Behaviour of Uniform Drava River Sand in Drained Condition—A Critical State Approach

Abstract

1. Introduction

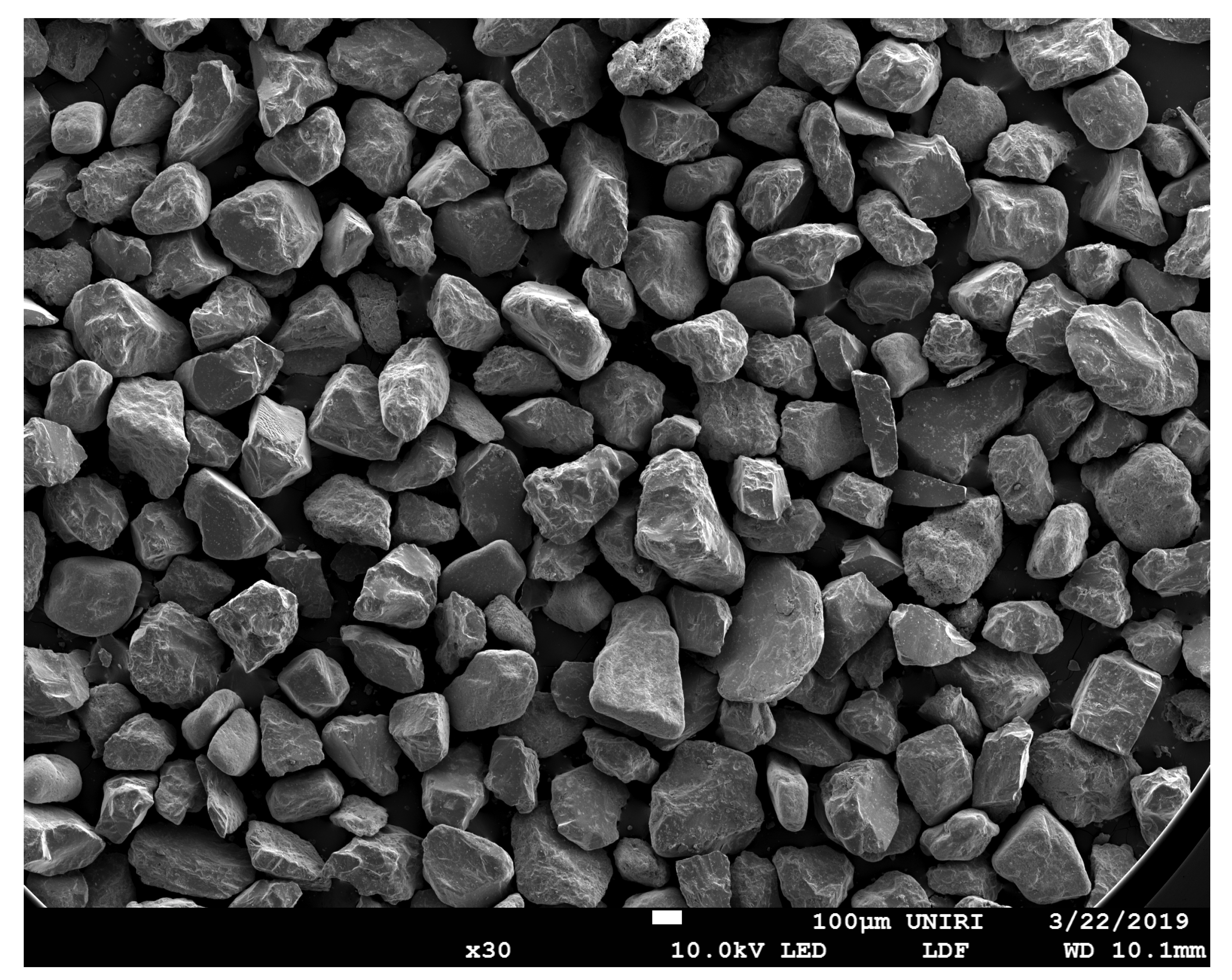

2. Physical Properties of Tested Material

2.1. Origin of Drava River Sands

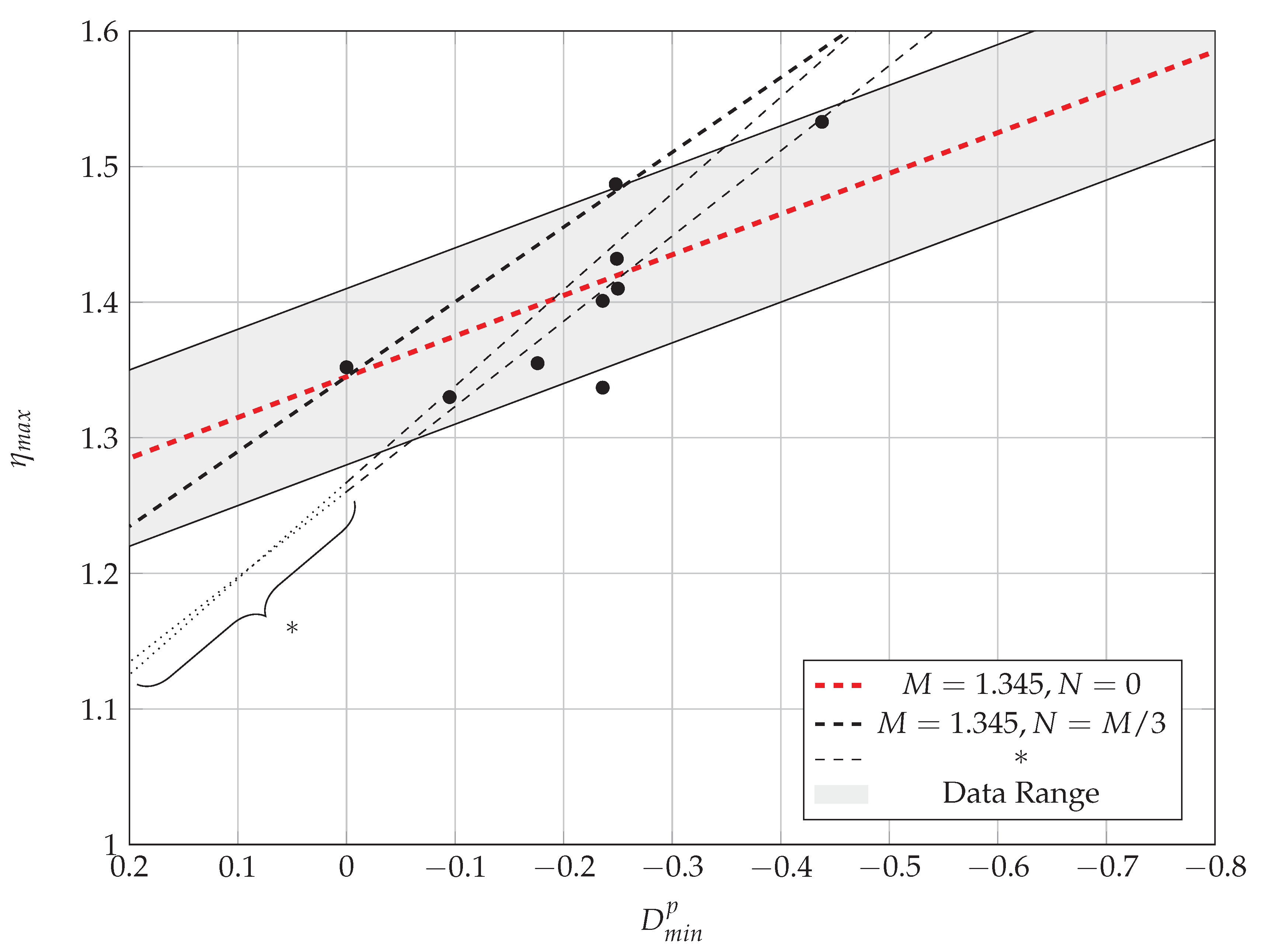

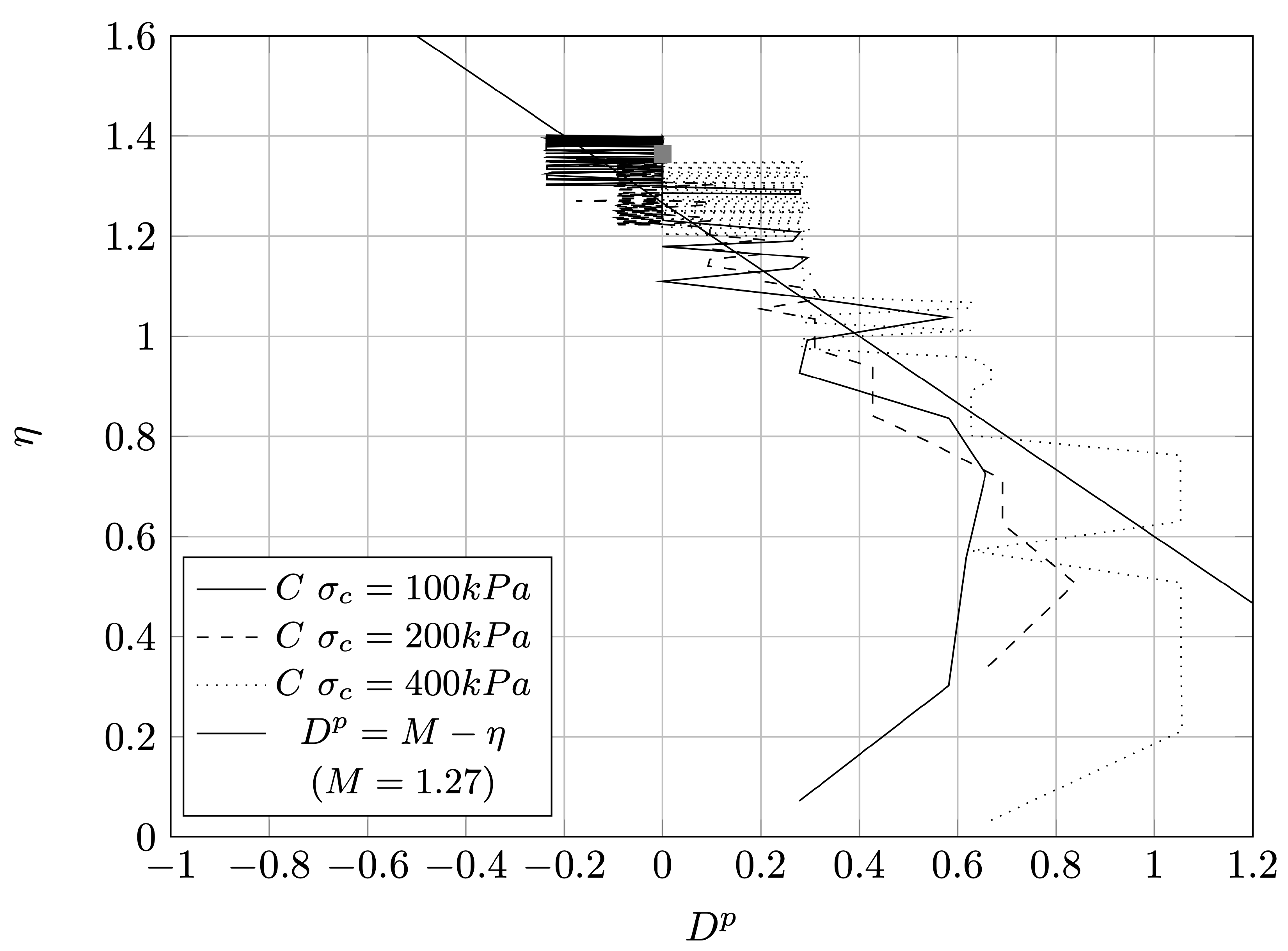

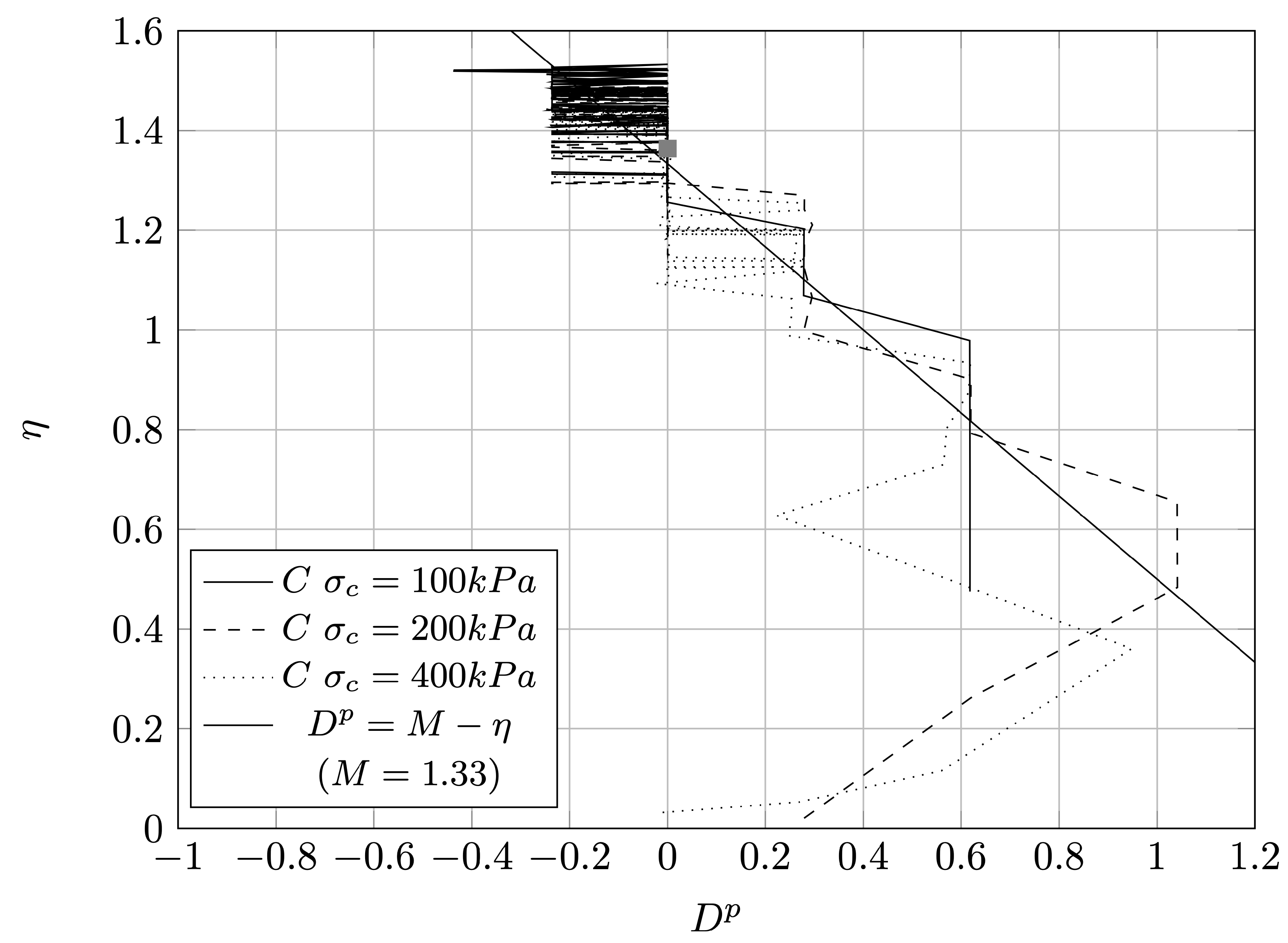

2.2. Specific Gravity

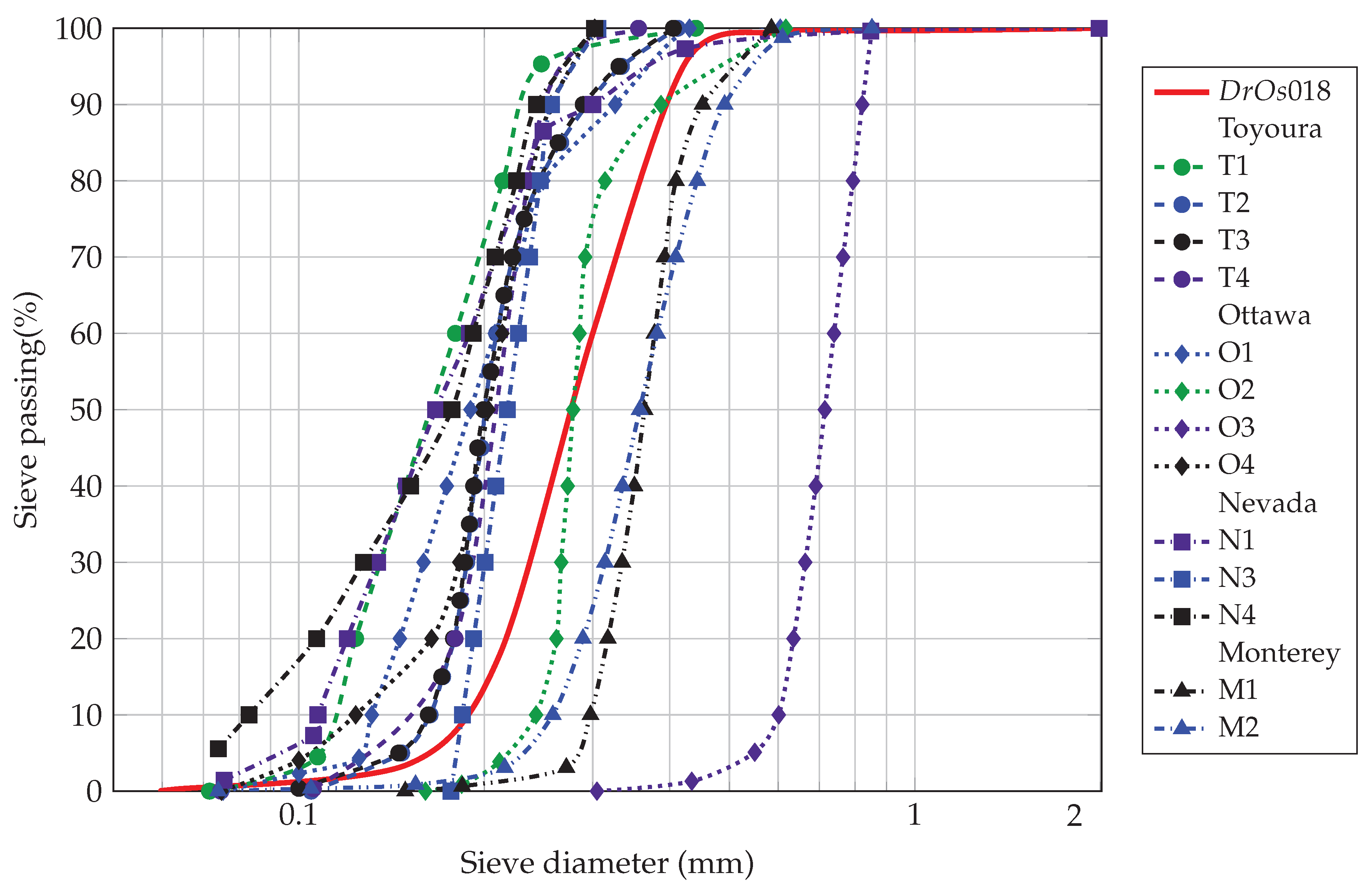

2.3. Grain Size Distribution

2.4. Minimum and Maximum Density

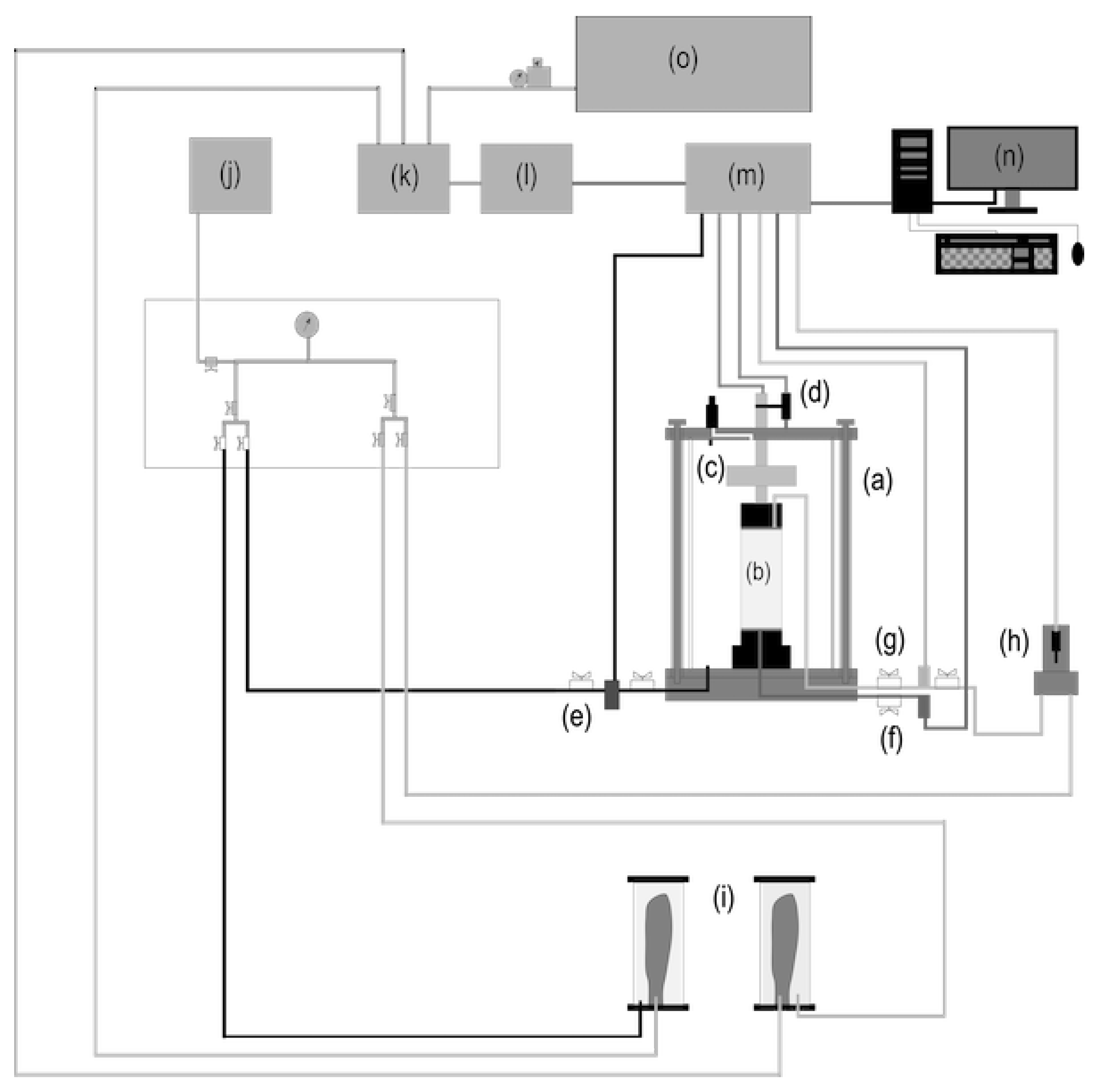

3. Tests Equipment and Procedures

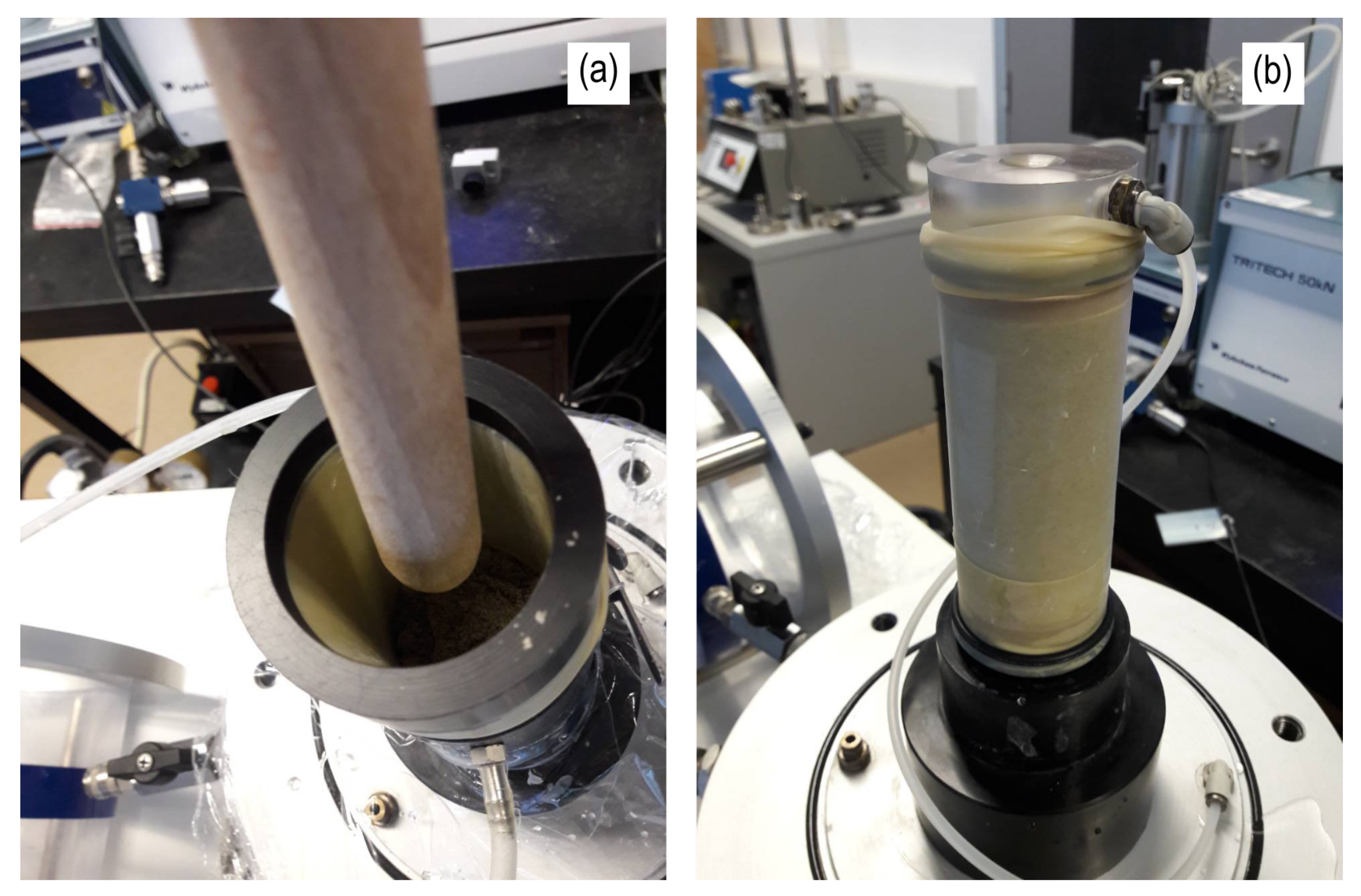

3.1. Triaxial Test Apparatus

3.2. Sample Preparation

3.3. Testing Program

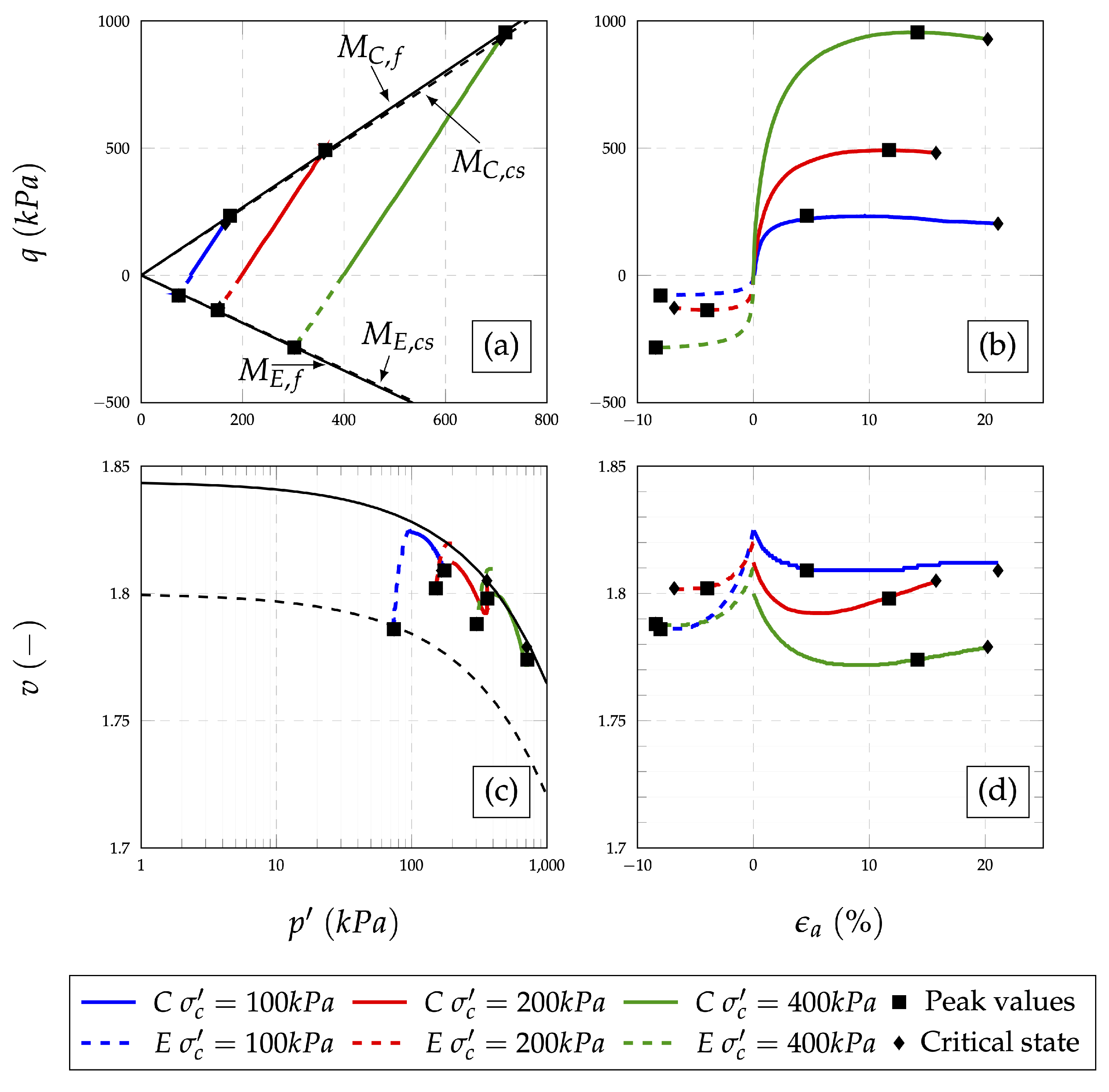

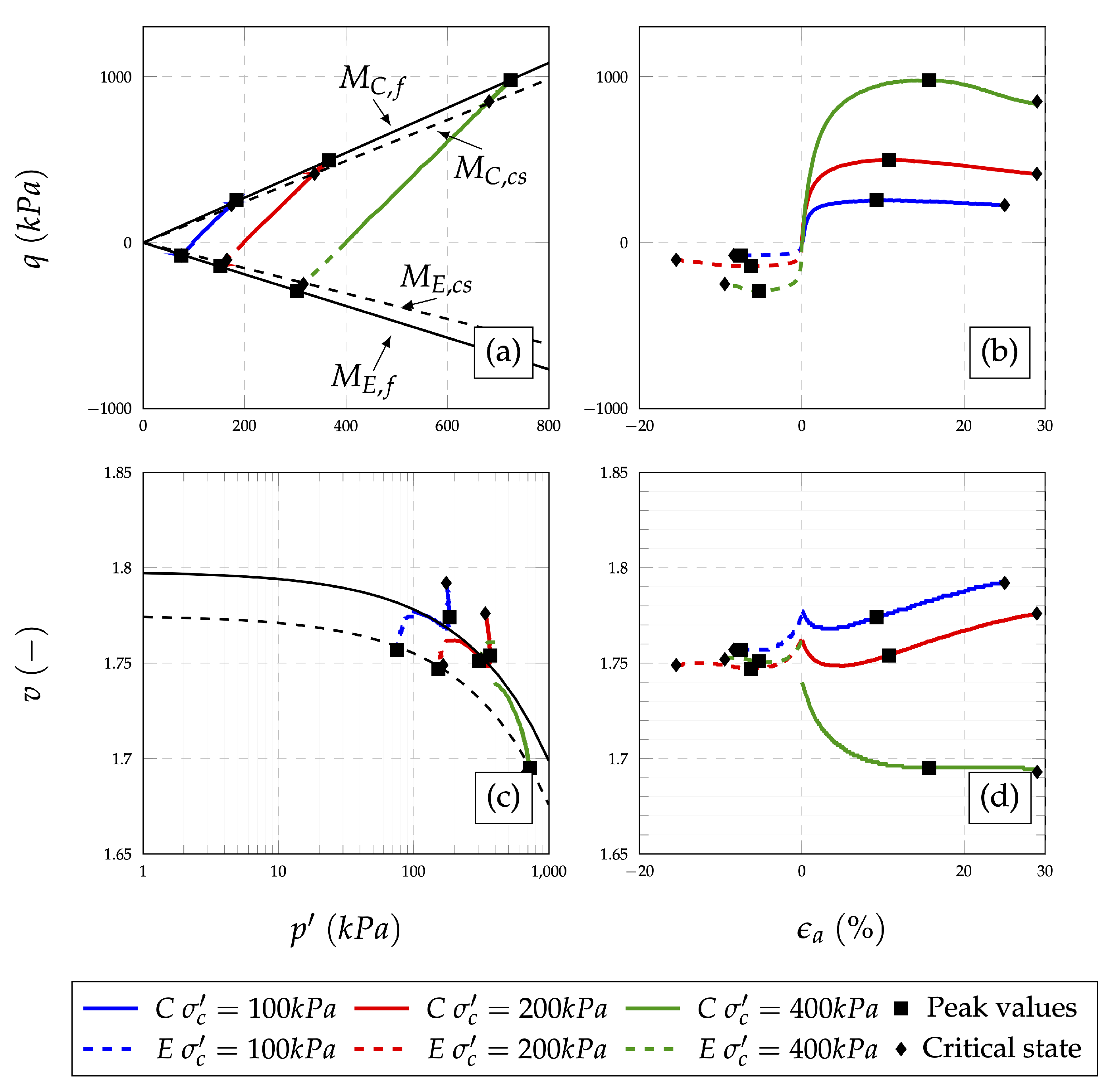

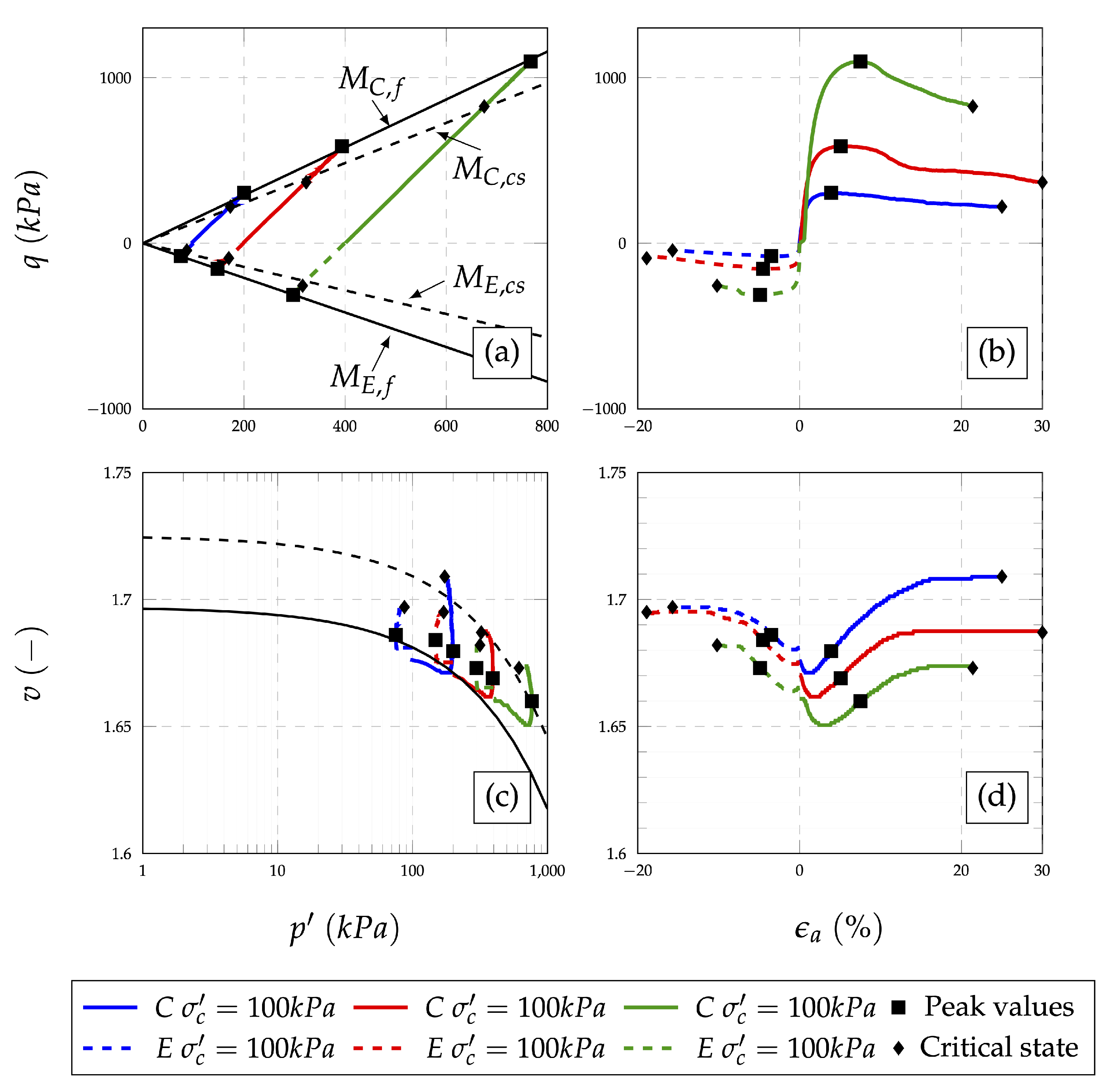

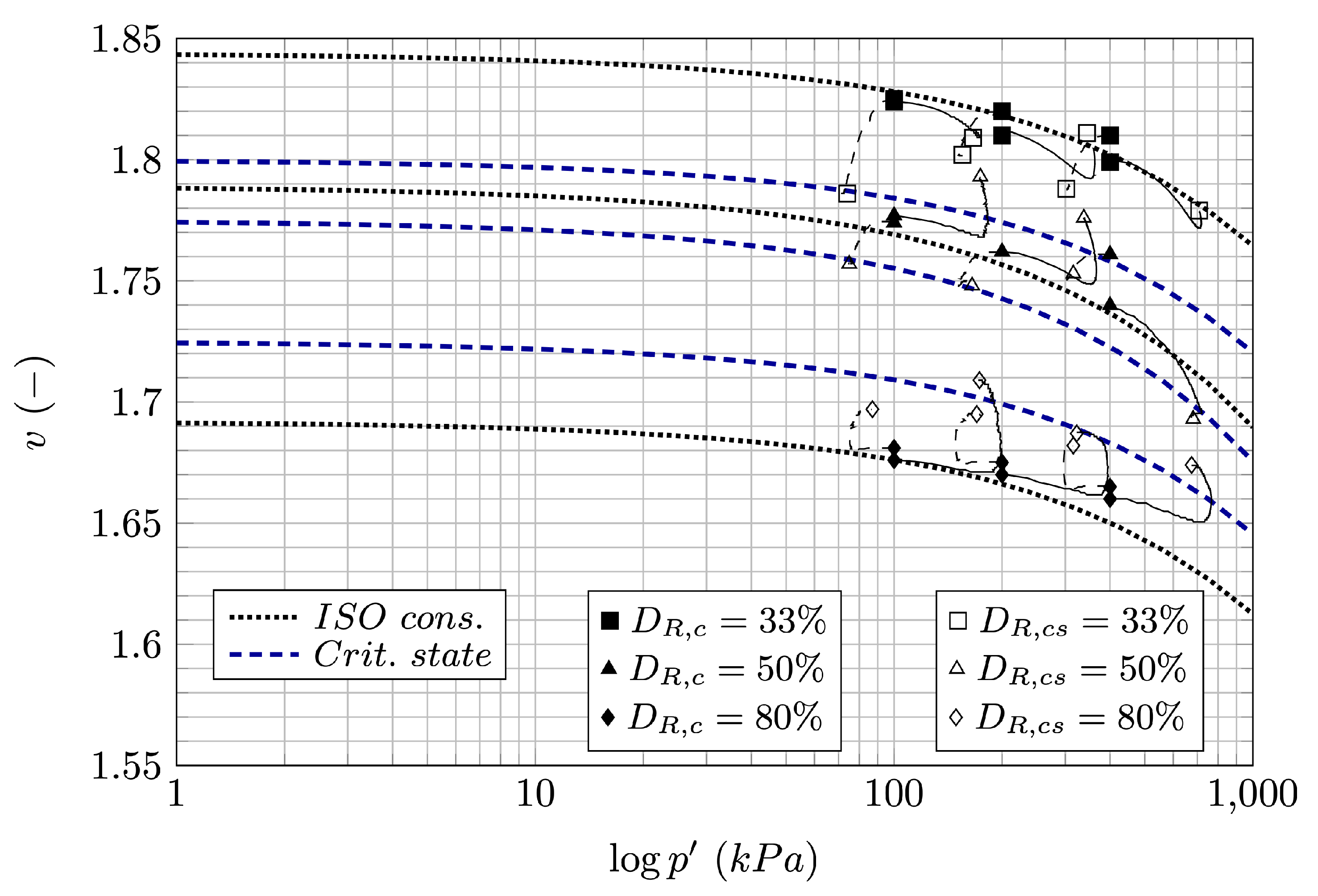

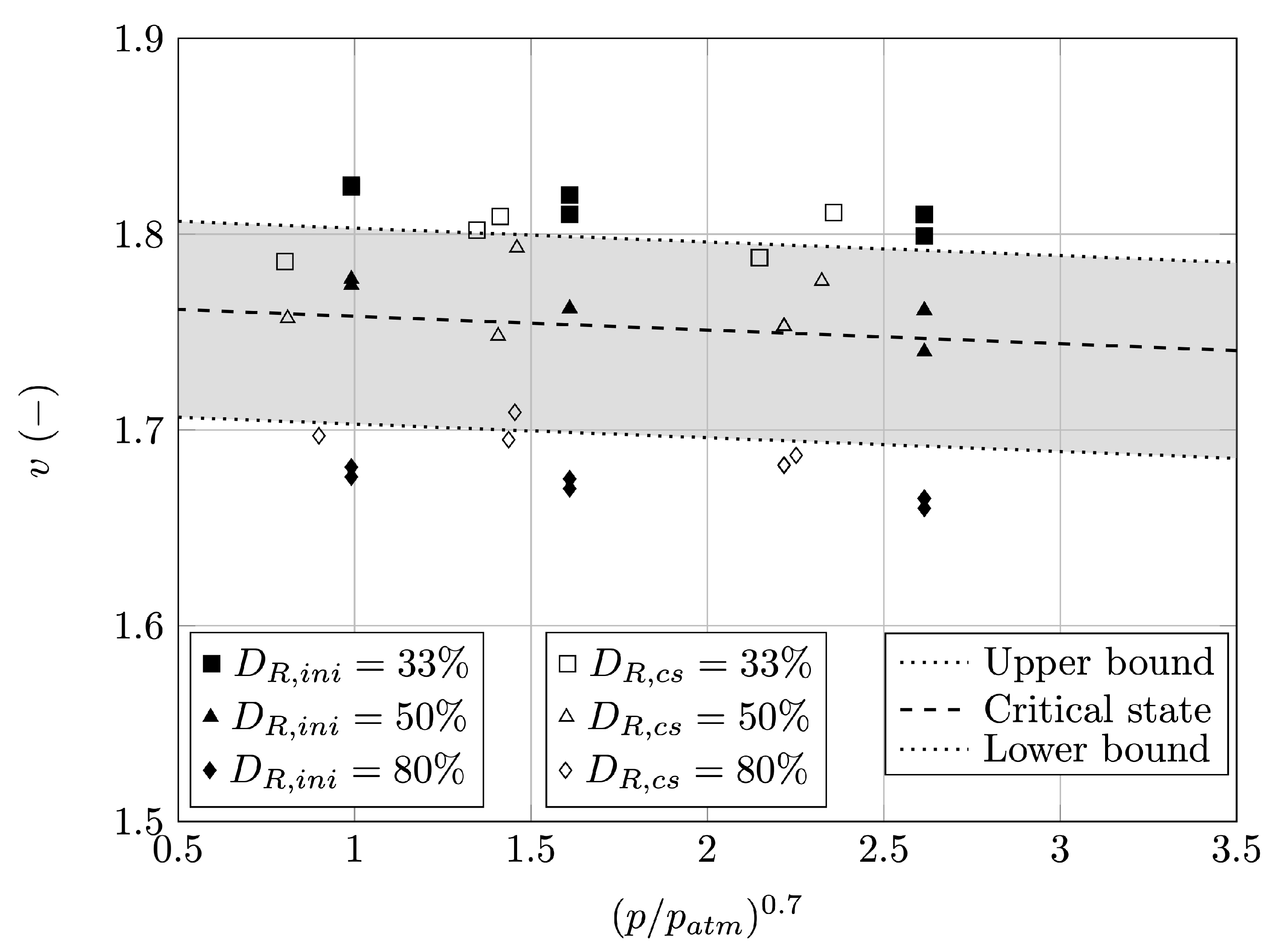

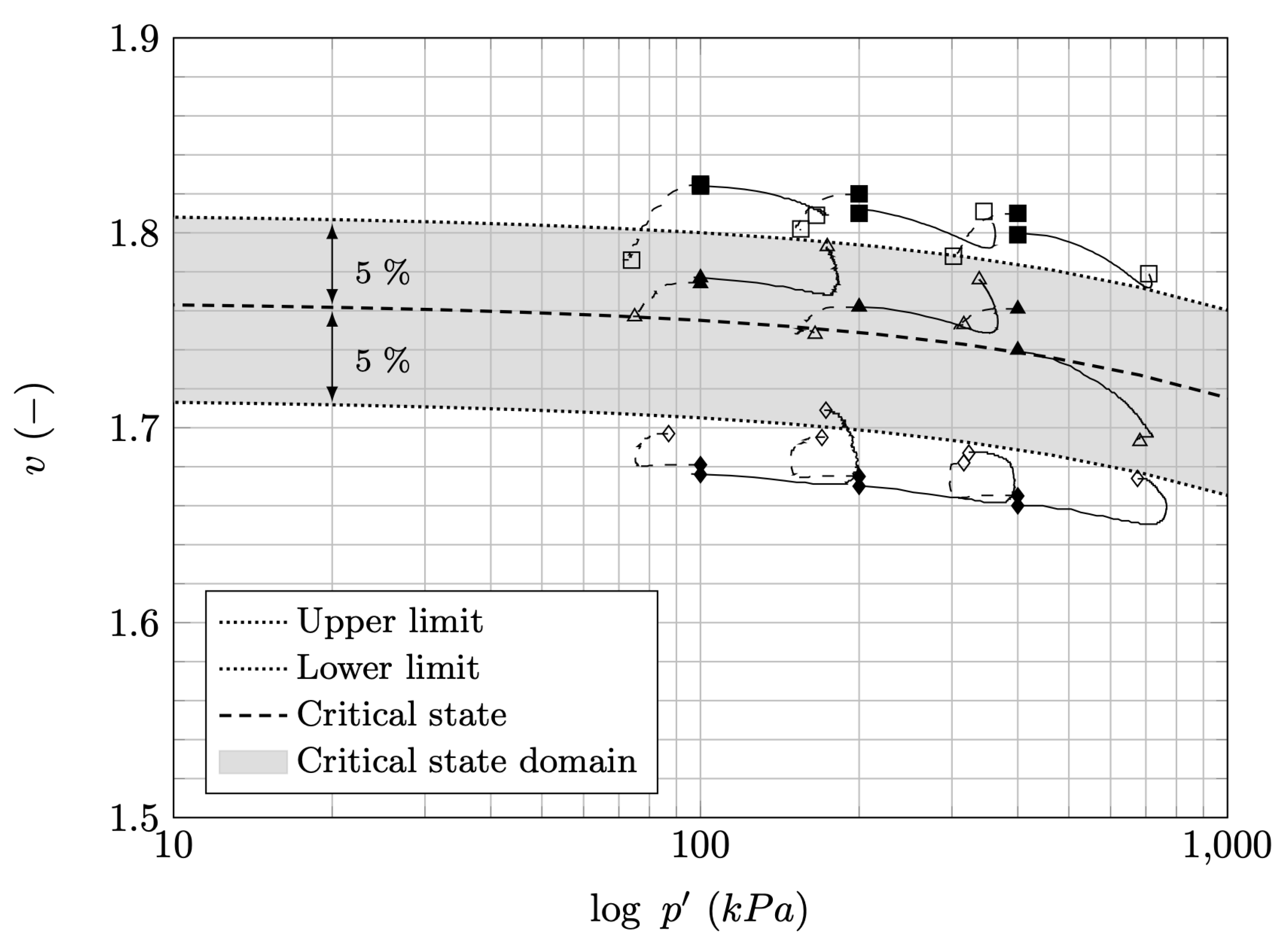

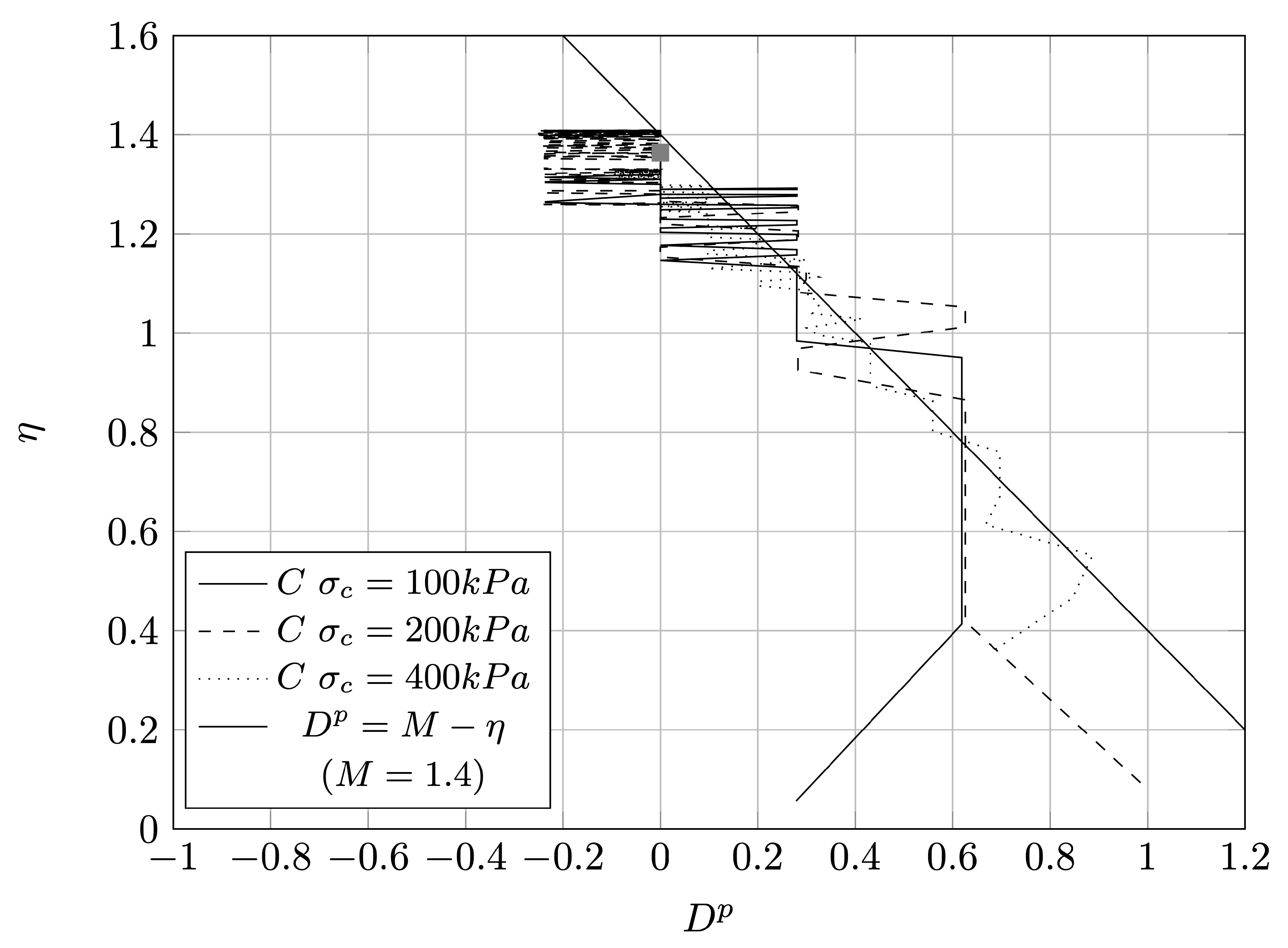

4. Results of Laboratory Tests

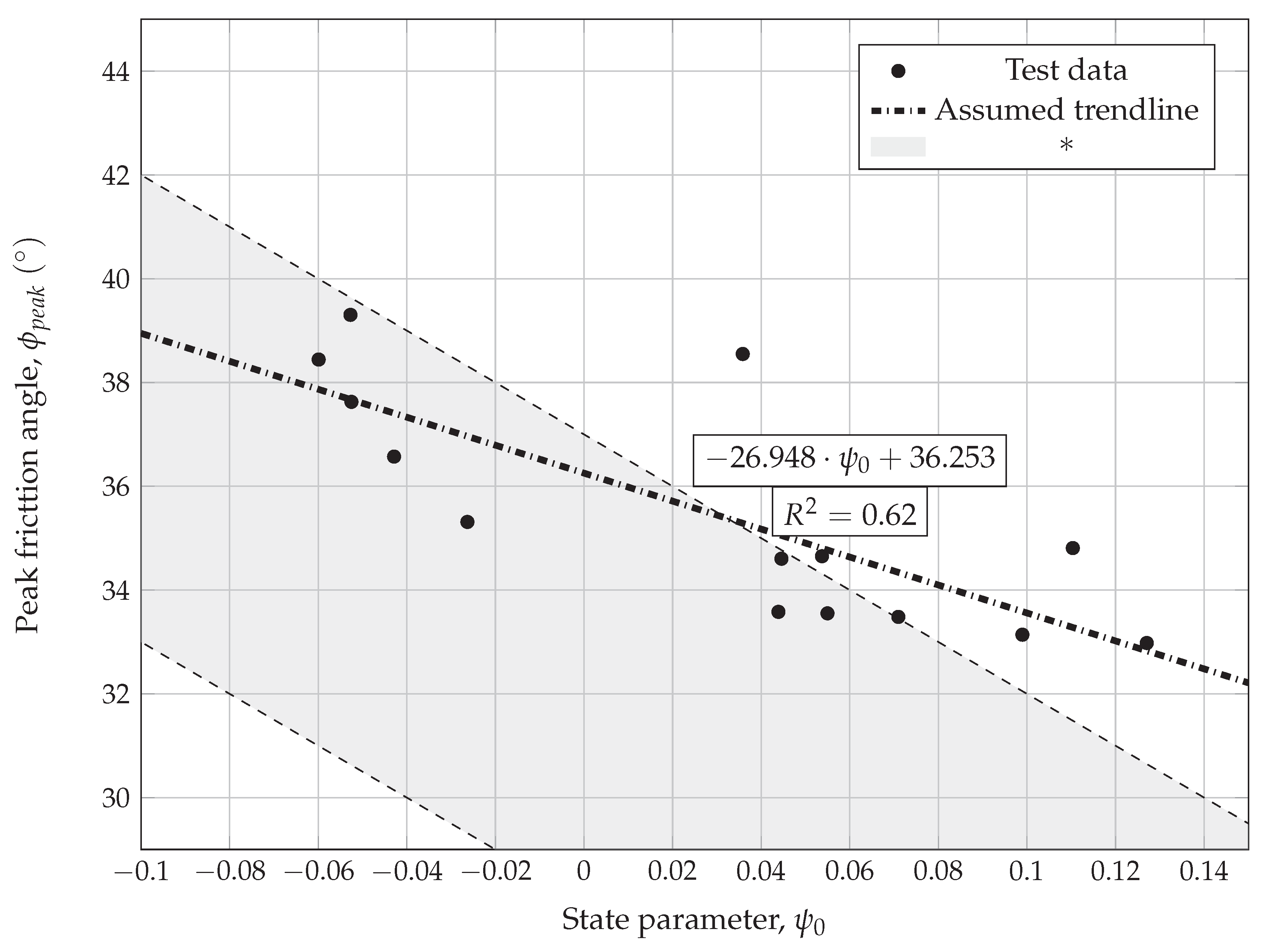

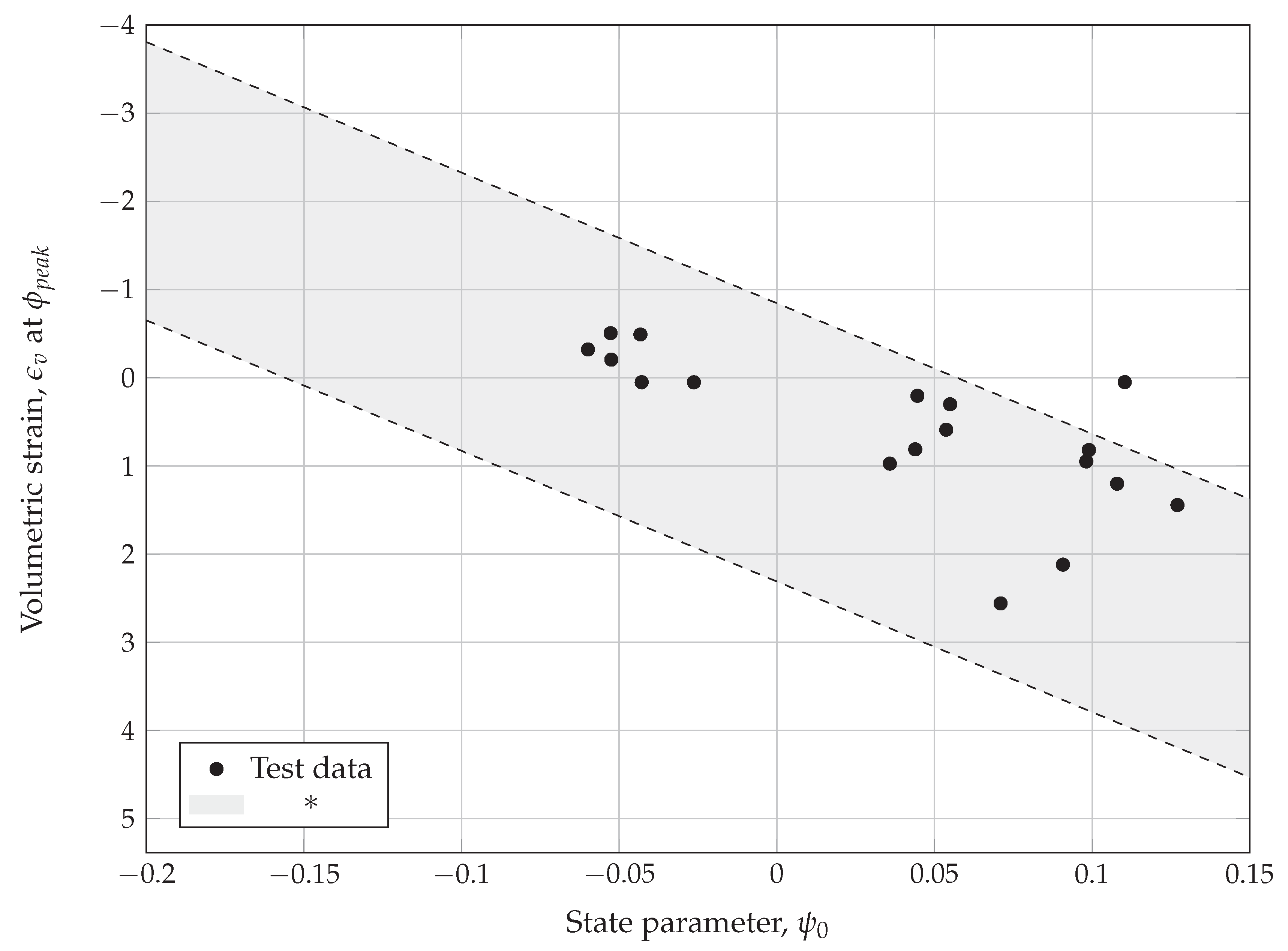

5. Discussion

6. Conclusions

- samples prepared at lower initial density () show delicate behaviour and the influence of initial density on shear behaviour;

- based on and plots, and the critical specific volume plot, it can be concluded that the density of 57% is the relative density of critical state. This is one of the reasons why the samples prepared at the initial density of 50% show high sensitivity to sample preparation;

- The difference in critical state for compression and extension is noticeable;

- The value of critical state parameter M is 1.364 which results the critical friction angle of .

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alarcon-Guzman, A.; Leonards, G.A.; Chameau, J.L. Undrained monotonic and cyclic strength of sands. J. Geotech. Eng. 1988, 114, 1089–1109. [Google Scholar] [CrossRef]

- Casagrande, A. Liquefaction and cyclic mobility of sands: A critical review. Harv. Soil Mech. Ser. 1976, 88, 1–26. [Google Scholar]

- Lade, P.V. Static instability and liquefaction of loose fine sandy slopes. J. Geotech. Eng. 1992, 118, 51–71. [Google Scholar] [CrossRef]

- Roscoe, K.H.; Schofield, A.N.; Wroth, C.P. On the yielding of soils. Géotechnique 1958, 8, 22–53. [Google Scholar] [CrossRef]

- Schofield, A.N.; Wroth, P. Critical State Soil Mechanics; McGraw-Hill: New York, NY, USA, 1968. [Google Scholar]

- Wood, D. Soil Behaviour and Critical State Soil Mechanics; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

- Yamamuro, J.A.; Lade, P.V. Static liquefaction of very loose sands. Can. Geotech. J. 1997, 34, 905–917. [Google Scholar] [CrossRef]

- Bond, A.; Harris, A. Decoding Eurocode 7; CRC Press: London, UK, 2006. [Google Scholar]

- Been, K.; Jefferies, M.G.; Hachey, J. The critical state of sands. Géotechnique 1991, 41, 365–381. [Google Scholar] [CrossRef]

- Ishihara, K.; Koga, Y. Case studies of liquefaction in the 1964 Niigata earthquake. Soils Found. 1981, 21, 35–52. [Google Scholar] [CrossRef]

- Seed, H.B.; Idriss, I.M. Analysis of soil liquefaction: Niigata earthquake. J. Soil Mech. Found. Div. 1967, 93, 83–108. [Google Scholar]

- Builes, M.; García, E.; Riveros, C.A. Dynamic and static measurements of small strain moduli of toyoura sand. Rev. Fac. Ing. Univ. Antioq. 2008, 43, 86–101. [Google Scholar]

- Dong, Q.; Xu, C.; Cai, Y.; Juang, H.; Wang, J.; Yang, Z.; Gu, C. Drained instability in loose granular material. Int. J. Geomech. 2016, 16. [Google Scholar] [CrossRef]

- Le, B.N.; Toyota, H.; Takada, S. Detection of Elastic Region Varied by Inherent Anisotropy of Reconstituted Toyoura Sand; Springer: Berlin/Heidelberg, Germany, 2018; pp. 76–89. [Google Scholar] [CrossRef]

- Oda, M.; Koishikawa, I.; Higuchi, T. Experimental study of anisotropic shear strength of sand by plane strain test. Soils Found. 1978, 18, 25–38. [Google Scholar] [CrossRef]

- Verdugo, R.; Ishihara, K. The steady state of sandy soils. Soils Found. 1996, 36, 81–91. [Google Scholar] [CrossRef]

- Yang, Z.X.; Li, X.S.; Yang, J. Undrained anisotropy and rotational shear in granular soil. Geotechnique 2007, 57, 371–384. [Google Scholar] [CrossRef]

- Youn, J.U.; Choo, Y.W.; Kim, D.S. Measurement of small-strain shear modulus Gmax of dry and saturated sands by bender element, resonant column, and torsional shear tests. Can. Geotech. J. 2008, 45, 1426–1438. [Google Scholar] [CrossRef]

- Lade, P.V.; Liggio, C.D.; Yamamuro, J.A. Effects of non-plastic fines on minimum and maximum void ratios of sand. Geotech. Test. J. 1998, 21, 336–347. [Google Scholar] [CrossRef]

- Won, M.S.; Ling, H.I.; Kim, Y.S. A study of the deformation of flexible pipes buried under model reinforced sand. KSCE J. Civ. Eng. 2004, 8, 377–385. [Google Scholar] [CrossRef]

- Bastidas, A.M.P.; Boulanger, R.W.; Carey, T.; DeJong, J. Ottawa F-65 Sand Data from Ana Maria Parra Bastidas, NEEShub. 2016. Available online: https://datacenterhub.org/resources/14288 (accessed on 8 May 2020).

- Yang, L.; Salvati, L. Small strain properties of sands with different cement types. In Proceedings of the International Conferences on Recent Advances in Geotechnical Earthquake Engineering and Soil Dynamics 2010, San Diego, CA, USA, 26 May 2010. [Google Scholar]

- Zhang, H. Steady State Behaviour of Sands and Limitations of the Triaxial Test. Ph.D. Thesis, University of Ottawa, Ottawa, ON, Canada, 1997. [Google Scholar]

- Chang, N.; Hseih, N.; Samuelson, D.; Horita, M. Static and cyclic behaviour of monterey# 0 sand. In Proceedings of the 3rd Microzonation Conference, Seattle, WA, USA, 28 June–1 July 1981; pp. 929–944. [Google Scholar]

- Mulilis, J.P.; Horz, R.C.; Townsend, F.C. The Effects of Cyclic Triaxial Testing Techniques on the Liquefaction Behavior of Monterey No. 0 Sand; US Department of Defense, Department of the Army, Corps of Engineers: Washington, DC, USA, 1976.

- Saxena, S.K.; Reddy, K.R. Dynamic moduli and damping ratios for Monterey No.0 sand by resonant column tests. Soils Found. 1989, 29, 37–51. [Google Scholar] [CrossRef]

- Been, K.; Jefferies, M.G. A state parameter for sands. Géotechnique 1985, 35, 99–112. [Google Scholar] [CrossRef]

- Been, K.; Jefferies, M. Stressdilatancy in very loose sand. Can. Geotech. J. 2004, 41, 972–989. [Google Scholar] [CrossRef]

- Kang, X.; Xia, Z.; Chen, R.; Ge, L.; Liu, X. The critical state and steady state of sand: A literature review. Mar. Georesour. Geotechnol. 2019, 37, 1105–1118. [Google Scholar] [CrossRef]

- Malvić, T.; Velić, J. Neogene tectonics in croatian part of the pannonian basin and reflectance in hydrocarbon accumulations. In New Frontiers in Tectonic Research; Schattner, U., Ed.; IntechOpen: Rijeka, Croatia, 2011; Chapter 8. [Google Scholar] [CrossRef]

- Bošnjak, J. Construction of roads with sand. In Road Management in Republic of Croatia; Sršen, M., Ed.; Croatian Road Society Via-Vita: Zagreb, Croatia, 1995; pp. 536–543. (In Croatian) [Google Scholar]

- Dimter, S.; Babić, B. Stabilizing effect of fly ash on the Drava sand. Gradevinar 1997, 49, 685–693. [Google Scholar]

- Dimter, S.; Rukavina, T.; Dragčević, V. Strength properties of fly ash stabilized mixes. Road Mater. Pavement Des. 2011, 12, 687–697. [Google Scholar] [CrossRef][Green Version]

- Magaš, N. Basic Geological Map of SFRY 1:100,000, Osijek Sheet L34-86); Geološki Zavod Zagreb, Savezni Geološki Zavod: Beograd, Serbia, 1987. (In Croatian) [Google Scholar]

- Kavre Piltaver, I.; Peter, R.; Šarić, I.; Salamon, K.; Jelovica Badovinac, I.; Koshmak, K.; Nannarone, S.; Delač Marion, I.; Petravić, M. Controlling the grain size of polycrystalline TiO2 films grown by atomic layer deposition. Appl. Surf. Sci. 2017, 419, 564–572. [Google Scholar] [CrossRef]

- Šarić, I.; Peter, R.; Markovic, M.K.; Badovinac, I.J.; Rogero, C.; Ilyn, M.; Knez, M.; Ambrožić, G. Introducing the concept of pulsed vapor phase copper-free surface click-chemistry using the ALD technique. Chem. Commun. 2019, 55, 3109–3112. [Google Scholar] [CrossRef] [PubMed]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior; John Wiley & Sons: Hoboken, NJ, USA, 2005; p. 577. [Google Scholar]

- ISO 17892-3:2015. Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 3: Determination of Particle Density; Technical Report; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- ISO 17892-3:2016. Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution; Technical Report; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- ASTM D4254-16. Standard Test Methods for Minimum Index Density and Unit Weight of Soils and Calculation of Relative Density; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM D4253-16. Test Methods for Maximum Index Density and Unit Weight of Soils Using a Vibratory Table; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Holtz, R.D.; Kovacs, W.D.; Sheahan, T.C. An Introduction to Geotechnical Engineering; Pearson: London, UK, 2011. [Google Scholar]

- Smith, I. Smith’s Elements of Soil Mechanics; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Controls. Automatic Triaxial Tests System—AUTOTRIAX 2, Soil Mechanics Testing Equipment; Controls: Liscate MI, Italy, 2020. [Google Scholar]

- ASTM. Method for Consolidated Drained Triaxial Compression Test for Soils; ASTM: West Conshohocken, PA, USA, 2011. [Google Scholar] [CrossRef]

- Lade, P.V. Triaxial Testing of Soils; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Panda, R.C. Introduction to PID Controllers: Theory, Tuning and Application to Frontier Areas; OCLC: 908265492; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Omar, T.; Sadrekarimi, A. Specimen size effects on behavior of loose sand in triaxial compression tests. Can. Geotech. J. 2015, 52, 732–746. [Google Scholar] [CrossRef]

- Ladd, R. Preparing test specimens using under compaction. Geotech. Test. J. 1978, 1, 16–23. [Google Scholar] [CrossRef]

- Oda, M. Initial fabrics and their relations to mechanical properties of granular material. Soils Found. 1972, 12, 17–36. [Google Scholar] [CrossRef]

- Frost, J.; Park, J.Y. A critical assessment of the moist tamping technique. Geotech. Test. J. 2003, 26, 57–70. [Google Scholar] [CrossRef]

- Murthy, T.G.; Loukidis, D.; Carraro, J.A.H.; Prezzi, M.; Salgado, R. Undrained monotonic response of clean and silty sands. Géotechnique 2007, 57, 273–288. [Google Scholar] [CrossRef]

- Vucetic, M.; Dobry, R. Cyclic triaxial strain-controlled testing of liquefiable sands. In Advanced Triaxial Testing of Soil and Rock; ASTM International: West Conshohocken, PA, USA, 1988; pp. 475–485. [Google Scholar] [CrossRef]

- Ratkowsky, D. Handbook of Nonlinear Regression Models; Statistics, Textbooks and Monographs; M. Dekker: New York, NY, USA, 1990. [Google Scholar]

- Seber, G.; Wild, C. Nonlinear Regression; Wiley Series in Probability and Statistics; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Massaron, L.; Boschetti, A. Regression Analysis with Python; Packt Publishing: Birmingham, UK, 2016. [Google Scholar]

- Yang, J.; Luo, X. Exploring the relationship between critical state and particle shape for granular materials. J. Mech. Phys. Solids 2015, 84, 196–213. [Google Scholar] [CrossRef]

- Azeiteiro, R.J.N.; Coelho, P.A.L.F.; Taborda, D.M.G.; Grazina, J.C.D. Critical state–based interpretation of the monotonic behavior of hostun sand. J. Geotech. Geoenviron. Eng. 2017, 143, 04017004. [Google Scholar] [CrossRef]

- Loukidis, D.; Salgado, R. Modeling sand response using two-surface plasticity. Comput. Geotech. 2009, 36, 166–186. [Google Scholar] [CrossRef]

- Vaid, Y.; Sasitharan, S. The strength and dilatancy of sand. Can. Geotech. J. 1992, 29, 522–526. [Google Scholar] [CrossRef]

- Nova, R.; Wood, D. A constitutive model for soil under monotonic and cyclic loading. In Soil Mechanics-Transient and Cyclic Loading; Wiley: New York, NY, USA, 1982; pp. 343–373. [Google Scholar]

- Jefferies, M.G.; Shuttle, D.A. Dilatancy in general Cambridge-type models. Géotechnique 2002, 52, 625–638. [Google Scholar] [CrossRef]

- Szypcio, Z. Stress-dilatancy for soils. Part II: Experimental validation for triaxial tests. Studia Geotech. Mech. 2016, 38, 59–65. [Google Scholar] [CrossRef]

- Jefferies, M.; Been, K. Soil Liquefaction; CRC Press: London, UK, 2015. [Google Scholar] [CrossRef]

- Cornforth, D.H. Plane Strain Failure Characteristics of Saturated Sand. Ph.D. Thesis, Imperial College London, London, UK, 1961. [Google Scholar]

| Sand Types | |||||||

|---|---|---|---|---|---|---|---|

| DrOS018 | 2.66 | 1.67 | 1.07 | 0.28 | 0.18 | 0.951 | 0.627 |

| Toyoura [12,13,14,18] | 2.65 | 1.29–1.7 | 1–1.07 | 0.17–0.21 | −0.16 | 0.977–0.992 | 0.597–0.632 |

| Nevada [7,19,20] | 2.67 | 1.22–2.31 | 0.89–1.02 | 0.16–0.21 | 0.08–0.18 | 0.858–0.887 | 0.511–0.581 |

| Monterey [22,25] | 2.65 | 1.28–1.5 | 0.99–1 | 0.35–0.36 | 0.26–0.3 | 0.85–0.86 | 0.55–0.56 |

| Ottawa [7,21,22,23] | 2.64–2.67 | 1.18–1.73 | 0.96–1.26 | 0.17–0.7 | 0.12–0.6 | 0.67–0.83 | 0.46–0.51 |

| Test Number | Test ID | Effective Confining Stress, (kPa) | Relative Density, (%) | Loading Type |

|---|---|---|---|---|

| 1 | 049C10033DRN | 100 | 33 | Compression |

| 2 | 056C20033DRN | 200 | ||

| 3 | 055C40033DRN | 400 | ||

| 4 | 044E10033DRN | 100 | Extension | |

| 5 | 045E20033DRN | 200 | ||

| 6 | 047E40033DRN | 400 | ||

| 7 | 040C10050DRN | 100 | 50 | Compression |

| 8 | 039C20050DRN | 200 | ||

| 9 | 005C40050DRN | 400 | ||

| 10 | 008E10050DRN | 100 | Extension | |

| 11 | 012E20050DRN | 200 | ||

| 12 | 048E40050DRN | 400 | ||

| 13 | 007C10080DRN | 100 | 80 | Compression |

| 14 | 009C20080DRN | 200 | ||

| 15 | 011C40080DRN | 400 | ||

| 16 | 016E10080DRN | 100 | Extension | |

| 17 | 017E10080DRN | 200 | ||

| 18 | 018E40080DRN | 400 |

| Relative Tensity, | ||||||||

|---|---|---|---|---|---|---|---|---|

| 33 | 1.3349 | 0.936 | 1.3109 | 0.9221 | 33.09 | 33.68 | 32.54 | 33.01 |

| 50 | 1.3547 | 0.9541 | 1.2326 | 0.7657 | 33.54 | 34.56 | 30.75 | 26.03 |

| 80 | 1.4468 | 1.0443 | 1.2114 | 0.7113 | 35.65 | 39.21 | 30.26 | 23.79 |

| Relative Density, | ||||||

|---|---|---|---|---|---|---|

| 33 | 1.844 | 0.016 | 0.7 | 1.80 | 0.016 | 0.7 |

| 50 | 1.789 | 0.02 | 0.7 | 1.775 | 0.02 | 0.7 |

| 80 | 1.692 | 0.016 | 0.7 | 1.725 | 0.016 | 0.7 |

| Relative Density [%] | Confining Pressure [kPa] | Test Type * | Young Modulus [kPa] | Shear Modulus [kPa] | Bulk Modulus [kPa] | Poisson Ratio |

|---|---|---|---|---|---|---|

| 33 | 100 | C | 40,772 | 16,394 | 26,494 | 0.24 |

| 33 | 200 | 76,935 | 30,995 | 49,527 | 0.24 | |

| 33 | 400 | 126,870 | 52,567 | 72,107 | 0.21 | |

| 50 | 100 | 25,511 | 10,253 | 16,612 | 0.24 | |

| 50 | 200 | 57,736 | 23,492 | 35,486 | 0.23 | |

| 50 | 400 | 76,618 | 30,880 | 49,220 | 0.24 | |

| 80 | 100 | 36,739 | 14,769 | 23,898 | 0.24 | |

| 80 | 200 | 52,652 | 21,177 | 34,168 | 0.24 | |

| 80 | 400 | 105,298 | 44,292 | 56,370 | 0.19 | |

| 33 | 100 | E | 37,283 | 16,553 | 16,624 | 0.13 |

| 33 | 200 | 58,768 | 22,632 | 48,570 | 0.30 | |

| 33 | 400 | 124,151 | 45,362 | 157,277 | 0.37 | |

| 50 | 100 | 27,508 | 10,555 | 23,277 | 0.30 | |

| 50 | 200 | 93,624 | 35,578 | 84,701 | 0.32 | |

| 50 | 400 | 235,196 | 93,098 | 165,511 | 0.26 | |

| 80 | 100 | 44,685 | 16,680 | 46,405 | 0.34 | |

| 80 | 200 | 106,226 | 42,662 | 69,423 | 0.24 | |

| 80 | 400 | 219,668 | 77,520 | 440,288 | 0.42 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jagodnik, V.; Kraus, I.; Ivanda, S.; Arbanas, Ž. Behaviour of Uniform Drava River Sand in Drained Condition—A Critical State Approach. Appl. Sci. 2020, 10, 5733. https://doi.org/10.3390/app10175733

Jagodnik V, Kraus I, Ivanda S, Arbanas Ž. Behaviour of Uniform Drava River Sand in Drained Condition—A Critical State Approach. Applied Sciences. 2020; 10(17):5733. https://doi.org/10.3390/app10175733

Chicago/Turabian StyleJagodnik, Vedran, Ivan Kraus, Sandi Ivanda, and Željko Arbanas. 2020. "Behaviour of Uniform Drava River Sand in Drained Condition—A Critical State Approach" Applied Sciences 10, no. 17: 5733. https://doi.org/10.3390/app10175733

APA StyleJagodnik, V., Kraus, I., Ivanda, S., & Arbanas, Ž. (2020). Behaviour of Uniform Drava River Sand in Drained Condition—A Critical State Approach. Applied Sciences, 10(17), 5733. https://doi.org/10.3390/app10175733