Comparative Analysis of Energy Consumption, Indoor Thermal–Hygrometric Conditions, and Air Quality for HVAC, LDAC, and RDAC Systems Used in Operating Rooms

Abstract

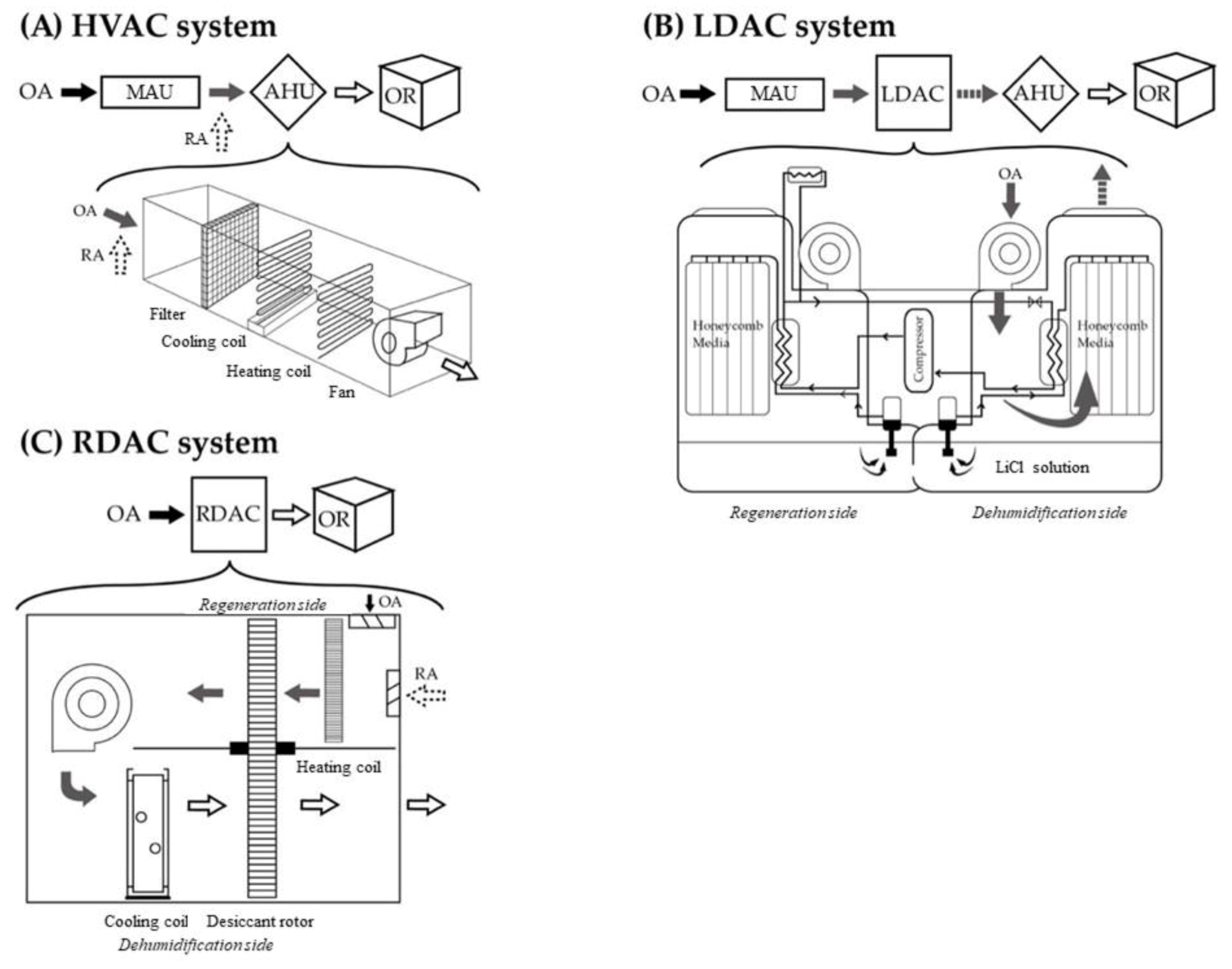

1. Introduction

2. Materials and Methods

2.1. Study Location

2.2. Indoor Thermal–Hygrometric Conditions and Air Quality Monitoring

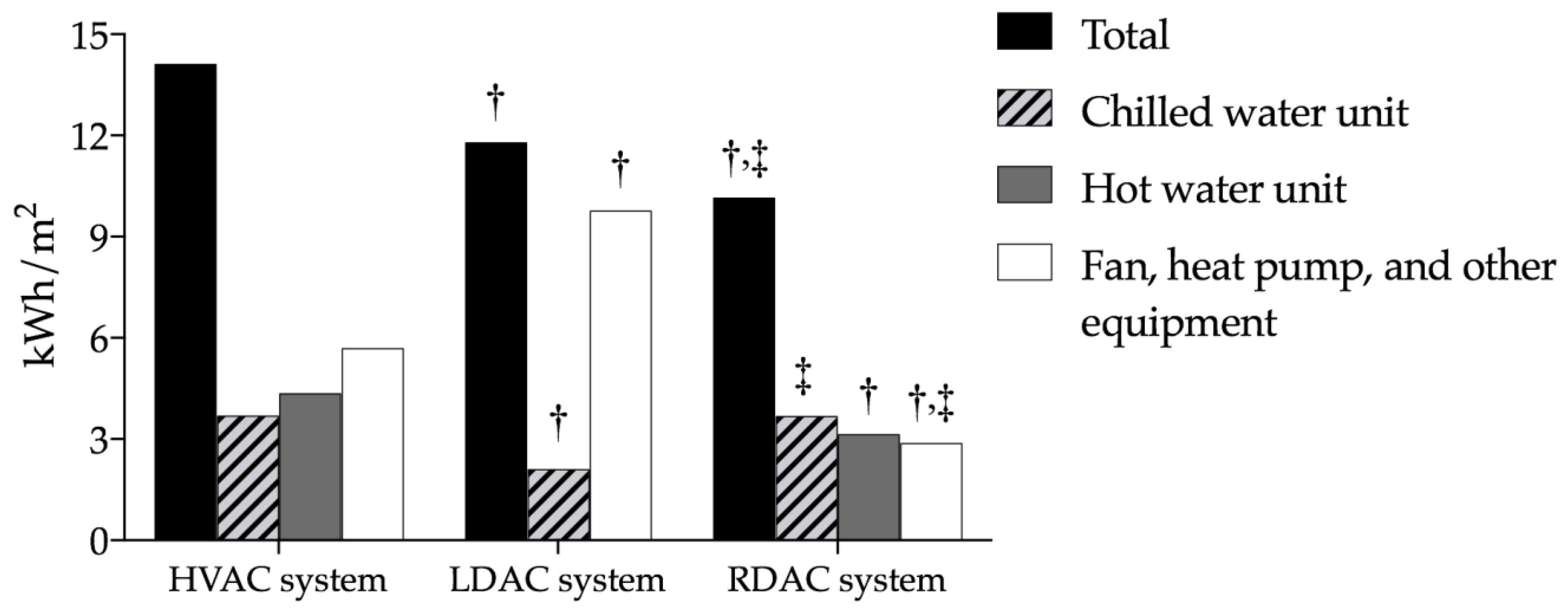

2.3. Energy Consumption

2.4. Statistical Analysis

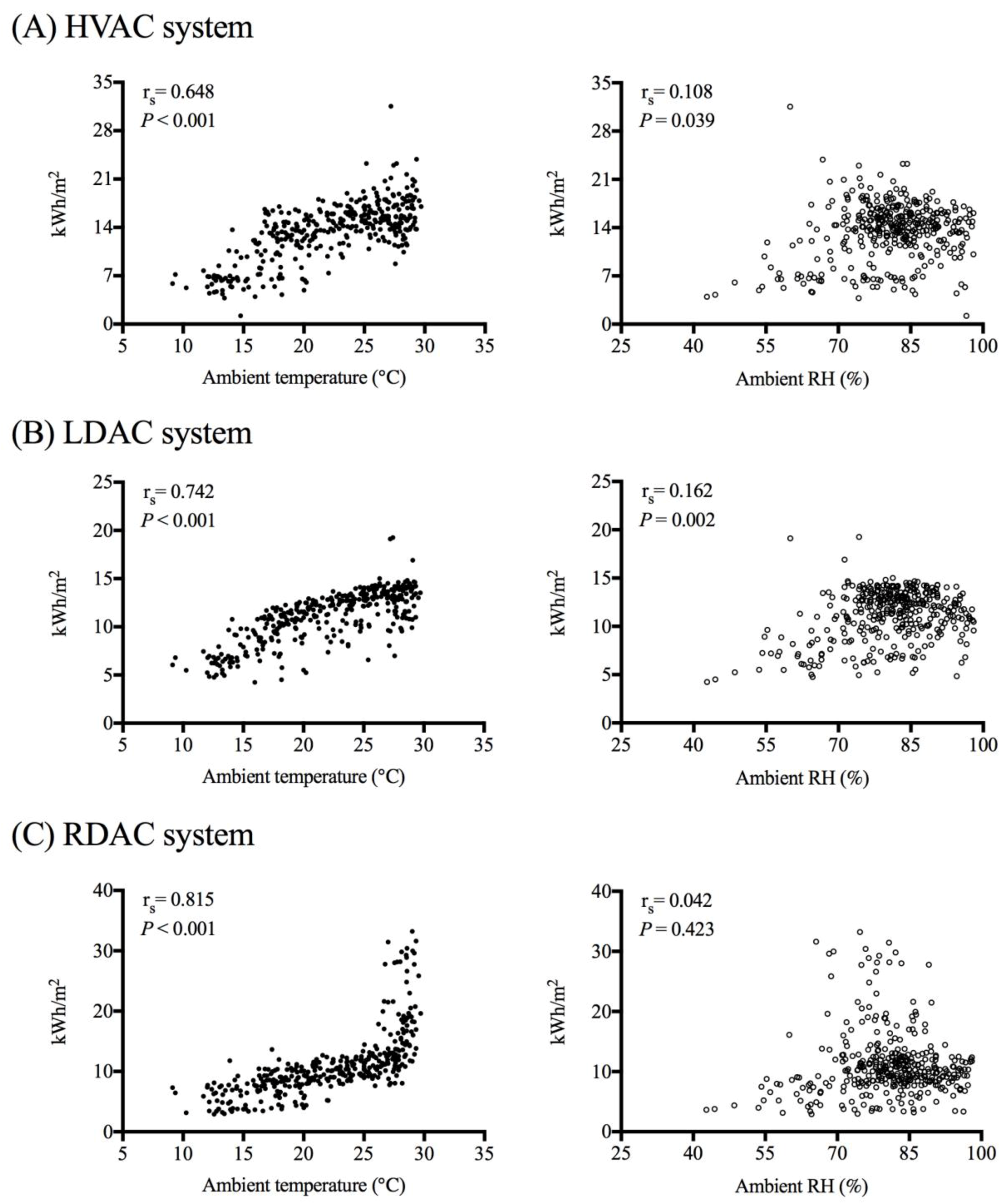

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ACH | air changes per hour |

| AHU | air-handling unit |

| CFU | colony forming unit |

| CO2 | carbon dioxide |

| CSA | Canadian Standards Association |

| EIA | Energy Information Administration |

| FGI | Facility Guidelines Institute |

| HEPA | high-efficiency particulate air |

| HVAC | heating, ventilation, and air conditioning |

| LDAC | liquid desiccant air conditioning |

| LPM | liter per minute |

| LiCl | lithium chloride |

| MERV | minimum efficiency reporting value |

| ORs | operating rooms |

| PMs | particulate matters |

| RT | refrigeration ton |

| RDAC | rotary desiccant air conditioning |

| RH | relative humidity |

| TSA | tryptic soy agar |

References

- Magill, S.S.; Edwards, J.R.; Bamberg, W.; Beldavs, Z.G.; Dumyati, G.; Kainer, M.A.; Lynfield, R.; Maloney, M.; McAllister-Hollod, L.; Nadle, J.; et al. Multistate point-prevalence survey of health care-associated infections. N. Engl. J. Med. 2014, 370, 1198–1208. [Google Scholar] [CrossRef] [PubMed]

- CDC (Centers for Disease Control), Guideline for Prevention of Surgical Site Infection. 1999. Available online: https://www.cdc.gov/hai/pdfs/SSIguidelines.pdf (accessed on 5 July 2018).

- Yau, Y.H.; Ng, W.K. A comparison study on energy savings and fungus growth control using heat recovery devices in a modern tropical operating theatre. Energy Convers. Manag. 2011, 52, 1850–1860. [Google Scholar] [CrossRef]

- Kelkar, U.; Bal, A.M.; Kulkarni, S. Fungal contamination of air conditioning units in operating theatres in India. J. Hosp. Infect. 2005, 60, 81–84. [Google Scholar] [CrossRef] [PubMed]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers. ANSI/ASHRAE/ASHE Standard 170-2017: ASHRAE/ASHE Standard Ventilation of Health Care Facilities; Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE): Atlanta, GA, USA, 2017. [Google Scholar]

- Burril, G.D.; Snell, R.; Bagworth, S.; Belanger, R.J.; Bogdan, S.; Bonavota, D.; Carson, W.D.; Dixon, R.; Drolet, C.; Ellinas, L.; et al. Special Requirements for Heating, Ventilation and Air-Conditioning (HVAC) Systems in Health Care Facilities; CSA Standard: Z317.2-15; Canadian Standards Association: Toronto, ON, Canada, 2015. [Google Scholar]

- The Facilities Guidelines Institute. Facilities Guidelines Institute Status Update: Guidelines for Design and Construction of Health Care Facilities. 2018. Available online: http://www.fgiguidelines.org (accessed on 5 September 2019).

- Vellei, M.; Herrera, M.; Fosas, D.; Natarajan, S. The influence of relative humidity on adaptive thermal comfort. Build. Environ. 2017, 124, 171–185. [Google Scholar] [CrossRef]

- Fu Shaw, L.; Chen, I.H.; Chen, C.S.; Wu, H.H.; Lai, L.S.; Chen, Y.Y.; Wang, F. Factors influencing microbial colonies in the air of operating rooms. BMC Infect. Dis. 2018, 18, 4. [Google Scholar] [CrossRef]

- Yufeng, Z.; Zhaoji, W.; Mingyang, Z.; Jinbo, M.; Ling, J.; Fulin, W. Smart indoor humidity and condensation control in the spring in hot-humid areas. Build. Environ. 2018, 135, 42–45. [Google Scholar]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). HVAC Design Manual for Hospitals and Clinics; American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE): Atlanta, GA, USA, 2013. [Google Scholar]

- ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers). Heating, Ventilating, and Air-Conditioning Systems and Equipment; SI Ed.; American: Atlanta, GA, USA, 2012. [Google Scholar]

- Goetzler, W.; Zogg, R.; Young, J.; Johnson, C. Energy Savings Potential and RD&D Opportunities for Non-Vapor-Compression HVAC Technologies; Technical Report for Energy Efficiency and Renewable Energy: Washington, DC, USA, 2014. [Google Scholar]

- Mei, L.; Dai, Y.J. A technical review on use of liquid-desiccant dehumidification for air-conditioning application. Renew. Sustain. Energy Rev. 2008, 12, 662–689. [Google Scholar] [CrossRef]

- Fu, H.X.; Liu, X.H. Review of the impact of liquid desiccant dehumidification on indoor air quality. Build. Environ. 2017, 116, 158–172. [Google Scholar] [CrossRef]

- TRANE. CDQ™ Desiccant Dehumidification. 2019. Available online: https://www.trane.com/content/dam/Trane/Commercial/global/products-systems/equipment/air-handling/air-handler-options/CLCH-PRB020-EN_1110_CDQ_EB.pdf (accessed on 15 April 2019).

- Slayzak, S.J.; Anderson, R.S.; Judkoff, R.D.; Blake, D.M.; Vinzant, T.B.; Ryan, J.P. Using Liquid Desiccant as a Regenerable Filter for Capturing and Deactivating Contaminants. U.S. Patent 7,306,650, 11 December 2007. [Google Scholar]

- Dai, Y.J.; Li, Y.; Wang, R.Z.; Ge, T.S. Technical development of rotary desiccant dehumidification and air conditioning: A review. Renew. Sustain. Energy Rev. 2010, 14, 130–147. [Google Scholar] [CrossRef]

- Gormley, T.; Markel, T.A.; Jones, H.; Greeley, D.; Ostojic, J.; Clarke, J.H.; Abkowitz, M.; Wagner, J. Cost-benefit analysis of different air change rates in an operating room environment. Am. J. Infect. Control 2017, 45, 1318–1323. [Google Scholar] [CrossRef]

- Cubí Montanyà, E.; Salom Tormo, J.; Garrido Soriano, N. Indoor environmental quality and infection control in surgery rooms: Code requirements vs performance motivation. A critical review. HvacR Res. 2014, 20, 643–654. [Google Scholar] [CrossRef]

- Constantinos, A.B.; Elena, D.; Athina, G. HVAC and indoor thermal conditions in hospital operating rooms. Energy Build. 2007, 39, 454–470. [Google Scholar] [CrossRef]

- Goetzler, W.; Shandross, R.; Young, J.; Petritchenko, O.; Ringo, D.; McClive, S. Energy Savings Potential and RD&D Opportunities for Commercial Building HVAC Systems (No. DOE/EE-1703); Navigant Consulting: Burlington, MA, USA, 2017. [Google Scholar]

- Ozyogurtcu, G.; Mobedi, M.; Ozerdem, B. Economical assessment of different HVAC systems for an operating room: Case study for different Turkish climate regions. Energy Build. 2011, 43, 1536–1543. [Google Scholar] [CrossRef]

- Macher, J.M. Positive-hole correction of multiple-jet impactors for collecting viable microorganisms. Am. Ind. Hyg. Assoc. J. 1989, 50, 561–568. [Google Scholar] [CrossRef]

- Angrisani, G.; Minichiello, F.; Sasso, M. Improvements of an unconventional desiccant air conditioning system based on experimental investigations. Energy Convers. Manag. 2016, 112, 423–434. [Google Scholar] [CrossRef]

- Renno, C.; D’Agostino, D.; Minichiello, F.; Petito, F.; Balen, I. Performance analysis of a CPV/T-DC integrated system adopted for the energy requirements of a supermarket. Appl. Therm. Eng. 2019, 25, 231–248. [Google Scholar] [CrossRef]

- Thomas, H. All-Variable Speed Centrifugal Chiller Plants. Ashrae J. 2001, 43, 43–53. [Google Scholar]

- Katz, J.D. Control of the Environment in the Operating Room. Anesth. Analg. 2017, 125, 1214–1218. [Google Scholar] [CrossRef]

- NHFPC (National Health and Family Planning Commission of China). Architectural Technical Code for Hospital Clean Operating Department GB50333-2013. 2013. Available online: http://www.sdnicc.com/UploadFile/file/20140716/20140716141216_3410.pdf (accessed on 5 July 2018).

- Al-Benna, S. Infection control in operating theatres. J. Perioper. Pract. 2012, 22, 318–322. [Google Scholar] [CrossRef]

- Bureau of Energy, Ministry of Economic Affairs, R.O.C. Hospital Energy Conservation Technical Manual. 2016. Available online: http://www.ecct.org.tw/ReadFile/?p=Knowledge&n=dd74e7eb-05c4-45d5-a65c-c0bd58f34a3b.pdf (accessed on 23 March 2019).

- L’ASPEC. NF S 90351: Quels changements 2003–2013. 2013. Available online: http://aspec.fr/wp-content/uploads/tableaux_evolution-NF-S-90351-2013-2003.pdf (accessed on 2 July 2019).

- Wan, G.H.; Chung, F.F.; Tang, C.S. Long-term surveillance of air quality in medical center operating rooms. Am. J. Infect. Control 2011, 39, 302–308. [Google Scholar] [CrossRef]

- Stephen, D.W.; Mark, G.; Roger, R.; Thorsten, S.; Abdullah, G.; Dae-Young, L. Characterization of desiccant wheels with alternative materials at low regeneration temperatures. Int. J. Refrig. 2011, 34, 1786–1789. [Google Scholar] [CrossRef]

- Weiwei, L.; Zhiwei, L.; Reinhard, R.; Ye, Y. Energy consumption analysis on a dedicated outdoor air system with rotary desiccant wheel. Energy 2007, 32, 1749–1760. [Google Scholar]

- Mandegari, M.A.; Pahlavanzadeh, H. Introduction of a new definition for effectiveness of desiccant wheels. Energy 2009, 34, 797–803. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). Cleanrooms and Associated Controlled Environments. Part 1: Classification of Air Cleanliness by Particle Concentration; ISO standard 14644-1:1999; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- The Stationery Office. Department of Health/Estates and Facilities Division. Health Technical Memorandum 03-01: Specialised Ventilation for Healthcare Premises: Part A—Design and Installation. 2007. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/144029/HTM_03-01_Part_A.pdf (accessed on 23 March 2019).

- Wang, S.L. Pilot Study of Indoor Air Quality of Liquid Desiccant Air Conditioning. Master’s Thesis, Guangzhou University, Guangzhou, China, 2007. [Google Scholar]

- Landrin, A.; Bissery, A.; Kac, G. Monitoring air sampling in operating theatres: Can particle counting replace microbiological sampling? J. Hosp. Infect. 2005, 61, 27–29. [Google Scholar] [CrossRef] [PubMed]

| AC Systems | HVAC System | LDAC System | RDAC System | p Value | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Parameters | |||||||||||

| Mean | Median | 25–75 percentiles | Mean | Median | 25–75 percentiles | Mean | Median | 25–75 percentiles | |||

| Temperature, °C | 19.73 | 19.68 | (19.40–20.01) | 19.44 | 19.44 | (18.74–19.79) † | 20.51 | 20.40 | (19.93–20.83) †,‡ | <0.001 | |

| RH, % | 65.14 | 66.73 | (62.99–67.85) | 59.78 | 60.84 | (59.44–62.68) † | 55.90 | 60.49 | (47.96–63.31) † | <0.001 | |

| CO2, ppm | 344.90 | 357.51 | (302.29–383.34) | 427.49 | 421.20 | (405.08–440.73) † | 412.32 | 408.88 | (401.16–420.46) †,‡ | <0.001 | |

| PM≥0.5, particles/L | 161.22 | 101.53 | (31.60–173.89) | 146.00 | 88.08 | (12.71–172.95) | 107.09 | 1.33 | (11.12–48.60) †,‡ | <0.001 | |

| PM10, μg/m3 | 1.31 | 0.58 | (0.28–1.76) | 0.98 | 0.68 | (0.10–1.00) | 0.53 | 0.14 | (0.06–0.33) †,‡ | <0.001 | |

| PM2.5, μg/m3 | 0.46 | 0.31 | (0.12–0.56) | 0.35 | 0.33 | (0.07–0.50) | 0.40 | 0.07 | (0.04–0.15) †,‡ | <0.001 | |

| PM1, μg/m3 | 0.21 | 0.12 | (0.01–0.20) | 0.15 | 0.13 | (0.01–0.24) | 0.33 | 0.01 | (0–0.02) †,‡ | <0.001 | |

| Airborne bacteria, CFU/m3 | |||||||||||

| Operating area | 109.71 | 50.75 | (24.98–69.38) | 133.17 | 56.42 | (35.44–110.86) | 50.01 | 38.26 | (32.54–79.90) | 0.671 | |

| Surrounding area | 154.13 | 112.87 | (43.73–219.75) | 152.50 | 83.51 | (49.29–121.84) | 104.67 | 59.80 | (45.45–167.43) | 0.887 | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | |

|---|---|---|---|---|---|---|---|---|

| HVAC system | ||||||||

| (1) Temperature | 1 | |||||||

| (2) RH | −0.624 ** | 1 | ||||||

| (3) CO2 | 0.468 ** | −0.769 ** | 1 | |||||

| (4) PM≥0.5 | −0.036 | 0.232 | −0.123 | 1 | ||||

| (5) PM10 | 0.030 | 0.165 | −0.093 | 0.965 ** | 1 | |||

| (6) PM2.5 | 0.002 | 0.197 | −0.145 | 0.981 ** | 0.974 ** | 1 | ||

| (7) PM1 | 0.002 | 0.182 | −0.236 | 0.862 ** | 0.793 ** | 0.888 ** | 1 | |

| (8) Airborne bacteria | −0.219 | 0.467 | −0.685 * | 0.576 | 0.321 | 0.523 | 0.571 | 1 |

| LDAC system | ||||||||

| (1) Temperature | 1 | |||||||

| (2) RH | −0.732 ** | 1 | ||||||

| (3) CO2 | −0.521 ** | 0.335 * | 1 | |||||

| (4) PM≥0.5 | −0.005 | 0.263 | 0.152 | 1 | ||||

| (5) PM10 | −0.117 | 0.216 | 0.219 | 0.895 ** | 1 | |||

| (6) PM2.5 | −0.133 | 0.321 * | 0.282 | 0.953 ** | 0.924 ** | 1 | ||

| (7) PM1 | −0.215 | 0.464 ** | 0.349 * | 0.851 ** | 0.678 ** | 0.843 ** | 1 | |

| (8) Airborne bacteria | −0.006 | 0.358 | 0.164 | 0.127 | 0.321 | 0.200 | 0.201 | 1 |

| RDAC system | ||||||||

| (1) Temperature | 1 | |||||||

| (2) RH | −0.629 ** | 1 | ||||||

| (3) CO2 | −0.228 | −0.077 | 1 | |||||

| (4) PM≥0.5 | −0.407 ** | 0.393 * | 0.422 ** | 1 | ||||

| (5) PM10 | −0.366 * | 0.380 * | 0.321 * | 0.930 ** | 1 | |||

| (6) PM2.5 | −0.392 * | 0.383 * | 0.395 * | 0.954 ** | 0.967 ** | 1 | ||

| (7) PM1 | −0.418 ** | 0.362 * | 0.345 * | 0.816 ** | 0.694 ** | 0.786 ** | 1 | |

| (8) Airborne bacteria | −0.333 | 0.370 | −0.139 | 0.564 | 0.779 ** | 0.681 * | 0.374 | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chien, T.-Y.; Liang, C.-C.; Wu, F.-J.; Chen, C.-T.; Pan, T.-H.; Wan, G.-H. Comparative Analysis of Energy Consumption, Indoor Thermal–Hygrometric Conditions, and Air Quality for HVAC, LDAC, and RDAC Systems Used in Operating Rooms. Appl. Sci. 2020, 10, 3721. https://doi.org/10.3390/app10113721

Chien T-Y, Liang C-C, Wu F-J, Chen C-T, Pan T-H, Wan G-H. Comparative Analysis of Energy Consumption, Indoor Thermal–Hygrometric Conditions, and Air Quality for HVAC, LDAC, and RDAC Systems Used in Operating Rooms. Applied Sciences. 2020; 10(11):3721. https://doi.org/10.3390/app10113721

Chicago/Turabian StyleChien, Tsung-Yi, Ching-Chieh Liang, Feng-Jen Wu, Chi-Tsung Chen, Ting-Hsin Pan, and Gwo-Hwa Wan. 2020. "Comparative Analysis of Energy Consumption, Indoor Thermal–Hygrometric Conditions, and Air Quality for HVAC, LDAC, and RDAC Systems Used in Operating Rooms" Applied Sciences 10, no. 11: 3721. https://doi.org/10.3390/app10113721

APA StyleChien, T.-Y., Liang, C.-C., Wu, F.-J., Chen, C.-T., Pan, T.-H., & Wan, G.-H. (2020). Comparative Analysis of Energy Consumption, Indoor Thermal–Hygrometric Conditions, and Air Quality for HVAC, LDAC, and RDAC Systems Used in Operating Rooms. Applied Sciences, 10(11), 3721. https://doi.org/10.3390/app10113721