Influences of High-Sulphur Fly Ash on the Properties of Lightweight Cement-Treated Materials Subjected to Sulphate Corrosion

Abstract

1. Introduction

2. Materials

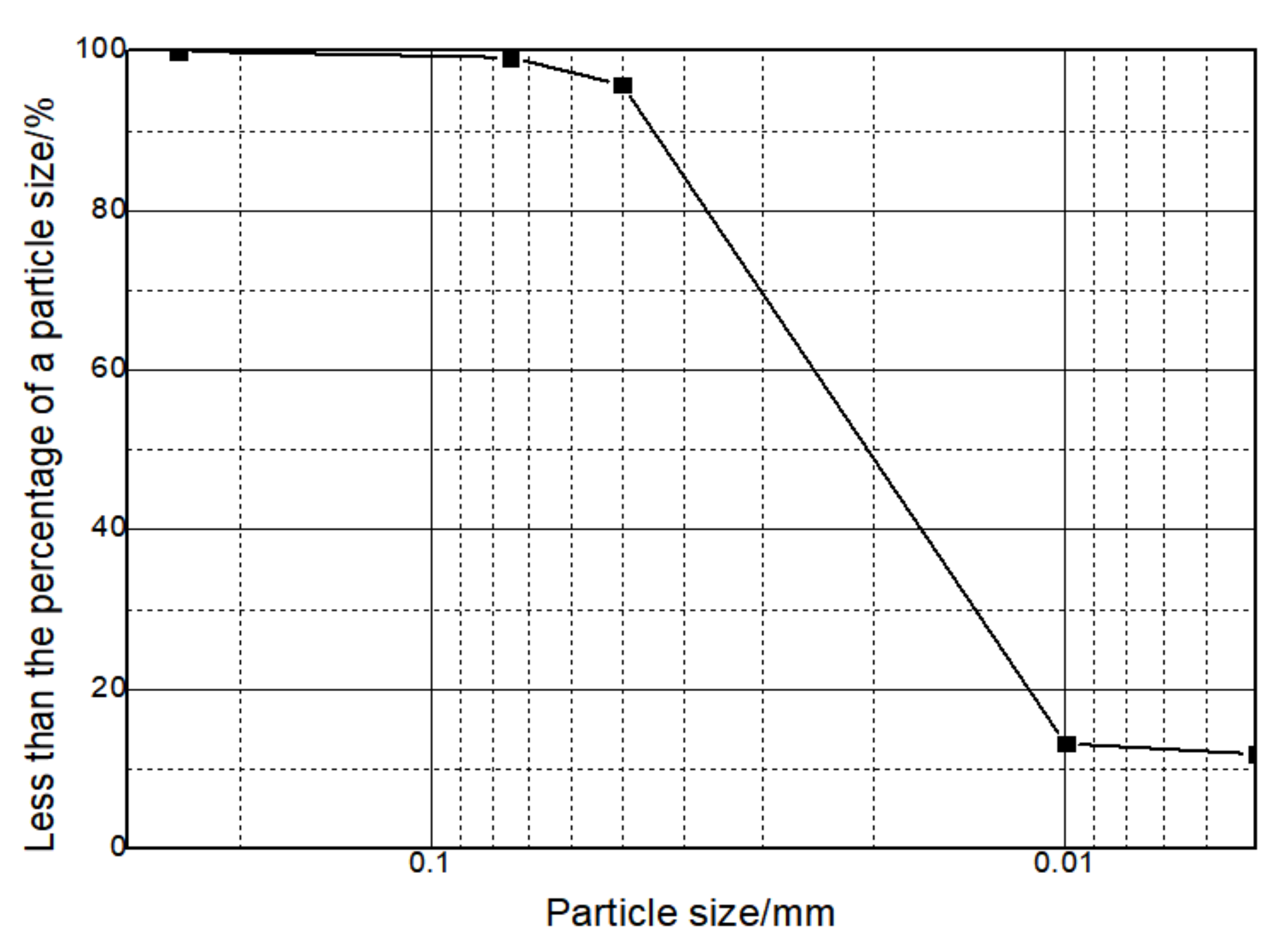

2.1. Test Materials

2.2. Test Preparation

2.3. Test Method

3. Results and Discussion

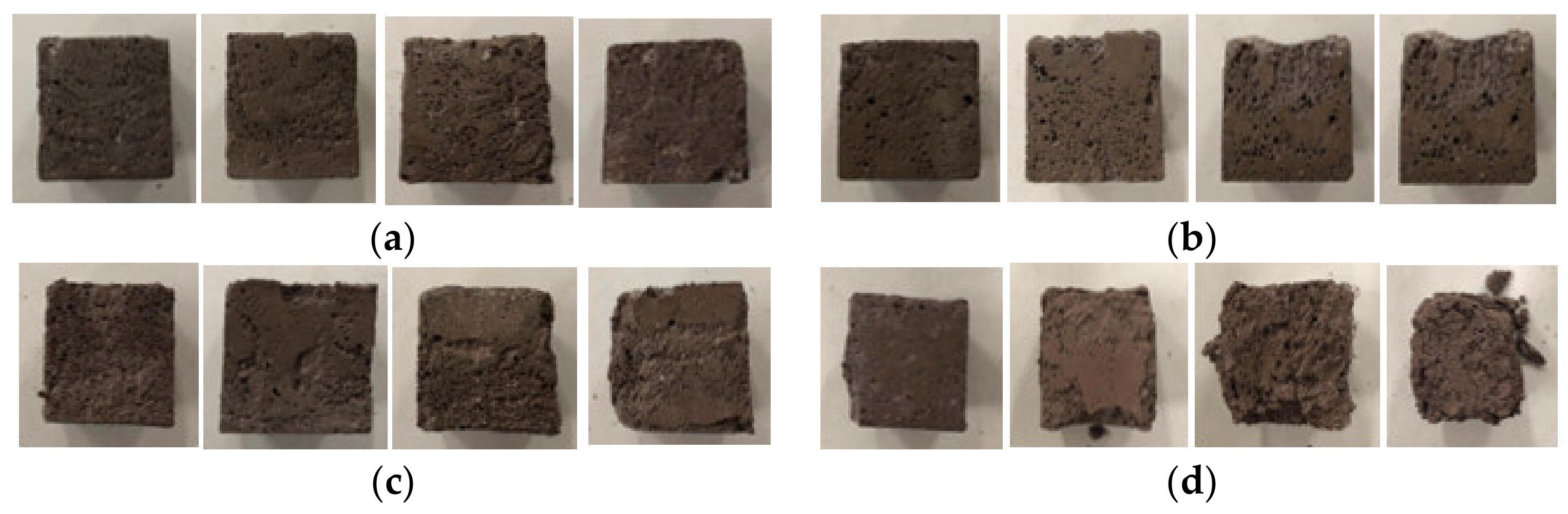

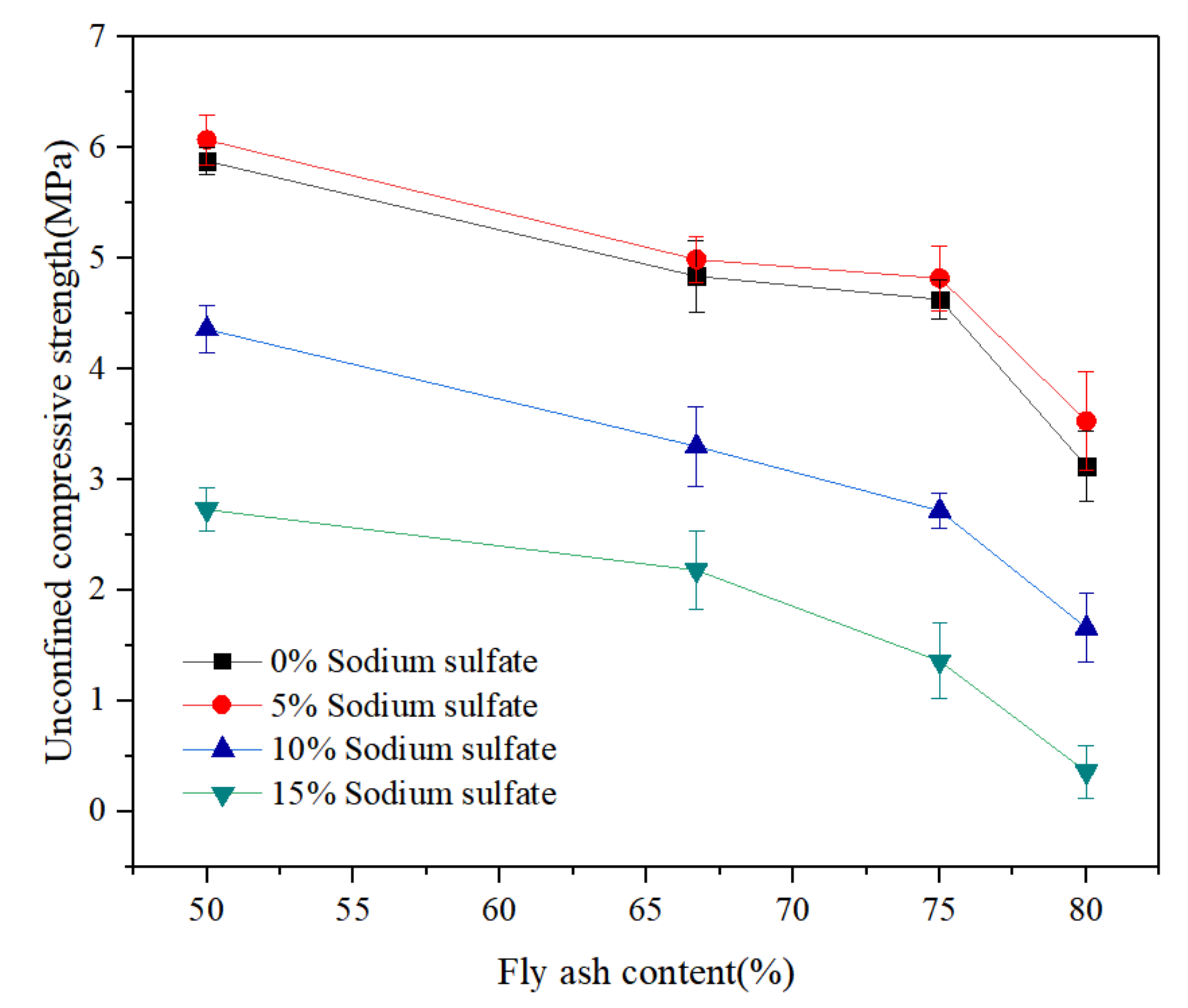

3.1. Mechanical Properties of LCMs under Sodium Sulphate Corrosion

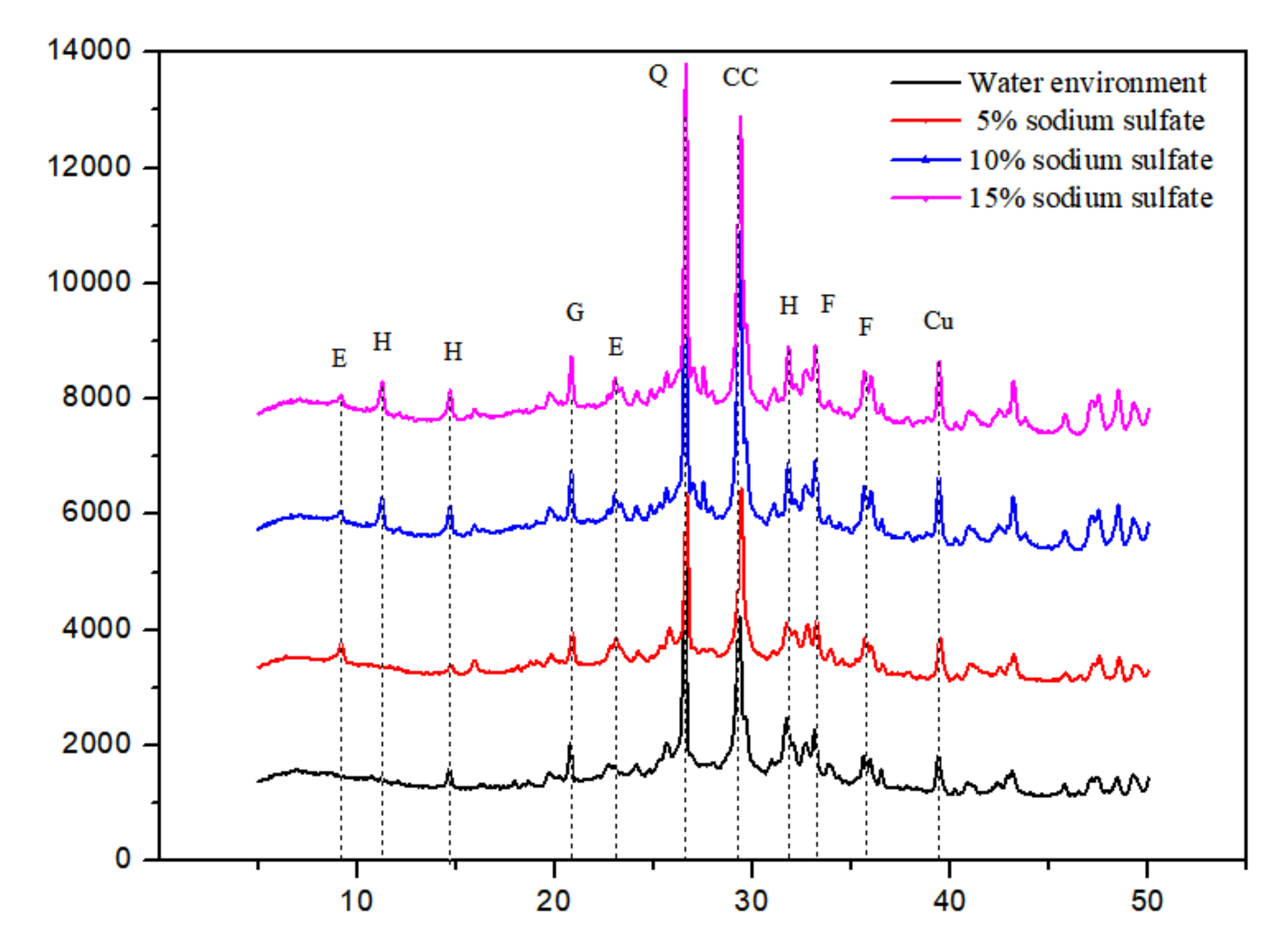

3.2. X-ray Diffraction Analysis

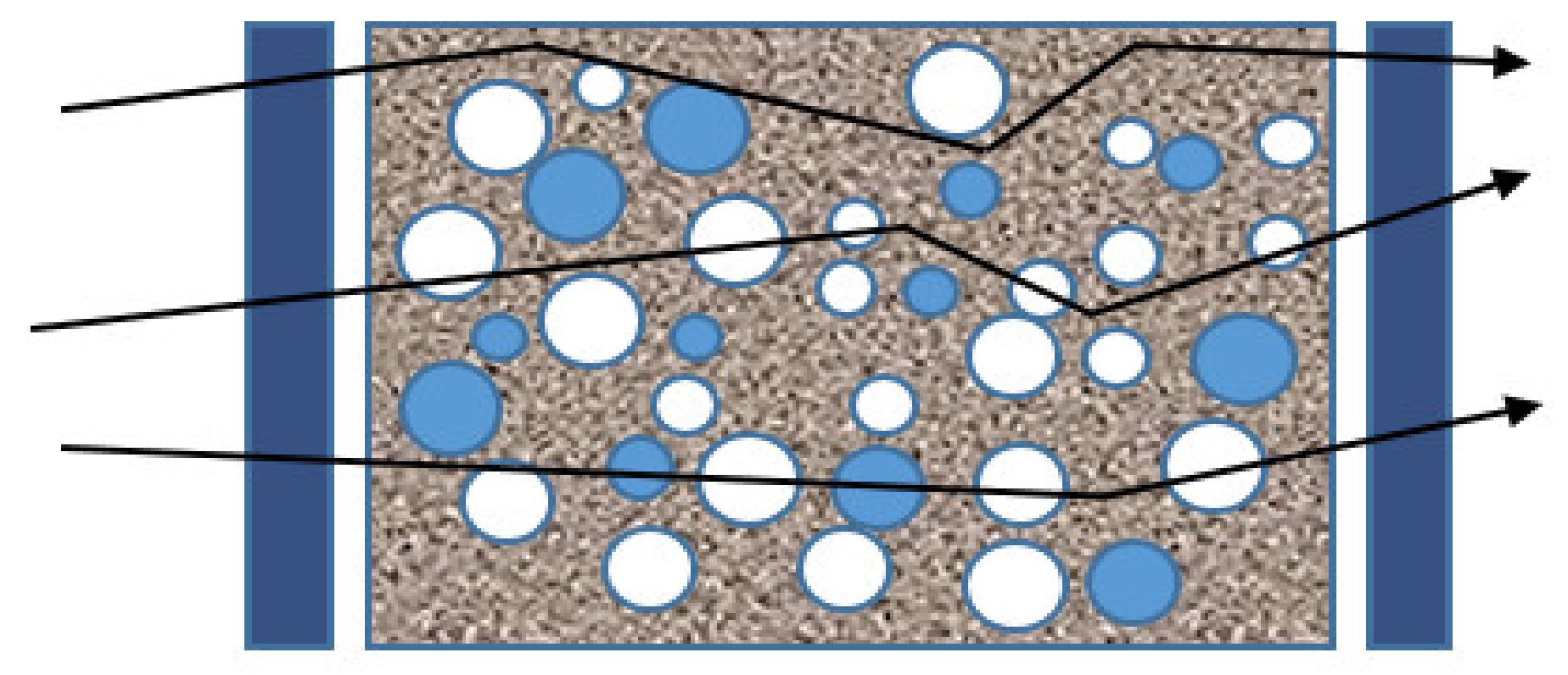

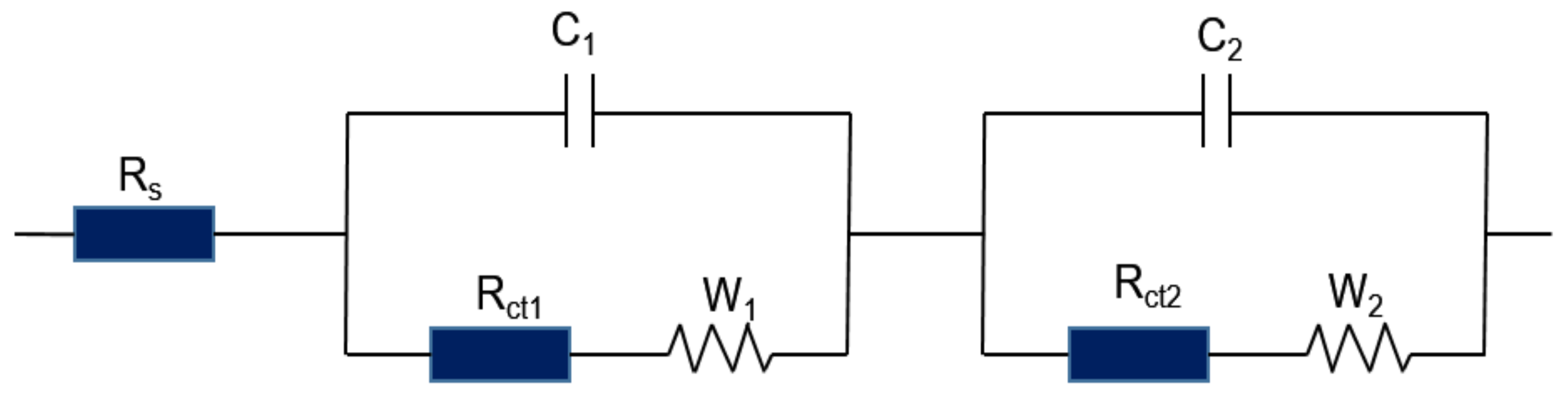

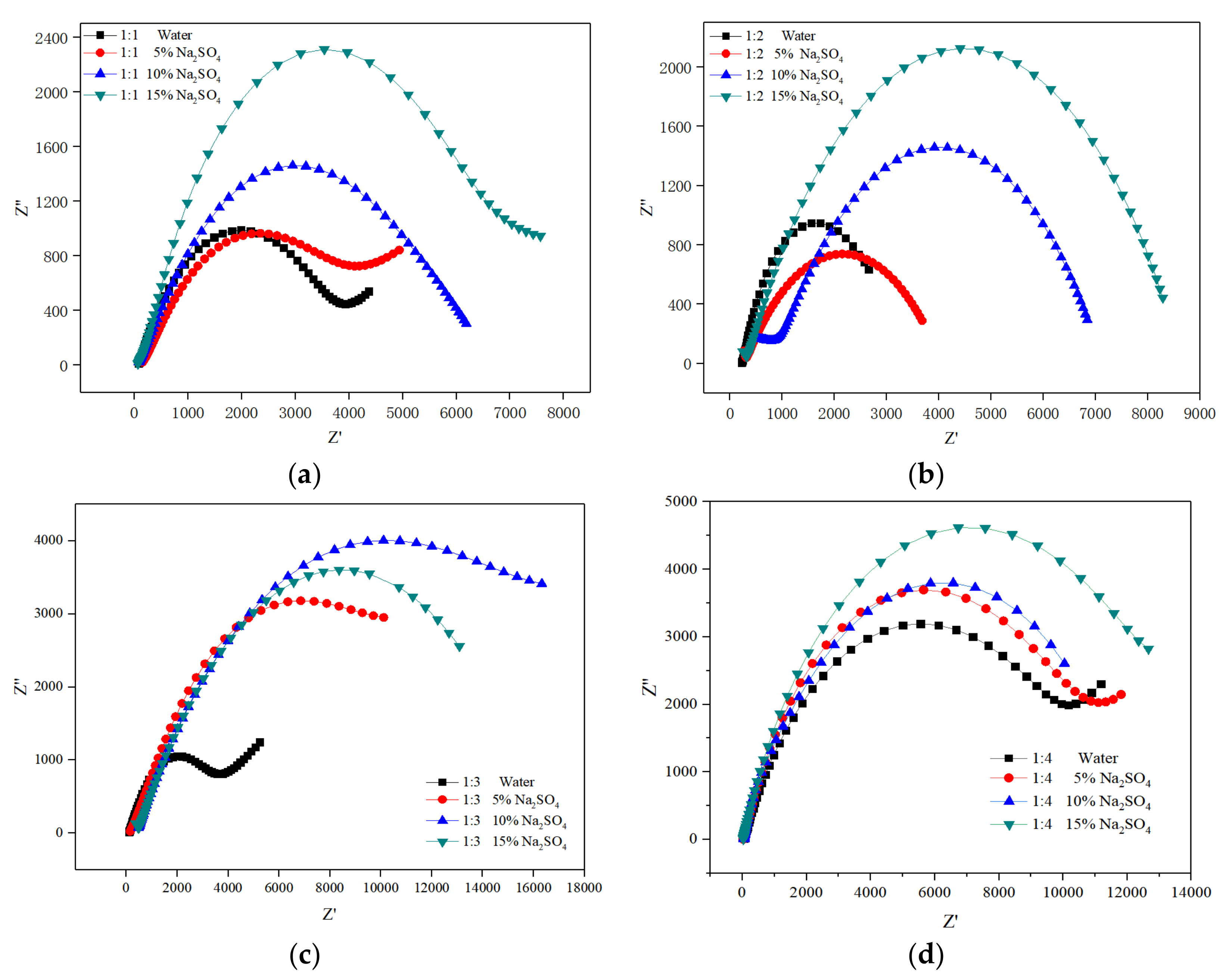

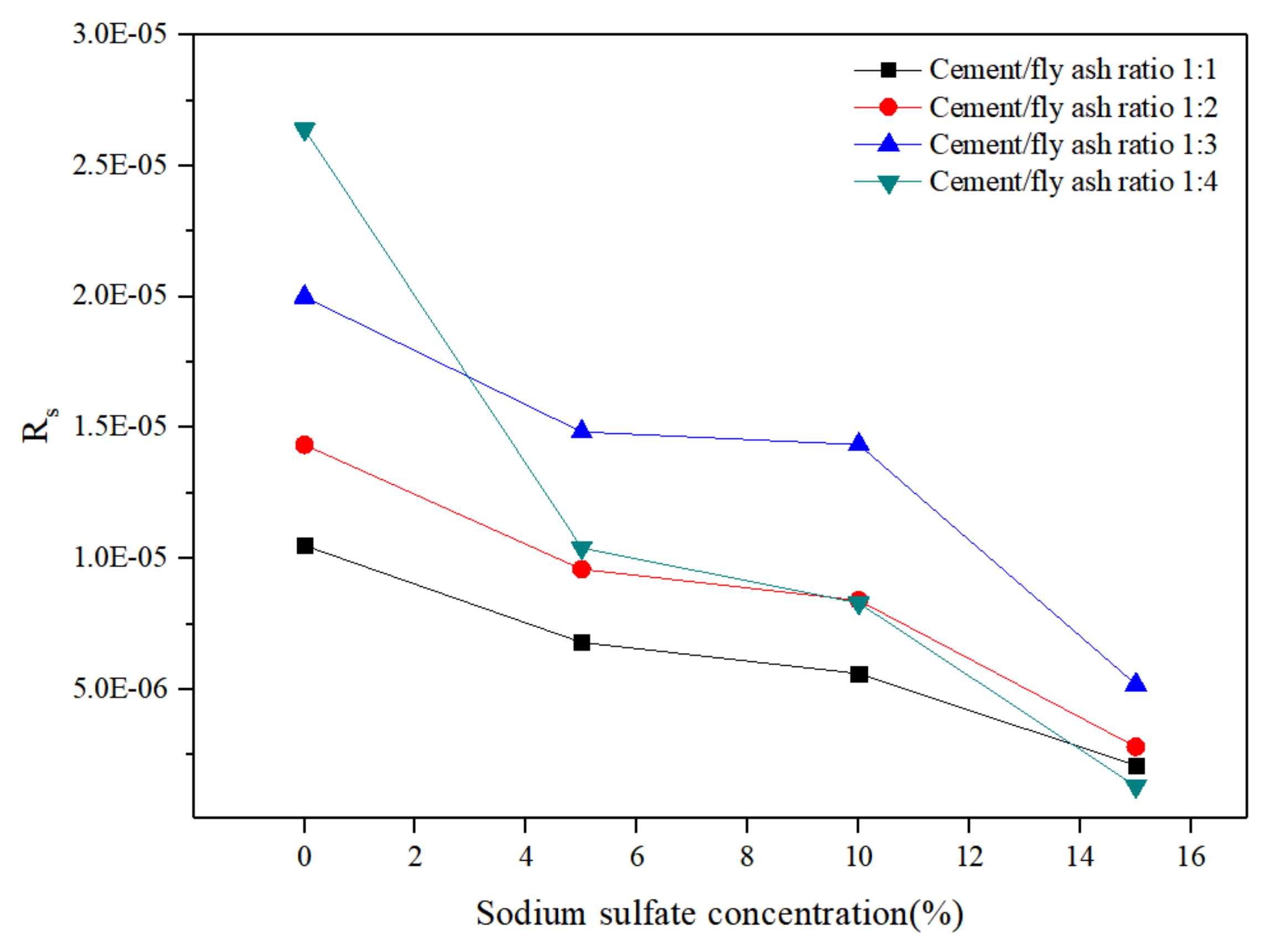

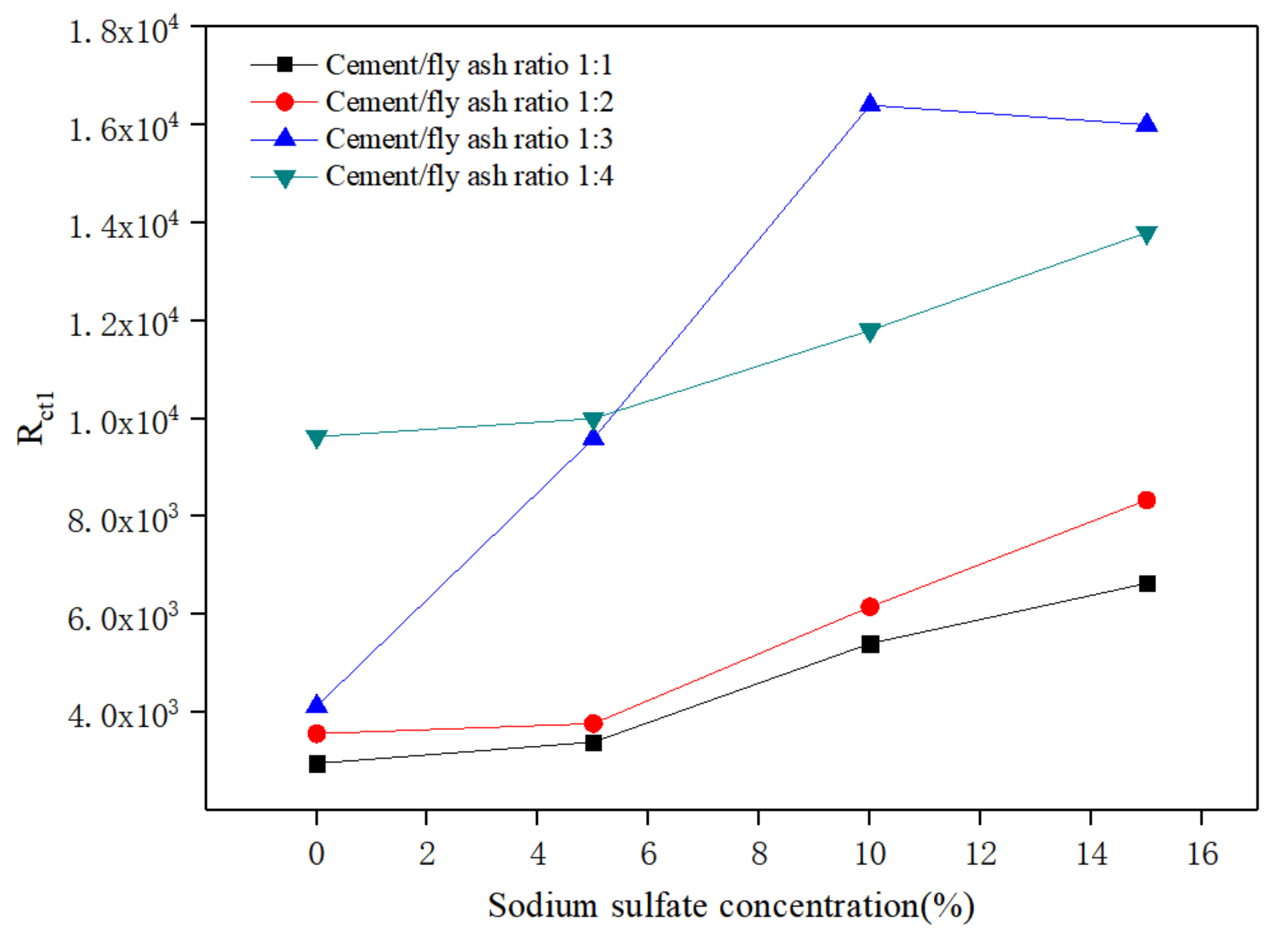

3.3. Electrochemical Impedance Spectroscopy Analysis

| Rs | Pore solution resistance |

| C1 | Pore capacitance |

| Rct1 | Material ion transfer resistance |

| W1 | Diffusion impedance of pore solution |

| C2 | Dual capacitance on the electrode/material surface |

| Rct2 | Surface ion transfer resistance of electrode plate |

| W2 | Diffusion impedance at the electrode plate |

3.4. SEM Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chauhan, M.S.; Mittal, S.; Mohanty, B. Performance evaluation of silty sand subgrade reinforced with fly ash and fibre. Geotext. Geomembr. 2008, 26, 429–435. [Google Scholar] [CrossRef]

- Phetchuay, C.; Horpibulsuk, S.; Suksiripattanapong, C.; Chinkulkijniwat, A.; Arulrajah, A.; Disfani, M.M. Calcium carbide residue: Alkaline activator for clay-fly ash geopolymer. Constr. Build. Mater. 2014, 69, 285–294. [Google Scholar] [CrossRef]

- Kua, T.-A.; Arulrajah, A.; Horpibulsuk, S.; Du, Y.-J.; Shen, S.-L. Strength assessment of spent coffee grounds-geopolymer cement utilizing slag and fly ash precursors. Constr. Build. Mater. 2016, 115, 565–575. [Google Scholar] [CrossRef]

- Wei, H.; Jiao, Y.; Liu, H. Effect of freeze-thaw cycles on mechanical property of silty clay modified by fly ash and crumb rubber. Cold Reg. Sci. Technol. 2015, 116, 70–77. [Google Scholar] [CrossRef]

- Kua, T.-A.; Arulrajah, A.; Mohammadinia, A.; Horpibulsuk, S.; Mirzababaei, M. Stiffness and deformation properties of spent coffee grounds based geopolymers. Constr. Build. Mater. 2017, 138, 79–87. [Google Scholar] [CrossRef]

- Jiang, N.-J.; Du, Y.-J.; Liu, K. Durability of lightweight alkali-activated ground granulated blast furnace slag (GGBS) stabilized clayey soils subjected to sulfate attack. Appl. Clay Sci. 2018, 161, 70–75. [Google Scholar] [CrossRef]

- Solanki, P.; Zaman, M.M. Laboratory Performance Evaluation of Subgrade Soils Stabilized with Sulfate-Bearing Cementitious Additives. J. Test. Eval. 2010, 38, 1–12. [Google Scholar]

- Knopp, J.; Moormann, C. Ettringite Swelling in the Treatment of Sulfate-Containing Soils Used as Subgrade for Road Constructions. Procedia Eng. 2016, 143, 128–137. [Google Scholar]

- Islam, M.A.; Golrokh, A.J.; Lu, Y. Chemomechanical Modeling of Sulfate Attack-Induced Damage Process in Cement-Stabilized Pavements. J. Eng. Mech. 2019, 145. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Y.; Gao, L. Effect of low-calcium fly ash on sulfate resistance of cement paste under different exposure conditions. Adv. Concr. Constr. 2019, 7, 175–181. [Google Scholar]

- Neramitkornburi, A.; Horpibulsuk, S.; Shen, S.L.; Chinkulkijniwat, A.; Arulrajah, A.; Disfani, M.M. Durability against wetting-drying cycles of sustainable Lightweight Cellular Cemented construction material comprising clay and fly ash wastes. Constr. Build. Mater. 2015, 77, 41–49. [Google Scholar] [CrossRef]

- Neramitkornburi, A.; Horpibulsuk, S.; Shen, S.L.; Arulrajah, A.; Disfani, M.M. Engineering properties of lightweight cellular cemented clay-fly ash material. Soils Found. 2015, 55, 471–483. [Google Scholar] [CrossRef]

- Rasheed, M.A.; Prakash, S.S. Behavior of hybrid-synthetic fiber reinforced cellular lightweight concrete under uniaxial tension—Experimental and analytical studies. Constr. Build. Mater. 2018, 162, 857–870. [Google Scholar] [CrossRef]

- Huang, J.-J.; Su, Q.; Zhao, W.-H.; Li, T.; Zhang, X.-X. Experimental study on use of lightweight foam concrete as subgrade bed filler of ballastless track. Constr. Build. Mater. 2017, 149, 911–920. [Google Scholar] [CrossRef]

- Kim, Y.T.; Kim, H.J.; Lee, G.H. Mechanical behavior of lightweight soil reinforced with waste fishing net. Geotext. Geomembr. 2008, 26, 512–518. [Google Scholar] [CrossRef]

- Kraemer, C.; Schauerte, M.; Kowald, T.L.; Trettin, R.H.F. Three-phase-foams for foam concrete application. Mater. Charact. 2015, 102, 173–179. [Google Scholar] [CrossRef]

- She, W.; Du, Y.; Zhao, G.; Feng, P.; Zhang, Y.; Cao, X. Influence of coarse fly ash on the performance of foam concrete and its application in high-speed railway roadbeds. Constr. Build. Mater. 2018, 170, 153–166. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Farzadnia, N.; Ali, A.A.A. Properties and applications of foamed concrete; A review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Kadela, M.; Kozłowski, M.; Kukiełka, A. Application of Foamed Concrete in Road Pavement—Weak Soil System. Procedia Eng. 2017, 193, 439–446. [Google Scholar] [CrossRef]

- Kang, S.-H.; Jeong, Y.; Kim, M.O.; Moon, J. Pozzolanic reaction on alkali-activated Class F fly ash for ambient condition curable structural materials. Constr. Build. Mater. 2019, 218, 235–244. [Google Scholar] [CrossRef]

- Wang, T.; Ishida, T. Multiphase pozzolanic reaction model of low-calcium fly ash in cement systems. Cem. Concr. Res. 2019, 122, 274–287. [Google Scholar] [CrossRef]

- Gadouri, H.; Harichane, K.; Ghrici, M. Assessment of sulphates effect on pH and pozzolanic reactions of soil-lime-natural pozzolana mixtures. Int. J. Pavement Eng. 2019, 20, 761–774. [Google Scholar] [CrossRef]

- Kan, L.; Zhang, L.; Shi, H. Hydration Kinetics of Municipal Solid Wastes Incineration (MSWI) Fly Ash-Cement. J. Wuhan Univ. Technol. -Mater. Sci. Ed. 2019, 34, 596–603. [Google Scholar] [CrossRef]

- Liao, W.; Sun, X.; Kumar, A.; Sun, H.; Ma, H. Hydration of Binary Portland Cement Blends Containing Silica Fume: A Decoupling Method to Estimate Degrees of Hydration and Pozzolanic Reaction. Front. Mater. 2019, 6. [Google Scholar] [CrossRef]

- Ramanathan, S.; Moon, H.; Croly, M.; Chung, C.-W.; Suraneni, P. Predicting the degree of reaction of supplementary cementitious materials in cementitious pastes using a pozzolanic test. Constr. Build. Mater. 2019, 204, 621–630. [Google Scholar] [CrossRef]

- Contrafatto, L. Recycled Etna volcanic ash for cement, mortar and concrete manufacturing. Constr. Build. Mater. 2017, 151, 704–713. [Google Scholar] [CrossRef]

- Contrafatto, L.; Danzuso, C.L.; Gazzo, S.; Greco, L. Physical, mechanical and thermal properties of lightweight insulating mortar with recycled Etna volcanic aggregates. Constr. Build. Mater. 2020, 240, 117917. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, F.; Liu, R.; Zhang, R.; Liu, Z.; Liu, H. Effects of pozzolanic and non-pozzolanic nanomaterials on cement-based materials. Constr. Build. Mater. 2019, 213, 1–9. [Google Scholar] [CrossRef]

- Pourkhorshidi, A.R.; Najimi, M.; Parhizkar, T.; Jafarpour, F.; Hillemeier, B. Applicability of the standard specifications of ASTM C618 for evaluation of natural pozzolans. Cem. Concr. Compos. 2010, 32, 794–800. [Google Scholar] [CrossRef]

- Celik, K.; Hay, R.; Hargis, C.W.; Moon, J. Effect of volcanic ash pozzolan or limestone replacement on hydration of Portland cement. Constr. Build. Mater. 2019, 197, 803–812. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Liu, C.; Chen, X.; Xu, Z. The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement. J. Clean. Prod. 2020, 242, 118521. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Palkovic, S.D.; Bumajdad, A.; Soriano, C.; Büyüköztürk, O. Use of silica fume and natural volcanic ash as a replacement to Portland cement: Micro and pore structural investigation using NMR, XRD, FTIR and X-ray microtomography. Constr. Build. Mater. 2018, 158, 574–590. [Google Scholar] [CrossRef]

- Kalakada, Z.; Doh, J.H.; Zi, G. Utilisation of coarse glass powder as pozzolanic cement—A mix design investigation. Constr. Build. Mater. 2020, 240, 117916. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Lachemi, M. Performance of volcanic ash and pumice based blended cement concrete in mixed sulfate environment. Cem. Concr. Res. 2006, 36, 1123–1133. [Google Scholar] [CrossRef]

- Puthipad, N.; Ouchi, M.; Attachaiyawuth, A. Effects of fly ash, mixing procedure and type of air-entraining agent on coalescence of entrained air bubbles in mortar of self-compacting concrete at fresh state. Constr. Build. Mater. 2018, 180, 437–444. [Google Scholar] [CrossRef]

- Chen, X.; Yan, Y.; Liu, Y.; Hu, Z. Utilization of circulating fluidized bed fly ash for the preparation of foam concrete. Constr. Build. Mater. 2014, 54, 137–146. [Google Scholar] [CrossRef]

- Jones, M.R.; McCarthy, A. Utilising unprocessed low-lime coal fly ash in foamed concrete. Fuel 2005, 84, 1398–1409. [Google Scholar] [CrossRef]

- Posi, P.; Ridtirud, C.; Ekvong, C.; Chammanee, D.; Janthowong, K.; Chindaprasirt, P. Properties of lightweight high calcium fly ash geopolymer concretes containing recycled packaging foam. Constr. Build. Mater. 2015, 94, 408–413. [Google Scholar] [CrossRef]

- Gokce, H.S.; Hatungimana, D.; Ramyar, K. Effect of fly ash and silica fume on hardened properties of foam concrete. Constr. Build. Mater. 2019, 194, 1–11. [Google Scholar] [CrossRef]

- Falliano, D.; de Domenico, D.; Ricciardi, G.; Gugliandolo, E. Experimental investigation on the compressive strength of foamed concrete: Effect of curing conditions, cement type, foaming agent and dry density. Constr. Build. Mater. 2018, 165, 735–749. [Google Scholar] [CrossRef]

- Hussin, M.W.; Muthusamy, K.; Zakaria, F. Effect of Mixing Constituent toward Engineering Properties of POFA Cement-Based Aerated Concrete. J. Mater. Civ. Eng. 2010, 22, 287–295. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U. Shrinkage behavior of structural foam lightweight concrete containing glycol compounds and fly ash. Mater. Des. 2011, 32, 723–727. [Google Scholar] [CrossRef]

- Ma, C.; Chen, B. Experimental study on the preparation and properties of a novel foamed concrete based on magnesium phosphate cement. Constr. Build. Mater. 2017, 137, 160–168. [Google Scholar] [CrossRef]

- Jones, M.R.; McCarthy, A. Heat of hydration in foamed concrete: Effect of mix constituents and plastic density. Cem. Concr. Res. 2006, 36, 1032–1041. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Investigation of engineering properties of normal and high strength fly ash based geopolymer and alkali-activated slag concrete compared to ordinary Portland cement concrete. Constr. Build. Mater. 2019, 196, 26–42. [Google Scholar] [CrossRef]

- Uthaman, S.; Vishwakarma, V.; George, R.P.; Ramachandran, D.; Kumari, K.; Preetha, R.; Premila, M.; Rajaraman, R.; Mudali, U.K.; Amarendra, G. Enhancement of strength and durability of fly ash concrete in seawater environments: Synergistic effect of nanoparticles. Constr. Build. Mater. 2018, 187, 448–459. [Google Scholar] [CrossRef]

- Li, J.; Ji, Y.; Zhang, L.; Liu, B. Resistance to sulfate attack of magnesium phosphate cement-coated concrete. Constr. Build. Mater. 2019, 195, 156–164. [Google Scholar]

- Sirisawat, I.; Baingam, L.; Saengsoy, W.; Krammart, P.; Tangtermsirikul, S. Sodium and Magnesium Sulfate Resistance of Mortars with Interground Limestone and Limestone Powder Replacing Cements. J. Adv. Concr. Technol. 2014, 12, 403–412. [Google Scholar] [CrossRef]

- Li, J.; Ji, Y.; Huang, G.; Zhang, L. Microstructure Evolution of a Magnesium Phosphate Protective Layer on Concrete Structures in a Sulfate Environment. Coatings 2018, 8, 140. [Google Scholar] [CrossRef]

- Tixier, R.; Mobasher, B. Modeling of Damage in Cement-Based Materials Subjected to External Sulfate Attack. II: Comparison with Experiments. J. Mater. Civ. Eng. 2003, 15, 314–322. [Google Scholar] [CrossRef]

- Haufe, J.; Vollpracht, A. Tensile strength of concrete exposed to sulfate attack. Cem. Concr. Res. 2019, 116, 81–88. [Google Scholar] [CrossRef]

- Siad, H.; Kamali-Bernard, S.; Mesbah, H.A.; Escadeillas, G.; Mouli, M.; Khelafi, H. Characterization of the degradation of self-compacting concretes in sodium sulfate environment: Influence of different mineral admixtures. Constr. Build. Mater. 2013, 47, 1188–1200. [Google Scholar] [CrossRef]

- Sun, H.; Ren, Z.; Memon, S.A.; Zhao, D.; Zhang, X.; Li, D.; Xing, F. Investigating drying behavior of cement mortar through electrochemical impedance spectroscopy analysis. Constr. Build. Mater. 2017, 135, 361–368. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, H.; Zhang, Z.; Yao, Y. Electrochemical impedance spectroscopy (EIS) of hydration process and drying shrinkage for cement paste with W/C of 0.25 affected by high range water reducer. Constr. Build. Mater. 2017, 131, 536–541. [Google Scholar] [CrossRef]

- Dong, B.; Li, G.; Zhang, J.; Liu, Y.; Xing, F.; Hong, S. Non-destructive tracing on hydration feature of slag blended cement with electrochemical method. Constr. Build. Mater. 2017, 149, 467–473. [Google Scholar] [CrossRef]

- Dong, B.; Gu, Z.; Qiu, Q.; Liu, Y.; Ding, W.; Xing, F.; Hong, S. Electrochemical feature for chloride ion transportation in fly ash blended cementitious materials. Constr. Build. Mater. 2018, 161, 577–586. [Google Scholar] [CrossRef]

| Component | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | Na2O | K2O | Loss |

|---|---|---|---|---|---|---|---|---|---|

| Content (by mass %) | 66.35 | 18.81 | 5.86 | 3.34 | 1.04 | 2.53 | 0.31 | 0.41 | 0.45 |

| Fineness | Water Requirement Ratio | Loss on Ignition | Sulphur Trioxide | Water Content | Free Calcium Oxide |

|---|---|---|---|---|---|

| 10.2 | 107 | 5.21 | 6.99 | 0.32 | 2.45 |

| Component | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | f-CaO | Loss |

|---|---|---|---|---|---|---|---|---|

| Content (by mass %) | 23.57 | 34.6 | 18.57 | 7.66 | 3.41 | 6.99 | 2.45 | 2.75 |

| Number | Cement (kg/m3) | High-Sulphur Fly Ash (kg/m3) | Water (kg/m3) | Early Strength Agent (kg/m3) | Foam (L/m3) | Dry Density of Mixture (kg/m3) |

|---|---|---|---|---|---|---|

| A1-1 | 465 | 465 | 650 | 18.6 | 1200 | 816 |

| A1-2 | 310 | 620 | 650 | 18.6 | 1200 | 874 |

| A1-3 | 235 | 695 | 650 | 18.6 | 1200 | 860 |

| A1-4 | 190 | 740 | 650 | 18.6 | 1200 | 758 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Han, P.; Dong, X.; Li, X.; Bai, X.; He, B.; Niu, S.; Sun, F. Influences of High-Sulphur Fly Ash on the Properties of Lightweight Cement-Treated Materials Subjected to Sulphate Corrosion. Appl. Sci. 2020, 10, 5217. https://doi.org/10.3390/app10155217

Wang X, Han P, Dong X, Li X, Bai X, He B, Niu S, Sun F. Influences of High-Sulphur Fly Ash on the Properties of Lightweight Cement-Treated Materials Subjected to Sulphate Corrosion. Applied Sciences. 2020; 10(15):5217. https://doi.org/10.3390/app10155217

Chicago/Turabian StyleWang, Xiaoyuan, Pengju Han, Xiaoqiang Dong, Xiangyu Li, Xiaohong Bai, Bin He, Shiwei Niu, and Funan Sun. 2020. "Influences of High-Sulphur Fly Ash on the Properties of Lightweight Cement-Treated Materials Subjected to Sulphate Corrosion" Applied Sciences 10, no. 15: 5217. https://doi.org/10.3390/app10155217

APA StyleWang, X., Han, P., Dong, X., Li, X., Bai, X., He, B., Niu, S., & Sun, F. (2020). Influences of High-Sulphur Fly Ash on the Properties of Lightweight Cement-Treated Materials Subjected to Sulphate Corrosion. Applied Sciences, 10(15), 5217. https://doi.org/10.3390/app10155217