Development of A Linear Delta Robot with Three Horizontal-Axial Pneumatic Actuators for 3-DOF Trajectory Tracking

Abstract

:1. Introduction

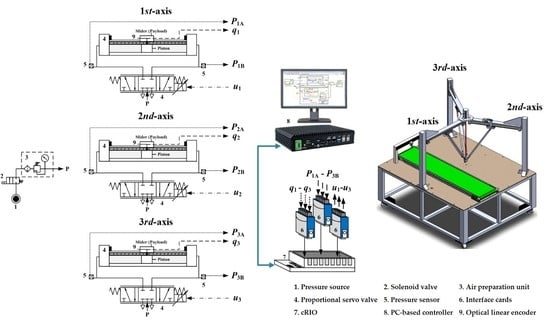

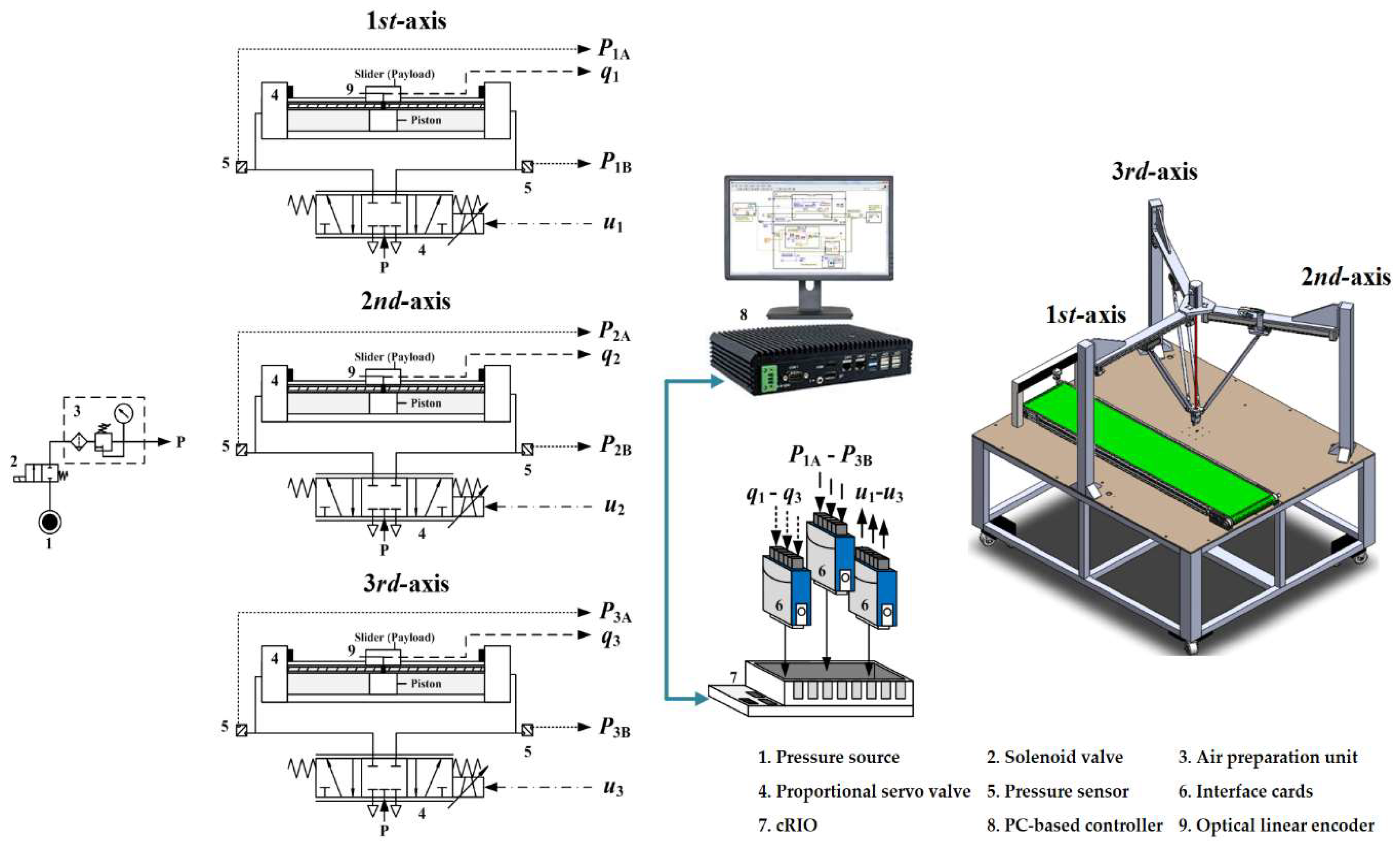

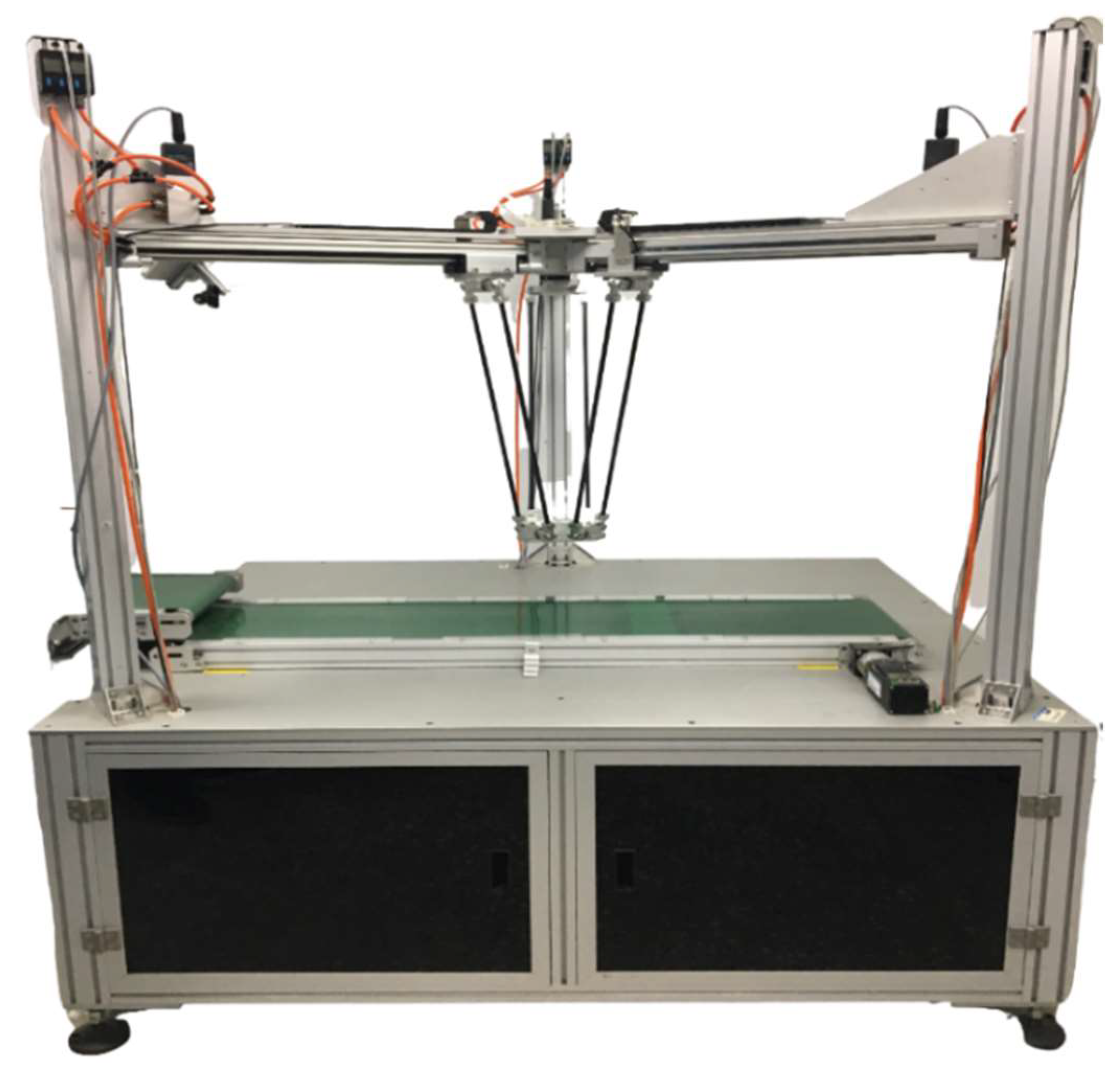

2. Test Rig Layout

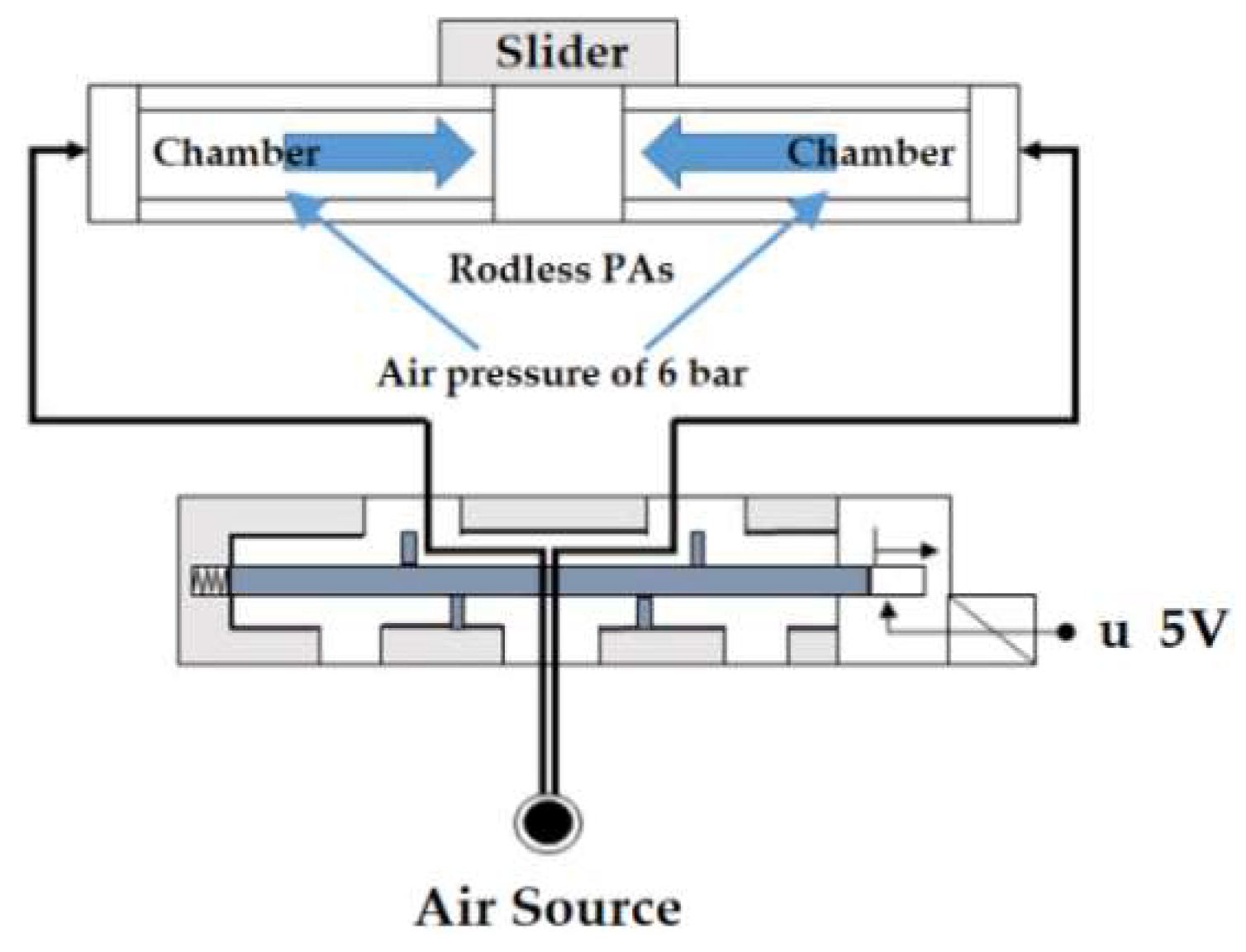

3. Analysis of Kinematics

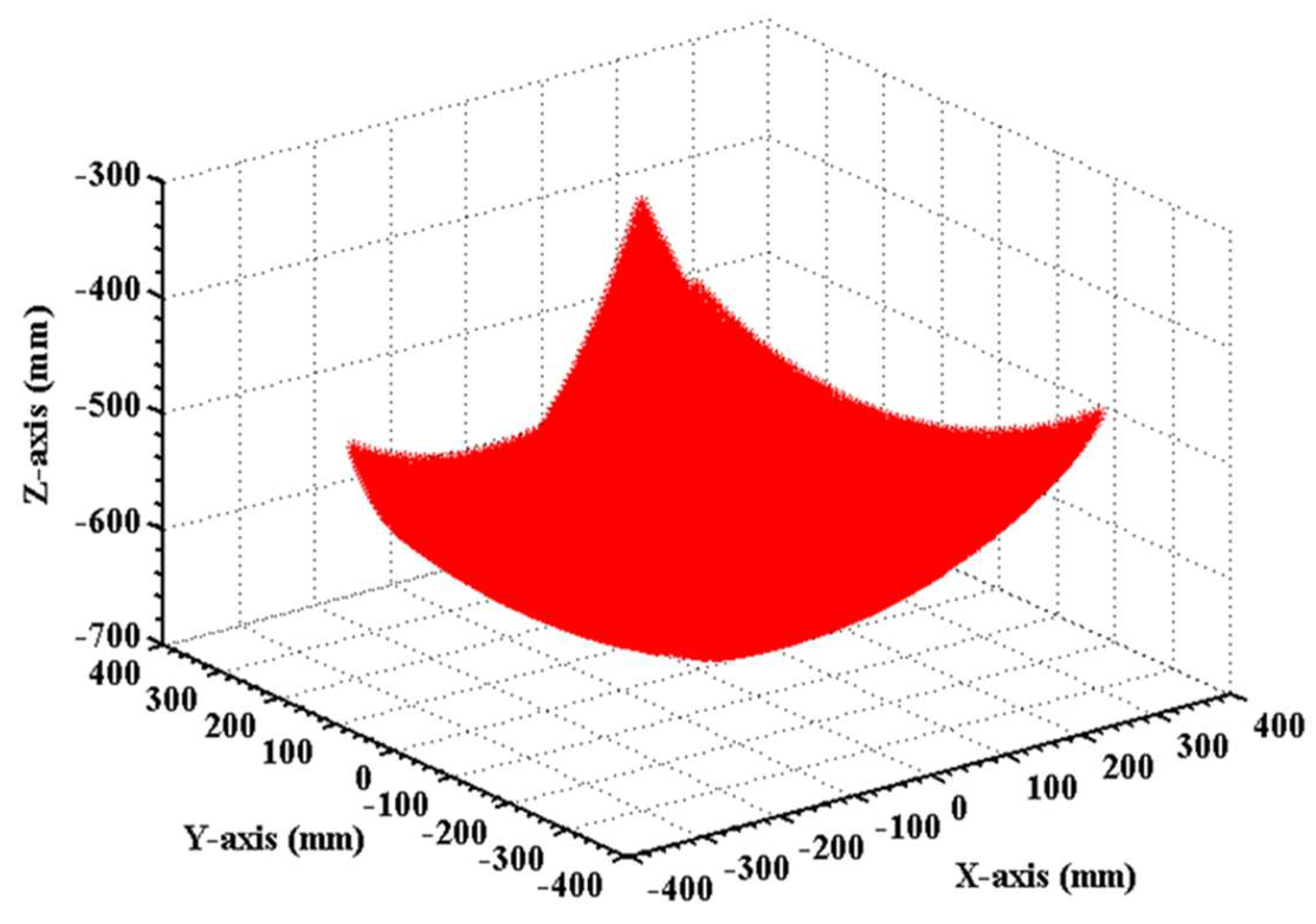

3.1. Inverse Position Kinematics

3.2. Forward Position Kinematics

3.3. Velocity Analysis

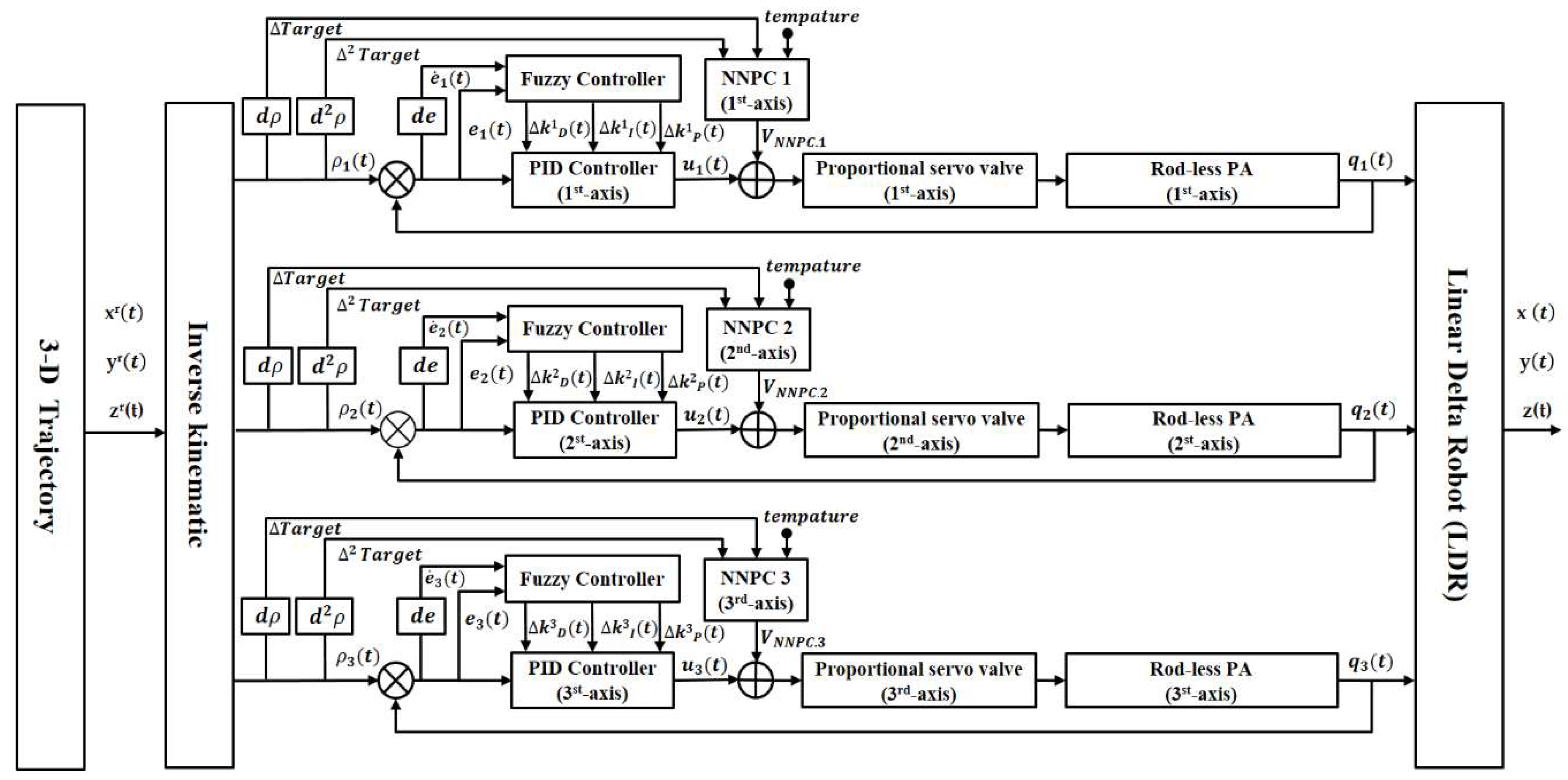

4. Controller Design

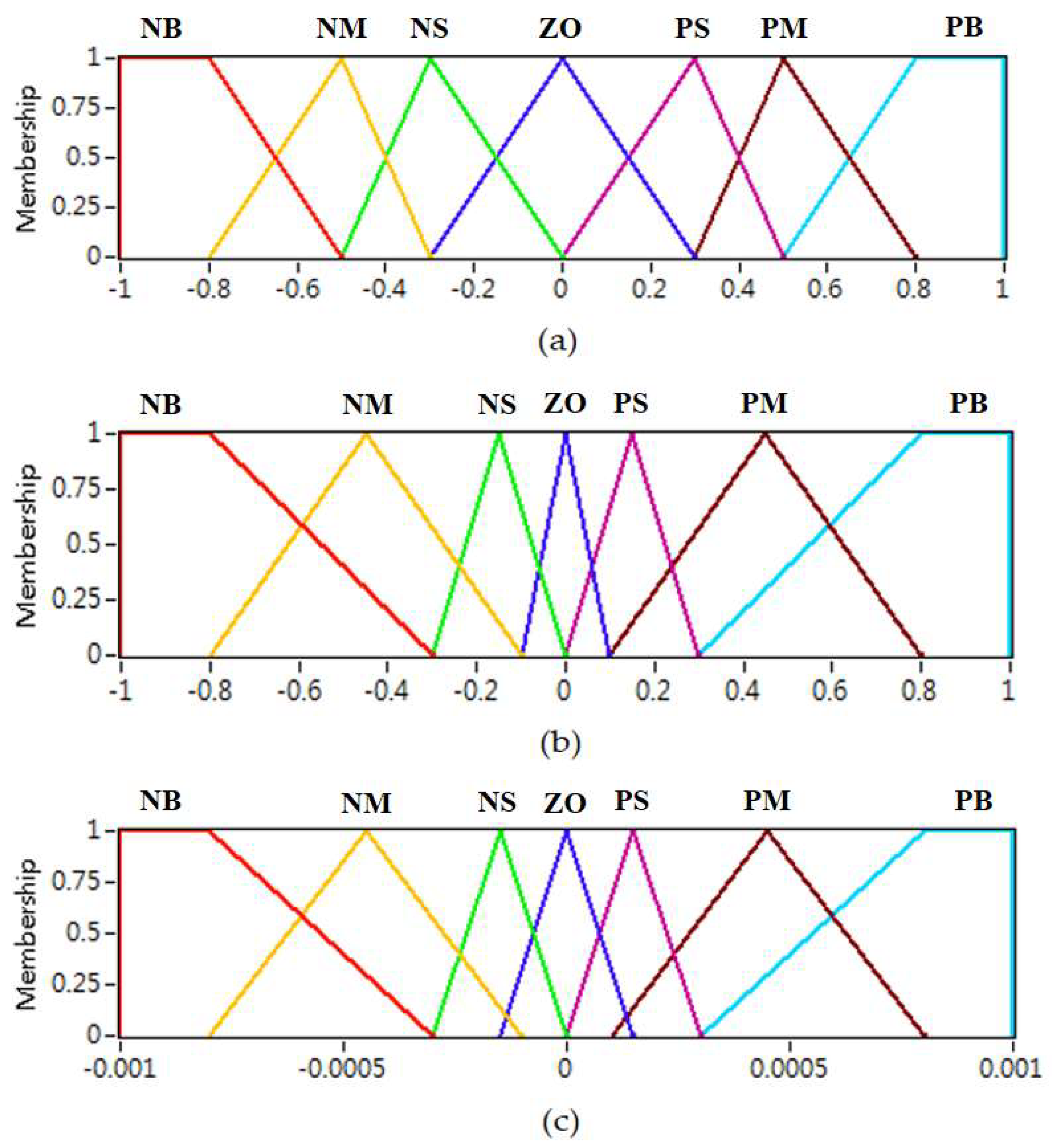

4.1. Fuzzy-PID Controller Design

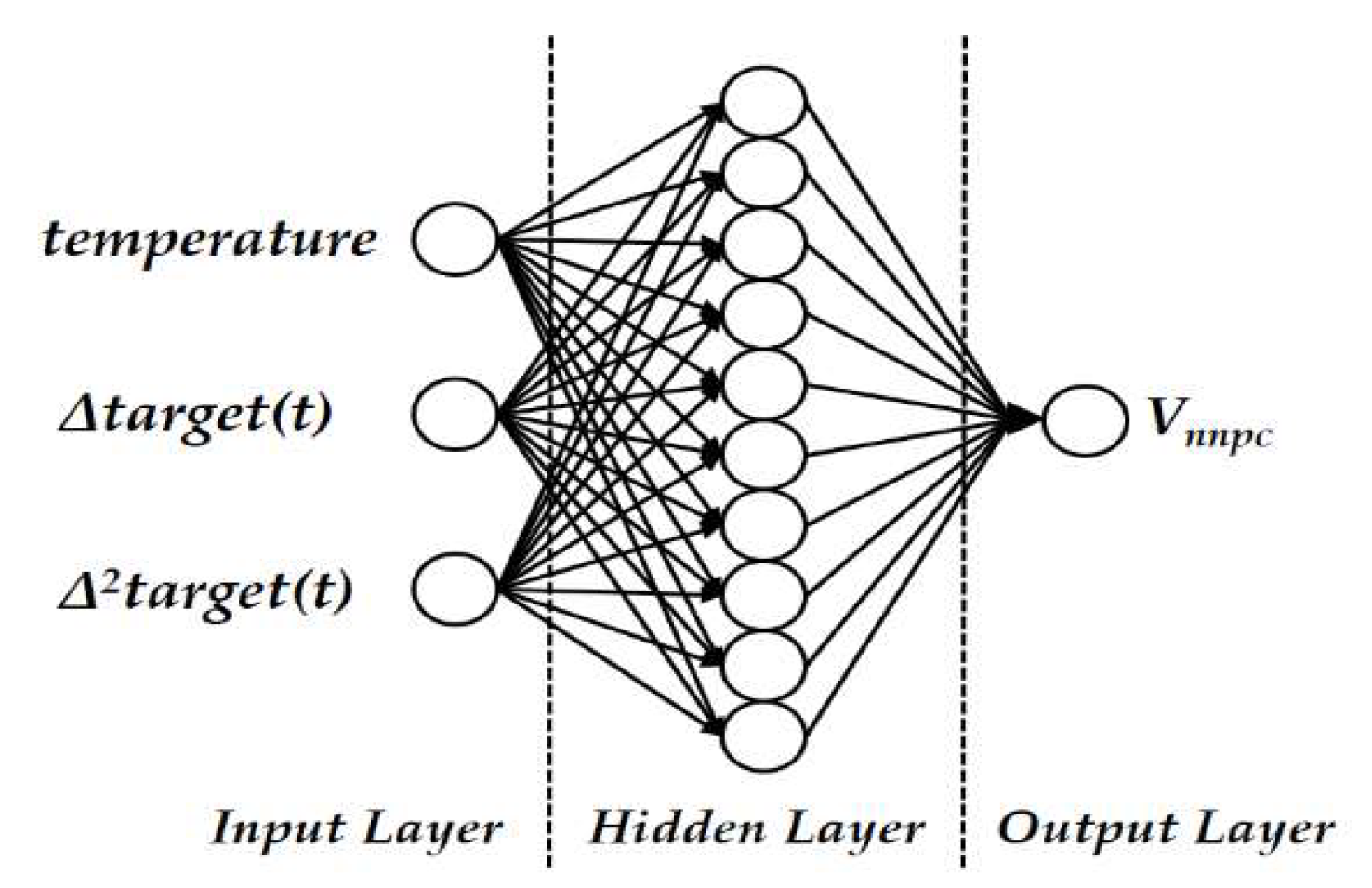

4.2. NNPC Design

5. Experiments

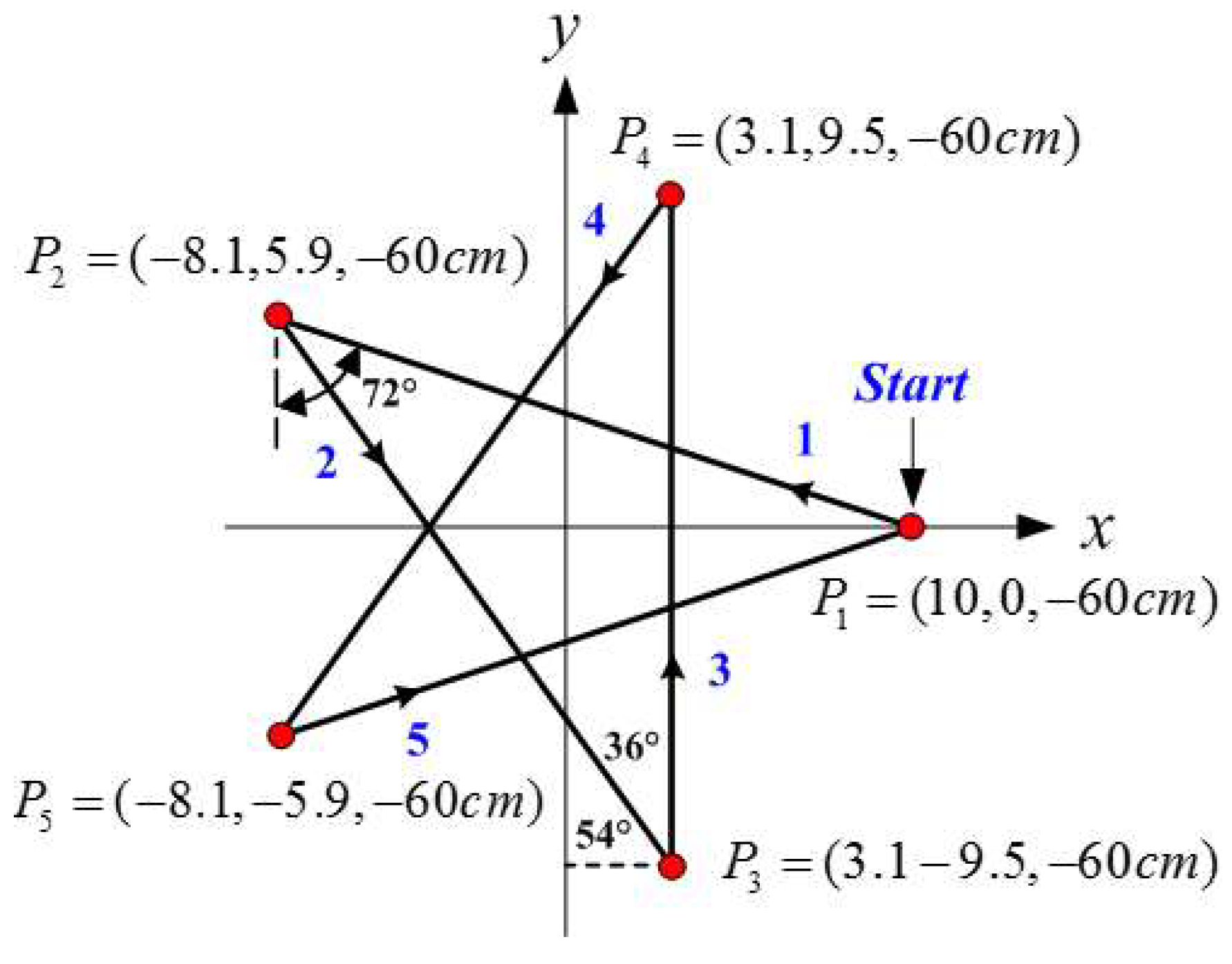

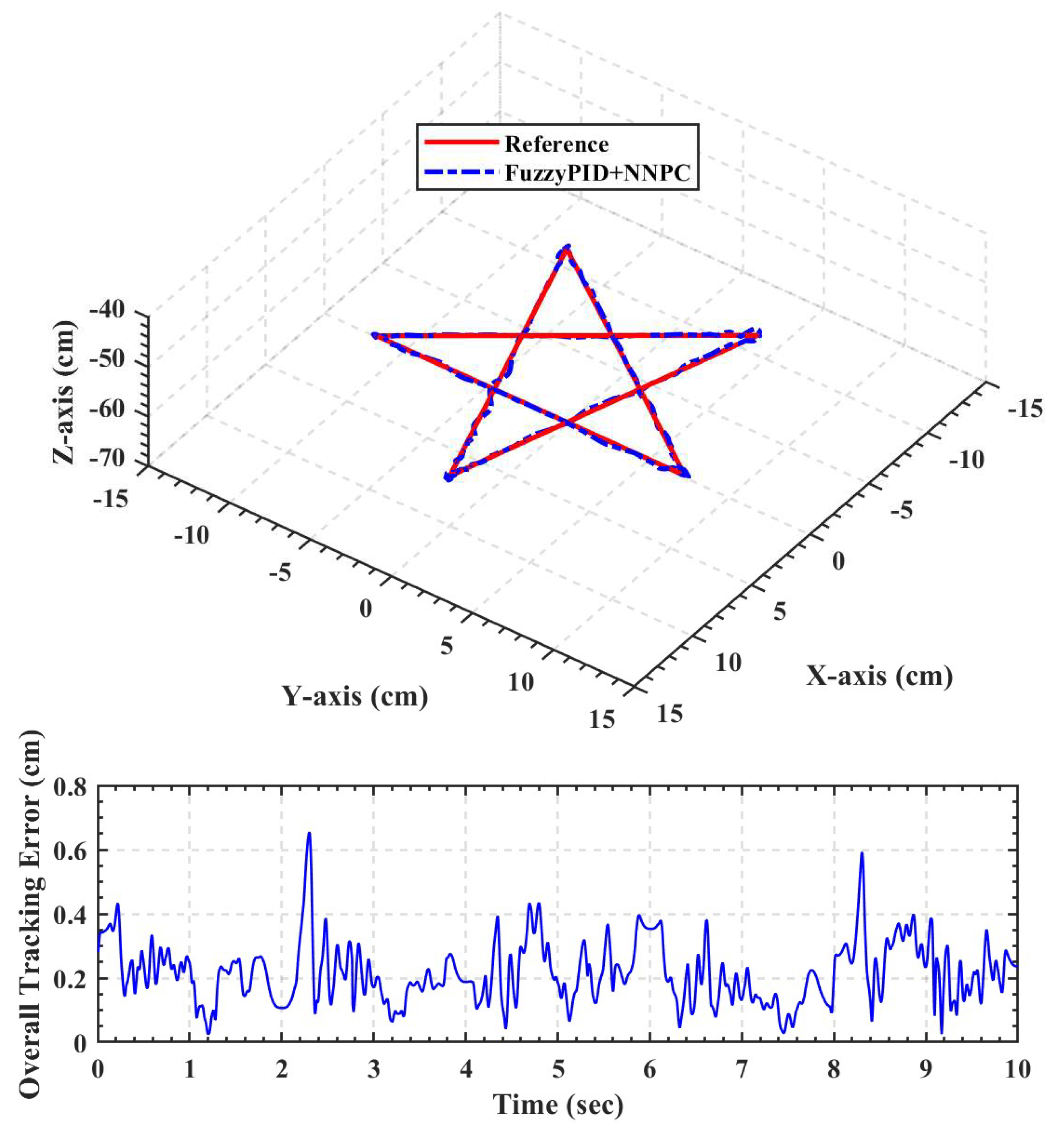

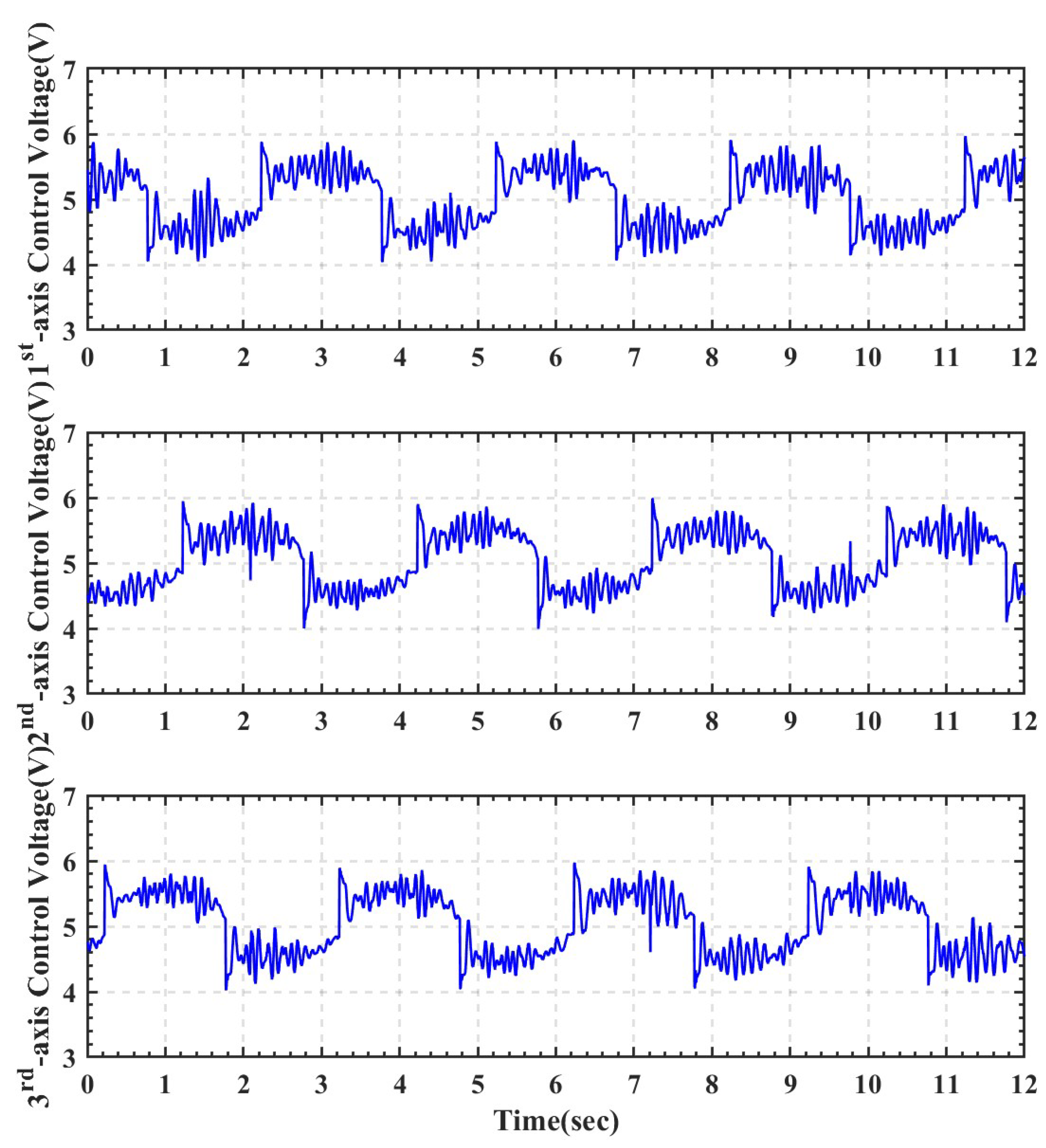

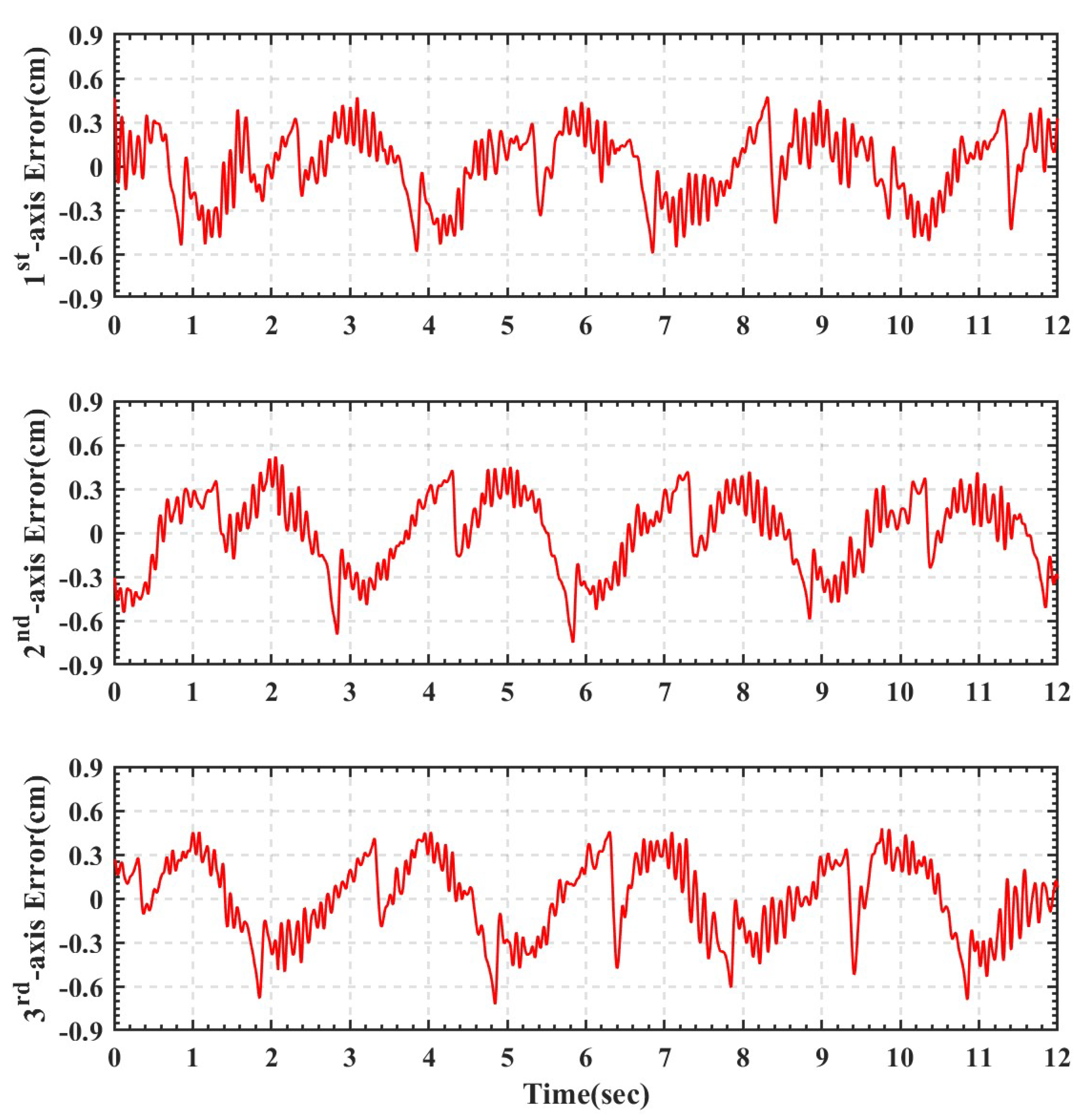

5.1. Experiment 1-Star Loop Motion Trajectory (a Two-Dimensional Motion)

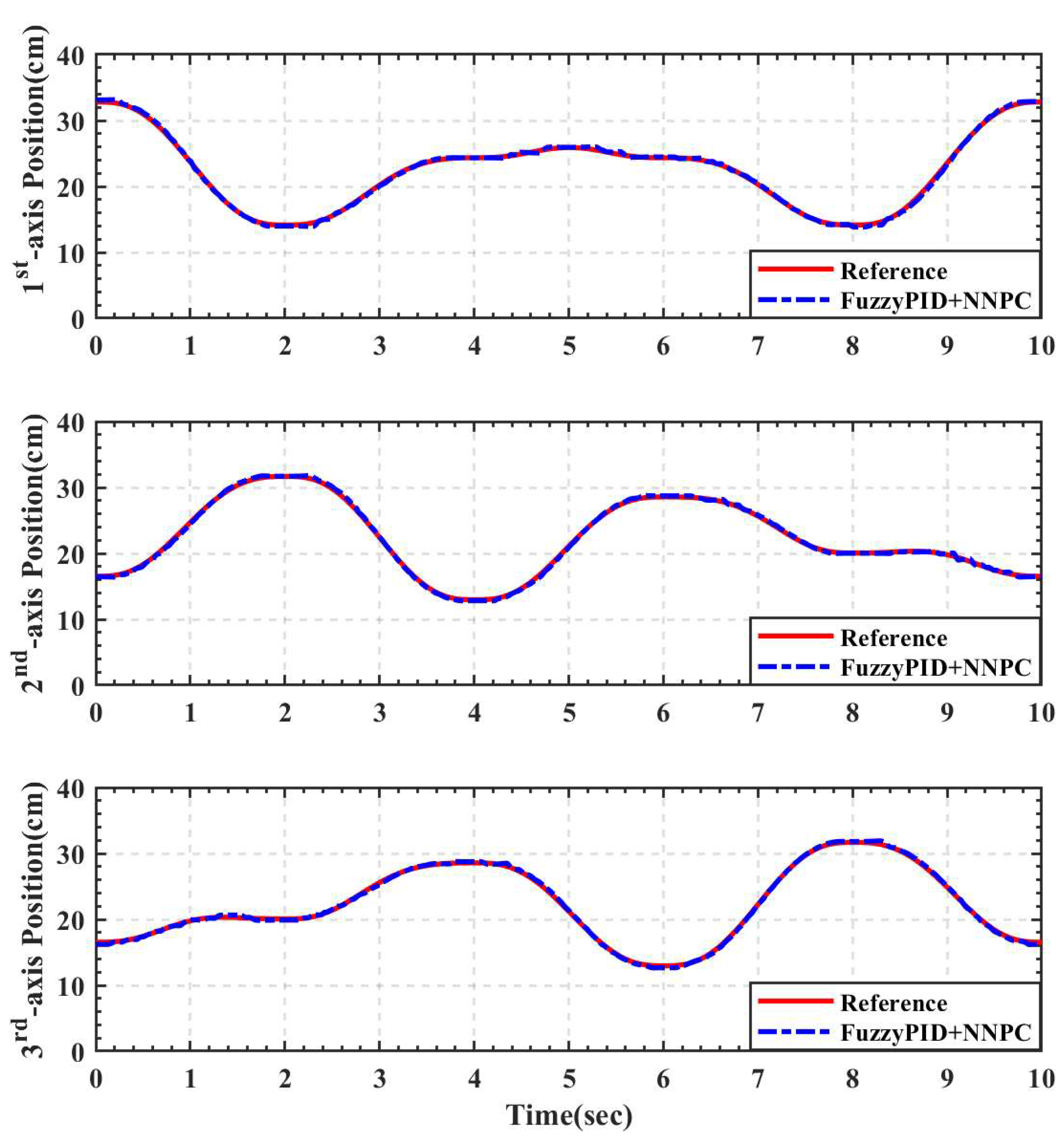

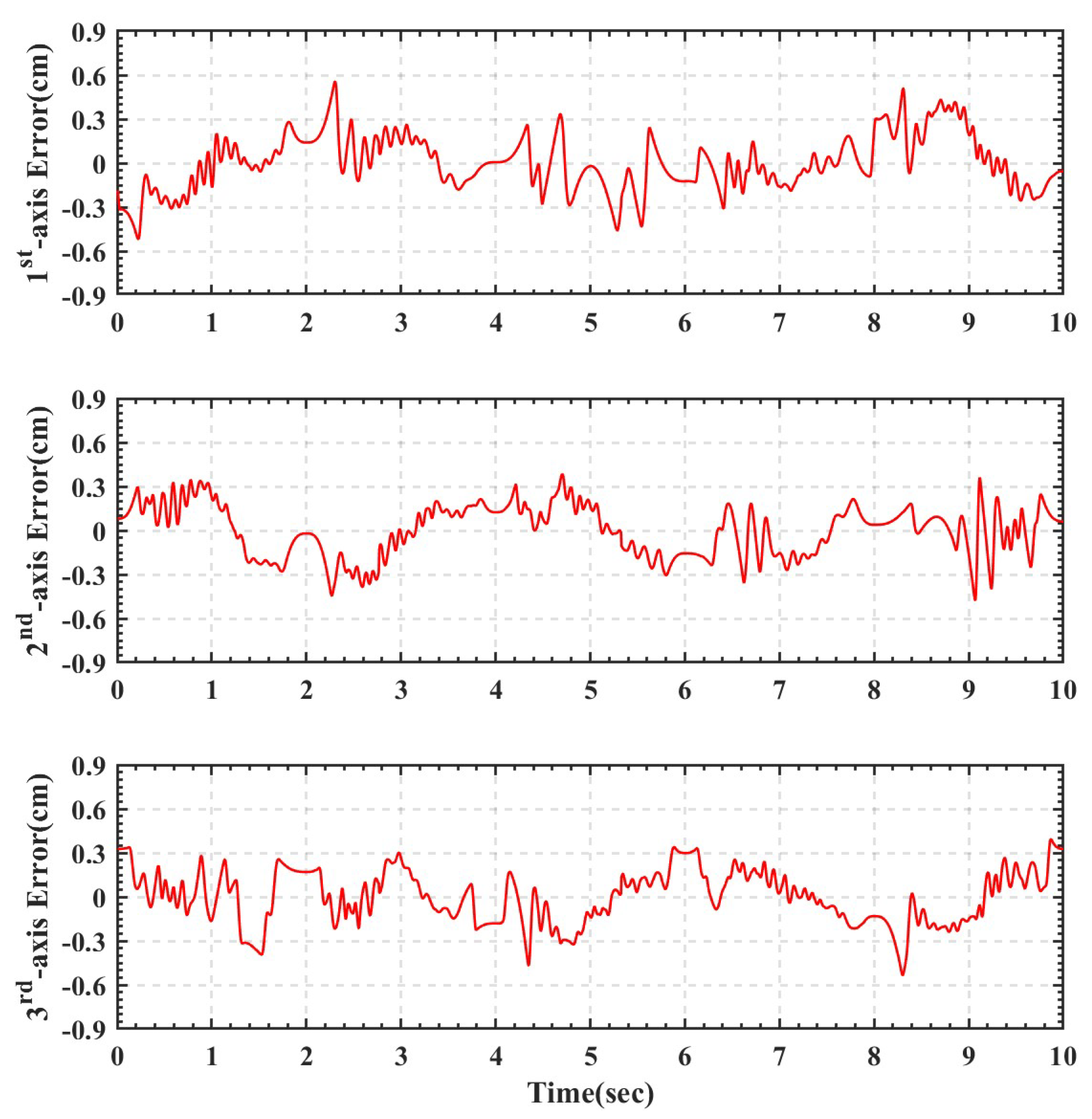

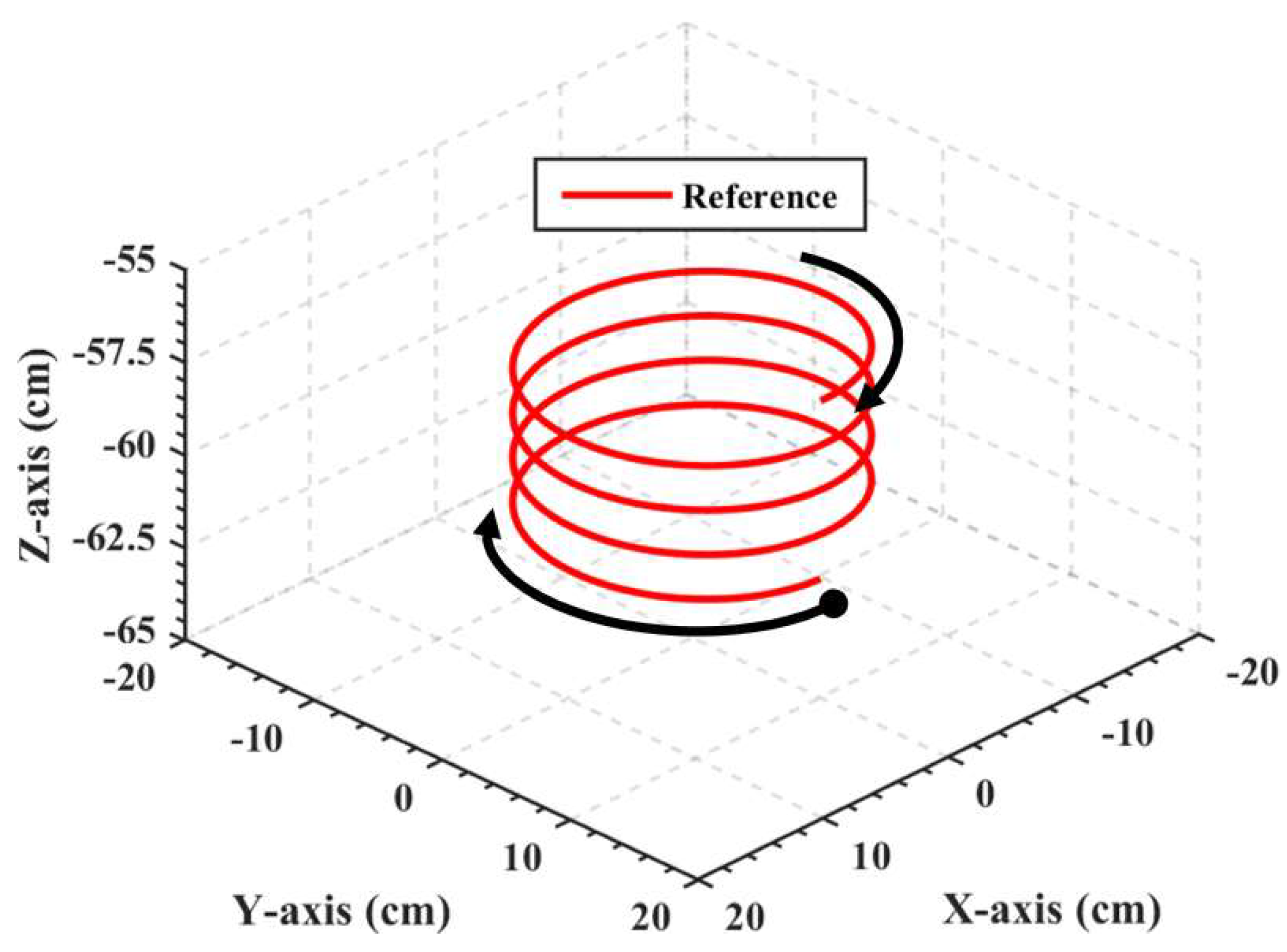

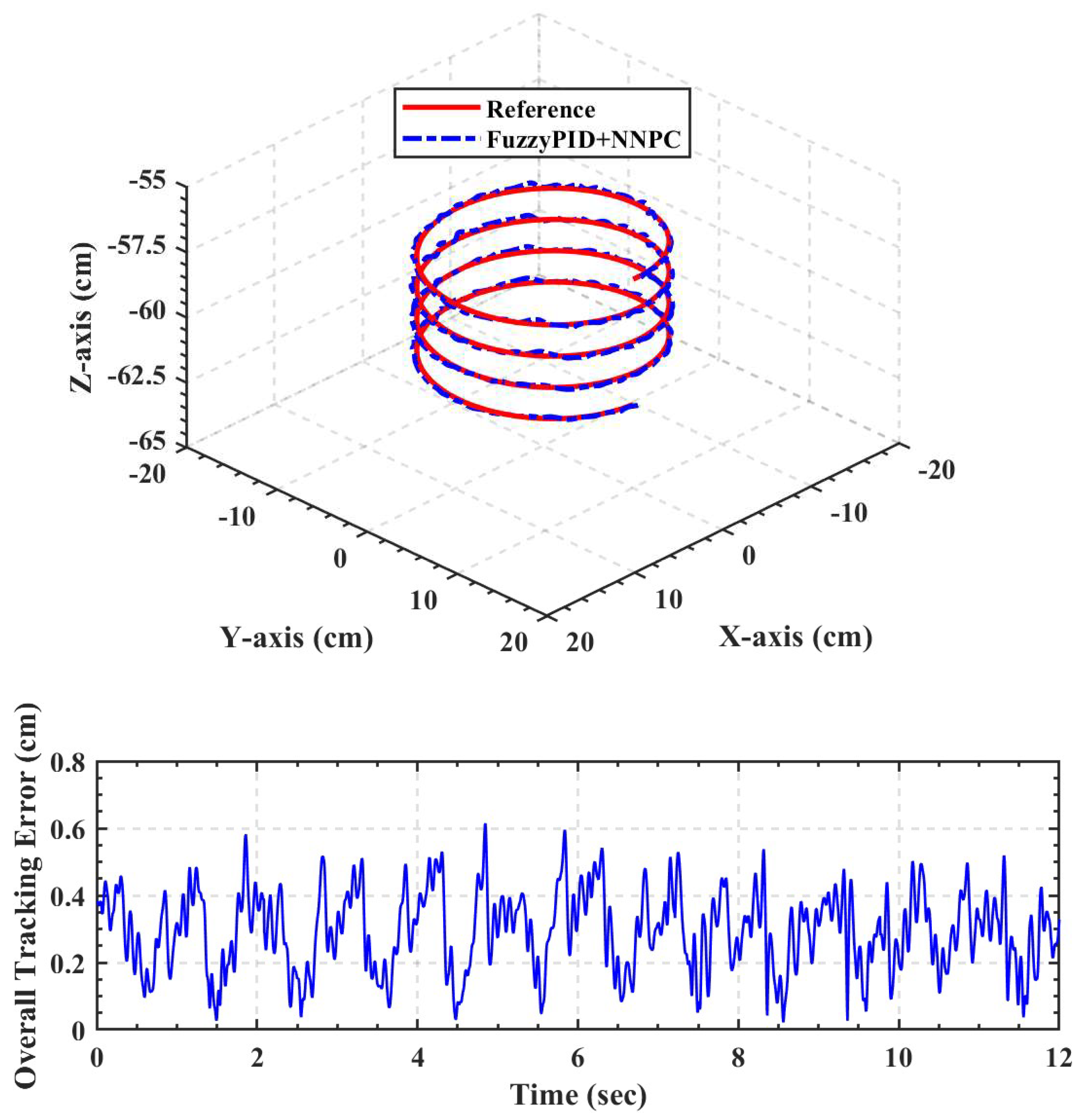

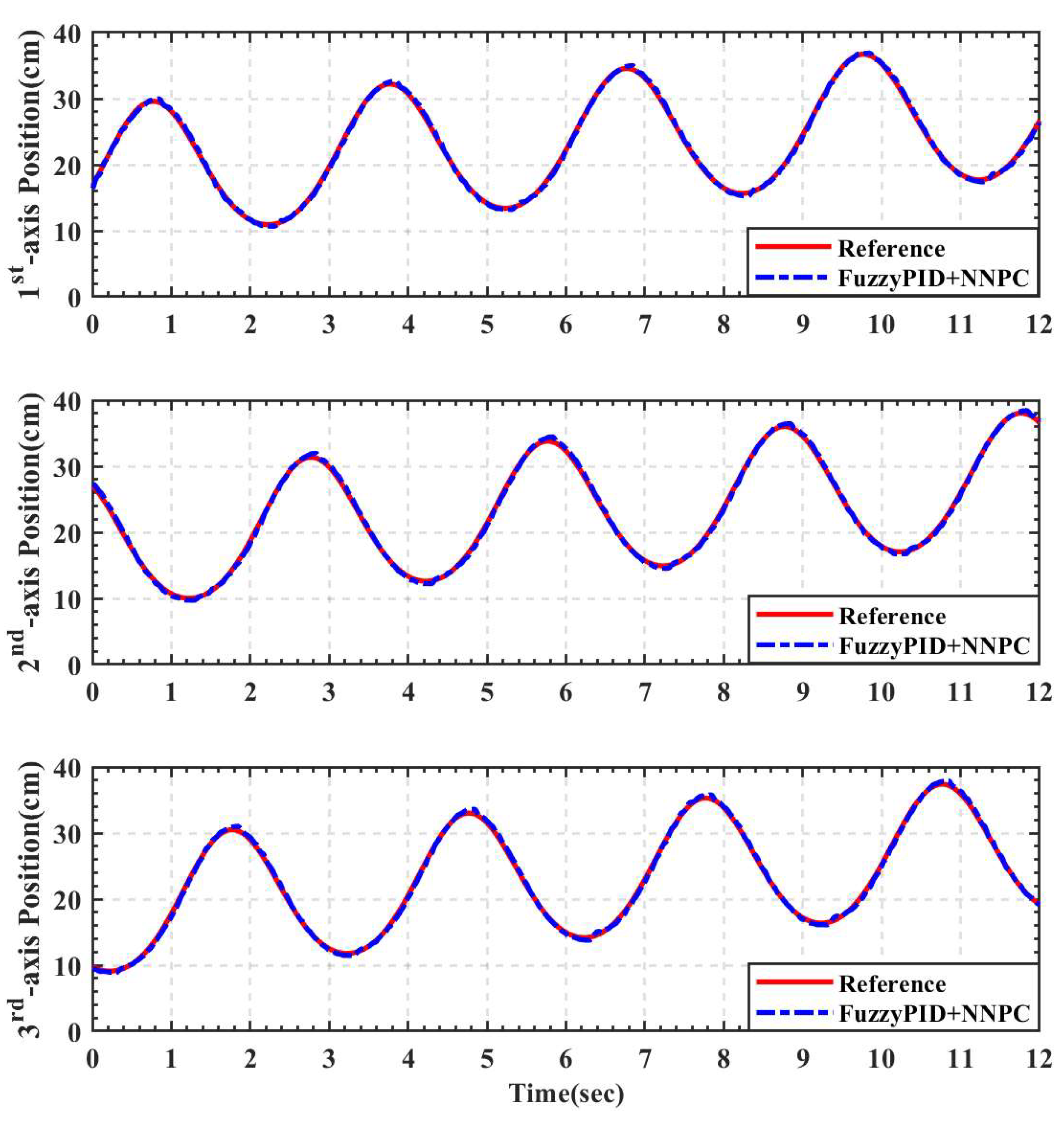

5.2. Experiment 2—Helical Circular Motion Trajectory

6. Conclusions

7. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Shang, D.; Fan, X.; Liu, Y. Motion reliability analysis of the delta parallel robot considering mechanism errors. Math. Probl. Eng. 2019. [Google Scholar] [CrossRef]

- Arockia, S.A.; Arul, K.M. Experimental investigation on position analysis of 3—DOF parallel manipulators. Procedia Eng. 2014, 97, 1126–1134. [Google Scholar]

- Patel, Y.D.; George, P.M. Parallel manipulators applications—A survey. Mod. Mech. Eng. 2012, 2, 57–64. [Google Scholar] [CrossRef] [Green Version]

- Ben-Dov, E.; Salcudean, S.E. A force-controlled pneumatic actuator. IEEE Trans. Robot. Autom. 1995, 11, 906–911. [Google Scholar] [CrossRef]

- Richer, E.; Hurmuzlu, Y. A high performance pneumatic force actuator system: Part II—Nonlinear controller design. J. Dyn. Syst. Meas. Control 1999, 122, 426–434. [Google Scholar] [CrossRef]

- Wang, J.; Wang, D.; Moore, P.R.; Pu, J. Modelling study, analysis and robust servocontrol of pneumatic cylinder actuator systems. IEE Proc. Control Theory Appl. 2001, 148, 35–42. [Google Scholar] [CrossRef]

- Milutinovic, D.; Slavkovic, N.; Kokotovic, B.M.; Zivanovic, S.; Dimic, Z. Kinematic modeling of reconfigurable parallel robots based on delta concept. J. Prod. Eng. 2013, 15, 71–74. [Google Scholar]

- Choi, H.S.; Han, C.S.; Lee, K.Y.; Lee, S.H. Development of hybrid robot for construction works with pneumatic actuator. Autom. Constr. 2005, 14, 452–459. [Google Scholar] [CrossRef]

- Chiang, M.H.; Lin, H.T. Development of a 3D parallel mechanism robot arm with three vertical-axial pneumatic actuators combined with a stereo vision system. Sensors 2011, 11, 11476–11494. [Google Scholar] [CrossRef] [Green Version]

- Chiang, M.H.; Chen, Y.H.; Chou, W.H. Analysis and control of a three-axial pyramidal pneumatic parallel manipulator. In Proceedings of the 9th JFPS International Symposium on Fluid Power, Matsue, Japan, 28–31 October 2014. [Google Scholar]

- Boudjedir, C.E.; Boukhetala, D.; Bouri, M. Nonlinear PD plus sliding mode control with application to a parallel delta robot. J. Electr. Eng. 2018, 69, 329–336. [Google Scholar] [CrossRef] [Green Version]

- Andrzej, L.P.; Emanuel, T.J.; Slawomir, B. Design of a 3-DOF tripod electro-pneumatic parallel manipulator. Robot. Auton. Syst. 2015, 72, 59–70. [Google Scholar]

- Lafmejani, A.S.; Masouleh, M.T.; Kalhor, A. Trajectory tracking control of a pneumatically actuated 6-DOF Gough–Stewart parallel robot using backstepping-sliding mode controller. Robot. Comput. Integr. Manuf. 2018, 54, 96–114. [Google Scholar] [CrossRef]

- Yan, S.J.; Ong, S.K.; Nee, A.Y.C. Optimization design of general triglide parallel manipulators. Adv. Robot. 2016, 30, 1027–1038. [Google Scholar] [CrossRef]

- Dongton, X.; Sun, Z. Kinematic reliability and sensitivity analysis of the modified delta parallel mechanism. Mach. Des. Manuf. 2016, 10, 167–169. [Google Scholar]

- Fu, J.; Gao, F.; Chen, W.; Pan, Y.; Lin, R. Kinematic accuracy research of a novel six-degree-of-freedom parallel robot with three legs. Mech. Mach. Theory 2016, 102, 86–102. [Google Scholar] [CrossRef]

- Liu, S.; Bobrow, J.E. An analysis of a pneumatic servo system and its application to a computer-controlled robot. J. Dyn. Syst. Meas. Control 1988, 110, 228–235. [Google Scholar] [CrossRef]

- Bone, G.M.; Shu, N. Experimental comparison of position tracking control algorithms for pneumatic cylinder actuators. IEEE ASME Trans. Mechatron. 2007, 12, 557–561. [Google Scholar] [CrossRef]

- Lee, L.W.; Li, I.H. Wavelet-based adaptive sliding-mode control with tracking performance for pneumatic servo system position tracking control. IET Control Theory Appl. 2012, 6, 1–16. [Google Scholar] [CrossRef]

- Lee, L.W.; Li, I.H. Design and implementation of a robust FNN-based adaptive sliding-mode controller for pneumatic actuator systems. J. Mech. Sci. Technol. 2016, 30, 381–396. [Google Scholar] [CrossRef]

- Tsai, L.W. Robot Analysis: The Mechanics of Serial and Parallel Manipulators; Wiley-Interscience: Hoboken, NJ, USA, 1999. [Google Scholar]

- Waldron, K.J.; Hunt, K.H. Series-parallel dualities in actively coordinated mechanisms. Int. J. Robot. Res. 1991, 10, 473–480. [Google Scholar] [CrossRef]

- Jankowski, K. Inverse Dynamics Control in Robotics Applications; Trafford Publishing: Bloomington, IN, USA, 2004. [Google Scholar]

- Hou, Y.; Zhao, Y. Workspace analysis and optimization of 3-PUU parallel mechanism in medicine base on genetic algorithm. Open Biomed. Eng. J. 2015, 9, 214–218. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kung, Y.S.; Lin, J.M.; Chen, Y.J.; Chou, H.H. Model sim/simulink cosimulation and FPGA realization of a multiaxis motion controller. Math. Probl. Eng. 2015, 2015, 1–17. [Google Scholar] [CrossRef] [Green Version]

| Parameters | Description | Value |

|---|---|---|

| The length between and | 60 mm | |

| The length of kinematic chain | 670 mm | |

| The maximum of the actuated joint variables (the maximum stroke) | 500 mm |

| NB | NM | NS | ZO | PS | PM | PB | ||

|---|---|---|---|---|---|---|---|---|

| NB | PB | PB | PM | PM | PS | ZO | ZO | |

| NM | PB | PB | PM | PS | PS | ZO | NS | |

| NS | PM | PM | PM | PS | ZO | NS | NS | |

| ZO | PM | PM | PS | ZO | NS | NM | NM | |

| PS | PS | PS | ZO | NS | NS | NM | NM | |

| PM | PS | ZO | NS | NM | NM | NM | NB | |

| PB | ZO | ZO | NM | NM | NM | NB | NB | |

| NB | NM | NS | ZO | PS | PM | PB | ||

|---|---|---|---|---|---|---|---|---|

| NB | NB | NB | NM | NM | NS | ZO | ZO | |

| NM | NB | NB | NM | NS | NS | ZO | ZO | |

| NS | NB | NM | NS | NS | ZO | PS | PS | |

| ZO | NM | NM | NS | ZO | PS | PM | PM | |

| PS | NM | NS | ZO | NS | PS | PM | PB | |

| PM | ZO | ZO | PS | PS | PM | PB | PB | |

| PB | ZO | ZO | PS | PM | PM | PB | PB | |

| NB | NM | NS | ZO | PS | PM | PB | ||

|---|---|---|---|---|---|---|---|---|

| NB | PS | NS | NB | NB | NB | NB | PS | |

| NM | PS | NS | NB | NM | NM | NS | ZO | |

| NS | ZO | NS | NM | NM | NS | NS | ZO | |

| ZO | ZO | NS | NS | NS | NS | NS | ZO | |

| PS | ZO | ZO | ZO | ZO | ZO | ZO | ZO | |

| PM | PB | NS | PS | PS | PS | PS | PB | |

| PB | PB | PM | PM | PM | PS | PS | PB | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, I.-H.; Chiang, H.-H.; Lee, L.-W. Development of A Linear Delta Robot with Three Horizontal-Axial Pneumatic Actuators for 3-DOF Trajectory Tracking. Appl. Sci. 2020, 10, 3526. https://doi.org/10.3390/app10103526

Li I-H, Chiang H-H, Lee L-W. Development of A Linear Delta Robot with Three Horizontal-Axial Pneumatic Actuators for 3-DOF Trajectory Tracking. Applied Sciences. 2020; 10(10):3526. https://doi.org/10.3390/app10103526

Chicago/Turabian StyleLi, I-Hsum, Hsin-Han Chiang, and Lian-Wang Lee. 2020. "Development of A Linear Delta Robot with Three Horizontal-Axial Pneumatic Actuators for 3-DOF Trajectory Tracking" Applied Sciences 10, no. 10: 3526. https://doi.org/10.3390/app10103526