Development of a Highly Densified Magnetic Sheet for Inductors and Advanced Processes through Silane Surface Treatment of Fe Nanopowder

Abstract

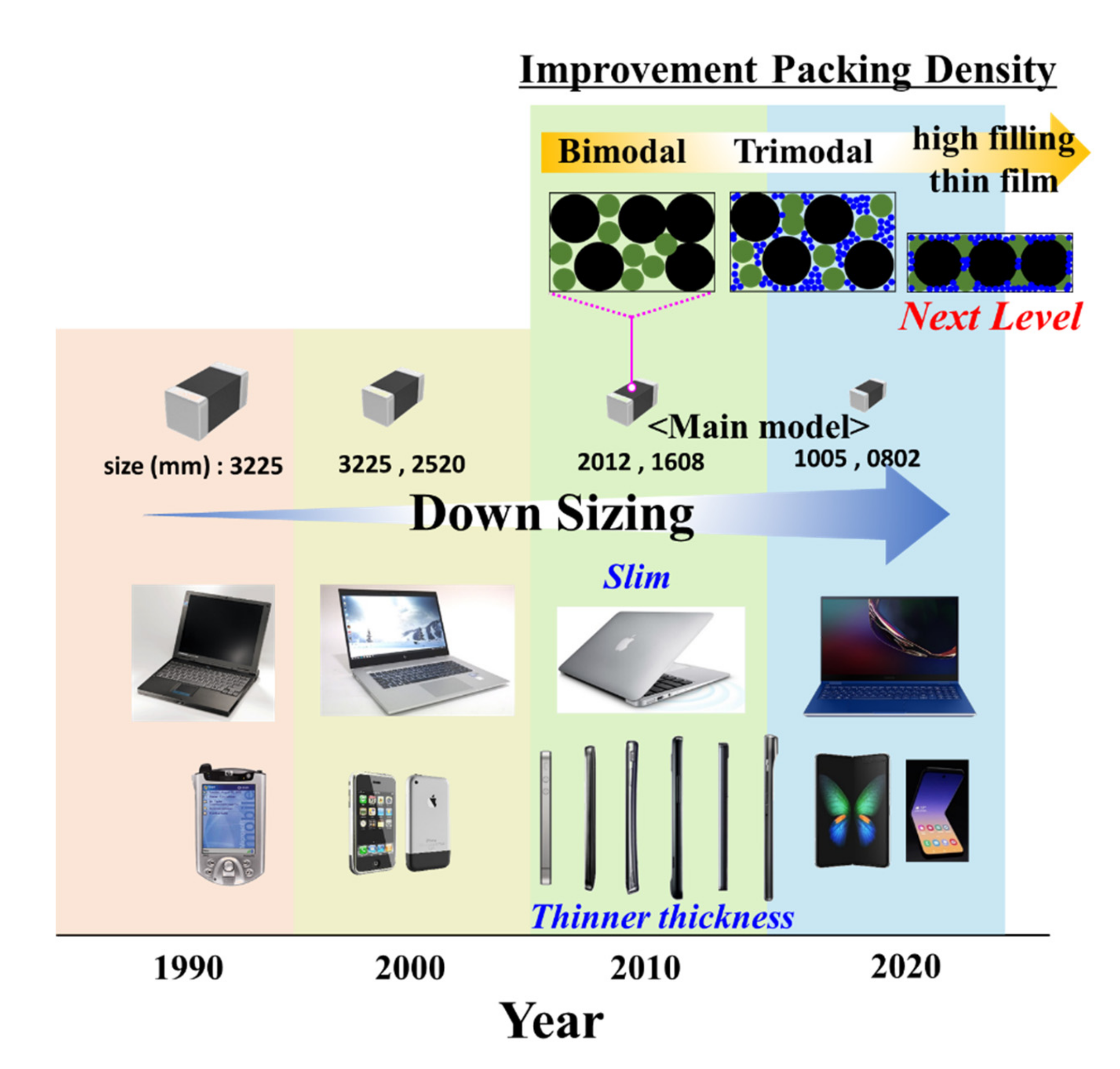

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

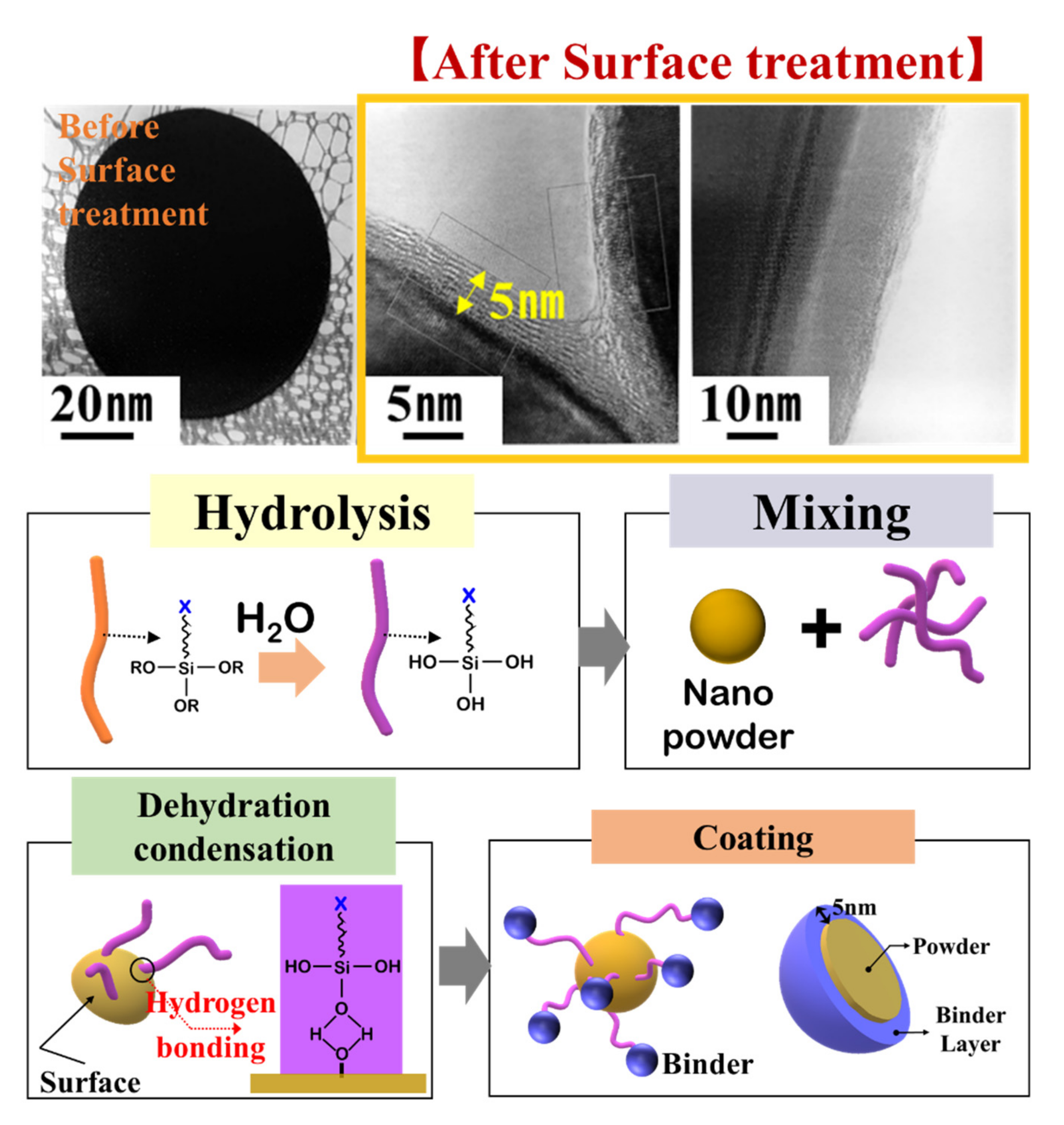

- Nanopowder is receptive to surface treatment by epoxy-based silane coupling agents.

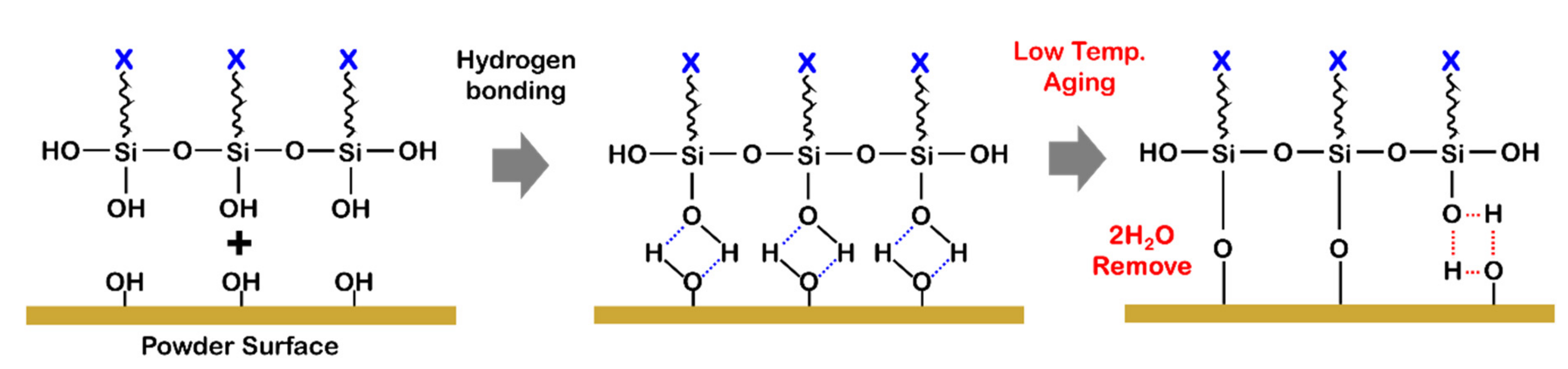

- The surface treatment condition of the nanopowder involves mixing the nanopowder with 1% silane coupling agent, followed by aging for 24 h at 3 °C.

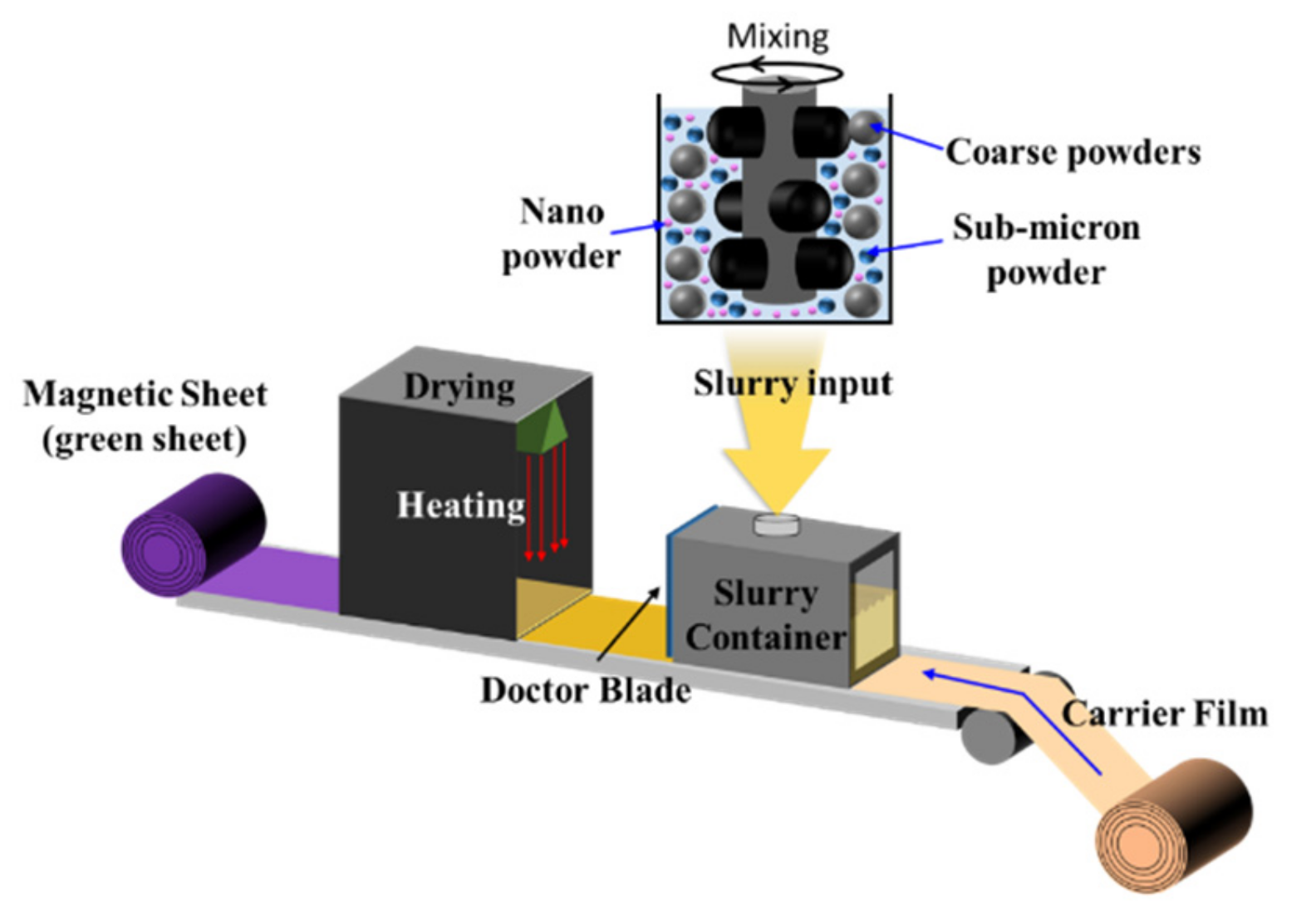

- An effective dispersion process for effective dispersion of nanopowders was developed.

- A press-sheet casting process to fill powder effectively when forming a sheet was developed.

Author Contributions

Funding

Conflicts of Interest

References

- Femia, N.; Stoyka, K.; Capua, G.D. Impact of Inductors Saturation on Peak-Current Mode Control Operation. IEEE Trans. Power Electron. 2020, 35, 10969–10981. [Google Scholar] [CrossRef]

- Chen, H.; Wang, X.; Gao, Y.; Shi, X.; Wang, Z.; Sun, N.; Zaeimbashi, M.; Liang, X.; He, Y.; Dong, C.; et al. Integrated Tunable Magnetoelectric RF Inductors. IEEE Trans. Microw. Theory Tech. 2020, 68, 951–963. [Google Scholar] [CrossRef]

- Katayama, Y.; Sugahara, S.; Nakazawa, H.; Edo, M. High-power-density MHz-switching monolithic DC-DC converter with thin-film inductor. In Proceedings of the 2000 IEEE 31st Annual Power Electronics Specialists Conference. Conference Proceedings (Cat. No. 00CH37018), Galway, Ireland, 23 June 2000; pp. 1485–1490. [Google Scholar]

- Saleh, N.; Qureshi, A. Permalloy thin-film inductors. Electron. Lett. 1970, 6, 850–852. [Google Scholar] [CrossRef]

- Soohoo, R. Magnetic thin film inductors for integrated circuit applications. IEEE Trans. Magn. 1979, 15, 1803–1805. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Suezawa, K.; Arai, K.; Takahashi, Y.; Kikuchi, S.; Shimada, Y.; Li, W.; Tanabe, S.; Ito, K. Microfabrication and characteristics of magnetic thin-film inductors in the ultrahigh frequency region. J. Appl. Phys. 1999, 85, 7919–7922. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Suezawa, K.; Takahashi, Y.; Arai, K.; Kikuchi, S.; Shimada, Y.; Tanabe, S.; Ito, K. Magnetic thin-film inductors for RF-integrated circuits. J. Magn. Magn. Mater. 2000, 215, 807–810. [Google Scholar] [CrossRef]

- Bang, D.H.; Park, J.Y. Ni-Zn Ferrite Screen Printed Power Inductors for Compact DC-DC Power Converter Applications. IEEE Trans. Magn. 2009, 45, 2762–2765. [Google Scholar] [CrossRef]

- Qiu, J.; Sullivan, C.R. Design and Fabrication of VHF Tapped Power Inductors Using Nanogranular Magnetic Films. IEEE Trans. Power Electron. 2012, 27, 4965–4975. [Google Scholar] [CrossRef]

- Ouyang, G.; Chen, X.; Liang, Y.; Macziewski, C.; Cui, J. Review of Fe-6.5 wt%Si high silicon steel—A promising soft magnetic material for sub-kHz application. J. Magn. Magn. Mater. 2019, 481, 234–250. [Google Scholar] [CrossRef]

- Maillet, Y.; Lai, R.; Wang, S.; Wang, F.; Burgos, R.; Boroyevich, D. High-Density EMI Filter Design for DC-Fed Motor Drives. IEEE Trans. Power Electron. 2010, 25, 1163–1172. [Google Scholar] [CrossRef]

- Kącki, M.; Rylko, M.S.; Hayes, J.G.; Sullivan, C.R. Magnetic material selection for EMI filters. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 2350–2356. [Google Scholar]

- Luborsky, F.; Becker, J.; Frischmann, P.; Johnson, L. Potential of amorphous alloys for application in magnetic devices. J. Appl. Phys. 1978, 49, 1769–1774. [Google Scholar] [CrossRef]

- Stojanovic, G.; Damnjanovic, M.; Desnica, V.; Zivanov, L.; Raghavendra, R.; Bellew, P.; McLoughlin, N. High-performance zig-zag and meander inductors embedded in ferrite material. J. Magn. Magn. Mater. 2006, 297, 76–83. [Google Scholar] [CrossRef]

- Roshen, W.A. Effect of finite thickness of magnetic substrate on planar inductors. IEEE Trans. Magn. 1990, 26, 270–275. [Google Scholar] [CrossRef]

- Cao, J.; Chung, D. Improving the dispersion of steel fibers in cement mortar by the addition of silane. Cem. Concr. Res. 2001, 31, 309–311. [Google Scholar] [CrossRef]

- Ma, P.C.; Kim, J.-K.; Tang, B.Z. Functionalization of carbon nanotubes using a silane coupling agent. Carbon 2006, 44, 3232–3238. [Google Scholar] [CrossRef]

- Miller, A.; Berg, J. Effect of silane coupling agent adsorbate structure on adhesion performance with a polymeric matrix. Compos. Part. A Appl. Sci. Manuf. 2003, 34, 327–332. [Google Scholar] [CrossRef]

- Park, S.-J.; Jin, J.-S. Effect of Silane Coupling Agent on Interphase and Performance of Glass Fibers/Unsaturated Polyester Composites. J. Colloid Interface Sci. 2001, 242, 174–179. [Google Scholar] [CrossRef]

- Plueddemann, E.P. Adhesion through silane coupling agents. J. Adhes. 1970, 2, 184–201. [Google Scholar] [CrossRef]

- Ito, Y.; Igarashi, H. Computation of macroscopic electromagnetic properties of soft magnetic composite. IEEE Trans. Magn. 2013, 49, 1953–1956. [Google Scholar] [CrossRef]

| Ratio | Pressure (ton/cm2) | Permeability (μ) | Volume Fraction (%) | |

|---|---|---|---|---|

| Fe-6.5Si | 10:0 | 1.8 | 29.35 | 72.11 |

| 2.5 | 32.1 | 73.45 | ||

| 3.75 | 36.73 | 75.73 | ||

| 6.25 | 45.08 | 79.29 | ||

| 8:2 | 1.8 | 30.82 | 79.77 | |

| 2.5 | 32.42 | 80.89 | ||

| 3.75 | 33.67 | 81.39 | ||

| 6.25 | 35.17 | 82.37 | ||

| 7:3 | 1.8 | 35.03 | 80.2 | |

| 2.5 | 35.66 | 80.75 | ||

| 3.75 | 38.14 | 82.21 | ||

| 6.25 | 40.33 | 83.27 |

| Condition | Ra (μm) | Rz (μm) | Density (g/cc) | Volume Fraction (%) |

|---|---|---|---|---|

| 7:3 | 2.04 | 13.2 | 5.62 | 75.1 |

| 2.05 | 12.4 | 5.54 | 77.4 | |

| 2.03 | 12.9 | 5.71 | 76.3 | |

| 1.92 | 12.8 | 5.69 | 77.8 | |

| 2.01 | 12.5 | 5.68 | 78.4 | |

| 7:2.5:0.5 (non-aging) | 1.74 | 11.4 | 5.91 | 79.8 |

| 1.76 | 10.3 | 5.83 | 80.1 | |

| 1.67 | 10.4 | 5.79 | 80.3 | |

| 1.77 | 11.2 | 5.93 | 79.6 | |

| 1.69 | 10.8 | 5.75 | 80.4 | |

| 7:2.5:0.5 (aging @ 3℃ for 24hr) | 0.87 | 5.2 | 6.47 | 84.8 |

| 0.81 | 5.0 | 6.54 | 84.5 | |

| 0.70 | 4.9 | 6.38 | 86.7 | |

| 0.95 | 5.7 | 6.58 | 84.1 | |

| 0.83 | 5.4 | 6.67 | 85.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, T.; Jung, H.; Song, Y.; Cho, S.; Kim, D.-H.; Kim, Y.; Lee, Y.-S.; Park, Y.; Choi, M. Development of a Highly Densified Magnetic Sheet for Inductors and Advanced Processes through Silane Surface Treatment of Fe Nanopowder. Appl. Sci. 2020, 10, 4770. https://doi.org/10.3390/app10144770

Lee T, Jung H, Song Y, Cho S, Kim D-H, Kim Y, Lee Y-S, Park Y, Choi M. Development of a Highly Densified Magnetic Sheet for Inductors and Advanced Processes through Silane Surface Treatment of Fe Nanopowder. Applied Sciences. 2020; 10(14):4770. https://doi.org/10.3390/app10144770

Chicago/Turabian StyleLee, Taegyu, Hyeonjin Jung, Yeonghwan Song, Seungchan Cho, Dong-Hyun Kim, Yangdo Kim, Yoon-Seok Lee, Yongho Park, and Moonhee Choi. 2020. "Development of a Highly Densified Magnetic Sheet for Inductors and Advanced Processes through Silane Surface Treatment of Fe Nanopowder" Applied Sciences 10, no. 14: 4770. https://doi.org/10.3390/app10144770

APA StyleLee, T., Jung, H., Song, Y., Cho, S., Kim, D.-H., Kim, Y., Lee, Y.-S., Park, Y., & Choi, M. (2020). Development of a Highly Densified Magnetic Sheet for Inductors and Advanced Processes through Silane Surface Treatment of Fe Nanopowder. Applied Sciences, 10(14), 4770. https://doi.org/10.3390/app10144770