1. Introduction

Currently, in response to the rising cost of goods, many companies are committed to minimizing logistics costs through improved logistics processes. In particular, because the transportation cost accounts for 29.4% [

1] of the total cost of the logistics service (e.g. inventory, management, transportation, packing, ordering, movement, and warehousing), many researchers and companies have developed methodologies to find the optimal solutions and algorithms to reduce transportation costs. In addition, due to the current rapid changes of the logistics and distribution industry (e.g. online shopping businesses, last-mile delivery, and fulfillment centers) and the demand for effective utilization of resources, the reverse logistics have been integrated with current model focused on forwarding flow of material. Integrated logistics processes can be devised at the various points, from sourcing and manufacturing to transporting products along the supply chain [

2]. Also, most logistics service providers try to reduce the transportation costs by re-engineering the current silo processes to include simultaneous delivery and pick-up.

The mathematical model to find the optimal route for pick-up and delivery at the same time (VRPSDP) [

3] has been extended according to constraints such as the time window (VRPSDP-TW) and the condition of vehicles [

4]. For a daily pick-up and delivery service like those supporting several convenience stores, it is required to consider the reusable transport container unit, as well as the capacity of trucks, traveling distance, and traffic congestion. Most previous studies have considered the development of an optimal algorithm which can solve this mathematical problem within a practical timeframe while satisfying all constraints such as the capacity of delivery and pick-up, and time windows. Still, it is very hard to find cases which have applied mathematical models or algorithms to practical business environment cases, especially daily operating logistics services like those serving convenience stores.

In particular, reusable transport containers such as trays, shipping containers, and packages, should be regarded as the important assets of logistics centers. However, if the mathematical model focuses on only satisfying constraints related to delivery and does not consider the cost of managing reusable assets, it is often to leave the empty assets at the pick-up points. For example, in daily distribution services supporting convenience stores, the empty trays are often left at the outside of the stores. In addition, the trays are sometimes broken or missing. All of these events cause additional costs to re-arrange trucks to return trays, fix the broken trays, and keep more trays than expected.

In this study, a vehicle routing problem with simultaneous delivery and pick-up under a time window, considering left over cost (VRPSDP-TW-LO) is proposed. The mathematical model has been devised to extend the previous model VRPSDP-TW by adding more cost factors and constrains related to the trays that are left. The model was applied to a small business case with the practical locations of stores and demand in terms of trays. With the numerical example of independent daily operation and consecutive operation for one month by generating random demand, we compared the performance of the proposed model with various quantitative metrics. Based on the results of statistical tests, it may be possible to develop the optimal strategy for finding the vehicle for picking up and delivering the trays. Also, it is possible to reduce the total cost, including transportation cost, left over cost, and penalty from violating the time window constraints.

The rest of this paper is organized as follows: in the following section, previous research related to the vehicle routing problem (VRP), VRP with soft time windows, and VRPSDP is summarized and criticized. In

Section 3, we described how to build a mathematical model with the assumptions, the objective function, and the constraints, by considering a practical business environment. In

Section 4 we describe the numerical experiment and the performance, and show that practical applicability has been proved. Finally, we conclude with the contributions and limitations in

Section 5.

2. Literature Review

It has been proved that VRP is one of the nondeterministic polynomial hard (NP-hard) problems by Danzing and Ramser [

5]. Therefore, the early VRP models assumed that only one vehicle is assigned for each route, starting from a single depot and returning to the same depot. Burak Eksiougle et al. [

6] and Kris Braekers et al. [

7] classified various VRP models according to the nature of the problems. VRP models can be classified into the capacitated VRP (CVRP), VRP with time windows (VRPTW), the multi-depot VRP (MDVRP), and the VRP with delivery and pick-up (VRPDP).

This study focused on VRPTW and VRP with simultaneous delivery and pick-up, as described in

Section 1. In contrast to other groups of VRP, in VRPTW it is assumed that the vehicles have to visit customers within the predefined time schedule (time windows). The objective of VRPTW is to find a set of routes for the vehicle without violating the capacity and time constraints of the vehicle [

8]. VRPTW models can be characterized based on how relaxed the time window constraints are [

9]. If it is allowed to violate the time windows constraints by paying the penalty, this model has soft time windows. Otherwise, the model has hard time window constraints. Several previous studies have presented derived models considering different conditions. A.C. Wade et al. [

10] studied the vehicle routing problem with backhaul (VRPB) service after servicing linehaul customers. They applied the Restricted Intersection Neighborhood Search (R-INS) heuristic algorithm to collect the vehicle’s capacity-based linehaul customer service in the middle of the service. Joao Teixeira et al. [

11] presented a step-by-step approach heuristic method to address the periodic vehicle routing problem involving reusable waste in Colombia. In this method the first step is to separate each area into zones, the second step is to set the type of waste to collect and the area to visit, and the last step is to determine the route. Byung-In Kim et al. [

12] studied VRPTW under the time constraints for actual garbage collection, taking into account the compactness and workload balancing They presented a solution using first clustering and an extended insertion algorithm. Katja Buhrkal et al. [

13] studied the problem of optimizing the route of the waste collection vehicle considering the rest and lunch time of the vehicle drivers and proposed an Adaptive Large Neighborhood Search (ALNS) algorithm using clustering and actual data from the waste collection company.

Aldair Albarez et al. [

14] presented a hybrid method of a metaheuristic using large neighborhood search (LNS) and iterated local search (ILS) for VRP with time windows and multi delivery service providers (VRPTWMD). It showed better performance than the branch-price-and-cut method. Galina Iassinovskaia et al. [

15] studied a delivery and pick-up inventory-routing problem within time windows (PDIRTW) in situations where each partner shares returnable transport items (RTIs) in an integrated supply chain network due to environmental impact and corporate regulation. They developed a cluster first-route second metaheuristic and then it produced a good solution for realistic instance. Yangkun Xia et al. [

16] conducted a study on the open VRP with soft time window and pattern rate (OVRPSTWSR) that increase customer satisfaction in OVRP situations. They proposed the Improved Tabu Search algorithm (ITSA), which showed the better result than traditional heuristics.

Eric Taillard et al. [

17] has developed a cross-exchange method for Tabu Search among metaheuristics to improve the performance of VRP with soft time windows (VRPSTW). Pieter Vansteenwegen et al. [

18] studied the vehicle routing problem of Tele Atlas, a company that makes digital maps. This paper aimed to minimize the number of days required to travel, and soft time windows were considered to avoid taking pictures in the solar direction. The first step was to minimize the visit time of VRPSTW, and the second step was to utilize the hybrid metaheuristic method, which minimizes time violation. Jiuping Xu et al. [

19] considered the VRPSTW with two objectives: minimizing total cost in a fuzzy random environment and maximizing customer average satisfaction. They proposed the Global-local-neighbor particle swarm optimization with exchangeable particles (GLNPSO-ep) method. The GLNPSO-ep method was applied to the transportation of materials for an actual hydroelectric power construction project in China, and as a result, the cost was greatly reduced, without reducing customer satisfaction. Duygu Tas et al. [

20] proposed VRPSTW taking into account transportation costs (total distance, number of vehicles used, and driver’s total expected overtime) and service costs. The travel time of each vehicle was considered using a stochastic method. To solve the proposed problem, they started with the initial solution and derived the optimal value through the Tabu search algorithm method. Sumaiy lqbal et al. [

21] analyzed VRPSTW using the meta heuristic method of an artificial bee colony (ABC). This approach was taken to minimize travel distance, number of vehicle and time violation. The proposed Bee_VRPSTW method showed good quality solutions and calculation time. This methodology suggests that various vehicle routing problem (VRP with Hard Time Windows, Heterogeneous Fleet VRP, Fleet Size and Mix Vehicle Routing Problem with Time Windows) can be utilized. Mostafa Setak et al. [

22] considered the semi-soft time window constraint, a way to confer a penalty when arriving late and no penalty for early arrival. They compared mixed integer programming (MIP), a genetic algorithm, and a simulated annealing algorithm. The MIP model was good for small sizes; it was suggested that the large size of the VRPSTW, the better in terms of quality and CPU time of the simulated annealing (SA) algorithm. Miguel Andres Figliozzi [

23] applied a penalty cost if the service time starts early or starts late. They proposed the new iterative route construction and improvement (IRCI) method and applied Solomon’s benchmark problems for VRPSTW. Thanasak Muktongang et al. [

24] aims to find a robust solution that offers the best performance in the worst-case scenario of VRPSTW under these uncertain travel times. As a result, uncertainty has the greatest effect on finding the VRPSTW optimal value and demonstrated that robust deviation and relative robustness are good consideration criteria.

In contrast to VRPTW, it has been considered in terms of a simultaneous delivery and pick-up service when visiting customers, not considering the visiting time for VRPSDP, which was first introduced by Min [

25]. Mustafa Avci et al. [

26] considered problems with heterogenous VRP with multiple delivery and pick-up (HVRPSDP). They developed the HLS algorithm by applying simulated annealing (SA) and Tabu search (TS) to solve the problem, and proposed that a strategy to relocate goods in a vehicle can reduce transportation costs for VRPSDP. Henriette Koch et al. [

27] studied a vehicle routing problem with multiple delivery and pickup, time windows, and three-dimensioning loading (3L-VRPDPTW) that take into account the volume of backhaul products collected when the vehicle visits a line haul node. To solve the problem of 3L-VRPSDPTW, they applied the heuristic algorithm of a Local Search Open Space (LS_OS) and a Local Search Deepest Bottom left fill (LS_DBLF) a deepest-bottom-left-fill and ALNS. Min J et al. [

28] studied the VRPSDP model taking into account the set-up cost, distance cost, and penalty cost for violating time windows of the vehicle, they designed a two-step approach to solve the problem. The first step was to apply the Improved Genetic Algorithm (I-GA) heuristic to minimize the set-up and distance costs for the vehicle, and Improved Genetic Algorithm2 (I-GA2) to find the global optimum through I-GA.

Most studies related to VRP have presented derived models like VRPTW, VRPSDP, and VRPSDPTW by addressing several different conditions, such as time window constraints, violation penalties, the predefined visiting sequences, and the capacity of vehicles. In addition, most previous studies have tried to minimize the total cost, which consists of transportation costs and operating costs such as fuel costs, and lease or rent of vehicles, including drivers, travelling time, and distance. However, it is very hard to find previous research which has considered reusable assets for delivery and pick-up services as the cost factors. In practical business environments like daily delivery services for convenience stores, the capacity of trucks in terms of trays, as well as the traveling distance and time, are very important factor in developing an optimal vehicle routing plan The available capacity of trucks is variable according to the demand for delivery and pick-up, which are determined by the sequence of visiting customers. If the model is developed by not considering the available capacity for pick-up, leaving the trays cannot be avoided. To consider this condition, the vehicle routing problem with simultaneously delivery and pick-up, time windows, and left-over cost (VRPSDP-TW-LO) has been presented.

3. Model for Vehicle Routing Problem

3.1. Basic Assumptions and Constraints for Building Model

We consider a vehicle routing problem in which there are a fixed number of vehicles and demands served by these vehicles. Each demand represents the number of trays. Furthermore, we also consider time windows within which the deliveries of trays are requested. We assume that the time window constraints are “soft” ones, that is, it is allowed that the realized deliveries can violate the constraints with appropriate penalties for either early or late arrivals.

A vehicle delivers anything requested by some customers in trays, but the number of trays are limited by C, which denotes the capacity of vehicles. It has been assumed that each vehicle starts its service at the depot and returns to the depot after completing the pick-up and delivery service. Also, each customer can be served by only one vehicle. It means that the number of trays loaded in a vehicle from the depot is equal to the sum of the number of trays which should be delivered to the customers included on the route of the vehicles.

Once again, it should be noted that all of the items will be delivered packed in the trays. Thus, it is required that there are enough empty trays at the depot. The empty trays can be collected from the customers the day after delivery. Therefore, the optimal picking and delivery plan should be devised considering the number of trays delivered and those that will be delivered at the same time. As the maximum capacity of the vehicles is fixed as C, some of the delivered trays may be left with the customer if there is not enough space in the vehicle. Note that the capacity represents the number of trays a vehicle can load, and it includes both empty and non-empty trays. The picked-up trays are returned to the depot and the total number of picked-up trays should be greater than a lower bound, L.

In this devising our method there were two factors: (1) the sequence of customers that a vehicle visits; and (2) the number of empty trays picked up from each customer when the vehicle visits. These factors can be merged into a single problem to minimize the total cost, which consists of the travelling cost for visiting customers, the left-over cost which comes from the empty trays not returned from the customers, and penalty cost from the early or late arrivals of vehicles. This problem of vehicle routing can be denoted as VRPSDP-TW-LO, which means the vehicle routing problem in which delivery and pick-up are simultaneously considered with the time window and left-over cost.

3.2. Mathematical Model for VRPSDP-TW-LO

In this section, we describe the mixed integer programming (MIP) model devised for VRPSDP-TW-LO.

Table 1 summarizes the notations used in the MIP formulation.

Using the flow-arc formulation [

7], the vehicle routing problem can be described as follows. Let

be a graph where

is the set of vertices and

is the set of arcs. Note that both

and

denote the depot. Thus, any tour which starts and ends at the depot can be represented as a path from

to

. Each vertex

in

V has an associated demand

, a pickup quantity

, and a time window

. Especially, the depot has

,

, and

. For notional convenience, we introduce the set of customers,

. The topology of the underlying graph is assumed to be given in the cost matrix

and the travel-time matrix

for

.

The decision variables for the proposed model are defined as follows:

: the binary variable whose value is 1 if a vehicle travel from customer to and 0 otherwise;

: the number of empty trays loaded on the vehicle at customer i;

: the number of trays (both empty and non-empty trays) loaded on the vehicle when it departs from customer ;

: the time at which a vehicle departs from customer ;

: the binary variable whose value is 1 if a vehicle arrives at customer earlier than and 0 otherwise;

: the binary variable whose value is 1 if a vehicle arrives at customer later than and 0 otherwise;

: the binary variable whose value is 1 if a vehicle arrives at customer within the time window and 0 otherwise.

The objective function is defined as follows:

A feasible solution for the proposed model satisfies the following constraints.

Path constraints: for each vehicle, a tour which starts and ends at the depot can be represented as a path from

to

. The feasible movements of vehicles satisfy the following three set of constraints:

Disjoint path constraints: by the assumption that each customer is served by exactly one vehicle, the feasible movements of vehicles must be disjointed paths in the underlying graph.

Tray capacity constraints: at any particular instant, the total number of trays in a vehicle cannot exceed the capacity.

Loading empty-tray constraints: the number of empty trays a vehicle which visit a customer can load is limited.

Departure time constraints: the time at which a vehicle departs from a customer satisfies the following set of constraints. The constraints imply that when

, the difference in departure times at customer

j and

i should be greater than or equal to the sum of the travel time between

i and

j and the service time at customer

j.

Early and late arrival constraints: according to the set of customers and sequence of them a vehicle choose, there are three possibilities: early arrival, late arrival, or on-time arrival. We introduce decision variables to denote these mutually exclusive events,

,

, and

, respectively. Since we assume that a vehicle can start its service as soon as it arrives at the customer’s location,

represents the arrival time of vehicle

k at customer

j. The three sets of constraints below correspond to the cases of

,

, and

, respectively.

Binary variable constraints:

4. Computational Experiments

At first, the proposed model, VRPSPD-TW-LO, has been verified in small instances by checking the feasibility and practical profitability based on a statistical test. All of the computational experiments are executed on a personal desktop computer (Intel i7-7000 3.60GHz, 16GB) and the solutions of VRPSDP-TW-LO and VRPSDP-TW are obtained by using Gurobi 8.1. Python API (vesion: Gurobi 8.1, GUROBI OPTIMIZATION, Berlin, German). Gurobi solver is a commercial software for solving mixed integer linear programs such as the formulation given in

Section 3.2. For each instance, the code generates the mathematical model and feeds it to the Gurobi solver.

4.1. Instance Generation

For the statistical test, all parameters are assumed based on the case study of a delivery service for convenience stores, as follows:

A set of customers, n = 11: ;

A set of vehicles, v = 3: ;

Capacity of all vehicles has a capacity Q = 25;

Average speed of a vehicle s = 60 km/h;

Service time at each customer: 10 min;

Penalty cost for violating time windows both early arrival and late arrival: ₩1000;

Penalty cost for left over tray: ₩500;

For the simple numerical examples, a new set of spatial coordinates for each customer is randomly generated as integers in a square of 100 units, and the location of depot is set at (0, 0) in the center of the square. The distances between all visiting points, including the depot and customers, are calculated with the Harversine method, because well-known methods such as the Euclidean method and the Manhattan distance method have limitations in calculating the actual distance based on the actual latitude and longitude coordinates. The driving speed of the vehicles is set as 60 km/hr. It has also been assumed that the fuel mileage is 6 km/L, and the unit oil price is 1000 Korean Won (KRW).

The demands of customers, including pick-up and delivery, are randomly generated between 1 and 8 trays. It has been assumed that the number of trays follows a uniform distribution. The time window constraint for visiting each customer is determined by considering the number of visiting nodes on the path combined with the arrival time of the previous node; 30 min for operations like delivery and pick-up. If the vehicle could not meet the predefined time windows, the penalty, 1000 KRW, will be charged. Also, if the vehicle does not pick up a tray previously delivered to a certain node, the penalty for a left-over tray, 500 KRW per tray in a day, will be charged. The left-over penalty and time window penalty were set by the actual logistics company which supports convenience stores. To get rid of the effects of randomness, the experiment was repeated 30 times.

4.2. Result of Small Instances

Based on the independent 30 instances, the performance of proposed models, VRPSDP-TW-LO, was evaluated by comparing it with VRPSDP-TW, which does not consider the left-over cost.

Table 2 shows the results of each instance of the VRPSDP-TW and the VRPSDP-TW-LO models. The performance was evaluated with the metrics such total cost, total travelling distance, number of time window penalties, and number of left-over trays. At first, the results showed that the average total cost of VRPSDP-TW is higher than VRPSDP-TW-LO by as much as 2.9%. It could be found that there is a trade-off between total travelling distance, the number of time window penalties, and number of left-over trays.

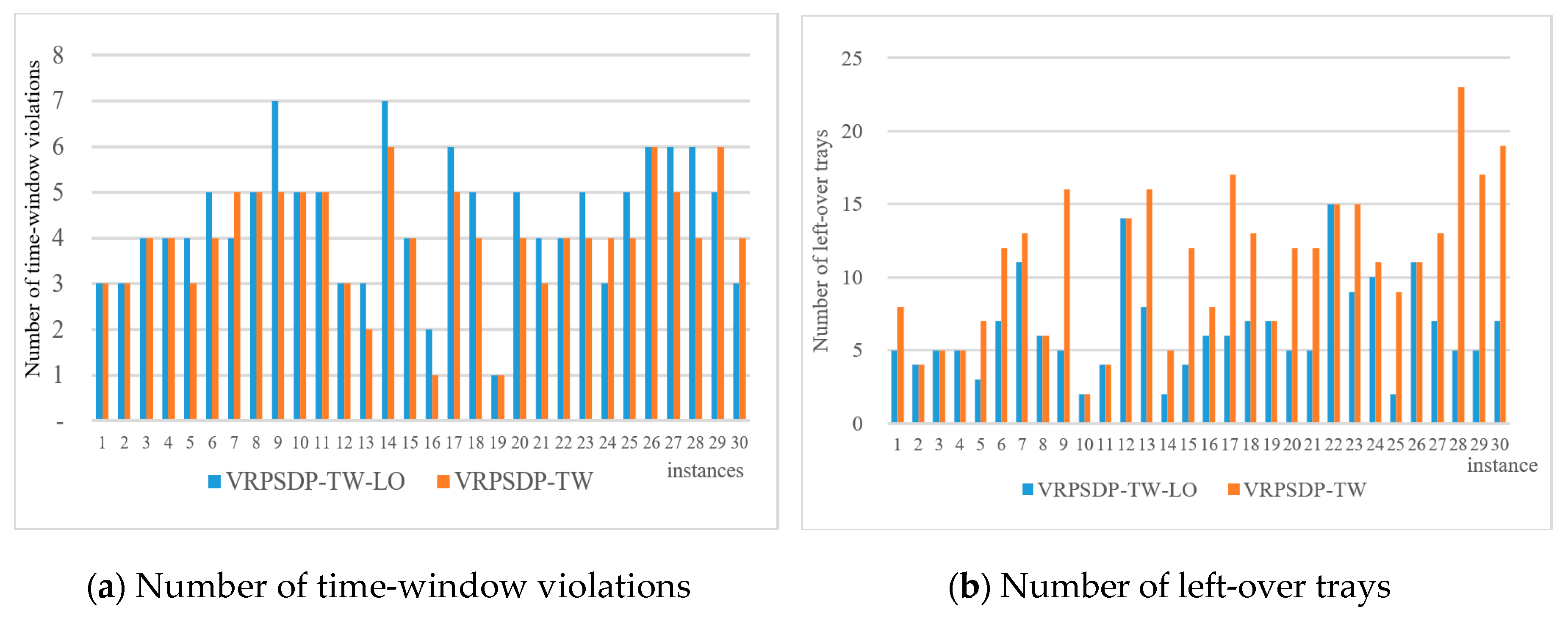

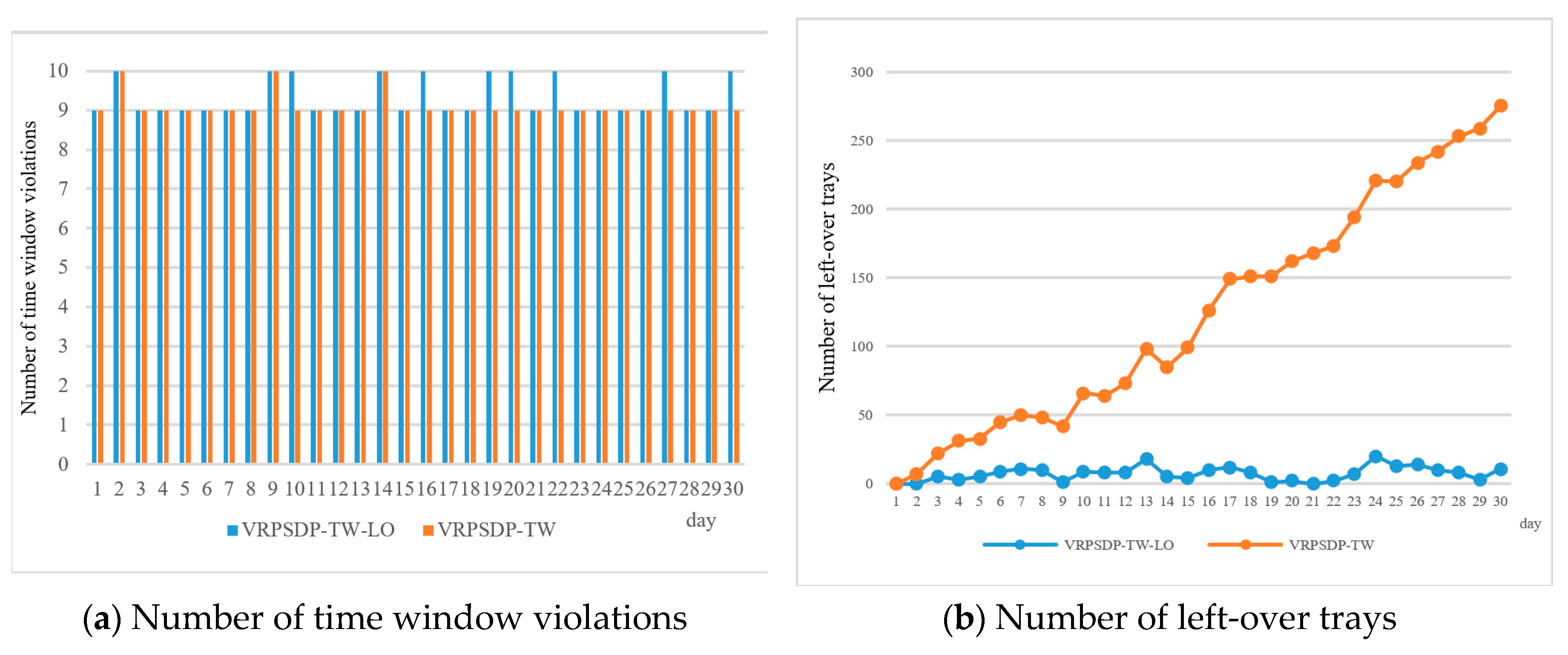

Figure 1 and

Figure 2 show the details of the difference in the number of time window violations and number of left-over trays.

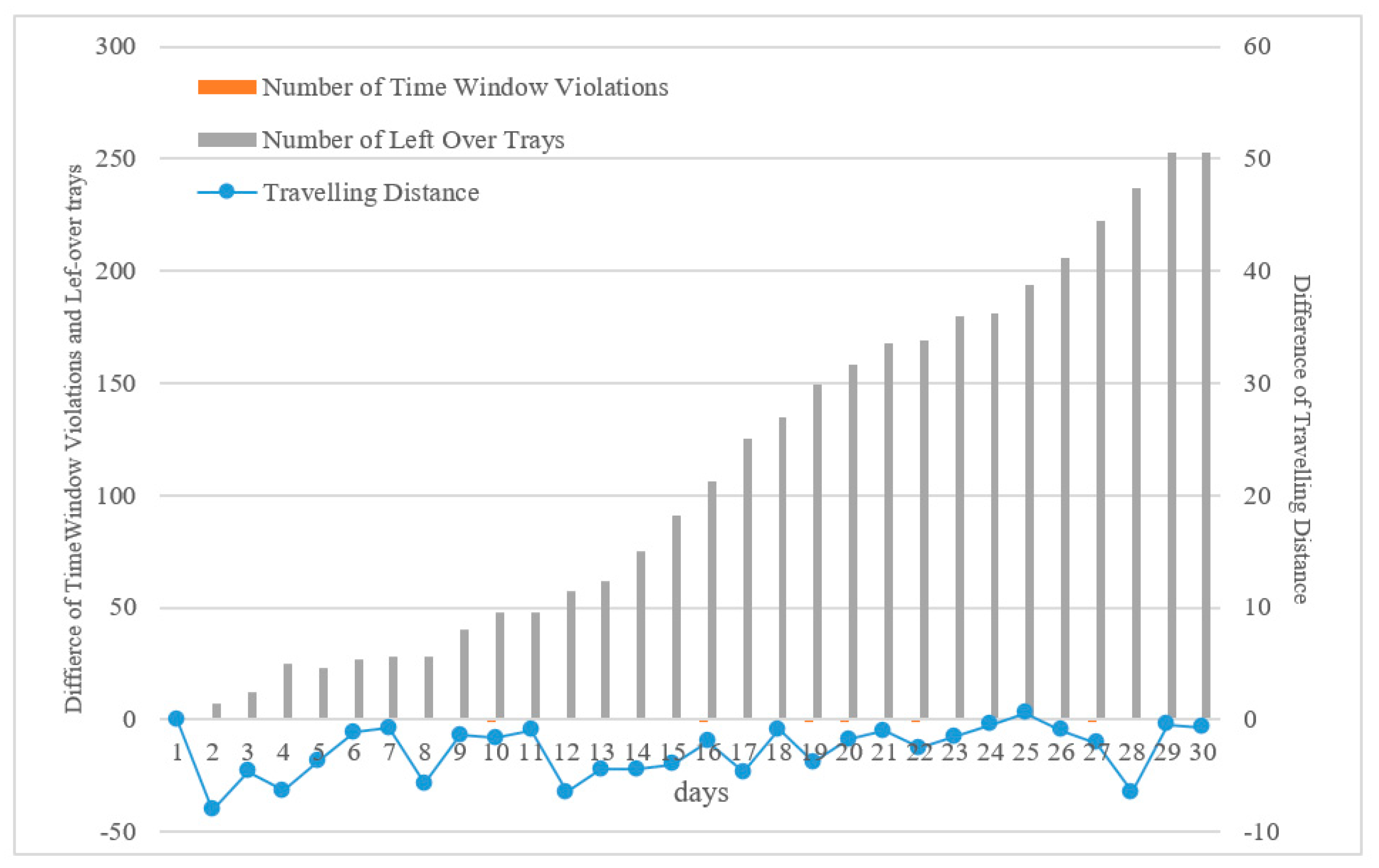

Figure 2 shows the differences in performance between the two models. The values are acquired by subtracting the performance of VRPSDP-TW-LO from VRPSDP-TW.

Generally, the total travelling distance of the VRPSDP-TW-LO model was longer than the VRPSDP-TW model, because the dotted line was located under the zero. Also, it is possible to see that the number of time-window violations is bigger than for the VRPSDP-TW. However, the total number of left-over trays is lower than for the VRPSDP-TW because it is included in the objective function. In order to secure the statistical validity, a paired

t-test was conducted, which showed a statistically significant difference in the total cost between VRPSDP-TW and VRPSDP-TW-LO.

Table 3 shows the pair mean differences for instances and

p value. The mean difference of VRPSDP-TW and VRPSDP-TW-LO was −2445.7, with a

p value of 0.014. This indicates that VRPSDP-TW-LO is statistically significantly different and can show better solutions.

Therefore, it can be said that that VRPSDP-TW-LO may guarantee a better solution than VRPSDP-TW, which can accept the alternative hypothesis, H1, given the below:

5. Case Study from Practical Business

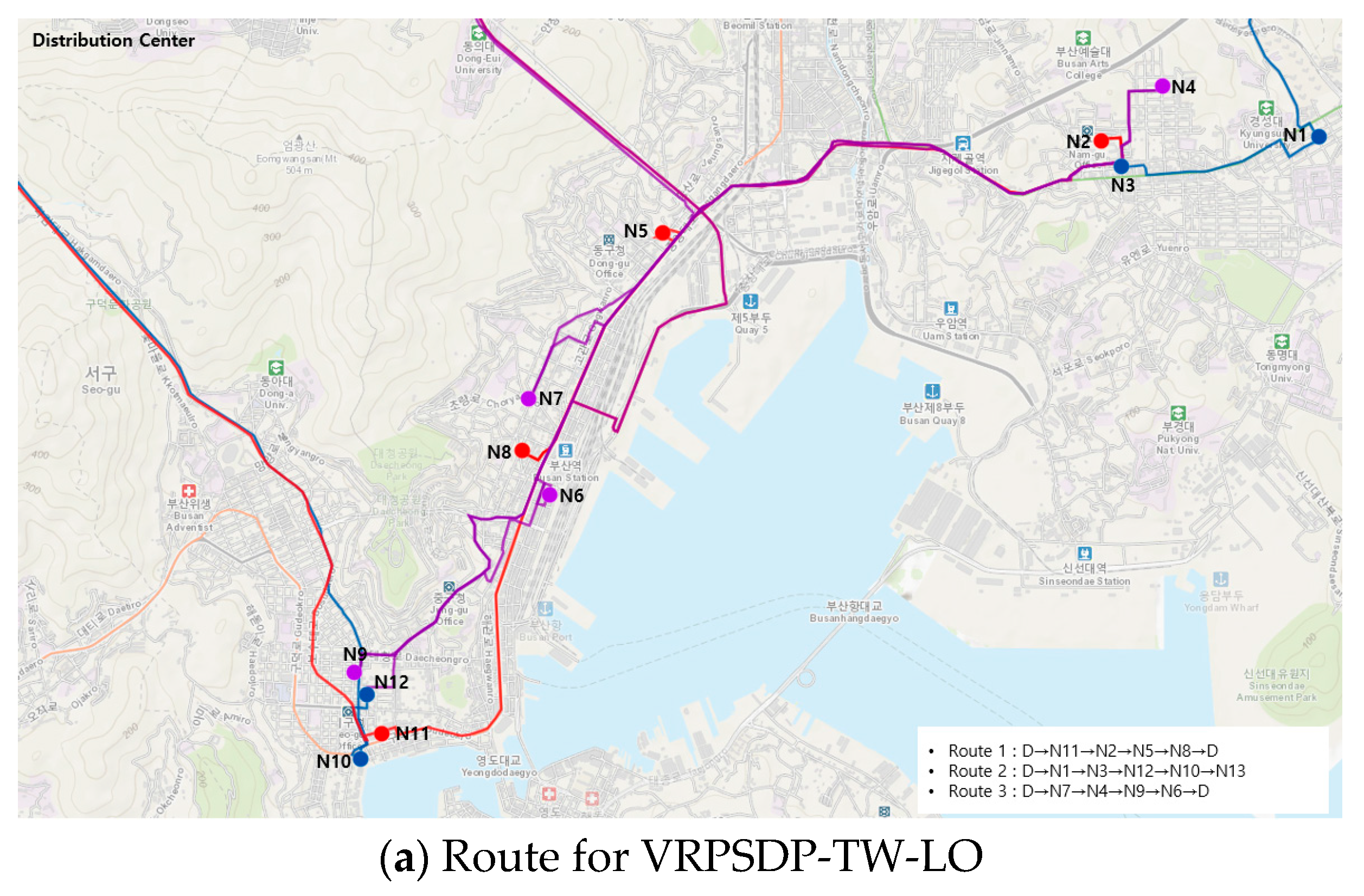

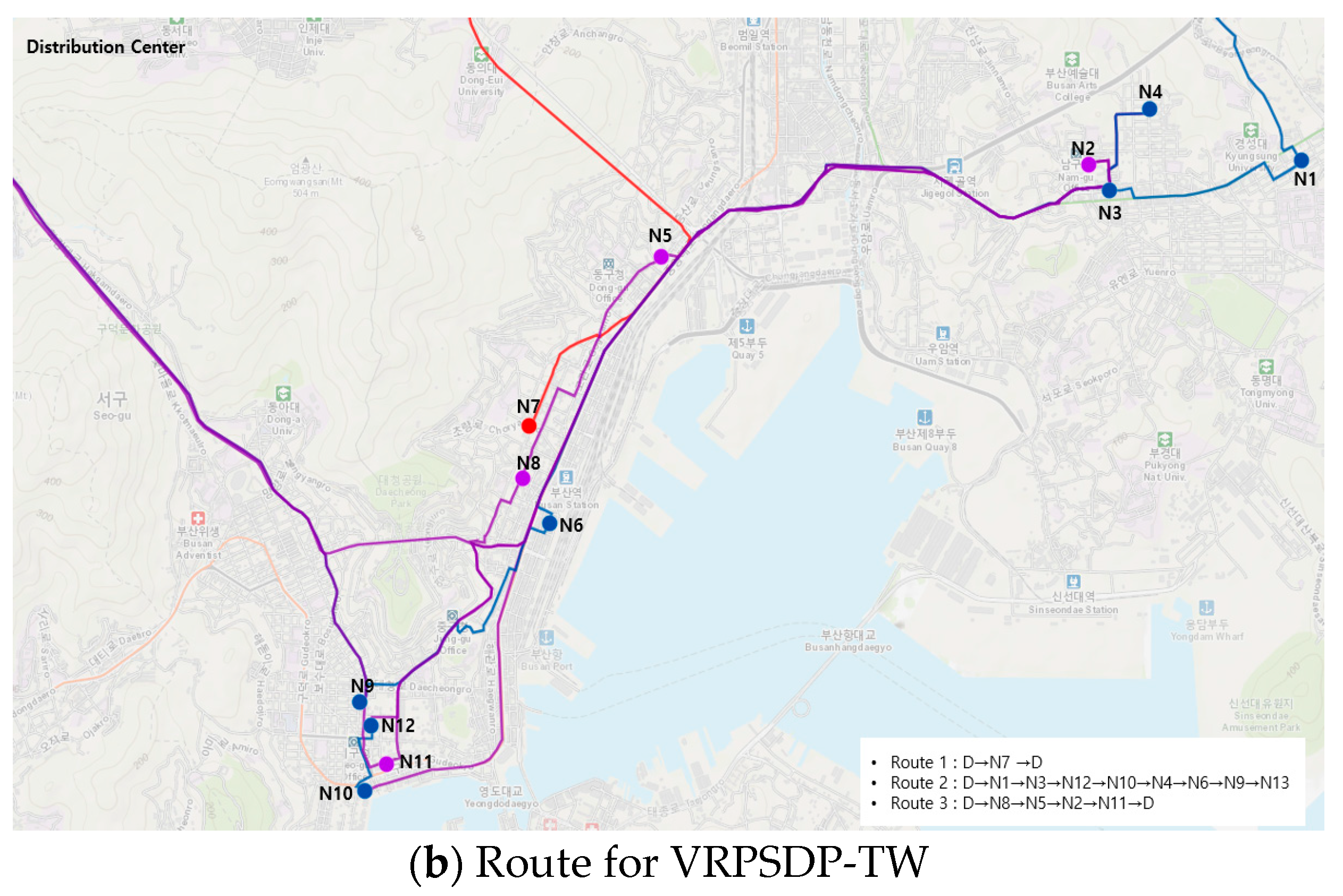

In this section, we describe the results of validity and efficiency tests of the proposed VRPSDP-TW-LO model based on the practical distribution business of Company A. Company A is currently supporting the convenience stores in a region of Pusan, Korea. A vehicle visits an average of 30 stores a day. This company has a similar problem due to the left-over trays, which could not picked up by the vehicle. They get a lot of complaints from the store, costs from the missed or damaged trays, and they usually dispatch additional vehicles to pick up the left-over trays. To make the experiments simple without loss of generality, it was assumed that the capacity of the vehicles is 30 trays, the total number of visiting nodes is 12, and the maximum operating time is 240 min (6 h). The daily demand of delivery to each node was randomly generated from the uniform distribution, from 1 to 8 trays. From the actual location of convenience stores, the distances between visiting nodes were calculated considering the actual travelling route using the software, ArcGIS. The demand for pick-up is determined as the number of trays which are previously delivered and left over, not having been picked up yet. To analyze the cumulative effect of daily operations, the performance over a consecutive 30 day period was analyzed. For the first day, it was set that there were no left-over trays.

Figure 3 shows one example of 30 daily operations. For both VRPSDP-TW and VRPSDP-TW-LO, all 12 stores in a same region are supported by three vehicles. The routes for each vehicle are different. The results of daily operations for 30 days were acquired based on these different vehicle routes.

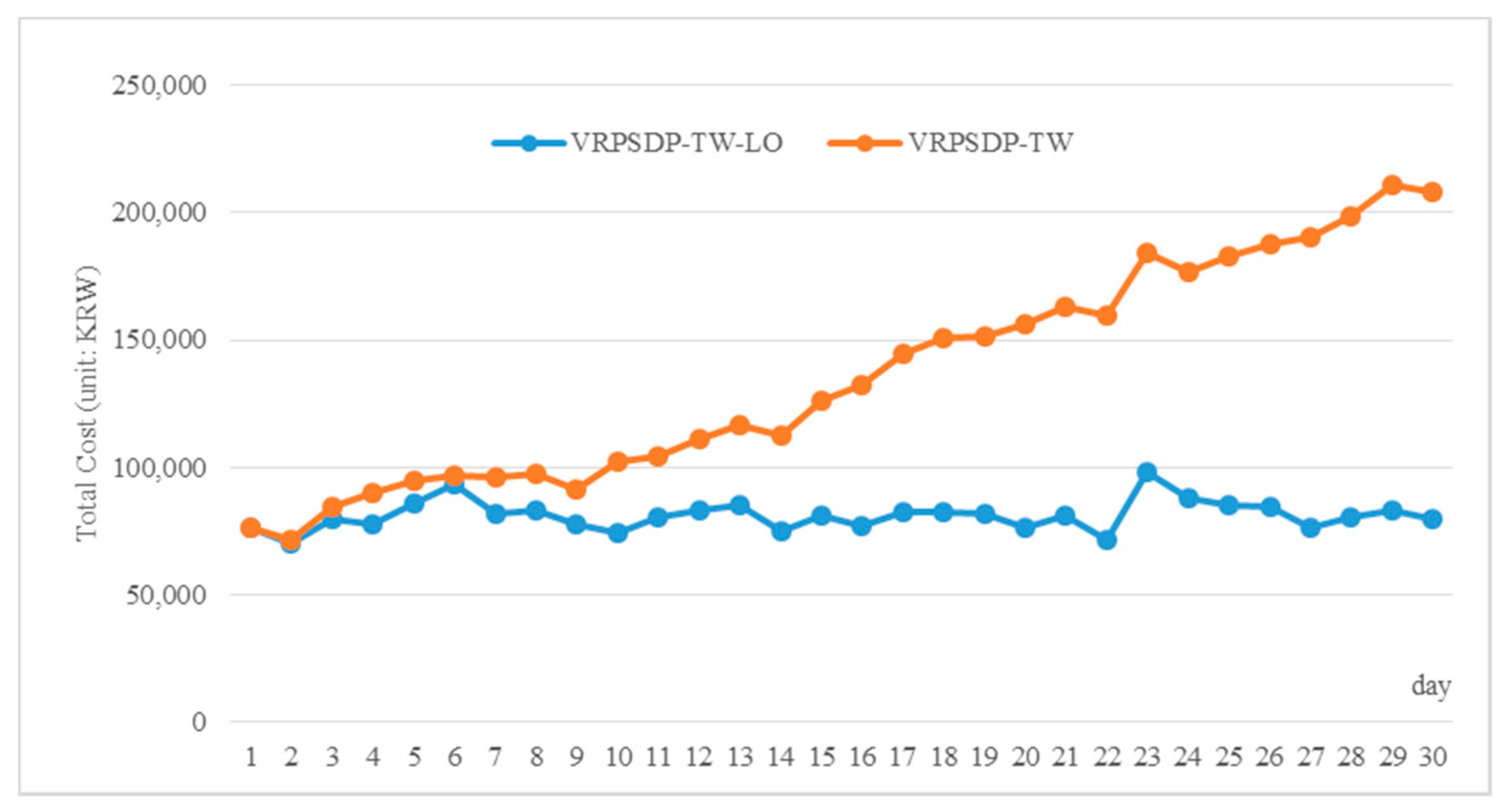

Figure 4 shows the daily total operating cost including travelling, penalties for violating time windows, and penalties for left-over trays for 30 days.

The difference between the two models in terms of total cost on each day were not significant during the initial 10 days; no greater than 14.9%. However, it gradually increased after 10 days. Eventually, the total cost became 61.8% on the 30th and final day. This means that VRPSDP-TW-LO can save more than 60% of the cost of VRPSDP-TW. It can be inferred that the cost difference arises from the number of left-over trays.

Figure 5 shows the number of time window violations (a), and number of left-over trays (b).

Figure 6 shows the result of the integrated comparison of the differences in travelling distance, number of time window violations, and number of left-over trays. Where the number of time window violations was not significantly different, the difference of the number of left-over trays gets bigger as time goes on. In addition, the total travelling distance did not show significant differences between the two models; it was less than 10 km. As previously described, VRPSDP-TW does not consider the number of left-over trays for the pick-up service and load as many as the remained capacity of the vehicle after delivery service. Therefore, the number of left-over trays gets bigger as time goes on. In addition, there is a limitation to the trays which each distribution center can keep and manage; the additional vehicles should be arranged to only pick up the left-over trays. This causes additional costs and several issues for keeping and managing trays.

From the results, it can be clearly concluded that that the proposed VRPSDP-TW-LO model may improve the efficiency of the service operations and reduce the total cost by considering the left-over cost, which was not included in previous research. For the example of a distribution service supporting convenience stores used in this case study, it is possible to secure a significant benefit for daily operations by reducing the cost from left-over trays, improving the service for stores. The proposed model can be applied not only to a distribution service for supporting convenience stores, but also to other services using unit containers, such as grocery stores, pharmacies, and marine container shipping businesses.

6. Conclusions

In order to secure a competitive advantage in the current market, an efficient logistics service has been regarded as one of the most important strategies. In particular, the transportation, which accounts for the largest cost in logistics activities, is critical for enhancing the service level and saving the cost. However, the current transport management system (TMS) focuses on designing the optimal route, which minimizes the objective function consisting of different factors such as travelling distance, required vehicles, and drivers, while meeting several different constraints, like maximum capacities, time windows to visit, and demand for delivery and pick-up. Many previous studies have presented very advanced models, methods, and algorithms to solve the mathematical problems related to VRP. Still, it is not easy to find previous research which considers the valuable assets for transportation services, like containers and trays, except vehicles and drivers, even though these assets are very critical to enhancing the service level and may cause additional operating costs.

In this work, we devised a novel mathematical problem, VRPSDP-TW-LO, which considers the cost from the left-over trays, travelling distance, and time-window penalty at the same time. This model may reflect the practical circumstances of daily distribution services by relaxing some constraints of traditional VRPSDP or VRPSDP-TW and adding more factors.

With small and simple numerical experiments and statistical tests, we verified the practical applicability of the proposed model by comparing the various performance metrics, such as travelling distance, number of time-window penalties, and number of left-over trays, not only the total cost. The results show that the proposed model can save 2.9% of the average total cost for every day when compared to the VRPSDP-TW model in the simple numerical example. In addition, we evaluated the performance based on a practical business environment for 30 days, to check the cumulative effect of daily operations. As could be seen in the examples, a trade-off exists between the time window penalty and left-over trays. However, the proposed model, VRPSDP-TW-LO, can reduce the number of left-over trays with a very small difference in time window violations. Therefore, it could be concluded that the proposed model may guarantee a better service level, as well as reducing the cost. In addition, it seems possible to apply the proposed model to the various industries and services in which reusable assets are regarded as very important, such as unit containers and trays.

Still, this research has some limitations to being applied to a real practical business environment. External environmental factors like the traffic conditions, which have great impacts on the arrival time to the customer and transportation costs, have not been considered. Also, the number of left-over trays could not be deterministic, because the trays may be missed or damaged. Therefore, in future research, the constraints of external environmental factors and stochastic variables and parameters, which are out of scope of this research, should be considered. In addition, even though the two penalty costs, time window violations, and left-over trays have been acquired from an actual logistics company, it may be helpful to evaluate the sensitivity and robustness of the solution by changing the value of penalty costs.

In addition, in this research, the proposed model was only verified with small numerical experiments. Thus, to apply the proposed model to a real business environment and find the optimal solution, it is required to design heuristic algorithms like Tabu search, genetic algorithms, or swarm optimization approaches to solve the bigger problem with the larger number of delivery points.