Ductile Fracture Behavior of Mild and High-Tensile Strength Shipbuilding Steels

Abstract

1. Introduction

2. Ductile Fracture Model

2.1. Model Formulation

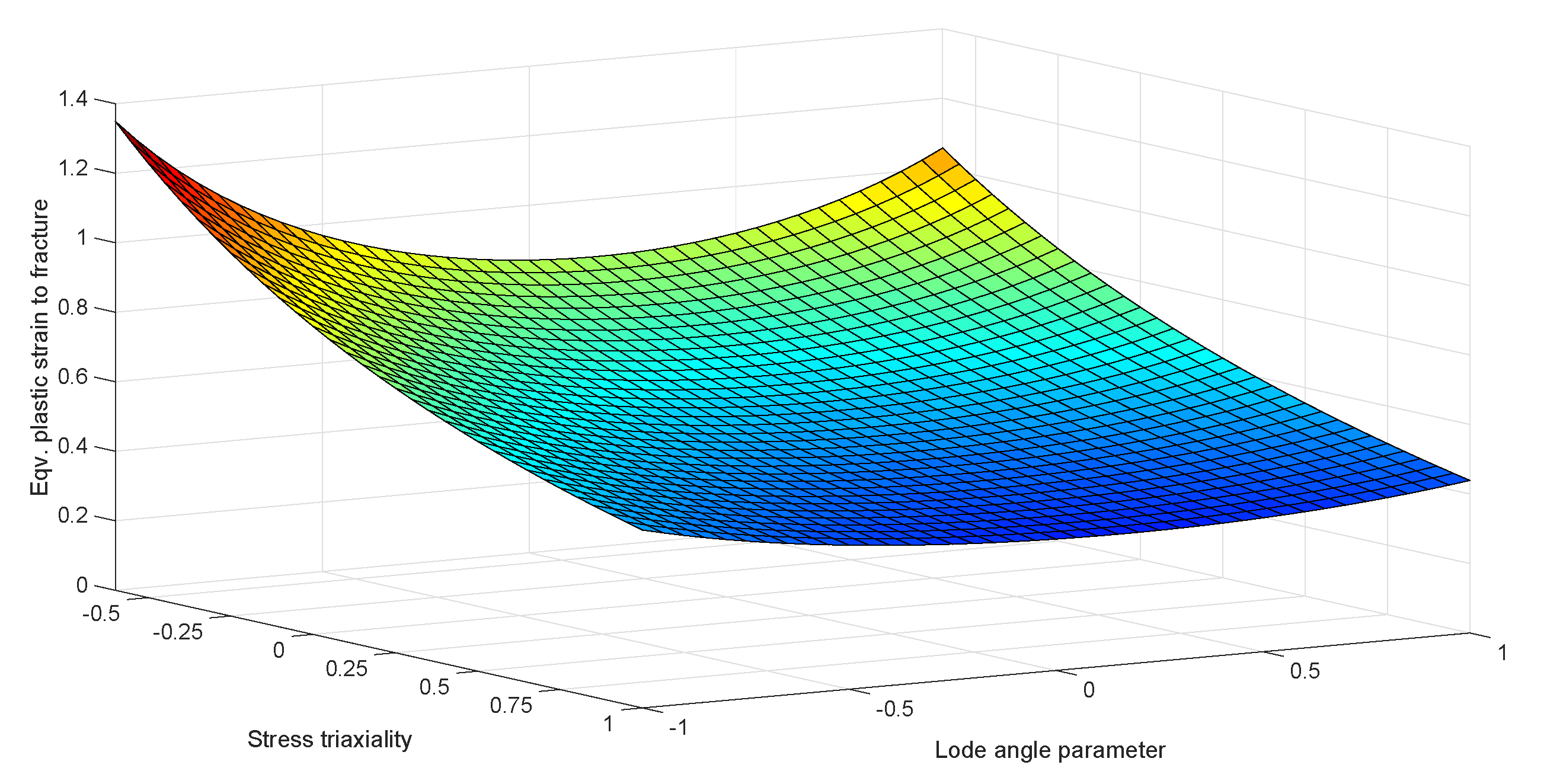

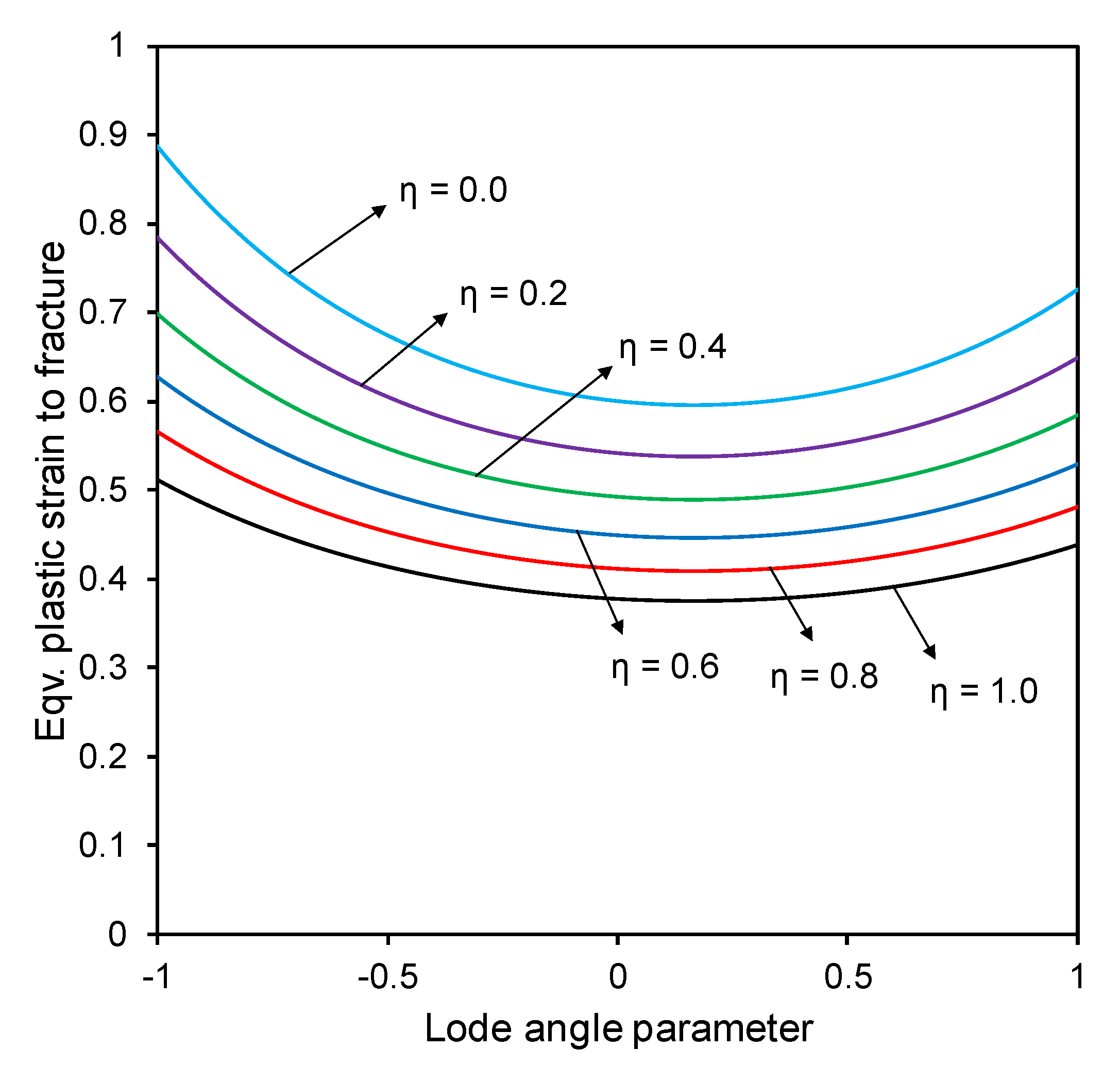

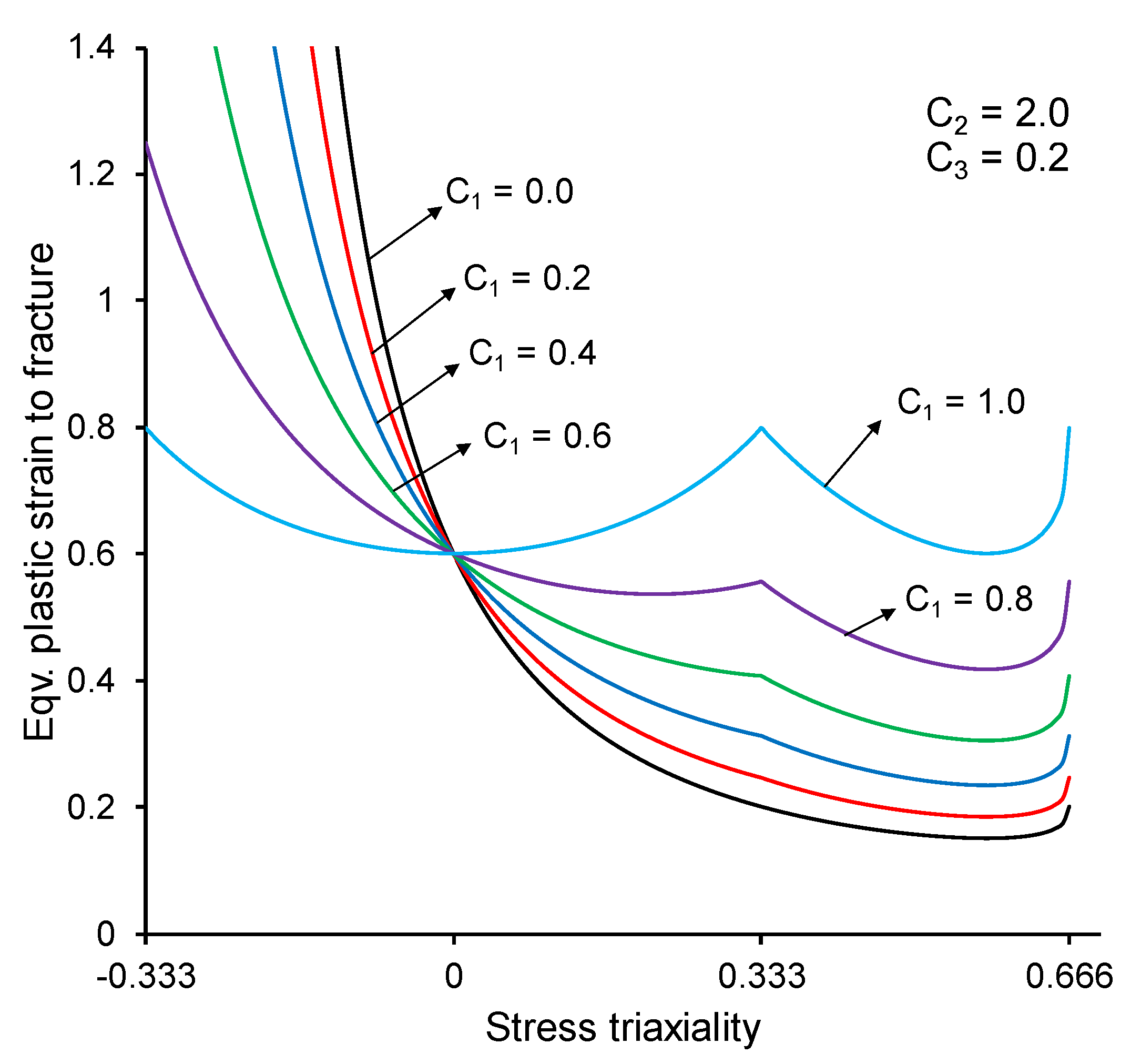

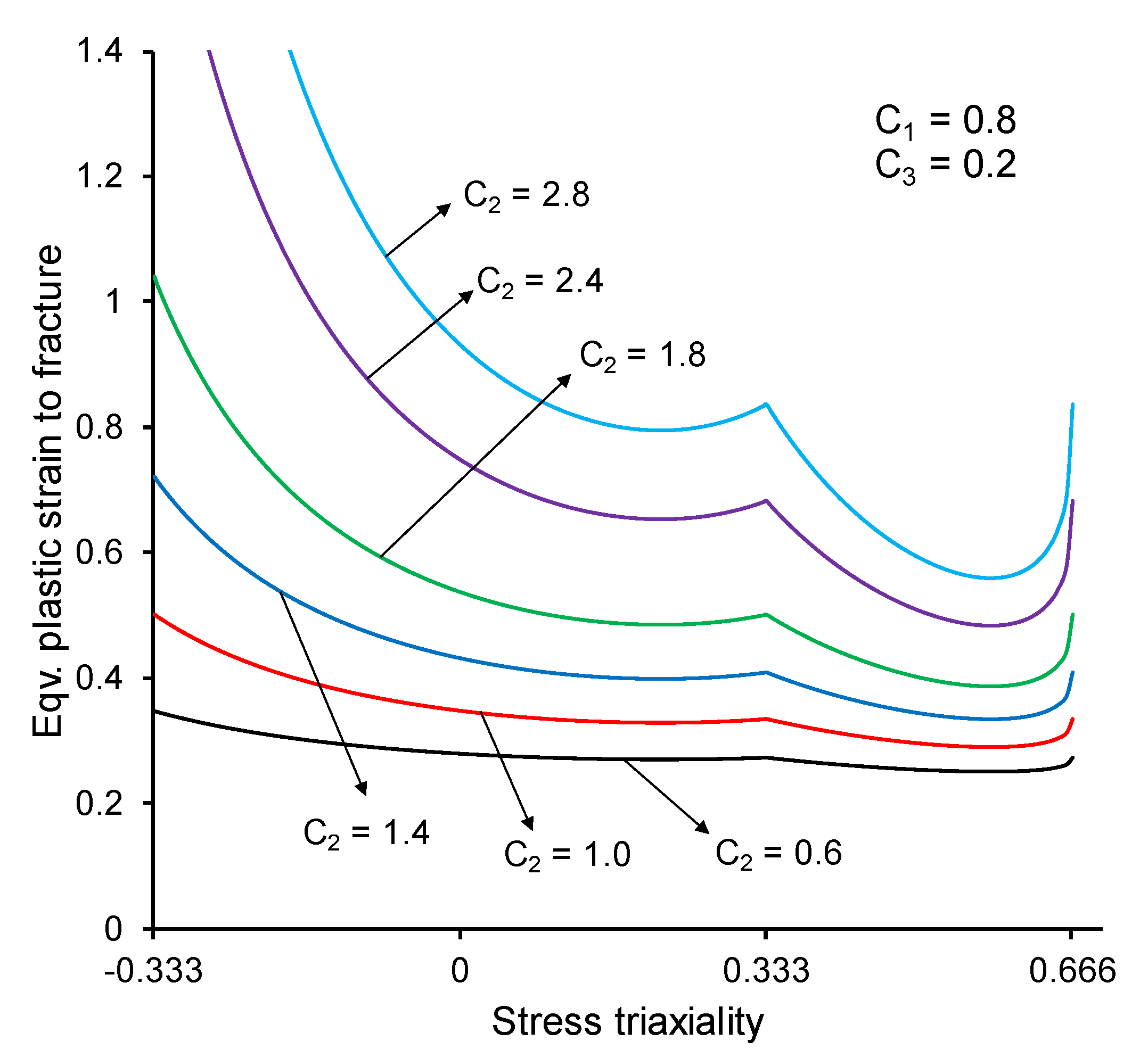

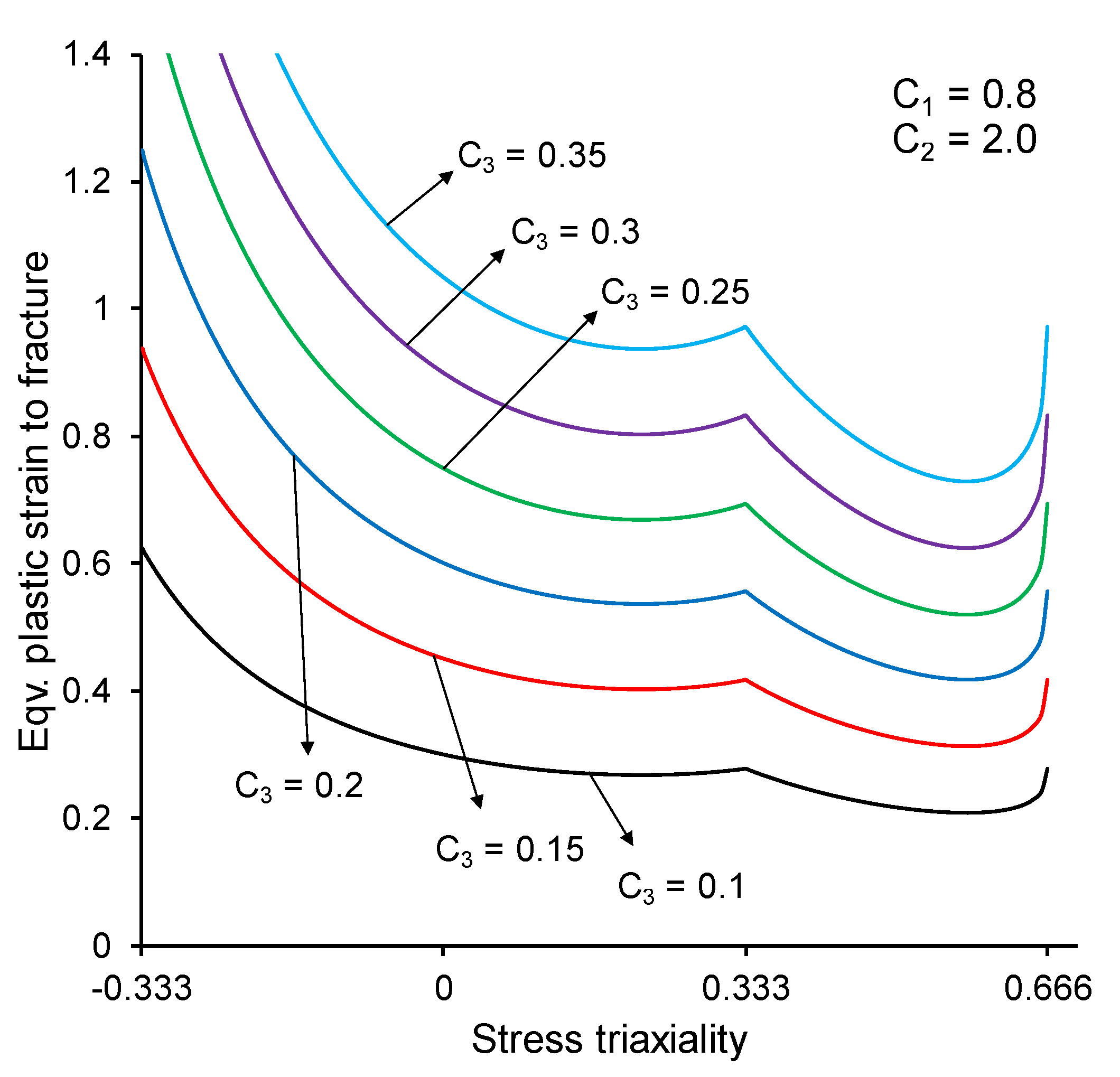

2.2. Parameter Sensitivity

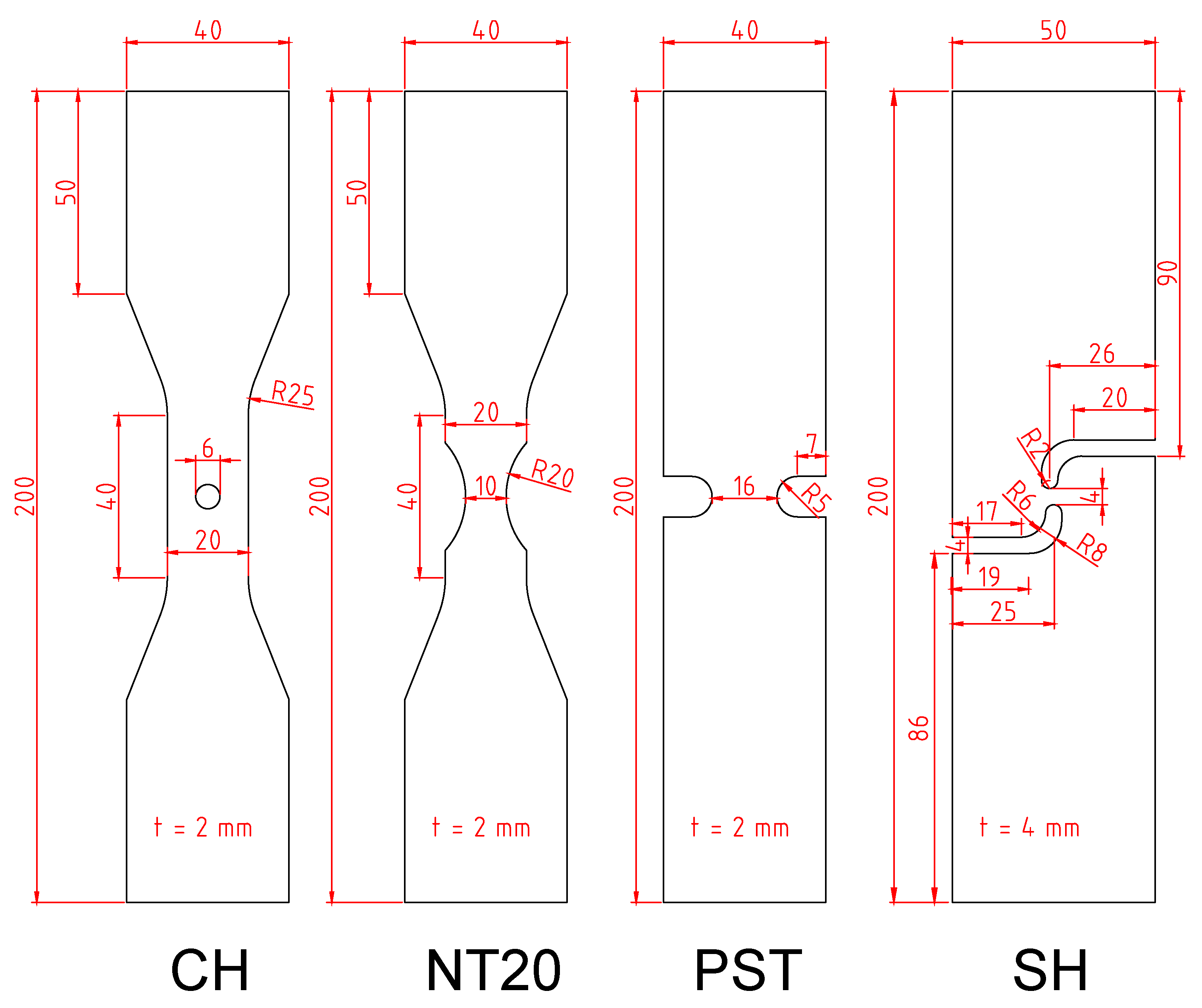

3. Experiments

- A grade (KR) normal-strength (mild) steel plate (6 mm);

- AH36 grade (ASTM A131) high-strength steel plate (6 mm);

- DH36 grade (LR) high-strength steel plate (7 mm).

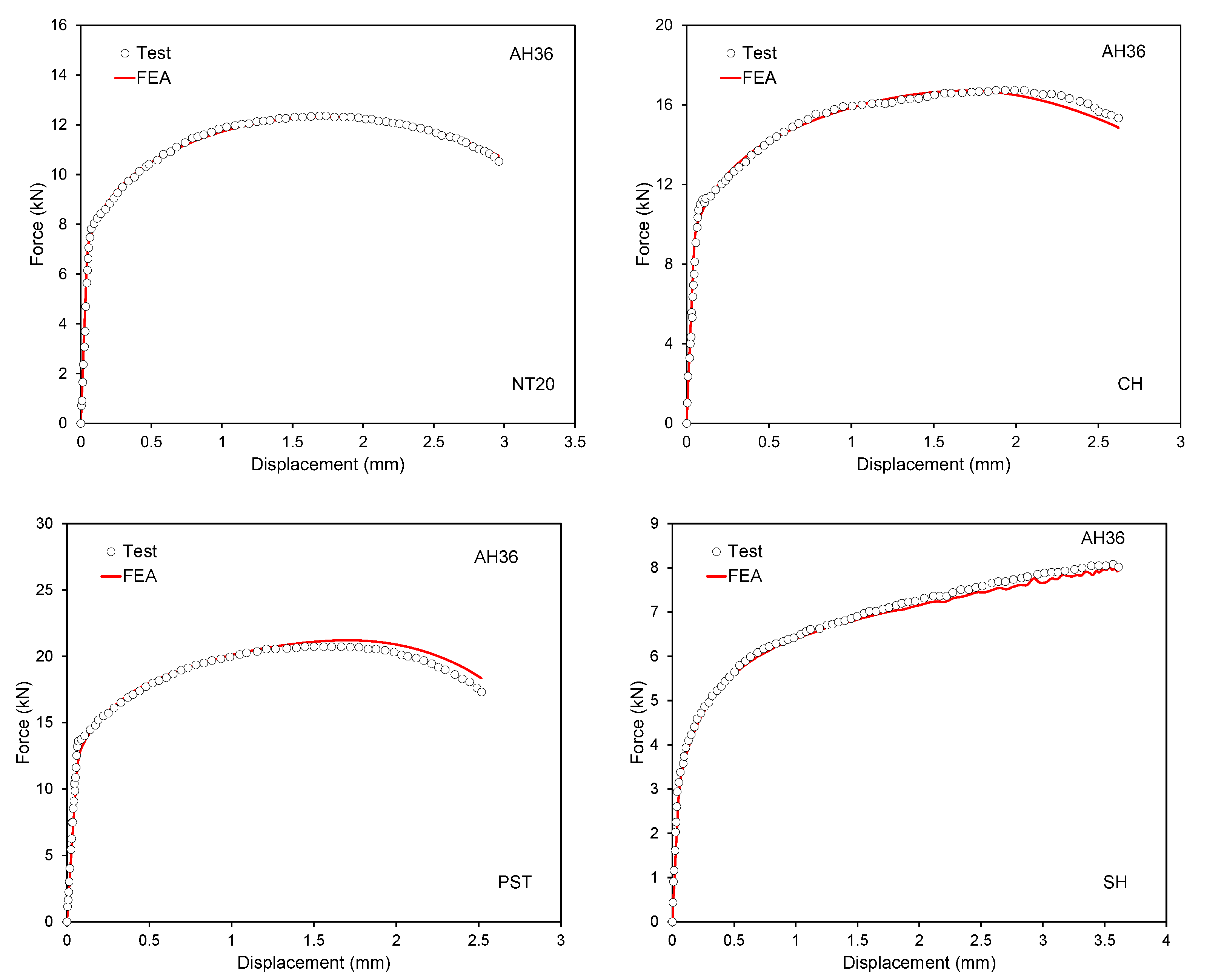

4. Fracture Model Calibration

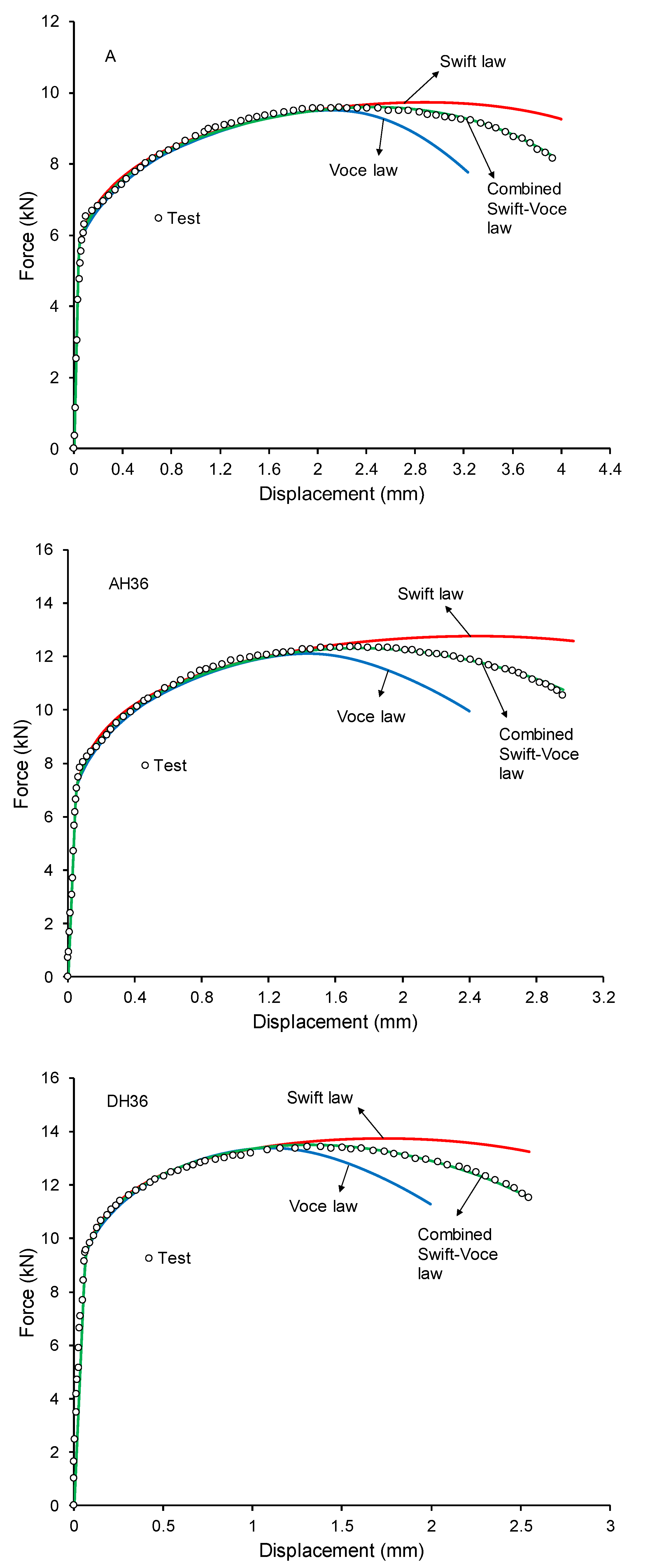

4.1. Hardening Model

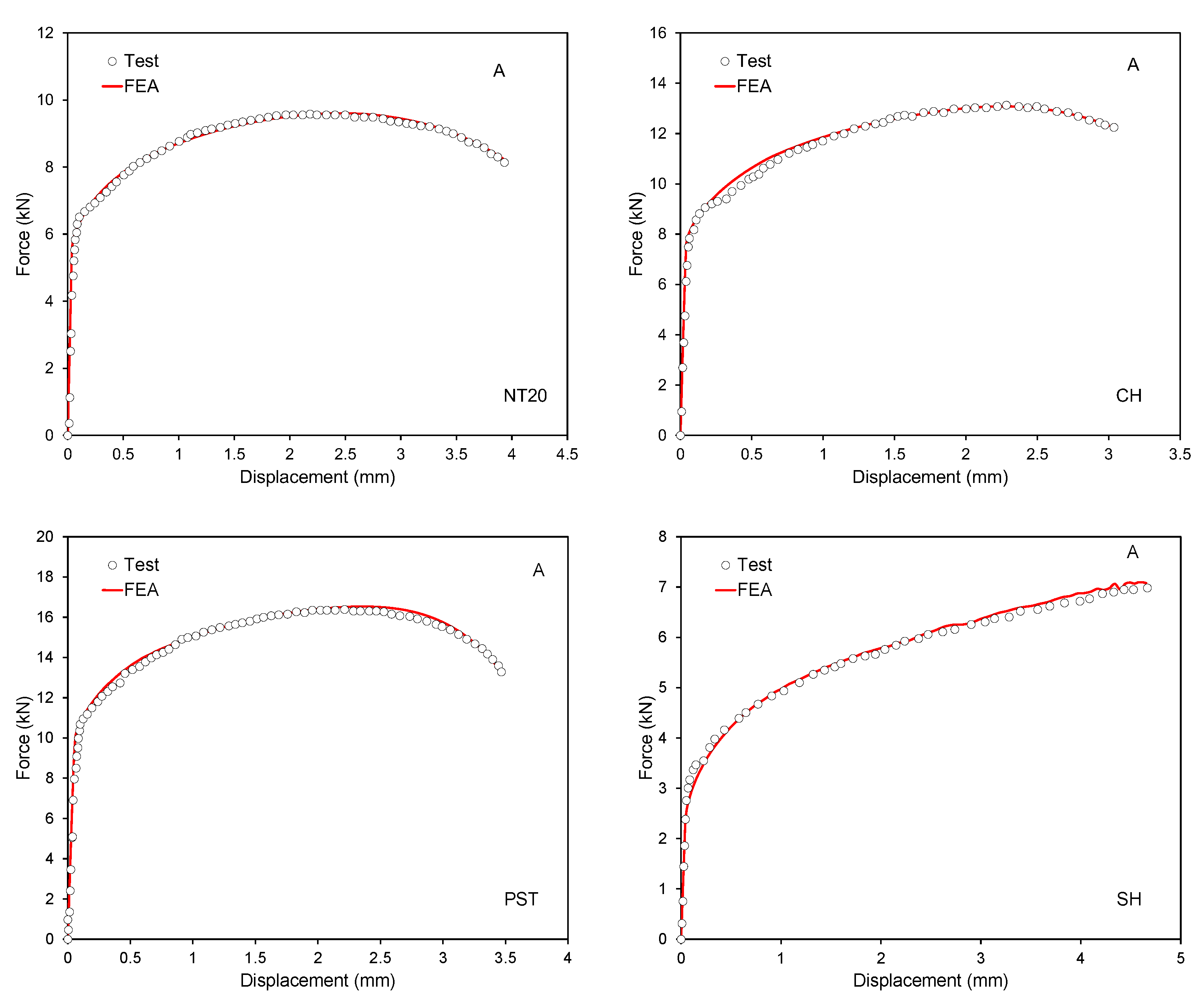

4.2. Loading Paths

4.3. Determination of Fracture Model Parameters

5. Conclusions

- Ductile fracture behavior is closely associated with hardening behavior in large strains;

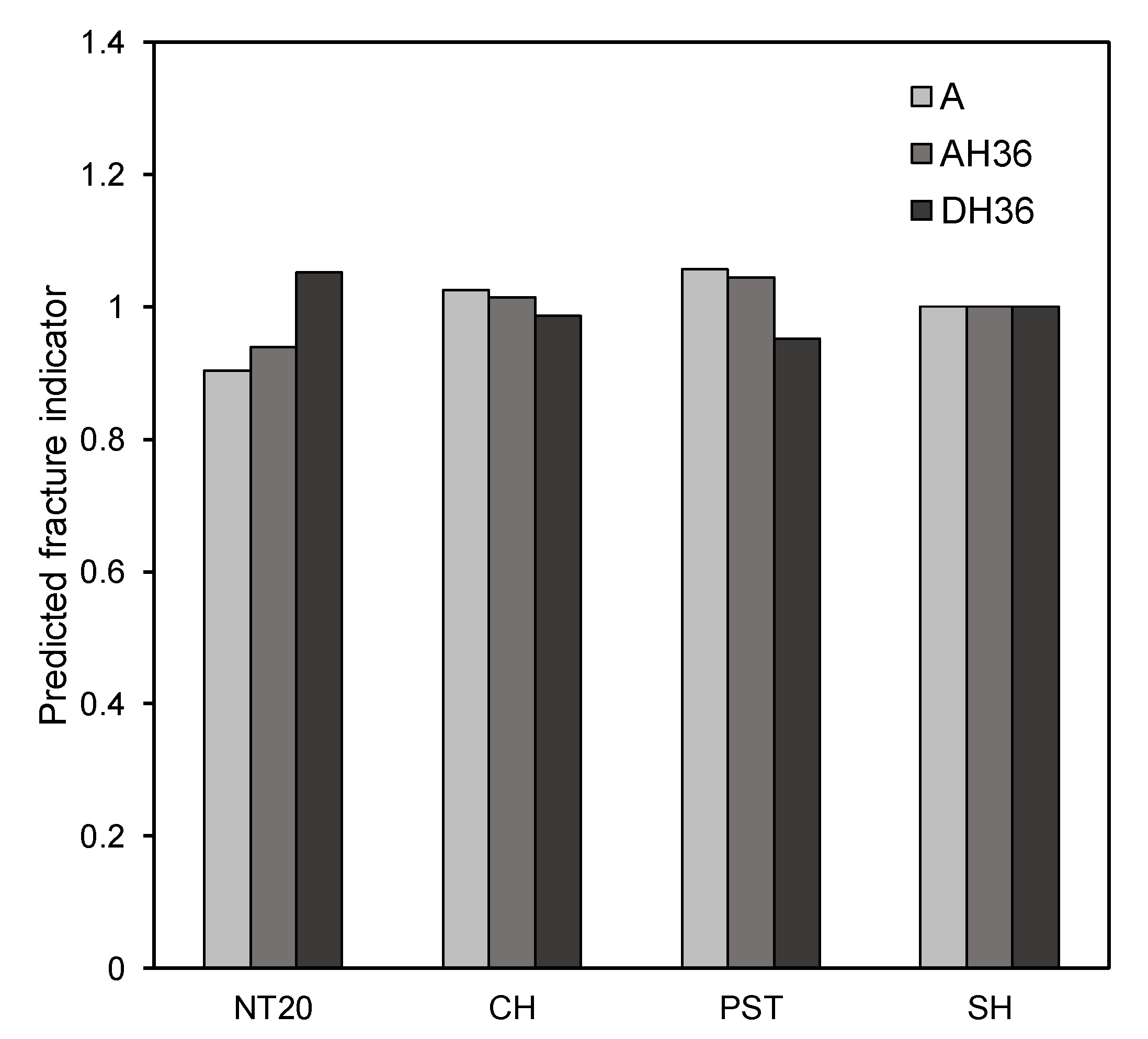

- The proposed model shows good flexibility for calibration and could predict the onset of fracture accurately for all the test specimens and steel grades considered;

- The ductility limits of normal strength steel, grade A, showed a relatively low Lode angle dependence. The Cockcroft–Latham model is appropriate for describing the ductile fracture locus of grade A steel;

- AH36 shows considerable Lode angle sensitivity. Despite being a high-tensile strength steel, AH36 shows higher ductility as compared to mild steel A for certain stress states, such as uniaxial tension and equi-biaxial tension;

- The fracture locus of DH36 exhibited a relatively high stress-triaxiality-dependence but moderate Lode angle effect.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ASTM | American Society for Testing and Materials |

| CL | Cockcroft–Latham |

| CNC | Computer numerical control |

| KR | Korean Register |

| LR | Lloyd’s Register |

| MSS | Maximum shear stress |

Appendix A.

Appendix A.1. Definition of the Stress State

Appendix A.2. Plasticity

References

- Matic, P.; Geltmacher, A.; Rath, B. Computational aspects of steel fracturing pertinent to naval requirements. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2015, 373, 20140127. [Google Scholar] [CrossRef]

- Takahashi, K.; Yamatoki, S.; Namegawa, T.; Kinoshita, M.; Fujioka, M. Dominant factors influencing ductile fracture on cutting surface during cold forming. In Proceedings of the ASME 2018 37th International Conference on Ocean, Offshore and Arctic Engineering, Madrid, Spain, 17–22 June 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018; Volume 4: Materials Technology. [Google Scholar] [CrossRef]

- Kanno, K.; Nishino, S.; Ohya, K. Evaluation of the form-forming mechanism for high-tensile-strength steel plate. Mater. Trans. 2017, 58, 1708–1714. [Google Scholar] [CrossRef]

- McClintock, F.A. A criterion for ductile fracture by the growth of holes. J. Appl. Mech. 1968, 35, 363–371. [Google Scholar] [CrossRef]

- Rice, J.; Tracey, D. On the ductile enlargement of voids in triaxial stress fields. J. Mech. Phys. Solids 1969, 17, 201–217. [Google Scholar] [CrossRef]

- Hancock, J.; MacKenzie, A. On the mechanisms of ductile failure in high-strength steels subjected to multi-axial stress-states. J. Mech. Phys. Solids 1976, 24, 147–160. [Google Scholar] [CrossRef]

- Hancock, J.; Brown, D. On the role of strain and stress state in ductile failure. J. Mech. Phys. Solids 1983, 31, 1–24. [Google Scholar] [CrossRef]

- Gurson, A.L. Continuum theory of ductile rupture by void nucleation and growth: Part I-yield criteria and flow rules for porous ductile media. J. Eng. Mater. Technol. 1977, 99, 2–15. [Google Scholar] [CrossRef]

- Tvergaard, V. Influence of voids on shear band instabilities under plane strain conditions. Int. J. Fract. 1981, 17, 389–407. [Google Scholar] [CrossRef]

- Tvergaard, V.; Needleman, A. Analysis of the cup-cone fracture in a round tensile bar. Acta Metall. 1984, 32, 157–169. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Cockcroft, M.G.; Latham, D.J. Ductility and the workability of metals. J. Inst. Met. 1968, 96, 33–39. [Google Scholar]

- Oh, S.I.; Chen, C.C.; Kobayashi, S. Ductile fracture in axisymmetric extrusion and drawing-part 2: Workability in extrusion and drawing. J. Eng. Ind. 1979, 101, 36. [Google Scholar] [CrossRef]

- Xue, L. Ductile Fracture Modeling: Theory, Experimental Investigation and Numerical Verification. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2007. [Google Scholar]

- Bao, Y.; Wierzbicki, T. On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 2004, 46, 81–98. [Google Scholar] [CrossRef]

- Barsoum, I.; Faleskog, J. Rupture mechanisms in combined tension and shear-experiments. Int. J. Solids Struct. 2007, 44, 1768–1786. [Google Scholar] [CrossRef]

- Clausing, D. Effect of plastic strain state on ductility and toughness. Int. J. Fract. Mech. 1970, 6. [Google Scholar] [CrossRef]

- Xue, L. Damage accumulation and fracture initiation in uncracked ductile solids subject to triaxial loading. Int. J. Solids Struct. 2007, 44, 5163–5181. [Google Scholar] [CrossRef]

- Xue, L. Constitutive modeling of void shearing effect in ductile fracture of porous materials. Eng. Fract. Mech. 2008, 75, 3343–3366. [Google Scholar] [CrossRef]

- Wierzbicki, T.; Bao, Y.; Lee, Y.W.; Bai, Y. Calibration and evaluation of seven fracture models. Int. J. Mech. Sci. 2005, 47, 719–743. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. A new model of metal plasticity and fracture with pressure and Lode dependence. Int. J. Plast. 2008, 24, 1071–1096. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. Application of extended Mohr-Coulomb criterion to ductile fracture. Int. J. Fract. 2010, 161, 1–20. [Google Scholar] [CrossRef]

- Lou, Y.; Huh, H. Extension of a shear-controlled ductile fracture model considering the stress triaxiality and the Lode parameter. Int. J. Solids Struct. 2013, 50, 447–455. [Google Scholar] [CrossRef]

- Wen, H.; Mahmoud, H. New model for ductile fracture of metal alloys. I: Monotonic loading. J. Eng. Mech. 2016, 142, 04015088. [Google Scholar] [CrossRef]

- Hu, Q.; Li, X.; Han, X.; Chen, J. A new shear and tension based ductile fracture criterion: Modeling and validation. Eur. J. Mech. A/Solids 2017, 66, 370–386. [Google Scholar] [CrossRef]

- Mu, L.; Zang, Y.; Wang, Y.; Li, X.L.; Araujo Stemler, P.M. Phenomenological uncoupled ductile fracture model considering different void deformation modes for sheet metal forming. Int. J. Mech. Sci. 2018, 141, 408–423. [Google Scholar] [CrossRef]

- Quach, H.; Kim, J.J.; Nguyen, D.T.; Kim, Y.S. Uncoupled ductile fracture criterion considering secondary void band behaviors for failure prediction in sheet metal forming. Int. J. Mech. Sci. 2020, 169, 105297. [Google Scholar] [CrossRef]

- Park, S.J.; Cerik, B.C.; Choung, J. Comparative study on ductile fracture prediction of high-tensile strength marine structural steels. Ships Offshore Struct. 2020. [Google Scholar] [CrossRef]

- Cerik, B.C.; Park, S.J.; Choung, J. Ductile fracture modeling of DH36 grade steels. In Proceedings of the 37th International Conference on Ocean, Offshore and Arctic Engineering, Madrid, Spain, 17–22 June 2018; ASME: New York, NY, USA, 2018; p. V11AT12A008. [Google Scholar] [CrossRef]

- Cerik, B.C.; Lee, K.; Park, S.J.; Choung, J. Simulation of ship collision and grounding damage using Hosford-Coulomb fracture model for shell elements. Ocean Eng. 2019, 173, 415–432. [Google Scholar] [CrossRef]

- Cerik, B.C.; Ringsberg, J.W.; Choung, J. Revisiting MARSTRUCT benchmark study on side-shell collision with a combined localized necking and stress-state dependent ductile fracture model. Ocean Eng. 2019, 187, 106173. [Google Scholar] [CrossRef]

- Cerik, B.C.; Park, B.; Park, S.J.; Choung, J. Modeling, testing and calibration of ductile crack formation in grade DH36 ship plates. Mar. Struct. 2019, 66, 27–43. [Google Scholar] [CrossRef]

- Cerik, B.C.; Choung, J. On the prediction of ductile fracture in ship structures with shell elements at low temperatures. Thin-Walled Struct. 2020. [Google Scholar] [CrossRef]

- Cerik, B.C.; Park, S.J.; Choung, J. Use of localized necking and fracture as a failure criterion in ship collision analysis. Mar. Struct. 2020, 73, 102787. [Google Scholar] [CrossRef]

- Cerik, B.C.; Choung, J. Rate-dependent combined necking and fracture model for predicting ductile fracture with shell elements at high strain rates. Int. J. Impact Eng. 2020, 146, 103697. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, K.; Cerik, B.C.; Choung, J. Ductile fracture prediction of EH36 grade steel based on Hosford-Coulomb model. Ships Offshore Struct. 2019, 14, 219–230. [Google Scholar] [CrossRef]

- Gruben, G.; Hopperstad, O.; Børvik, T. Evaluation of uncoupled ductile fracture criteria for the dual-phase steel Docol 600DL. Int. J. Mech. Sci. 2012, 62, 133–146. [Google Scholar] [CrossRef]

- Peirs, J.; Verleysen, P.; Degrieck, J. Novel technique for static and dynamic shear testing of Ti6Al4V sheet. Exp. Mech. 2012, 52, 729–741. [Google Scholar] [CrossRef]

- Sung, J.H.; Kim, J.H.; Wagoner, R.H. A plastic constitutive equation incorporating strain, strain-rate, and temperature. Int. J. Plast. 2010, 26, 1746–1771. [Google Scholar] [CrossRef]

| Grade | C | Si | Mn | P | S | Cu | Cr | Ni | Mo | Al | Nb | V | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 0.1395 | 0.183 | 0.511 | 0.0101 | 0.0042 | - | - | - | - | - | - | - | - |

| AH36 | 0.16 | 0.34 | 1.4 | 0.019 | 0.005 | 0.03 | 0.02 | 0.01 | 0.003 | 0 | 0.002 | 0.003 | 0.001 |

| DH36 | 0.1254 | 0.272 | 1.495 | 0.0114 | 0.0038 | 0.085 | 0.05 | 0.09 | 0 | 0.042 | 0.029 | 0.002 | 0.016 |

| Grade | A (MPa) | n | (MPa) | Q (MPa) | |||

|---|---|---|---|---|---|---|---|

| A | 848 | 0.012914 | 0.2627 | 270.5 | 312.4 | 11.49 | 0.65 |

| AH36 | 1053 | 0.005407 | 0.2194 | 335.0 | 340.2 | 22.14 | 0.52 |

| DH36 | 1058 | 0.007986 | 0.1794 | 444.7 | 293.1 | 21.89 | 0.55 |

| Grade | |||

|---|---|---|---|

| A | 0.069 | 0.648 | 1.154 |

| AH36 | 0.882 | 3.860 | 0.148 |

| DH36 | 0.529 | 1.330 | 0.633 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cerik, B.C.; Choung, J. Ductile Fracture Behavior of Mild and High-Tensile Strength Shipbuilding Steels. Appl. Sci. 2020, 10, 7034. https://doi.org/10.3390/app10207034

Cerik BC, Choung J. Ductile Fracture Behavior of Mild and High-Tensile Strength Shipbuilding Steels. Applied Sciences. 2020; 10(20):7034. https://doi.org/10.3390/app10207034

Chicago/Turabian StyleCerik, Burak Can, and Joonmo Choung. 2020. "Ductile Fracture Behavior of Mild and High-Tensile Strength Shipbuilding Steels" Applied Sciences 10, no. 20: 7034. https://doi.org/10.3390/app10207034

APA StyleCerik, B. C., & Choung, J. (2020). Ductile Fracture Behavior of Mild and High-Tensile Strength Shipbuilding Steels. Applied Sciences, 10(20), 7034. https://doi.org/10.3390/app10207034