Amplification of Radiation-Induced Signal of LED Strip by Increasing Number of LED Chips and Using Amplifier Board

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

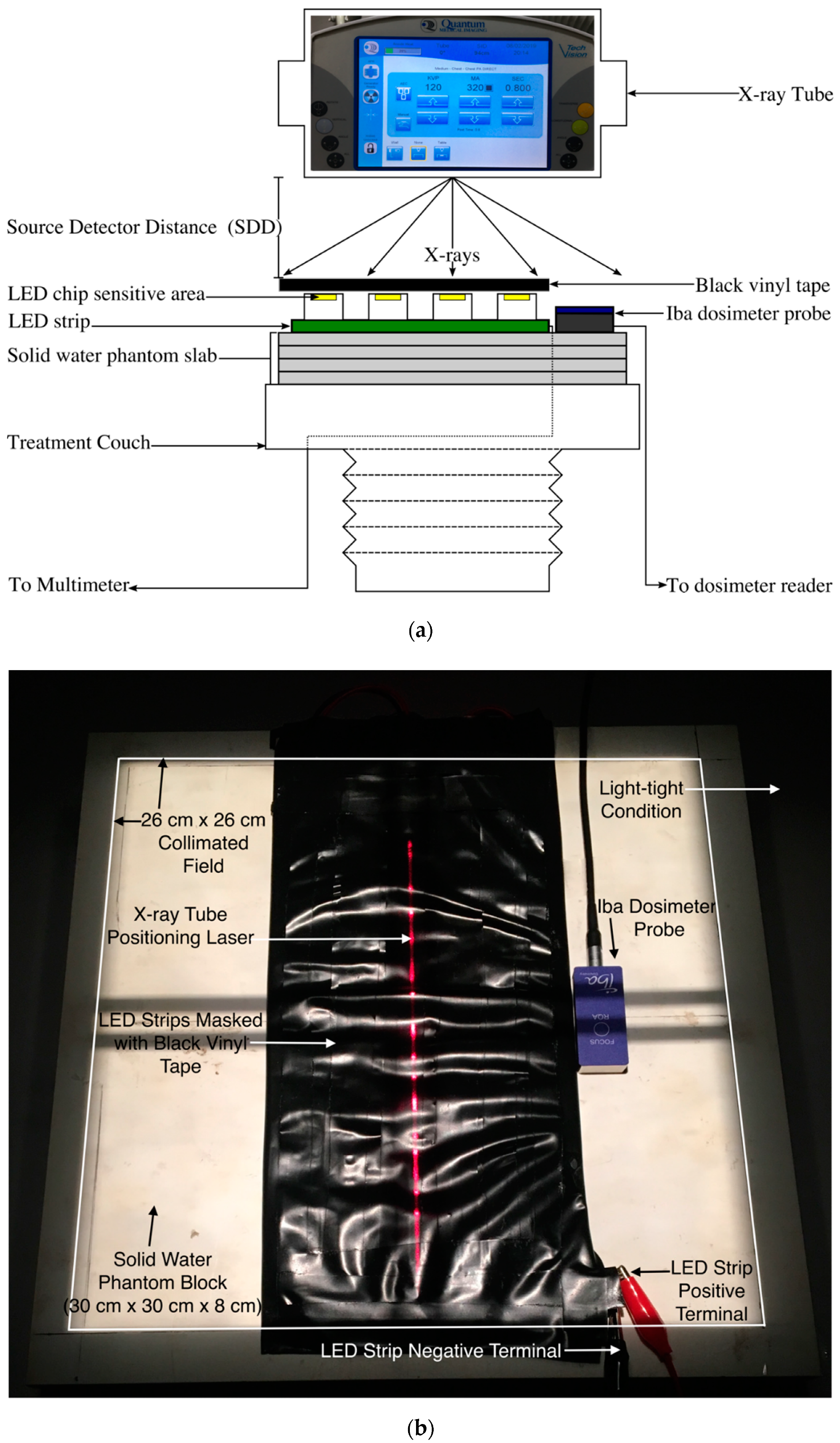

2.1. Experimental Set-Up

2.2. Signal Enhancement

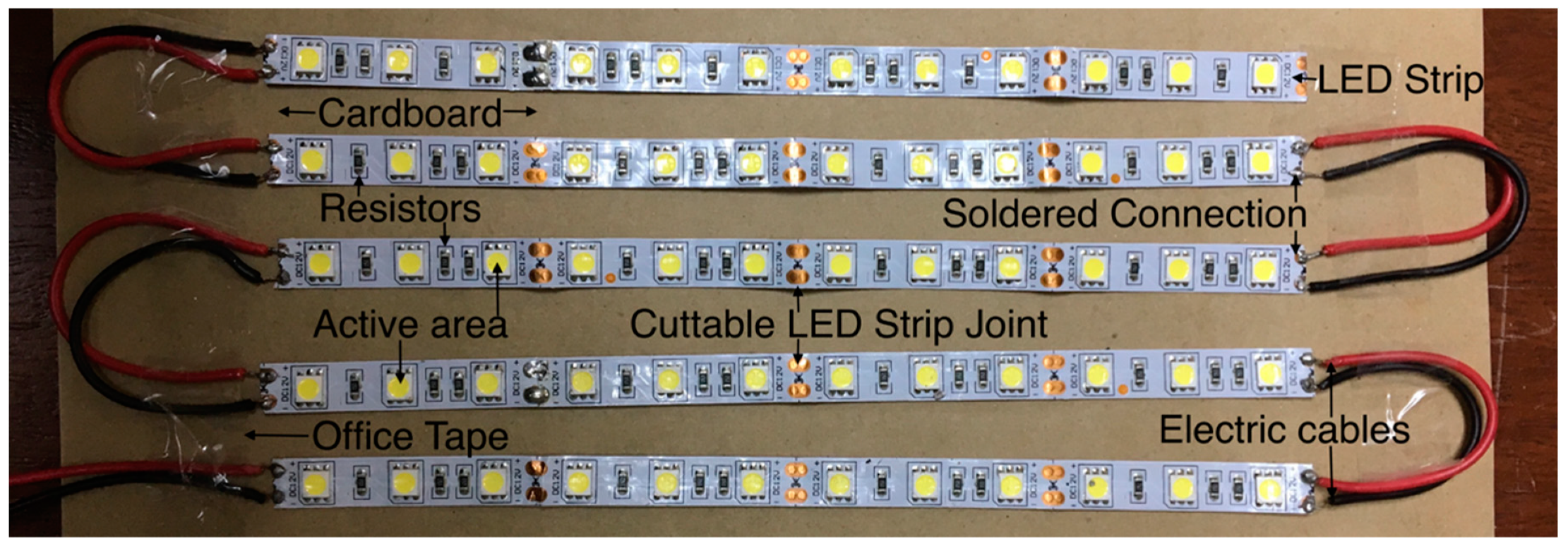

2.2.1. LED Chip Number/Active Area Increment

Preliminary Exposure to Visible Light

Exposure to Diagnostic X-rays

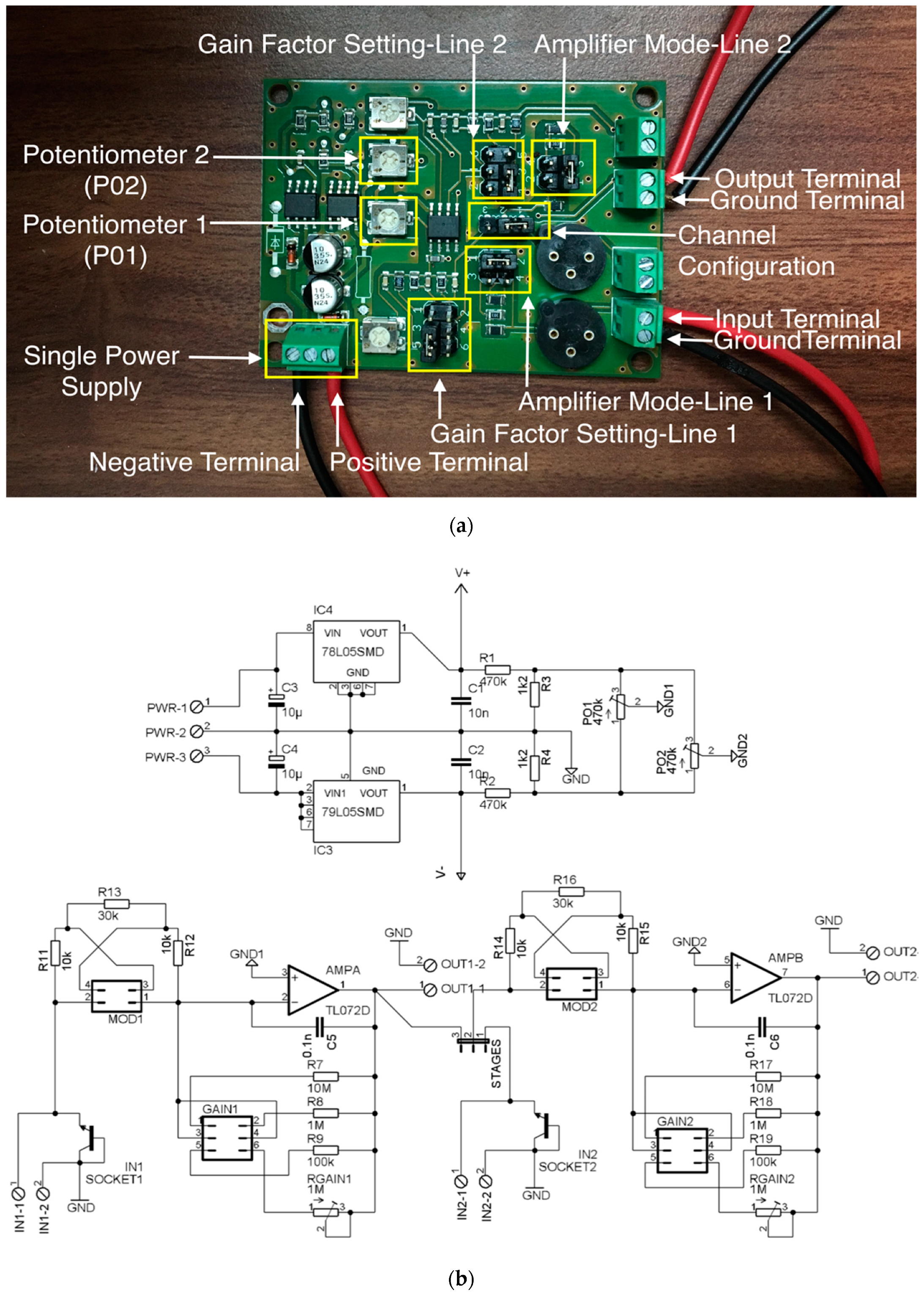

2.2.2. Amplifier Board

3. Results

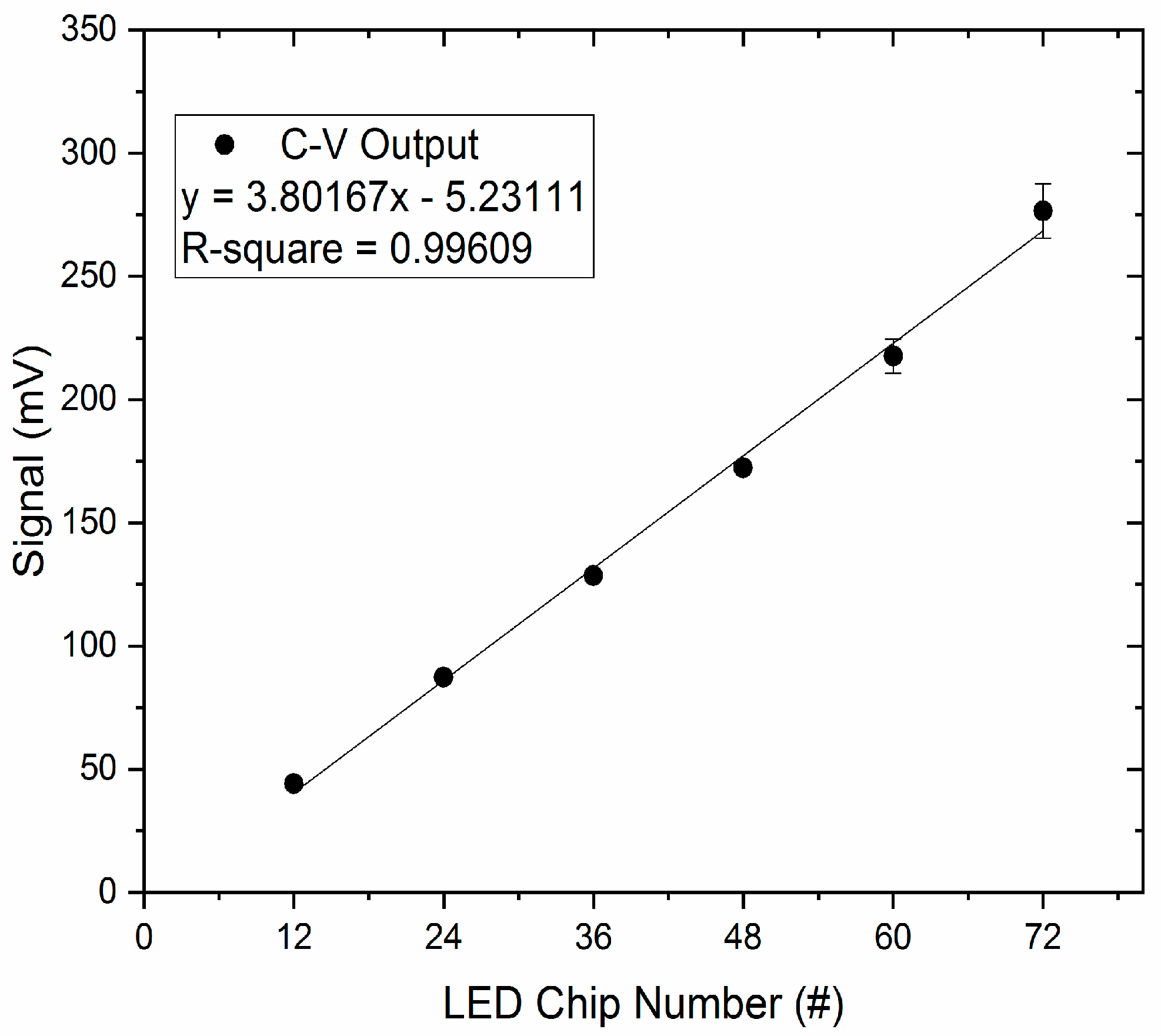

3.1. Effect of Active Area Increment on LED Sensitivity to Visible Light

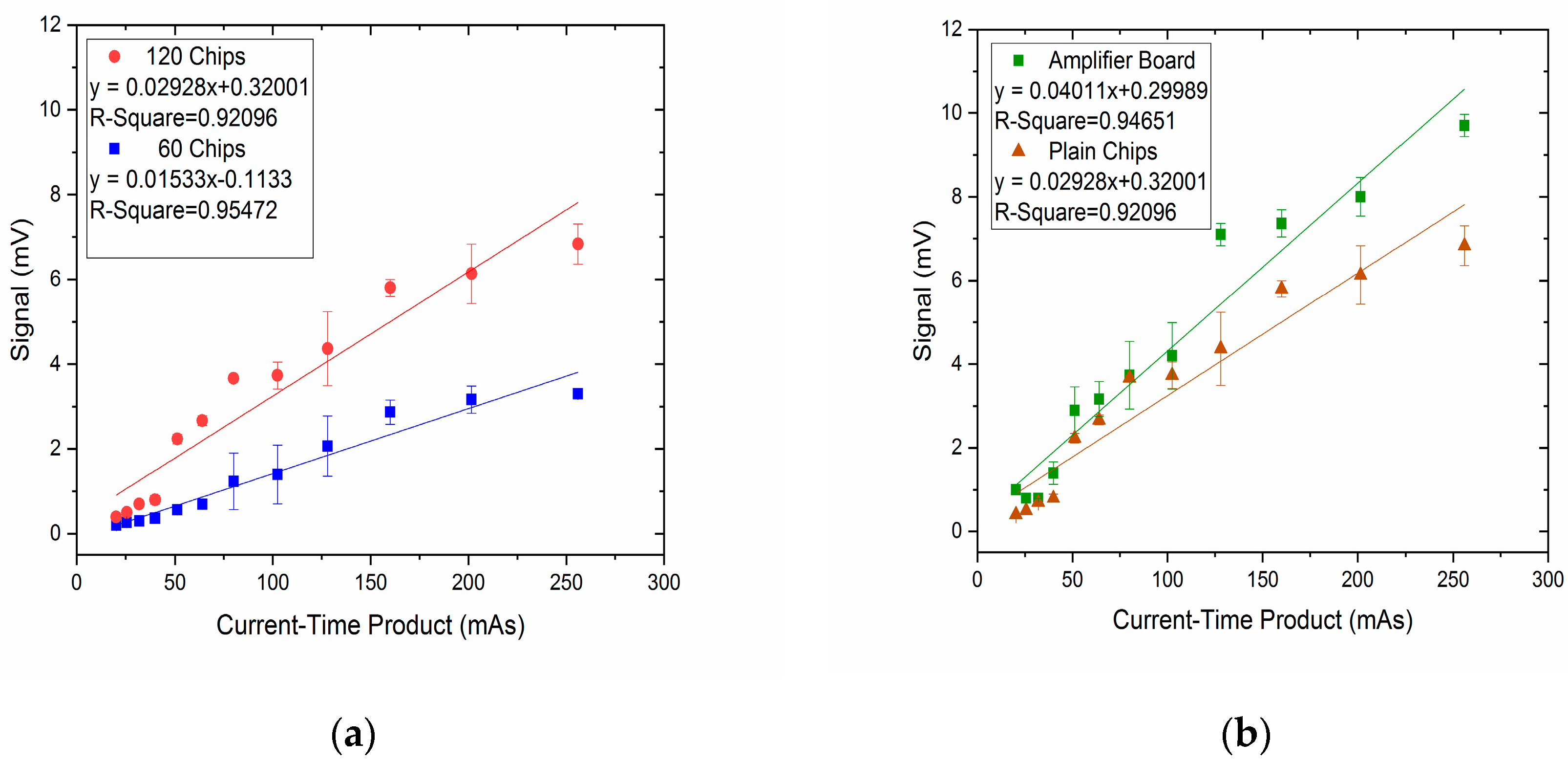

3.2. Amplification during Tube Current-Time Product (mAs) Variation

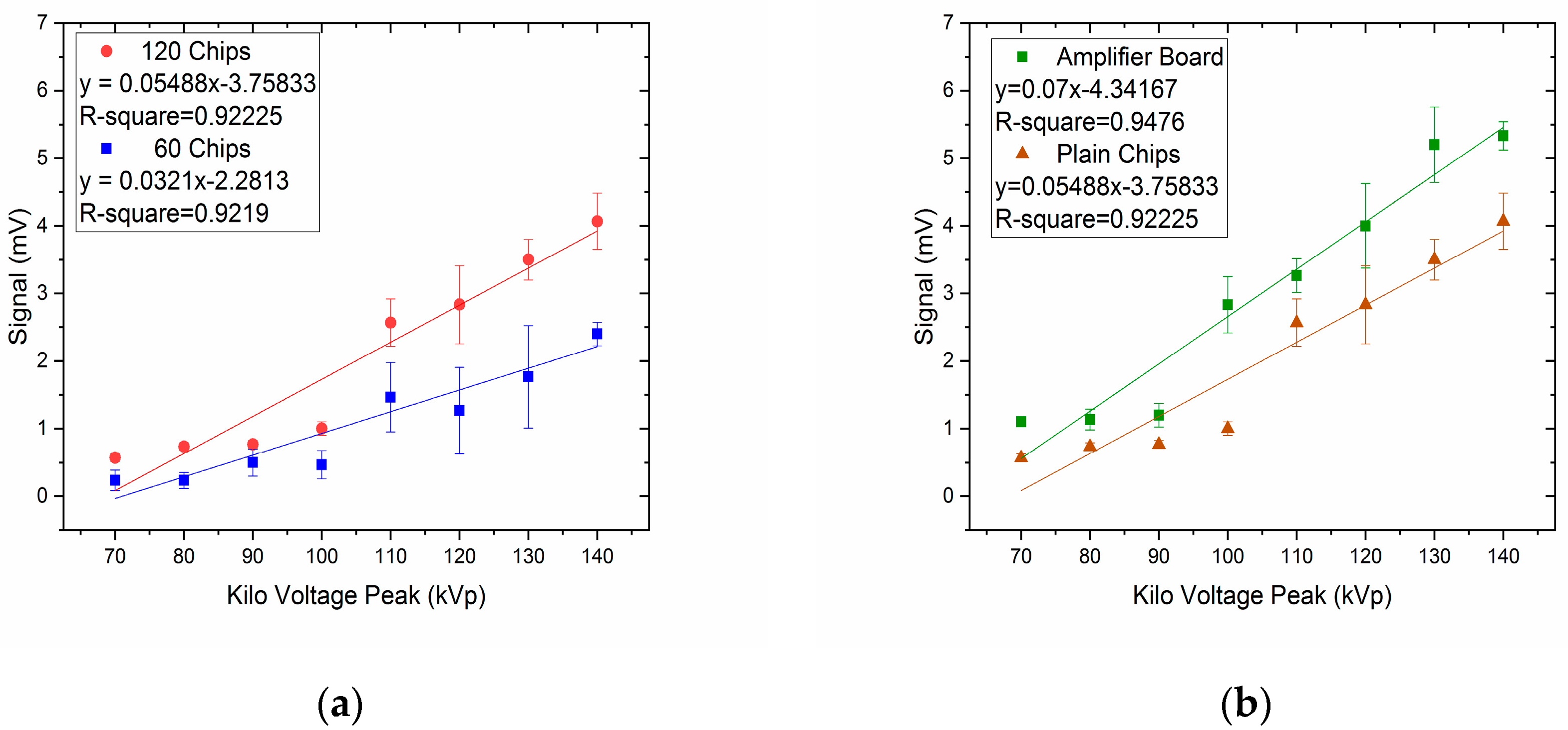

3.3. Amplification during Tube Voltage (kVp) Variation

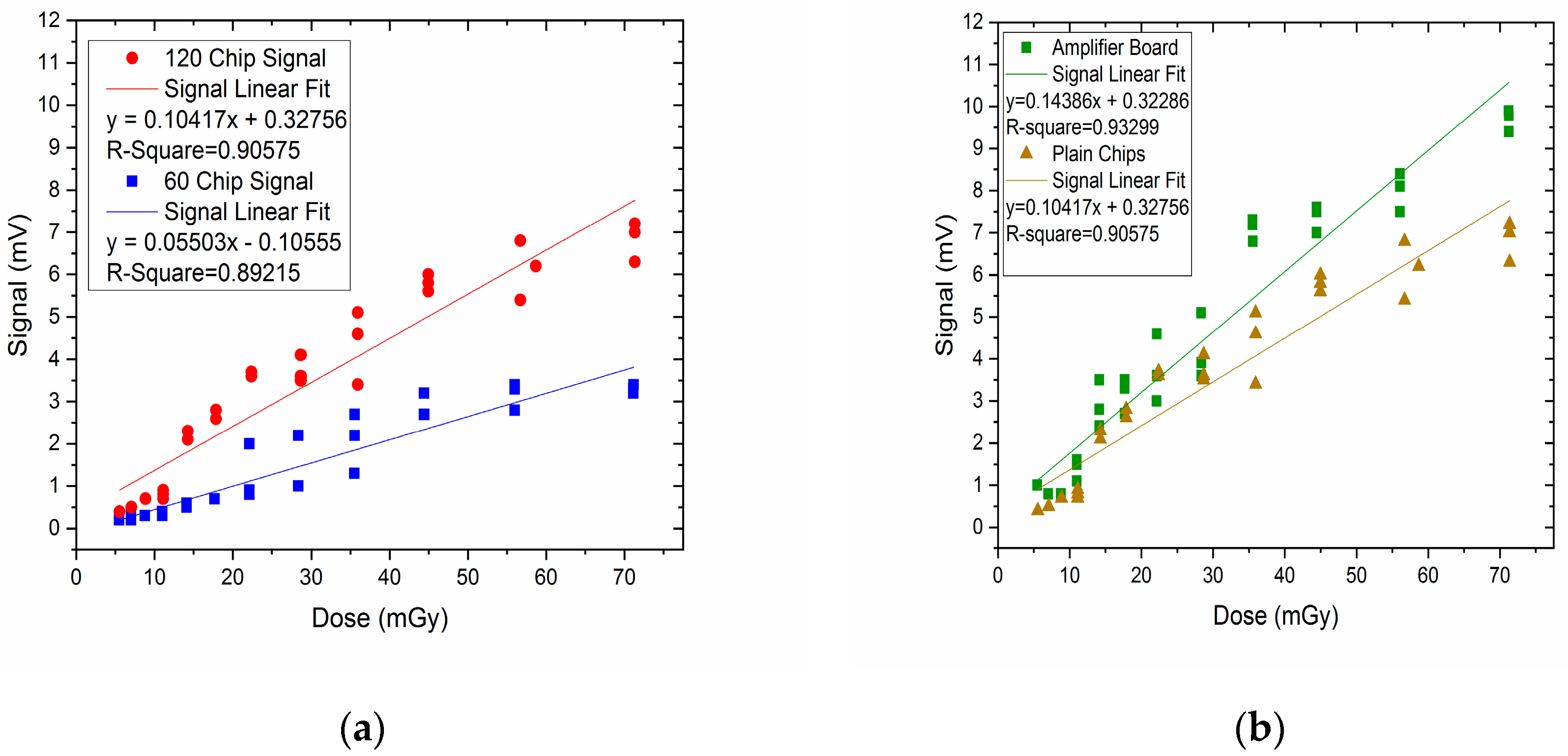

3.4. Amplification during Absorbed Dose Variation

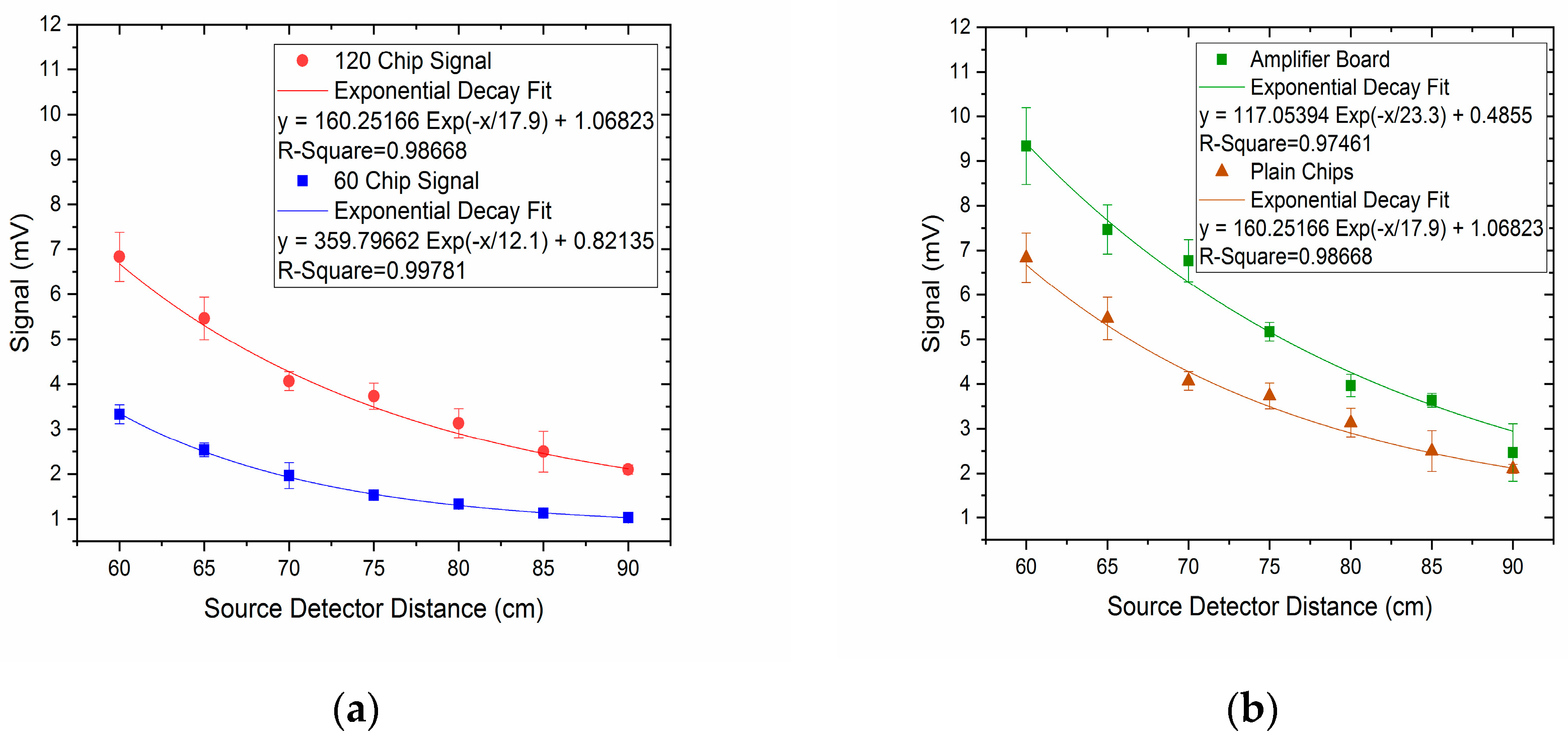

3.5. Amplification during Source-To-Detector Distance (SDD) Variation

3.6. Summary of Signal Amplification

3.7. Coefficients of Variation (CoVs) during Signal Amplification

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Remello, S.N.; Hirano, T.; Kuttassery, F.; Nabetani, Y.; Yamamoto, D.; Onuki, S.; Tachibana, H.; Inoue, H. Visible light induced oxygenation of alkenes with water sensitized by silicon-porphyrins with the second most earth-abundant element. J. Photochem. Photobiol. A Chem. 2015, 313, 176–183. [Google Scholar] [CrossRef]

- Damulira, E.; Yusoff, M.N.S.; Omar, A.F.; Taib, M.; Hartini, N. A Review: Photonic Devices Used for Dosimetry in Medical Radiation. Sensors 2019, 19, 2226. [Google Scholar] [CrossRef] [PubMed]

- Ciarrocchi, E.; Belcari, N. Cerenkov luminescence imaging: Physics principles and potential applications in biomedical sciences. EJNMMI Phys. 2017, 4, 14. [Google Scholar] [CrossRef] [PubMed]

- Yatsu, Y.; Kuramoto, Y.; Kataoka, J.; Kotoku, J.; Saito, T.; Ikagawa, T.; Sato, R.; Kawai, N.; Kishimoto, S.; Mori, K.; et al. Study of avalanche photodiodes for soft X-ray detection below 20 keV. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2006, 564, 134–143. [Google Scholar] [CrossRef]

- Romei, C.; Di Fulvio, A.; Traino, C.A.; Ciolini, R.; d’Errico, F. Characterization of a low-cost PIN photodiode for dosimetry in diagnostic radiology. Phys. Med. 2015, 31, 112–116. [Google Scholar] [CrossRef]

- Anđelković, M.S.; Ristić, G.S. Feasibility study of a current mode gamma radiation dosimeter based on a commercial PIN photodiode and a custom made auto-ranging electrometer. Nucl. Technol. Radiat. Prot. 2013, 28, 73–83. [Google Scholar] [CrossRef]

- Bryant, J. Photodiodes and Other Light Sensors. 2014. Available online: https://www.analog.com/cn/index.html# (accessed on 10 December 2018).

- Zhao, S.; Lioliou, G.; Barnett, A. Temperature dependence of commercial 4H-SiC UV Schottky photodiodes for X-ray detection and spectroscopy. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2017, 859, 76–82. [Google Scholar] [CrossRef]

- Kester, W.; Bryant, J.; Jung, W.; Wurcer, S.; Kitchin, C. Sensor signal conditioning. Sens. Technol. Handb. 1999, 2, 31–136. [Google Scholar]

- Zygmanski, P.; Abkai, C.; Han, Z.; Shulevich, Y.; Menichelli, D.; Hesser, J. Low-cost flexible thin-film detector for medical dosimetry applications. J. Appl. Clin. Med. Phys. 2014, 15, 311–326. [Google Scholar] [CrossRef]

- Bui, D.A.; Hauser, P.C. Absorbance measurements with light-emitting diodes as sources: Silicon photodiodes or light-emitting diodes as detectors? Talanta 2013, 116, 1073–1078. [Google Scholar] [CrossRef]

- Tymecki, Ł.; Brodacka, L.; Rozum, B.; Koncki, R. UV-PEDD photometry dedicated for bioanalytical uses. Analyst 2009, 134, 1333–1337. [Google Scholar] [CrossRef] [PubMed]

- Tymecki, Ł.; Pokrzywnicka, M.; Koncki, R. Paired emitter detector diode (PEDD)-based photometry—An alternative approach. Analyst 2008, 133, 1501–1504. [Google Scholar] [CrossRef] [PubMed]

- Damulira, E.; Yusoff, M.N.S.; Sulaiman, S.; Zulkafli, N.F.H.; Zulkifli, N.A.; Shakir, N.S.A.; Zainun, M.A.; Omar, A.F.; Taib, N.H.M.; Ali, N.K.Y. Comparison of Current–Voltage Response to Diagnostic X-rays of Five Light-Emitting Diode Strips. Appl. Sci. 2020, 10, 200. [Google Scholar] [CrossRef]

- Mims, F.M. Sun photometer with light-emitting diodes as spectrally selective detectors. Appl. Opt. 1992, 31, 6965–6967. [Google Scholar] [CrossRef] [PubMed]

- Beringer, J.; Borer, K.; Mommsen, R.K.; Nickerson, R.B.; Weidberg, A.R.; Monnier, E.; Hou, H.Q.; Lear, K.L. Radiation hardness and lifetime studies of LEDs and VCSELs for the optical readout of the ATLAS SCT. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 1999, 435, 375–392. [Google Scholar] [CrossRef]

- Dowell, J.D.; Homer, R.J.; Kenyon, I.R.; Mahout, G.; Oglesby, S.J.; Shaylor, H.R.; Wilson, J.A.; Nickerson, R.B.; Wastie, R.; Weidberg, A.R. Irradiation tests of photodiodes for the ATLAS SCT readout. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 1999, 424, 483–494. [Google Scholar] [CrossRef][Green Version]

- Li, Z.; Feng, B.; Deng, B.; Liu, L.; Huang, Y.; Feng, M.; Zhou, Y.; Zhao, H.; Sun, Q.; Yang, X. Light output improvement of GaN-based light-emitting diodes grown on Si (111) by a via-thin-film structure. J. Semicond. 2018, 39, 044002. [Google Scholar] [CrossRef]

- Farnell, P. Multifunctional 2-Channel Amplifier Board Leeds; Farnell: Leeds, UK, 2019; Available online: https://www.farnell.com/datasheets/65044.pdf (accessed on 15 March 2019).

- Kubo, T.; Lin, P.J.P.; Stiller, W.; Takahashi, M.; Kauczor, H.U.; Ohno, Y.; Hatabu, H. Radiation dose reduction in chest CT: A review. Am. J. Roentgenol. 2008, 190, 335–343. [Google Scholar] [CrossRef]

- Riederer, I.; Zimmer, C.; Pfeiffer, D.; Wunderlich, S.; Poppert, H.; Rummeny, E.J.; Huber, A. Radiation dose reduction in perfusion CT imaging of the brain using a 256-slice CT: 80 mAs versus 160 mAs. Clin. Imaging 2018, 50, 188–193. [Google Scholar] [CrossRef]

- Huda, W.; Sajewicz, A.M.; Ogden, K.M.; Dance, D.R. Experimental investigation of the dose and image quality characteristics of a digital mammography imaging system. Med. Phys. 2003, 30, 442–448. [Google Scholar] [CrossRef]

- Mitch, M.G.; De Werd, L.A.; Minniti, R.; Williamson, J.F. Treatment of Uncertainties in Radiation Dosimetry; Medical Physics Publishing: Madison, WI, USA, 2009. [Google Scholar]

- Mazda, F. Telecommunications Engineer’s Reference Book; Butterworth-Heinemann: Oxford, UK, 2014; ISBN 1483193799. [Google Scholar]

- Lanza, J.J.; Mauderli, W.; Fitzgerald, L.; Roessler, G. An Automated Dosimetry System For Computed Tomography X-ray Scanners Using Silicon Pin Diodes.: P/63. Health Phys. 1980, 39, 1020. [Google Scholar] [CrossRef]

- Choi, H.-W.; Choi, M.H.; Ko, J.-H. Effect of temperature on the luminous properties of white-light-emitting diodes with red and green phosphors. New Phys. Sae Mulli. 2013, 63, 1149–1154. [Google Scholar] [CrossRef]

- Gayral, B. LEDs for lighting: Basic physics and prospects for energy savings. Comptes Rendus Phys. 2017, 18, 453–461. [Google Scholar] [CrossRef]

- NLPIP. How Are LEDs Affected by Heat? New York, United States National Lighting Product Information Program. Available online: https://www.lrc.rpi.edu/programs/nlpip/lightinganswers/led/heat.asp (accessed on 4 January 2020).

- Paschotta, R. Light-Emitting Diodes. The Encyclopedia of Laser Physics and Technology 2008. Available online: https://www.rp-photonics.com/light_emitting_diodes.html (accessed on 7 April 2018).

- Duboz, J.Y.; Lauegt, M.; Schenk, D.; Beaumont, B.; Reverchon, J.L.; Wieck, A.D.; Zimmerling, T. GaN for x-ray detection. Appl. Phys. Lett. 2008, 92, 263501. [Google Scholar] [CrossRef]

| Signal Amplification Mode | X-ray Beam Parameter | ||||

|---|---|---|---|---|---|

| Tube current-time product (mV/mAs) | Tube Voltage (mV/kVp) | Dose (mV/mGy) | Source-to-Detector Distance, SDD (mV/cm) | ||

| 60 cm | 90 cm | ||||

| Percentage Signal Increase (%) | Percentage increase in Signal Fading (%) | ||||

| Chip number increment from 60 to 120 chips | 90.99 | 70.97 | 89.30 | 99.52 | 105.03 |

| Amplifier Board with a gain of 109 V/A | 36.99 | 27.55 | 38.10 | 40.70 | 39.05 |

| Amplification Mode | CoV for Each X-ray Beam Parameter | Average CoV | ||

|---|---|---|---|---|

| Tube current-time product—mAs (%) | Tube Voltage—kVp (%) | Source-to-Detector Distance—SDD (%) | Based on each amplification mode (%) | |

| Chip number increment from 60 to 120 chips | 6.167 | 11.058 | 8.987 | 8.737 |

| Amplifier Board with a gain of 109 V/A | 9.028 | 10.067 | 9.177 | 9.424 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Damulira, E.; Yusoff, M.N.S.; Omar, A.F.; Taib, N.H.M. Amplification of Radiation-Induced Signal of LED Strip by Increasing Number of LED Chips and Using Amplifier Board. Appl. Sci. 2020, 10, 651. https://doi.org/10.3390/app10020651

Damulira E, Yusoff MNS, Omar AF, Taib NHM. Amplification of Radiation-Induced Signal of LED Strip by Increasing Number of LED Chips and Using Amplifier Board. Applied Sciences. 2020; 10(2):651. https://doi.org/10.3390/app10020651

Chicago/Turabian StyleDamulira, Edrine, Muhammad Nur Salihin Yusoff, Ahmad Fairuz Omar, and Nur Hartini Mohd Taib. 2020. "Amplification of Radiation-Induced Signal of LED Strip by Increasing Number of LED Chips and Using Amplifier Board" Applied Sciences 10, no. 2: 651. https://doi.org/10.3390/app10020651

APA StyleDamulira, E., Yusoff, M. N. S., Omar, A. F., & Taib, N. H. M. (2020). Amplification of Radiation-Induced Signal of LED Strip by Increasing Number of LED Chips and Using Amplifier Board. Applied Sciences, 10(2), 651. https://doi.org/10.3390/app10020651