Energy and Exergy Analyses of an Existing Solar-Assisted Combined Cycle Power Plant

Abstract

1. Introduction

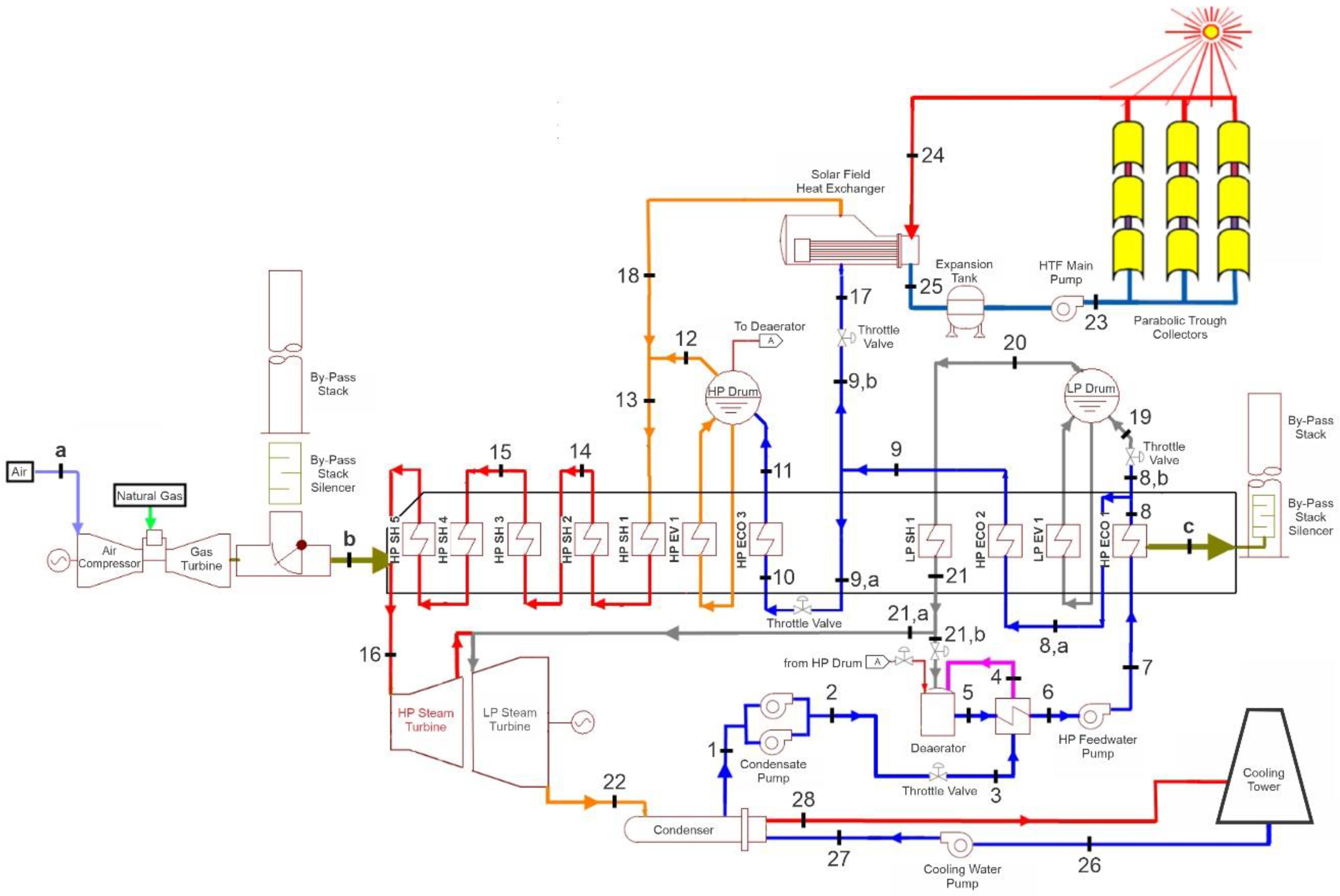

2. Plant Description

2.1. Solar Field

2.2. Combined Cycle

3. Thermodynamic Analysis

3.1. Energy Balance

3.2. Exergetic Efficiencies

3.2.1. The Exergetic Efficiency of the Solar Field

3.2.2. The Exergetic Efficiency of the ISCC

4. Results and Discussion

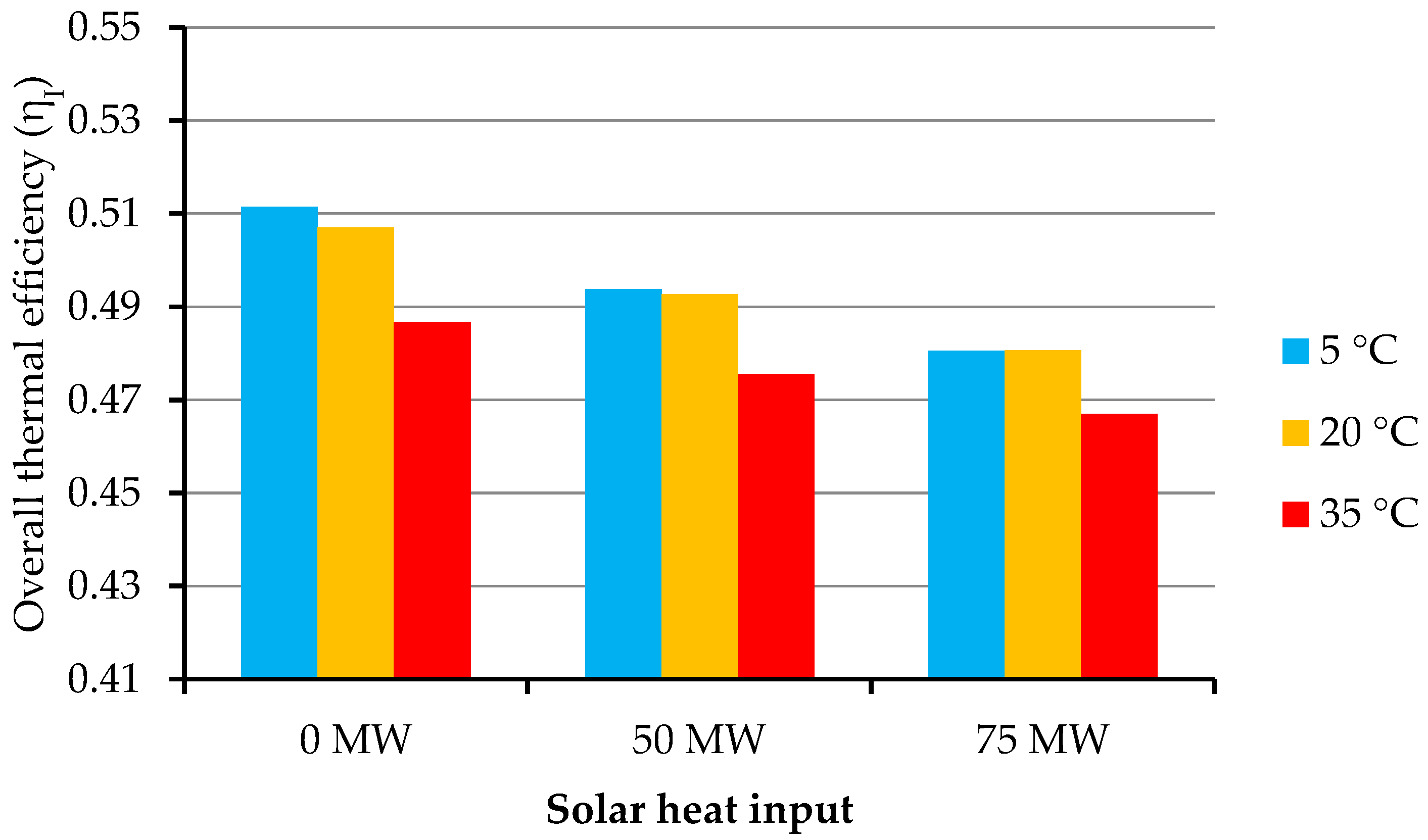

4.1. The Overall Thermal Efficiency of the ISCC Power Plant

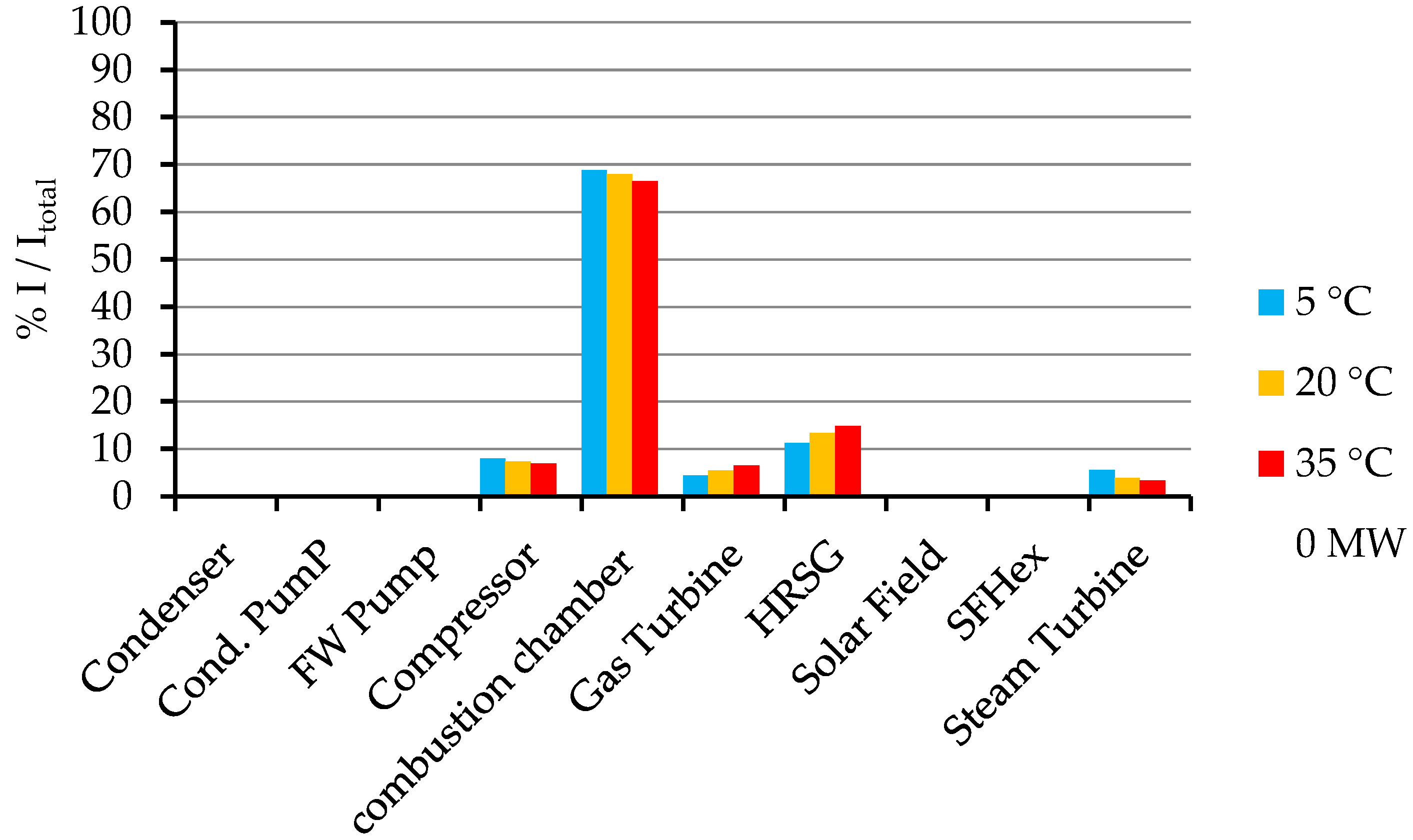

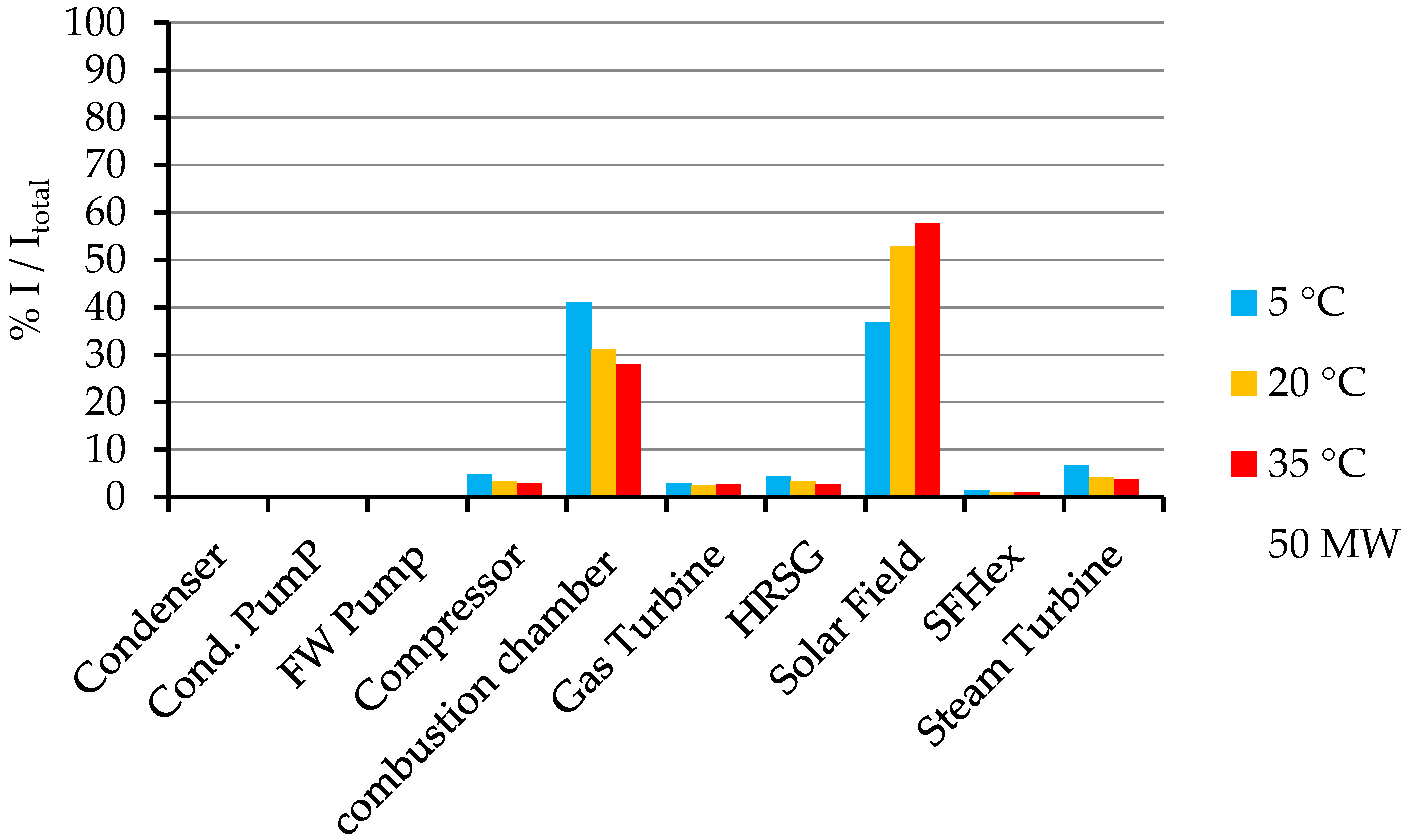

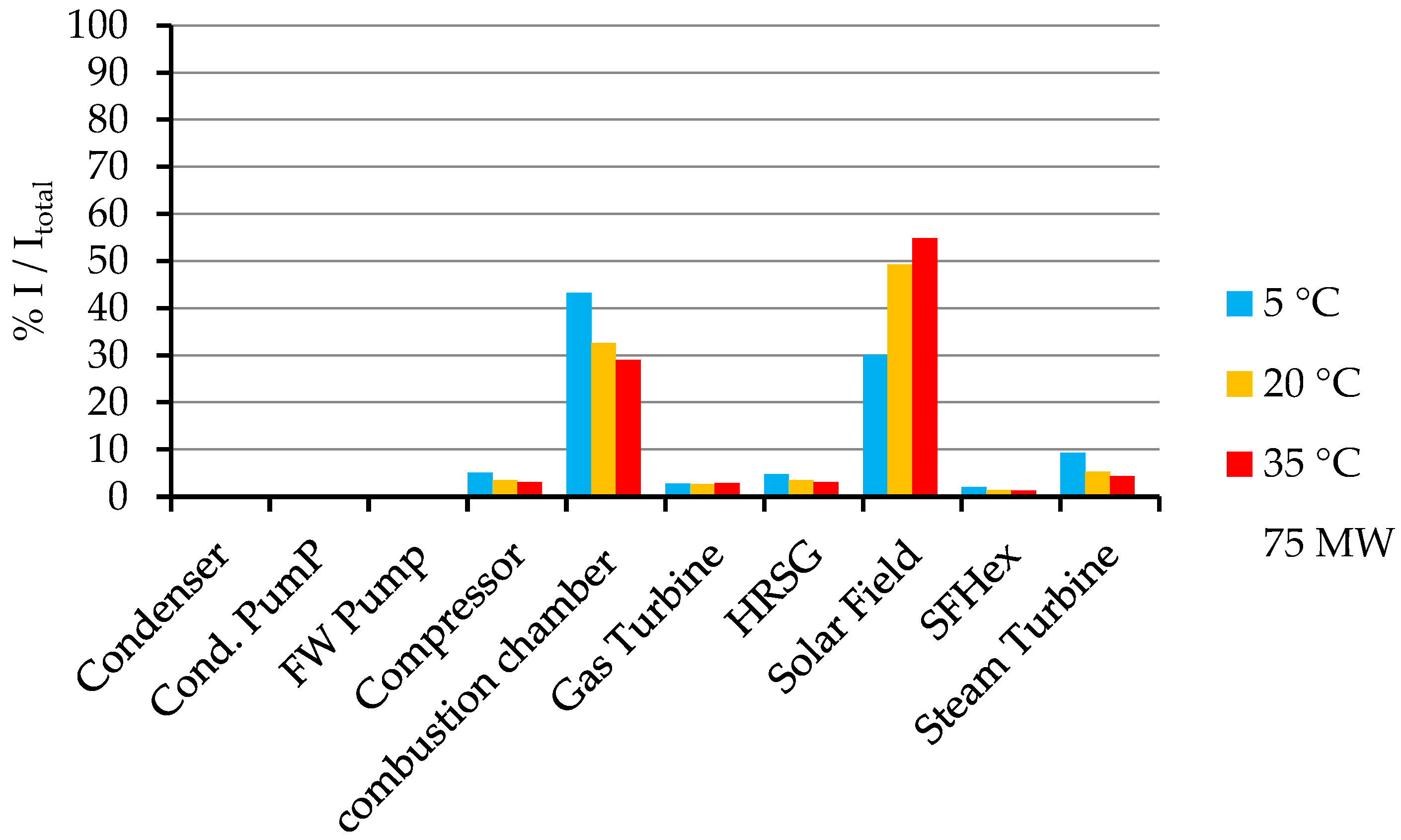

4.2. Exergy Destruction in Each Component of the ISCC as a Percentage of the Total Exergy Destruction in the Whole ISCC

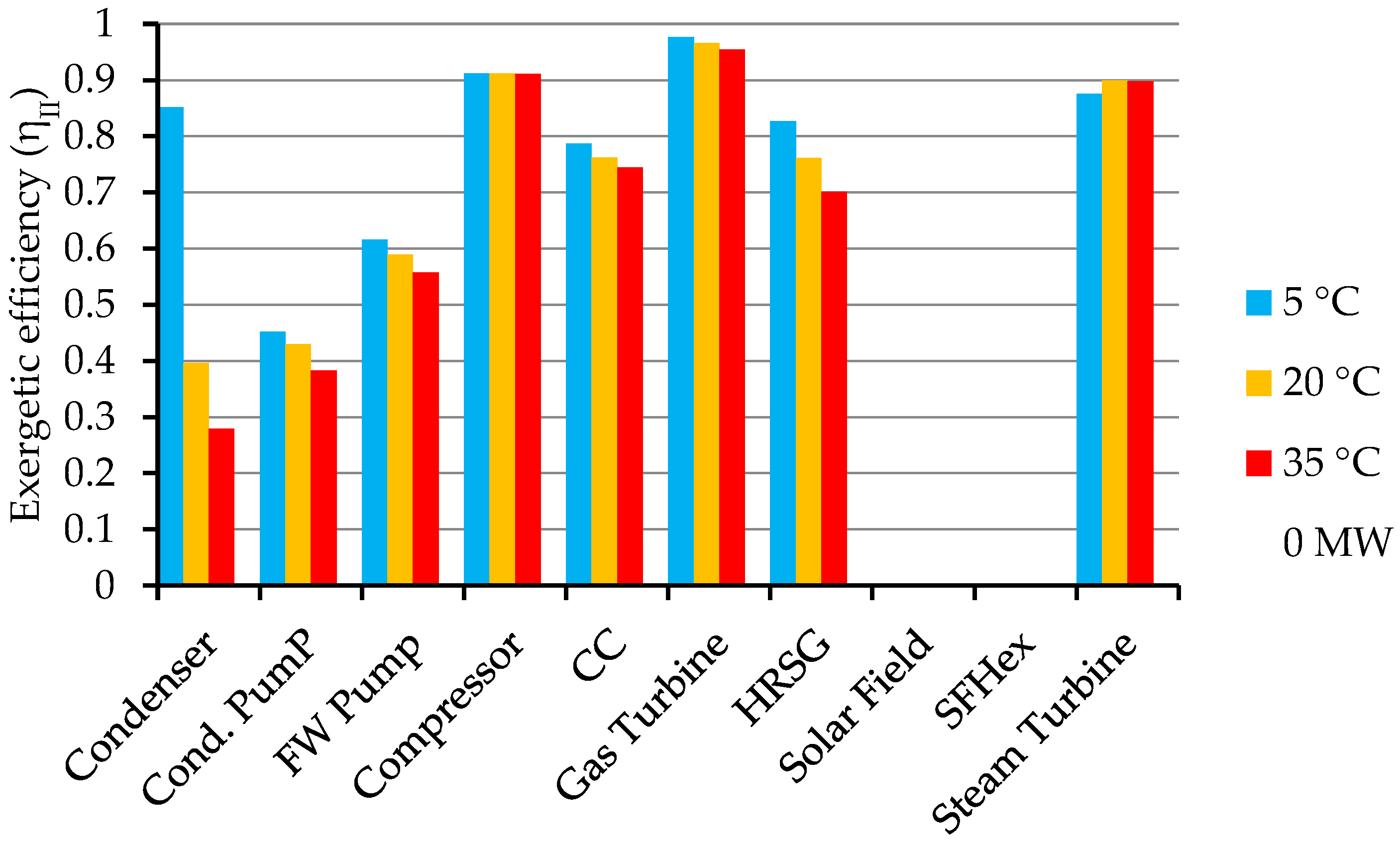

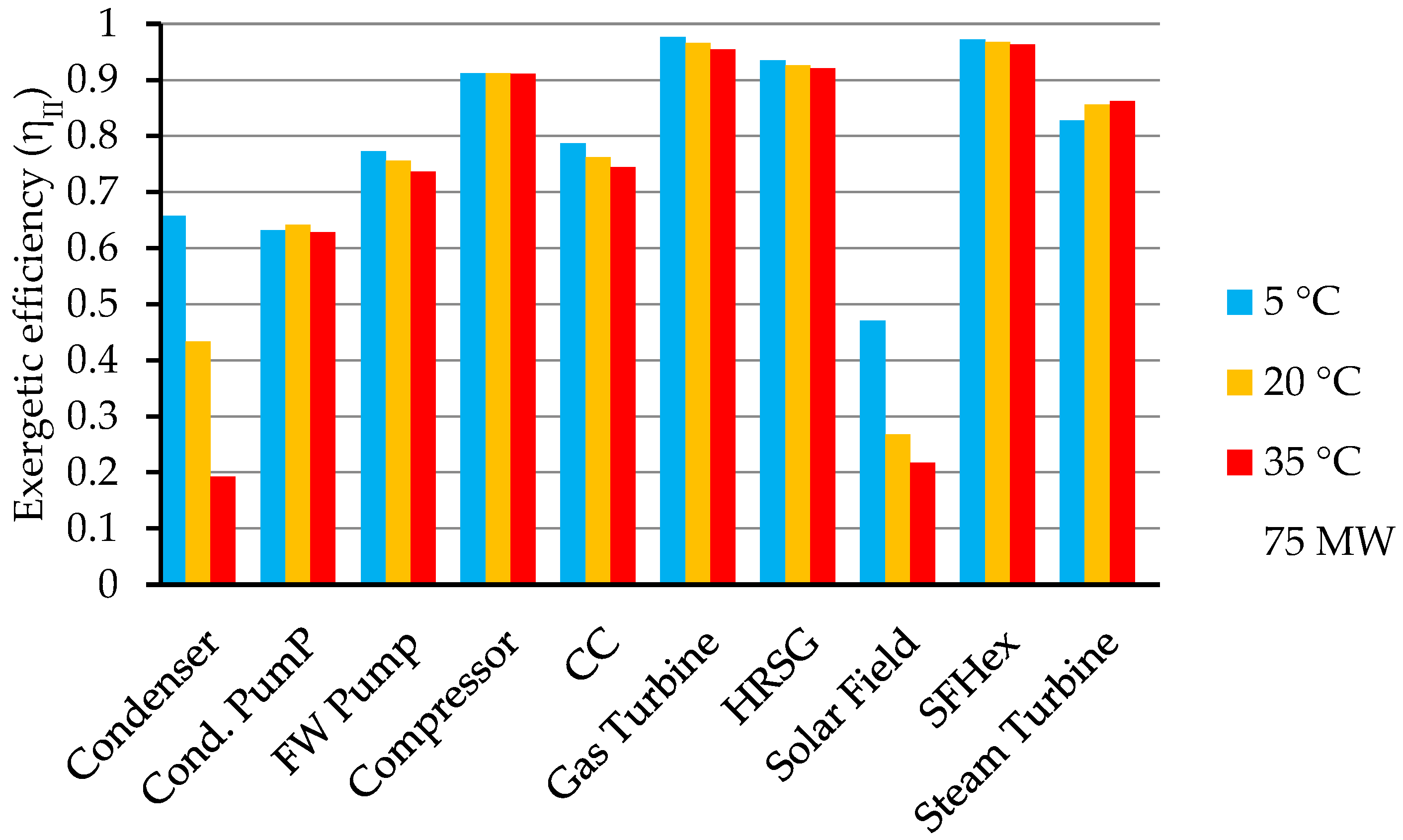

4.3. The Exergetic Efficiency of the Main Components of the ISCC

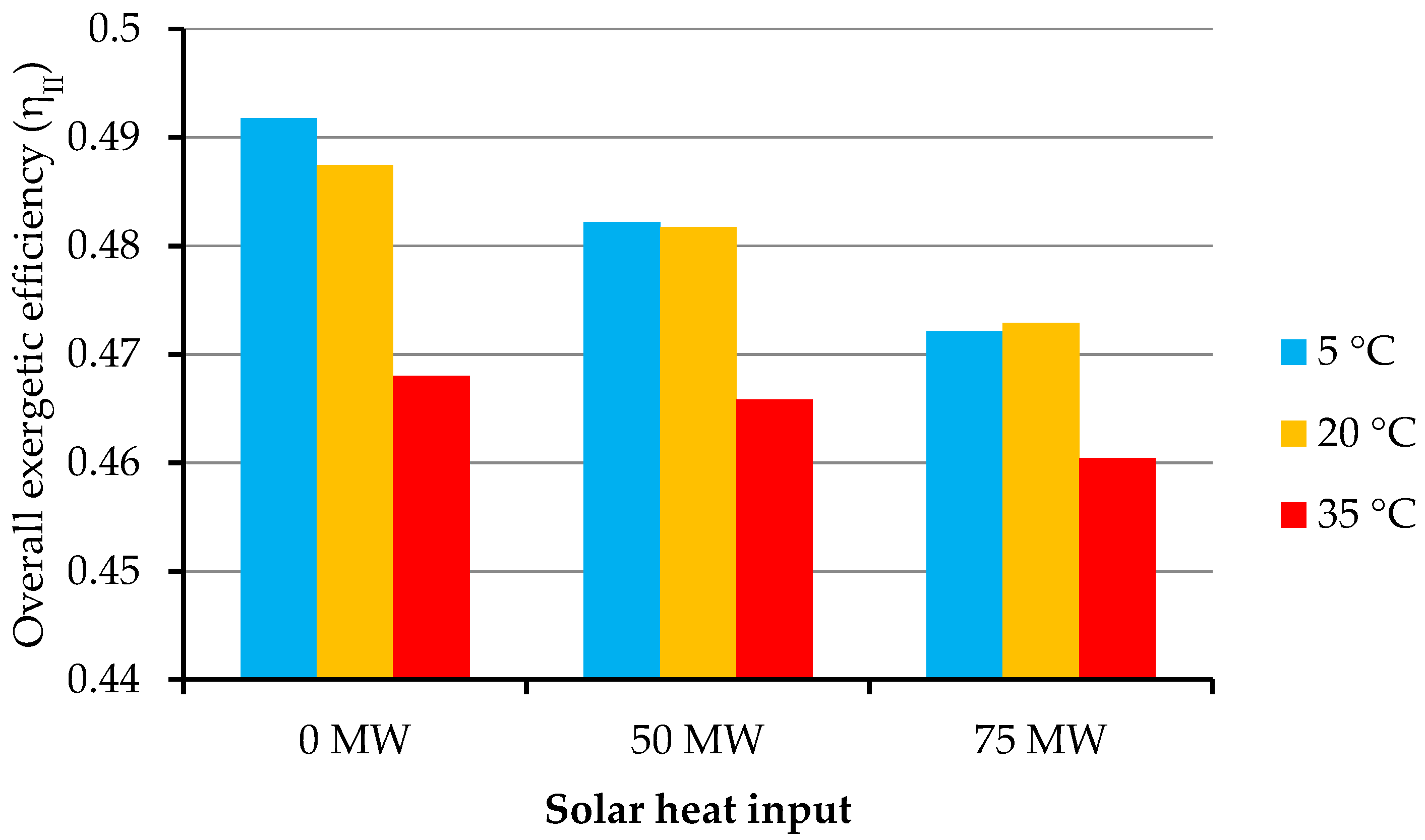

4.4. The Exergetic Efficiency of the ISCC Power Plant

4.5. Investigating the Sources of Exergy Destruction

4.5.1. Irreversibility in the Solar Field

4.5.2. Irreversibility in the Combustion Chamber

- Diffusion of reactants (mixing of fuel and air molecules) and chemical reaction (fuel oxidation) where energy is consumed to overcome the activation energy.

- Heat transfer between combustion products and other neighbors of particles; this is called “internal thermal energy exchange”.

- Mixing of combustion products with other constituents.

5. Conclusions

- The solar field has the lowest exergetic efficiency (17.8%), followed by the condenser (42.2%), at ambient temperature 20 °C and solar heat input 50 MW.

- The exergy destruction in the solar field is the largest part of the exergy destruction in the ISCC power plant (52.9% at ambient temperature 20 °C and solar heat input 50 MW).

- The thermal efficiency and the exergetic efficiency of the ISCC decrease with increasing solar field thermal input, where it has its highest values (51.14% and 49.18%, respectively) at no solar field thermal input (combined cycle regime) and ambient temperature 5 °C.

- The thermal efficiency and the exergetic efficiency of both the ISCC and the combined cycle (i.e., at no solar field heat input) decrease with increasing ambient temperature at different solar heat inputs (0, 50, 75 MW). This is due to the decrease of the exergetic efficiency of the gas turbine, the solar field, the condenser, and the HRSG with increasing ambient temperature.

- The integration of a solar field with a combined cycle (i.e., ISCC) reduced the thermal and exergetic efficiencies of the power plant under the combined cycle regime due to the low thermal and exergetic efficiencies of the solar field because the solar fuel cost was considered in this study.

- The target of the ISCC power plants is not to increase the overall thermal efficiency of the Brayton cycle, like the combined cycle, but to increase the economic feasibility of solar power plants. Elimination of the thermal storage system reduces the cost of the power plant [24,25,26]. So, this integration of a solar field is recommended regarding the given challenges for the electricity market with the continuing expansion of intermittent renewables.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, H.L.; Baeyens, J.; Degrève, J.; Cacères, G.; Cac, G.; Zhang, H.L.; Baeyens, J.; Degrève, J.; Cacères, G. Concentrated solar power plants: Review and design methodology. Renew Sustain. Energy Rev. 2013, 22, 466–481. [Google Scholar] [CrossRef]

- Mills, D. Advances in solar thermal electricity technology. Sol. Energy 2004, 76, 19–31. [Google Scholar] [CrossRef]

- Ratliff, P.; Garbett, P.; Fischer, W. The new siemens gas turbine sgt5-8000h for more customer benefit. VGB Powertech 2007, 87, 128–132. [Google Scholar]

- Scholz, C.; Zimmermann, H.; an der Ruhr, M. First Long-Term Experience with the Operational Flexibility of the SGT5-8000H. 2012. Available online: https://www.osti.gov/etdeweb/biblio/22090573 (accessed on 1 July 2020).

- Vandervort, C.; Wetzel, T.; Leach, D. Engineering and validating a world record gas turbine. Mech. Eng. 2017, 139, 48–50. [Google Scholar] [CrossRef]

- Vandervort, C. Advancements in h class gas turbines and combined cycle power plants. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Spliethoff, H. Power Generation from Solid Fuels; Springer Science & Business Media: Berlin, Germany, 2010; ISBN 364202856X. [Google Scholar]

- Behar, O.; Khellaf, A.; Mohammedi, K.; Ait-kaci, S. A review of integrated solar combined cycle system (ISCCS) with a parabolic trough technology. Renew. Sustain. Energy Rev. 2014, 39, 223–250. [Google Scholar] [CrossRef]

- Montes, M.J.; Rovira, A.; Muñoz, M.; Martínez-val, J.M. Performance analysis of an integrated solar combined cycle using direct steam generation in parabolic trough collectors. Appl. Energy 2011, 88, 3228–3238. [Google Scholar] [CrossRef]

- Rovira, A.; Montes, M.J.; Varela, F.; Gil, M. Comparison of heat transfer fluid and direct steam generation technologies for integrated solar combined cycles. Appl. Therm. Eng. 2013, 52, 264–274. [Google Scholar] [CrossRef]

- Dersch, J.; Geyer, M.; Herrmann, U.; Jones, S.; Kelly, B.; Kistner, R.; Ortmanns, W.; Pitz-Paal, R.; Price, H. Trough integration into power plants—A study on the performance and economy of integrated solar combined cycle systems. Energy 2004, 29, 947–959. [Google Scholar] [CrossRef]

- Kelly, B.; Herrmann, U.; Hale, M.J. Optimization studies for integrated solar combined cycle systems. In Proceedings of the Solar Forum 2001 Solar Energy: The Power to Choose, Washington, DC, USA, 21–25 April 2001; ASME: Washington, DC, USA, 2001; pp. 393–398. [Google Scholar]

- Bonforte, G.; Buchgeister, J.; Manfrida, G.; Petela, K. Exergoeconomic and exergoenvironmental analysis of an integrated solar gas turbine/combined cycle power plant. Energy 2018, 156, 352–359. [Google Scholar] [CrossRef]

- Iora, P.; Beretta, G.P.; Ghoniem, A.F. Exergy loss based allocation method for hybrid renewable-fossil power plants applied to an integrated solar combined cycle. Energy 2019, 173, 893–901. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Tosang, E.; Dadak, A. Investigation of a combined cycle power plant coupled with a parabolic trough solar field and high temperature energy storage system. Energy Convers. Manag. 2018, 171, 1662–1674. [Google Scholar] [CrossRef]

- Baghernejad, A.; Yaghoubi, M. Exergy analysis of an integrated solar combined cycle system. Renew. Energy 2010, 35, 2157–2164. [Google Scholar] [CrossRef]

- Behar, O.; Kellaf, A.; Mohamedi, K.; Belhamel, M. Instantaneous performance of the first integrated solar combined cycle system in algeria. Energy Procedia 2011, 6, 185–193. [Google Scholar] [CrossRef]

- Wang, S.; Fu, Z.; Zhang, G.; Zhang, T. Advanced thermodynamic analysis applied to an integrated solar combined cycle system. Energies 2018, 11, 1574. [Google Scholar] [CrossRef]

- Brakmann, G.; Mohammad, F.A.; Dolejsi, M.; Wiemann, M. Construction of the ISCC Kuraymat. In Proceedings of the International SolarPACES Conference, Berlin, Germany, 15–18 September 2009; pp. 1–8. [Google Scholar]

- SOLUTIA. Data Sheet. p. 7. Available online: http://iapws.ru/MCS/Worksheets/HEDH/.%5C..%5C..%5C..%5CTTHB%5CHEDH%5CHTF-62.PDF (accessed on 17 January 2008).

- Eastman Selection Guide High-Performance Fluids for Precise Temperature Control 10. Available online: http://www.synthec.com.pe/media_synthec/uploads/pdf_brochures/therminol_selection_guide.pdf (accessed on 14 May 2020).

- Anderson, I.; Craig, A.D.; Kamal, J.A.; Veevers-Carter, P.; Govindarajalu, C.; Hassan, F. Report No: ICR2173 Implementation Completion and Results Report on a Grant In The Amount of US$ 49.80 Million to the Arab Republic of Egypt for the Kureimat Solar Thermal Hybrid Project. 2012. Available online: http://documents1.worldbank.org/curated/en/739501468021865667/pdf/ICR21730P050560C0disclosed050100120.pdf (accessed on 10 April 2012).

- Kotas, T.J. The Exergy Method of Thermal Plant Analysis, 1st ed.; Anchor Brendon Ltd, Tiptree, Essex: London, UK, 1985; ISBN 0408013508. [Google Scholar]

- Zhu, G.; Neises, T.; Turchi, C.; Bedilion, R. Thermodynamic evaluation of solar integration into a natural gas combined cycle power plant. Renew. Energy 2015, 74, 815–824. [Google Scholar] [CrossRef]

- Elmohlawy, A.E.; Ochkov, V.F.; Kazandzhan, B.I. Thermal performance analysis of a concentrated solar power system (CSP) integrated with natural gas combined cycle (NGCC) power plant. Case Stud. Therm. Eng. 2019, 14, 100458. [Google Scholar] [CrossRef]

- Rovira, A.; Abbas, R.; Sánchez, C.; Muñoz, M. Proposal and analysis of an integrated solar combined cycle with partial recuperation. Energy 2020, 198, 117379. [Google Scholar] [CrossRef]

- Temraz, A.; Rashad, A.; Alweteedy, A.; Elshazly, K. Seasonal performance evaluation of ISCCS solar field in Kureimat, Egypt. In Proceedings of the 18th International Conference on Applied Mechanics and Mechanical Engineering (AMME18), At Military Technical College Kobry El-Kobbah, Cairo, Egypt, 3–5 April 2017; pp. 91–98. [Google Scholar]

- Padilla, R.V.; Fontalvo, A.; Demirkaya, G.; Martinez, A.; Quiroga, A.G. Exergy analysis of parabolic trough solar receiver. Appl. Therm. Eng. 2014, 67, 579–586. [Google Scholar] [CrossRef]

- Dunbar, W.R.; Lior, N. Sources of combustion irreversibility. Combust. Sci. Tech. 1994, 103, 41–61. [Google Scholar] [CrossRef]

- Athari, H.; Soltani, S.; Rosen, M.A.; Seyed Mahmoudi, S.M.; Morosuk, T. Comparative exergoeconomic analyses of gas turbine steam injection cycles with and without fogging inlet cooling. Sustainability 2015, 7, 12236–12257. [Google Scholar] [CrossRef]

- Anheden, M. Analysis of Gas Turbine Systems for Sustainable Energy Conversion; Royal Institute of Technology: Stockholm, Switzerland, 2000. [Google Scholar]

| Solar Field Operation Parameter | Unit | Value |

|---|---|---|

| Solar Field Total Aperture Area | m2 | 130,800 |

| Number of Collectors | N° | 160 |

| Number of Collector Loops | N° | 40 |

| Design Irradiation | W/m2 | 700 |

| Maximum Solar Field Thermal Power Output | MW | 61 |

| Output Temperature of the HTF | °C | 393 |

| Input Temperature of the HTF | °C | 293 |

| Component | Exergy Destruction | Second Law Efficiency |

|---|---|---|

| Pumps | ||

| Heaters | ||

| Turbine | ||

| Condenser | ||

| Cycle |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Temraz, A.; Rashad, A.; Elweteedy, A.; Alobaid, F.; Epple, B. Energy and Exergy Analyses of an Existing Solar-Assisted Combined Cycle Power Plant. Appl. Sci. 2020, 10, 4980. https://doi.org/10.3390/app10144980

Temraz A, Rashad A, Elweteedy A, Alobaid F, Epple B. Energy and Exergy Analyses of an Existing Solar-Assisted Combined Cycle Power Plant. Applied Sciences. 2020; 10(14):4980. https://doi.org/10.3390/app10144980

Chicago/Turabian StyleTemraz, Ayman, Ahmed Rashad, Ahmed Elweteedy, Falah Alobaid, and Bernd Epple. 2020. "Energy and Exergy Analyses of an Existing Solar-Assisted Combined Cycle Power Plant" Applied Sciences 10, no. 14: 4980. https://doi.org/10.3390/app10144980

APA StyleTemraz, A., Rashad, A., Elweteedy, A., Alobaid, F., & Epple, B. (2020). Energy and Exergy Analyses of an Existing Solar-Assisted Combined Cycle Power Plant. Applied Sciences, 10(14), 4980. https://doi.org/10.3390/app10144980