Key Strata Identification of Overburden Based on Magnetotelluric Detection: A Case Study

Abstract

1. Introduction

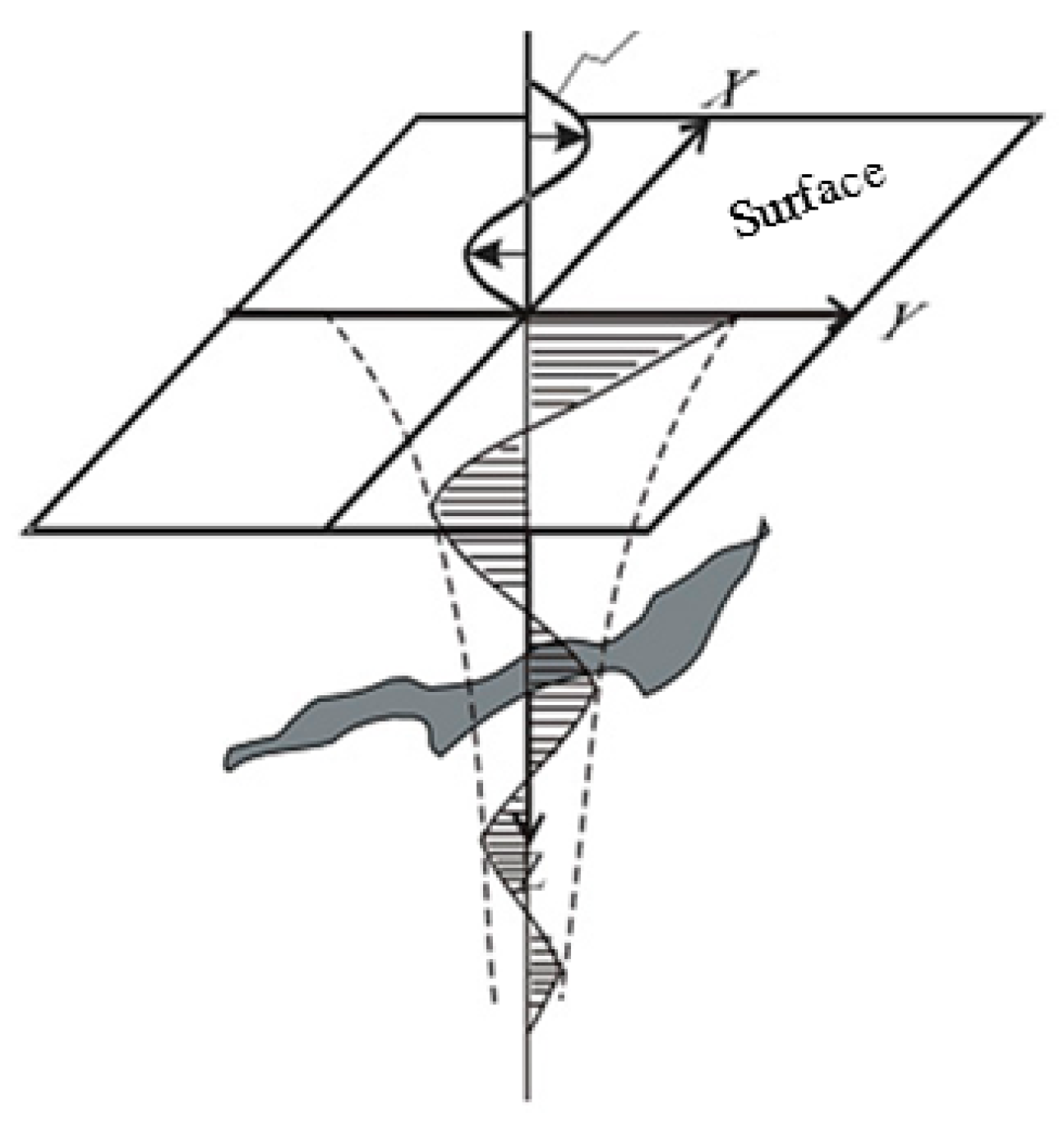

2. MT Detection Method

2.1. Technical Principle

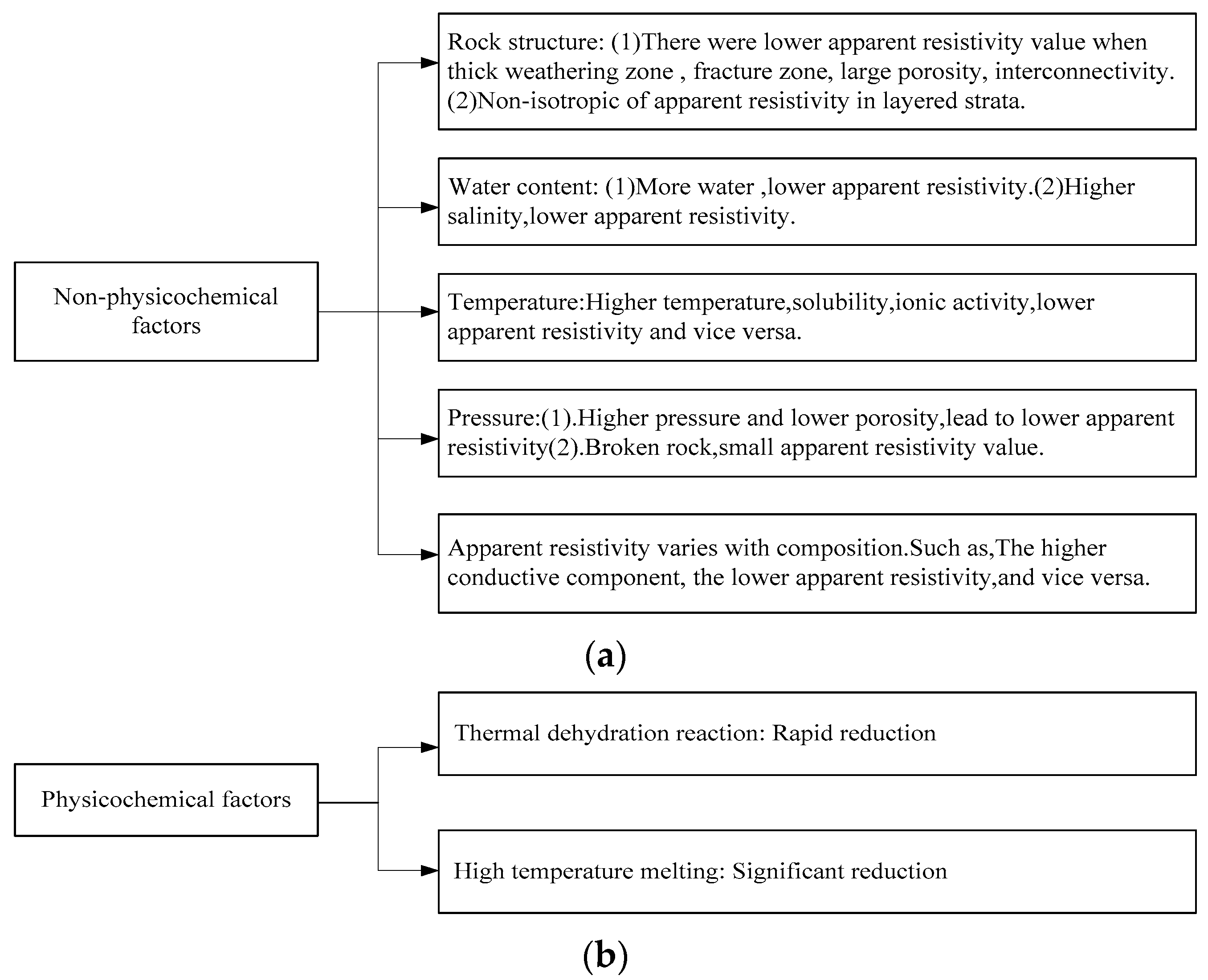

2.2. Influencing Factors

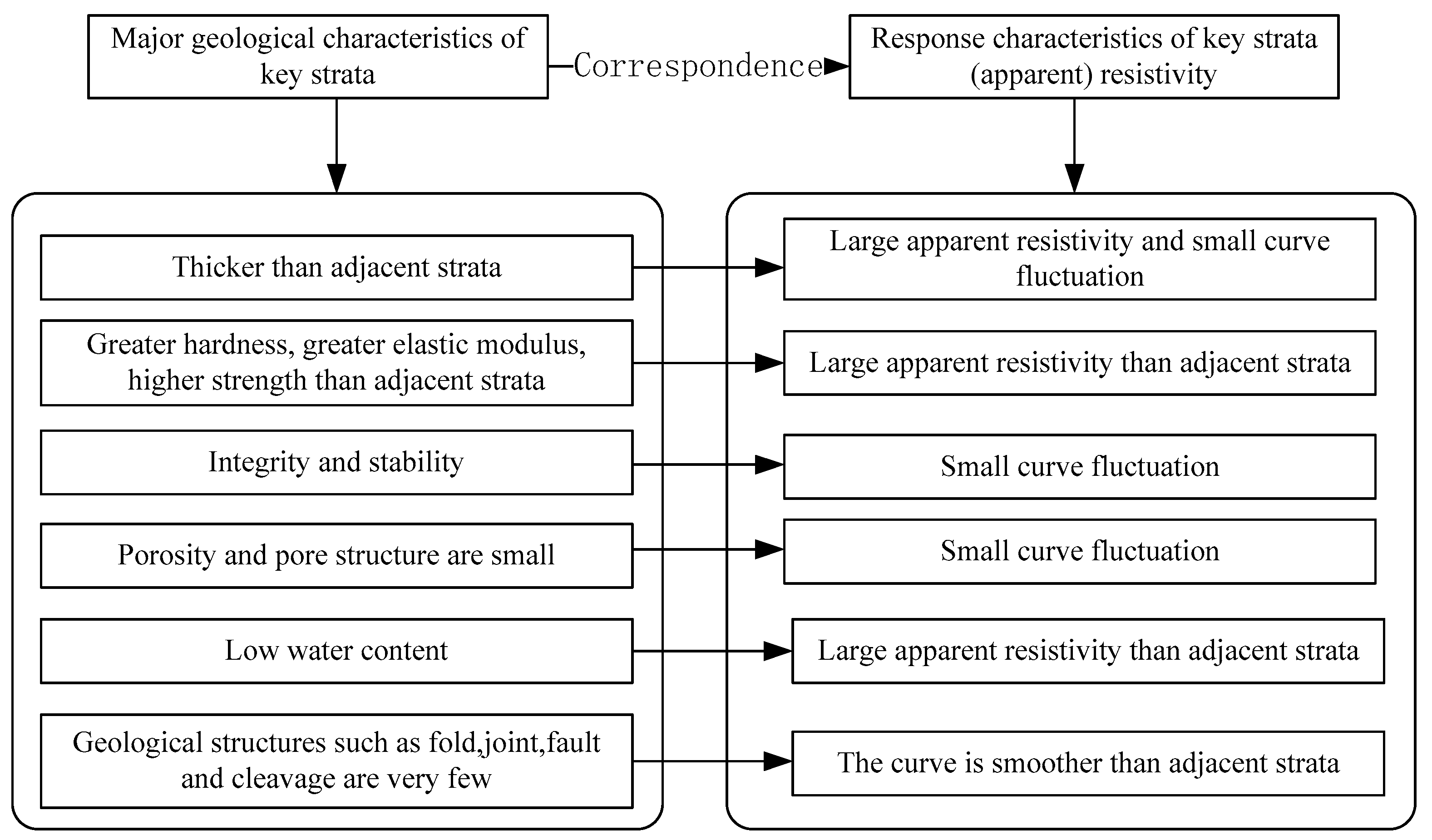

3. Identification Mechanism of MT Detection

3.1. The Characteristics of Overburden AR

3.2. Strata Identification Mechanism

4. Engineering Application

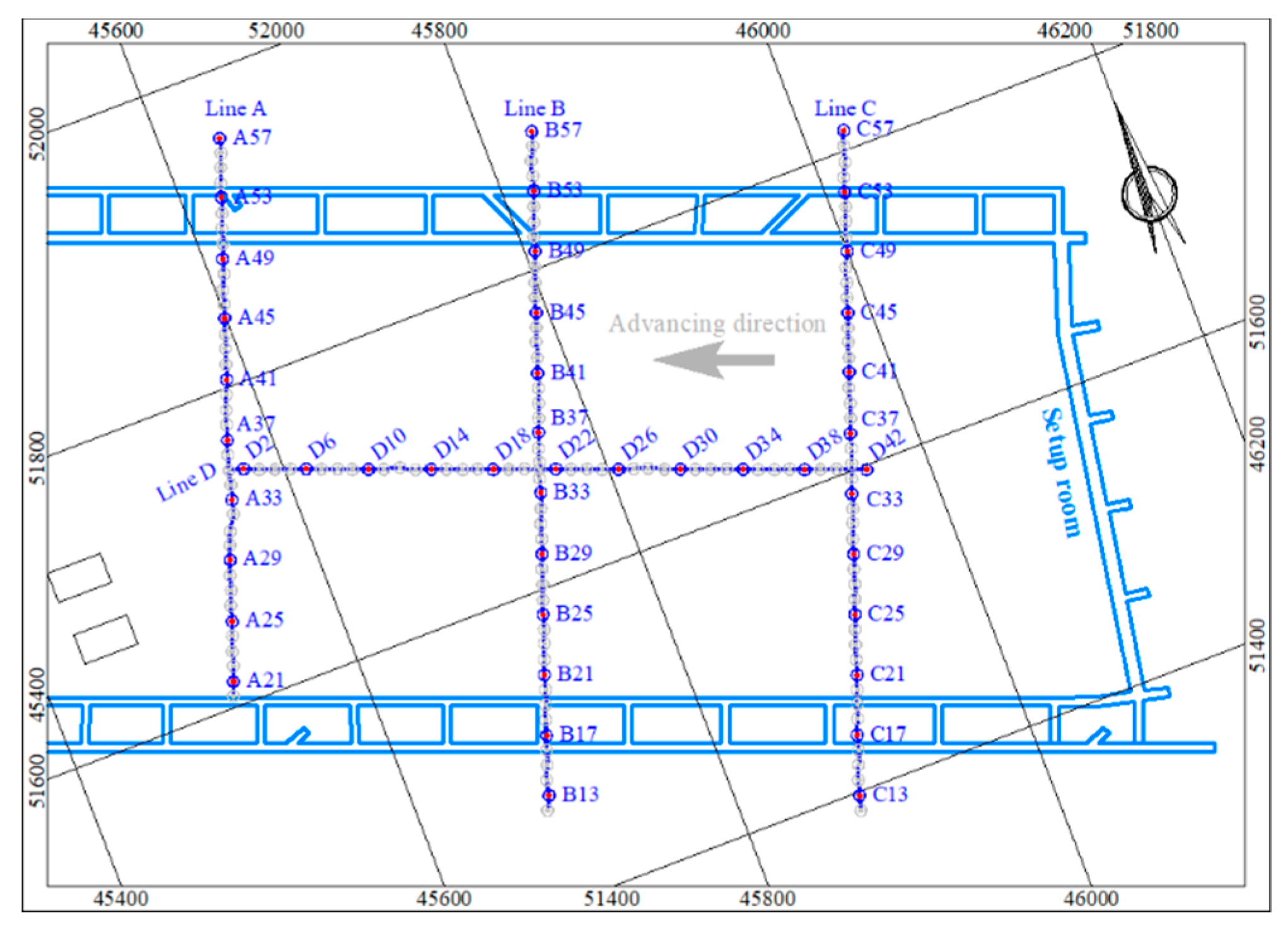

4.1. Region Overview

4.2. Observation Scheme

4.3. Key Strata Analysis and Discussion

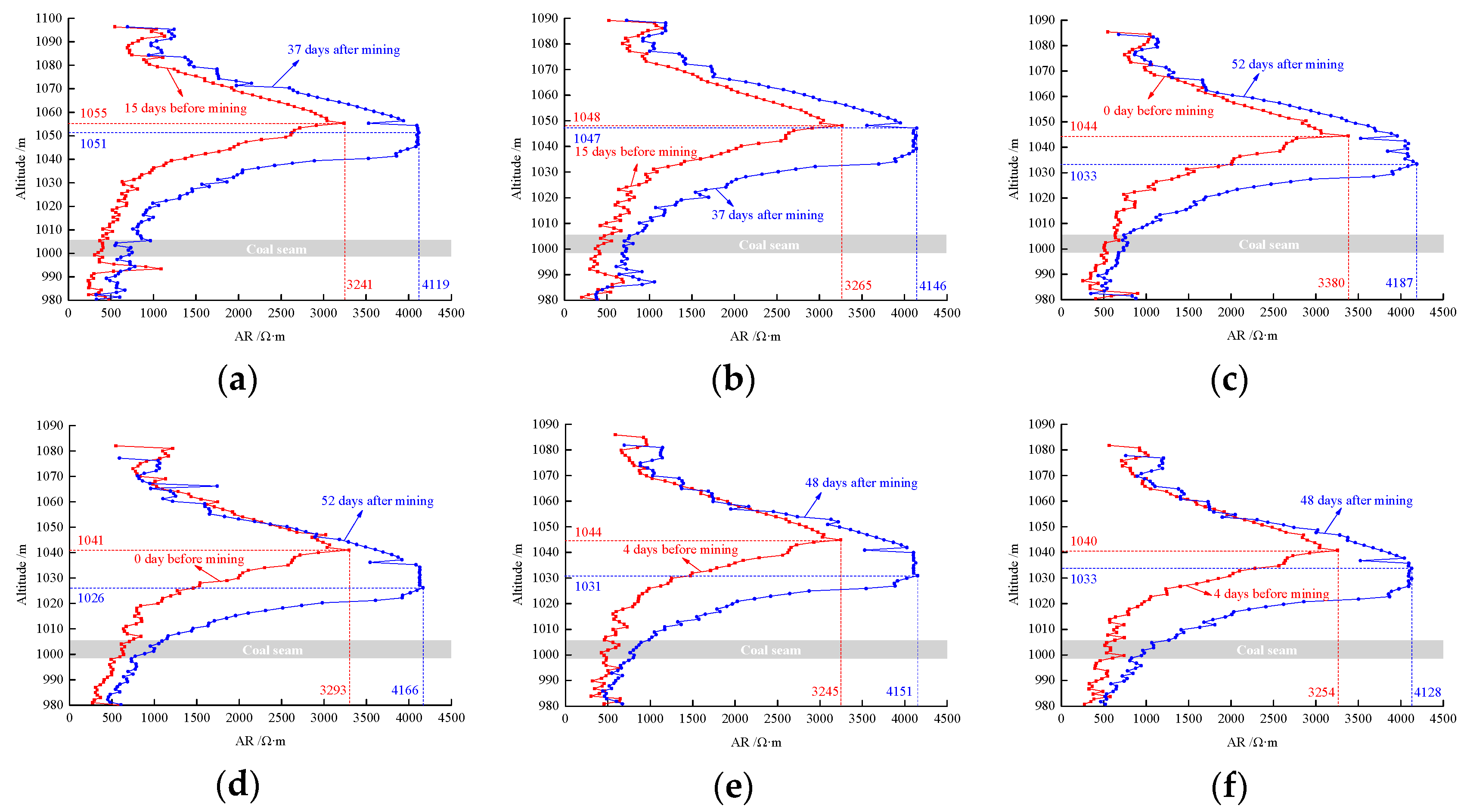

4.3.1. AR of Characteristic Points

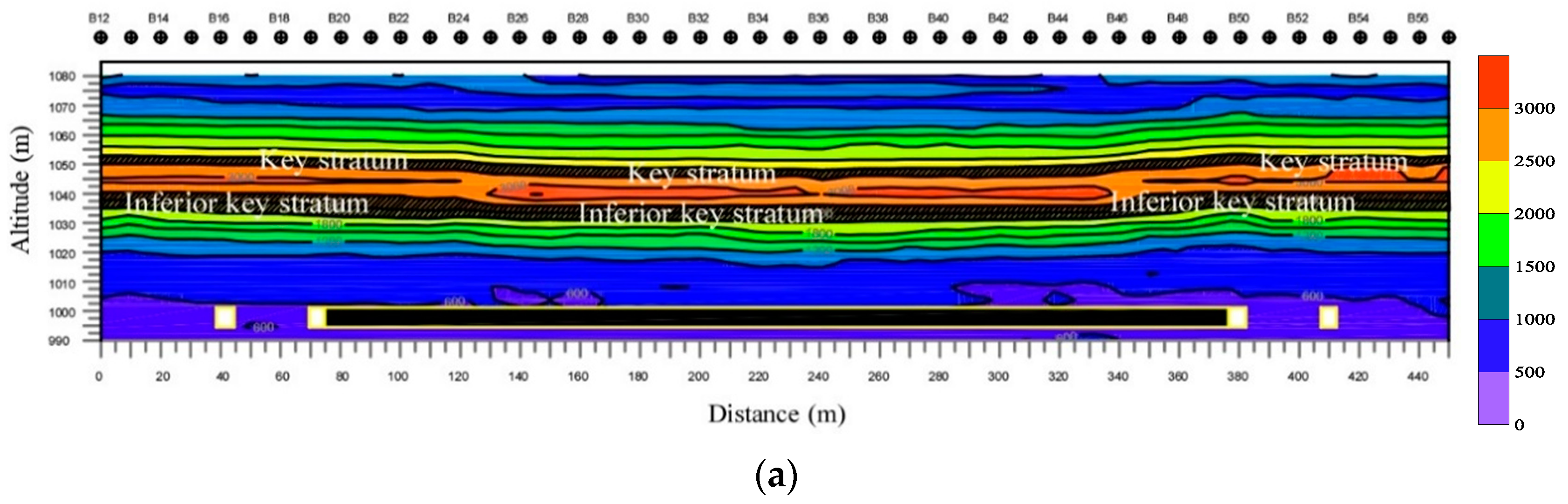

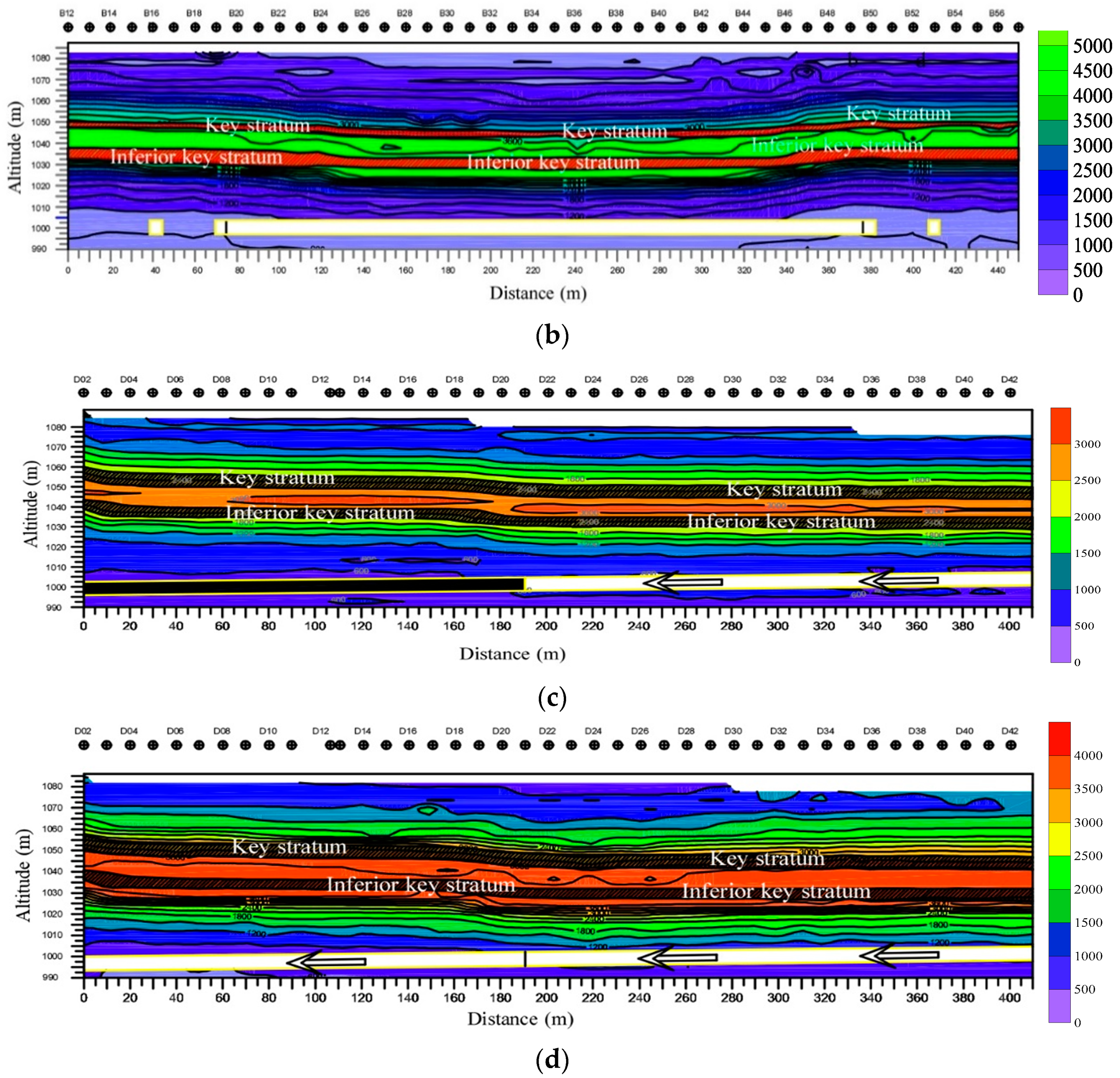

4.3.2. AR of the Major Section

4.3.3. KS Characteristics

4.4. Reliability Verification

5. Conclusions

- (1)

- Overburden failure will inevitably lead to the changing of electromagnetic characteristics. Due to the different degrees of failure, the overburden AR characteristics with different buried depths are different. In theory, the more severe of overburden failure after mining, the greater change of apparent resistivity.

- (2)

- According to the field application, the strata characteristics revealed by MT detection are consistent with KS, especially in the aspect of lithology, mechanical properties, failure characteristics, and electromagnetic response characteristics, which provides a basis for the analysis of KS in MT detection.

- (3)

- Based on the comparison between field application and analysis, MT detection can be used as a convenient and fast method to identify the overburden KS by analyzing the AR characteristics, which provides a new technical support for the mine pressure control, construction of digital model, and precise mining.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lin, B.Q.; Liu, J.H. Estimating coal production peak and trends of coal imports in China. Energy Policy 2010, 38, 512–519. [Google Scholar] [CrossRef]

- Guo, W.B.; Bai, E.H.; Yang, D.M. Study on the technical characteristics and index of thick coal seam high-intensity mining in coalmine. J. China Coal Soc. 2018, 43, 2117–2125. [Google Scholar]

- Hsieh, C.S.; Shih, T.Y.; Hu, J.C.; Tung, H.; Huang, M.H.; Angelier, J. Using differential SAR interferometry to map land subsidence: A case study in the Pingtung Plain of SW Taiwan. Nat. Hazards 2011, 58, 1311–1332. [Google Scholar] [CrossRef]

- Bai, E.H.; Guo, W.B.; Tan, Y. Negative externalities of high-intensity mining and disaster prevention technology in China. Bull. Eng. Geol. Environ. 2019, 78, 5219–5235. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, F.W.; Yao, H.C.; Han, Z.T.; Qian, L.; Chen, L.; Jiang, C.C. Using of key stratum theory to study the structural development of roof aquifer. Acta Geol. Sin. (Engl. Ed.) 2015, 89, 2091. [Google Scholar]

- Liang, S.; Elsworth, D.; Li, X.H.; Fu, X.H.; Sun, B.Y.; Yao, Q.L. Key strata characteristics controlling the integrity of deep wells in longwall mining areas. Int. J. Coal Geol. 2017, 172, 31–42. [Google Scholar] [CrossRef]

- Ju, J.F.; Xu, J.L. Structural characteristics of key strata and strata behaviour of a fully mechanized longwall face with 7.0 m height chocks. Int. J. Rock Mech. Min. Sci. 2013, 58, 46–54. [Google Scholar] [CrossRef]

- Dou, L.M.; He, X.Q.; He, H.; He, J.; Fan, J. Spatial structure evolution of overlying strata and inducing mechanism of rockburst in coal mine. Trans. Nonferrous Met. Soc. China 2014, 24, 1255–1261. [Google Scholar] [CrossRef]

- Yuan, Y.; Tu, S.H.; Zhang, X.G.; Li, B. Dynamic effect and control of key strata break of immediate roof in fully mechanized mining with large mining height. Shock Vib. 2015, 2015, 657818. [Google Scholar]

- Zhou, D.W.; Wu, K.; Bai, Z.H.; Hu, Z.Q.; Li, L.; Xu, Y.K.; Diao, X.P. Formation and development mechanism of ground crack caused by coal mining: Effects of overlying key strata. Bull. Eng. Geol. Environ. 2019, 78, 1025–1044. [Google Scholar]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Key strata theory in strata control. J. China Coal Soc. 1996, 21, 225–230. [Google Scholar]

- Li, Z.; Xu, J.L.; Ju, J.F.; Zhu, W.B.; Xu, J.M. The effects of the rotational speed of voussoir beam structures formed by key strata on the ground pressure of stopes. Int. J. Rock Mech. Min. Sci. 2018, 108, 67–79. [Google Scholar] [CrossRef]

- Zhu, W.B.; Xu, J.M.; Xu, J.L.; Chen, D.Y.; Shi, J.X. Pier-column backfill mining technology for controlling surface subsidence. Int. J. Rock Mech. Min. Sci. 2017, 96, 58–65. [Google Scholar] [CrossRef]

- Wen, Z.J.; Xing, E.R.; Shi, S.S.; Jiang, Y.J. Overlying strata structural modeling and support applicability analysis for large mining-height stopes. J. Loss Prev. Process Ind. 2019, 57, 94–100. [Google Scholar] [CrossRef]

- Ju, J.F.; Xu, J.L.; Xu, J.M. A case study of surface borehole wall dislocation induced by top-coal longwall mining. Energies 2017, 10, 2100. [Google Scholar] [CrossRef]

- Kuang, T.J.; Li, Z.; Zhu, W.B.; Xie, J.L.; Ju, J.F.; Liu, J.R.; Xu, J.M. The impact of key strata movement on ground pressure behaviour in the Datong coalfield. Int. J. Rock Mech. Min. Sci. 2019, 119, 193–204. [Google Scholar] [CrossRef]

- Li, B.; Liang, Y.P.; Zou, Q.L. Determination of working resistance based on movement type of the first subordinate key stratum in a fully mechanized face with large mining height. Energies 2019, 7, 777–798. [Google Scholar] [CrossRef]

- Xie, J.L.; Xu, J.L. Effect of key stratum on the mining abutment pressure of a coal seam. Geosci. J. 2017, 21, 267–276. [Google Scholar] [CrossRef]

- Xu, J.L.; Qian, M.G. Method to distinguish key strata in overburden. J. China Univ. Min. Technol. 2000, 29, 463–467. [Google Scholar]

- Asaue, H.; Sasahara, M.; Yoshinaga, T.; Obara, Y.; Uchida, K.; Matsumoto, H. Clarifying geological structure for coal and marsh gas development using magnetotelluric method. Acta Geodyn. Geomater. 2013, 10, 155–162. [Google Scholar] [CrossRef][Green Version]

- Nigel, R.; Graham, H.; Lars, K. Magnetotelluric monitoring of coal seam gas depressurization. Geophysics 2016, 81, 423–432. [Google Scholar]

- Li, J.; Pang, Z.H.; Kong, Y.L.; Lin, F.L.; Wang, Y.L.; Wang, G.J.; Lv, L.H. An integrated magnetotelluric and gamma exploration of groundwater in fractured granite for small-scale freshwater supply: A case study from the Boshan region, Shandong Province, China. Environ. Earth Sci. 2017, 76, 163. [Google Scholar] [CrossRef]

- Zhang, R.Z.; Li, T.L.; Zhou, S.; Deng, X.H. Joint MT and gravity inversion using structural constraints: A case study from the Linjiang copper mining area, Jilin, China. Minerals 2019, 9, 407. [Google Scholar] [CrossRef]

- Chen, L.; Qin, Q.; Wang, N.; Bai, Y.B.; Zhao, S.S. Review of the forward modeling and inversion in magnetotelluric sounding field. Acta Sci. Nat. Univ. Pekin. 2014, 50, 979–984. [Google Scholar]

- Wei, W.; Luo, X.Z.; Cai, J.C.; Hu, X.J.; Li, Y.N. Fractal study on skin depth of electromagnetic wave through porous rocks. Progress Geophys. 2014, 29, 2416–2421. [Google Scholar]

- Zhang, Z.; Zhang, J.; Yin, B.B. Analysis of apparent resistivity characteristics and influence factors of the sphere model. Comput. Tech. Geophys. Geochem. Explor. 2010, 32, 402–407. [Google Scholar]

- Chen, X.B.; Lv, Q.T.; Zhang, K. Review of magnetotelluric data inversion methods. Progress Geophys. 2011, 26, 1607–1619. [Google Scholar]

- Evjen, H.M. Depth factor and resolving power of electrical measurements. Geophysical 1938, 3, 78–95. [Google Scholar] [CrossRef]

- Huang, H.P. Depth of investigation for small broadband electromagnetic sensors. Geophysical 2005, 70, 135–142. [Google Scholar] [CrossRef]

- Guo, W.B.; Wang, Y.G. The definition of high-intensity mining based on green coal mining and its index system. J. Min. Saf. Eng. 2017, 34, 616–623. [Google Scholar]

- Bai, E.H.; Guo, W.B.; Zhang, D.S.; Tan, Y.; Guo, M.J.; Zhao, G.B. Using the magnetotelluric method for detecting aquifer failure characteristics under high-intensity mining of thick coal seams. Energies 2019, 12, 4397. [Google Scholar] [CrossRef]

| Year | Site | Purpose | Depth (m) |

|---|---|---|---|

| 2007 | Jiaozuo mining section of South-to-North Water Diversion Project, Henan | Goaf distribution | 410 |

| 2008 | Concealed mine area, Fujian | “Three-under” coal mining | 1500 |

| 2009 | Bauxite mining area of Mianchi county, Henan | Identifying thin interbed | 600 |

| 2010 | Hongliu Coalmine, Ningxia | Height of water flowing fracture zone | 350 |

| 2011 | Panyi Coalmine, Anhui | Overburden failure characteristics | 360 |

| 2012 | Coalmines of Xinjiang & Shanxi | Goaf location and aquifer distribution | 400 |

| 2014 | Jingdong Coalmine, Shanxi | Goaf distribution | 200 |

| 2015 | Tectonic fault basin, Northeast Inner Mongolia | Coal mining | 500 |

| 2016 | Liudong Coaimine, Anhui | Structure exploration | 900 |

| Number | Lithology | Thickness h (m) | Bulk Density γ (kg/m3) | Elastic Modulus E (GPa) | Tensile Strength σc (MPa) | KS Location |

|---|---|---|---|---|---|---|

| 1 | Aeolian sand | 8.75 | 1600 | / | / | |

| 2 | Siltstone | 7.02 | 2650 | 40 | 3.83 | |

| 3 | Coal | 0.98 | 1400 | / | 0.80 | |

| 4 | Siltstone | 11.68 | 2650 | 40 | 3.83 | |

| 5 | Sandy mudstone | 1.9 | 2520 | 18 | 1.53 | |

| 6 | Siltstone | 14.56 | 2650 | 40 | 3.83 | PKS |

| 7 | Fine sandstone | 1.56 | 2680 | 37 | 2.70 | |

| 8 | Sandy mudstone | 3.1 | 2520 | 18 | 1.53 | |

| 9 | Fine sandstone | 0.62 | 2680 | 37 | 2.70 | |

| 10 | Siltstone | 12.05 | 2650 | 40 | 3.83 | SKS |

| 11 | Kern stone | 3.36 | 2580 | 27 | 2.10 | |

| 12 | Fine sandstone | 12.7 | 2680 | 37 | 2.70 | |

| 13 | Siltstone | 1.3 | 2650 | 40 | 3.83 | SKS |

| 14 | Mudstone | 0.1 | 2250 | 8 | 1.23 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Guo, W.; Bai, E.; Wang, Y. Key Strata Identification of Overburden Based on Magnetotelluric Detection: A Case Study. Appl. Sci. 2020, 10, 558. https://doi.org/10.3390/app10020558

Wang Y, Guo W, Bai E, Wang Y. Key Strata Identification of Overburden Based on Magnetotelluric Detection: A Case Study. Applied Sciences. 2020; 10(2):558. https://doi.org/10.3390/app10020558

Chicago/Turabian StyleWang, Yunguang, Wenbing Guo, Erhu Bai, and Yuxi Wang. 2020. "Key Strata Identification of Overburden Based on Magnetotelluric Detection: A Case Study" Applied Sciences 10, no. 2: 558. https://doi.org/10.3390/app10020558

APA StyleWang, Y., Guo, W., Bai, E., & Wang, Y. (2020). Key Strata Identification of Overburden Based on Magnetotelluric Detection: A Case Study. Applied Sciences, 10(2), 558. https://doi.org/10.3390/app10020558