1. Introduction

Orthotropic steel decks (OSDs) are widely used in cable supported bridges and girder bridges due to their light weight and the short onsite construction time [

1,

2,

3]. However, several types of fatigue cracks occur at the edges of added holes and at welded joints in OSD bridges [

4,

5,

6]. In particular, the types of cracks that originate from the edges of diaphragm cutouts at the connections of U-ribs to diaphragms account for 42.3% to 85.5% of the total number of fatigue cracks in OSDs [

4,

5,

6,

7,

8,

9,

10]. The lack of timely and essential retrofits causes these cracks to elongate and propagate throughout the entire diaphragm, which decreases the serviceability of OSDs, and hence reduces the service life and safety of these bridges.

Conventional repair and retrofit technology of fatigue damages in steel structures include the stop-hole method [

11,

12,

13], weld repair method [

14,

15,

16], reinforcement with steel/carbon fiber reinforced polymer(CFRP) plates method [

17,

18,

19,

20,

21], concrete overlay methodology [

22], etc. These methods are common in fatigue reinforcement engineering projects of OSDs. However, removing short cracks by enlarging and optimizing the geometry of the cutout is a fast and effective method of mitigating fatigue damage; such a process excises short cracks around diaphragm cutouts and simultaneously reduces stress concentrations [

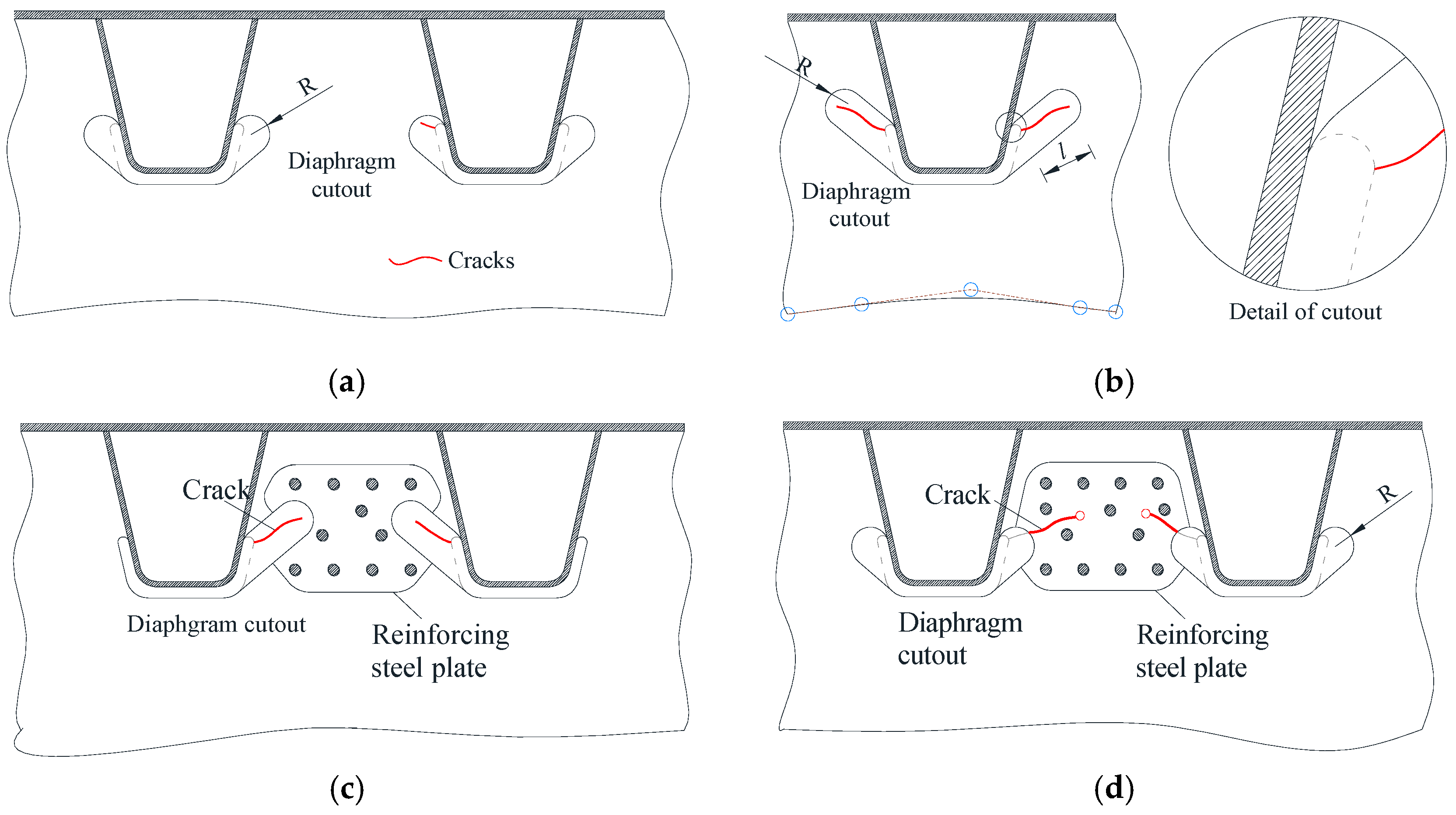

7,

23]. In addition, partial or complete removal of long fatigue cracks around diaphragm cutouts is often necessary before diaphragm rehabilitation by bolting or bonding with steel plates near the cutouts. Therefore, the geometry of diaphragm cutouts is very important for effective fatigue repair.

The effectiveness of fatigue retrofits of diaphragm cutouts is often determined by the maximum concentration stress [

23,

24,

25]. The cycling stresses and the magnitudes of stress amplitude lead to fatigue failure [

26,

27,

28,

29], which is also reflected in the “safe life” design [

30,

31,

32]. It has been incorporated in the AASHTO LRFD code (AASHTO 2017), Eurocode 3 (“Design of steel structures”), and other specifications, where the S-N curve and similar algorithm of diaphragm cutouts are given based on nominal stress or hot spot stress [

33,

34]. Another local stress method, named the effective notch stress approach, is adopted in the recommendations of the international institute of welding (IIW) as an alternative method.

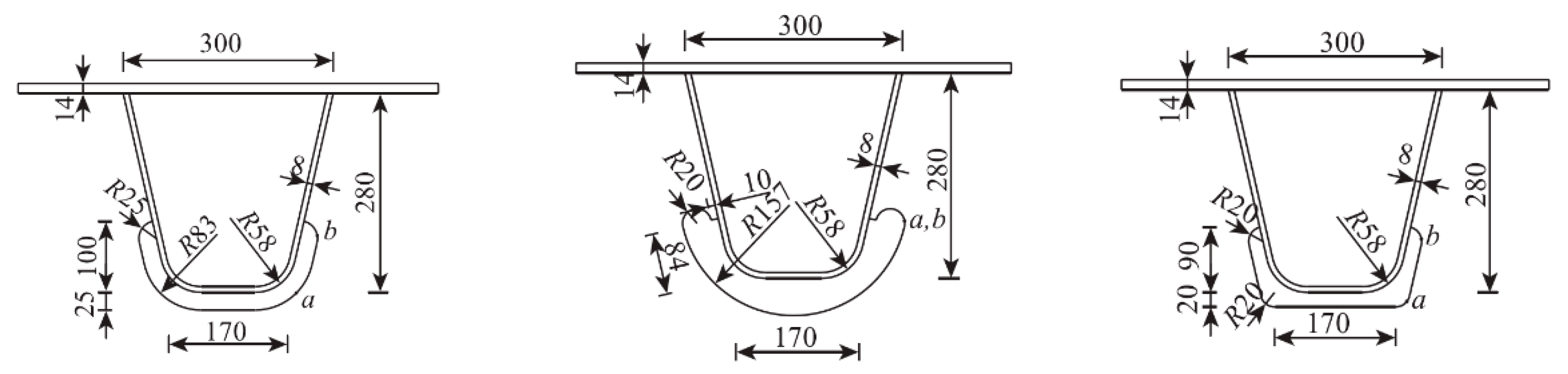

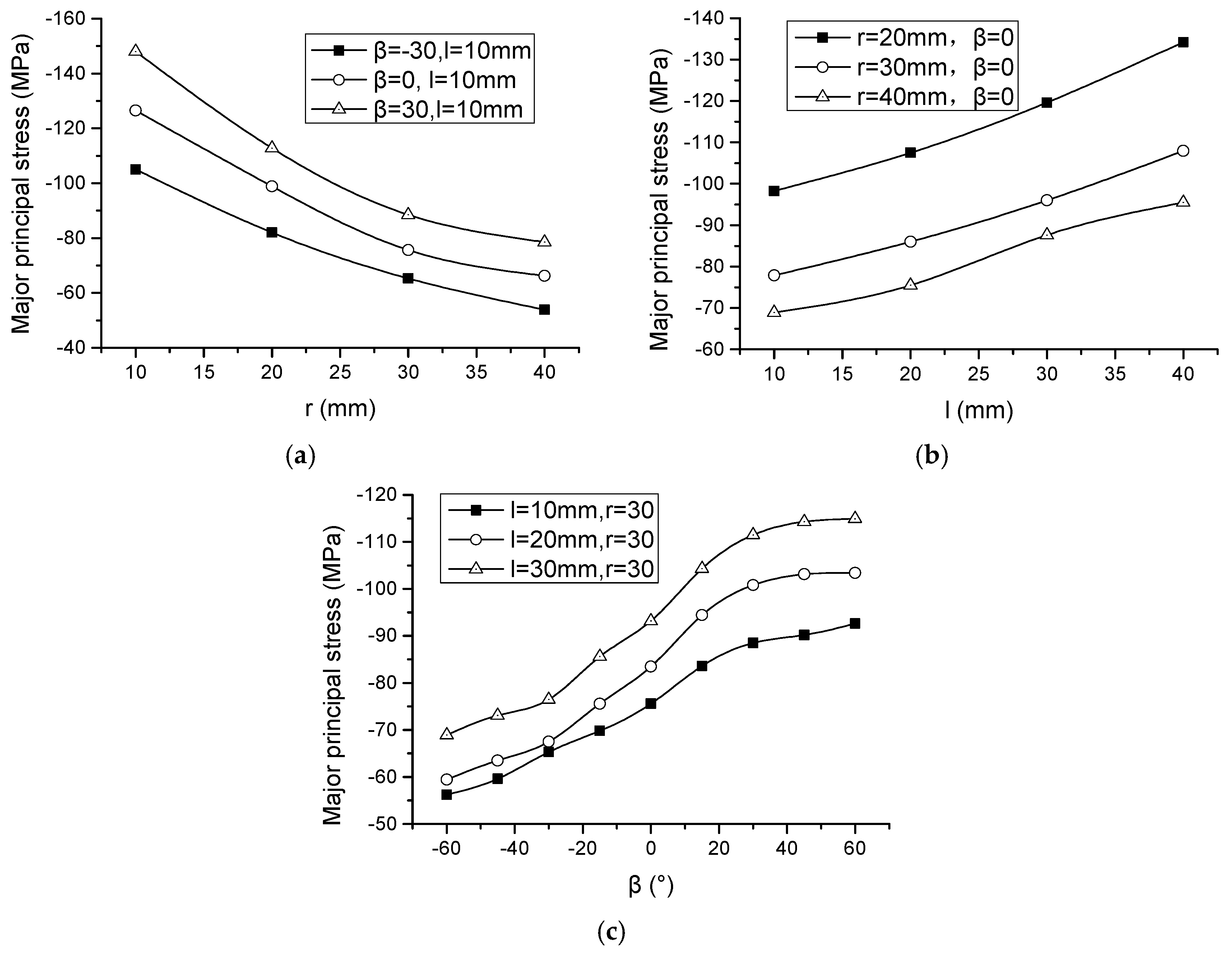

To improve the fatigue life of diaphragm cutouts, several normative documents and experiences suggest some typical cutout geometries for newly built bridges. Six typical diaphragm cutouts are shown in

Figure 1 that include the cutout in highway bridge (Type I) and cutout in railway bridge (Type II) in Eurocode 3, AASHTO cutout (Type III), Japanese standard cutout (Type IV), the cutouts used in the Williamsburg bridge in US and the Humen bridge in China (Type V), and the large radius cutout (Type VI). Comparative studies have been carried out for these typical cutout geometries. In these studies, the rib spacing is often set constant at 600 mm, which is the most commonly-used value. The values of the upper width of the U rib and the depth are often 300 and 280 mm, respectively. The deck plate and rib thicknesses were taken into consideration in some research, but the results showed that the above parameters have a slight influence. Several typical diaphragm cutouts have been studied to compare their stress state. They found that the stress concentration regions are located at the free edges of diaphragm cutouts, and the geometry and size of diaphragm cutouts are vital parameters affecting the maximum principal stress [

35,

36]. Ju et al. [

37] investigated the effect of the diaphragm cutout height on the stress distribution and the max-principal stress of typical diaphragm cutouts. Furthermore, the cutout radius, diaphragm thickness, and the position of longitudinal ribs were taken into consideration, which affect the stress distribution and concentration around the diaphragm cutouts, due to the effects of bending and shearing, in-plane supports, asymmetrical loading, and relative longitudinal deformations [

38,

39]. Based on studies conducted with cutout types (I), (II), (III), and (V), in which the spacing and thickness of diaphragms were taken into consideration, it was concluded that the design of the geometric dimensions of diaphragm cutouts has a great influence on the fatigue performance of the diaphragms [

40,

41,

42]. However, previous studies were only limited to typical diaphragm cutouts in newly built bridges. Little research has been conducted on the retrofitting of diaphragm cutouts in as-built bridges that have developed fatigue cracks using atypical geometries.

Diaphragm cutout retrofitting in as-built bridges should consider the geometry of the original shape, and the improved geometries generally are not the typical cutout type recommended by the related specifications. When changing the shape of diaphragm cutouts by cutting and grinding methods, the maximum stress of the diaphragm cutouts with a radius of 35 mm was reduced by 54.6% [

5]. Another scheme shows that based on the crack length, the fatigue stress can be reduced by 20–29% if the cracks were cut using a combination of straight and arc sections [

42]. In these above methods, stress reduction differs mainly because of the different cutting shapes used for the fatigue cracks in diaphragm cutouts. Given that the cutout geometry used to repair as-built bridges is different from that in newly built bridges, the retrofitting mechanisms and the actual effects of cutout repairs need to be analyzed and verified.

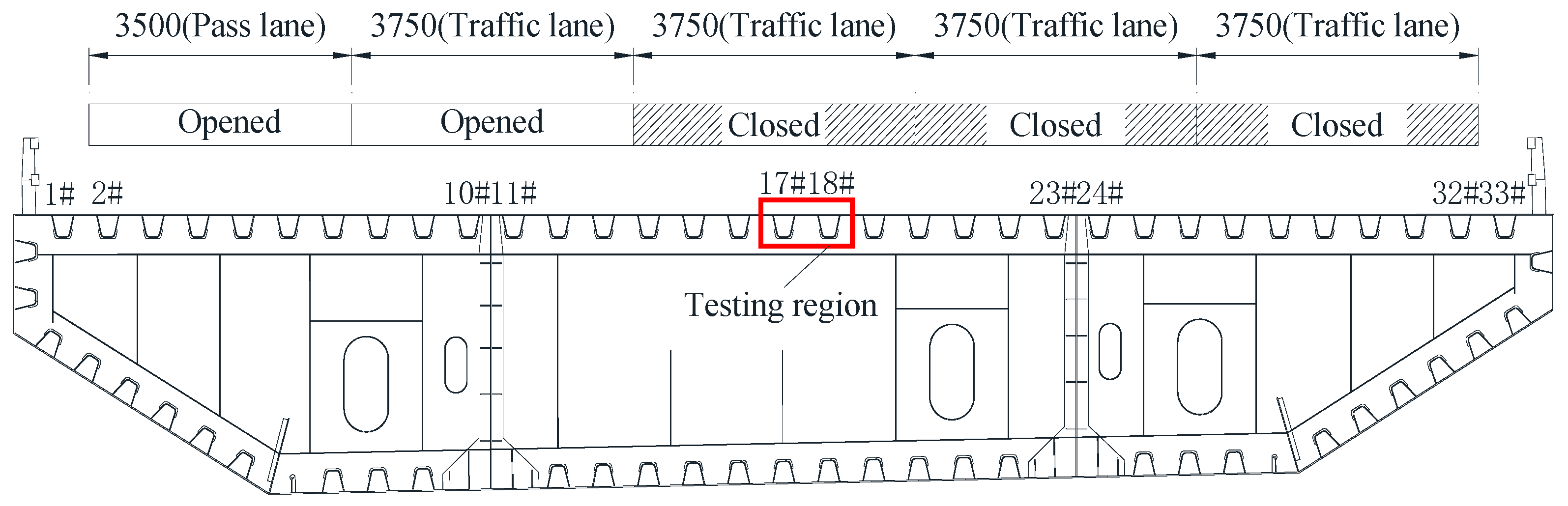

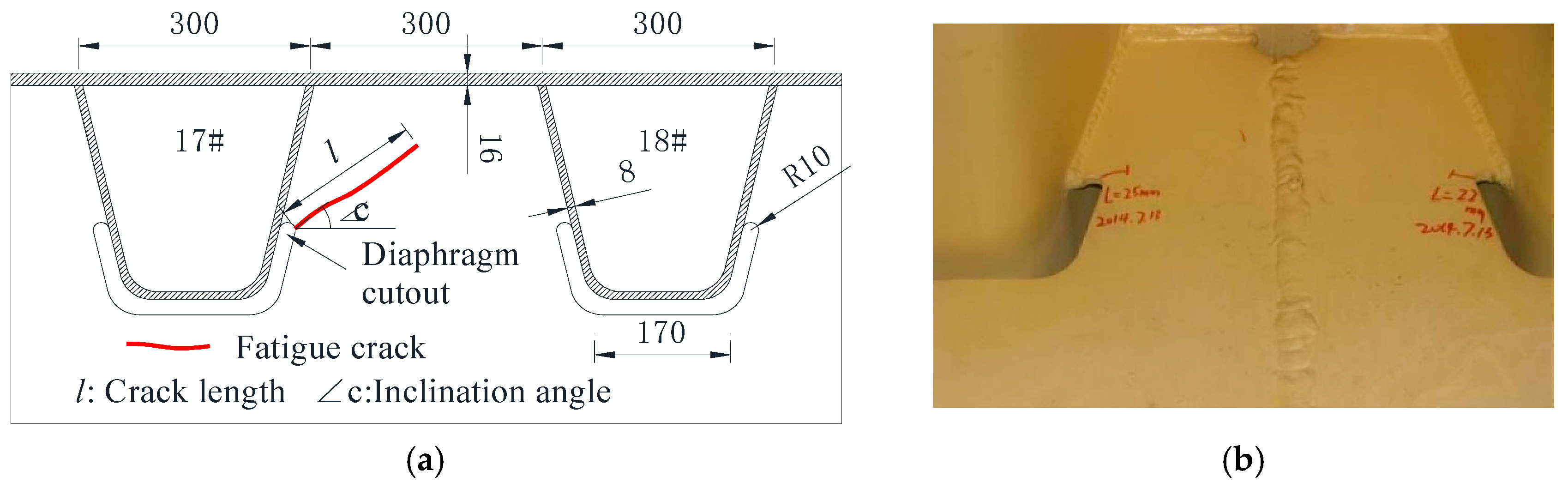

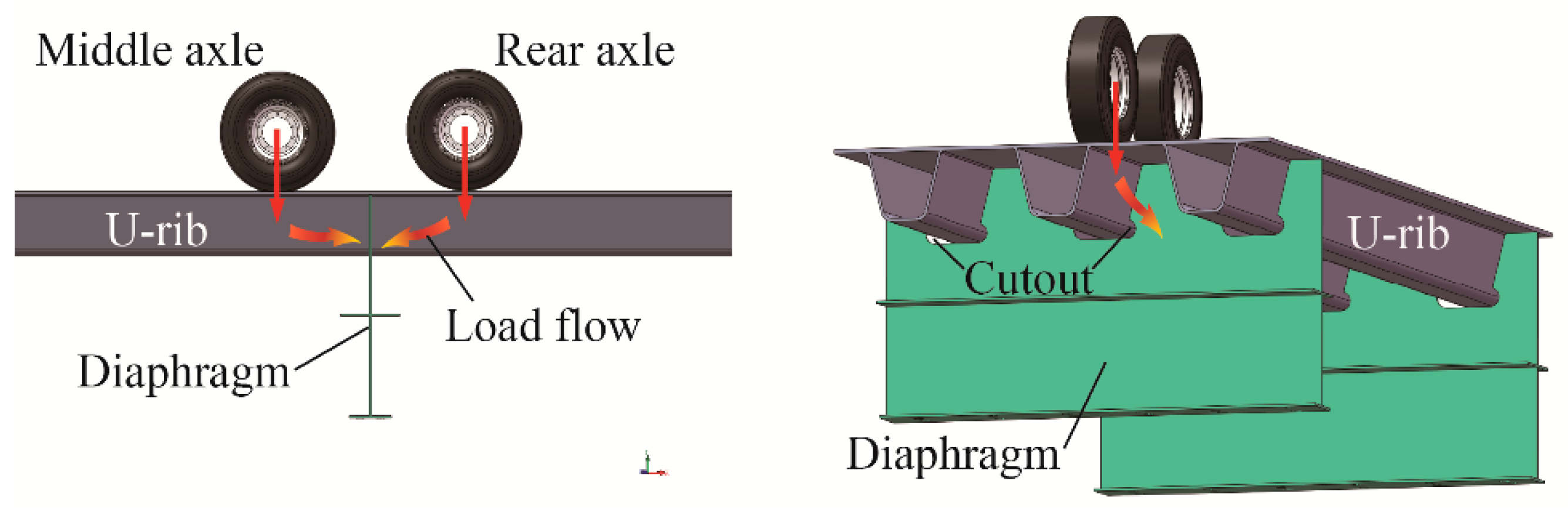

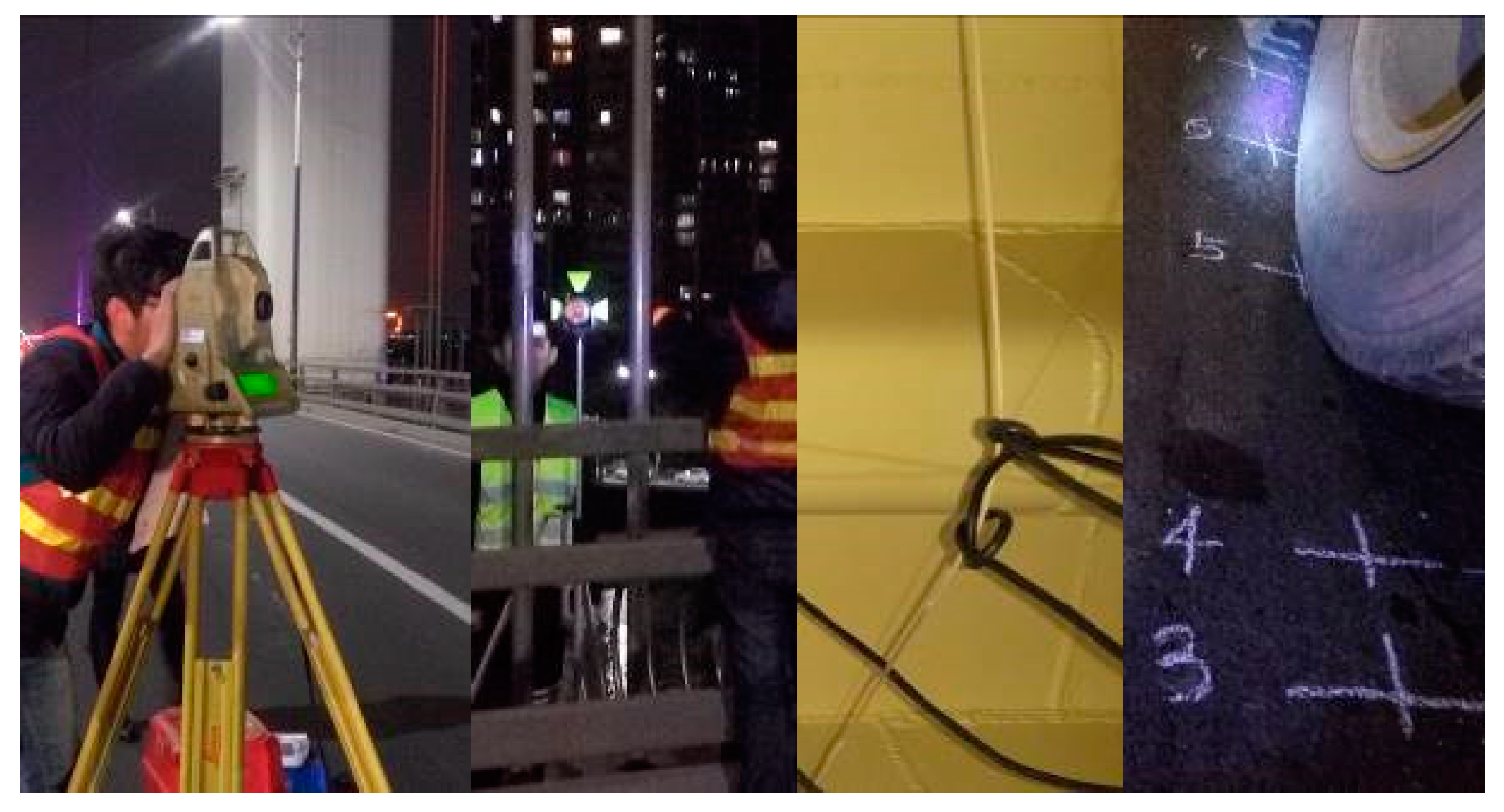

This paper explores the stress concentration mechanisms around diaphragm cutouts using stress flow methods, based on an OSD in a suspension bridge that had developed fatigue cracks during its service period, after nine years of operation. Thereafter, some principles of optimization and retrofitting strategies of diaphragm cutouts were proposed to reduce stress concentration and eliminate short fatigue cracks. Repair schemes were designed on the basis of these optimization principles, and were carried out at a test segment of OSD with a length of 30 m in this bridge. Wheel loads were applied with standard trucks and stresses were measured during loading test on this bridge. The stress state on the original and retrofitted diaphragm cutouts were compared and analyzed. The retrofitting mechanisms and experimental data presented in this study can provide reference in the rehabilitation of OSDs with diaphragm cutout cracks.

5. Results and Discussion

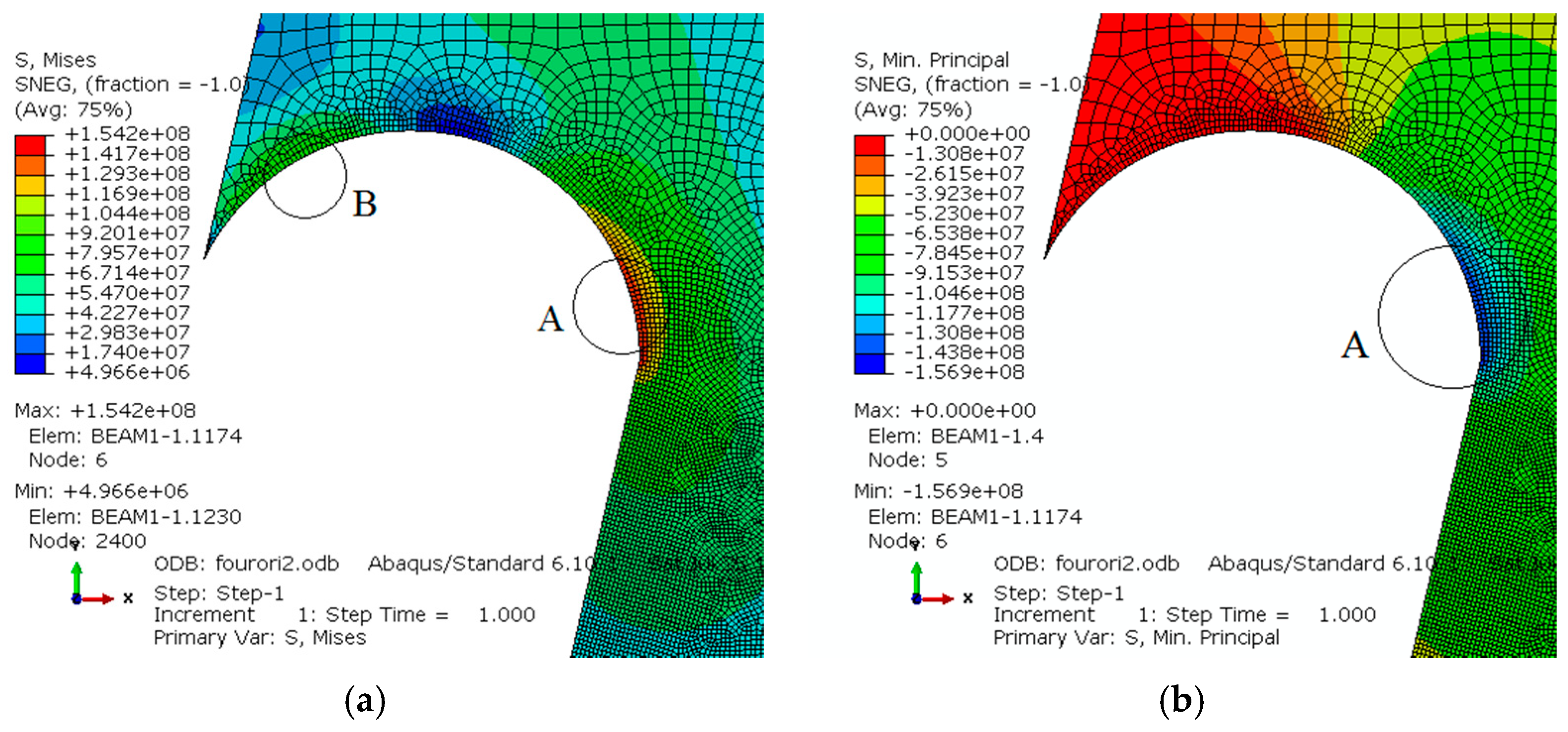

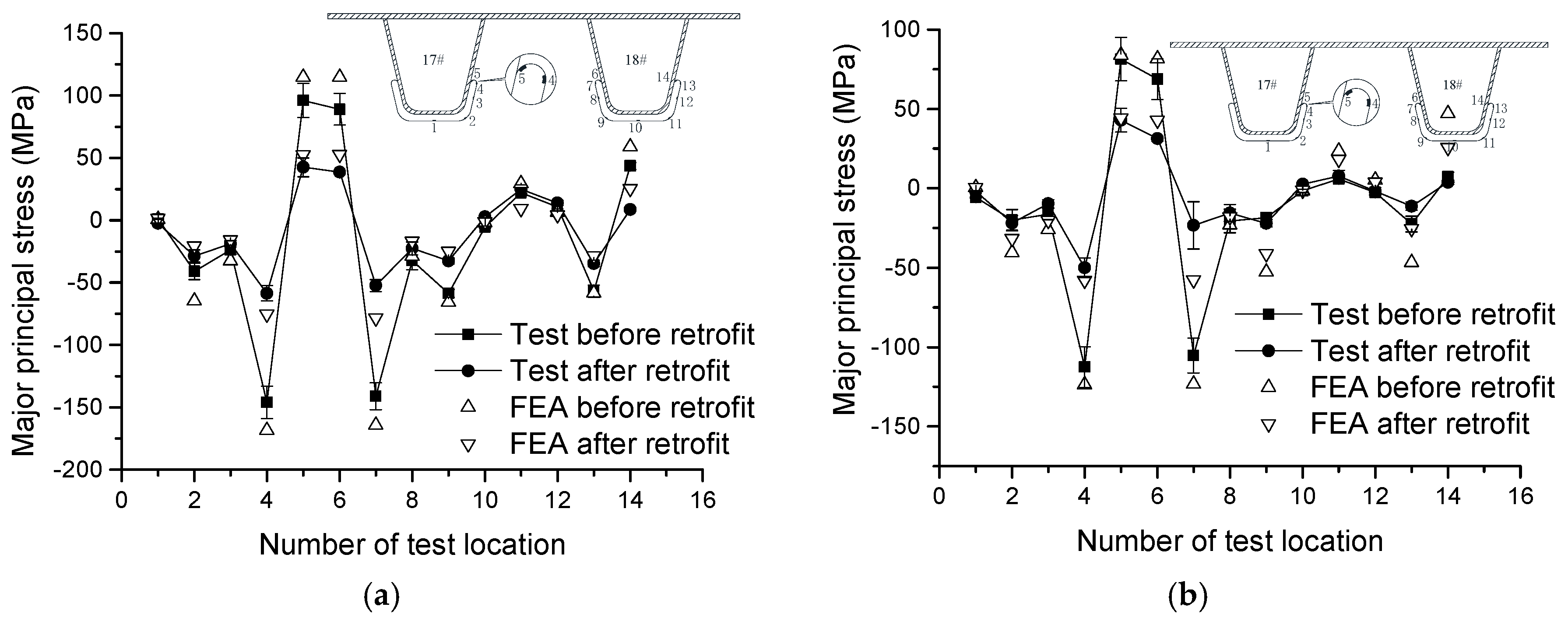

5.1. Stress Distribution Along the Edge of Diaphragm Cutouts

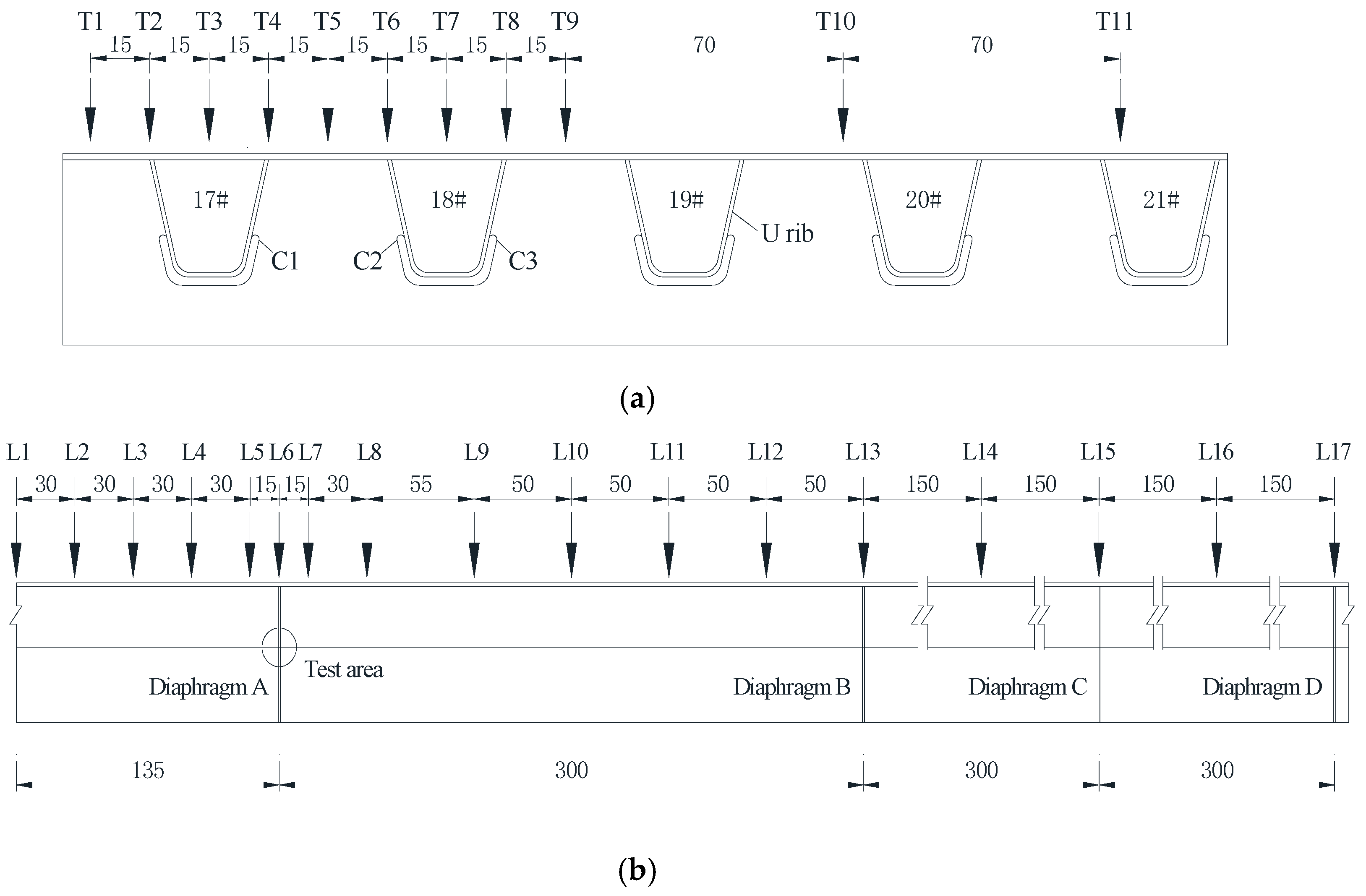

The test results of two typical longitudinal loading cases, at locations L3 and L10 in

Figure 14b, are presented and analyzed to verify the effects of geometry optimization of cutouts and summarize the stress distributions along the edges of diaphragm cutouts. In the load case L3, the central axis and the rear axis were located on either side of the test diaphragm at equal spacing (0.75 m). The out-of-plane moment of the diaphragm is equal to zero, and the in-plane forces within the diaphragm are transmitted mainly from the U-ribs as shear forces. The maximum stress was recorded in zone A around the diaphragm cutout for this load case, and its stress distribution is shown in

Figure 16. In the load case L10, the center of the rear axle is 1.5 m away from the diaphragm and is located midway between the two diaphragm plates. From the test and FEA results, it can be found that:

(1) The experimental data is in good agreement with the FEA results, in terms of the stress distributions. The experimental data from several stress gauges, such as those at locations 5 and 6, are less than the corresponding maximum stress in FEA, because the stress values obtained by strain gauges is the mean value over a strain gauge’s length of 2 mm. The comparison indicates that large stress concentrations occur under vehicular loads leading to fatigue cracks around diaphragm cutouts.

(2) The maximum principal stress measured in zone A, which is at cutouts C1 and C2, is –146.8 MPa for the load case L3, before the diaphragm cutout was retrofitted. The tested stress after retrofitting is −58.5 MPa, and the stress range is reduced by 59.9%. For the load case L10, the stress range decreases by 55.5%, as shown in

Figure 16b, which indicates that the optimization of diaphragm cutouts can effectively reduce the stress range in zone A and hence improve fatigue life.

(3) The maximum tensile stress measured in zone B at cutouts C1 and C2 is 96.2 MPa before the retrofitting of the diaphragm cutout for the load case L3. The tested stress after retrofitting is minus 42.7 MPa, and the stress range is reduced by 55.6%. For the load case L10, the stress amplitude decreases by 47.4%, indicating that the optimization of diaphragm cutouts can also effectively reduce the stress range in zone B and improve fatigue life.

(4) The stress around cutout C3, which is 600 mm from cutout C1, is much smaller, because the influence of the wheel load in the transverse region is limited around the location of a U-rib. It is also observed that the stress reduction of zone A and zone B in cutout C3 is minus 35.2 MPa after retrofitting, which is about half the stress before retrofitting.

(5) Except for the gauges located in zone A and zone B, the gauges at other locations along the edge of diaphragm cutouts were less affected by cutout retrofitting; since the vehicular load induced stress is small at these locations the potential fatigue damage may not take place.

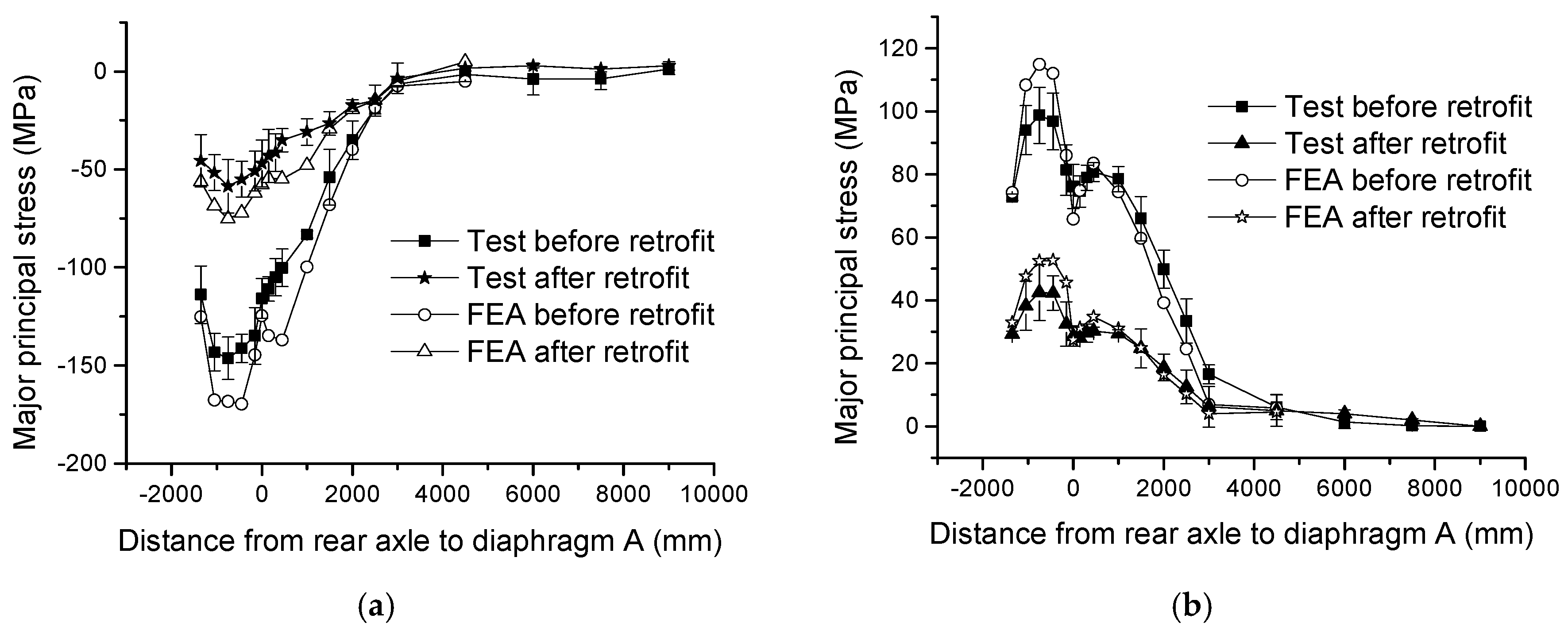

5.2. Stress Spectra due to a Longitudinally Moved Vehicle

The stress spectra of zone A and zone B for the standard vehicle tests are presented in

Figure 17. The stresses in these figures are the average value and the error bars reflect the deviations from the average value.

(1) Under longitudinal wheel loading, the value of the maximum stress obtained from the tests is generally less than the FEA value, and the difference is less than 12.5%. Considering that it is difficult to experimentally capture the maximum stress at the locations of the strain gauges, the error is within an allowable range.

(2) For the longitudinal loading, the measured stresses in zone A are all compressive stresses. The maximum compressive stress measured before retrofit is 146.2 MPa with a measurement error of 10.8 MPa. In comparison, the maximum compressive stress measured after retrofit is 58.6 MPa with a measurement error of 13.6 MPa. The maximum reduction in stress is 87.6 MPa, at the location L3. The maximum stress reduction ratio is 58.4%, at the location L5.

(3) The measured stresses in zone B under various longitudinal movement conditions are tensile stresses. The maximum tensile stress measured before retrofit is 95.8 MPa with a measurement error of 8.6 MPa, while the maximum measured stress after retrofit is 42.4 MPa with a measurement error of 6.2 MPa. The maximum reduction in stress is 53.4 MPa, at the location L3. The maximum stress reduction ratio was 62.5%, at the location L11.

(4) The principal compressive stress is large, when the deck is subjected to the load cases L2, L3 and L4. For these cases, the central axis is located at the front of the diaphragm and the rear axis is located at the back of the diaphragm simultaneously. The wheel load does not directly act on the upper part of the diaphragm. Because the wheel load acting on the bridge deck is mainly transmitted to the diaphragm through the U-ribs.

5.3. Stress Spectra due to a Transversally Moved Vehicle

For the lateral loading, the measured stress and FEA results of zone A and zone B are shown in

Figure 18. The origin of the transverse coordinate is located at T5, and the transverse distance in

Figure 18 indicates the distance of the left wheel from T5.

(1) When the lateral position of the wheel load is directly above the test diaphragm cutout, the stress at zone A is relatively large. The stress is greatest when the wheel load is at T3 and T5. After the retrofit, the stress amplitude in zone A decreases by 58.7%.

(2) The stresses in zone B are tensile stresses, which are related to the shape of the diaphragm cutout. When the wheel load is applied at T5, the value of the stress at the measuring point 5 is the maximum one. The stress decreases significantly when the wheel load is far away from the measuring point 5.

(3) According to Eurocode 3, when the fatigue loading model III is used for checking the locally stressed components, the lateral probability of the wheels in the lane should be considered. The spacing between the loading areas 1, 2(3) and 4(5) is 100 mm, and the probability of occurrence at each line is respectively 7%, 18% and 50% according to Eurocode 3 (“Design of steel structures”). The equivalent constant amplitude stress with transverse probability distribution is reduced to 55.2% and 51.8% respectively.

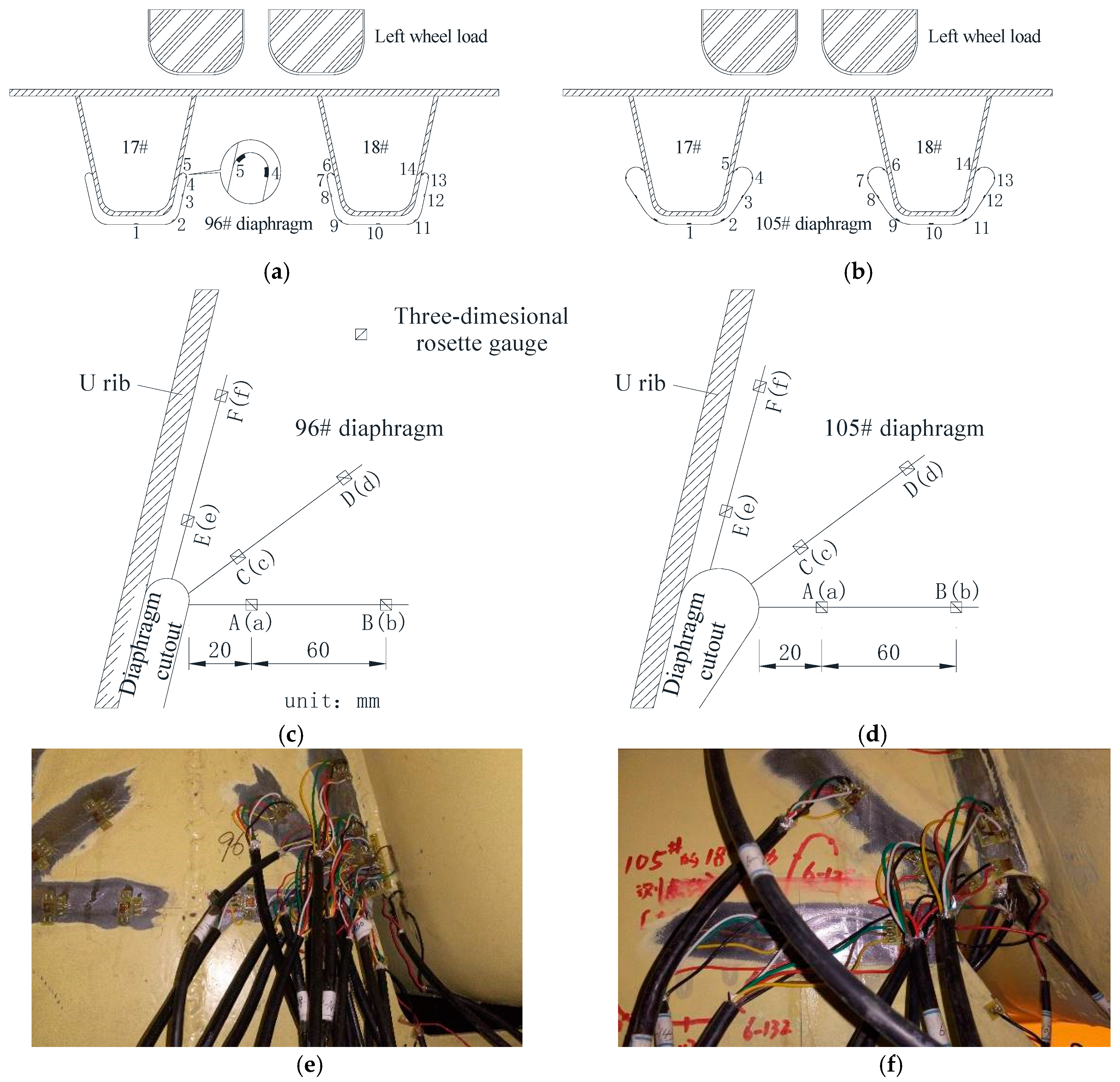

5.4. Principal Stresses around Diaphragm Cutouts

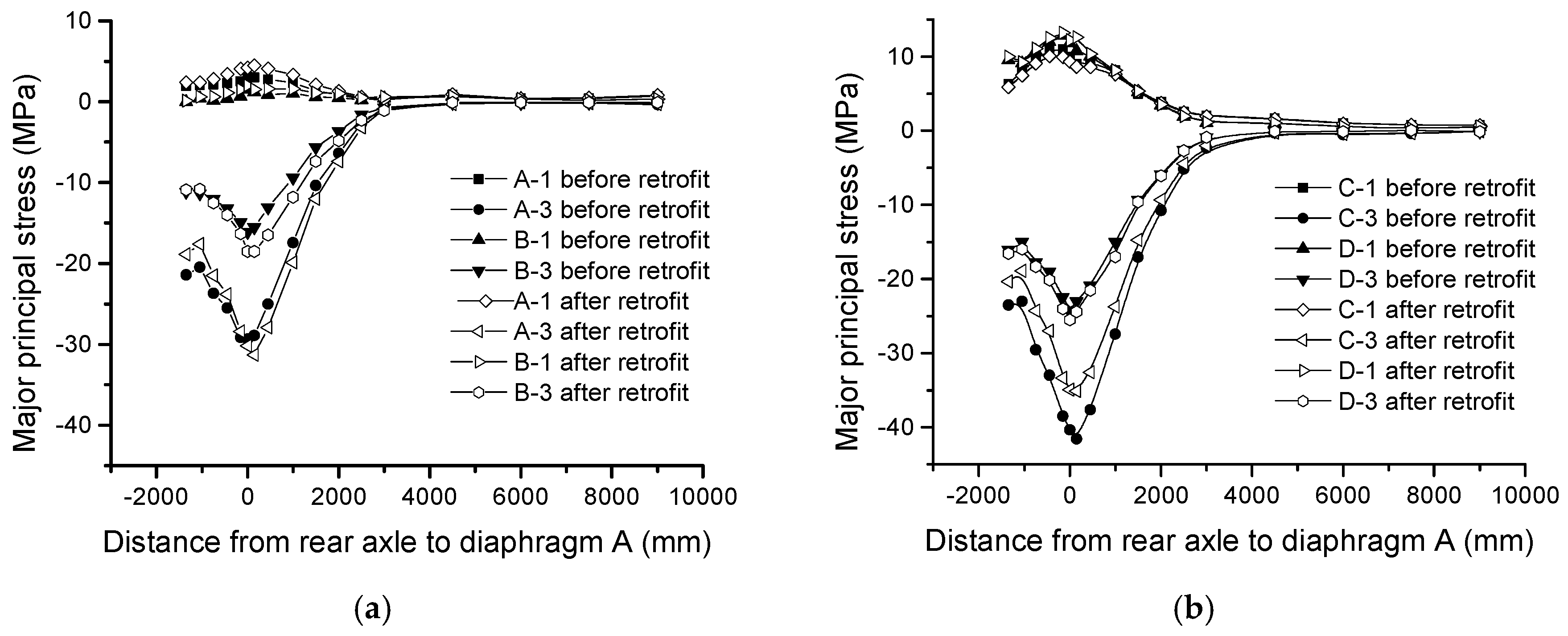

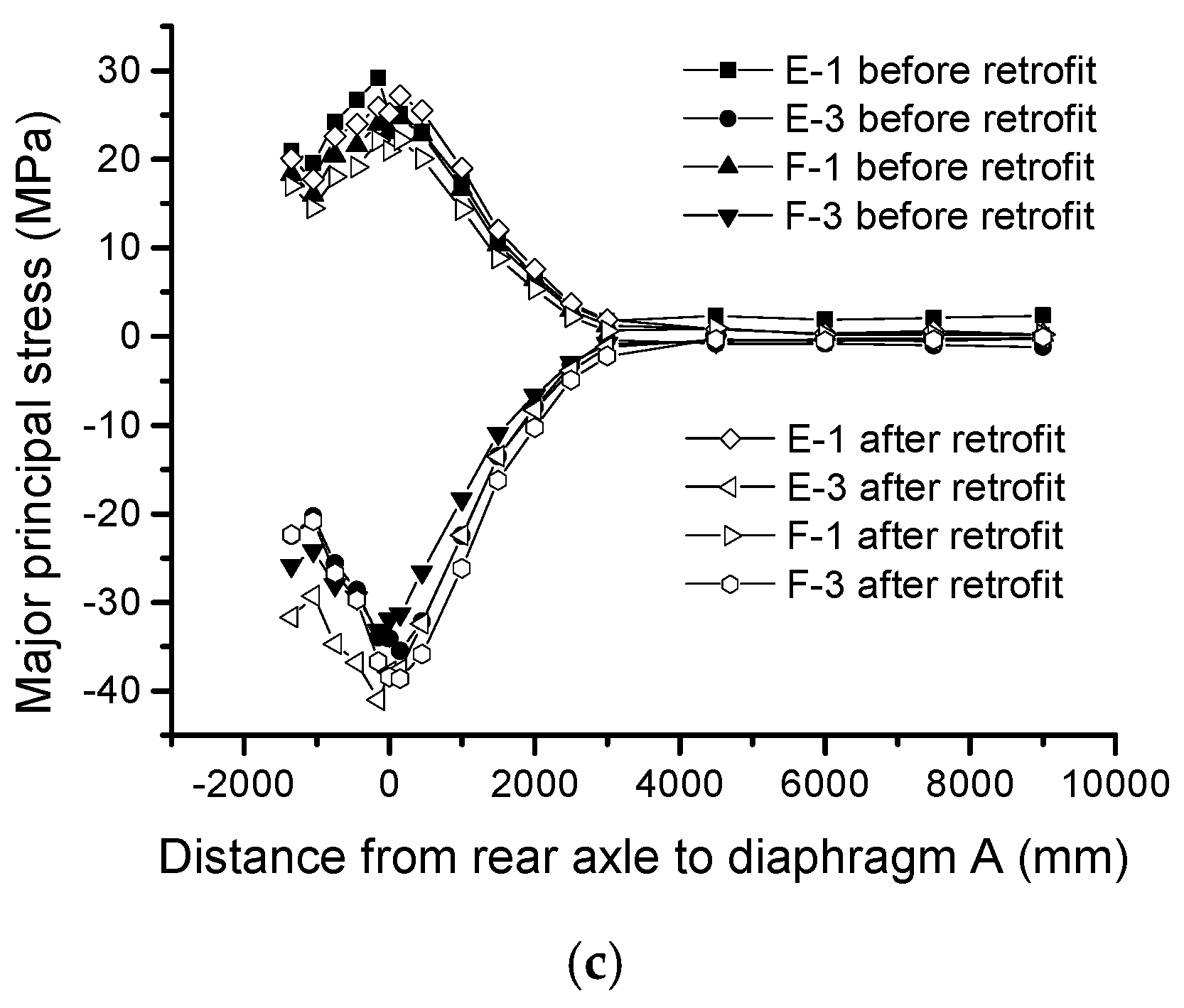

Principal stresses were acquired by three-direction rosette gauges arranged at the side of the diaphragm, 20 and 80 mm away from the edge of the diaphragm cutout. The measurements from the rosette gauges on both sides of the diaphragm were averaged.

Figure 19a–c shows the test data along the horizontal line, 45° directional line and parallel U-rib web line, respectively. The abbreviations A-1 and A-3 represent the first and the third principal stresses of gauge A.

Figure 19a shows that at measuring points A and B, the third principal stresses after retrofit are generally larger than those before retrofit, and the maximum stress at the measuring point B increases by 6.4%. It shows that increasing the diaphragm cutout weakens the sectional area of the diaphragm, leading to the increase in stress in the diaphragm, but this increment in stress is small, and could not result in new fatigue cracks. The third principal stresses at the measuring points before and after the retrofit are large, and the first principal stresses are small, indicating that this is an area of primarily compressive stress, and the direction of the principal stress is vertically downward. The stress at point A near the diaphragm cutout is greater than that at point B, and the third principal stress difference at the location of peak stress is about 15 MPa, indicating that the stress concentration effect of the incision does occur but is not significant. After the retrofit of the diaphragm cutout, the stress concentration effect of the incision is reduced.

According to the data presented in

Figure 19b, the third principal stress (C-3) of measuring point C before the retrofit is larger than that after the retrofit. The effect of stress concentration on the diaphragm cutout before reinforcement on the measuring point C is greater than the effect of the change in the cross-sectional area of the diaphragm, thus causing an increase in the average stress. Increasing the radius of the diaphragm cutout can effectively reduce the stress concentration effect in the area around the diaphragm cutout. The third principal stress at the measuring point C after retrofit is larger than that at the measuring point D, and the maximum difference between the stress curves is about 10 MPa. The stress gradient between measurement point C and measurement point D after retrofit is 166.6 MPa/m. Before the retrofit, the stress gradient between point C and point D was 283.3 MPa/m. The results show that the stress gradient on the diaphragm can be effectively reduced with diaphragm cutout optimization.

The data in

Figure 19c demonstrates that before and after the diaphragm cutouts were retrofitted, the change in stress of the diaphragm near the U-rib is small, which does not affect the fatigue performance of the weld joint between the diaphragm and U-rib. Therefore, the stress concentration effect of the diaphragm cutout has little effect at this position. The first and third principal stresses at the measurement points of the diaphragm in the direction parallel U-ribs are almost equal, but in opposite direction.

5.5. Fatigue Life Assessment of Diaphragm Cutouts

The cutout retrofit method of hot cutting combined with edge-corner grinding causes residual tensile stress, which affects the stress ratio of the wheel load induced stress spectrum. But the stress ratio has little effect on the fatigue life of the whole steel structure, since fatigue life is mainly related to stress amplitude. Therefore, the effect of residual cutting stress on fatigue life is ignored in this paper.

In Eurocode 3 (“Design of steel structures” (Parts 1–9)), the fatigue analysis method named the Vierendeel-model is presented to calculate the fatigue life of diaphragm cutouts, which ignores the effect of the cutout geometry. Therefore, it is not suitable to evaluate the fatigue life of cutouts in this paper. Another approximate assessment method is mentioned in Eurocode 3, in which the modified nominal stress is used to evaluate fatigue life for a geometric discontinuity that has not been considered in the classification of a particular construction detail. Therefore, the construction detail No. 4 in Parts 1–9 of Eurocode 3 (details in Table 8.1 of Eurocode 3) with the detail category 140 is selected for the following two reasons: firstly, both methods involve fatigue crack initiation at the cutting edge, as shown in

Figure 3; secondly, the direction of crack propagation is perpendicular to the direction of principal stress. The modified nominal stress is defined as the nominal stress multiplied by the stress concentration factor. Therefore, the modified nominal stress around diaphragm cutout can be used to evaluate fatigue life based on the construction detail No. 4.

The modified nominal stress ranges in zone A, that considers the lateral probability distributions of five-wheel positions, is defined as follows:

where

is the modified nominal stress range in zone A, which is caused by the fatigue loads with a standard vehicle, and takes into account the local stress magnification in relation to detail geometry, that is not included in the reference curves.

The ultimate state equation of the relation between fatigue strength and modified nominal stress range is represented as follows based on a series of S-N-curves, which correspond to typical detail categories.

where:

and

are the partial factors for equivalent constant amplitude stress ranges and fatigue strength, respectively, and set as 1.0 for design security and were not taken into consideration in fatigue life prediction in this research;

is the reference value of the fatigue strength at 2 million cycles, which is 140 for constructional detail No. 4;

is the value of modified nominal stress range subjected to 2 million cycles, which be determined as follows:

is the damage effect factor, which takes the fatigue model III and the length of the influence line into consideration, and the value is 1.85 for diaphragm cutouts.

is the traffic flow factor for fatigue model III, which considers the daily traffic volume.

is the design life effect factor, which is directly related to fatigue life.

is the multi-lane effect coefficient, the value is 1 for fatigue model III.

In the above equations, t is the fatigue life in years, j is the total number of traffic lanes, Ny is the daily traffic volume on one box girder, and p is the ratio of heavy traffic to total traffic, which is assumed to be 40% for highways in case of a lack of statistical data. When the modified nominal stress ranges of the detail No. 4 are greater than 103.1 MPa, the x is 3; otherwise the x is 5 in the above equations.

Substituting Equations (1), (2), (4) and (5) into Equation (3), we obtain Equation (6) as follows.

According to the statistics of WIM for this suspension bridge, the average daily traffic of a steel box girder was 45,900 in 2016. The fatigue life

t (in units of year) can be obtained, and the calculation process and results are presented in

Table 2.

The evaluated fatigue life of diaphragm cutouts in this bridge is 1.7 years from FEA and 4.9 years from test stress data before the cutouts were retrofitted, based on the daily traffic in the year 2016. However, the predicted fatigue life increases to 78.1 years from FEA and 155.5 years from test stress data after the diaphragm cutouts were retrofitted. The fatigue life increased by 46.0 and 31.4 times based on the FEA and test stress data, respectively. These evaluated results indicate that proposed retrofitting technology is suitable for fatigue damage rehabilitation in zone A at diaphragm cutouts and the optimized geometry used to increase fatigue life has a beneficial effect on diaphragm cutouts.

6. Conclusions

The stress flow method is used to analyze the cause of stress concentration at the diaphragm, the wheel loads on the deck transmit stress to the diaphragms through the U-ribs. In the process of load transmission, the stress flows are obstructed by diaphragm cutouts, resulting in the local high density of stress flows, and hence leading to stress concentrations around the cutouts.

According to the analysis of the geometric parameters of diaphragm cutouts, it is found that the geometrical size of the diaphragm cutout should be small, while the radius should be large, the included angle should be negative, and the stress flow should not be obstructed by cutouts. Therefore, an optimized geometry with a radius of 35 mm is recommended to reduce stress concentrations in zone A and zone B and to remove short fatigue cracks at diaphragm cutouts.

The maximum principal stresses in zone A and zone B around the cutouts were decreased significantly after the diaphragm cutouts were retrofitted. The local stresses decreased up to 87.6 MPa, and the stress reduction ratio is 59.9%. When the lateral probability distribution is considered, the equivalent constant amplitude stress is reduced by 55.2%. However, the stress at the critical section, which is near the cutout and at the horizontal line in the diaphragm, is increased slightly because this critical section is narrowed due to the increase in the radius of the cutout.

Based on the construction detail No. 4 in Table 8.1 in Eurocode 3, the modified nominal stress method, which takes the influence of geometry into consideration, is used to evaluate the fatigue life of diaphragm cutouts. The evaluated fatigue life of diaphragm cutouts, based on FEA and test results, are 1.7 years and 4.9 years respectively, before the cutouts are retrofitted, and increase to 78.1 years and 155.5 years respectively after retrofitting. These results indicate that this retrofitting technology is suitable for fatigue damage rehabilitation in zone A of the diaphragm cutouts.

The hot cutting method combined with corner grinding used to retrofit the geometry of diaphragm cutouts causes residual tensile stress, which is ignored in this paper. The residual stress distribution, the influence of the R ratio and a high-precision assessment method for diaphragm cutouts need to be further studied.