Reconfiguration Decision-Making of IoT based Reconfigurable Manufacturing Systems

Abstract

1. Introduction

2. Related Works

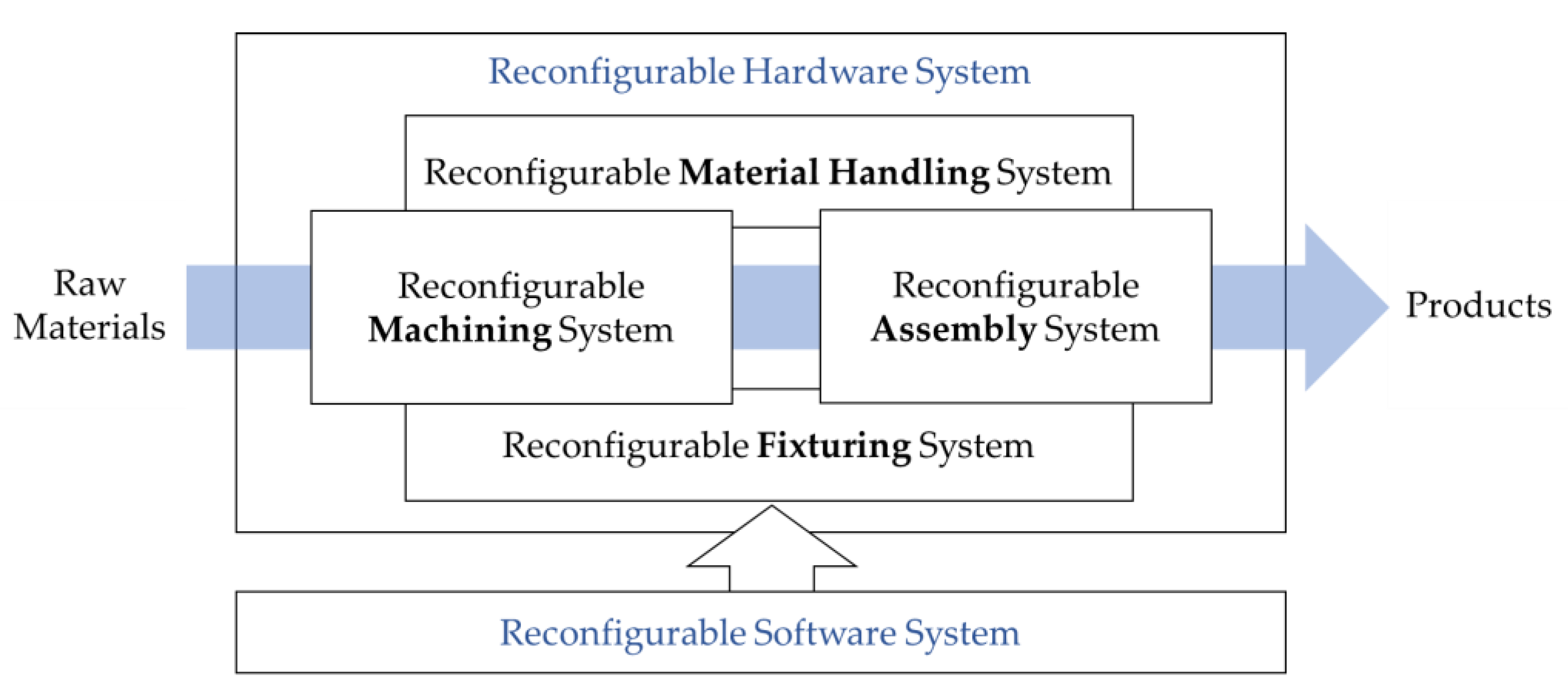

3. Concepts of Reconfigurable Manufacturing Systems (RMSs)

3.1. Definition of Reconfigurable Manufacturing System (RMS)

3.2. Factors in RMS

3.3. Characteristics of RMS

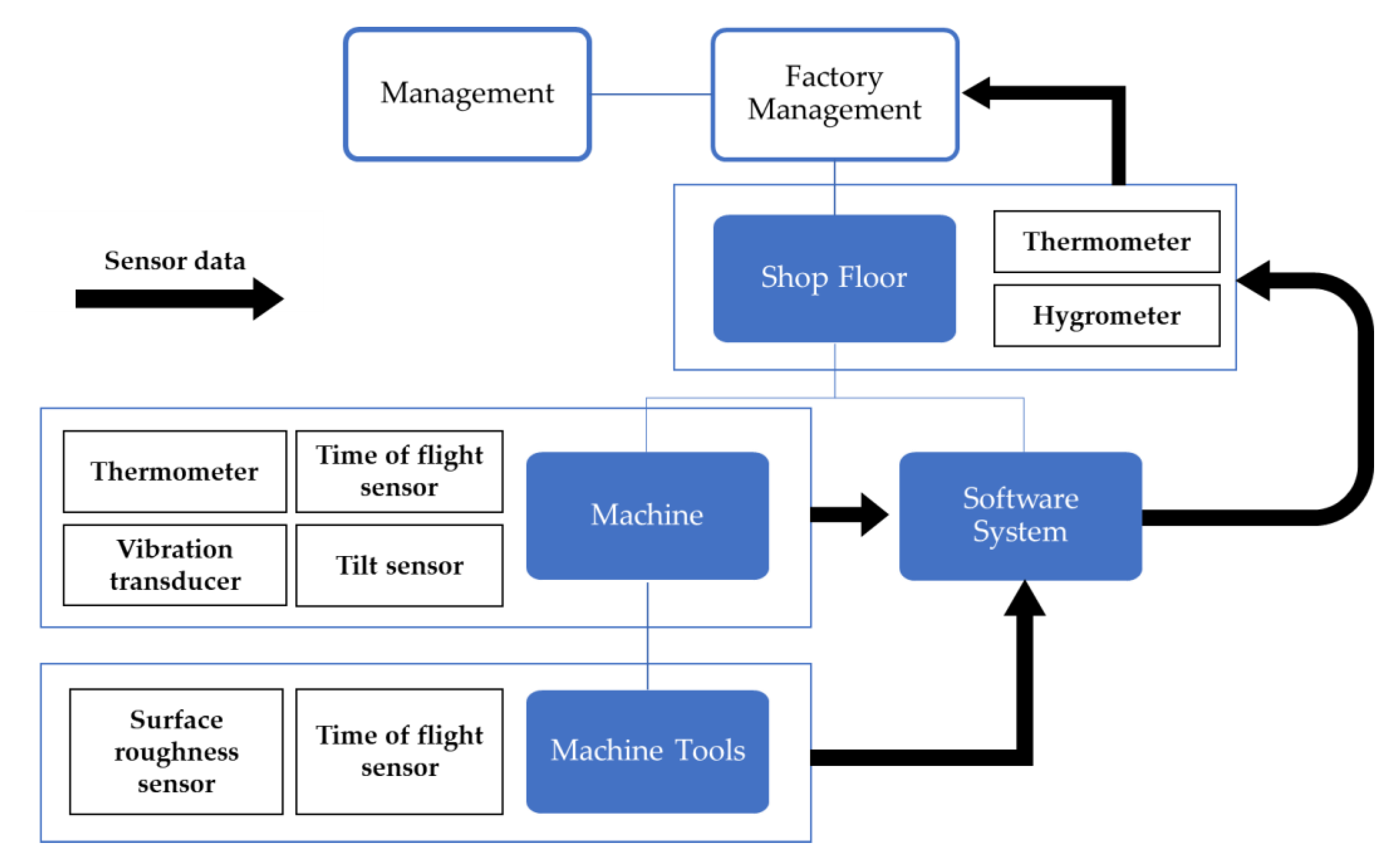

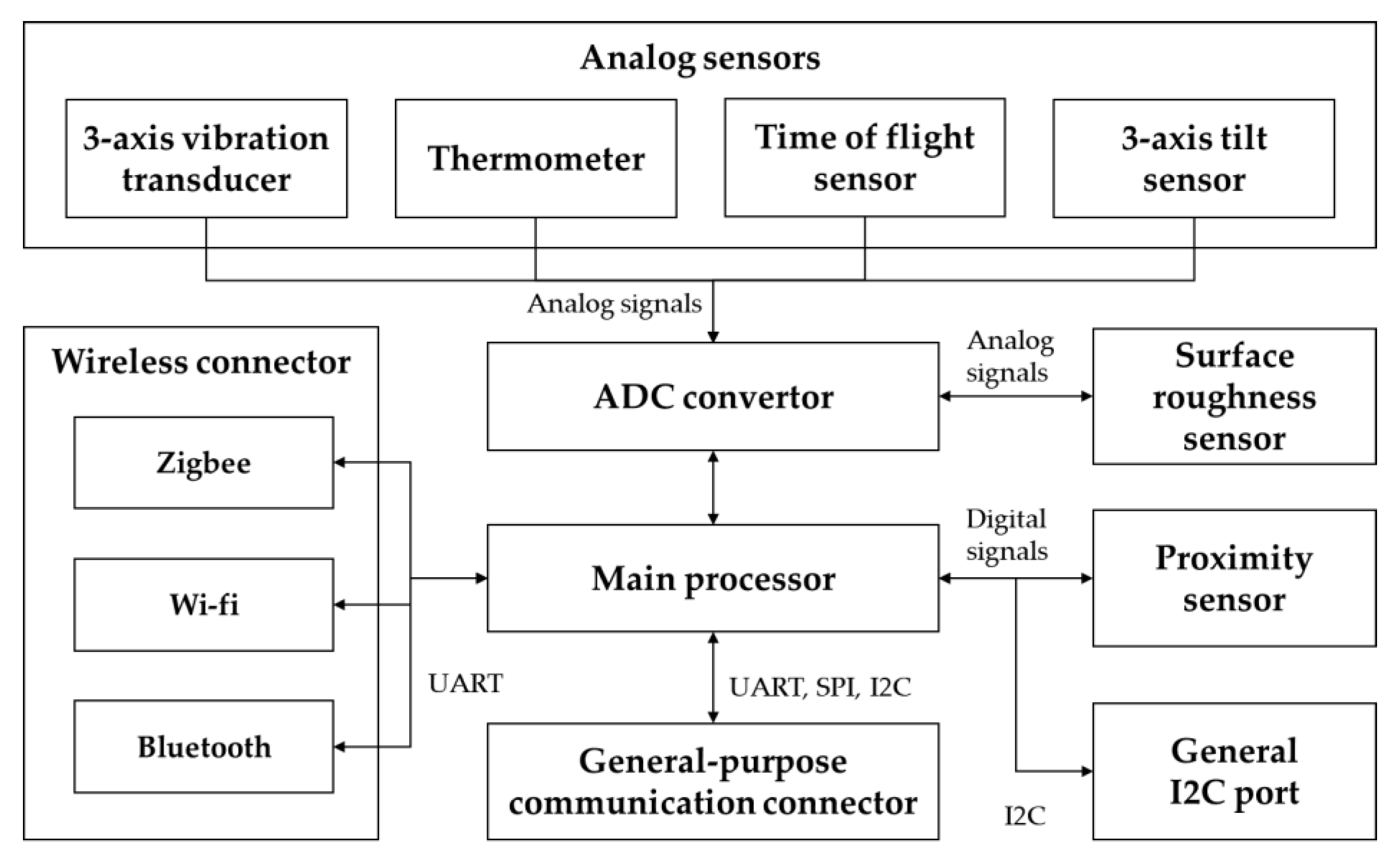

4. Internet of Things (IoT) Based Data Collection System for RMS

4.1. Necessity of Internet of Things (IoT) Application

4.2. Data Acquisition and Flow in RMS

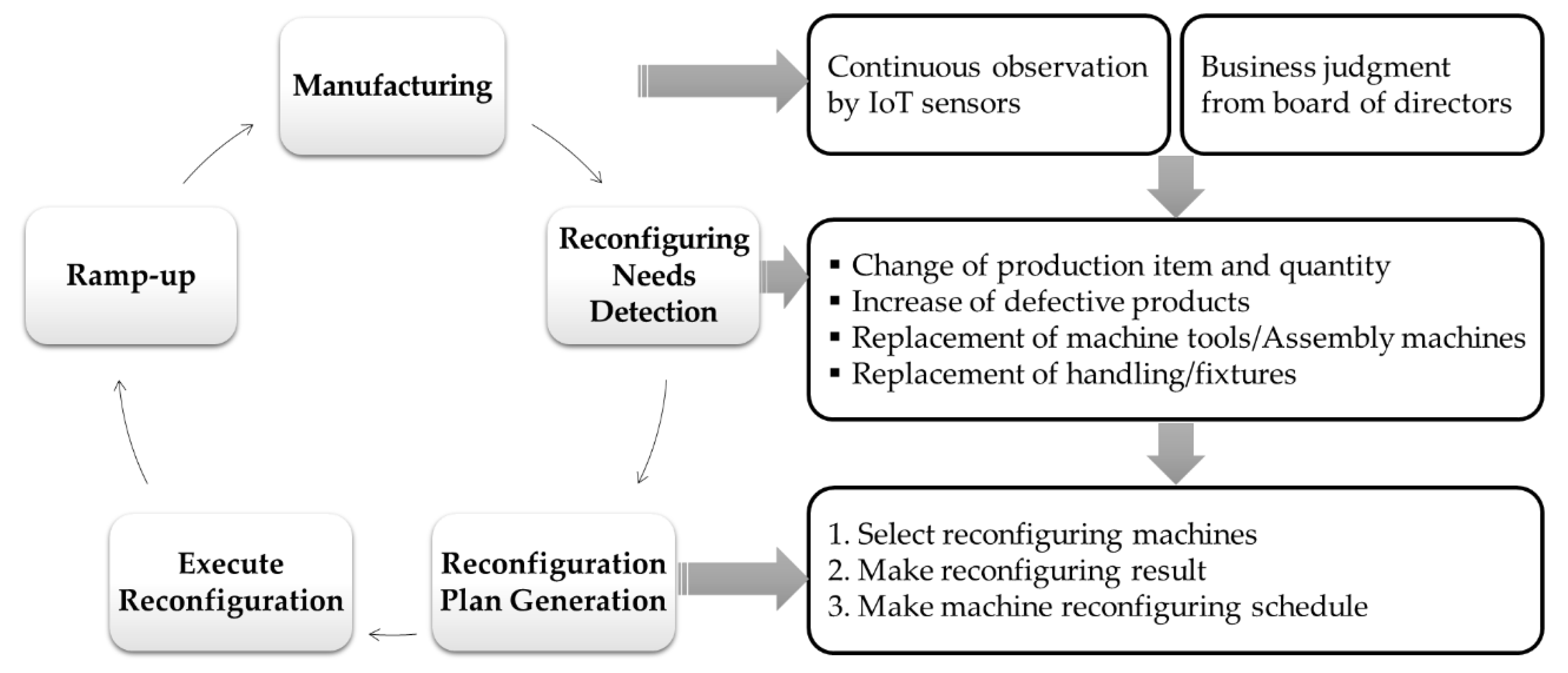

5. Decision-Making System

5.1. Decision-Making Process

5.1.1. Reconfiguration Situations

5.1.2. Decision-Making Factors

5.2. Definition of Reconfiguration Problem

5.3. Algorithm for Reconfiguration Planning

| Algorithm 1: Process of VNS algorithm. |

| 1. Generate neighbor structure Nk(k =1,⋯,kmax) |

| 2. Generate initial solution x |

| 3. k=1 |

| 4. Repeat until k = kmax |

| 4.1. Shaking: Randomly select one of the neighbor structure Nk(x) of solution x to randomly select x’ from Nk(x) |

| 4.2. Local search by VNS |

| 4.2.1. l=1 |

| 4.2.2. Repeat until l = lmax |

| 4.2.2.1. Search best neighbor x’ from Nl(x’) and set as x” |

| 4.2.2.2. if x” is better than x’, replace x’ to x” and set l = 1 |

| 4.2.2.3. if not, set l = 1 + 1 |

| 4.3. Local search: Compare x and x” |

| 4.3.1. if x’’ is better than x, replace x as x” and set k = 1 |

| 4.3.2. if not, set k = k + 1 |

5.3.1. Generation of Initial Solution

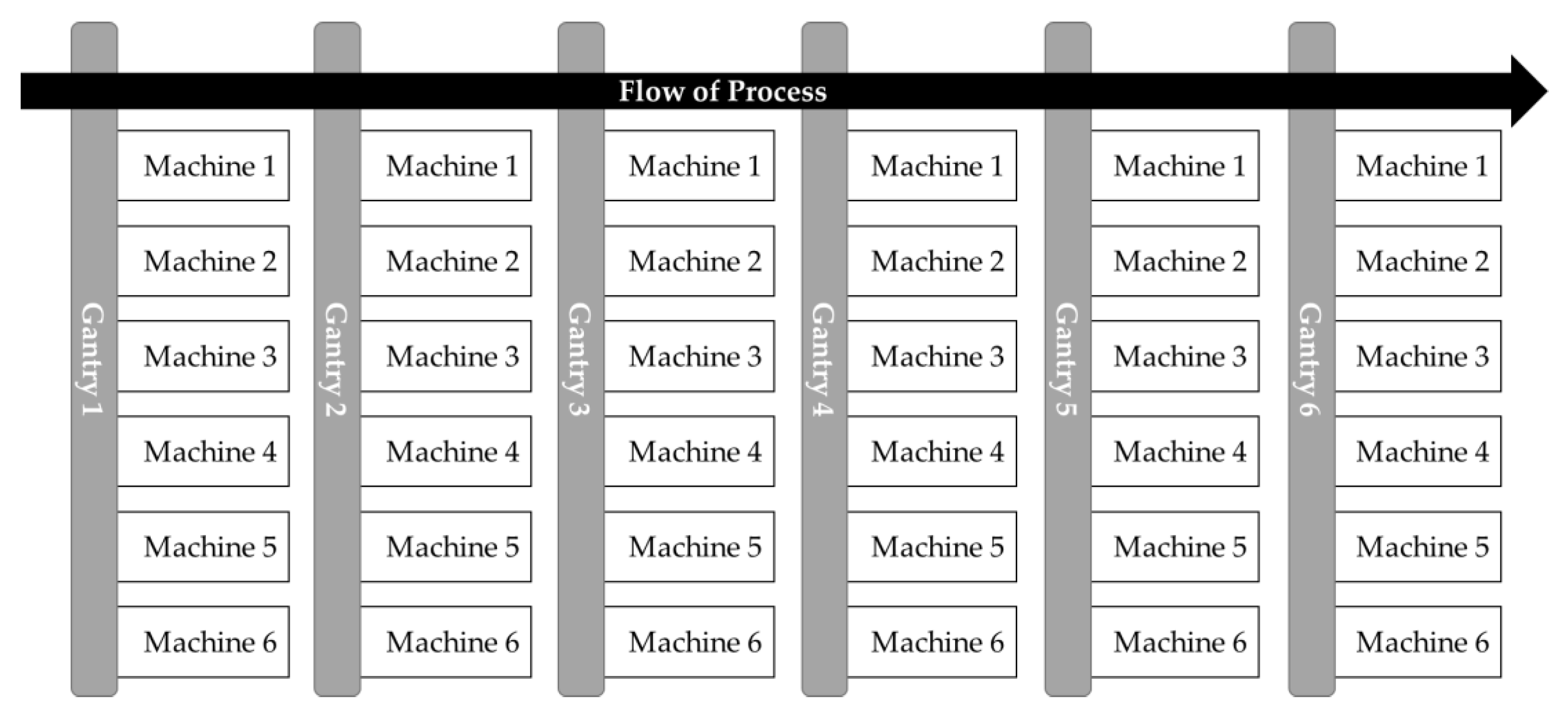

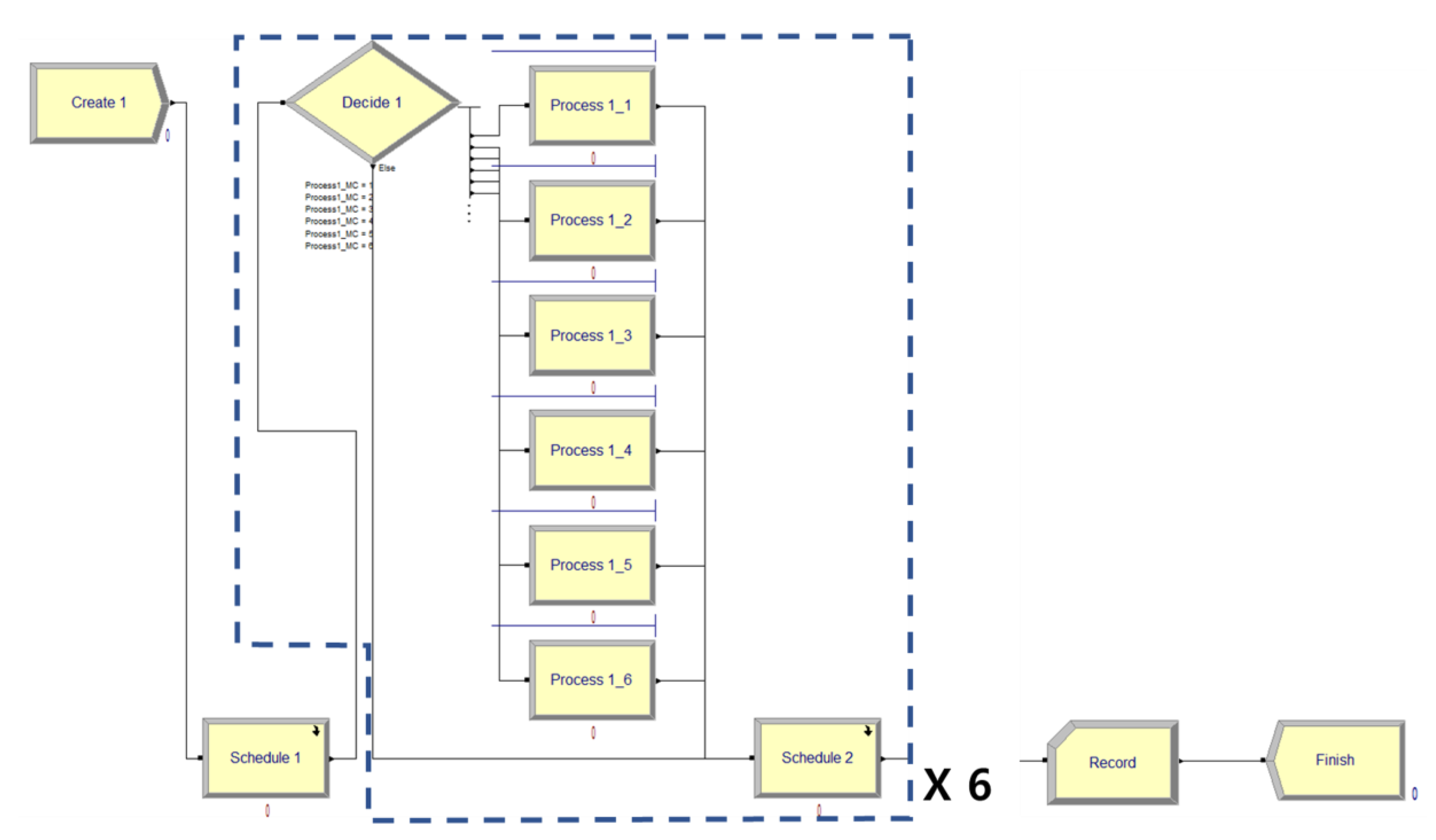

5.3.2. Factory Layout and Neighbor Structure

5.3.3. Evaluation of Solution

6. Experimental Verification

6.1. Experimental Setting

6.2. Result Analysis

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bi, Z.M.; Lang, S.Y.T.; Shen, W.; Wang, L. Reconfigurable manufacturing systems: The state of the art. Int. J. Prod. Res. 2008, 46, 967–992. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; Zhang, L.; Nee, A.Y. Advanced manufacturing systems: Socialization characteristics and trends. J. Intell. Manuf. 2017, 28, 1079–1094. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Egineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Koren, Y.; Gu, X.; Guo, W. Reconfigurable manufacturing systems: Principles, design, and future trends. Front. Mech. Eng. 2018, 13, 121–136. [Google Scholar] [CrossRef]

- Minhas, S.H.; Lehmann, C.; Städter, J.P.; Berger, U. Reconfigurable strategies for manufacturing setups to confront mass customization challenges. In Proceedings of the 21st International Conference on Production Research (ICPR 21), Stuttgart, Germany, 31 July–4 August 2011. [Google Scholar]

- Xia, T.; Xi, L.; Pan, E.; Ni, J. Reconfiguration-oriented opportunistic maintenance policy for reconfigurable manufacturing systems. Reliab. Eng. Syst. Saf. 2017, 166, 87–98. [Google Scholar] [CrossRef]

- Koren, Y.; Wang, W.; Gu, X. Value creation through design for scalability of reconfigurable manufacturing systems. Int. J. Prod. Res. 2017, 55, 1227–1242. [Google Scholar] [CrossRef]

- Kumar, A.; Pattanaik, L.N.; Agrawal, R. Multi-objective Scheduling Model for Reconfigurable Assembly Systems. In Innovations in Soft Computing and Information Technology; Springer: Singapore, 2019; pp. 209–217. [Google Scholar]

- Huang, S.; Wang, G.; Shang, X.; Yan, Y. Reconfiguration point decision method based on dynamic complexity for reconfigurable manufacturing system (RMS). J. Intell. Manuf. 2018, 29, 1031–1043. [Google Scholar] [CrossRef]

- Hsieh, F.S.; Lin, J.B. A dynamic scheme for scheduling complex tasks in manufacturing systems based on collaboration of agents. Appl. Intell. 2014, 41, 366–382. [Google Scholar] [CrossRef]

- Hsieh, F.S. A Meta-Heuristic Approach for Dynamic Process Planning in Reconfigurable Manufacturing Systems. In Proceedings of the 2017 18th International Conference on Parallel and Distributed Computing, Applications and Technologies (PDCAT), Taipei, Taiwan, 18–20 December 2017; pp. 164–169. [Google Scholar]

- Tang, H.; Li, D.; Wan, J.; Imran, M.; Shoaib, M. A Reconfigurable Method for Intelligent Manufacturing Based on Industrial Cloud and Edge Intelligence. IEEE Internet Things J. 2019, 7, 4248–4259. [Google Scholar] [CrossRef]

- Han, S.M.; Seo, J.W.; Park, J.W.; Lee, J.G.; Kang, G.C.; Lee, S.H.; Moon, J.S. Pallet-fixture Allocation in Reconfigurable Manufacturing Cells: An Integrative Approach. J. KSPE 2012, 29, 357–366. [Google Scholar] [CrossRef]

- Kurniadi, K.A.; Ryu, K. Development of IoT-based reconfigurable manufacturing system to solve reconfiguration planning problem. Procedia Manuf. 2017, 11, 965–972. [Google Scholar] [CrossRef]

- Bi, Z.; Da Xu, L.; Wang, C. Internet of things for enterprise systems of modern manufacturing. IEEE Trans. Ind. Inform. 2014, 18, 1537–1546. [Google Scholar]

- Scholz, S.; Mueller, T.; Plasch, M.; Limbeck, H.; Adamietz, R.; Iseringhausen, T.; Kimmig, D.; Dickerhof, M.; Woegerer, C. A modular flexible scalable and reconfigurable system for manufacturing of microsystems based on additive manufacturing and e-printing. Robot. Comput. Integr. Manuf. 2016, 40, 14–23. [Google Scholar] [CrossRef]

- Mourtzis, D.; Milas, N.; Vlachou, A. An internet of things-based monitoring system for shop-floor control. J. Comput. Inf. Sci. Eng. 2018, 18, 1–10. [Google Scholar] [CrossRef]

- Mourtzis, D.; Milas, N.; Athinaios, N. Towards Machine Shop 4.0: A General Machine Model for CNC machine-tools through OPC-UA. Procedia CIRP 2018, 78, 301–306. [Google Scholar] [CrossRef]

- Pellicciari, M.; Leali, F.; Andrisano, A.O.; Pini, F. Enhancing changeability of automotive Hybrid Reconfigurable Systems in digital environments. IJIDeM 2012, 6, 251–263. [Google Scholar] [CrossRef]

- Ferreira, P.; Reyes, V.; Mestre, J. A web-based integration procedure for the development of reconfigurable robotic work-cells. IJARS 2013, 10, 295. [Google Scholar] [CrossRef]

- Shin, H.J.; Cho, K.W.; Oh, C.H. SVM-based dynamic reconfiguration CPS for manufacturing system in Industry 4.0. Wirel. Commun. Mob. Comput. 2018, 2018, 5795037. [Google Scholar] [CrossRef]

- Koren, Y.; Heisel, U.; Jovane, F.; Moriwaki, T.; Pritschow, G.; Ulsoy, G.; Van Brussel, H. Reconfigurable manufacturing systems. CIRP Ann. 1999, 48, 527–540. [Google Scholar] [CrossRef]

- Sastoque Pinilla, L.; Llorente Rodríguez, R.; Toledo Gandarias, N.; López de Lacalle, L.N.; Ramezani Farokhad, M. TRLs 5–7 advanced manufacturing centres, practical model to boost technology transfer in manufacturing. Sustainability 2019, 11, 4890. [Google Scholar] [CrossRef]

- Andersen, A.; Nielsen, K.; Brunoe, T.D. Prerequisites and barriers for the development of reconfigurable manufacturing systems for high speed ramp-up. Procedia CIRP 2016, 51, 7–12. [Google Scholar] [CrossRef]

| Category | Sensor | Collecting Item |

|---|---|---|

| Machine status | Thermometer | Internal temperature of a machine |

| 3-Axis vibration transducer | Vibration during machining | |

| Time of flight sensor | Assembly status of machining tools | |

| 3-Axis tilt sensor | Tilted angle of an installed machine | |

| Machine Tools and Parts status | Surface roughness sensor | Surface wear of tools |

| Cracks of tools | ||

| Time of flight sensor | Expansion of tools or parts | |

| Whether tools and parts are in place | ||

| Shop floor | Thermometer | Temperature of factory |

| Hygrometer | Humidity of factory |

| Category | Situation | |

|---|---|---|

| External | Change of product mix | Introduction of new products changes in product combinations |

| Introduction of additional processes | Introduction of additional processes due to environmental regulation or additional features | |

| Internal | Lack of productivity | Reconfiguration for enhancing the productivity of a production line |

| Breakdown | Replacement due to sudden failure of the machine and reconfiguration | |

| Preventive maintenance | Preventive maintenance and reconfiguration according to tool life and internal condition | |

| Category | Detail | |

|---|---|---|

| Machine | Index of line (1~|L|) | |

| Index of room for machines in each line (1~R) | ||

| Index of machine type (1~I) | ||

| Initial type of rth machine in lth line | ||

| Cost | Installation cost of machine with machine type i in lth line (without IoT) | |

| Penalty of an unfulfilled demand | ||

| Installation time of machine with machine type i in lth line | ||

| Demands | Index of demand type (1~|T|) | |

| Index of demand with type t before change (1~) | ||

| Due of demand dt with type t | ||

| Whether demand type t is available in machine type i in lth line (0 or 1) | ||

| Process time of demand type t in machine type i in lth line. | ||

| Whether demand dt with demand type t is canceled (0-cancelled or 1-not cancelled) | ||

| Whether change of demand dt with demand type t is recognized in planning type (0-not recognized or 1-recognized) | ||

| Time when the demand change is recognized | ||

| Decision variables | Changed type of rth machine in lth line (Integer) | |

| Whether machine type of rth machine in lth line is changed (0-not changed or 1-changed) | ||

| Reconfiguration time of rth machine in lth line (Integer) | ||

| Starting time of demand dt with type t in rth machine in lth line (Integer) | ||

| Whether demand dt with type t is processed by rth machine lth line before reconfiguration (0-not processed or 1-processed) | ||

| Whether demand dt with type t is processed by rth machine lth line after reconfiguration (0-not processed or 1-processed) | ||

| Whether due of demand dt with type t is satisfied (0-not satisfied or 1-satisfied) | ||

| Category | Item | Setting |

|---|---|---|

| Characteristics of factory | Length of the whole line | 6 |

| Number of installable machines per process | 5 | |

| Type of machines (per each process) | 3 | |

| Reconfiguration cost | 5000 | |

| Penalty of an unfulfilled demand | 1000 | |

| IoT Senor | Delay in recognizing reconfiguration situation when IoT sensor is not used | 5 days |

| Delay in finishing reconfiguration when IoT sensor is not used | 5 days | |

| Installation cost of IoT sensors | 1000 |

| Category | Item | Setting |

|---|---|---|

| Processing Time | Minimum process time per process | 1 day |

| Maximum process time per process | 7 days | |

| Process | Number of production processes | 3 processes/6 processes |

| Number of types per each process | 3 types per process | |

| Due | Minimum due | Total process time + 1 day |

| Maximum due | Total process time + 20 days | |

| Quantity | Total number of demands | 50 |

| Type of demands | 10 |

| No. | Situation | Prediction | Remarks | |

|---|---|---|---|---|

| 1 | Change of production ratio | Unpredicted ratio changes one week after starting | Unpredictable | |

| 2 | Introduction of additional processes | Insert additional processes one week after starting | Predictable | |

| 3 | Breakdown | Sudden breakdown of the machine and subsequent reconfiguration | Unpredictable | Delay in recognition when IoT is not used |

| 4 | Preventive maintenance | Preventive maintenance and reconfiguration are planned after one week | Predictable | |

| IoT | Situation | Number of Satisfied Demands | Performance Ratio Compared without Reconfiguration (%) | Total Cost | Calculation Time (sec) |

|---|---|---|---|---|---|

| Applied | 1 | 29.53 | 82.92 | 2047.3 | 92.02 |

| 2 | 30.69 | 86.15 | 2057.1 | 89.25 | |

| 3 | 28.19 | 79.14 | 3972.4 | 97.6 | |

| 4 | 29.97 | 84.15 | 4020 | 93.68 | |

| Not applied | 1 | 27.37 | 76.85 | 2116.9 | 97.81 |

| 2 | 29.91 | 83.96 | 1975.5 | 87.17 | |

| 3 | 22.77 | 63.92 | 1884.8 | 89.38 | |

| 4 | 28.12 | 78.94 | 2025.3 | 86.91 | |

| Average | 28.32 | 79.50 | 2,512.41 | 91.73 | |

| Number of Processes | Situation | Number of Satisfied Demands | Performance Ratio Compared without Reconfiguration (%) | Total Cost | Calculation Time (sec) |

|---|---|---|---|---|---|

| 3 | 1 | 28.85 | 80.99 | 1781.2 | 82.14 |

| 2 | 32.31 | 90.71 | 1143.4 | 86.59 | |

| 3 | 27.71 | 77.80 | 2897.9 | 74.90 | |

| 4 | 31.13 | 87.40 | 2917.7 | 81.27 | |

| 6 | 1 | 28.06 | 78.77 | 2383.0 | 107.48 |

| 2 | 28.28 | 79.41 | 2889.2 | 100.60 | |

| 3 | 23.24 | 65.25 | 2959.3 | 108.03 | |

| 4 | 26.96 | 75.69 | 3127.6 | 92.81 |

| Rule | Situation | Number of Satisfied Demands | Performance Ratio Compared without Reconfiguration (%) | Total Cost | Calculation Time (sec) |

|---|---|---|---|---|---|

| FIFO | 1 | 27.33 | 83.35 | 2082.70 | 93.56 |

| 2 | 24.58 | 74.95 | 2000.37 | 95.41 | |

| 3 | 23.58 | 71.91 | 2928.02 | 90.73 | |

| 4 | 29.02 | 88.49 | 3022.61 | 85.06 | |

| SPT | 1 | 27.71 | 82.13 | 2083.00 | 92.93 |

| 2 | 26.48 | 78.51 | 1992.40 | 96.31 | |

| 3 | 24.21 | 71.78 | 2927.75 | 90.36 | |

| 4 | 29.03 | 86.04 | 3022.59 | 84.07 | |

| EDD | 1 | 30.32 | 75.18 | 2080.55 | 97.94 |

| 2 | 39.83 | 98.75 | 2056.09 | 89.06 | |

| 3 | 28.64 | 71.01 | 2929.95 | 93.30 | |

| 4 | 29.09 | 72.13 | 3022.80 | 91.99 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, S.; Chang, T.-W.; Hong, Y.S.; Park, J. Reconfiguration Decision-Making of IoT based Reconfigurable Manufacturing Systems. Appl. Sci. 2020, 10, 4807. https://doi.org/10.3390/app10144807

Han S, Chang T-W, Hong YS, Park J. Reconfiguration Decision-Making of IoT based Reconfigurable Manufacturing Systems. Applied Sciences. 2020; 10(14):4807. https://doi.org/10.3390/app10144807

Chicago/Turabian StyleHan, Sumin, Tai-Woo Chang, Yoo Suk Hong, and Jinwoo Park. 2020. "Reconfiguration Decision-Making of IoT based Reconfigurable Manufacturing Systems" Applied Sciences 10, no. 14: 4807. https://doi.org/10.3390/app10144807

APA StyleHan, S., Chang, T.-W., Hong, Y. S., & Park, J. (2020). Reconfiguration Decision-Making of IoT based Reconfigurable Manufacturing Systems. Applied Sciences, 10(14), 4807. https://doi.org/10.3390/app10144807