Impact Damage Resistance and Post-Impact Tolerance of Optimum Banana-Pseudo-Stem-Fiber-Reinforced Epoxy Sandwich Structures

Abstract

:1. Introduction

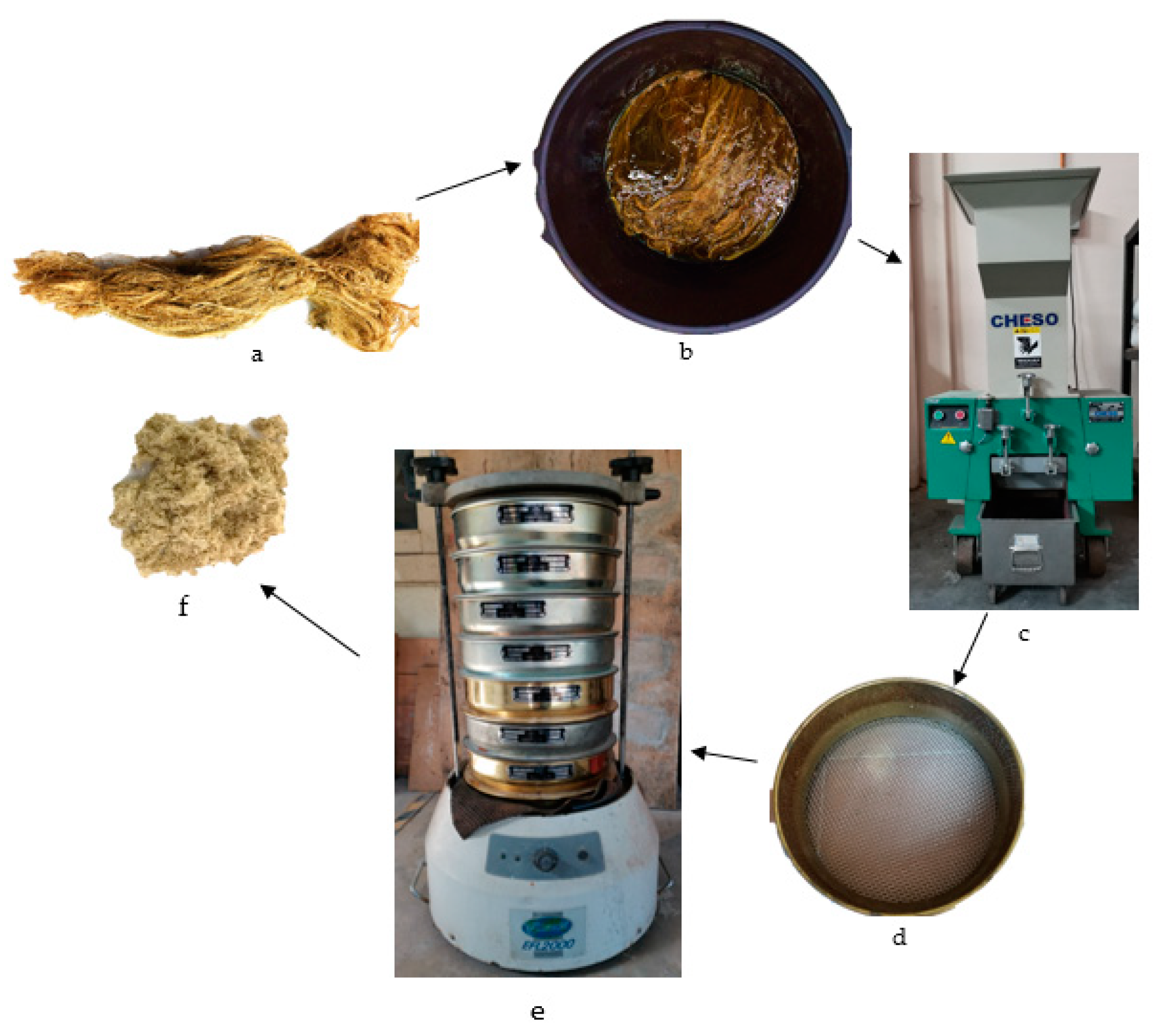

2. Materials and Methods

2.1. Materials

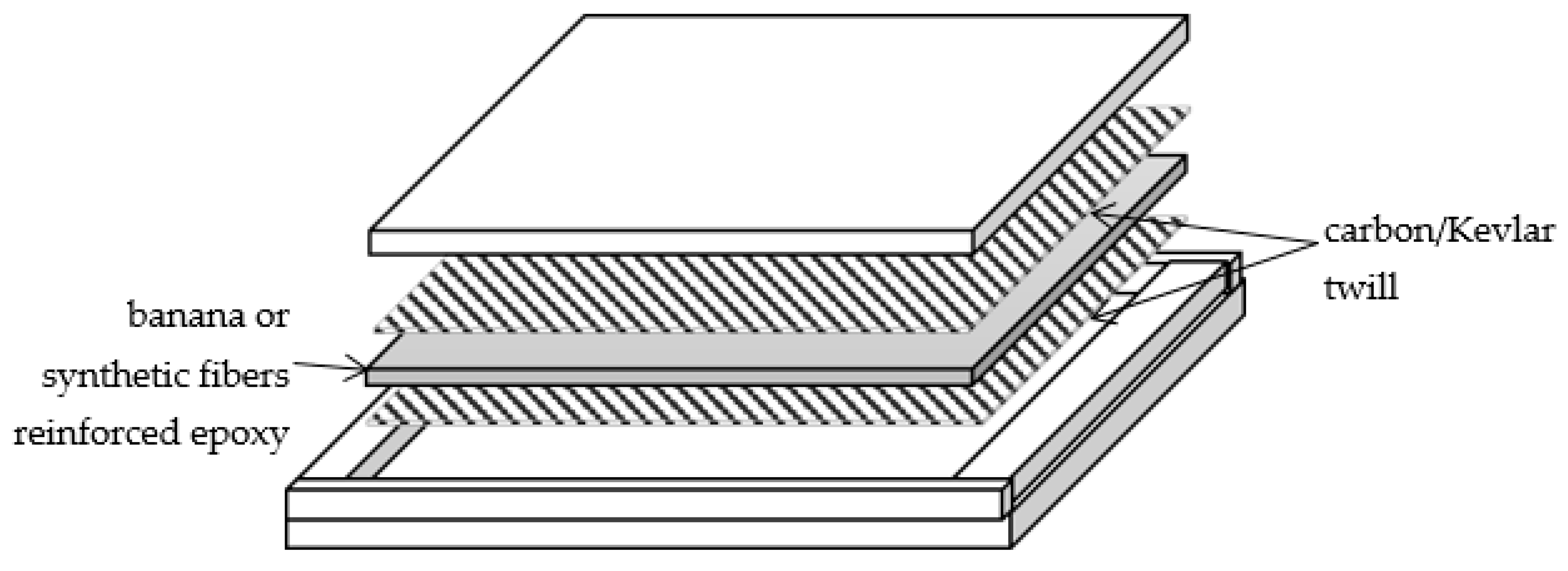

2.2. Fabrication of Composites

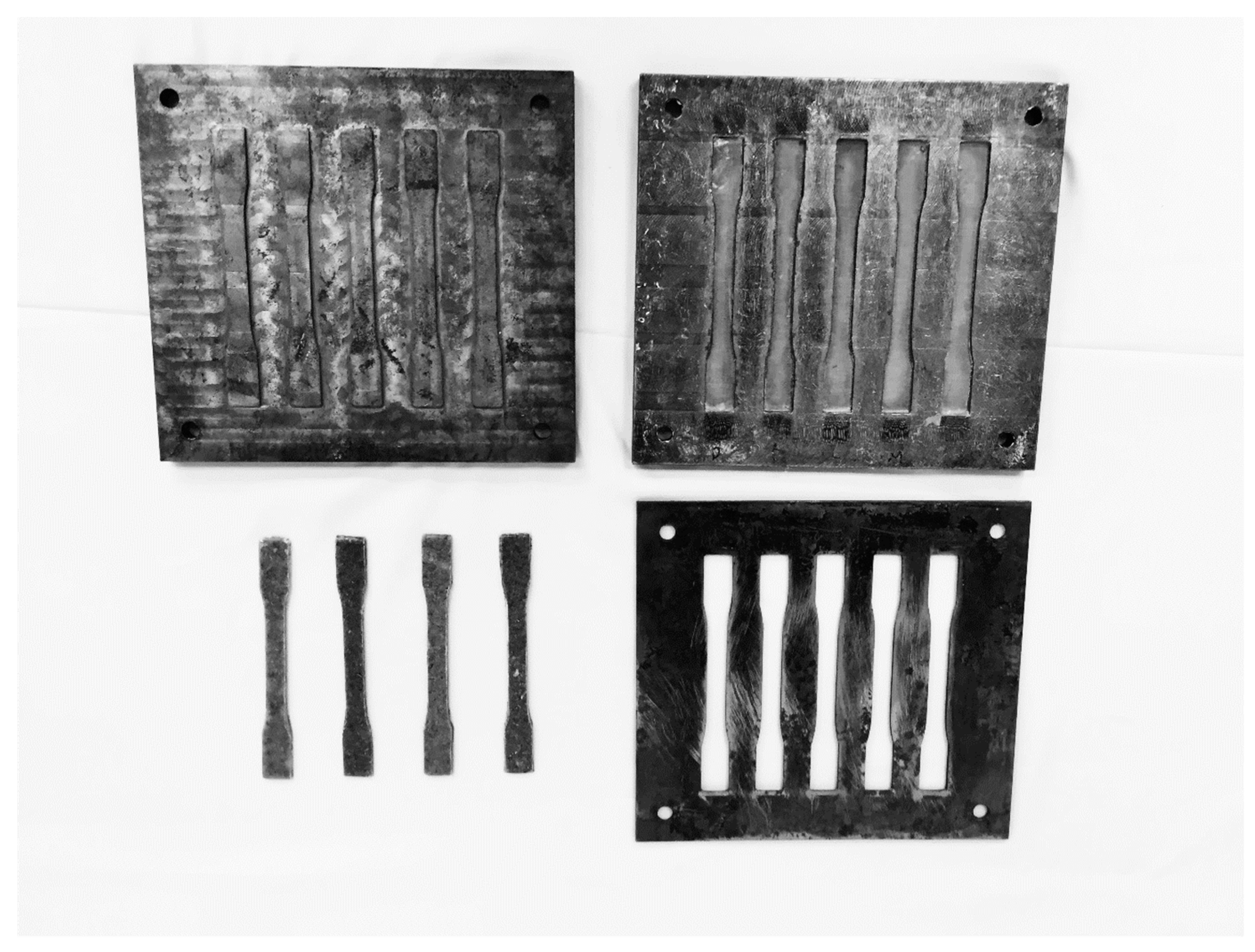

2.3. Tensile and Sandwich Structure Preparation

2.4. Tensile Test Properties

2.5. Low-Velocity Impact Test

2.6. Dye Penetrant Application

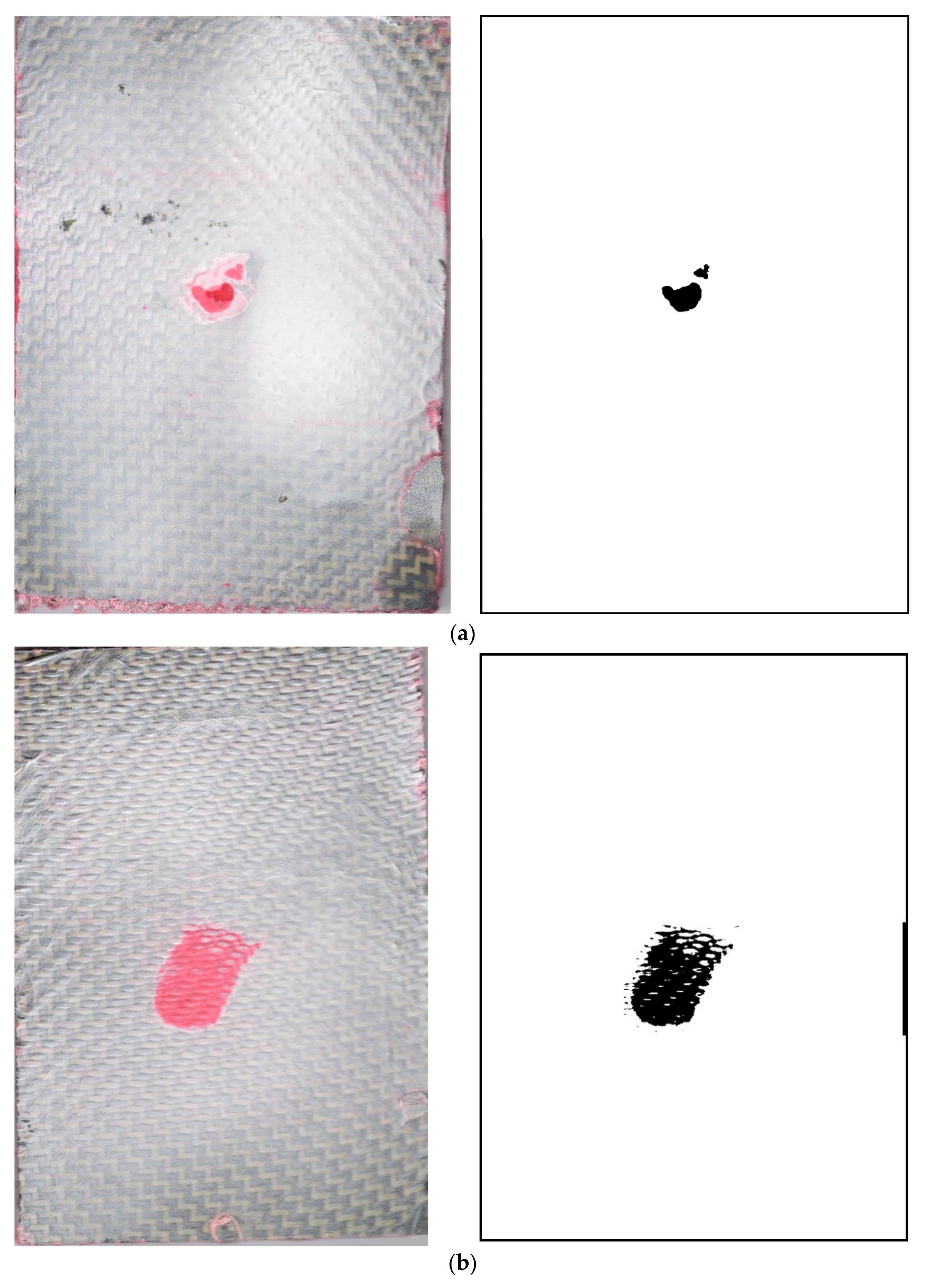

2.7. Damage Area Measurement

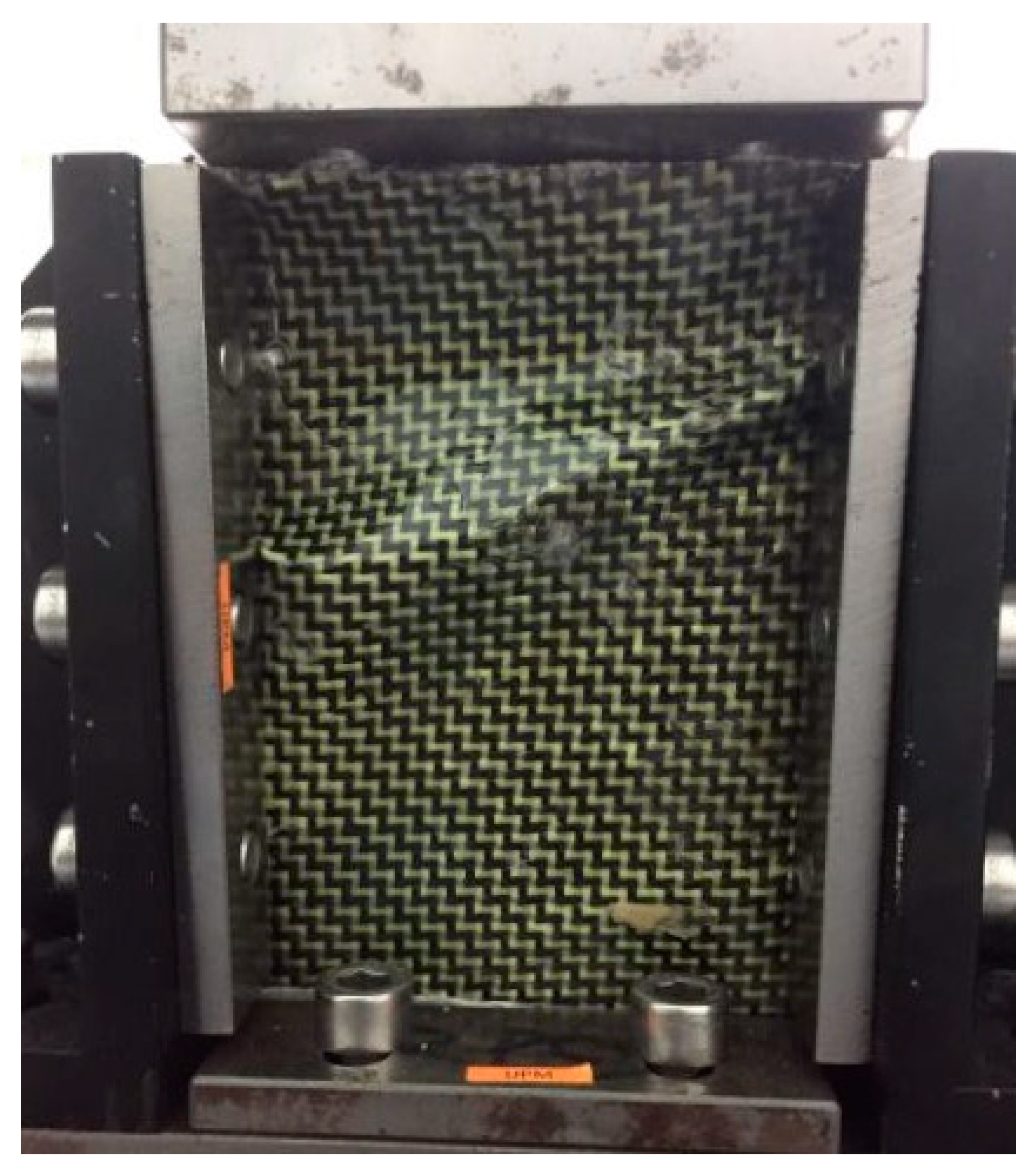

2.8. The Compression after Impact Test

3. Results and Discussion

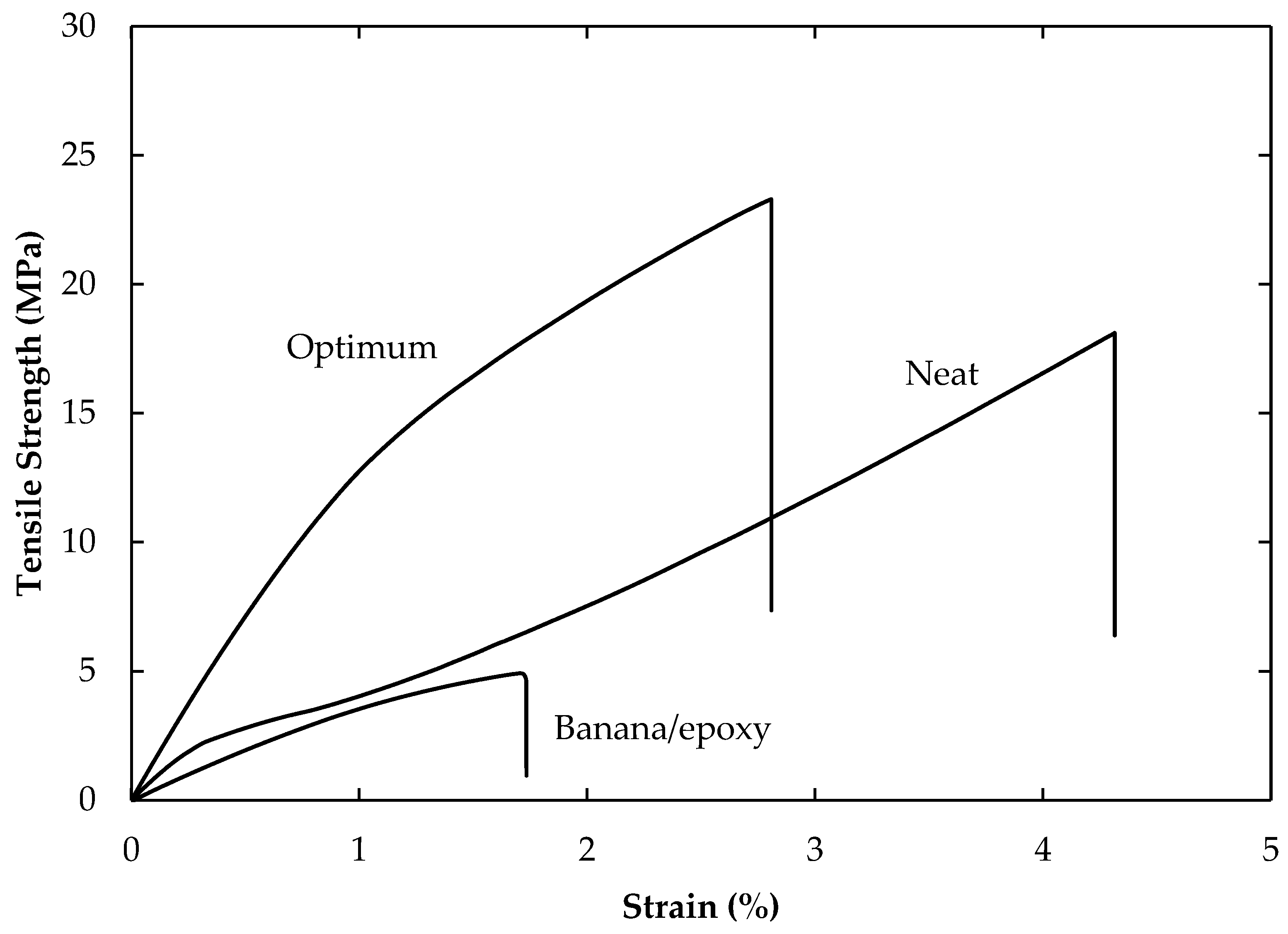

3.1. Tensile Properties of Composites

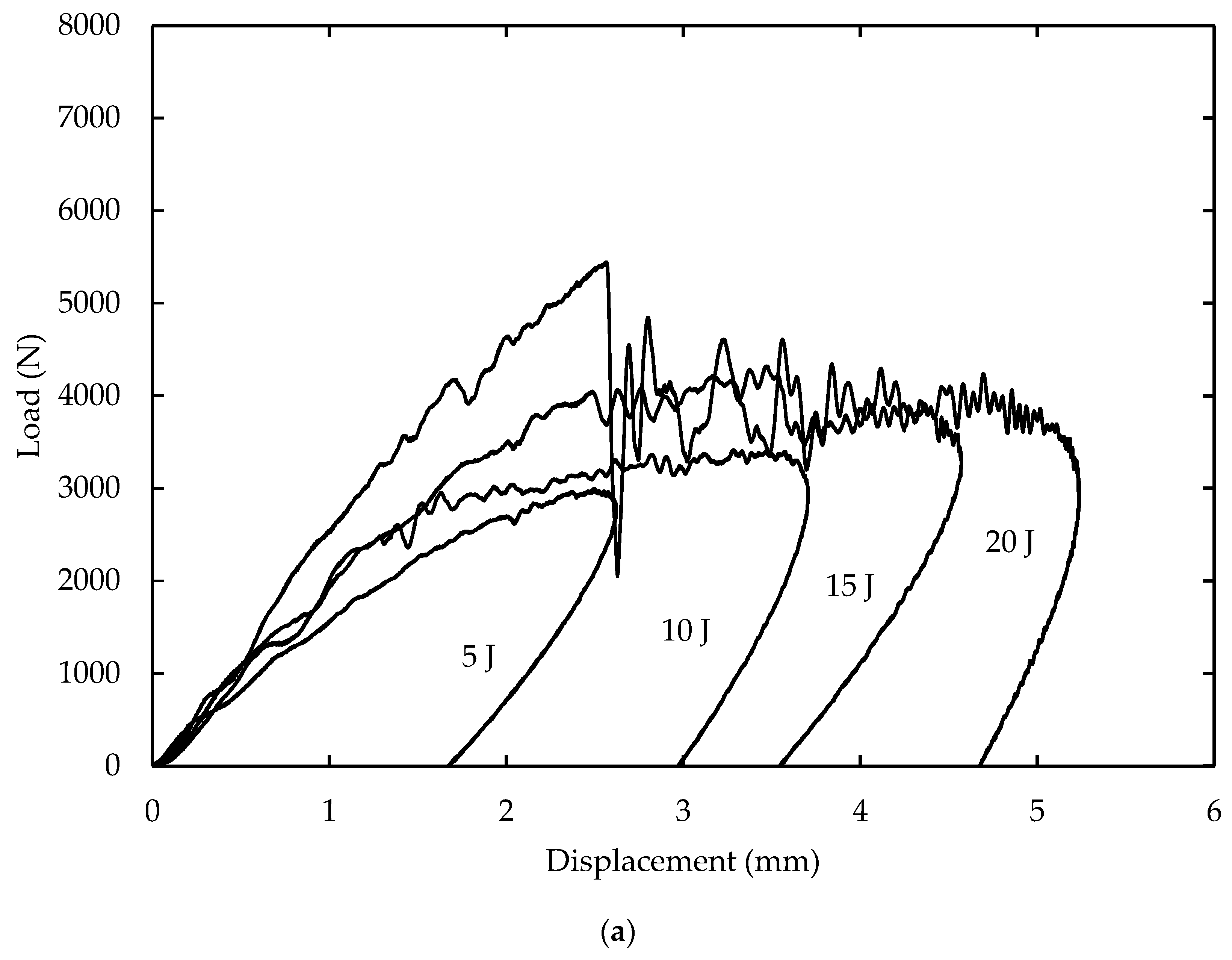

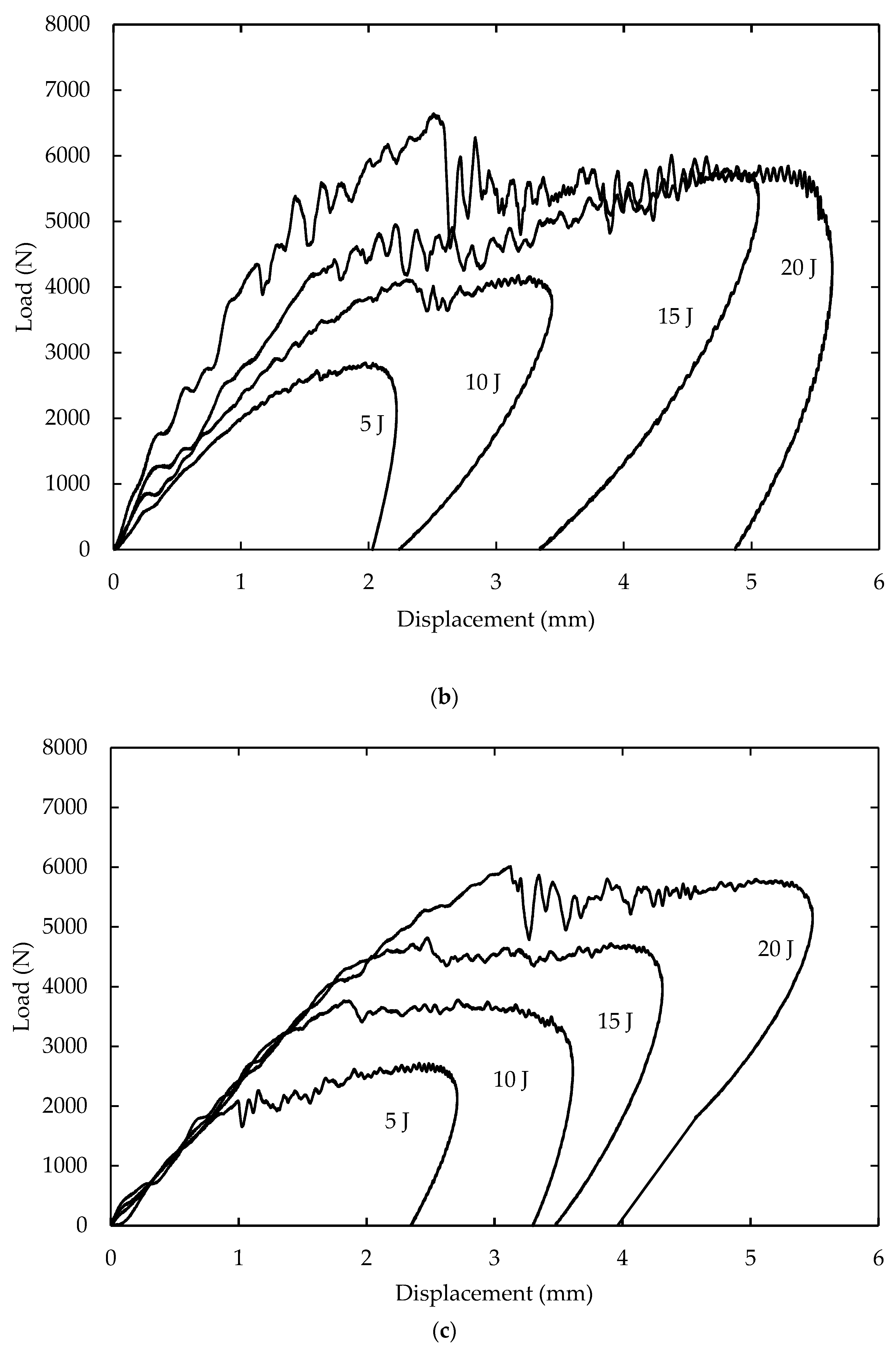

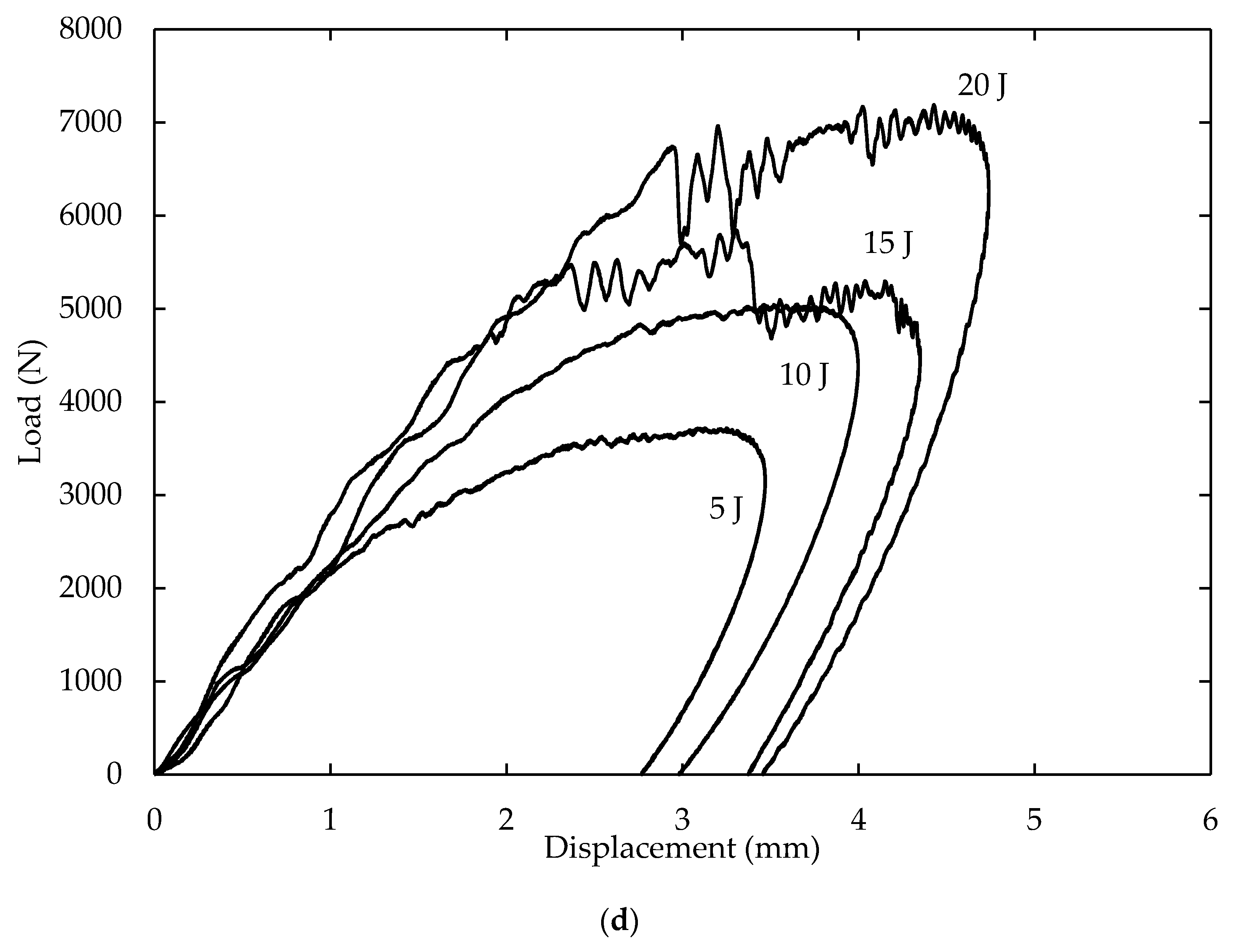

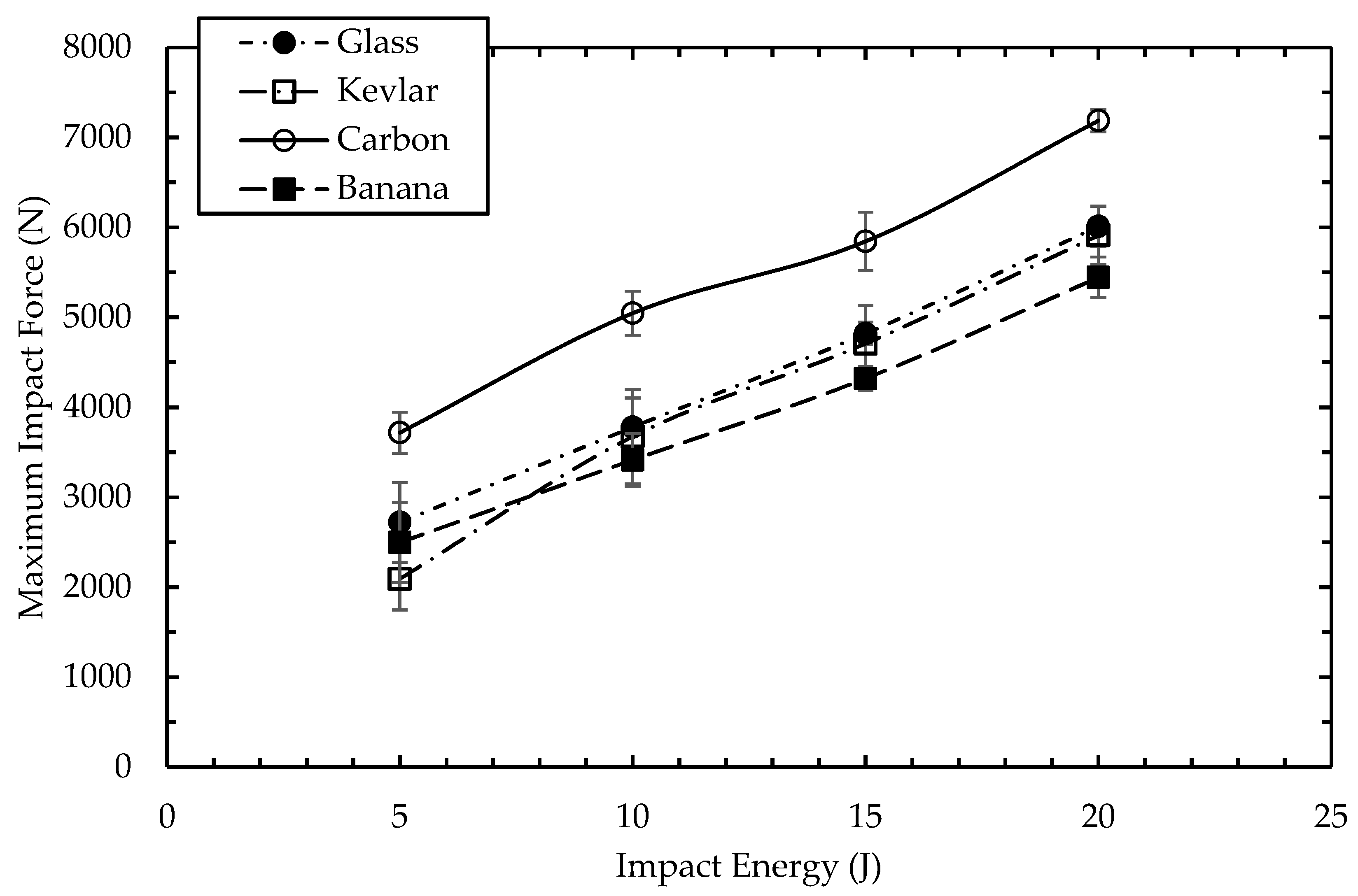

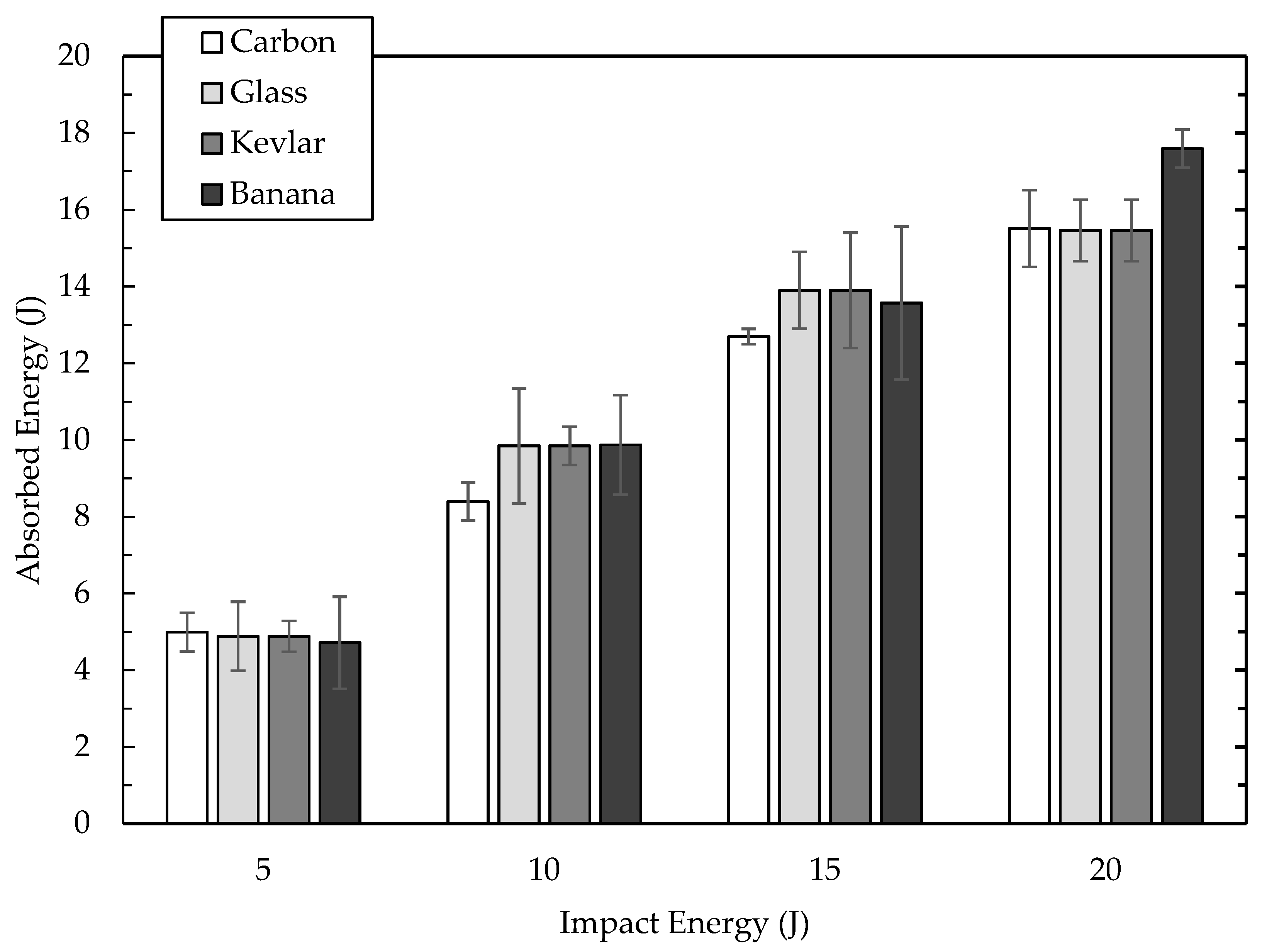

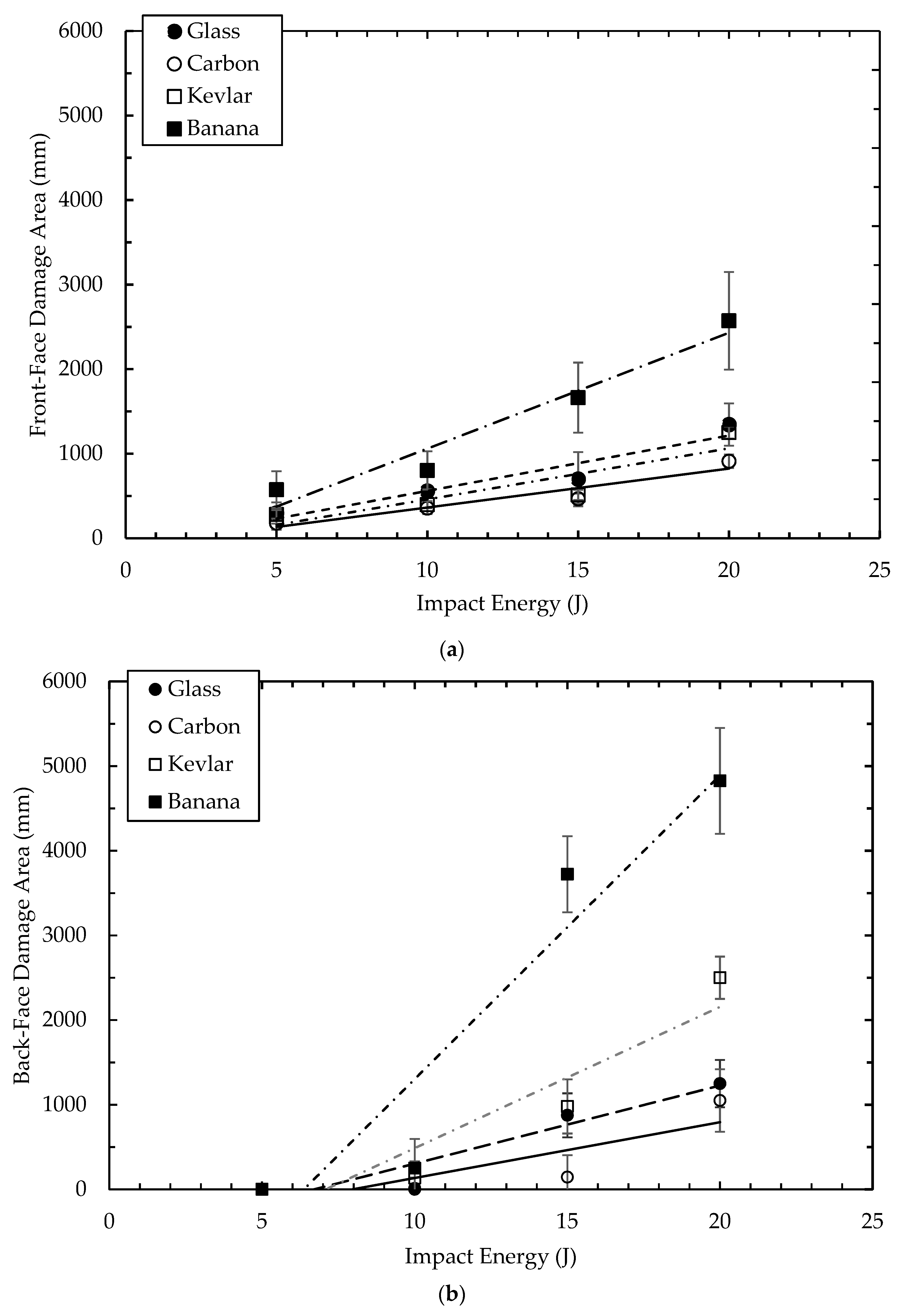

3.2. Low-Velocity Impact Response of Sandwich Structures

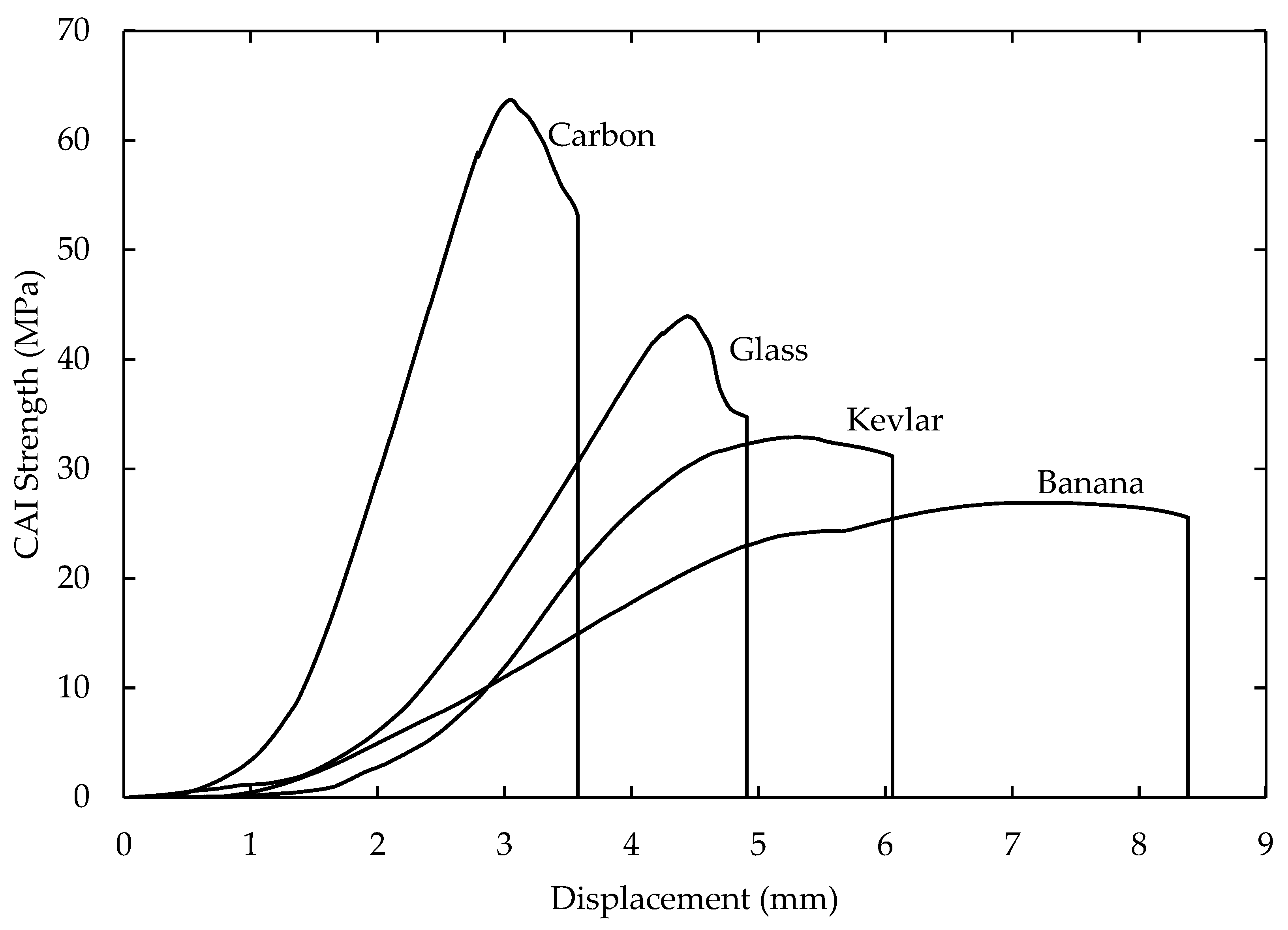

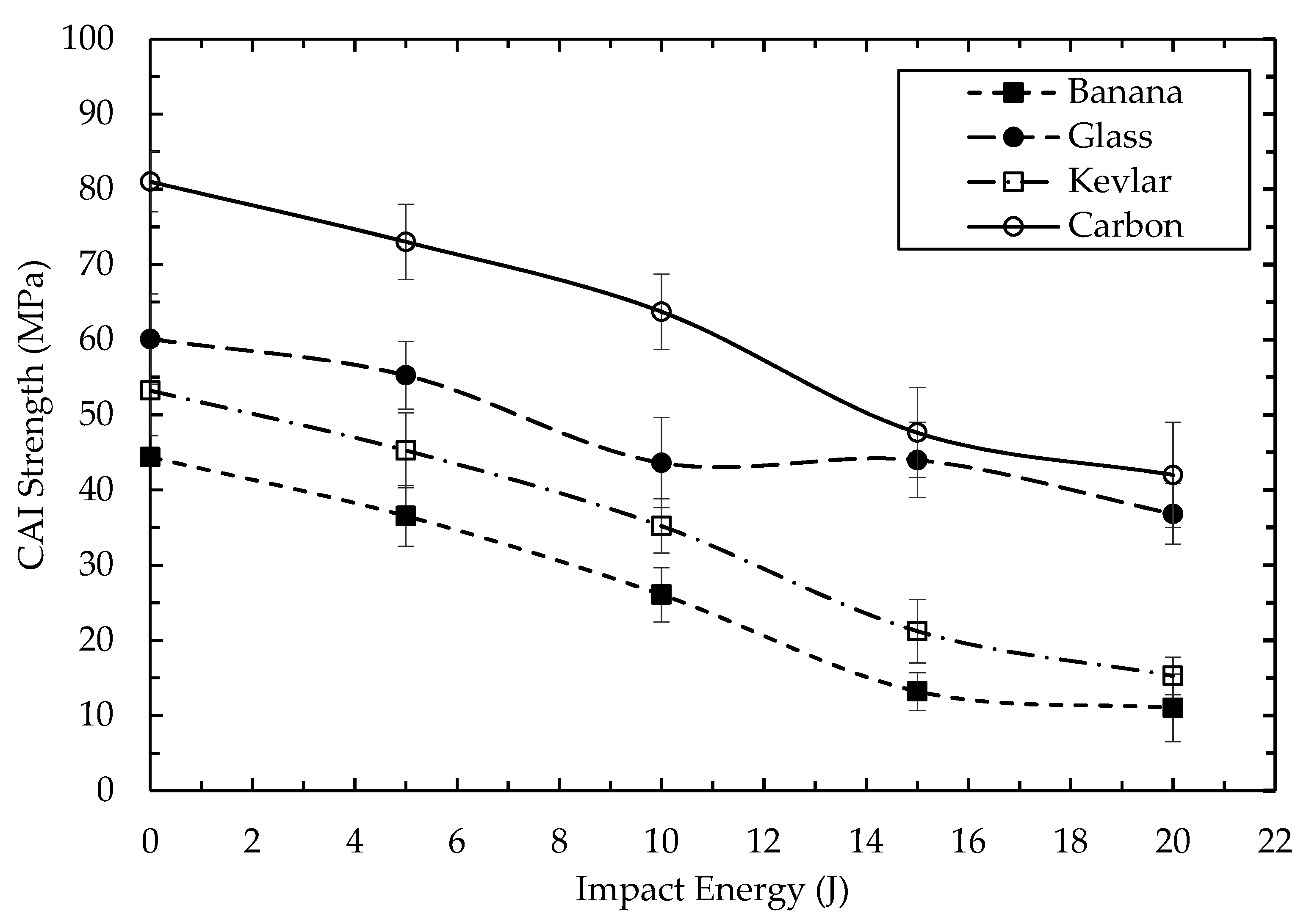

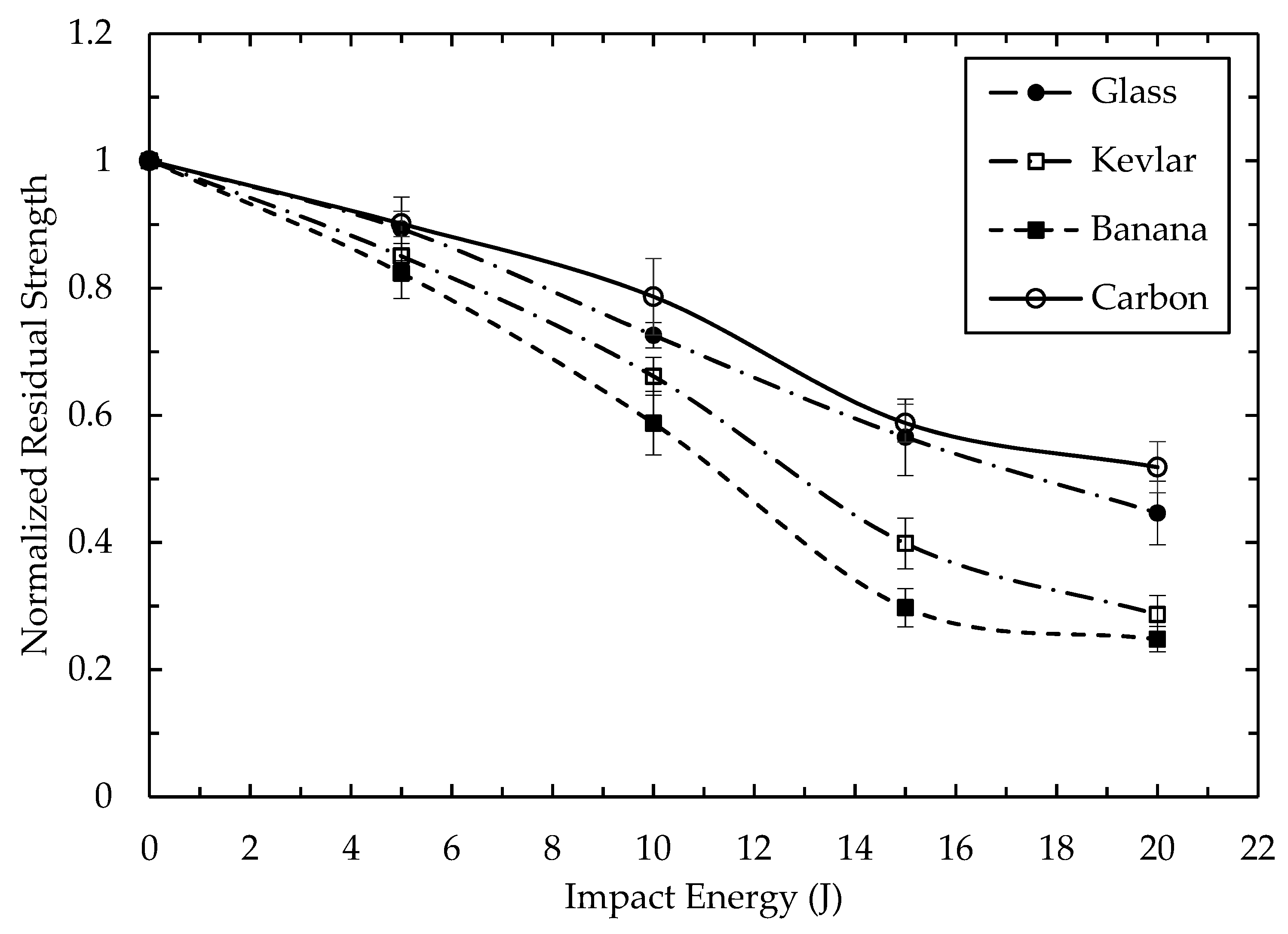

3.3. Compression after Impact (CAI) of Structure Properties

4. Conclusions

- i.

- The maximum stress and tensile modulus of the optimal banana-fiber-reinforced epoxy composite were increased up to 90% and 22%, respectively, compared to the epoxy-resin system.

- ii.

- The effect of optimizing the compounding parameters of banana-reinforced epoxy was significantly comparable in terms of impact, damage tolerance, and residual impact due to higher bonding between fibers and matrices.

- iii.

- The low-velocity impact response of the optimal banana/epoxy composite gave a lower peak load. However, a significantly large damage area, higher energy absorption, and greater dent depth were obtained.

- iv.

- The banana fiber sandwich structure recorded a lower CAI resistance and a greater reduction in normalized strength than those using synthetic fibers.

- v.

- Delamination and core fracture were mainly observed in the optimal banana/epoxy structure. However, under the CAI testing matrix, shear cracking dominated in the Kevlar, carbon, and glass composites.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aziz, N.A.; Ho, L.H.; Azahari, B.; Bhat, R.; Cheng, L.H.; Ibrahim, M.N.M. Chemical and functional properties of the native banana (Musaacuminata × balbisiana Colla cv. Awak) pseudo-stem and pseudo-stem tender core flours. Food Chem. 2011, 128, 748–753. [Google Scholar] [CrossRef]

- Subagyo, A.; Chafidz, A. Banana Pseudo-Stem Fiber: Preparation, Characteristics, and Applications. IntechOpen 2018. [Google Scholar] [CrossRef] [Green Version]

- Abdullah, N.; Sulaiman, F.; Miskam, M.A.; Taib, R.M. Characterization of banana (Musa spp.) pseudo-stem and fruit-bunch-stem as a potential renewable energy resource. Int. J. Biol. Vet. Agric. Food. Eng. 2014, 8, 712. [Google Scholar]

- Hassan, M.Z.S.S.; Rasid, Z.A. Thermal Degradation and Mechanical Behavior of Banana Pseudo-Stem Reinforced Composite. Int. J. Recent Technol. Eng. 2019, 8, 4. [Google Scholar]

- Sapuan, M.S.; Leenie, A.; Harimi, M.; Beng, Y.K. Mechanical properties of woven banana fibre reinforced epoxy composites. Mater. Des. 2006, 27, 689–693. [Google Scholar] [CrossRef]

- Maleque, M.; Belal, F.; Sapuan, S. Mechanical properties study of pseudo-stem banana fiber reinforced epoxy composite. Arab. J. Sci. Eng. 2007, 32, 359–364. [Google Scholar]

- Ogunsile, B.O.; Oladeji, T.G. Utilization of banana stalk fiber as reinforcement in low density polyethylene composite. Matéria 2016, 21, 953–963. [Google Scholar] [CrossRef] [Green Version]

- Prasad, N.; Agarwal, V.K.; Sinha, S. Banana fiber reinforced low-density polyethylene composites: Effect of chemical treatment and compatibilizer addition. Iran. Polym. J. 2016, 25, 229–241. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Attia, T.; El-Wahab, A.A.A.; El-Gamsy, R.; El-latif, M.H.A. Effect of adding banana pseudo stem on the mechanical properties of ABS composites. J. Al-Azhar Univ. Eng. Sect. 2018, 13, 1090–1098. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; ElayaPerumal, A.; Jagatheeshwaran, M. Effect of fiber length and fiber content on mechanical properties of banana fiber/epoxy composite. J. Reinf. Plast. Compos. 2011, 30, 1621–1627. [Google Scholar] [CrossRef]

- Udaya Kiran, C.; Ramachandra Reddy, G.; Dabade, B.; Rajesham, S. Tensile properties of sun hemp, banana and sisal fiber reinforced polyester composites. J. Reinf. Plas. Compos. 2007, 26, 1043–1050. [Google Scholar] [CrossRef]

- Zainudin, E.; Sapuan, S. Impact strength and hardness properties of banana pseudo-stem filled unplastisized PVC composites Multidiscip. Model. Mater. Struct. 2009, 5, 277–282. [Google Scholar] [CrossRef]

- Pavithran, C.; Mukherjee, P.; Brahmakumar, M.; Damodaran, A. Impact properties of natural fibre composites. J. Mater. Sci. Lett. 1987, 6, 882–884. [Google Scholar] [CrossRef]

- Balaji, A.; Sivaramakrishnan, K.; Karthikeyan, B.; Purushothaman, R.; Swaminathan, J.; Kannan, S.; Udhayasankar, R.; Madieen, A.H. Study on mechanical and morphological properties of sisal/banana/coir fiber-reinforced hybrid polymer composites. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 386. [Google Scholar] [CrossRef]

- Pothan, L.A.; Thomas, S.; Neelakantan, N. Short banana fiber reinforced polyester composites: Mechanical, failure and aging characteristics. J. Reinf. Plas. Compos. 1997, 16, 744–765. [Google Scholar] [CrossRef]

- Devireddy, S.B.R.; Biswas, S. Physical and thermal properties of unidirectional banana–jute hybrid fiber-reinforced epoxy composites. J. Reinf. Plas. Compos. 2016, 35, 1157–1172. [Google Scholar] [CrossRef]

- Narayana, K.S.; Suman, K.; Ravindra, A. Experimental Investigation on Mechanical Characterization of Nanoclay-Reinforced Banana Fiber/E-Glass/Epoxy Resin Hybrid Nanocomposite. In Recent Advances in Material Sciences; Springer: Singapore, 2019; pp. 609–625. [Google Scholar]

- Dhakal, H.; Arumugam, V.; Aswinraj, A.; Santulli, C.; Zhang, Z.; Lopez-Arraiza, A. Influence of temperature and impact velocity on the impact response of jute/UP composites. Polym. Test. 2014, 35, 10–19. [Google Scholar] [CrossRef] [Green Version]

- Ismail, M.F.; Sultan, M.T.; Hamdan, A.; Shah, A.U.; Jawaid, M. Low velocity impact behaviour and post-impact characteristics of kenaf/glass hybrid composites with various weight ratios. J. Mater. Res. Technol. 2019, 8, 2662–2673. [Google Scholar] [CrossRef]

- Nor, A.F.M.; Sultan, M.T.H.; Jawaid, M.; Azmi, A.M.R.; Shah, A.U.M. Analysing impact properties of CNT filled bamboo/glass hybrid nanocomposites through drop-weight impact testing, UWPI and compression-after-impact behaviour. Compos. Part B Eng. 2019, 168, 166–174. [Google Scholar] [CrossRef]

- Rubio-López, A.; Artero-Guerrero, J.; Pernas-Sánchez, J.; Santiuste, C. Compression after impact of flax/PLA biodegradable composites. Polym. Test. 2017, 59, 127–135. [Google Scholar] [CrossRef]

- Akubue, P.C.; Igbokwe, P.K.; Nwabanne, J.T. Production of kenaf fibre reinforced polyethylene composite for ballistic protection. Int. J. Sci. Eng. Res. 2015, 6, 7. [Google Scholar]

- Yaghoobi, H.; Fereidoon, A. Modeling and optimization of tensile strength and modulus of polypropylene/kenaf fiber biocomposites using Box–Behnken response surface method. Polym. Compos. 2018, 39, E463–E479. [Google Scholar] [CrossRef]

- Roslan, S.A.; Hassan, M.Z.; Rasid, Z.A.; Bani, N.A.; Sarip, S.; Daud, M.Y.M.; Muhammad-Sukki, F. Mode I Fracture Toughness of Optimized Alkali-Treated Bambusa Vulgaris Bamboo by Box-Behnken Design. In Advances in Material Sciences and Engineering; Springer: Singapore, 2020; pp. 565–575. [Google Scholar]

- Hassan, M.Z.; Sapuan, S.; Roslan, S.A.; Sarip, S. Optimization of tensile behavior of banana pseudo-stem (Musa acuminate) fiber reinforced epoxy composites using response surface methodology. J. Mater. Res. Technol. 2019, 8, 3517–3528. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; Elayaperumal, A.; Sathiya, G. Prediction of tensile properties of hybrid-natural fiber composites. Compos. Part B Eng. 2012, 43, 793–796. [Google Scholar] [CrossRef]

- EpoxAmite™. Available online: https://www.smooth-on.com/product-line/epoxamite/ (accessed on 17 January 2020).

- Materials, Equipment and Supplies for Advanced Composites. Available online: https://www.easycomposites.co.uk (accessed on 17 January 2020).

- ASTM International. ASTM D638-14, Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM International. ASTM D3763-18, Standard Test Method for High Speed Puncture Properties of Plastics Using Load and Displacement Sensors; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM International. ASTM E1417/E1417M-16, Standard Practice for Liquid Penetrant Testing; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM International. ASTM D7137/D7137M-17, Standard Test Method for Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- He, W.; Liu, J.; Wang, S.; Xie, D. Low-velocity impact response and post-impact flexural behaviour of composite sandwich structures with corrugated cores. Compos. Struc. 2018, 189, 37–53. [Google Scholar] [CrossRef]

- Olsson, R.; Block, T.B. Criteria for skin rupture and core shear cracking induced by impact on sandwich panels. Compos. Struc. 2015, 125, 81–87. [Google Scholar] [CrossRef]

- Joseph, S.; Sreekala, M.; Oommen, Z.; Koshy, P.; Thomas, S. A comparison of the mechanical properties of phenol formaldehyde composites reinforced with banana fibres and glass fibres. Compos. Sci. Technol. 2002, 62, 1857–1868. [Google Scholar] [CrossRef]

- Chen, F.; Hodgkinson, J. Impact behaviour of composites with different fibre architecture. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2009, 223, 1009–1017. [Google Scholar] [CrossRef]

- Foo, C.C.; Seah, L.K.; Chai, G.B. Chai Low-velocity impact failure of aluminium honeycomb sandwich panels. Compos. Struc. 2008, 85, 20. [Google Scholar] [CrossRef]

- Safri, S.; Sultan, M.; Cardona, F. Impact damage evaluation of Glass-Fiber Reinforced Polymer (GFRP) using the drop test rig–an experimental based approach. ARPN J. Eng. Appl. Sci. 2015, 10, 9916–9928. [Google Scholar]

- Hassan, M.; Umer, R.; Balawi, S.; Cantwell, W. The impact response of environmental-friendly sandwich structures. J. Compos. Mater. 2014, 48, 3083–3090. [Google Scholar] [CrossRef]

- Liu, T.; Hou, S.; Nguyen, X.; Han, X. Energy absorption characteristics of sandwich structures with composite sheets and bio coconut core. Compos. Part B Eng. 2017, 114, 328–338. [Google Scholar] [CrossRef]

- Hassan, M.; Cantwell, W. The influence of core properties on the perforation resistance of sandwich structures—An experimental study. Compos. Part B Eng. 2012, 43, 3231–3238. [Google Scholar] [CrossRef]

- Hassan, M.; Cantwell, W. Strain rate effects in the mechanical properties of polymer foams. Int. J. Polym. Technol. 2011, 3, 27–34. [Google Scholar]

- Maierhofer, C.; Krankenhagen, R.; Röllig, M. Application of thermographic testing for the characterization of impact damage during and after impact load. Compos. Part B Eng. 2019, 173, 106899. [Google Scholar] [CrossRef]

- Selver, E.; Potluri, P.; Hogg, P.; Soutis, C. Impact damage tolerance of thermoset composites reinforced with hybrid commingled yarns. Compos. Part B Eng. 2016, 91, 522–538. [Google Scholar] [CrossRef]

- Zhang, T.; Yan, Y.; Li, J. Experiments and numerical simulations of low-velocity impact of sandwich composite panels. Polym. Compos. 2017, 38, 646–656. [Google Scholar] [CrossRef]

- Giannopoulos, I.K.; Theotokoglou, E.E.; Zhang, X. Impact damage and CAI strength of a woven CFRP material with fire retardant properties. Compos. Part B Eng. 2016, 91, 8–17. [Google Scholar] [CrossRef] [Green Version]

- Caminero, M.; García-Moreno, I.; Rodríguez, G. Experimental study of the influence of thickness and ply-stacking sequence on the compression after impact strength of carbon fibre reinforced epoxy laminates. Polym. Test. 2018, 66, 360–370. [Google Scholar] [CrossRef]

- Yang, B.; Wang, Z.; Zhou, L.; Zhang, J.; Tong, L.; Liang, W. Study on the low-velocity impact response and CAI behavior of foam-filled sandwich panels with hybrid facesheet. Compos. Struc. 2015, 132, 1129–1140. [Google Scholar] [CrossRef]

- Castanié, B.; Aminanda, Y.; Bouvet, C.; Barrau, J.J. Core crush criterion to determine the strength of sandwich composite structures subjected to compression after impact. Compos. Struc. 2008, 86, 243–250. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Chen, B.; Wang, H.; Waas, A.M. Experimental study on the compression-after-impact behavior of foam-core sandwich panels. J. Sandw. Struct. Mater. 2015, 17, 446–465. [Google Scholar] [CrossRef]

- Sanchez-Saez, S.; Barbero, E.; Zaera, R.; Navarro, C. Compression after impact of thin composite laminates. Compos. Sci. Technol. 2005, 65, 1911–1919. [Google Scholar] [CrossRef] [Green Version]

- Bai, R.; Guo, J.; Lei, Z.; Liu, D.; Ma, Y.; Yan, C. Compression after impact behavior of composite foam-core sandwich panels. Compos. Struc. 2019, 225. [Google Scholar] [CrossRef]

| Banana | Kevlar | Carbon | Glass | Carbon Kevlar Twill | EpoxAmite™-102 Hardener | |

|---|---|---|---|---|---|---|

| [26] | [28] | [28] | [28] | [28] | [27] | |

| Density (kg/m3) | 1350 | 1340 | 1780 | 2600 | 1110 | |

| Flexural Strength (MPa) | 52 | 84.25 | ||||

| Tensile Strength (MPa) | 54 | 3260 | 4900 | 3450 | 56.4 | |

| Young’s Modulus (GPa) | 3.49 | 60–80 | 250 | 72–77 | 3.1 | |

| Elongation (%) | 4.4 | 2 | 4.7 | |||

| Weight (g/m2) | 210 | |||||

| Weft | 2(C)-1(K) | |||||

| Warp | 2(C)-1(K) | |||||

| Cellulose (%) | 63–64 | - | ||||

| Hemicellulose (%) | 19 | - | ||||

| Lignin (%) | 5 | - | ||||

| Mixed viscosity (kg/ms) | - | 0.65 | ||||

| Specific volume (m3/kg) | - | 9.03 × 10−4 |

| Material | Tensile Strength | Modulus of Elasticity | Elongation (%) |

|---|---|---|---|

| (MPa) | (MPa) | ||

| Neat Epoxy | 19.18 ± 2.6 | 980 ± 1.8 | 4.21 ± 0.8 |

| Banana/Epoxy | 8.23 ± 1.4 | 792 ± 2.6 | 1.72 ± 1.3 |

| Optimum Banana/Epoxy | 23.30 ± 2.3 | 1628 ± 4.8 | 2.81 ± 2.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan, M.Z.; Sapuan, S.M.; A. Rasid, Z.; Nor, A.F.M.; Dolah, R.; Md Daud, M.Y. Impact Damage Resistance and Post-Impact Tolerance of Optimum Banana-Pseudo-Stem-Fiber-Reinforced Epoxy Sandwich Structures. Appl. Sci. 2020, 10, 684. https://doi.org/10.3390/app10020684

Hassan MZ, Sapuan SM, A. Rasid Z, Nor AFM, Dolah R, Md Daud MY. Impact Damage Resistance and Post-Impact Tolerance of Optimum Banana-Pseudo-Stem-Fiber-Reinforced Epoxy Sandwich Structures. Applied Sciences. 2020; 10(2):684. https://doi.org/10.3390/app10020684

Chicago/Turabian StyleHassan, Mohamad Zaki, S. M. Sapuan, Zainudin A. Rasid, Ariff Farhan Mohd Nor, Rozzeta Dolah, and Mohd Yusof Md Daud. 2020. "Impact Damage Resistance and Post-Impact Tolerance of Optimum Banana-Pseudo-Stem-Fiber-Reinforced Epoxy Sandwich Structures" Applied Sciences 10, no. 2: 684. https://doi.org/10.3390/app10020684

APA StyleHassan, M. Z., Sapuan, S. M., A. Rasid, Z., Nor, A. F. M., Dolah, R., & Md Daud, M. Y. (2020). Impact Damage Resistance and Post-Impact Tolerance of Optimum Banana-Pseudo-Stem-Fiber-Reinforced Epoxy Sandwich Structures. Applied Sciences, 10(2), 684. https://doi.org/10.3390/app10020684