1. Introduction

The increasing demand for the use of electrical energy, taking place in the recent years, has led to serious concerns about sustainability and the related environmental issues. Consequently, a great attention is being given to the production of electrical energy using renewable energy resources such as photovoltaic (PV) generators and wind turbines due to their abundance and almost zero environmental impacts [

1]. Therefore, distributed renewable generation of electricity both in small-scale and large-scale power systems is gaining much interest in the recent years. In particular, PV energy has been wide spread during the last ten years due to the reduction in the cost of PV modules, increase of their efficiency and easy maintenance [

2,

3]. Although the basic PV system principles and elements remain the same, three main types of of PV systems can be distinguished: stand-alone, grid-connected, and hybrid. Grid-connected PV systems account for more than 99% of the PV-installed capacity compared to stand-alone systems [

4]. Grid connection of PV systems requires a highly efficient inverter which is considered the main element in PV installations.

Grid-connected PV systems can be built by using either two-stage or single-stage approaches. In the two-stage approach an intermediate DC–DC power stage is inserted between the PV module and the DC–AC grid-tied inverter [

5,

6,

7]. This intermediate stage is responsible for decoupling the PV system operating point from the PV inverter grid control by enabling a suitable average voltage at the inverter DC side. In two-stage grid-connected PV systems, each stage has its independent task and the control design is relatively simple for each stage. The single-stage grid-connected PV system consists of a PV generator, a DC-link capacitor and DC–AC inverter used both to extract the maximum power from the PV generator and to inject a sinusoidal current into the grid with near unity power factor [

8,

9].

In conventional PV systems, a single inverter, called a central inverter, is connected with several PV panels and if a partial shading takes place, the efficiency of the entire PV field is degraded. This main disadvantage of central inverters is overcome by using microinverters that are suitable for small-scale residential uses where each PV module is connected to an inverter separately forming an AC module with its own Maximum Power Point Tracking MPPT control. Therefore, the total harvested power increases under a partial shadowing condition since the power of each PV panel is controlled independently and separately from the others. Moreover, single-stage microinverters are connected to the AC side directly, hence eliminating the DC cable losses and therefore improving further the system efficiency.

Voltage step-down DC–AC inverters based on H-bridge topology are conventionally used to connect a PV system to the grid generating a sinusoidal output voltage for supplying an AC load. These kinds of inverters are conventionally preferred because they have inherent control-to-output linearity in large-signal sense. Nevertheless, in these kinds of inverters, the maximum output voltage at the AC side must be always smaller than the DC voltage. Therefore, in single-stage cases based on voltage source H-bridge topology, many strings of PV panels are connected in series to increase the output voltage [

10].

The efficiency of the two-stage system is negatively affected by using increased component count and switching devices. Moreover, the size and the cost are higher compared to single-stage grid-connected PV systems. The low reliability is another shortcoming of the two-stage approach. To reduce the overall cost and complexity, single-stage structures can be used.

Single-stage grid-connected DC–AC conversion systems with boosting voltage capability has recently attracted the attention of many researchers. Single-stage structures of microinverters not only perform DC–AC conversion but also perform voltage boosting. Moreover, differential inverter topologies seem to prevail in price and size due to the utilization of small passive elements of DC–DC converters hence improving the efficiency [

11].

Some inverter topologies with voltage boosting capability such as the Z-source inverter [

12] and the quasi-Z-source inverters [

13,

14] have been also developed. Another topology with voltage boosting capability is the DC–AC differential boost inverter that has been presented in [

15]. This topology was obtained by connecting the load differentially across two identical DC–DC boost converters sharing the same input. The same concept can be applied to any DC–DC converter to form a differential inverter. A study of boost, buck, buck-boost and Ćuk differential inverters has been presented in [

16]. The differential boost inverter has been used for power processing stage fuel-cell energy system [

17,

18]. It has been also used for high quality sine wave generation with a high oscillation frequency [

19] where a dynamic modulator has been adopted to control the capacitor voltage of the boost inverter.

Since its introduction in [

15], many control strategies have been applied to the differential boost inverter. The nonlinear control-to-output behavior in large-signal dynamic sense and the non-minimum phase nature in the small-signal sense of the boost inverter make the direct tracking of the sinusoidal voltage reference in this kind of topologies a difficult task [

20]. Sliding mode control was first applied in which a switching surface composed by weighted errors in the output capacitor voltages and the inductor currents is used [

15]. The inverter model with a constant voltage source and a resistive load system and its controller design has been addressed in [

21] using a sliding mode control of the inner current loop and a PI controller for the AC output voltage. Adaptive control for the boost inverter has been designed in [

22] where by using energy shaping methodology with a suitable Hamiltonian function an autonomous oscillator is generated without an external reference signal hence being the approach suitable for resistive loads.

Other Pulse Width Modulation (PWM) techniques, mostly based on two-loop linear control scheme, have been used with a slow outer loop for the capacitor voltages and a fast inner loop for inductor currents. Two separate control loops are usually used for each converter. Examples of this control strategy can be found in [

17,

20]. Most of the previous studies reported on the differential boost inverters have been tested by a resistive load. Grid-connected boost inverter was also considered in [

23,

24] for integrating energy storage devices such as a battery, fuel cell or supercapacitor to a single-phase AC grid. A load-adaptation mechanism for the boost inverter has been carried out to design a state observer for some of the converter variables in order to estimate the load [

22] leading to a fast system response and successful adaptation of the load parameter as confirmed by numerical simulations in the same paper. A current control strategy with zero steady-state tracking error has been applied to a differential grid-connected boost inverter supplied from an ideal input voltage source [

25]. In that work, based on the internal model principle, Proportional-Resonant (PR) controllers instead of Proportional-Integral (PI) controllers were used to achieve zero phase and amplitude tracking error demonstrating experimentally that the proposed control meet grid-connection harmonics standards. The grid-connection of the differential boost inverter and the use of PR controller for the grid current loop was also addressed in [

26] where a sliding mode control for the inner inductor current loop and a PI controller was used.

In most of the published works, a decoupling between the two branches of the differential inverter is performed with the aim to simplify the control design. Using such an approach, the inverter is not taken as a whole system but two identical decoupled converters and the output of each branch is controlled individually and separately from the other branch. The control of the inverter is performed by controlling each DC–DC boost converter separately. In this approach, each boost converter is controlled to generate a DC biased sinusoidal voltage with a phase shift of 180

such that the difference between both output voltages is an AC sine wave signal that is used to supply the AC load. The DC–DC boost converter cannot generate a voltage lower than its DC input voltage, the DC component of the voltage generated by each DC–DC boost converter must be larger than the DC input voltage. For that, two controllers for each loop and two modulators are used for the entire system. Hence increasing the number of components in the control system. Moreover, the two branches of the inverter are coupled both at the input and the output sides. In particular, in PV application, the input side is no more a constant voltage but a state variable that is coupled to both branches of the inverter. Model predictive control was applied to the differential boost inverter in [

27] used for PV grid-connected system applications where it was demonstrated by numerical simulations that a simple control comparable to classical control techniques can be used.

Most of the previous works have converted the problem of controlling the boost inverter to the problem of controlling two identical DC–DC boost converters. An exception where the inverter was controlled as an individual system is [

28] where a strategy for generating a sinusoidal voltage at the output of the inverter with resistive load directly from the difference between the capacitor voltages of both converters. The approach was finally implemented by a fixed frequency PWM approach based on a sliding mode control theory leading to a robust system under load and input voltage variations with simple implementation. One advantage of controlling the system as whole is a decrease in the number of required sensors and simplicity of the control scheme to be implemented. Sliding mode control has many advantages for nonlinear systems. Nevertheless, the main drawback of the sliding mode control in power electronics field is that it is ultimately implemented by using hysteretic comparators leading to variable switching frequency.

PR controllers have been used to overcome the issues related to the use of PI control in single-phase inverters [

11,

29]. Nevertheless, since the AC signals are much slower than the switching frequency, conventional controllers can still be used as will be shown in this paper. However, PI controllers can lead to steady-state errors and phase shifts when used to control sinusoidal signals. The bandwidth must be enough large but high bandwidth could lead to either instability due to the phase lag introduced by the PI controller. Therefore, a phase boosting is needed near the desired crossover frequency and this can be accomplished by using type III controllers widely adopted in the control of DC–DC converters [

30]. In most of the published works, resistive passive loads and constant input voltage were considered. Except [

21], real nonlinear real PV sources and grid connection have not been fully addressed for the differential boost inverter due particularly to its complexity when it is used in PV systems such as in grid-connected microinverter applications where the cost and the simplicity are to be taken into account.

When the system is supplied by a constant input voltage and loaded by a resistive load, its design can be roughly divided in the design of two identical boost converters resulting eventually to order reduction of the overall dynamics. In the case of a PV-fed grid connected inverter and due to the coupling between the two converters at the DC side by dynamics of the PV generator voltage and at the AC side by the dynamics of the grid current, such an approach cannot be applied and the differential inverter must be treated a whole system.

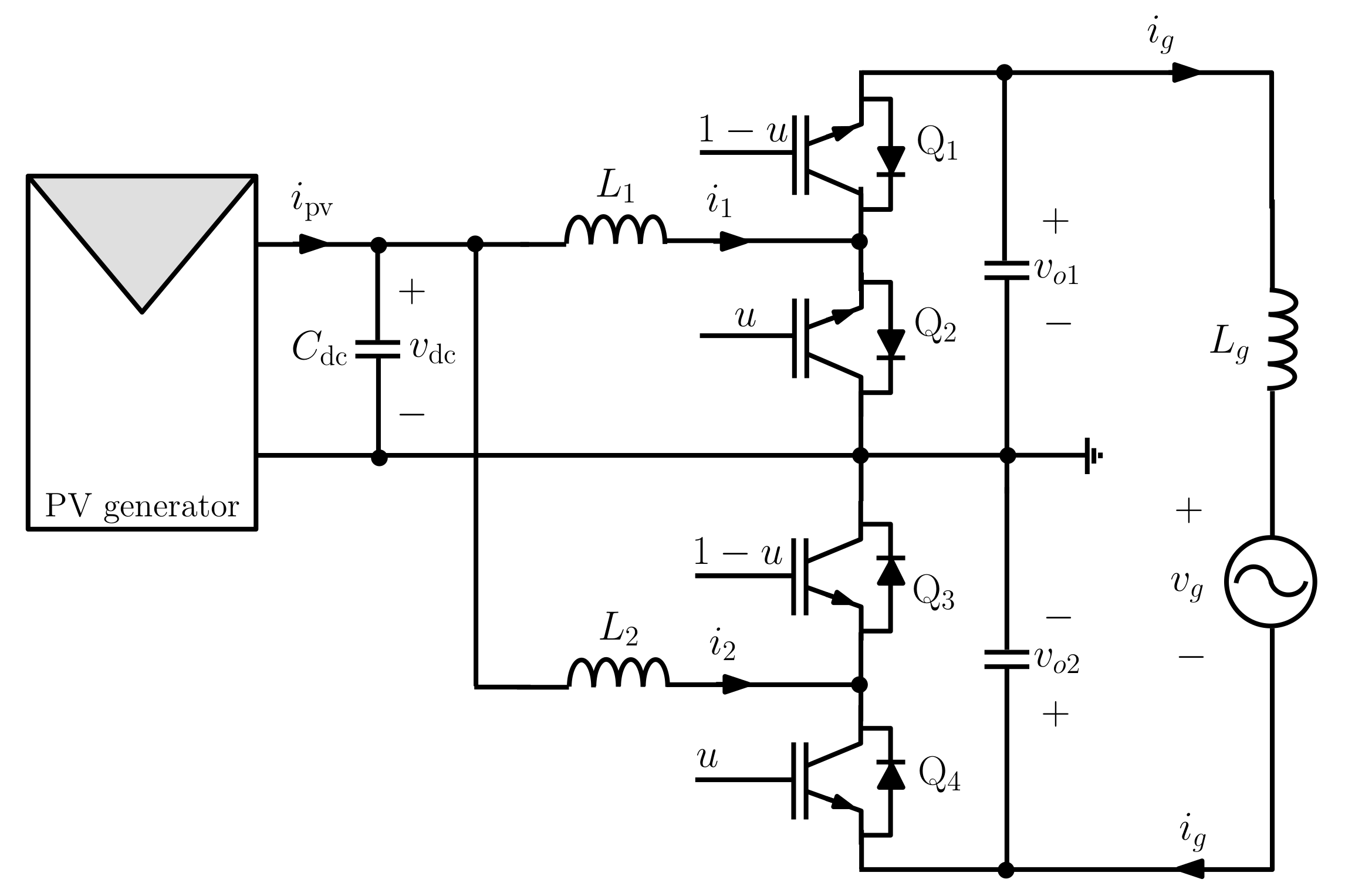

The main contributions of this work are the derivation of a control-oriented model and the design of a three control loop strategy for a PV-fed grid-tied boost inverter as whole system without any decoupling between the two inverters hence dealing with its full-order model. The strategy is based on peak current mode control for the fast inner loop, a type III compensator for the grid current loop and a PI regulator with a pre-filter for the DC PV voltage loop. The main concern is the design of the three control loops for the inverter supplied from a series strings of PV panels and connected to the AC grid performing both Maximum Power Point Tracking (MPPT) at the DC side and Power Factor Correction (PFC) control at the AC side. For that, the study starts with a suitable mathematical modeling of the inverter. The design of its different control loops is carried out using simple approaches widely adopted for DC–DC converters while resulting in excellent system performances. At first, the state-space time-domain averaged model of the inverter is derived and the small signal frequency domain model is obtained using a quasi-static approximation in which the inverter is treated as a DC–DC converter with a slowly varying output voltage. Then, the controller is designed using a three-loop control strategy in which the boost inductor currents loop is used for suitable compensation by means of a single driving signal and its logic negation.

The rest of this paper is organized as follows.

Section 2 presents the system description consisting of a grid-connected PV system based on a differential boost inverter. Details about the operating principle of the system are provided in the same section. The mathematical model and the controller design are presented in

Section 3. AC steady-state analysis is addressed in

Section 4. Numerical simulations for the PV system grid-connected are presented in

Section 5 validating the theoretical predictions. Conclusions of this work are summarized in the last section.

4. AC Steady-State Analysis

Let

be the DC power generated by the PV generator and

the instantaneous power injected to the grid by the inverter. By neglecting the losses, one has

The instantaneous power of the capacitor at the output of the PV generator is the difference between the produced power

P and the one absorbed by the inverter. Therefore, it can be expressed as follows

This capacitor power oscillates at the double of the grid frequency. It is positive during one half period and therefore the capacitor is charged and it is negative during the other half period and therefore the capacitor is discharged. During the charging period, the energy supplied to the capacitor when

is

In steady state, this energy is equal to the energy stored in the capacitor when its voltage changes from its minimum value

to its maximum value

where

is the peak-to-peak AC ripple of the PV capacitor voltage in steady-state operation. Using (

34) and (

35),

can be expressed as follows

This AC PV voltage ripple of the averaged variable

should not be confused by the switching ripple of the state variable

which is much smaller and can be neglected. Therefore, in steady-state operation, the time varying averaged input PV voltage

is composed by a DC component

imposed by the MPPT controller and an AC ripple that can be approximated by

given in (

36) and finally

can be accurately described by the following expression in steady-state operation

For a well designed inverter, the amplitude of the AC component of the PV voltage must be selected much smaller than its DC component, i.e,

. Let

be the maximum value of the allowed ripple in the DC PV voltage, then the value of capacitor must be selected such that

These theoretical predictions will be validated below by using the full-order switched model of the differential boost inverter implemented in PSIM software.

5. Numerical Simulation

The values of the control parameters are depicted in

Table 2. First, the different controller design is performed according to the theoretical analysis provided in the previous section. In particular, using the bode plot shown in

Figure 9, a crossover frequency

kHz at

was selected with a corresponding phase margin

above

within the entire range of the operating duty cycle. For achieving these values, the gain, the poles and zeros of the type-III controller are selected at the values depicted in

Table 2. The value of the amplitude of the ramp compensator is selected in such a way to avoid subharmonic oscillation within the entire range of the considered duty cycle values.

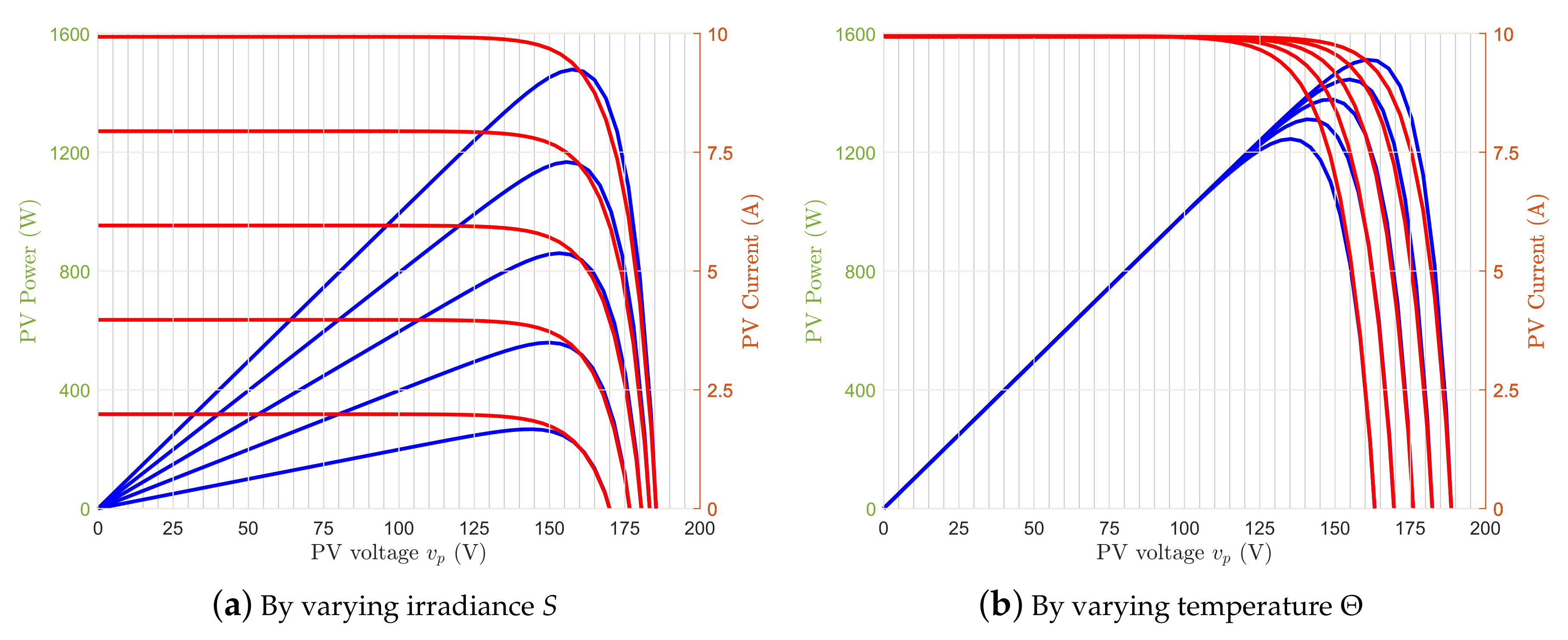

The used PV generator consists of a string of four series-connected modules each one with a maximum power point voltage

V, a maximum power current

A and a maximum power 350 (4 × 350 W = 1.4 kW) at standard test conditions. The manufacturer specifications for one single module are detailed in [

32] and summarized in

Table 3.

A PV generator from the Renewable Energies library of PSIM

software was used as an input to the inverter. The PV generator block has two inputs one corresponds to irradiance

S in W/m

and another to temperature

in

C. The temperature was maintained constant and the irradiance profile was defined by a piecewise linear signal generator which is connected to its corresponding PV generator input. The PV source is connected to a 50 Hz grid via the DC–AC differential boost inverter which converts the 154 V DC link PV voltage to 230 V RMS AC with power factor control. The MPPT was implemented in the inverter by means of a C block model using the P&O algorithm which provides the reference for the PV DC voltage. A PI regulator is used to control the PV voltage to its desired reference value. The design of the PV DC-link voltage controller was performed analytically based on the reduced-order model (

31). Using this expression, the parameters of this controller have been selected to provide a settling time of one grid voltage cycle. The sampling period of the MPPT controller has been chosen to be equal to five times this settling time. The sampling period is

s and the perturbation amplitude applied to

is

V.

According to (

36), with value of the extracted power and the grid frequency and the value of the DC-link capacitance

, the AC-ripple of the PV voltage amplitude is about

of its nominal value 154 V at irradiance

W/m

and temperature

C with a maximum power 1.4 kW.

The inverter control system uses three control loops: a first loop which regulates DC link PV voltage to 154 V, a second loop which regulates the grid current to its desired reference which synchronized to the grid voltage. The reference for the grid current is the output of the PV DC voltage external controller. The output of the grid current controller (a type-III controller) is first limited to an upper bound of about A to avoid inrush current during startup. A ramp compensator is added to the sensed voltage and the result is used as one of the inputs to the comparator. The calculated minimum value needed for avoiding subharmonic oscillation is V. Here, to play it safe, a larger value of V is used. The other input is the grid current reference converted to voltage by multiplying it by the current sensor gain . The output of the comparator is connected to the Reset of a flip-flop and a 50 kHz periodic clock signal is connected to its Set input. The driving signal u for the switches Q and Q and for Q and Q are the outputs Q and of the flip-flop. The inverter control system uses three control loops: a first loop which regulates DC link PV voltage to 154 V, a second loop which regulates the grid current to its desired reference which synchronized to the grid voltage. The reference for the grid current is the output of the PV DC voltage external controller. The output of the grid current controller (a type-III controller) is first limited to an upper bound of about A to avoid inrush current during startup. A ramp compensator with amplitude V is added to the sensed voltage and the result is used as one of the input to the comparator. The calculated minimum value needed for avoiding subharmonic oscillation is V. Here, to pay it safe, a larger value of was used. The other input is the grid current reference is converted to voltage by multiplying it by the current sensor gain . The output of the comparator is connected to the Reset pin of a flip-flop and a 50 kHz periodic clock signal is connected to its Set input. The driving signals u for the switches Q and Q and for Q and Q are the outputs Q and of the flip-flop.

The simulation starts with temperature

C and irradiance

1000 W/m

. The time-domain response of the complete system starting from zero initial conditions is depicted in

Figure 10. From

s to

s, the inverter is operated with constant reference voltage 100 V and the MPPT control is blocked. The irradiance level is started at

W/m

and the corresponding maximum power is 670 W. It can be observed that during this period, the voltage is well regulated to its reference value 100 V and since MPPT control is not used, the extracted power is less than what the PV generator can deliver.

At

s, the MPPT is enabled and the irradiance starts increasing. It can be observed that after a short transient, the DC link PV voltage is regulated at

= 154 V and the extracted power is very close to the maximum power corresponding to the irradiance level profile. At

s, the MPPT is still enabled and the irradiance is maintained at 1000 W/m

. The PV array output power is about 1.4 kW (see

plot on the left panel in

Figure 10) whereas specified maximum power with a 1000 W/m

irradiance is 1.4 kW. Maximum power (1.4 kW) is obtained when the voltage reference provided by the MPPT controller is 154 V.

At s, the irradiance is ramped down from 1000 W/m to 500 W/m and consequently the maximum power decreases. The PV voltage is still regulated and the power extracted by the inverter follows the maximum power delivered by the PV generator during all the time. PV array average voltage is still very close to 154 V in a good agreement with the value expected from PV module specifications. From s to s, sun irradiance is maintained at 500 W/m and MPPT continues to track the maximum power.

On the other hand, under irradiance changes, the DC-link PV voltage , undergoes a very small change and remains very close to the MPP voltage and the PI controller is capable of maintaining the voltage at the desired value after short transient period (0.02 s) due MPPT perturbations. The results clearly demonstrate the capability of the designed system to operate at the MPP regardless of the value of the irradiance and the MPPT control is capable of tracking the MPP when irradiance vary.

Figure 11 shows the steady-state waveforms of the PV voltage and its reference, the extracted power, the power

P from the PV source and its maximum power

, the inductor currents

and

and the capacitor voltages

and

for irradiance level

500

(

) and 1000

(

kW). It can be observed that in the vicinity of the MPP, the reference voltage

dictated by the MPPT controller oscillates according to the values of the MPPT sampling period

s and the perturbation amplitude

V as shown in

Figure 11a,b for the two different values of the sun irradiance. The inductor currents and capacitor voltage are well balanced and are phase shifted by 180

as depicted in

Figure 11c,d for the same values of the sun irradiance level. Moreover, the steady-state averaged values of the capacitor voltages and the inductor current are in a close agreement with the theoretical predictions given in (

8)–(

11) and depicted in

Figure 5. Note also that, the DC PV voltage is regulated to the MPP voltage and that it is practically a sinusoidal signal as predicted by (

37) with DC component equal to

dictated by the MPPT controller during the MPPT sampling period

s and peak-to-peak AC ripple

V for

kW and it is

V for

W in a remarkable agreement with (

36).

Figure 12 shows the steady-state waveforms of the grid current

together with the grid voltage

for irradiance level

(

W) and 1000

(

kW). Observe that grid voltage and current are in phase and have practically the same sinusoidal shape demonstrating a close to unity power factor. Moreover, the steady-state averaged values of the grid current is in a close agreement with the theoretical predictions. Namely, for irradiance level

(

W), the RMS value of the grid current

is about 2.91 A and for

1000

(

kW), the RMS value of

is about 6.1 A. To check the power quality, the THD of the grid current

in steady-state was calculated for both values of the irradiance. Namely, for irradiance level

(

W), the THD value of the grid current

is about 1% and for

1000

(

kW), the THD value of

is about 1.2%. Therefore, it can be observed that the grid current

exhibits a low THD of about

as calculated by PSIM

software for both values of sun irradiance level. The values are comparable to the ones obtained experimentally in [

26] where it was shown that the grid current spectrum comply with the IEEE standard 1547.