Experimental Investigation of Magnetic Particle Movement in Two-Phase Vertical Flow under an External Magnetic Field Using 2D LIF-PIV

Abstract

:1. Introduction

2. Experimental Apparatus and Procedure

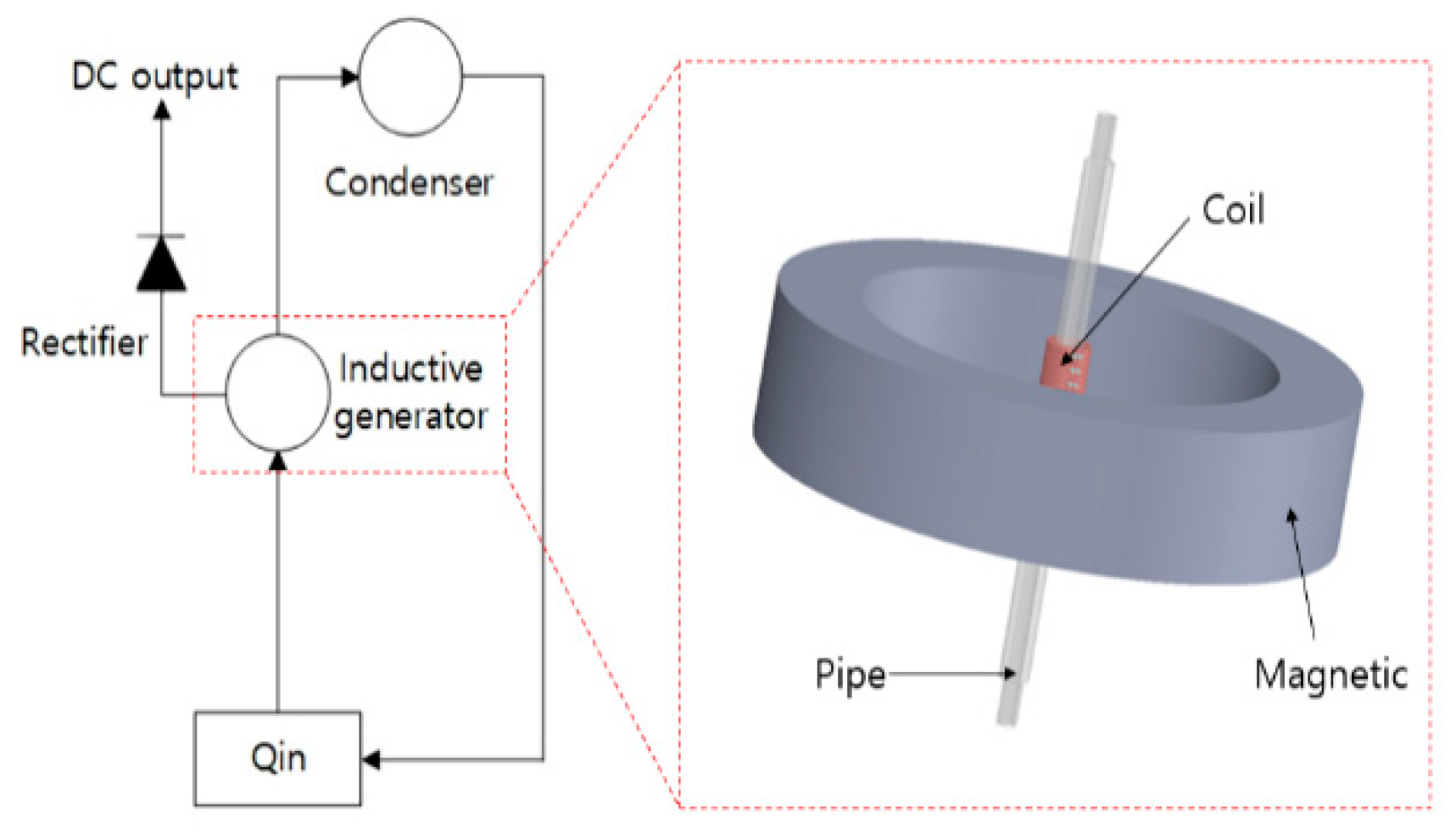

2.1. The Organic Inductive Cycle (OIC)

2.2. The Two-Phase Flow Circulation System

2.3. The LIF-PIV Setup

3. Results and Discussion

3.1. Single-Phase Flow Results

3.2. Two-Phase Flow Results

3.2.1. Velocity Fields

3.2.2. Vorticity Fields

4. Conclusions

Supplementary Materials

Supplementary File 1Author Contributions

Funding

Conflicts of Interest

References

- Asfer, M.; Prasad Prajapati, A.; Kumar, A.; Kumar Panigrahi, P. Visualization and Motion of Curcumin Loaded Iron Oxide Nanoparticles During Magnetic Drug Targeting. J. Nanotechnol. Eng. Med. 2015, 6, 011004. [Google Scholar] [CrossRef]

- Hamdipoor, V.; Afzal, M.; Le, T.-A.; Yoon, J. Haptic-Based Manipulation Scheme of Magnetic Nanoparticles in a Multi-Branch Blood Vessel for Targeted Drug Delivery. Micromachines 2018, 9, 14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bibo, A.; Masana, R.; King, A.; Li, G.; Daqaq, M.F. Electromagnetic ferrofluid-based energy harvester. Phys. Lett. Sect. A Gen. At. Solid State Phys. 2012, 376, 2163–2166. [Google Scholar] [CrossRef]

- Seol, M.-L.; Jeon, S.-B.; Han, J.-W.; Choi, Y.-K. Ferrofluid-based triboelectric-electromagnetic hybrid generator for sensitive and sustainable vibration energy harvesting. Nano Energy 2017, 31, 233–238. [Google Scholar] [CrossRef]

- Hartshorne, H.; Backhouse, C.J.; Lee, W.E. Ferrofluid-based microchip pump and valve. Sens. Actuators B Chem. 2004, 99, 592–600. [Google Scholar] [CrossRef]

- Zeng, J.; Deng, Y.; Vedantam, P.; Tzeng, T.-R.; Xuan, X. Magnetic separation of particles and cells in ferrofluid flow through a straight microchannel using two offset magnets. J. Magn. Magn. Mater. 2013, 346, 118–123. [Google Scholar] [CrossRef]

- Abdollahi, A.; Salimpour, M.R.; Etesami, N. Experimental analysis of magnetic field effect on the pool boiling heat transfer of a ferrofluid. Appl. Therm. Eng. 2017, 111, 1101–1110. [Google Scholar] [CrossRef]

- Berensmeier, S. Magnetic particles for the separation and purification of nucleic acids. Appl. Microbiol. Biotechnol. 2006, 73, 495–504. [Google Scholar] [CrossRef]

- Hejazian, M.; Nguyen, N.-T. A Rapid Magnetofluidic Micromixer Using Diluted Ferrofluid. Micromachines 2017, 8, 37. [Google Scholar] [CrossRef] [Green Version]

- Yun, H.R.; Lee, D.J.; Youn, J.R.; Song, Y.S. Ferrohydrodynamic energy harvesting based on air droplet movement. Nano Energy 2015, 11, 171–178. [Google Scholar] [CrossRef]

- Kim, S.-H.; Park, J.-H.; Choi, H.-S.; Lee, S.-H. Power Generation Properties of Flow Nanogenerator With Mixture of Magnetic Nanofluid and Bubbles in Circulating System. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Rokni, H.B. Simulation of nanofluid heat transfer in presence of magnetic field: A review. Int. J. Heat Mass Transf. 2017, 115, 1203–1233. [Google Scholar] [CrossRef]

- El-Amin, M.F.; Khaled, U.; Beroual, A. Numerical study of the magnetic field effect on ferromagnetic fluid flow and heat transfer in a square porous cavity. Energies 2018, 11, 3235. [Google Scholar] [CrossRef] [Green Version]

- Sheikholeslami, M.; Barzegar Gerdroodbary, M.; Mousavi, S.V.; Ganji, D.D.; Moradi, R. Heat transfer enhancement of ferrofluid inside an 90° elbow channel by non-uniform magnetic field. J. Magn. Magn. Mater. 2018, 460, 302–311. [Google Scholar] [CrossRef]

- Zare, R.N. My Life with LIF: A Personal Account of Developing Laser-Induced Fluorescence. Annu. Rev. Anal. Chem. 2012, 5, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Lobanov, P.; Pakhomov, M.; Terekhov, V. Experimental and Numerical Study of the Flow and Heat Transfer in a Bubbly Turbulent Flow in a Pipe with Sudden Expansion. Energies 2019, 12, 2735. [Google Scholar] [CrossRef] [Green Version]

- Peng, J.; Cao, Z.; Yu, X.; Yu, Y.; Chang, G.; Wang, Z. Investigation of Flame Evolution in Heavy Oil Boiler Bench Using High-Speed Planar Laser-Induced Fluorescence Imaging. Appl. Sci. 2018, 8, 1691. [Google Scholar] [CrossRef] [Green Version]

- Murgan, I.; Bunea, F.; Ciocan, G.D. Experimental PIV and LIF characterization of a bubble column flow. Flow Meas. Instrum. 2017, 54, 224–235. [Google Scholar] [CrossRef]

- Siddiqui, M.I.; Munir, S.; Heikal, M.R.; de Sercey, G.; Aziz, A.R.A.; Dass, S.C. Simultaneous velocity measurements and the coupling effect of the liquid and gas phases in slug flow using PIV-LIF technique. J. Vis. 2016, 19, 103–114. [Google Scholar] [CrossRef] [Green Version]

- Petrosky, B.J.; Lowe, K.T.; Danehy, P.M.; Wohl, C.J.; Tiemsin, P.I. Improvements in laser flare removal for particle image velocimetry using fluorescent dye-doped particles. Meas. Sci. Technol. 2015, 26, 115303. [Google Scholar] [CrossRef]

- Xiaodong, R.; Feng, W.; Yamamoto, F. PIV measurements for gas flow under gradient magnetic fields. Acta Mech. Sin. 2004, 20, 591–596. [Google Scholar] [CrossRef]

- Takeuchi, J.; Satake, S.; Kunugi, T.; Yokomine, T.; Morley, N.B.; Abdou, M.A. Development of PIV Technique under Magnetic Fields and Measurement of Turbulent Pipe Flow of Flibe Simulant Fluid. Fusion Sci. Technol. 2007, 52, 860–864. [Google Scholar] [CrossRef]

- Ali, J.; Kim, H.; Cheang, U.K.; Kim, M.J. Micro-PIV measurements of flows induced by rotating microparticles near a boundary. Microfluid. Nanofluidics 2016, 20, 131. [Google Scholar] [CrossRef]

- Gilard, V.; Gillon, P.; Blanchard, J.-N.; Sarh, B. Influence of a Horizontal Magnetic Field on a Co-Flow Methane/Air Diffusion Flame. Combust. Sci. Technol. 2008, 180, 1920–1935. [Google Scholar] [CrossRef]

- Munhoz, D.S.; Bityurin, V.A.; Zavershinskii, I.P.; Klimov, A.I.; Moralev, I.A.; Kazanskii, P.N.; Molevich, N.E.; Polyakov, L.B.; Porfir’ev, D.P.; Sugak, S.S.; et al. Air flow control around a cylindrical model induced by a rotating electric arc discharge in an external magnetic field. J. Phys. Conf. Ser. 2019, 1394, 012008. [Google Scholar] [CrossRef]

- Tan, L.; Ali, J.; Cheang, U.K.; Shi, X.; Kim, D.; Kim, M.J. µ-PIV Measurements of Flows Generated by Photolithography-Fabricated Achiral Microswimmers. Micromachines 2019, 10, 865. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Park, J.; Lee, J.; Cha, B.; Song, Y.; Yoon, H.G.; Huh, Y.M.; Haam, S. Motions of magnetic nanosphere under the magnetic field in the rectangular microchannel. J. Magn. Magn. Mater. 2007, 317, 34–40. [Google Scholar] [CrossRef]

- Takeuchi, J.; Satake, S.; Morley, N.B.; Kunugi, T.; Yokomine, T.; Abdou, M.A. Experimental study of MHD effects on turbulent flow of Flibe simulant fluid in circular pipe. Fusion Eng. Des. 2008, 83, 1082–1086. [Google Scholar] [CrossRef]

- Aminfar, H.; Mohammadpourfard, M.; Mohseni, F. Two-phase mixture model simulation of the hydro-thermal behavior of an electrical conductive ferrofluid in the presence of magnetic fields. J. Magn. Magn. Mater. 2012, 324, 830–842. [Google Scholar] [CrossRef]

- König, J.; Neumann, M.; Mühlenhoff, S.; Tschulik, K.; Albrecht, T.; Eckert, K.; Uhlemann, M.; Weier, T.; Büttner, L.; Czarske, J. Optical velocity measurements of electrolytic boundary layer flows influenced by magnetic fields. Eur. Phys. J. Spec. Top. 2013, 220, 79–89. [Google Scholar] [CrossRef]

- Hangi, M.; Bahiraei, M.; Rahbari, A. Forced convection of a temperature-sensitive ferrofluid in presence of magnetic field of electrical current-carrying wire: A two-phase approach. Adv. Powder Technol. 2018, 29, 2168–2175. [Google Scholar] [CrossRef]

- Shahsavar, A.; Ansarian, R.; Bahiraei, M. Effect of line dipole magnetic field on entropy generation of Mn-Zn ferrite ferrofluid flowing through a minichannel using two-phase mixture model. Powder Technol. 2018, 340, 370–379. [Google Scholar] [CrossRef]

- Characteristics of sliding bubble in aqueous electrolyte: In presence of an external magnetic field. Colloids Surf. A Physicochem. Eng. Asp. 2018, 538, 404–416. [CrossRef]

- Westergaard, C.H.; Buchhave, P. PIV: Comparison of three autocorrelation techniques. In Proceedings of the SPIE 205—Fifth International Conference on Laser Anemometry: Advances and Applications, Veldhoven, The Netherlands, 23–27 August 1993; pp. 535–541. [Google Scholar] [CrossRef]

- Keane, R.D.; Adrian, R.J. Optimization of particle image velocimeters. In Proceedings of the SPIE 1404—ICALEO’89: Optical Methods in Flow and Particle Diagnostics, Orlando, FL, USA, 10–25 October 1989; pp. 139–159. [Google Scholar] [CrossRef]

- Holman, J.P. Experimental Methods for Engineering, 5th ed.; McGraw-Hill: Singapore, 1989. [Google Scholar]

| Author | Technique | Phase | Seed Particle | Magnetic Flux Density | Year | Method |

|---|---|---|---|---|---|---|

| Xiaodong et al. [21] | 2D PIV | Single | CO2 | 1.5 T | 2004 | Experiment |

| Takeuchi et al. [22] | 2D PIV | Single | Methyl methacrylate–ethylene glycol dimethacylate copolymer | 2 T | 2007 | Experiment |

| Yang et al. [27] | 2D PTV | Single | FeCl3, FeCl2–4H2O | Up to 470 mT | 2007 | Experiment |

| Gilard et al. [24] | 2D PIV | Single | Methane/air | 0.35 T | 2008 | Experiment |

| Takeuchi et al. [28] | 2D PIV | Single | Li2BeF4 | 2 T | 2008 | Experiment |

| Aminfar et al. [29] | Two-phase mixture | Liquid–solid | Sea water, Fe3O4 | 6E5 A/m | 2012 | Numerical |

| König et al. [30] | LDV-PS *, 2D-PIV | Single | NaOH | Electrode (500 mA) | 2013 | Experiment |

| Zeng et al. [6] | Bright-field microscope | Single | EMG 408, Tween 20 | 1.32 T | 2013 | Experiment |

| Asfer et al. [1] | 2D PIV ** | Single | Fe3O4 | 0.15 T | 2015 | Experiment |

| Ali et al. [23] | 2D PIV | Single | Fluorescent 200 nm | 15 mT | 2016 | Experiment, Numerical |

| Munkhoz et al. [25] | 2D PIV | Single | Arc gas | 0.1 T | 2017 | Experiment |

| El-Amin et al. [13] | CFD *** | Single | Ferromagnetic fluid | 0.2 T | 2018 | Numerical |

| Hangi et al. [31] | Two-phase mixture | Liquid–solid | Fe2Mn0.5Zn0.5O4 magnetic nanoparticles | 1.2E6 A/m | 2018 | Numerical |

| Shahsavar et al. [32] | Two-phase mixture | Liquid–solid | Mn–Zn ferrite ferrofluid | Up to 0.1 Am | 2018 | Numerical |

| Weerasiri et al. [33] | 2D PIV | Liquid–gas | Hollow glass spheres 10 μm | Up to 0.72 T | 2018 | Experiment |

| Munkhoz et al. [25] | 2D PIV | Single | Arc gas | 0.1 T | 2019 | Experiment |

| Tan et al. [26] | 2D PIV | Single | Fluorescent 200 nm | Electromagnetic | 2019 | Experiment |

| No. | Manufacturer, Model | Specifications |

|---|---|---|

| 1 | Thorlabs, LA1252-A, Plano convex lens | F * 25.4 mm, D ** 25 mm |

| 2 | Thorlabs, LA1540-A, Plano convex lens | F 15 mm, D 12.5 mm |

| 3 | Thorlabs, LA1484-A, Plano convex lens | F 300 mm, D 25.4 mm |

| 4 | Thorlabs, LA1805-A, Plano convex lens | F 30 mm, D 25.4 mm |

| 5 | Edmund Optics, 43–473, Full fan angle laser line generator lens | 30 degree |

| 6 | Mitutoyo, Plan Apo infinity corrected long working distance(WD) objective lens | 10×, N.A. 0.28, WD 34 mm |

| 7 | Thorlabs, MRA25-E02, PS911, Right angle prism + right angle prism mirror | 25 mm |

| 8 | Thorlabs, CCM1-E02/M, Cube-mounted turning prism mirror with 50:50 beam splitter and prism mirror | 565 nm |

| 9 | Thorlabs, LA1509-A, Plano convex lens | F 100 mm, D 25.4 mm |

| 10 | Thorlabs, VA100C/M, Adjustable mechanical slits | 30 mm |

| 11 | Thorlabs, LA1433-A, Plano convex lens | F 150 mm, D 25.4 mm |

| 12 | Thorlabs, CDFW5/M, Manual dichroic filter wheel | 30 mm, 5 filters |

| 13 | Thorlabs, LA1461-A, Plano convex lens | F 250 mm, D 25.4 mm |

| 14 | Thorlabs, BB1-E02 Broadband dielectric mirror | D 25.4 mm |

| 15 | Thorlabs, MRAK25-P01, Knife-edge right prism | 25 mm |

| 16 | Semrock, NFD01-532, Notch filter | 532 nm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.; Choi, Y.-S. Experimental Investigation of Magnetic Particle Movement in Two-Phase Vertical Flow under an External Magnetic Field Using 2D LIF-PIV. Appl. Sci. 2020, 10, 3976. https://doi.org/10.3390/app10113976

Lee C, Choi Y-S. Experimental Investigation of Magnetic Particle Movement in Two-Phase Vertical Flow under an External Magnetic Field Using 2D LIF-PIV. Applied Sciences. 2020; 10(11):3976. https://doi.org/10.3390/app10113976

Chicago/Turabian StyleLee, Changje, and Yong-Seok Choi. 2020. "Experimental Investigation of Magnetic Particle Movement in Two-Phase Vertical Flow under an External Magnetic Field Using 2D LIF-PIV" Applied Sciences 10, no. 11: 3976. https://doi.org/10.3390/app10113976

APA StyleLee, C., & Choi, Y.-S. (2020). Experimental Investigation of Magnetic Particle Movement in Two-Phase Vertical Flow under an External Magnetic Field Using 2D LIF-PIV. Applied Sciences, 10(11), 3976. https://doi.org/10.3390/app10113976