A Hybrid Diffractive Optical Element Design Algorithm Combining Particle Swarm Optimization and a Simulated Annealing Algorithm

Abstract

1. Introduction

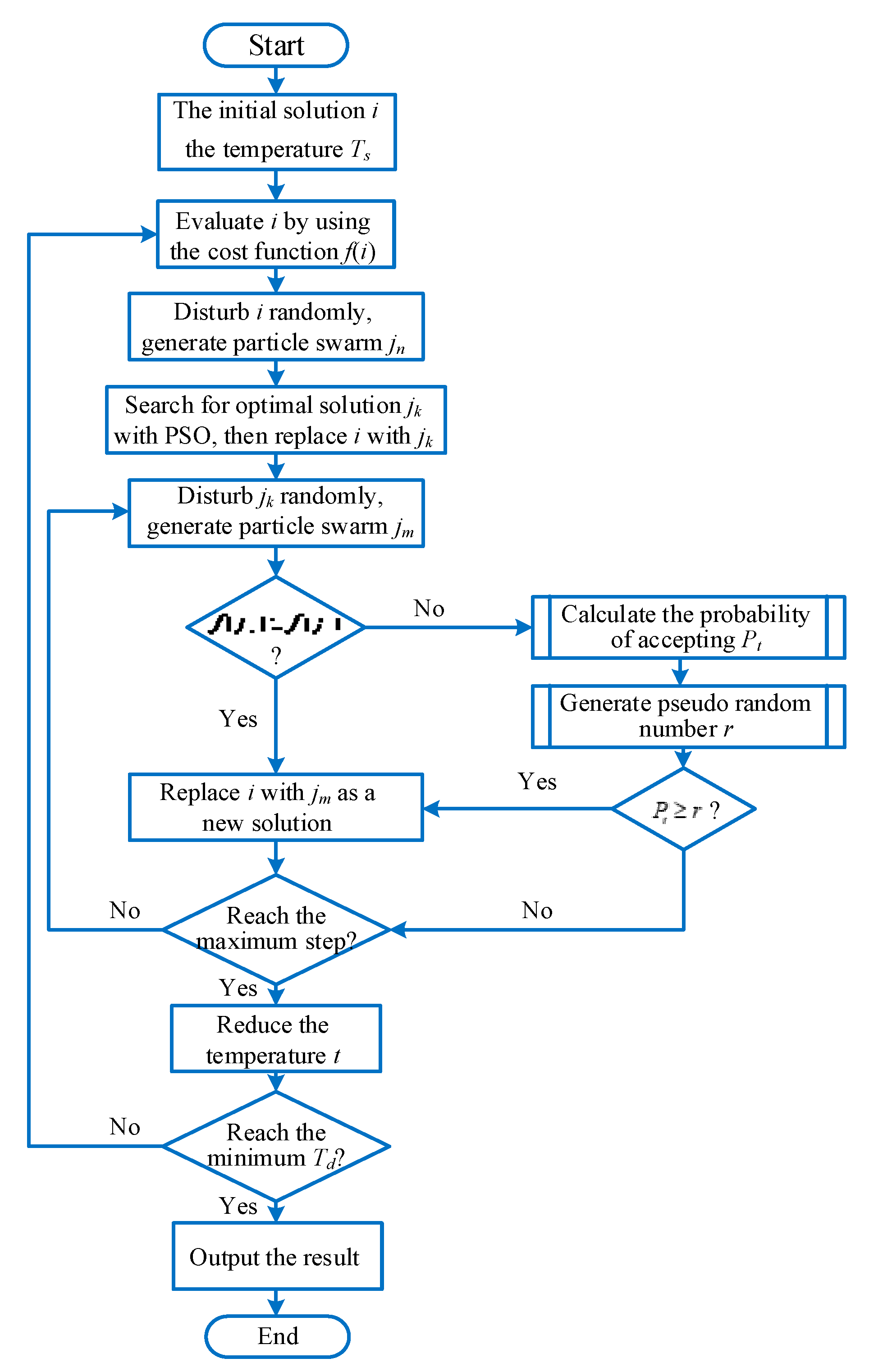

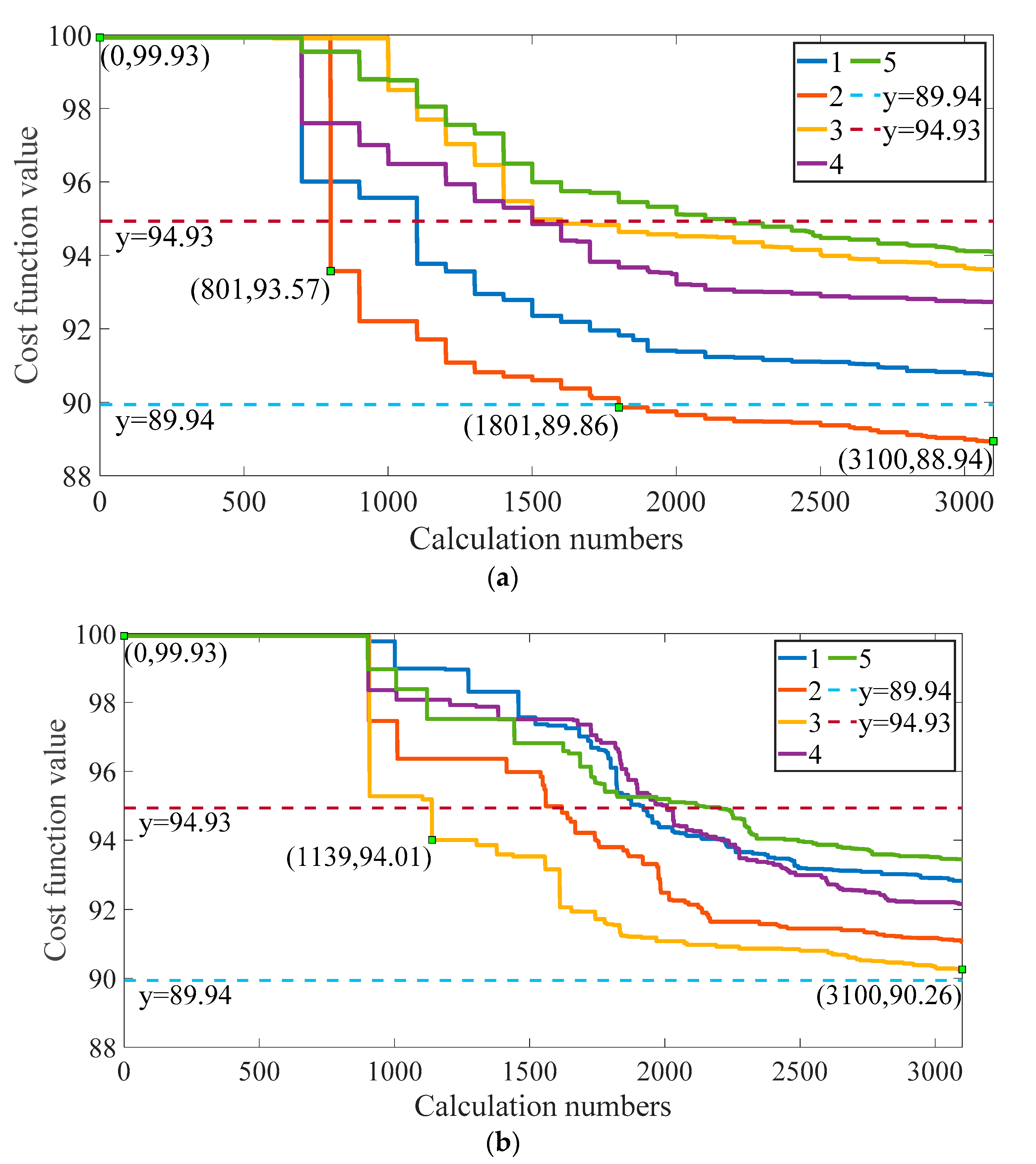

2. Algorithm

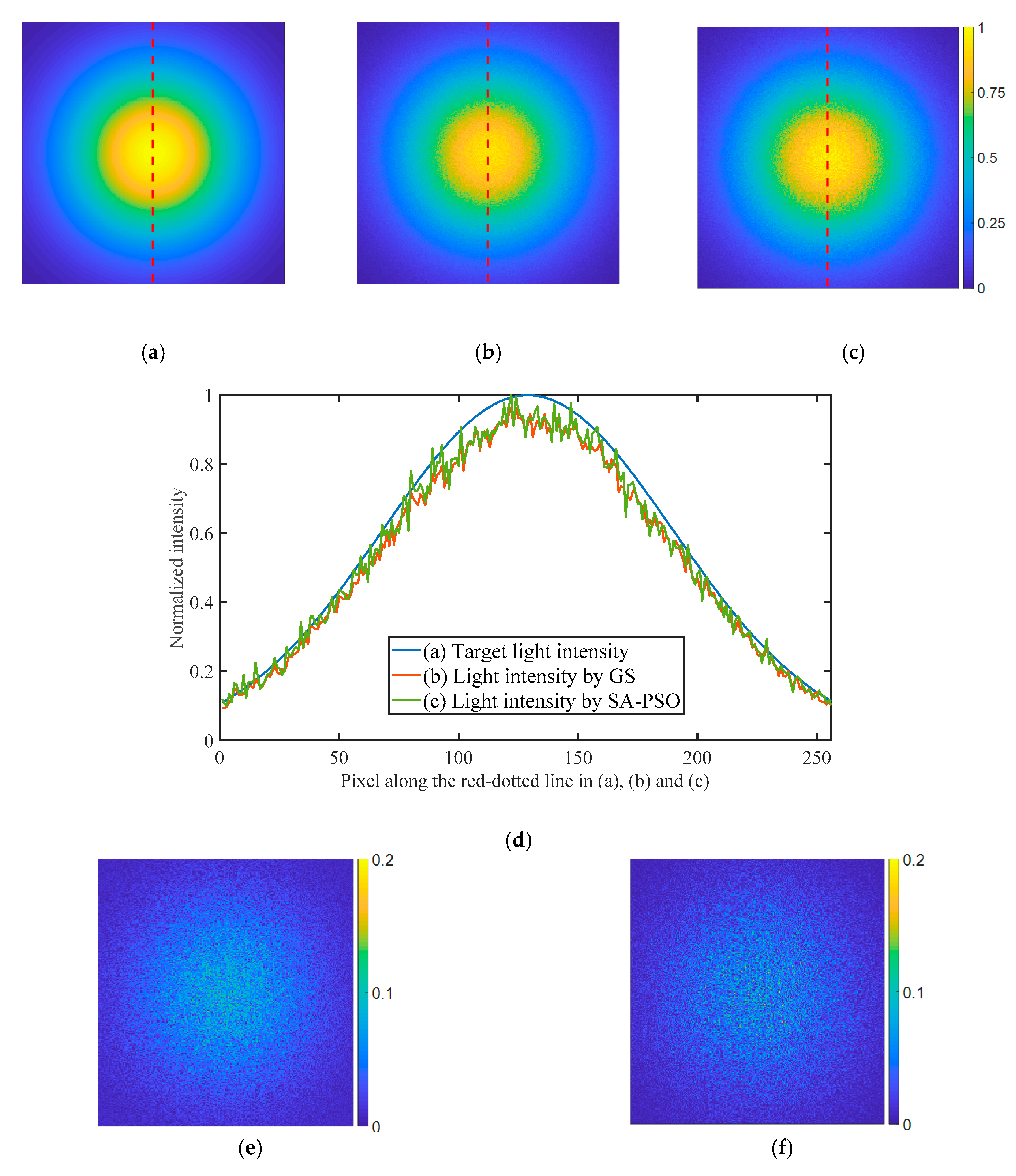

3. Simulation

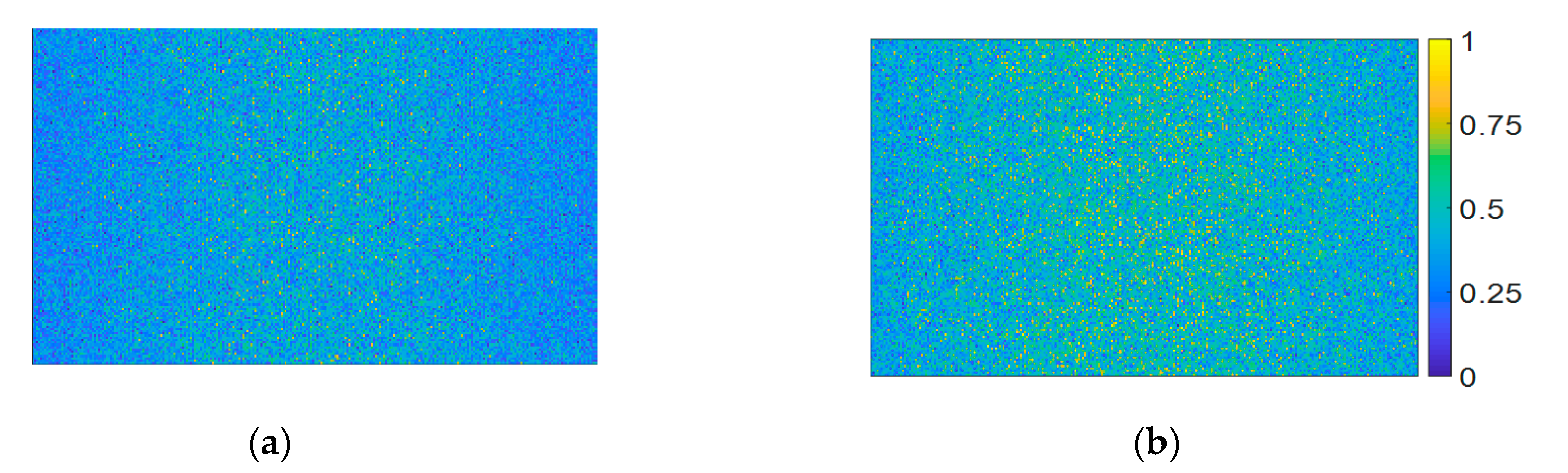

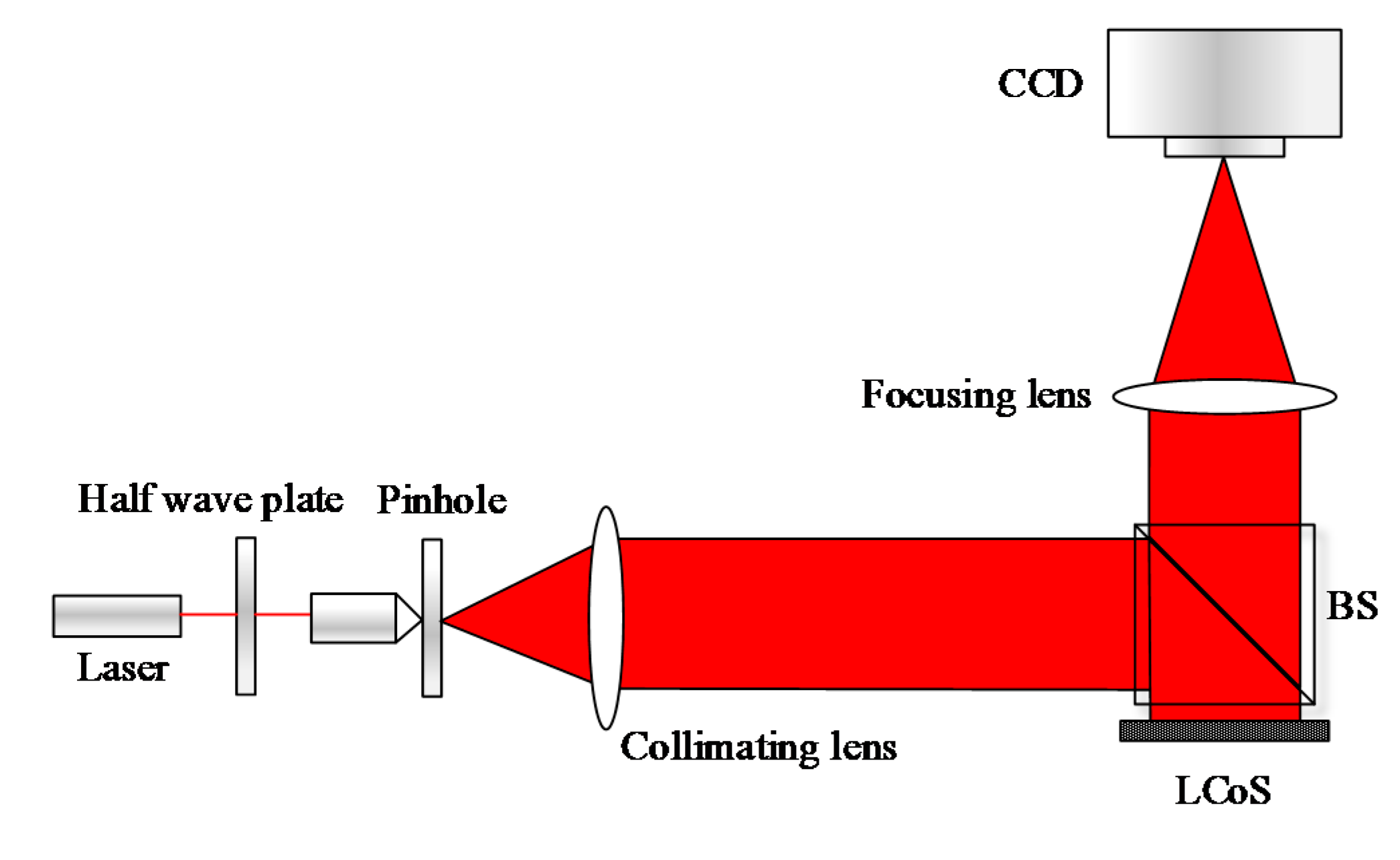

4. Experiment

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Grossinger, I.; Golub, M.A.; Shurman, V. Extended focus diffractive optical element for Gaussian laser beams. Appl. Opt. 2006, 45, 144–150. [Google Scholar]

- Bokor, N.; Davidson, N. Ideal collimation, concentration, and imaging with curved diffractive optical elements. Rev. Sci. Instrum. 2005, 76, 1968–2226. [Google Scholar] [CrossRef]

- Lim, J.; Jeong, G.B.; Kim, S.M.; Han, J.; Yoo, J.M.; Park, N.C.; Kang, S. Design and fabrication of a diffractive optical element for the objective lens of a small form factor optical data storage device. J. Micromech. Microeng. 2006, 16, 77. [Google Scholar] [CrossRef]

- Yoshida, S.; Unno, N.; Akamatsu, H.; Yamada, K.; Taniguchi, J.; Yamamoto, M. Diffractive optical element for optical data storage. Modeling aspects in optical metrology IV. Int. Soc. Opt. Photonics 2013, 8789, 87891E. [Google Scholar]

- Martinez, C.; Krotov, V.; Meynard, B.; Fowler, D. See-through holographic retinal projection display concept. Optica 2018, 5, 1200. [Google Scholar] [CrossRef]

- Chang, C.; Qi, Y.; Wu, J.; Xia, J.; Nie, S. Speckle reduced lensless holographic projection from phase-only computer-generated hologram. Opt. Express 2017, 25, 6568. [Google Scholar] [CrossRef]

- Tan, Q.; Qu, W.; Zhang, H.; Gu, H. Image magnification in lensless holographic projection using double-sampling Fresnel diffraction. Appl. Opt. 2015, 54, 10018–10021. [Google Scholar]

- Nordin, G.P.; Meier, J.T.; Jones, M.W. Diffractive optical element for Stokes vector measurement with a focal plane array[C]//Polarization: Measurement, Analysis, and Remote Sensing II. Int. Soc. Opt. Eng. 1999, 3754, 169–177. [Google Scholar]

- Jiang, Y.; Wang, J.; Xie, Q. Athermal design of refractive/diffractive hybrid infrared optical system. Electron. Opt. Control 2008, 131, 592–597. [Google Scholar]

- Antipa, N.; Kuo, G.; Heckel, R.; Mildenhall, B.; Bostan, E.; Ng, R.; Waller, L. DiffuserCam: Lensless single-exposure 3D imaging. Optica 2017, 5, 1–9. [Google Scholar] [CrossRef]

- Shechtman, Y.; Weiss, L.E.; Backer, A.S.; Lee, M.Y.; Moerner, W.E. Multicolour localization microscopy by point-spread-function engineering. Nat. Photonics 2016, 10, 590–594. [Google Scholar] [CrossRef] [PubMed]

- Jokubauskis, D.; Minkevičius, L.; Karaliūnas, M.; Indrisiunas, S.; Kasalynas, I.; Račiukaitis, G.; Valušis, G. Fibonacci terahertz imaging by silicon diffractive optics. Opt. Lett. 2018, 43, 2795–2798. [Google Scholar] [CrossRef]

- Gerchberg, R.W. Phase determination from image and diffraction plane pictures in the electron microscope. Optik 1971, 35, 275–284. [Google Scholar]

- Gerchberg, R.W.; Saxton, W.O. A practical algorithm for the determination of phase from image and diffraction plane pictures. Optik 1972, 35, 237–250. [Google Scholar]

- Fienup, J.R. Iterative method applied to image reconstruction and to computer-generated holograms. Opt. Eng. 1980, 19, 193297. [Google Scholar] [CrossRef]

- Liu, J.S.; Taghizadeh, M.R. Iterative algorithm for the design of diffractive phase elements for laser beam shaping. Opt. Lett. 2002, 27, 1463–1465. [Google Scholar] [CrossRef]

- Ma, H.; Zhou, P.; Wang, X.; Ma, Y.; Xi, F.; Xu, X.; Liu, Z. Near-diffraction-limited annular flattop beam shaping with dual phase only liquid crystal spatial light modulators. Opt. Express 2010, 18, 8251–8260. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, J. Adaptive-weight iterative algorithm for flat-top laser beam shaping. Opt. Eng. 2012, 51, 4301. [Google Scholar] [CrossRef]

- Yang, G.; Gu, B. On the amplitude-phase retrieval problem in optical systems. Acta Phys. Sin. 1981, 30, 410–413. [Google Scholar]

- Tan, X.; Gu, B.Y.; Yang, G.Z.; Dong, B.Z. Diffractive phase elements for beam shaping: A new design method. Appl. Opt. 1995, 34, 1314–1320. [Google Scholar] [CrossRef]

- Gesualdi, M.R.R.; Marinheiro, R.F. Holographic techniques using spatial light modulators applied to Maskless Photolithography. In SBMO/IEEE MTT-S International Microwave and Optoelectronics Conference, IMOC2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Melchels, F.P.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [PubMed]

- Gross, B.C.; Erkal, J.L.; Lockwood, S.Y.; Chen, C.; Spence, D.M. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences. Anal. Chem. 2014, 86, 3240–3253. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.D.; Simchowitz, M.; Jordan, M.I.; Recht, B. Gradient Descent Converges to Minimizers. arXiv 2016, arXiv:1602.04915. [Google Scholar]

- Sun, X.D.; Liu, J.; Wang, Y.Q.; Zhang, B.; Hu, B.; Di, S.; Wang, S.Q. Diffractive optical elements for implementing spatial demultiplexing and spectral synthesizing simultaneously. Opt. Commun. 2006, 266, 399–403. [Google Scholar] [CrossRef]

- Kim, G.; Domínguez-Caballero, J.A.; Menon, R. Design and analysis of multi-wavelength diffractive optics. Opt. Express 2012, 20, 2814. [Google Scholar] [CrossRef] [PubMed]

- Meister, M.; Winfield, R.J. Novel approaches to direct search algorithms for the design of diffractive optical elements. Opt. Commun. 2002, 203, 39–49. [Google Scholar] [CrossRef]

- Zhou, G.; Chen, Y.; Wang, Z.; Song, H. Genetic local search algorithm for optimization design of diffractive optical elements. Appl. Opt. 1999, 38, 4281. [Google Scholar] [CrossRef]

- Jiang, J.; Nordin, G. A rigorous unidirectional method for designing finite aperture diffractive optical elements. Opt. Express 2000, 7, 237–242. [Google Scholar] [CrossRef]

- Zhou, G.; Yuan, X.; Dowd, P.; Lam, Y.-L.; Chan, Y.-C. Design of diffractive phase elements for beam shaping: Hybrid approach. J. Opt. Soc. Am. A 2001, 18, 791–800. [Google Scholar] [CrossRef]

- Chen, M.; Wang, Q.; Gu, H.; Tan, Q. Diffractive optical element with same diffraction pattern for multicolor light-emitting diodes. Appl. Opt. 2016, 55, 159–164. [Google Scholar] [CrossRef]

- Shokooh-Saremi, M.; Magnusson, R. Particle swarm optimization and its application to the design of diffraction grating filters. Opt. Lett. 2007, 32, 894–896. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.; Peng, Y.; Guo, T.; Fu, Q.; Li, H.; Liu, X. Beam shaping for multicolour light-emitting diodes with diffractive optical elements. J. Mod. Opt. 2016, 64, 1–8. [Google Scholar] [CrossRef]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by simulated annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Goodman, J.W. Introduction to Fourier Optics; Roberts and Company Publishers: Greenwood Village, CO, USA, 2005. [Google Scholar]

| Parameters | Value |

|---|---|

| The size of the DOE | 8.64 mm |

| Diffraction distance | 300 mm |

| Sampling points | |

| Wavelength | 532 nm |

| , | 1.6, 1.9 |

| , | , 1 |

| 0.9 | |

| Parameters | Value |

|---|---|

| The size of the LCoS | 8.64 mm |

| Diffraction distance | 300 mm |

| Sampling points | |

| Wavelength | 632 nm |

| , | 1.6, 1.9 |

| , | , 1 |

| 0.9 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, P.; Cai, C.; Song, Y.; Ma, J.; Tan, Q. A Hybrid Diffractive Optical Element Design Algorithm Combining Particle Swarm Optimization and a Simulated Annealing Algorithm. Appl. Sci. 2020, 10, 5485. https://doi.org/10.3390/app10165485

Su P, Cai C, Song Y, Ma J, Tan Q. A Hybrid Diffractive Optical Element Design Algorithm Combining Particle Swarm Optimization and a Simulated Annealing Algorithm. Applied Sciences. 2020; 10(16):5485. https://doi.org/10.3390/app10165485

Chicago/Turabian StyleSu, Ping, Chao Cai, Yuming Song, Jianshe Ma, and Qiaofeng Tan. 2020. "A Hybrid Diffractive Optical Element Design Algorithm Combining Particle Swarm Optimization and a Simulated Annealing Algorithm" Applied Sciences 10, no. 16: 5485. https://doi.org/10.3390/app10165485

APA StyleSu, P., Cai, C., Song, Y., Ma, J., & Tan, Q. (2020). A Hybrid Diffractive Optical Element Design Algorithm Combining Particle Swarm Optimization and a Simulated Annealing Algorithm. Applied Sciences, 10(16), 5485. https://doi.org/10.3390/app10165485