An Experimental Investigation on the Influence of Port Injection at Valve on Combustion and Emission Characteristics of B5/Biogas RCCI Engine

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Set-Up and Measurement

2.2. Experimental Procedure

2.3. Test Fuels

3. Results

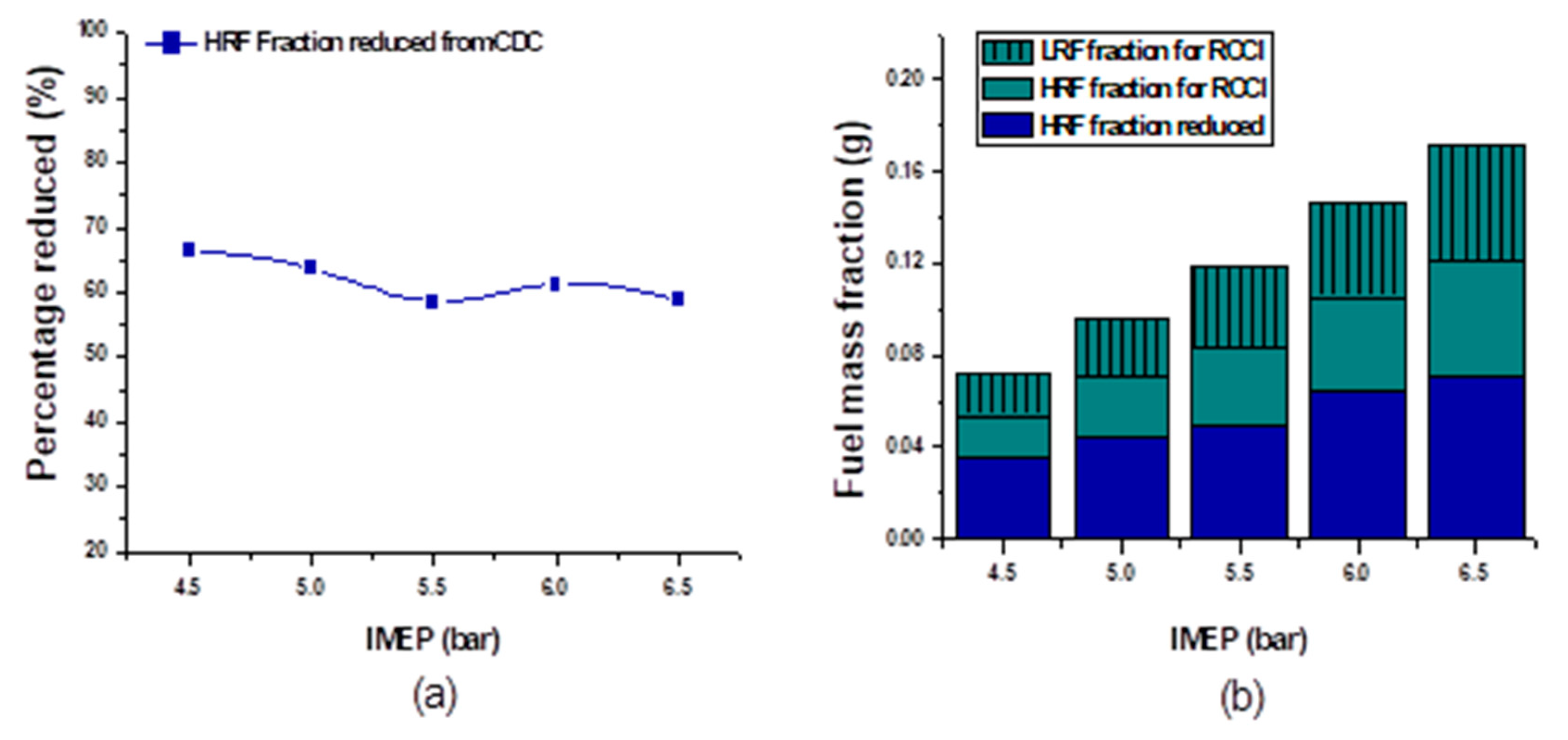

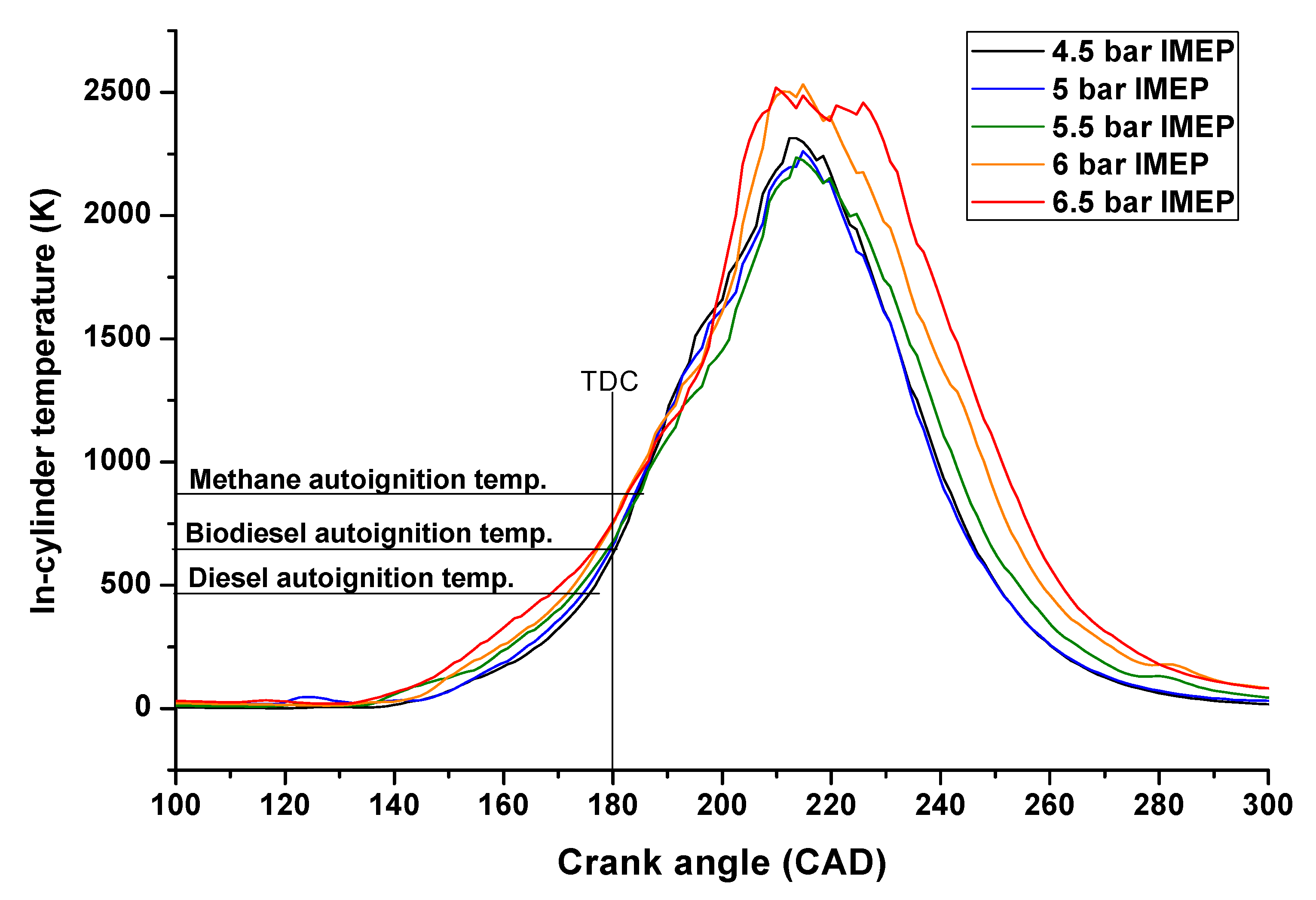

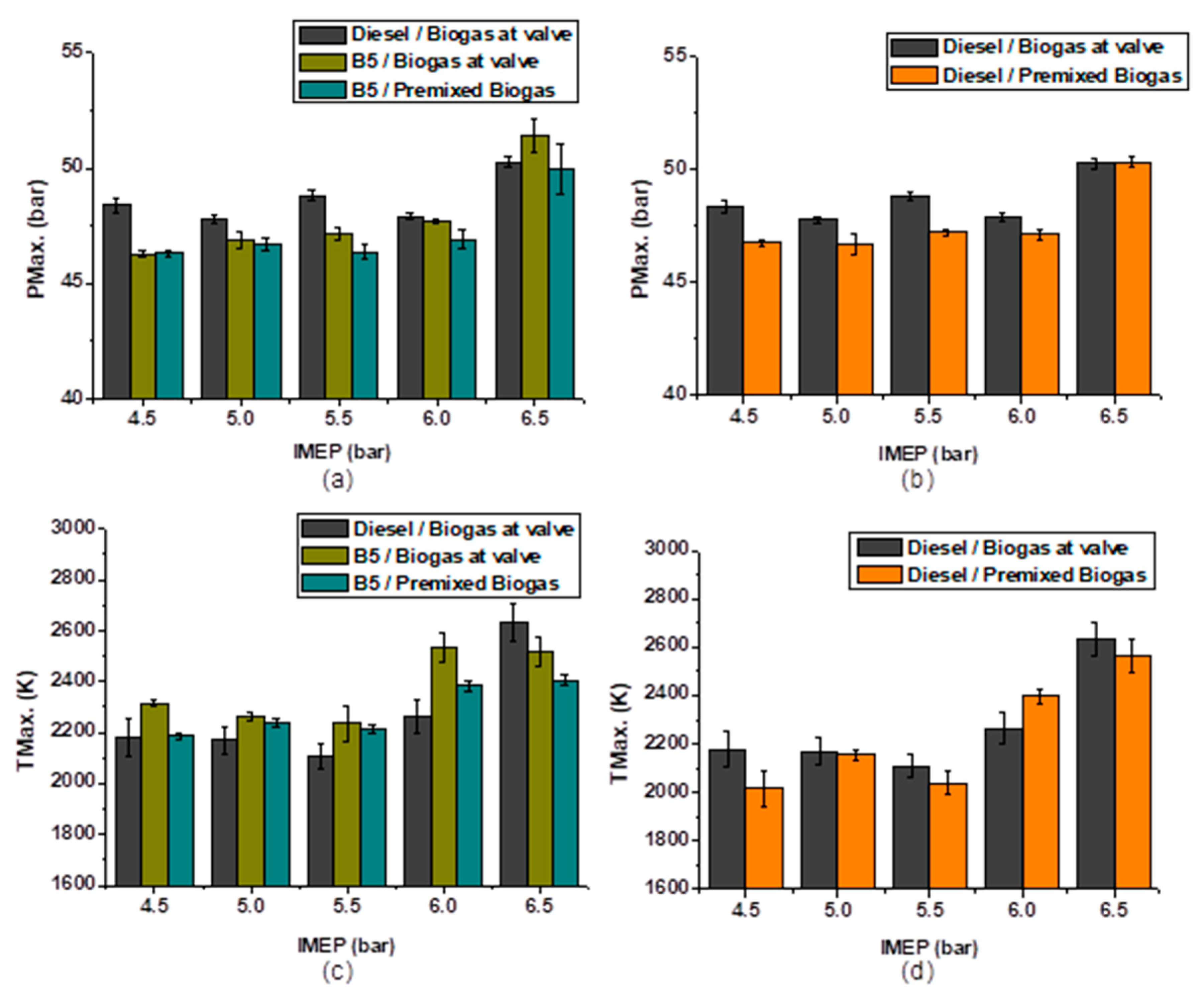

3.1. Effects of Injection at the Valve and Reactivity Fuels on the Combustion Attributes

3.1.1. Analysis of The In-Cylinder Pressure Traces

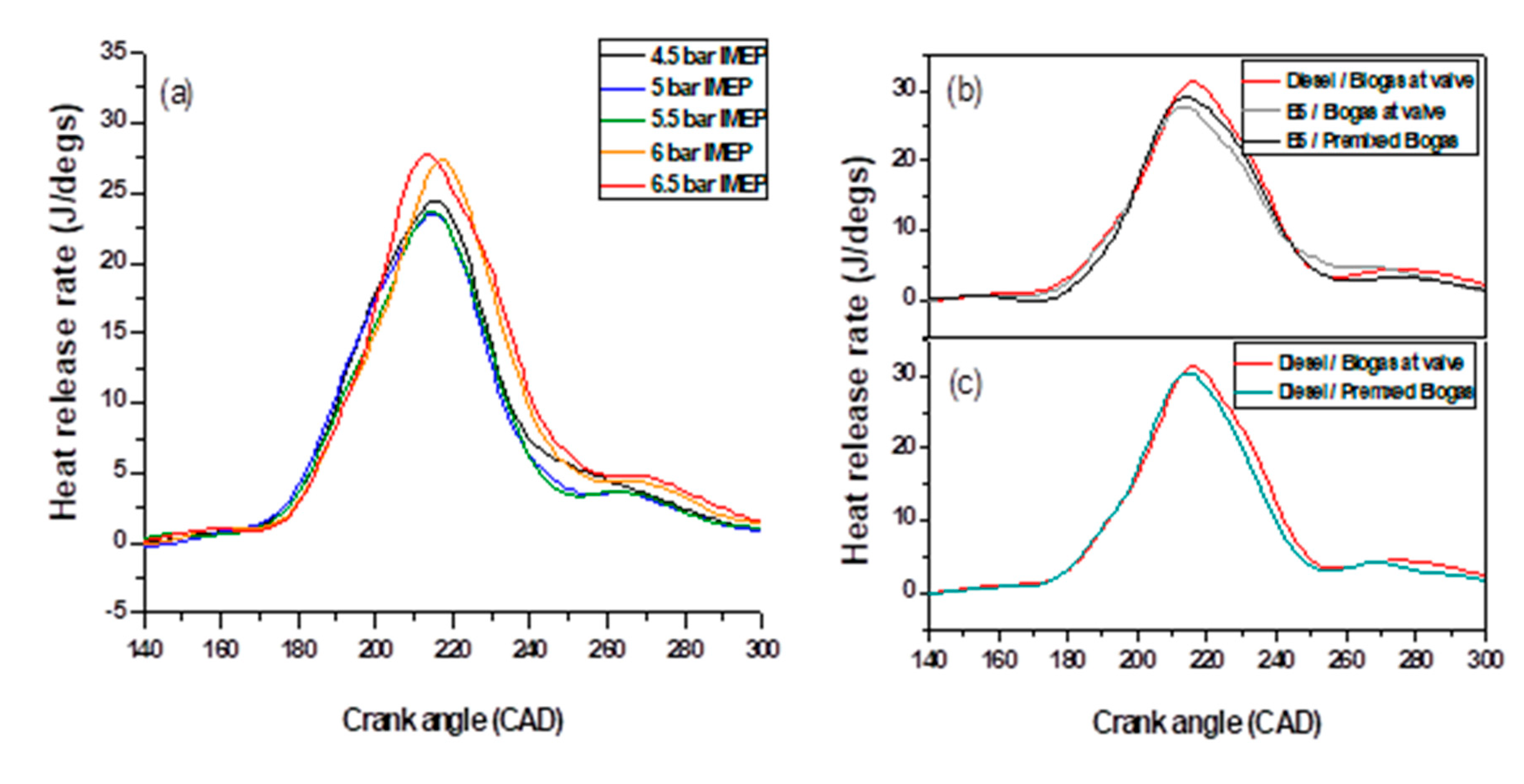

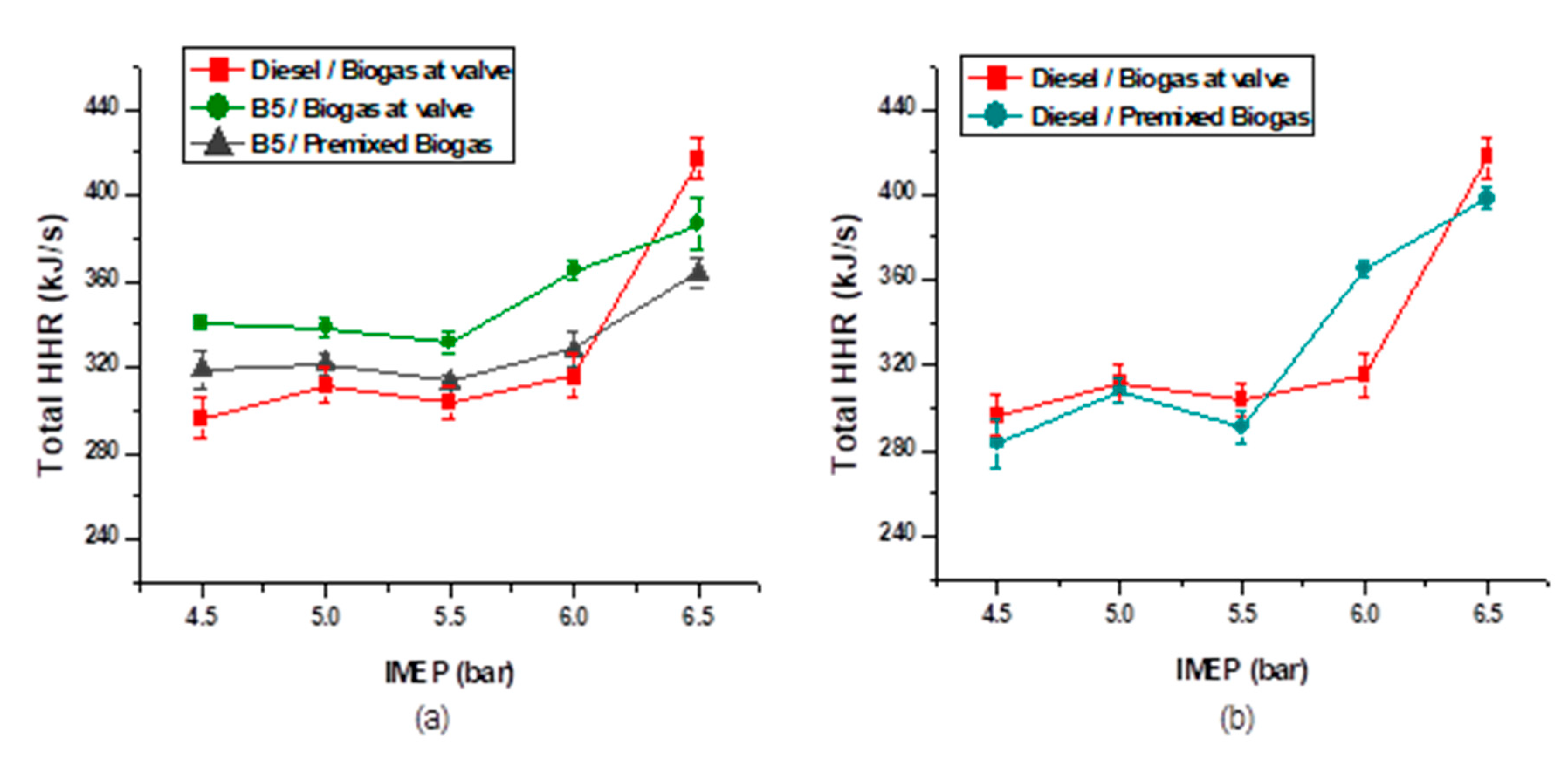

3.1.2. Rate of the Combustion Heat Release

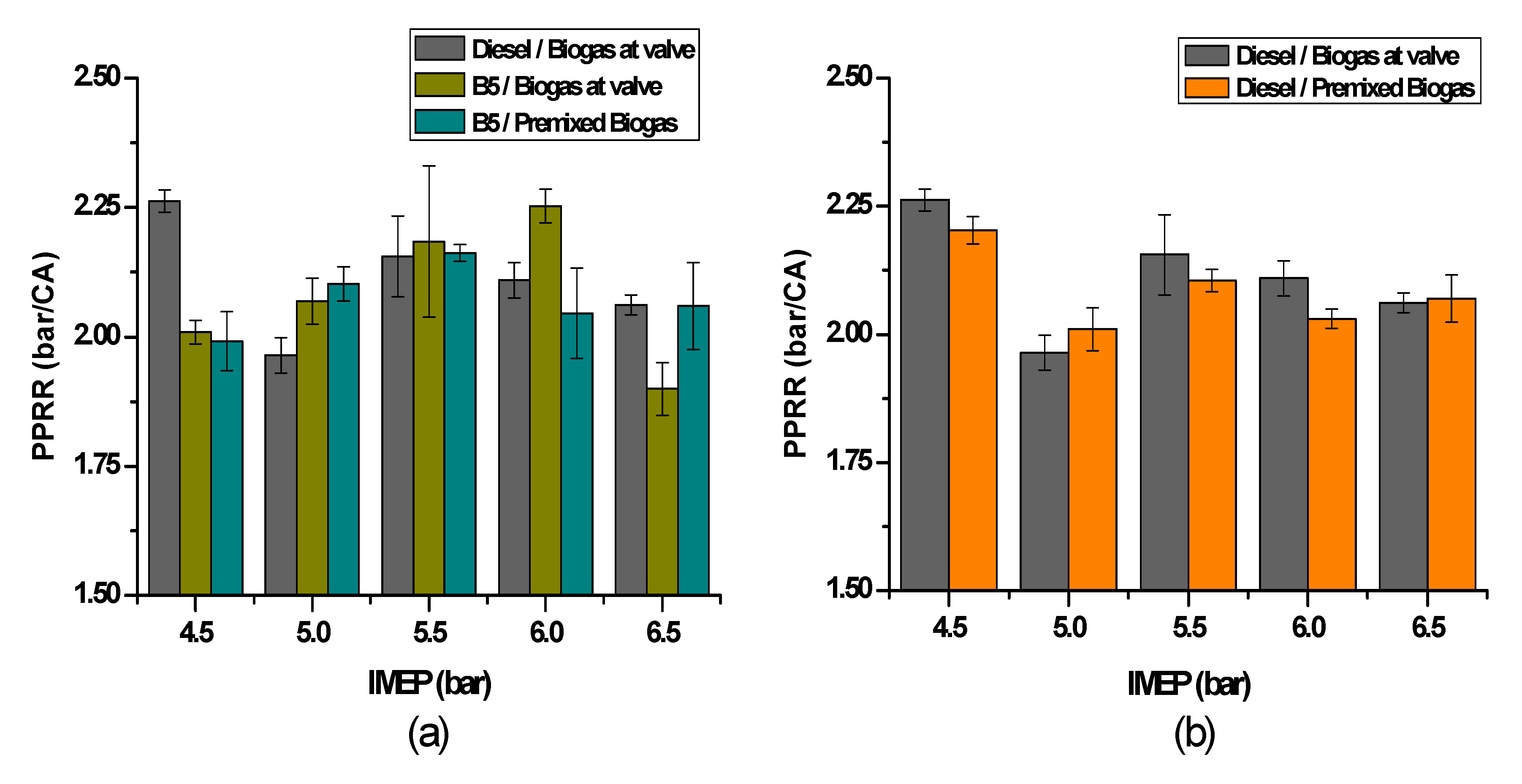

3.1.3. Rate of the In-Cylinder Peak Pressure Rise

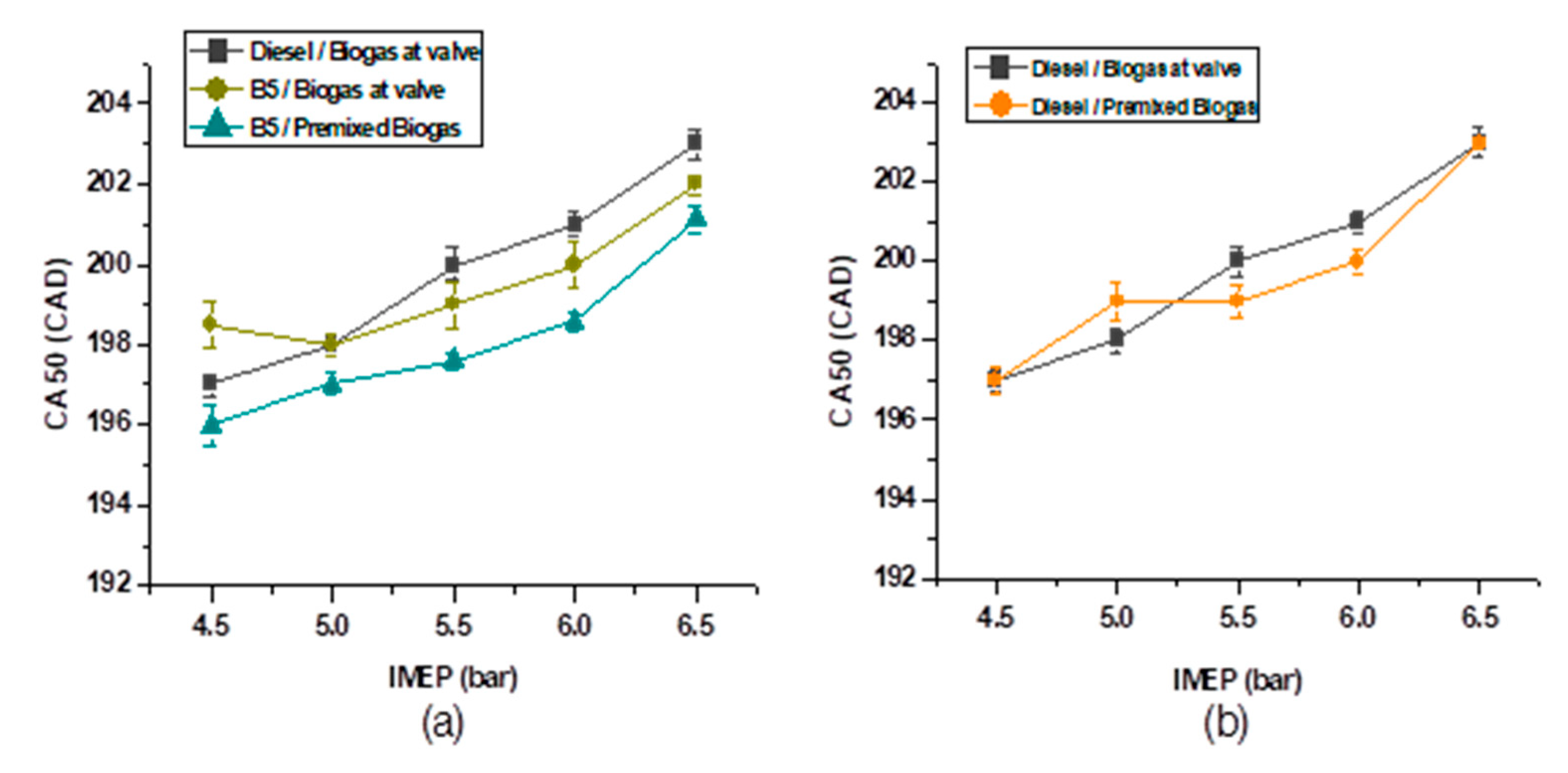

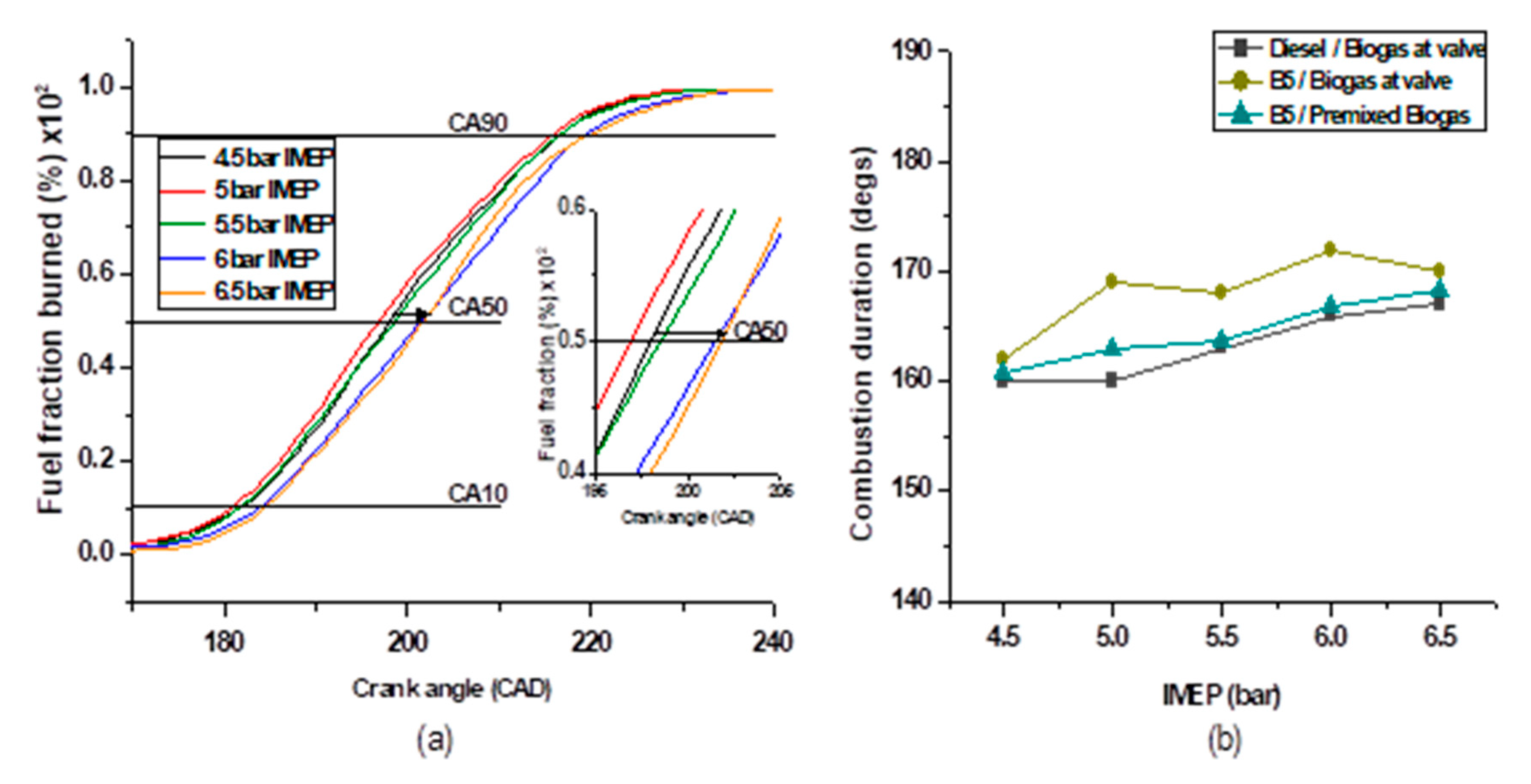

3.1.4. The Dynamism of the Combustion Phase

3.2. Effects of Injection at the Valve and Reactivity Fuels on Performance Attributes

3.3. Effects of Injection at the Valve and Reactivity Fuels on the Emission Attributes

3.3.1. CO2 Emission

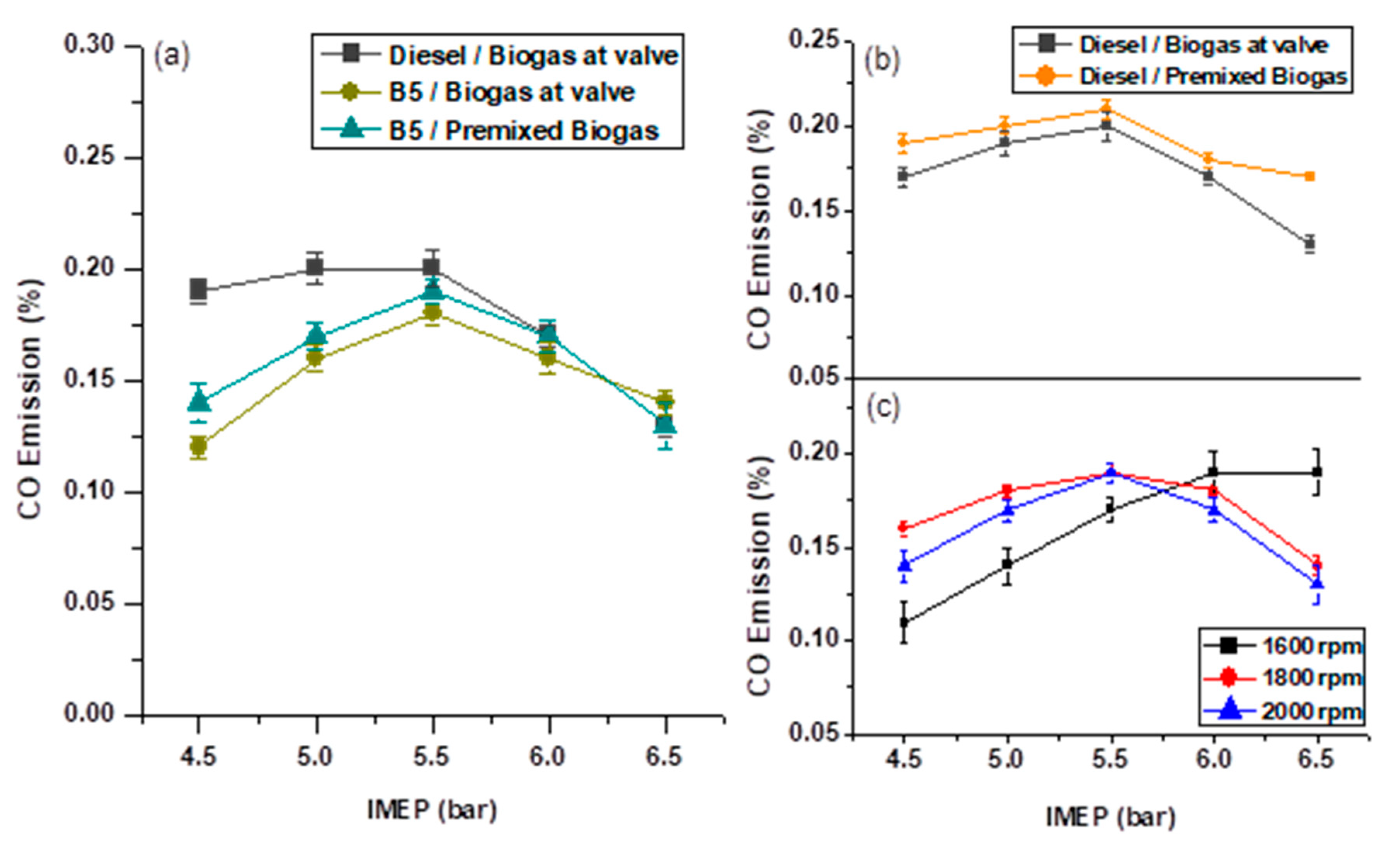

3.3.2. CO Emission

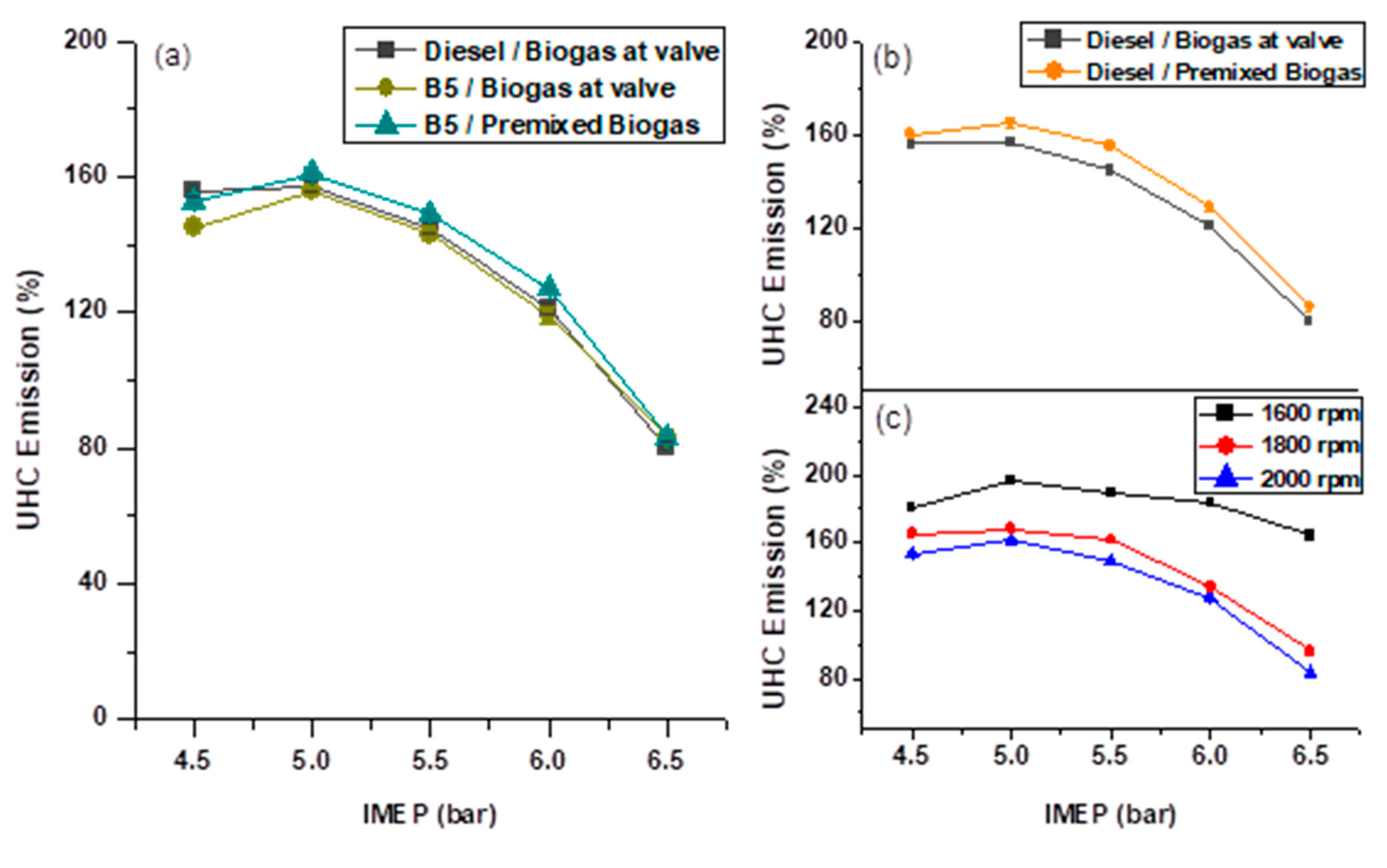

3.3.3. UHC Emission

3.3.4. NOx Emission

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Zhu, Z.; Yao, M.; Li, T.; Zhang, W.; Zheng, Z. An investigation into the RCCI engine operation under low load and its achievable operational range at different engine speeds. Energy Convers. Manag. 2016, 124, 399–413. [Google Scholar] [CrossRef]

- Salahi, M.M.; Esfahanian, V.; Gharehghani, A.; Mirsalim, M. Investigating the reactivity controlled compression ignition (RCCI) combustion strategy in a natural gas/diesel fueled engine with a pre-chamber. Energy Convers. Manag. 2017, 132, 40–53. [Google Scholar] [CrossRef]

- Reitz, R.D.; Duraisamy, G. Review of high efficiency and clean reactivity controlled compression ignition (RCCI) combustion in internal combustion engines. Prog. Energy Combust. Sci. 2015, 46, 12–71. [Google Scholar] [CrossRef]

- Li, J.; Yang, W.; Zhou, D. Review on the management of RCCI engines. Renew. Sustain. Energy Rev. 2017, 69, 65–79. [Google Scholar] [CrossRef]

- Benajes, J.; Molina, S.; García, A.; Belarte, E.; Vanvolsem, M. An investigation on RCCI combustion in a heavy-duty diesel engine using in-cylinder blending of diesel and gasoline fuels. Appl. Therm. Eng. 2014, 63, 66–76. [Google Scholar] [CrossRef]

- Dalha, I.B.; Said, M.A.; Karim, Z.A.A.; Firmansyah, F. Strategies and methods of RCCI combustion: A review. AIP Conf. Proc. 2018, 2035, 030006. [Google Scholar] [CrossRef]

- Firmansyah, F.; Aziz, A.A.R.; Heikal, M.; Zainal, A.E. Diesel/CNG Mixture Autoignition Control Using Fuel Composition and Injection Gap. Energies 2017, 10, 1639. [Google Scholar] [CrossRef]

- Lim, J.H.; Reitz, R.D. High Load (21 Bar IMEP) Dual Fuel RCCI Combustion Using Dual Direct Injection. J. Eng. Gas Turbines Power 2014, 136, 101514. [Google Scholar] [CrossRef]

- Luong, M.B.; Sankaran, R.; Yu, G.H.; Chung, S.H.; Yoo, C.S. On the effect of injection timing on the ignition of lean PRF/air/EGR mixtures under direct dual fuel stratification conditions. Combust Flame 2017, 183, 309–321. [Google Scholar] [CrossRef]

- Kavuri, C.; Paz, J.; Kokjohn, S.L. A comparison of Reactivity Controlled Compression Ignition (RCCI) and Gasoline Compression Ignition (GCI) strategies at high load, low-speed conditions. Energy Convers. Manag. 2016, 127, 324–341. [Google Scholar] [CrossRef]

- Lim, J.H.; Reitz, R. Improving high-efficiency reactivity controlled compression ignition combustion with diesel and gasoline direct injection. Proc. Inst. Mech. Eng. Part. D J. Automob Eng. 2013, 227, 17–30. [Google Scholar] [CrossRef]

- Wissink, M.; Reitz, R.D. Direct dual fuel stratification, a path to combine the benefits of RCCI and PPC. SAE Int. J. Engines 2015, 8, 878–889. [Google Scholar] [CrossRef]

- Mikulski, M.; Bekdemir, C. Understanding the role of low reactivity fuel stratification in a dual fuel RCCI engine—A simulation study. Appl. Energy 2017, 191, 689–708. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Shukl, P.C.; Patel, C.; Gupta, J.G.; Sharma, N.; Prasad, R.K.; Agarwal, R.A. Unregulated emissions and health risk potential from biodiesel (KB5, KB20) and methanol blend (M5) fuelled transportation diesel engines. Renew. Energy 2016, 98, 283–291. [Google Scholar] [CrossRef]

- Xu, Z.; Jia, M.; Li, Y.; Chang, Y.; Xu, G.; Xu, L.; Lu, X. Computational optimisation of fuel supply, syngas composition, and intake conditions for a syngas/diesel RCCI engine. Fuel 2018, 234, 120–134. [Google Scholar] [CrossRef]

- Qian, Y.; Zhang, Y.; Wang, X.; Lu, X. Particulate matter emission characteristics of a reactivity controlled compression ignition engine fueled with biogas/diesel dual fuel. J. Aerosol Sci. 2017, 113, 166–177. [Google Scholar] [CrossRef]

- Wang, X.; Qian, Y.; Zhou, Q.; Lu, X. Modulated diesel fuel injection strategy for efficient-clean utilisation of low-grade biogas. Appl. Therm. Eng. 2016, 107, 844–852. [Google Scholar] [CrossRef]

- Gashaw, A.; Getachew, T.; Teshita, A. A Review on Biodiesel Production as Alternative Fuel. J. For. Prod. Ind. 2015, 4, 80–85. [Google Scholar]

- Kumar, A.; Shukla, S.K.; Tierkey, J.V. A Review of Research and Policy on Using Different Biodiesel oils as Fuel for CI Engine. Energy Procedia 2016, 90, 292–304. [Google Scholar] [CrossRef]

- Saxena, P.; Jawale, S.; Joshipura, M.H. A review on prediction of properties of biodiesel and blends of biodiesel. Procedia Eng. 2013, 51, 395–402. [Google Scholar] [CrossRef]

- Benajes, J.; Molina, S.; García, A.; Monsalve-Serrano, J. Effects of direct injection timing and blending ratio on RCCI combustion with different low reactivity fuels. Energy Convers. Manag. 2015, 99, 193–209. [Google Scholar] [CrossRef]

- Isik, Z.M.; Hüseyin, A. Analysis of ethanol RCCI application with safflower biodiesel blends in a high load diesel power generator. Fuel 2016, 184, 248–260. [Google Scholar] [CrossRef]

- Li, J.; Yang, W.M.; Zhou, D.Z. Modeling study on the effect of piston bowl geometries in a gasoline/biodiesel fueled RCCI engine at high speed. Energy Convers. Manag. 2016, 112, 359–368. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, M.; Li, T.; Zhang, W.; Zheng, Z. A parametric study for enabling reactivity controlled compression ignition (RCCI) operation in diesel engines at various engine loads. Appl. Energy 2016, 175, 389–402. [Google Scholar] [CrossRef]

- Bora, B.J.; Saha, U.K. Optimisation of injection timing and a compression ratio of raw biogas powered dual fuel diesel engine. Appl. Therm. Eng. 2016, 92, 111–121. [Google Scholar] [CrossRef]

- Aklouche, F.Z.; Loubar, K.; Bentebbiche, A.; Awad, S.; Tazerout, M. Experimental investigation of the equivalence ratio influence on combustion, performance and exhaust emissions of a dual fuel diesel engine operating on synthetic biogas fuel. Energy Convers. Manag. 2017, 152, 291–299. [Google Scholar] [CrossRef]

- Bora, B.J.; Saha, U.K. Experimental evaluation of a rice bran biodiesel/biogas run dual fuel diesel engine at varying compression ratios. Renew. Energy 2016, 87, 782–790. [Google Scholar] [CrossRef]

- Shan, X.; Qian, Y.; Zhu, L.; Lu, X. Effects of EGR rate and hydrogen/carbon monoxide ratio on combustion and emission characteristics of biogas/diesel dual-fuel combustion engine. Fuel 2016, 181, 1050–1057. [Google Scholar] [CrossRef]

- Barik, D.; Murugan, S. Experimental investigation on the behavior of a DI diesel engine fueled with raw biogas/diesel dual fuel at different injection timing. J. Energy Inst. 2016, 89, 373–388. [Google Scholar] [CrossRef]

- Gund, M.D.; Tamboli, S.A.; Mohite, V.R. Performance Evaluation of Single Cylinder Diesel Engine in Dual Fuel Mode with Biogas as Primary Fuel and Diesel and Biodiesel as Pilot Fuel. Int. Res. J. Eng. Technol. 2017, 04, 1656–1660. [Google Scholar]

- Ohimain, E.I.; Izah, S.C. A review of biogas production from palm oil mill effluents using different configurations of bioreactors. Renew. Sustain. Energy Rev. 2017, 70, 242–253. [Google Scholar] [CrossRef]

- Bora, B.J.; Saha, U.K.; Chatterjee, S.; Veer, V. Effect of compression ratio on performance, combustion and emission characteristics of a dual fuel diesel engine run on raw biogas. Energy Convers. Manag. 2014, 87, 1000–1009. [Google Scholar] [CrossRef]

- Kadam, R.; Panwar, N.L. Recent advancement in biogas enrichment and its applications. Renew. Sustain. Energy Rev. 2017, 73, 892–903. [Google Scholar] [CrossRef]

- Senghor, A.; Dioh, R.M.N.; Müller, C.; Youm, I. Cereal crops for biogas production: A review of possible impact of elevated. Renew. Sustain. Energy Rev. 2017, 71, 548–554. [Google Scholar] [CrossRef]

- Jankowska, E.; Sahu, A.K.; Oleskowicz-popiel, P. Biogas from microalgae: Review on microalgae’s cultivation, harvesting and pretreatment for anaerobic digestion. Renew. Sustain. Energy Rev. 2017, 75, 692–709. [Google Scholar] [CrossRef]

- Ullah, I.; Othman, M.H.D.; Hashim, H.; Matsuura, T.; Ismail, A.F.; Rezaei-DashtArzhandi, M.; Azelee, I.W. Biogas as a renewable energy fuel—A review of biogas upgrading, utilisation and storage. Energy Convers. Manag. 2017, 150, 277–294. [Google Scholar] [CrossRef]

- Hagos, K.; Zong, J.; Li, D.; Liu, C.; Lu, X. Anaerobic co-digestion process for biogas production: Progress, challenges and perspectives. Renew. Sustain. Energy Rev. 2017, 76, 1485–1496. [Google Scholar] [CrossRef]

- Neshat, S.A.; Mohammadi, M.; Najafpour, G.D.; Lahijani, P. Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production. Renew. Sustain. Energy Rev. 2017, 79, 308–322. [Google Scholar] [CrossRef]

- Kakaee, A.; Rahnama, P.; Paykani, A. Influence of fuel composition on combustion and emissions characteristics of natural gas/diesel RCCI engine. J. Nat. Gas Sci. Eng. 2015, 25, 58–65. [Google Scholar] [CrossRef]

- Zamboni, G. Influence of fuel injection, turbocharging and EGR systems control on combustion parameters in an automotive diesel engine. Appl. Sci. 2019, 9, 484. [Google Scholar] [CrossRef]

- Dalha, I.B.; Said, M.A.; Abdul Karim, Z.A.; Abdul, A.R.A.; Firmansyah; Abidin, E.Z.Z.; Ismael, M.A. Reactivity controlled compression ignition: An advanced combustion mode for improved energy efficiency. In Energy Efficiency in Mobility Systems; Springer: Singapore, 2019; pp. 101–126. [Google Scholar] [CrossRef]

- Du, J.; Chen, X.; Liu, L.; Liu, D.; Ma, X. Mechanism of combustion noise influenced by pilot injection in PPCI diesel engines. Appl. Sci. 2019, 9, 875. [Google Scholar] [CrossRef]

- Shameer, P.M.; Ramesh, K. Assessment on the consequences of injection timing and injection pressure on combustion characteristics of sustainable biodiesel fuelled engine. Renew. Sustain. Energy Rev. 2018, 81, 45–61. [Google Scholar] [CrossRef]

- Shi, J.; Wang, T.; Zhao, Z.; Wu, Z.; Zhang, Z. Cycle-to-cycle variation of a diesel engine fueled with Fischer-Tropsch fuel synthesized from coal. Appl. Sci. 2019, 9, 32. [Google Scholar] [CrossRef]

- Bocci, E.; Sisinni, M.; Moneti, M.; Vecchione, L.; Di Carlo, A.; Villarini, M. State of art of small scale biomass gasification power systems: A review of the different typologies. Energy Procedia 2014, 45, 247–256. [Google Scholar] [CrossRef]

- Imtenan, S.; Varman, M.; Masjuki, H.H.; Kalam, M.A.; Sajjad, H.; Arbab, M.I.; Fattah, I.M.R. Impact of low temperature combustion attaining strategies on diesel engine emissions for diesel and biodiesels: A review. Energy Convers. Manag. 2014, 80, 329–356. [Google Scholar] [CrossRef]

| Description | Specifications | |

|---|---|---|

| Model | L100V | |

| Type | Single cylinder, 4-stroke, air-cooled engine | |

| Bore | 86 mm | |

| Stroke | 75 mm | |

| Displacement | 435 cm3 | |

| Compression ratio | 20.0 ± 0.3 | |

| Fuel injection timing | 21° CA BTDC | |

| Continuous Rate Output | Engine speed | 3600 rpm |

| Output | 6.2 kW | |

| Maximum Rated Output | Engine speed | 3600 rpm |

| Output | 6.8 kW |

| Engine Load | Diesel at 2000 rpm | B5 at 2000 rpm | HRF Mass | LRF Mass | |||||

|---|---|---|---|---|---|---|---|---|---|

| (%) | IMEP (bar) | SD | Brake (%) | Throttle (%) | Brake (%) | Throttle (%) | (g) | SD | (g) |

| 0 | 4.495 | ± 0.083 | 22 | 53 | 23 | 53 | 0.0181 | ±0.0066 | 0.0181 |

| 25 | 4.998 | ± 0.092 | 35 | 55 | 36 | 55 | 0.0256 | ±0.0058 | 0.0256 |

| 50 | 5.520 | ± 0.043 | 54 | 57 | 56 | 57 | 0.0347 | ±0.0051 | 0.0347 |

| 75 | 6.013 | ± 0.076 | 72 | 59 | 74 | 60 | 0.0408 | ±0.0073 | 0.0408 |

| 100 | 6.553 | ± 0.068 | 90 | 61 | 91 | 62 | 0.0499 | ±0.0021 | 0.0499 |

| Properties | Biogas | Diesel | B5-Diesel |

|---|---|---|---|

| Proportion by mole | 75% CH4, 25% CO2 | C10–24 | |

| Density (kg/m3) | 1.353 | 820–832 | 823.45 |

| Lower flammability limit (mol%) | 6.1–22.4 | 0.6–7.5 | 0.75–4.6 |

| Molecular weight (g/mol) | 23.5132 | 168 | 174 |

| Specific gravity at 0 °C | 1.05 | 0.85 | 0.852 |

| Specific volume (m3/kg) | 0.739 | 1.18–1.22 | |

| Kinematic viscosity (cSt) | 12.74 | 1.5–5.8 | 1.5–5.8 |

| Lower heating value (MJ/m3) | 26.24 | 36.0 | |

| Cetane number | 59.8 | 62–63 | |

| Stoichiometric air-fuel ratio | 4.56:1 | 15.05:1 | 14.97:1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dalha, I.B.; Said, M.A.; Abdul Karim, Z.A.; Mohammed, S.E. An Experimental Investigation on the Influence of Port Injection at Valve on Combustion and Emission Characteristics of B5/Biogas RCCI Engine. Appl. Sci. 2020, 10, 452. https://doi.org/10.3390/app10020452

Dalha IB, Said MA, Abdul Karim ZA, Mohammed SE. An Experimental Investigation on the Influence of Port Injection at Valve on Combustion and Emission Characteristics of B5/Biogas RCCI Engine. Applied Sciences. 2020; 10(2):452. https://doi.org/10.3390/app10020452

Chicago/Turabian StyleDalha, Ibrahim B., Mior A. Said, Zainal A. Abdul Karim, and Salah E. Mohammed. 2020. "An Experimental Investigation on the Influence of Port Injection at Valve on Combustion and Emission Characteristics of B5/Biogas RCCI Engine" Applied Sciences 10, no. 2: 452. https://doi.org/10.3390/app10020452

APA StyleDalha, I. B., Said, M. A., Abdul Karim, Z. A., & Mohammed, S. E. (2020). An Experimental Investigation on the Influence of Port Injection at Valve on Combustion and Emission Characteristics of B5/Biogas RCCI Engine. Applied Sciences, 10(2), 452. https://doi.org/10.3390/app10020452