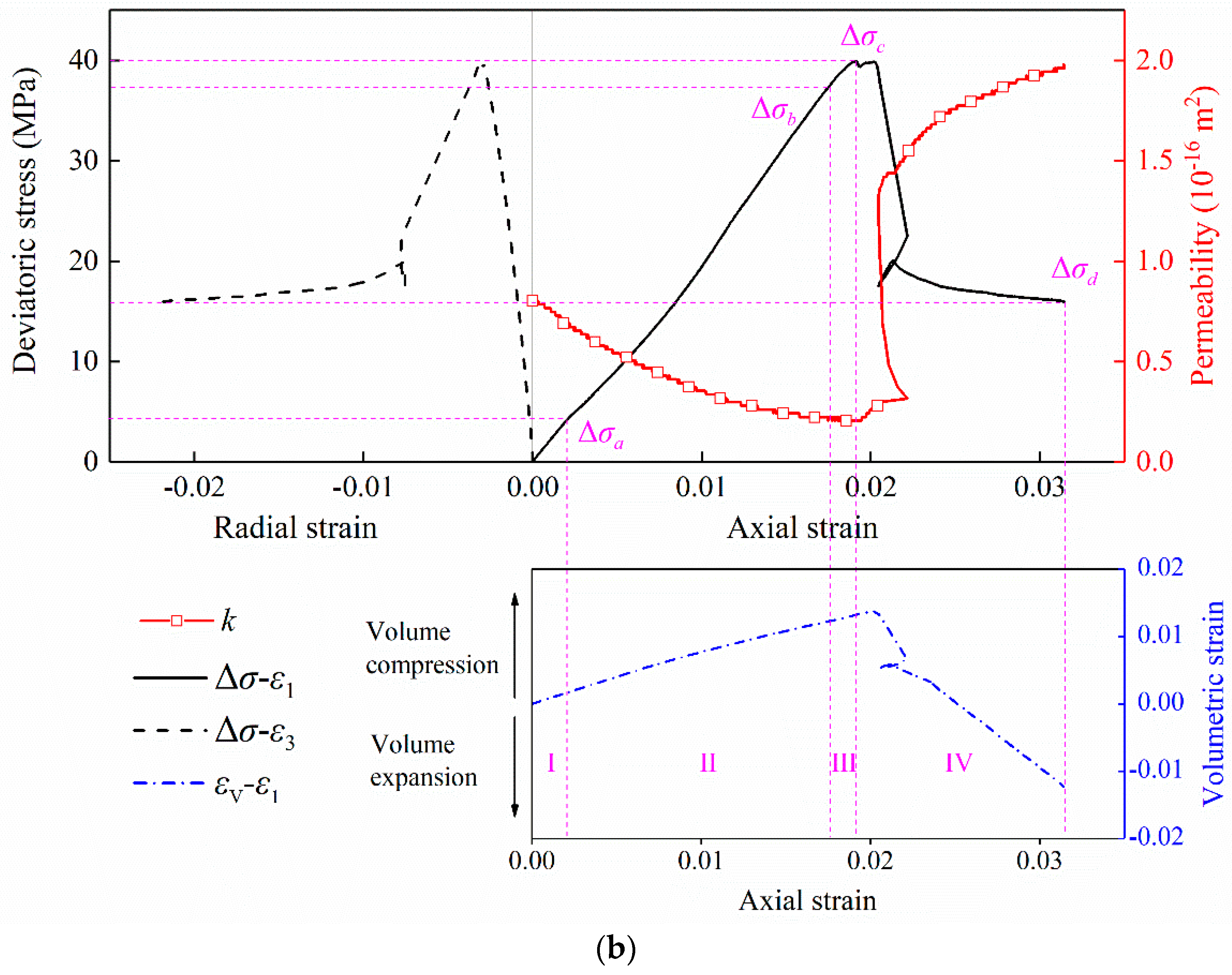

3.1. Mechanical Properties of Coal during Triaxial Compression

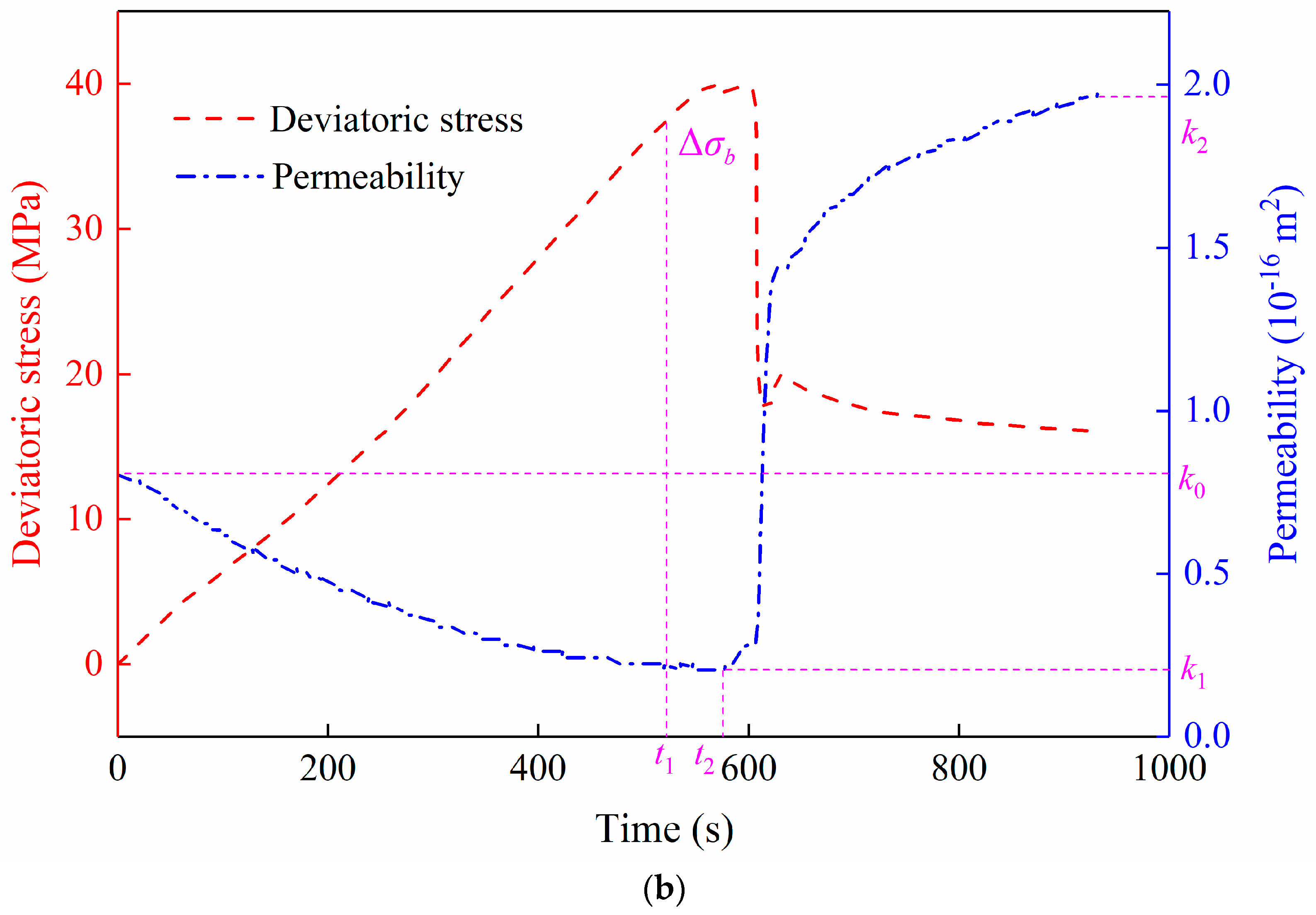

3.2. Seepage Lagging and Recovery Effect during Triaxial Compression

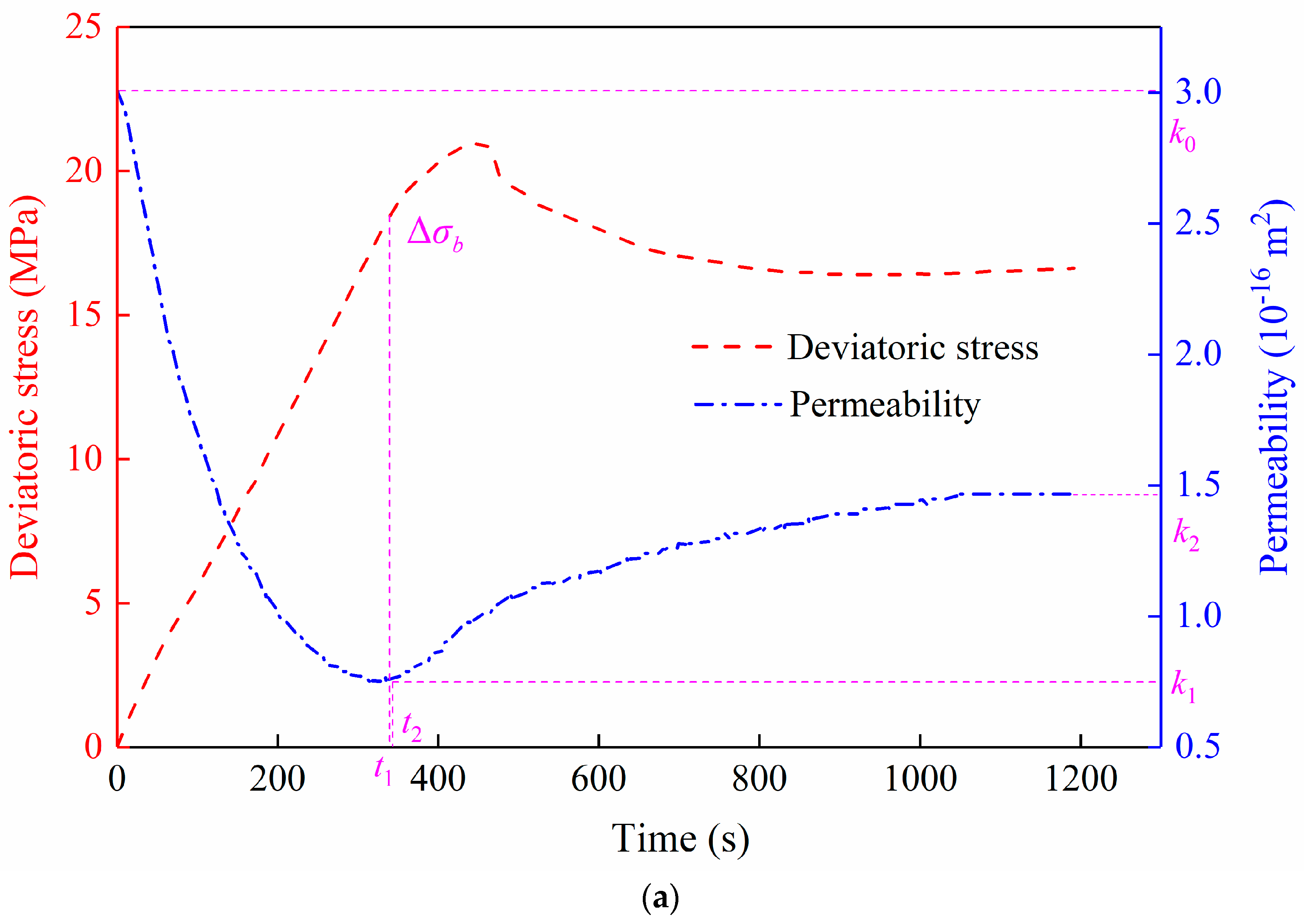

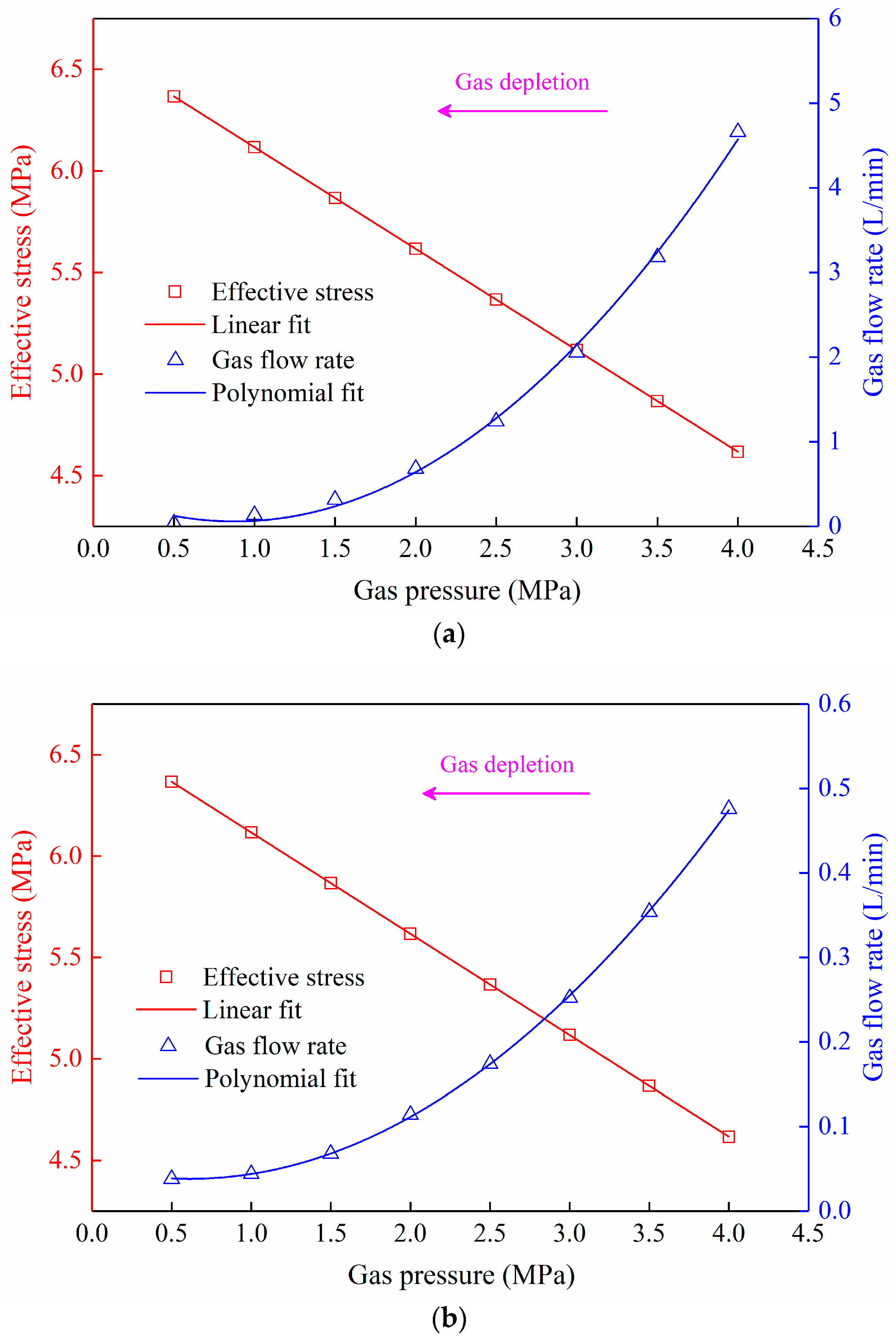

3.3. Permeability Sensitive Effect during Gas Depletion

4. Conclusions

- The triaxial compression process of coal can be divided into four stages. The damage stress and peak stress of tectonic coal is only half that of intact coal, while their compaction stress or residual stress are almost the same. The deviatoric stress of intact coal during the post-destruction stage has a sharp drop while that of tectonic coal decreases slowly which shows an apparent strain softening behavior.

- During the triaxial compression, the primary permeability and minimum permeability of tectonic coal are 3.76 times and 3.57 times that of intact coal. However, the permeability recovery value after intact coal failure is more than twice of its primary permeability, leading to that the residual permeability of tectonic is only 75.0% that of intact coal.

- During the gas depletion, the permeability drop ratio of tectonic coal from the maximum value to the minimum value (54.15%) is bigger than that of intact coal (7.45%), and the rebound gas pressure of tectonic coal (1.0 MPa) is smaller than that of intact coal (2.0 MPa). In addition, the permeability of tectonic coal is one order of magnitude larger than that of intact coal before the gas pressure drops to 2.0 MPa, and they become closer after that.

- The research results provide the reference and inspiration for the applications of coalbed methane recovery: the gas extraction time at high gas pressure stage should be stabilized in the tectonic coal area, while the gas extraction time at low gas pressure stage should be increased in the intact coal area. Moreover, the tectonic coal is suitable for hydraulic flushing technology while the intact coal is suitable for hydraulic fracturing technology in order to improve coal seam permeability and coalbed methane recovery.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, Q.Q.; Chu, P.; Zhu, J.T.; Cheng, Y.P.; Wang, D.Y.; Lu, Y.F.; Liu, Y.Y.; Xia, L.; Wang, L. Numerical assessment of the critical factors in determining coal seam permeability based on the field data. J. Nat. Gas Sci. Eng. 2020, 74, 103098. [Google Scholar] [CrossRef]

- Yan, F.Z.; Xu, J.; Peng, S.J.; Zou, Q.L.; Zhou, B.; Long, K.; Zhao, Z.G. Breakdown process and fragmentation characteristics of anthracite subjected to high-voltage electrical pulses treatment. Fuel 2020, 275, 117926. [Google Scholar] [CrossRef]

- Fu, H.J.; Tang, D.Z.; Xu, T.; Xu, H.; Tao, S.; Li, S.; Yin, Z.Y.; Chen, B.L.; Zhang, C.; Wang, L.L. Characteristics of pore structure and fractal dimension of low-rank coal: A case study of Lower Jurassic Xishanyao coal in the southern Junggar Basin, NW China. Fuel 2017, 193, 254–264. [Google Scholar] [CrossRef]

- Zhang, C.L.; Xu, J.; Peng, S.J.; Li, Q.X.; Yan, F.Z. Experimental study of drainage radius considering borehole interaction based on 3D monitoring of gas pressure in coal. Fuel 2019, 239, 955–963. [Google Scholar] [CrossRef]

- Mavor, M.J.; Vaughn, J.E. Increasing coal absolute permeability in the San Juan basin fruitland formation. SPE Reserv. Eval. Eng. 1998, 1, 201–207. [Google Scholar] [CrossRef]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Cheng, Y.P.; Pan, Z.J. Reservoir properties of Chinese tectonic coal: A review. Fuel 2020, 260, 116350. [Google Scholar] [CrossRef]

- Schweinfurth, S.P. Coal–A Complex Natural Resource: An Overview of Factors Affecting Coal Quality and Use in the United States; US department of the interior, US Geological Survey: Washington, DC, USA, 2003.

- Wang, E.; Shao, Q.; Han, S. Mechanics analysis of normal fault formation and control of structure coal. Coal Sci. Technol. 2009, 37, 104–113. [Google Scholar]

- Jin, K.; Cheng, Y.P.; Ren, T.; Zhao, W.; Tu, Q.; Dong, J.; Hu, B. Experimental investigation on the formation and transport mechanism of outburst coal-gas flow: Implications for the role of gas desorption in the development stage of outburst. Int. J. Coal Geol. 2018, 194, 45–58. [Google Scholar] [CrossRef]

- Lu, S.Q.; Cheng, Y.P.; Li, W.; Wang, L. Pore structure and its impact on CH4 adsorption capability and diffusion characteristics of normal and deformed coals from Qinshui Basin. Int. J. Oil Gas Coal Technol. 2015, 10, 76–84. [Google Scholar] [CrossRef]

- Jiang, B.; Ju, Y.W. Tectonic coal structure and its petrophysical features. Nat. Gas Ind. 2004, 24, 27–36. [Google Scholar]

- Li, W.; Liu, H.; Song, X. Multifractal analysis of Hg pore size distributions of tectonically deformed coals. Int. J. Coal Geol. 2015, 144, 138–152. [Google Scholar] [CrossRef]

- Skoczylas, N.; Dutka, B.; Sobczyk, J. Mechanical and gaseous properties of coal briquettes in terms of outburst risk. Fuel 2014, 134, 45–52. [Google Scholar] [CrossRef]

- Quosay, A.A.; Knez, D.; Ziaja, J. Hydraulic fracturing: New uncertainty based modeling approach for process design using Monte Carlo simulation technique. PLoS ONE 2020, 15, 0236726. [Google Scholar] [CrossRef] [PubMed]

- Quosay, A.A.; Knez, D. Sensitivity analysis on fracturing pressure using Monte Carlo simulation technique. Oil Gas Eur. Mag. 2016, 42, 140–144. [Google Scholar]

- Chaturvedi, T.; Schembre, J.M.; Kovscek, A.R. Spontaneous imbibition and wettability characteristics of Powder River Basin coal. Int. J. Coal Geol. 2009, 77, 34–42. [Google Scholar] [CrossRef]

- Zhang, C.; Tu, S.H.; Zhang, L. Pressure-relief and methane production performance of pressure relief gas extraction technology in the longwall mining. J. Geophys. Eng. 2017, 14, 77–89. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L. Permeability characteristics of broken coal and rock under cyclic loading and unloading. Nat. Resour. Res. 2019, 28, 1055–1069. [Google Scholar] [CrossRef]

- Chen, Y.X.; Xu, J.; Chu, T.X. Experimental study on the influence of moisture content during gas depressurization extraction. Adv. Mater. Sci. Eng. 2019, 9804825. [Google Scholar] [CrossRef]

- Zhang, C.L.; Xu, J.; Peng, S.J.; Zhang, X.L.; Liu, X.R.; Chen, Y.X. Dynamic evolution of coal reservoir parameters in CBM extraction by parallel boreholes along coal seam. Transp. Porous Media. 2018, 124, 325–343. [Google Scholar] [CrossRef]

- Zhang, C.L.; Xu, J.; Wang, E.Y.; Peng, S.J. Experimental study on the gas flow characteristics and pressure relief gas drainage effect under different unloading stress paths. Geofluids 2020, 8837962. [Google Scholar] [CrossRef]

- Yin, G.Z.; Jiang, C.B.; Xu, J. Geomechanical and flow properties of coal from loading axial stress and unloading confining pressure tests. Int. J. Rock Mech. Min. 2015, 76, 155–161. [Google Scholar] [CrossRef]

- Yin, G.; Li, M.; Jiang, C.B.; Xu, J.; Li, W.P. Mechanical behavior and permeability evolution of gas infiltrated coals during protective layer mining. Int. J. Rock Mech. Min. 2015, 80, 292–301. [Google Scholar] [CrossRef]

- Liu, T.; Liu, S.M.; Lin, B.Q.; Fu, X.H.; Zhu, C.J.; Yang, W.; Zhao, Y. Stress response during in-situ gas depletion and its impact on permeability and stability of CBM reservoir. Fuel 2020, 266, 117083. [Google Scholar] [CrossRef]

- Lu, S.; Cheng, Y.P.; Qin, L.M.; Li, W.; Zhou, H.X.; Guo, H.J. Gas desorption characteristics of the high-rank intact coal and fractured coal. Int. J. Min. Sci. Technol. 2015, 25, 819–844. [Google Scholar] [CrossRef]

- Dong, J.; Cheng, Y.P.; Hu, B.; Hao, C.M.; Tu, Q.Y.; Liu, Z.D. Experimental study of the mechanical properties of intact and tectonic coal via compression of a single particle. Powder Technol. 2018, 325, 412–419. [Google Scholar] [CrossRef]

- Liu, R.; He, Y.; Zhao, Y.F.; Jiang, X.; Ren, S. Statistical analysis of acoustic Emission in uniaxial compression of tectonic and non-tectonic coal. Appl. Sci. 2020, 10, 3555. [Google Scholar] [CrossRef]

- Yin, G.Z.; Jiang, C.B.; Xu, J.; Guo, L.S.; Peng, S.J.; Li, W.P. An experimental study on the effects of water content on coalbed gas permeability in ground stress fields. Transp. Porous Media 2012, 94, 87–99. [Google Scholar] [CrossRef]

- Zhang, C.L.; Xu, J.; Peng, S.J.; Li, Q.X.; Yan, F.Z.; Chen, Y.X. Dynamic behavior of gas pressure and optimization of borehole length in stress relaxation zone during coalbed methane production. Fuel 2018, 233, 816–824. [Google Scholar] [CrossRef]

- Li, B.B.; Ren, C.H.; Wang, Z.H.; Li, J.H.; Yang, K.; Xu, J. Experimental study on damage and the permeability evolution process of methane-containing coal under different temperature conditions. J. Petrol. Sci. Eng. 2020, 184, 106509. [Google Scholar] [CrossRef]

- Yin, G.Z.; Jiang, C.B.; Wang, J.G.; Xu, J. Combined effect of stress, pore pressure and temperature on methane permeability in anthracite coal: An experimental study. Transp. Porous Media 2013, 100, 1–16. [Google Scholar] [CrossRef]

- Cui, X.J.; Bustin, R.M. Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams. AAPG Bull. 2005, 89, 1181–1202. [Google Scholar] [CrossRef]

- Tao, Y.Q.; Liu, D.; Xu, J.; Peng, S.J.; Nie, W. Investigation of the klinkenberg effect on gas flow in coal matrices: A numerical study. J. Nat. Gas Sci. Eng. 2016, 30, 237–247. [Google Scholar] [CrossRef]

| Coal Sample | Moisture Content, Mad (%) | Ash Yield, Aad (%) | Volatile Matter, Vad (%) | Fixed Carbon, FCad (%) |

|---|---|---|---|---|

| Tectonic coal | 1.82 | 8.20 | 9.06 | 80.92 |

| Intact coal | 1.34 | 15.60 | 19.24 | 63.82 |

| Coal Sample | Δσa (MPa) | Δσb (MPa) | Δσc (MPa) | Δσd (MPa) | E (GPa) |

|---|---|---|---|---|---|

| Tectonic coal | 4.22 | 18.46 | 20.96 | 16.64 | 1.58 |

| Intact coal | 4.17 | 37.59 | 39.92 | 16.00 | 2.14 |

| Coal Sample | t1 (s) | t2 (s) | Δt (s) |

|---|---|---|---|

| Tectonic coal | 339.0 | 343.4 | 4.4 |

| Intact coal | 522.0 | 575.0 | 53.0 |

| Coal Sample | k0 (10−16 m2) | k1 (10−16 m2) | k2 (10−16 m2) | k1/k0 (%) | k2/k0 (%) |

|---|---|---|---|---|---|

| Tectonic coal | 3.01 | 0.75 | 1.47 | 24.9 | 48.8 |

| Intact coal | 0.80 | 0.21 | 1.96 | 26.3 | 245.0 |

| Coal Sample | Fitting Equation | R2 |

|---|---|---|

| Tectonic coal | q = 0.4634p2 − 0.8142p + 0.4154 | 0.9979 |

| Intact coal | q = 0.038p2 − 0.0465p + 0.0524 | 0.9999 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Wang, E.; Xu, J.; Peng, S. Experimental Investigation on Mechanics and Seepage Characteristics of Tectonic and Intact Coal Containing Gas. Appl. Sci. 2020, 10, 7290. https://doi.org/10.3390/app10207290

Zhang C, Wang E, Xu J, Peng S. Experimental Investigation on Mechanics and Seepage Characteristics of Tectonic and Intact Coal Containing Gas. Applied Sciences. 2020; 10(20):7290. https://doi.org/10.3390/app10207290

Chicago/Turabian StyleZhang, Chaolin, Enyuan Wang, Jiang Xu, and Shoujian Peng. 2020. "Experimental Investigation on Mechanics and Seepage Characteristics of Tectonic and Intact Coal Containing Gas" Applied Sciences 10, no. 20: 7290. https://doi.org/10.3390/app10207290

APA StyleZhang, C., Wang, E., Xu, J., & Peng, S. (2020). Experimental Investigation on Mechanics and Seepage Characteristics of Tectonic and Intact Coal Containing Gas. Applied Sciences, 10(20), 7290. https://doi.org/10.3390/app10207290