Abstract

Fire propagation and burning characteristics of upward flame spread over flexible polyurethane (FPU) foam board were investigated under coupling effects of pressure and orientation. As a further comparative research of our previous work, three pressures (70, 85 and 100 kPa) and four fuel surface inclination angles (0°, 30°, 60°, 90°) were applied, respectively, as before, to study the variation of typical parameters including flame spread rate (FSR), burning rate, heat transfer components, flame length, etc. First, a phenomenological interpretation was taken to show the special spreading process with melting flow combustion and flash burning observed. Second, an overall theoretical analysis was proposed to reveal the individual or coupling effects of pressure and inclined burning surface on spreading behavior. A semi-quantitative correlation was developed and formulated to show the tendency of FSR as a function of pressure, inclination and other burning parameters, which was validated by data in paper. Meanwhile, comparison of detailed differences between upward and downward spread was conducted to give a full insight on FPU fire development. At last, comprehensive discussions of coupling effects on variation of spreading characteristics and heat transfer mechanisms were performed based on fire dynamics.

1. Introduction

Pressure effects on flame spread over solids has been studied for several decades to provide guidance for fire protection in aircraft and high-altitude buildings. For example, in China, one of the interests is based on the fire safety research for important historical or Buddhism buildings in the Qinghai–Tibet plateau. As the essential parameter related to oxidation and flow in combustion, pressure was confirmed to have obvious influences on fire spreading behavior and burning characteristics for solid fuels, e.g., wood [1,2,3,4], rigid polyurethane (RPU) foam [5,6], flexible polyurethane (FPU) foam [7,8,9], extruded polystyrene (XPS) [10,11], or other polymers [12,13,14]. Nowadays, more attentions are paid to fire behavior of these materials because of rapid development in the construction industry.

The most classical theoretical modeling about pressure vs. flame spread could be traced back to the Pressure Modeling of Fires by de Ris [1] in 1973, which showed a concise and important correlation for flame spread over solids with various pressures by simplified dimensional analysis as . Subsequently in 2000, a further developed theory also by de Ris et al. known as Radiation Fire Modeling [2] was proposed to give a deeper insight into pressure effects on detailed heat and the mass transfer process. However, limitations of theoretical modellings still exist as the complexity of real fire scenarios with various combustibles and developing processes, i.e., extensive investigation of pressure effects on fire spreading and burning behavior for solid combustibles is meaningful.

Another key parameter is the inclination of flame spreading surface, indicating intense correlations with flame spread rate (FSR), fire configuration, etc., particularly. As early as 1992, upward fire propagation over inclined PMMA slab surface was studied experimentally by Drysdale and Macmillan [13], which reported the clear difference of spread for thin and thick fuels under different inclinations. Later, an important early semi-empirical model of upward flame spread with an orientation effect was proposed by Quintiere in 2001 using a polyethylene terephthalate (PET) board [14]. In addition, related works were conducted continuously by Gollner et al. [15,16] in recent years. However, it will be a different story when both effects of inclination and pressure are combined, complexly impacting the entire spreading process. Research studies referring to the coupling effects were mostly focused on phenomenological fire behavior changes at high altitude by experimental studies, e.g., [4,6,8]. Additionally, downward spreading tests over FPU board at various inclinations under sub-atmospheric pressures were performed in our latest work [9]. It was found that preheating mechanism variation, strongly dependent on the coupling effects and surface materials, would play an important part in flame spread. As a result of the complication in fuel types and forms mentioned, it is worth a more extensive exploration of this issue.

Within this paper, as a further investigation of our previous work in [9], both experimental and theoretical study were conducted to show a relatively full comparison of downward and upward flame spreading processes over FPU foam board with four inclination angles under three decreased pressures. Burning characteristics including flame spread rate (FSR), burning rate and flame morphology are concentrated to reveal the complicated influences of pressure and orientation. Semi-qualitative relationships of the coupling effects were formulated by overall theoretical analysis of heat transfer mechanisms. This work could be helpful for fire safety engineering design of buildings at high altitudes.

2. Experiments

Comparative experiments were conducted in a QR0-12 low pressure test chamber with an inner size of 3 m long, 2 m wide and 2 m high. It was designed for large scale fire tests with adjustable pressure environment from 26 to 101 kPa. More detailed information about this facility was described in [9], which is introduced briefly here. Three different ambient air pressures (70, 85 and 100 kPa) were applied to investigate the influences of pressure on upward flame spread over an FPU foam board with various inclinations. The FPU board, with width 20 cm, length 80 cm and density 41.5 kg/m3, was ignited linearly from the lower edge under 4 inclination angles 0°, 30°, 60°, and 90°, respectively.

Major characteristics recorded were FSR, burning rate, flame temperature and image information. During all the tests, the same initial environmental parameters (namely, temperature 20 ± 2.0 °C and humidity 50 ± 5%) were controlled and preserved inside experimental facility. Additionally, each test was repeated at least 3 times to ensure reproducible data with higher accuracy. Experimental results showed that measurement errors were mainly attributed to fire fluctuation and random melting flow combustion.

3. Results and Analysis

3.1. Upward Flame Spreading Behavior with Different Orientations

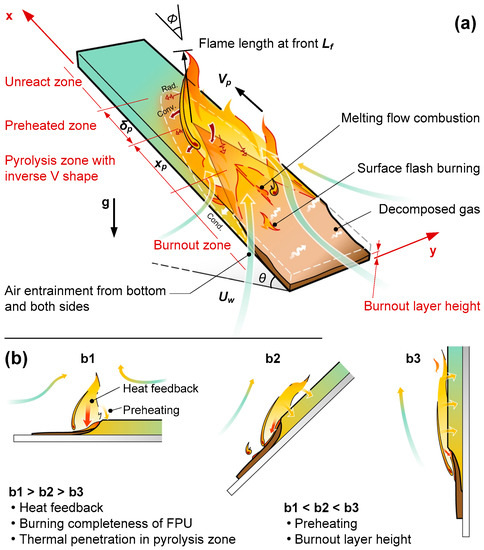

Typical configuration of upward flame spread over the FPU board is illustrated in Figure 1 based on experimental observation. Figure 1a shows the different zones and heat transfer mechanisms, where a significant large inverse “V” shape pyrolysis zone could be found in tests with inclination angle exceeding 30°. This kind of “V” shape was also reported in downward flame spread, e.g., [17,18], but with a much smaller scale and blunter included angle. The large inverse “V” pyrolysis zone is formed under both effects of flame tilt and ambient air entrainment by increasing . In addition, it makes the issue more complicated than downward spread, since spreading became a genuine two-dimensional (in surface or 2-plus-1 dimension considering thickness) process as,

Figure 1.

Configuration of upward flame spread over flexible polyurethane (FPU) foam (a) and variation of heat transfer intensities with increasing inclination (b).

To facilitate discussion, parameters along the central axis of the FPU board () are used for analysis below. Overall comparisons of characteristics between upward and downward flame spread are conducted in Section 3.4 for better understanding.

It is noticeable that two particular phenomena occurred during spreading (burnout zone in Figure 1a):

- (1)

- Melting flow combustion by high temperature molten fuel, owing to the thermoplastic-like FPU material selected, could bring heat and mass from upper to lower position through a rapid path, and also might make fire development worse as the secondary ignition source.

- (2)

- Flash burning in partial surfaces appeared intermittently, which was induced by the continuous lean decomposed gas (and some fuel vapor with small molecules) generated from the deep side of the “burnout” zone. As the customized FPU material is modified with clay bulk and special foaming agent, char-residue was formed along the surface after combustion, which would prevent the fuel board from complete burnout. Lean combustible gas or vapor would be released by smoldering, although pyrolysis front had already passed. Moreover, the porous structure of FPU will be helpful in gas release from depth, which has potential to be ignited by flame, hot plume or even melting flow combustion to turn into flash burning.

Burning completeness, mainly presented as burnout layer height, is also related to inclination by visual judgement. Figure 1b shows the comparison of heating intensities and burnout layer shape with . It is clear that with the increasing inclination, heat feedback to the pyrolysis zone was weakening, yet preheating to the preheated zone was enhanced due to the slanting and stretched flame, leading to a faster spread rate (or velocity) but less thermal penetration in the burning area. As a consequence, the burnout layer height and/or remaining fuel became thicker in general. Further, it becomes difficult to sustain self-propagating flame spreads for large conditions since critical heat feedback flux is required, which is also proved in Zhou’s work [6] that fire extinguished at for RPU boards.

3.2. Pyrolysis Boundary Evolution and Burning Characteristics

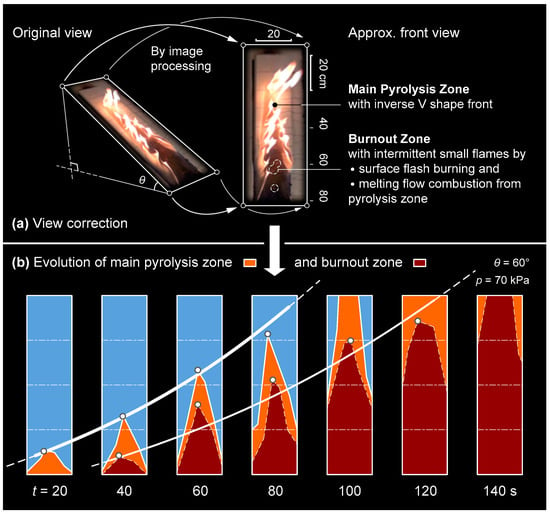

Upward flame spreading along the FPU board, as an unsteady burning process, showed evident acceleration with enlarged . Figure 2 demonstrates the boundary evolution of the inverse “V” shape pyrolysis zone by view angle calibration (case with air pressure 70 kPa and board inclination 60°, for example). To avoid heating or damage by fire within this limited test space, the camera was set in an oblique direction. Time-sequential images of the flame along the whole board by original perspective view were corrected into “front view”, to show a more precise spreading process based on the linear twist method.

Figure 2.

Evolution of pyrolysis and burnout zone profiles (typical results under 70 kPa and inclination 60° condition) during upward flame spread (b) by digital image view correction (a).

A “V” shape burning area marked by orange color was growing during the flame spreading until the pyrolysis front reached the upper edge of the board, which would then decrease gradually with increasing burnout area marked by red. Nevertheless, the FSR of the pyrolysis front was undoubtedly enhanced by enlarged inclination or pressure. Actually, the increasing length and FSR of the pyrolysis zone with time history were reproduced by Xie’s model [19] using 2D direct numerical simulation (DNS), which confirmed the importance of flame heat flux into both preheated and pyrolysis zones.

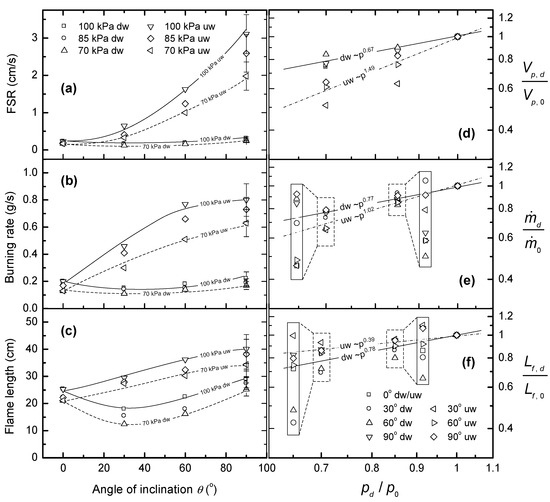

For a direct comparison with burning characteristics of downward flame spread reported in our study [9], the averaged value of FSR , burning rate and flame length were used as shown in Figure 3.

Figure 3.

Burning characteristics and related normalization including flame spread rate (FSR) (a,d), burning rate (b,e) and flame length (c,f) for downward and upward flame spread, respectively, with various inclination under different pressures.

The detailed measurement (or, i.e., calculation) method was also described in [9,20], where the FSR and burning rate were the average values from the same spreading distance of the pyrolysis front within 30–70 cm, and flame length was obtained by the digital image process based on Zukoski’s definition [20]. Figure 3a–c show the experimental results of , and for both upward and downward flame spread with various inclinations under different pressures. In addition, normalization of these parameters (defined as , and ) vs. air pressure is applied to give quantitative effects of pressure as shown in Figure 3d–f, where subscript d and 0 denote decreased pressure and normal pressure (~100 kPa), respectively. The indexes of pressure tagged in Figure 3d–f are fitted by data with inclination from 30° to 90° for upward or downward flame spread as overall comparisons.

It is interesting that the pressure effect on burning characteristics in downward spread showed somehow consistent as,

However, for upward flame spread, three indexes are totally distinct from each other,

Theoretical explanation for these tendencies is proposed hereinafter according to fire dynamic analysis.

3.3. Coupling Effects of Pressure and Inclination on Upward Flame Spread

As the key parameter in flame spread, the FSR is mainly determined by preheating in the preheated zone as for thermally thick solid [21]. It means that the FSR is evidently determined by preheating intensity and ignition temperature.

According to fundamental theory, the heat balance relationship of preheating in the upward flame spread process could be simplified by the following equation,

where the conduction heat flux component is negligible, attributed to the good thermal insulation performance of the FPU. Besides, the proved correlation of and with pressure are [9],

Considering the scale of the burning area (although larger than that in the downward flame spread for the same FPU board), convection heat flux still tends to be stronger than radiation for both preheated and pyrolysis zones for the board size selected [22]. Consequently, heat flux to the preheated zone could be approximately,

where is the apparent index of pressure effect. As mentioned in Equation (6), would be closer to 1/2, yet, the competition of convection and radiation heat fluxes will become tricky under certain inclination conditions, e.g.,

- (1)

- For horizontal (0°) flame spread, the preheated zone is definitely under convection control by the classical theory described above. Likewise, the preheated zone is almost immersed in flame for vertical (90°) spread; the convection between hot fire plume and fuel surface should also dominate the preheating mechanism (similar to pyrolysis zone). In these periods, is believed to approach 1/2.

- (2)

- However, for upward spread with certain inclination, radiation will be enhanced obviously due to stretched flame length and increasing radiation configuration factor owing to flame tilt, which might promote the ratio of radiation in preheating to make larger subsequently.

On the other hand, influences of inclination angle on preheating in upward spread was deduced by Quintiere [14] as,

Combining the pressure effect given in Equation (6), preheating heat flux could be expressed as,

where C is the pre-exponential coefficient by empirical correlation, which is independent of pressure or inclination. Therefore, coupling effects on the FSR could be integrated as follows,

In fact, Equation (9) is proposed to be a theoretical approximation, which is not strict for small inclinations (or with significant deviation since ). Fortunately, this mathematical limitation is not necessary to be concerned about under large inclination condition. With increasing , the length of the preheated zone would be approaching flame length as , and combining pressure effect on flame length , correlation of vs. p in Equation (9) could be,

We now return to the experimental results in Equation (3); where and , it could be found to agree well with the theoretical prediction of Equations (6) and (10). Moreover, the reason for similar pressure indexes between the FSR and burning rate of downward spread in Equation (2) is,

where burning area is mainly determined by cross-sectional area of board, and insensitive to both ambient pressure and inclination, which play an essential role in the tenability of Equation (11). On the contrary, the burning area of upward spread, depending on FSR, is distributed on the board surface rather than cross-section (Figure 1) as,

Due to the closer relationship of (rather than ) vs. p, relations and in Equations (2) and (3), respectively, would not be surprising. In fact, theoretical analyses on relations of burning rate or the FSR vs. inclination were proposed from another perspective by a fluid dimensionless quantity (Pr, Nu, Ra and Gr number) in previous research, e.g., [23] with reasonable prediction for inclination effect, whereas, it also indicated limitation for the pressure effect because of insufficient heat transfer mechanisms.

Additionally, the pressure effect on of upward spread showed much less than downward as stated above. This is probably attributable to the stronger stretching effect on the flame by enhanced air entrainment from the larger burning area, which hid the pressure effect partly.

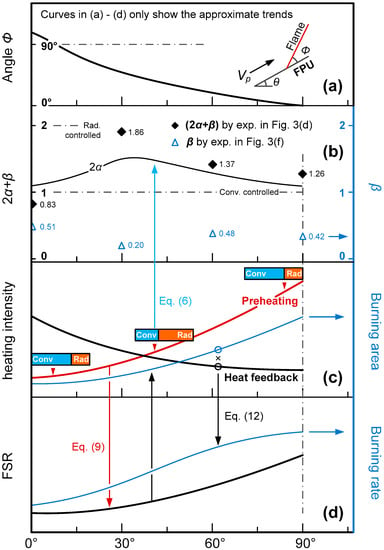

3.4. Discussion

Overall influences of pressure and inclination on the upward spreading process with various heat transfer mechanisms are proposed in Figure 4. When compared to Figure 8 in [9] for downward spread, obvious differences could be found by these two spreading forms. The core distinction is in Figure 4c, where preheating (to preheated zone) keeps increasing, meanwhile, heat feed back (to pyrolysis zone) is decreasing with enlarged for upward spread as interpreted in Section 3.1, owing to a stretched and tilted flame (Figure 4a). With ratio variation between convection and radiation preheating as described in Section 3.3, apparent index is plotted in Figure 4b, which is validated by experimental data in general tendency.

Figure 4.

Variation tendencies of flame tilt (a), pressure indexes (b), heat transfer intensity (c) and burning characteristics (d) by influences of inclination or pressure.

Furthermore, the FSR shows a similar trend with preheating as in Figure 4d by Equation (9), also, it shows a positive correlation with the size of the burning area in Figure 4c. At last, the increase in burning rate with inclination will be slowed down by Equation (12) as a result of the decaying heat feedback, which is also in agreement with experimental data in Figure 3.

4. Closing

As the follow-on work of our previous study, this paper has shown an overall relationship of pressure effects on upward flame spreading behavior and burning characteristics of an inclined FPU foam board. Considering the particular fuel type, we have given a careful investigation on the three-dimensional upward spreading process of FPU, also with special burning phenomenon observed. Based on fire dynamics analysis, comprehensive understandings of individual and coupling effects (of pressure and orientation) on FSR, burning rate, flame length and each heat transfer component are proposed or formulated with semi-quantitative correlations theoretically, which are consistent with the test results. The work is believed to be helpful for fire hazardous evaluation or supplementation of fire scientific theory under sub-atmospheric pressures. Future work is planned to be carried out with more combustibles and much lower pressures.

Author Contributions

Initial conceptualization, R.T. and X.M.; data curation, X.M. and X.Z.; formal analysis, R.T., X.M. and Y.Z.; funding acquisition, R.T., X.M. and X.Z.; methodology, R.T. and Y.Z.; project administration, R.T.; writing—original draft, R.T. and X.M.; writing—review and editing, X.Z. and Q.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (No. 52076084) and Huaqiao University Scientific Research Foundation (No. 16BS801). Ran Tu, Xin Ma and Xuejin Zhou are also supported by the Open Project Program of State Key Laboratory of Fire Science (HZ2020-KF07, HZ2019-KF13 and HZ2018-KF09).

Acknowledgments

We thank J. Wang for assistance with the experiment’s design.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Specific heat of fuel (J g−1 K−1) | |

| Gravity (m s−2) | |

| Flame length (m) | |

| Burning rate (g s−1) | |

| Air pressure (kPa) | |

| Convection and radiation preheating flux from fire (W m−2) | |

| Convection and radiation heat feedback from fire (W m−2) | |

| Conduction preheating flux from FPU (W m−2) | |

| Preheating heat flux to pyrolysis zone (W m−2) | |

| Burning area (m2) | |

| Ignition temperature (K) | |

| Ambient temperature (K) | |

| Velocity of air entrainment (m s−1) | |

| Flame spread rate (m s−1) | |

| w | Width of fuel board (m) |

| Distance of pyrolysis zone (m) | |

| Pressure index of preheating flux | |

| Pressure index of flame length | |

| Length of preheat zone (cm) | |

| Angle of inclination (°) | |

| Density (kg m−3) | |

| Subscripts | |

| 0 | Normal pressure |

| d | Decreased pressure |

| dw | Downward |

| Fire or flame | |

| uw | Upward |

| Ambient | |

References

- De Ris, J.L.; Kanury, A.M.; Yuen, M.C. Pressure modeling of fires. Proc. Combust. Inst. 1973, 14, 1033–1042. [Google Scholar] [CrossRef]

- De Ris, J.L.; Wu, P.K.; Heskestad, G. Radiation fire modeling. Proc. Combust. Inst. 2000, 28, 2751–2759. [Google Scholar] [CrossRef]

- Li, Z.H.; He, Y.P.; Zhang, H.; Wang, J. Combustion characteristics of n-heptane and wood crib fires at different altitude. Proc. Combust. Inst. 2009, 32, 2481–2488. [Google Scholar] [CrossRef]

- Zhang, Y.; Ji, J.; Wang, Q.S.; Huang, X.J.; Wang, Q.H.; Sun, J.H. Prediction of the critical condition for flame acceleration over wood surfacewith different sample orientations. Combust. Flame 2012, 159, 2999–3002. [Google Scholar] [CrossRef]

- Ma, X.; Tu, R.; Cheng, X.D.; Zhu, S.G.; Ma, J.W.; Fang, T.Y. Experimental study of thermal behavior of insulation material rigid polyurethane in parallel, symmetric, and adjacent building façade constructions. Polymers 2018, 10, 1104. [Google Scholar] [CrossRef]

- Zhou, Y.; Bu, R.W.; Yi, L.; Sun, J.H. Heat transfer mechanism of concurrent flame spread over rigidpolyurethane foam: Effect of ambient pressure and inclined angle. Int. J. Therm. Sci. 2020, 155, 106403. [Google Scholar] [CrossRef]

- Wieser, D.; Jauch, P.; Willi, U. The influence of high altitude on fire detector test fires. Fire Saf. J. 1997, 29, 195–204. [Google Scholar] [CrossRef]

- Ma, X.; Tu, R.; Ding, C.; Zeng, Y.; Xu, L.; Fang, T.Y. Experimental study on thermal safety of flexible polyurethane at various facade inclined structures under low ambient pressure condition. Eng. Struct. 2018, 176, 11–19. [Google Scholar] [CrossRef]

- Tu, R.; Ma, X.; Zeng, Y.; Zhou, X.J.; He, L.; Fang, T.Y.; Fang, J. Coupling effects of pressure and inclination on downward flame spread over flexible polyurethane foam board. Build. Environ. 2019, 164, 106339. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, X.J.; Wang, Q.S.; Ji, J.; Sun, J.H.; Yin, Y. Experimental study on the characteristics of horizontal flame spread over XPSsurface on plateau. J. Hazard. Mater. 2011, 189, 34–39. [Google Scholar] [CrossRef]

- Huang, X.J.; Zhao, J.; Tang, G.; Zhang, Y.; Sun, J.H. Effects of altitude and inclination on the flame structure over the insulation material PS based on heat and mass transfer. Int. J. Heat Mass Tran. 2015, 90, 1046–1055. [Google Scholar] [CrossRef]

- Hu, L.H.; Zhang, Y.S.; Yoshioka, K.; Izumo, H.; Fujita, O. Flame spread over electric wire with high thermal conductivitymetal core at different inclinations. Proc. Combust. Inst. 2015, 35, 2607–2614. [Google Scholar] [CrossRef]

- Drysdale, D.D.; Macmillan, A.J.R. Flame spread on inclined surfaces. Fire Saf. J. 1992, 18, 245–254. [Google Scholar] [CrossRef]

- Quintiere, J.G. The effects of angular orientation on flame spread over thin materials. Fire Saf. J. 2001, 36, 291–312. [Google Scholar] [CrossRef]

- Huang, X.; Gollner, M.J. Correlations for evaluation of flame spread over an inclined fuel surface. Fire Saf. Sci. 2014, 11, 222–233. [Google Scholar] [CrossRef]

- Gollner, M.J.; Huang, X.; Cobian, J.; Rangwala, A.; Williams, F. Experimental study ofupward flame spread of an inclined fuel surface. Proc. Combust. Inst. 2013, 34, 2531–2538. [Google Scholar] [CrossRef]

- Gong, J.H.; Zhou, X.D.; Li, J.; Yang, L.Z. Effect of finite dimension on downwardflame spread over PMMA slabs: Experimental and theoretical study. Int. J. Heat Mass Tran. 2015, 91, 225–234. [Google Scholar] [CrossRef]

- Tu, R.; Ma, X.; Zeng, Y.; Zhou, X.J.; Zhang, Q.X.; Wang, J.W.; Fang, J. Influences of sub-atmospheric pressure on downward flame spread overtypical insulation material with parallel glass curtain wall structure in underground buildings. Tunn. Undergr. Sp. Technol. 2020, 103, 103509. [Google Scholar] [CrossRef]

- Xie, W.; Desjardin, P.E. An embedded upward flame spread model using 2D direct numerical simulations. Combust. Flame 2009, 156, 522–530. [Google Scholar] [CrossRef]

- Zukoski, E.E.; Cetegen, B.M.; Kubota, T. Visible structure of buoyant diffusionflames. Proc. Combust. Inst. 1985, 20, 361–366. [Google Scholar] [CrossRef]

- Williams, F.A. Mechanisms of fire spread. Proc. Combust. Inst. 1977, 16, 1281–1294. [Google Scholar] [CrossRef]

- Hamins, A.; Yang, J.C.; Kashiwagi, T. A Global Model for Predicting the Burning Rates of Liquid Pool Fires, NISTIR 6381; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1999. [Google Scholar]

- Zhou, Y.; Gong, J.H.; Jiang, L.; Chen, C.K. Orientation effect on upward flame propagation over rigid polyurethane foam. Int. J. Therm. Sci. 2018, 132, 86–95. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).