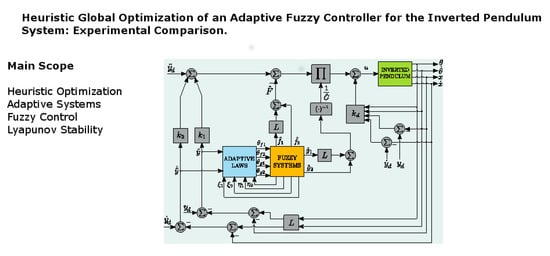

Heuristic Global Optimization of an Adaptive Fuzzy Controller for the Inverted Pendulum System: Experimental Comparison

Abstract

1. Introduction

- The proposed algorithm does not use any knowledge of the plant. Unlike previous works, a formal stability analysis of the closed-loop system is proven via Lyapunov theory and therefore, boundedness of the solutions (position and velocity of the pendulum on a cart) is guaranteed.

- A comparison among several evolutionary techniques are carried out in simulation, and then successfully exported to real-time experiments without any change in the optimized membership functions; only the gains of the controller were tuned again.

2. Methodology

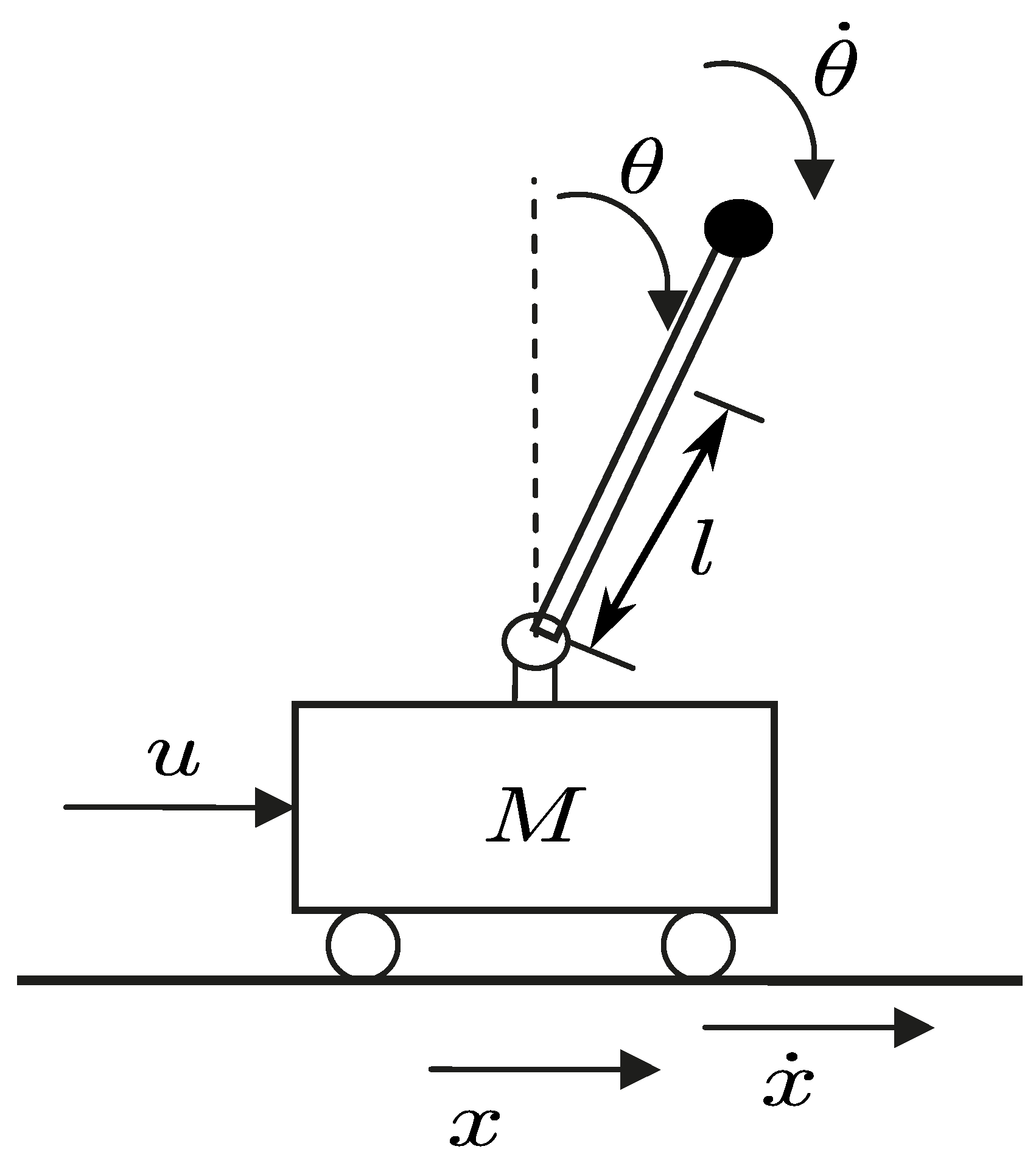

2.1. Dynamics of the Inverted Pendulum System

2.2. Fuzzy Systems Description

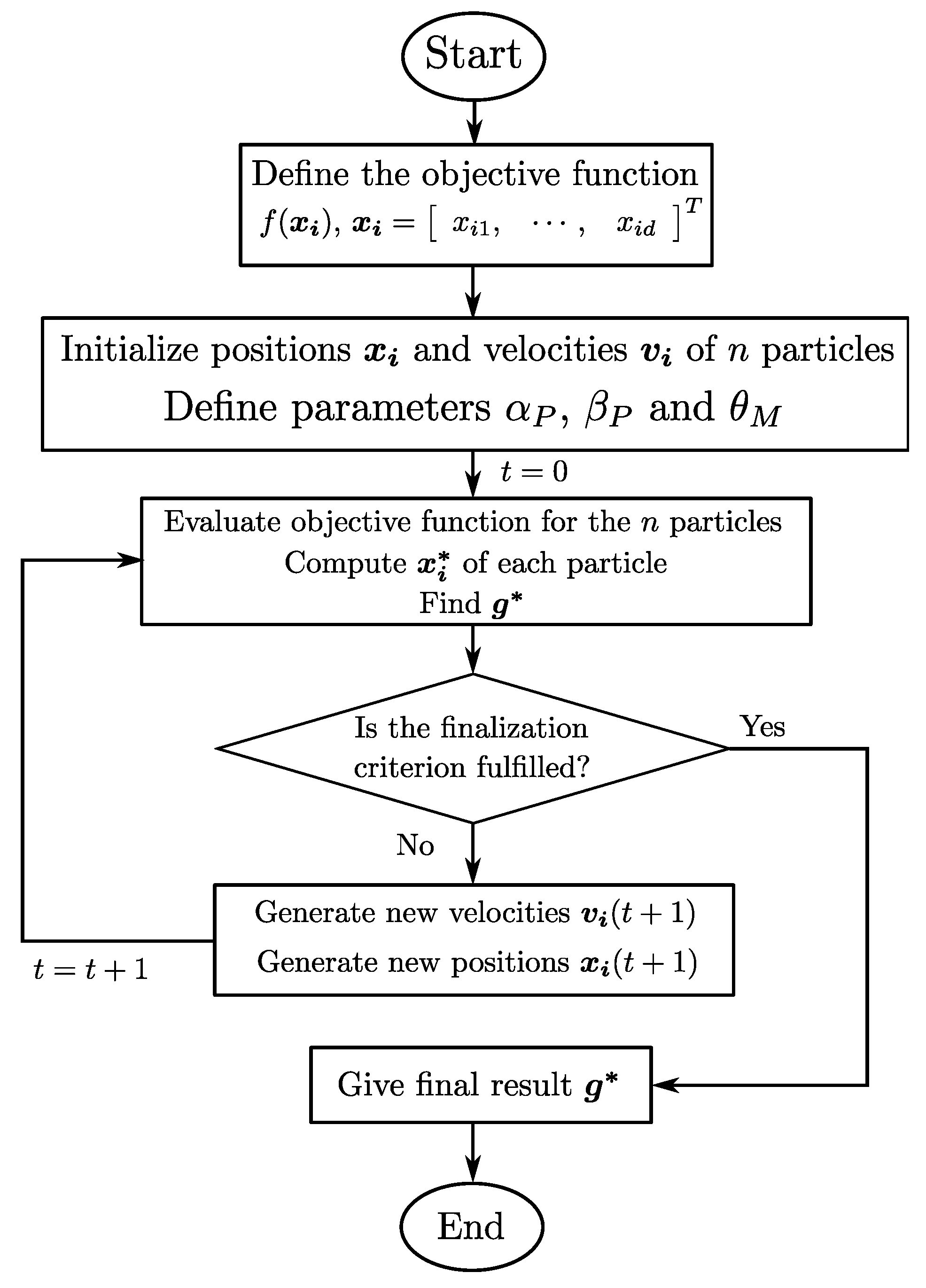

2.3. Evolutionary Algorithms for Optimization

2.3.1. Particle Swarm Optimization—PSO

2.3.2. Differential Evolution—DE

2.3.3. Firefly Algorithms—FFA

2.4. Proposed Controller Design

2.4.1. Controller Design

2.4.2. Stability Analysis

3. Results and Discussion

3.1. Optimization Logic

- Stage 1: Particles=10, Iterations=15, , and .

- Stage 2: Particles=10, Iterations=15 , and .

- Stage 1: Fireflies=11, Iterations=25, , , and

- Stage 2: Fireflies=11, Iterations=15, , , and

- Stage 1: Individuals=10, Generations=25, , and

- Stage 2; Individuals=10, Generations=15, , and

3.2. Inverted Pendulum on a Cart Application

3.3. Real-Time Experimental Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ACO-NM | Ant Colony Optimization method with a constrained Nelder–Mead algorithm |

| DC | Direct Current |

| DE | Differential Evolution |

| EA | Evolutionary Algorithms |

| FFA | Firefly Algorithm |

| ICP | Inverted Cart-Pendulum |

| I/O | Input-Output |

| LMI | Linear Matrix Inequality |

| LQR | Linear Quadratic Regulator |

| PD | Proportional-Derivative |

| PID | Proportional-Integral-Derivative |

| PSO | Particle Swarm Optimization |

| TSFSC | Takagi–Sugeno Fuzzy Servo Control |

References

- Llama, M.; Kelly, R.; Santibañez, V.; Centeno, H. An adaptive fuzzy controller for robot manipulators: Theory and experimentation. Int. J. Fact. Autom. Robot. Soft Comput. 2009, 1, 122–131. [Google Scholar]

- Wang, L.-X. A Course in Fuzzy Systems and Control; Prentice-Hall International, Inc.: Upper Saddle River, NJ, USA, 1997. [Google Scholar]

- El-Hawwary, M.I.; Elshafei, A.L.; Emara, H.M.; Fattah, H.A.A. Adaptive Fuzzy Control of the Inverted Pendulum Problem. IEEE Trans. Control Syst. Technol. 2006, 14, 1135–1144. [Google Scholar] [CrossRef]

- Chen, C.-S.; Chen, W.-L. Robust adaptive sliding-mode control using fuzzy modeling for an inverted-pendulum system. IEEE Trans. Ind. Electron. 1998, 45, 297–306. [Google Scholar] [CrossRef]

- Centeno, H. Adaptive Fuzzy Control for Mechatronic Systems: Experimental Implementation to an Inverted Pendulum and a 2-dof Robot Manipulator. Master’s Thesis, Instituto Tecnologico de La Laguna, Torreon, Mexico, 2008. [Google Scholar]

- Pal, A.K.; Chakrabarty, J. Adaptive Fuzzy Control of Inverted Pendulum with a Fuzzy-based Set-Point Weighting Scheme. In Proceedings of the Fourth International Conference of Emerging Applications of Information Technology, Kolkata, India, 19–21 December 2014; pp. 46–51. [Google Scholar]

- Maity, S.; Luecke, G.R. Stabilization and Optimization of Design Parameters for Control of Inverted Pendulum. J. Dyn. Syst. Meas. Control 2019, 141, 1–11. [Google Scholar] [CrossRef]

- Abut, T.; Soyguder, S. Real-time control and application with self-tuning PID type fuzzy adaptive controller of an inverted pendulum. Ind. Robot 2019, 46, 159–170. [Google Scholar] [CrossRef]

- Tang, Y.; Zhou, D.; Jiang, W. A new fuzzy evidential controller for stabilization of the planar inverted pendulum system. PLoS ONE 2016, 11, 1–16. [Google Scholar] [CrossRef]

- Ioannou, P.; Sun, J. Robust Adaptive Control; Dover Publications: New York, NY, USA, 1996. [Google Scholar]

- Yang, X.-S. Nature-Inspired Optimization Algorithms; Elsevier: London, UK, 2014. [Google Scholar]

- Ochoa, P.; Castillo, O.; Soria, J. Optimization of fuzzy controller design using a Differential Evolution algorithm with dynamic parameter adaptation based on Type-1 and Interval Type-2 fuzzy systems. Soft Comput. 2020, 24, 193–214. [Google Scholar] [CrossRef]

- Bendjeghaba, O. Continuous Firefly Algorithm for Optimal Tuning of PID Controller in AVR System. J. Electr. Eng. 2014, 65, 44–49. [Google Scholar] [CrossRef][Green Version]

- Bingül, Z.; Karahan, O. A Fuzzy Logic Controller tuned with PSO for 2 DOF robot trajectory control. Expert Syst. Appl. 2010, 38, 1017–1031. [Google Scholar] [CrossRef]

- Castillo, O.; Melin, P.; Alanis, A.; Montiel, O.; Sepulveda, R. Optimization of Interval Type-2 Fuzzy Logic Controllers Using Evolutionary Algorithms. Soft Comput. 2011, 15, 1145–1160. [Google Scholar] [CrossRef]

- Mahmoodabadi, M.J.; Haghbayan, H.K. An optimal adaptive hybrid controller for a fourth-order under-actuated nonlinear inverted pendulum system. Trans. Inst. Meas. Control 2019, 42, 285–294. [Google Scholar] [CrossRef]

- Blondin, M.J.; Pardalos, P.M. A holistic optimization approach for inverted cart-pendulum control tuning. Soft Comput. 2019, 24, 4343–4359. [Google Scholar] [CrossRef]

- Fantoni, I.; Lozano, R. Non-Linear Control for Underactuated Mechanical Systems; Springer: London, UK, 2002. [Google Scholar]

- Kennedy, J.; Eberhart, R.C. Particle swarm optimization. In Proceedings of the International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar]

- Kennedy, J.; Eberhart, R.C.; Shi, Y. Swarm Intelligence; Academic Press: London, UK, 2001. [Google Scholar]

- Chatterjee, A.; Siarry, P. Nonlinear inertia variation for dynamic adaptation in particle swarm optimization. Comput. Oper. Res. 2006, 33, 859–871. [Google Scholar] [CrossRef]

- Storn, R. On the usage of differential evolution for function optimization. In Proceedings of the North American Fuzzy Information Processing Society, Berkeley, CA, USA, 19–22 June 1996; pp. 519–523. [Google Scholar]

- Storn, R.; Price, K. Differential evolution—A simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Yang, X.-S. Firefly algorithms for multimodal optimization. In Stochastic Algorithms: Foundations and Applications. SAGA 2009; Watanabe, O., Zeugmann, T., Eds.; Lecture Notes in Computer Science; Springer: Berlin, Germany, 2009; Volume 5792, pp. 169–178. [Google Scholar]

- Ogata, K. State Space Analysis of Control Systems; Prentice-Hall, Inc.: Englewood Cliffs, NJ, USA, 1967. [Google Scholar]

- Khalil, H.K. Nonlinear Systems; Prentice-Hall, Inc.: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Haddad, W.M.; Chellaboina, V. Nonlinear Dynamical Systems and Control: A Lyapunov-Based Approach; Princeton University Press: Princeton, NJ, USA, 2008. [Google Scholar]

- Llama, M.A.; De La Torre, W.; Jurado, F.; Garcia-Hernandez, R. Robust Takagi-Sugeno Fuzzy Dynamic Regulator for Trajectory Tracking of a Pendulum-Cart System. Math. Probl. Eng. 2015, 1, 1–11. [Google Scholar] [CrossRef]

| Optimization Algorithm | |||||

|---|---|---|---|---|---|

| Input | Parameter | NOT OPT. | PSO | FFA | DE |

| 0.13 | 0.39 | 0.41 | 0.37 | ||

| 0.13 | 0.61 | 0.73 | 0.65 | ||

| 50 | 2.80 | 2.44 | 2.69 | ||

| 0.26 | 0.88 | 1.19 | 1.08 | ||

| 0.4 | 1.03 | 1.29 | 1.18 | ||

| 0.07 | 0.58 | 0.83 | 0.59 | ||

| 0.07 | 0.63 | 0.8 | 0.65 | ||

| x | 30 | 2.75 | 1.94 | 2.68 | |

| 0.1 | 0.48 | 0.56 | 0.53 | ||

| 0.3 | 0.61 | 0.96 | 0.63 | ||

| 0.65 | 0.29 | 0.25 | 0.37 | ||

| 0.65 | 0.56 | 0.52 | 0.56 | ||

| 10 | 8.52 | 6.80 | 2.79 | ||

| 1.30 | 0.99 | 0.96 | 0.93 | ||

| 2 | 1.43 | 1.37 | 1.2 | ||

| 0.4 | 0.1 | 0.15 | 0.1 | ||

| 0.4 | 0.11 | 0.1 | 0.1 | ||

| 6 | 12.24 | 12.55 | 9.8 | ||

| 0.5 | 0.22 | 0.21 | 0.2 | ||

| 0.55 | 0.32 | 0.33 | 0.42 | ||

| Description | Notation | Value |

|---|---|---|

| Mass of the cart | M | [kg] |

| Mass of the pendulum | m | [kg] |

| Length of the pendulum | [m] | |

| Length of the rail | [m] | |

| Length to the center of mass of the pendulum | l | [m] |

| Moment of Inertia | I | [] |

| Viscous friction of the pendulum | [Nm seg/rad] | |

| Viscous friction of the cart | [Nm seg/rad] | |

| Coulomb friction of the cart (positive sense) | [Nm] | |

| Coulomb friction of the cart (negative sense) | [Nm] | |

| Gravity acceleration | g | [] |

| Algorithm | Stage 1 | Stage 2 |

|---|---|---|

| NOT OPT. | ||

| FFA | ||

| DE | ||

| PSO |

| Algorithm | [deg] | [m] | [N] |

|---|---|---|---|

| NOT OPT. | |||

| DE | |||

| FFA | |||

| PSO |

| Algorithm | [deg] | [m] | [N] |

|---|---|---|---|

| TSFSC |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Llama, M.; Flores, A.; Garcia-Hernandez, R.; Santibañez, V. Heuristic Global Optimization of an Adaptive Fuzzy Controller for the Inverted Pendulum System: Experimental Comparison. Appl. Sci. 2020, 10, 6158. https://doi.org/10.3390/app10186158

Llama M, Flores A, Garcia-Hernandez R, Santibañez V. Heuristic Global Optimization of an Adaptive Fuzzy Controller for the Inverted Pendulum System: Experimental Comparison. Applied Sciences. 2020; 10(18):6158. https://doi.org/10.3390/app10186158

Chicago/Turabian StyleLlama, Miguel, Alejandro Flores, Ramon Garcia-Hernandez, and Victor Santibañez. 2020. "Heuristic Global Optimization of an Adaptive Fuzzy Controller for the Inverted Pendulum System: Experimental Comparison" Applied Sciences 10, no. 18: 6158. https://doi.org/10.3390/app10186158

APA StyleLlama, M., Flores, A., Garcia-Hernandez, R., & Santibañez, V. (2020). Heuristic Global Optimization of an Adaptive Fuzzy Controller for the Inverted Pendulum System: Experimental Comparison. Applied Sciences, 10(18), 6158. https://doi.org/10.3390/app10186158