Multilevel Bipolar Electroforming-Free Resistive Switching Memory Based on Silicon Oxynitride

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

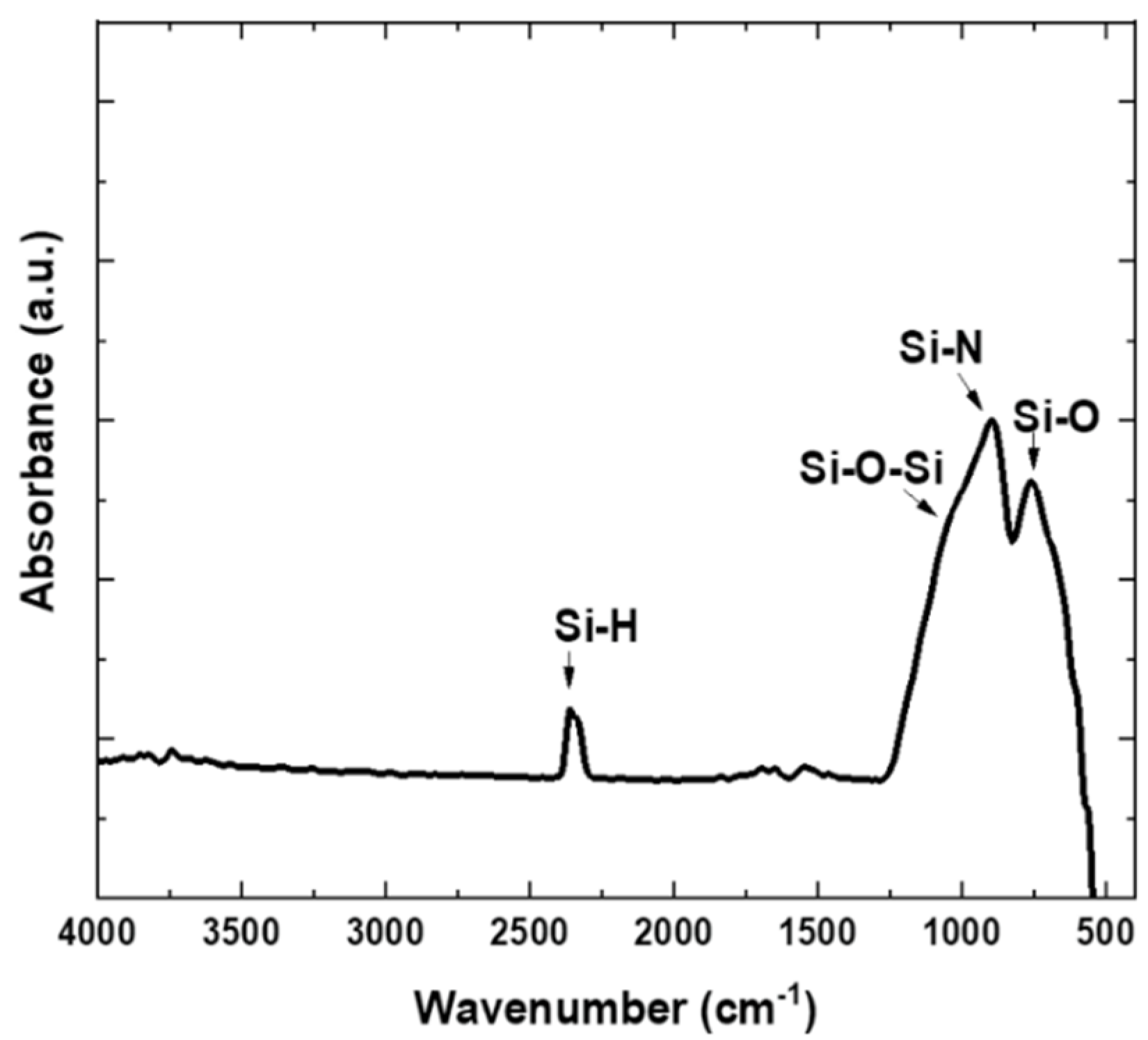

3.1. FTIR Measurement of the SiOxNy Film

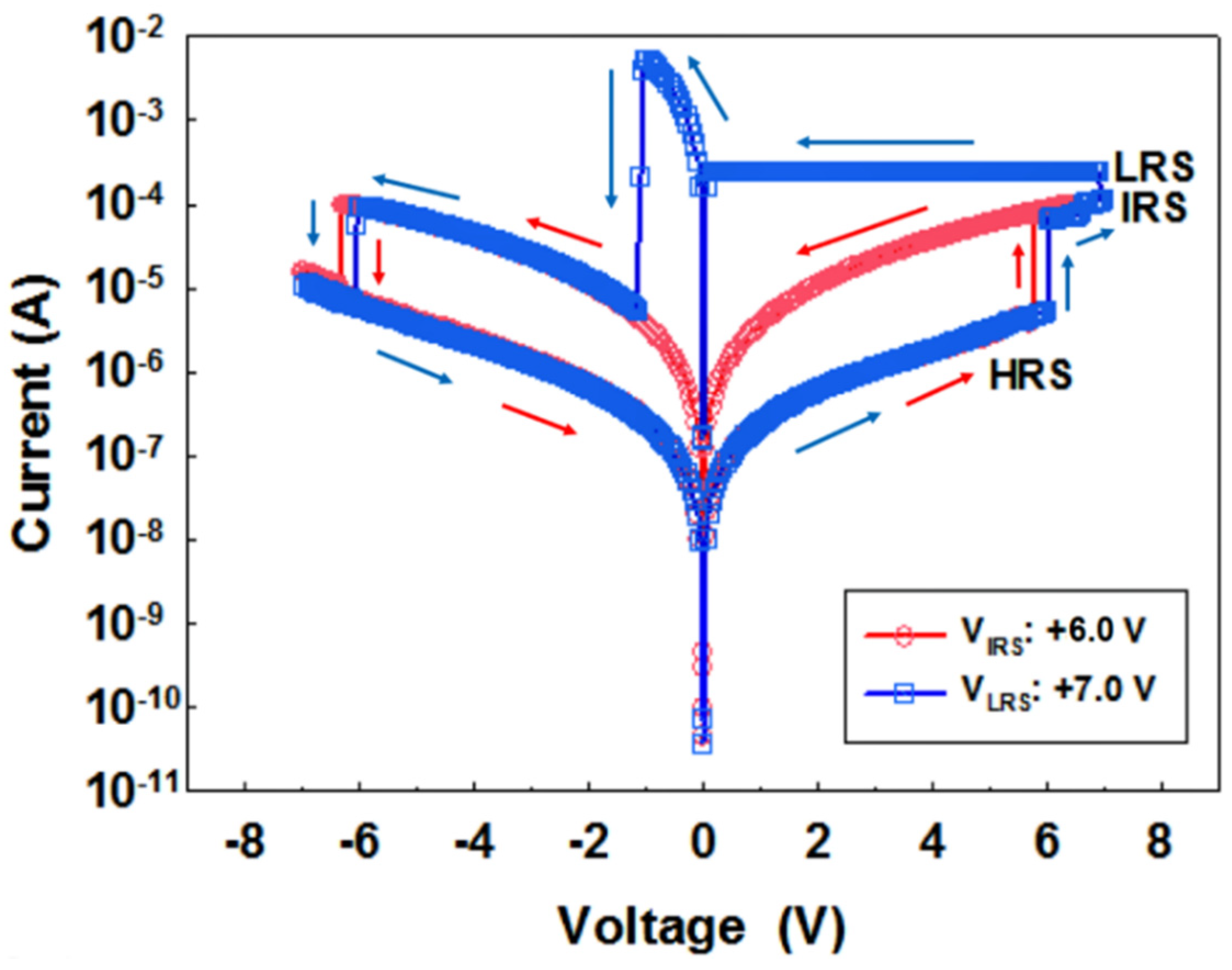

3.2. Electrical Characteristics

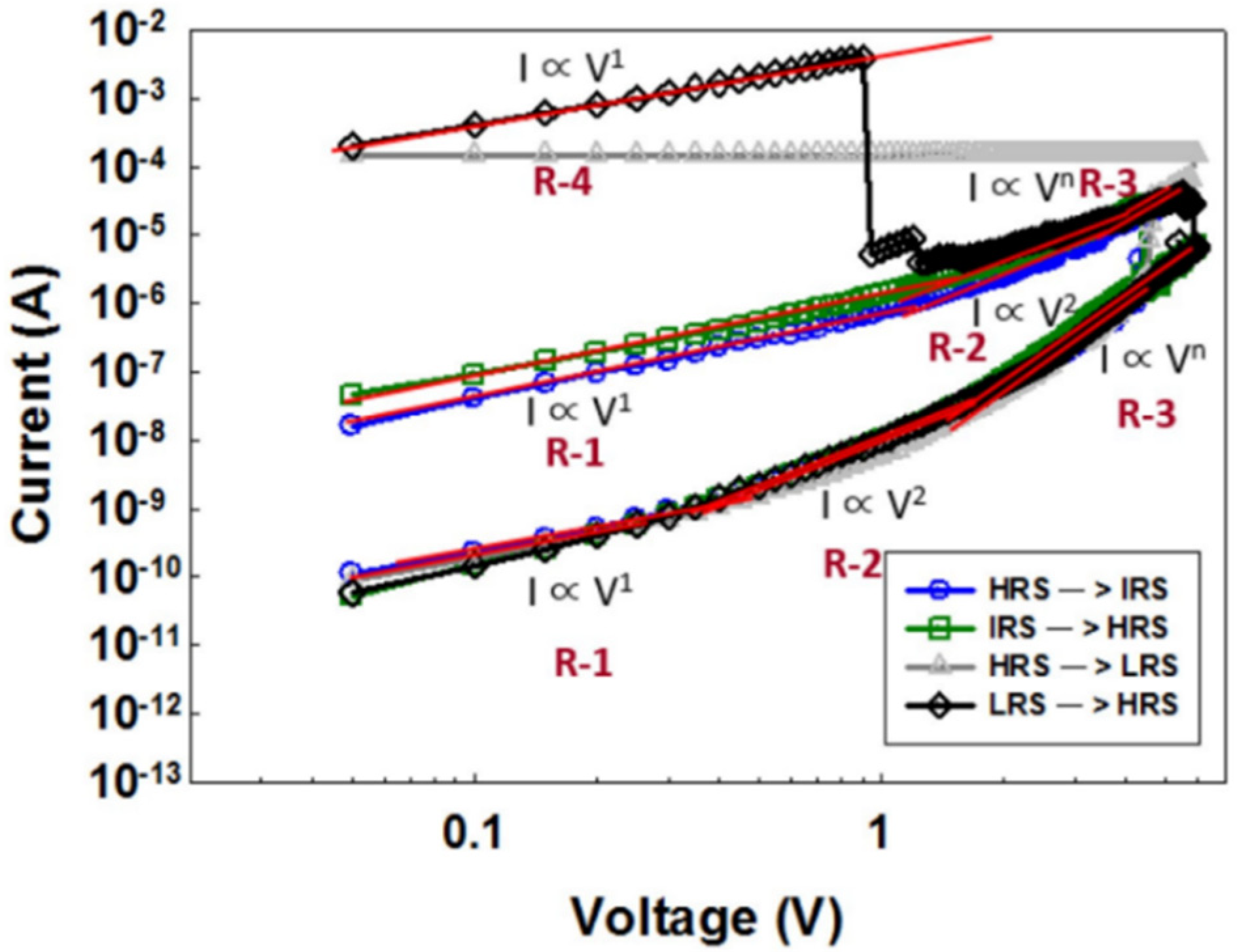

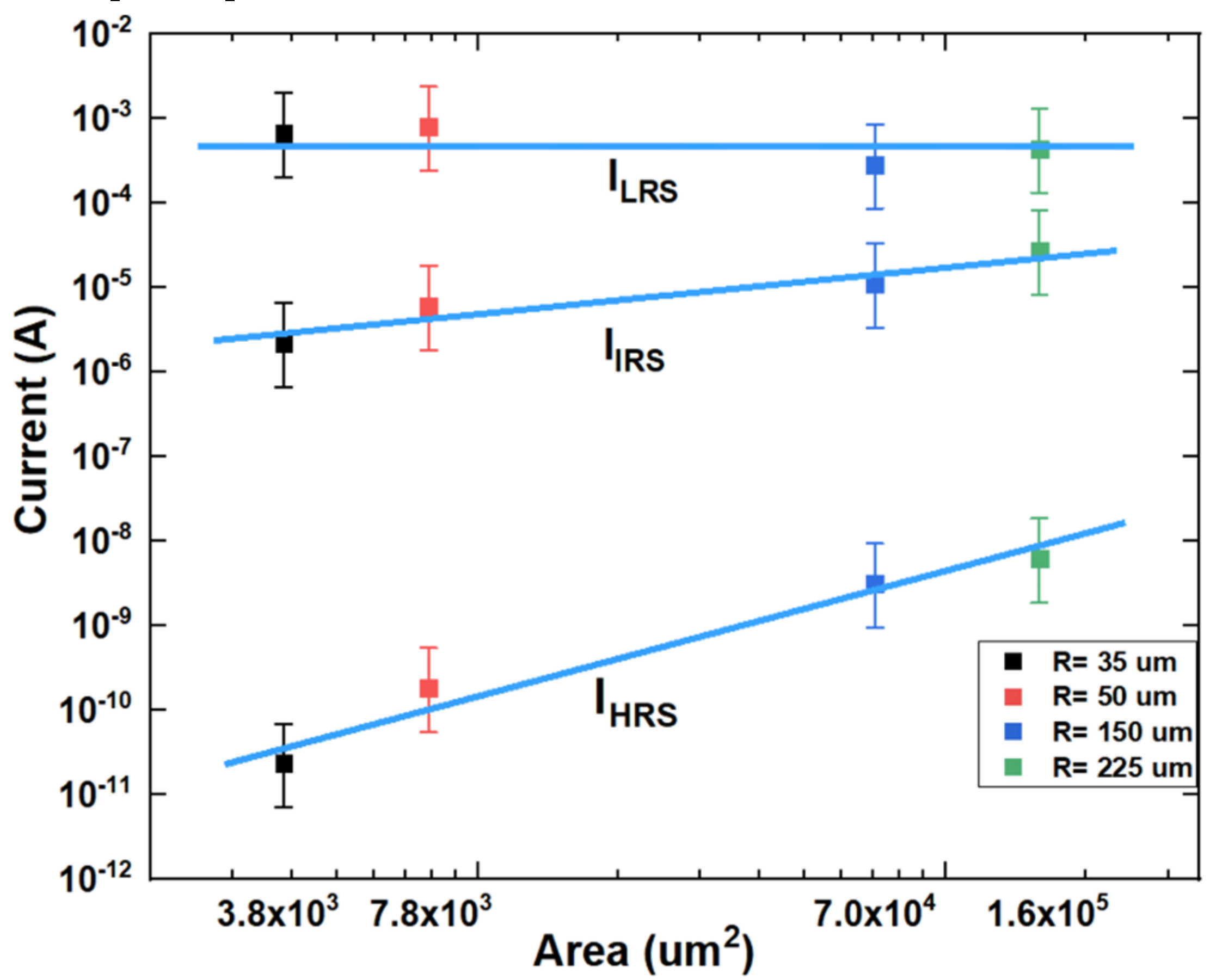

3.3. Resistive Switching Mechanism

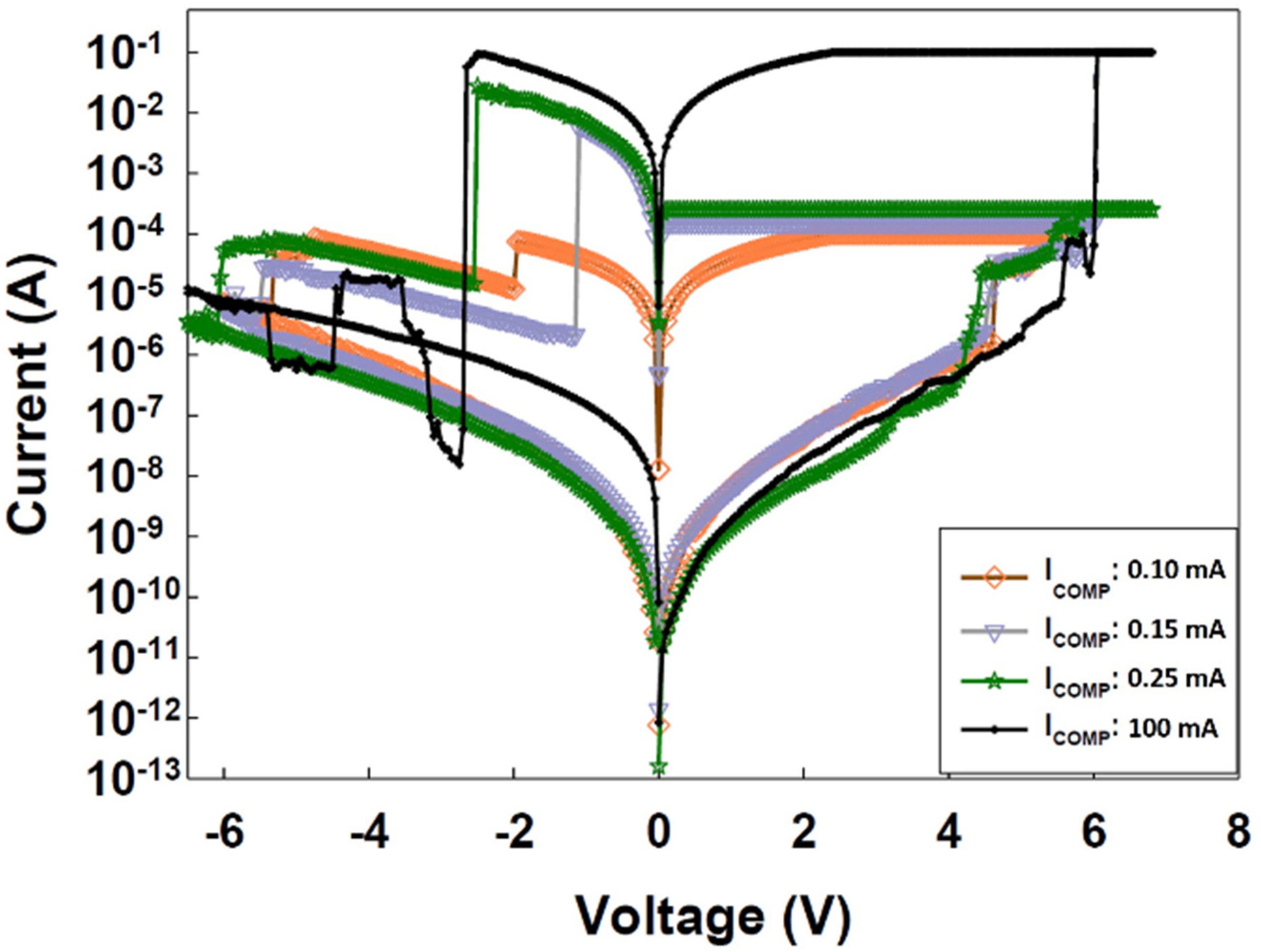

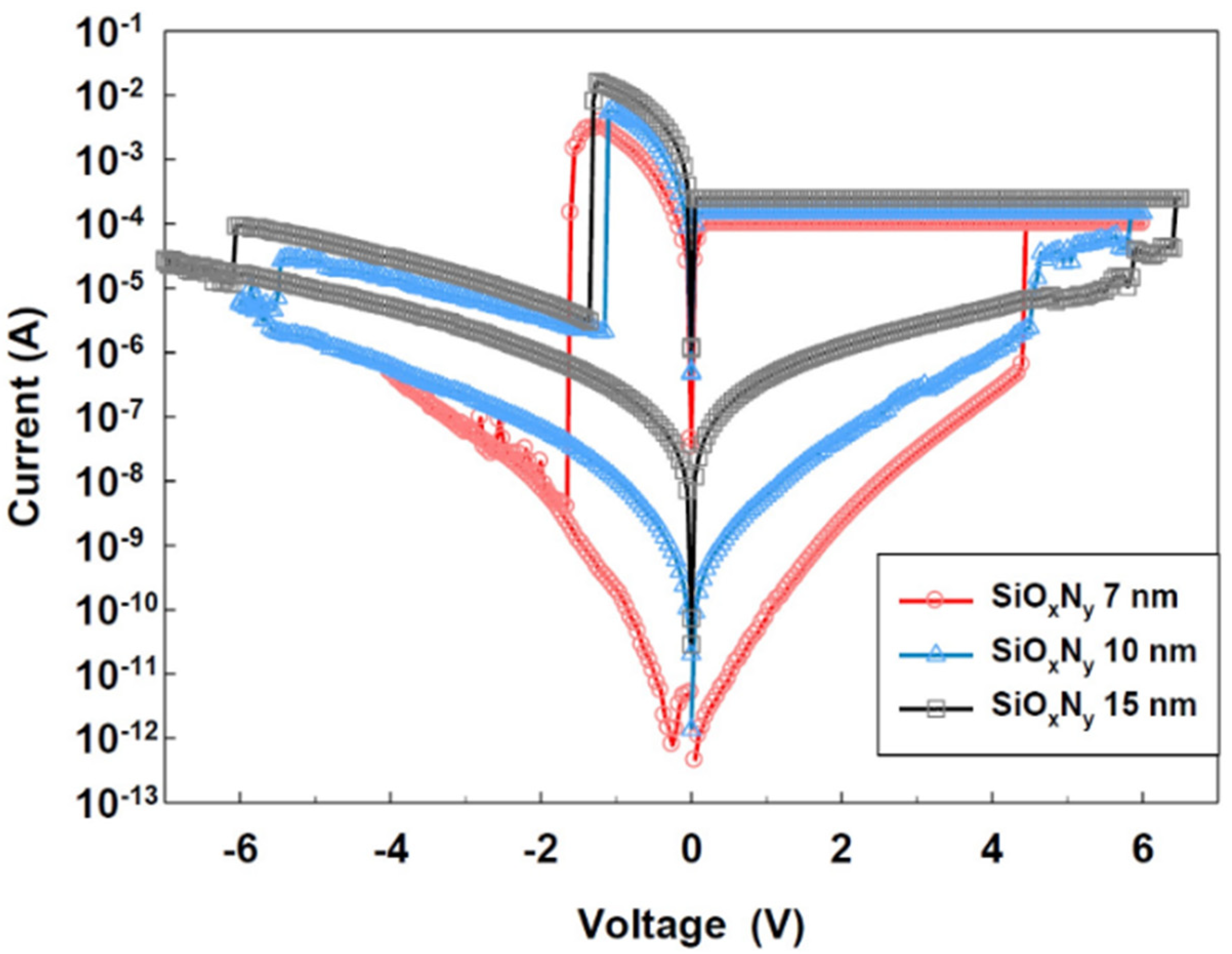

3.4. Effect of Write-Current Level and Silicon Oxynitride Thickness

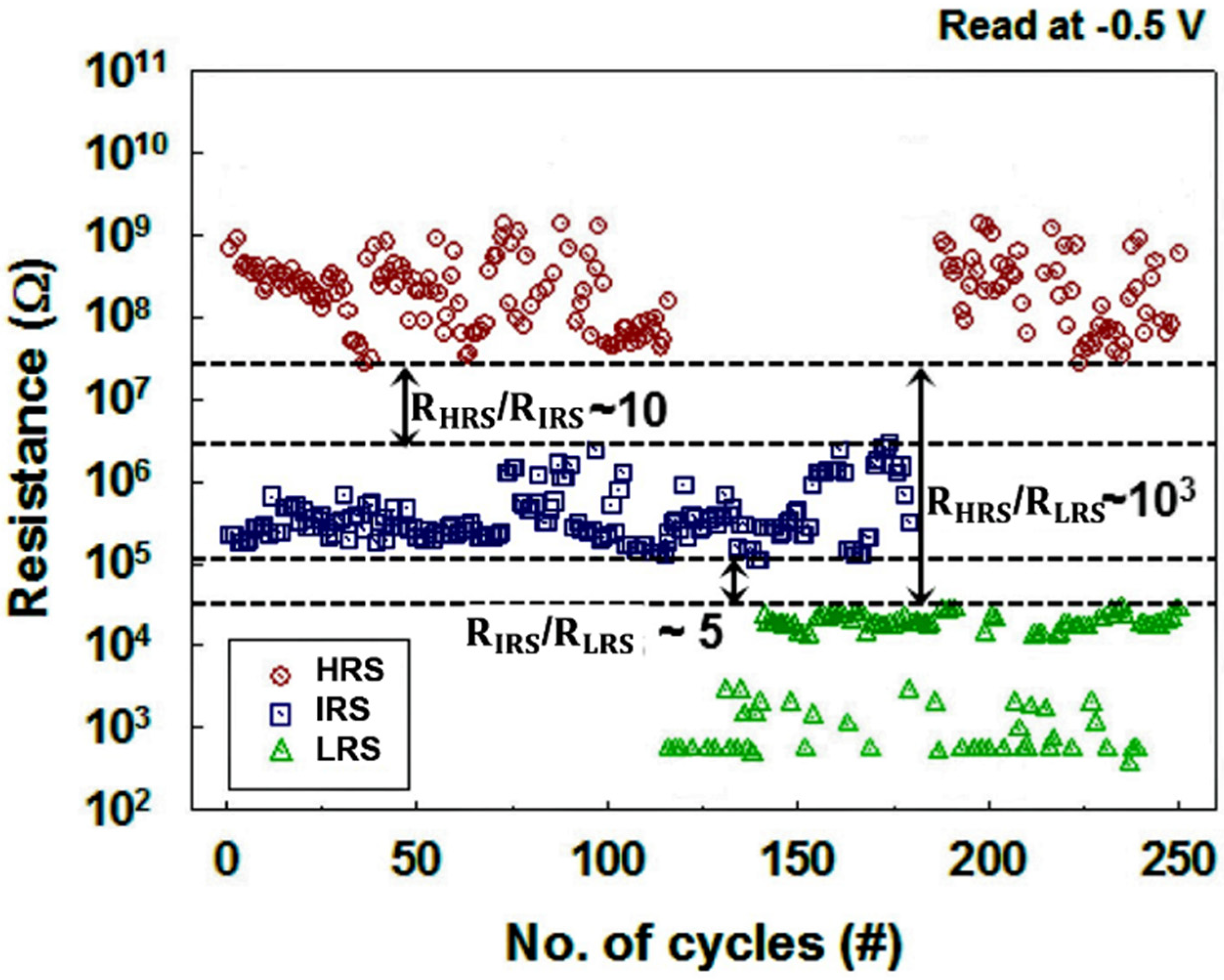

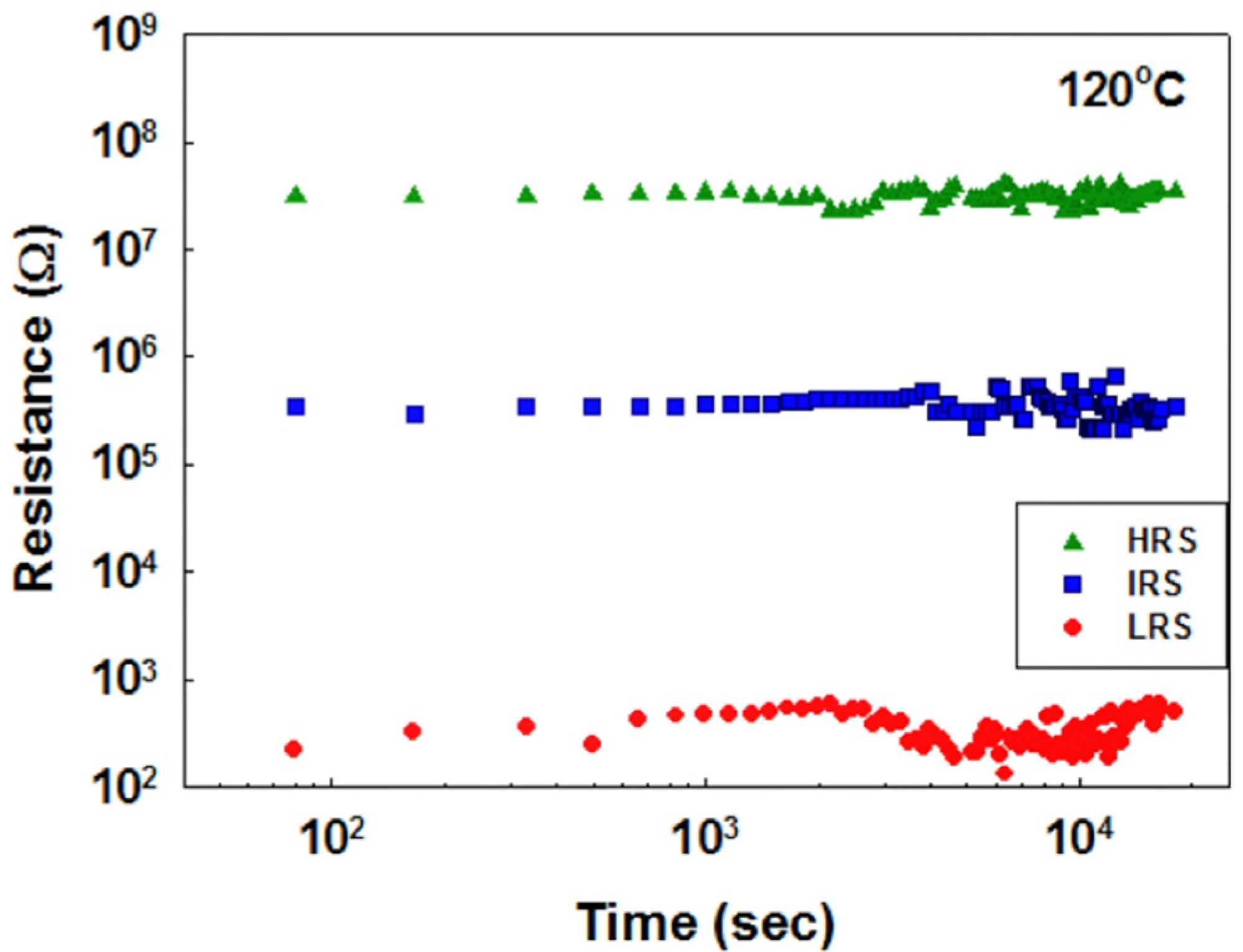

3.5. Endurance and Retention Characteristics

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Meijer, G. Materials science: Who wins the nonvolatile memory race? Science 2008, 319, 1625–1626. [Google Scholar] [CrossRef] [PubMed]

- Sawa, A. Resistive switching in transition metal oxides. Mater. Today 2008, 11, 28–36. [Google Scholar] [CrossRef]

- Waser, R.; Aono, M. Nanoionics-based resistive switching memories. Nat. Mater. 2007, 6, 833–840. [Google Scholar] [CrossRef] [PubMed]

- Seok, J.Y.; Song, S.J.; Yoon, J.H.; Yoon, K.J.; Park, T.H.; Kwon, D.E.; Lim, H.; Kim, G.H.; Jeong, D.S.; Hwang, C.S. A Review of three-dimensional resistive switching cross-bar array memories from the integration and materials property points of view. Adv. Funct. Mater. 2014, 24, 5316–5339. [Google Scholar] [CrossRef]

- Menzel, S.; Böttger, U.; Waser, R. Simulation of multilevel switching in electrochemical metallization memory cells. J. Appl. Phys. 2012, 111, 014501. [Google Scholar] [CrossRef]

- Balatti, S.; Larentis, S.; Gilmer, D.C.; Ielmini, D. Multiple memory states in resistive switching devices through controlled size and orientation of the conductive filament. Adv. Mater. 2013, 25, 1474–1478. [Google Scholar] [CrossRef]

- Yu, S.; Gao, B.; Fang, Z.; Yu, H.; Kang, J.; Wong, H.-S.P. A low energy oxide-based electronic synaptic device for neuromorphic visual systems with tolerance to device variation. Adv. Mater. 2013, 25, 1774–1779. [Google Scholar] [CrossRef]

- Jo, S.H.; Chang, T.; Ebong, I.; Bhadviya, B.B.; Mazumder, P.; Lu, W. Nanoscale memristor device as synapse in neuromorphic systems. Nano Lett. 2010, 10, 1297–1301. [Google Scholar] [CrossRef]

- Chien, W.C.; Chen, Y.C.; Chang, K.P.; Lai, E.K.; Yao, Y.D.; Lin, P.; Gong, J.; Tsai, S.C.; Hsieh, S.H.; Chen, C.F.; et al. Multi-level operation of fully CMOS compatible WOX Resistive Random Access Memory (RRAM). In Proceedings of the 2009 IEEE International Memory Workshop, Monterey, CA, USA, 10–14 May 2009. [Google Scholar]

- Reddy, V.S.; Karak, S.; Dhar, A. Multilevel conductance switching in organic memory devices based on AlQ3 and Al/Al2O3 core-shell nanoparticles. Appl. Phys. Lett. 2009, 94, 173304. [Google Scholar] [CrossRef]

- Russo, U.; Kamalanathan, D.; Ielmini, D.; Lacaita, A.L.; Kozicki, M.N. Study of multilevel programming in Programmable Metallization Cell (PMC) Memory. IEEE Trans. Electron Devices 2009, 56, 1040–1047. [Google Scholar] [CrossRef]

- Li, Y.; Long, S.; Liu, Q.; Wang, Q.; Zhang, M.; Lv, H.; Shao, L.; Wang, Y.; Zhang, S.; Zuo, Q.; et al. Nonvolatile multilevel memory effect in Cu/WO3/Pt device structures. Phys. Status Solidi (RRL) -Rapid Res. Lett. 2010, 4, 124–126. [Google Scholar] [CrossRef]

- Jo, S.H.; Lu, W. CMOS compatible nanoscale nonvolatile resistance switching memory. Nano Lett. 2008, 8, 392–397. [Google Scholar] [CrossRef] [PubMed]

- Tang, G.S.; Zeng, F.; Chen, C.; Liu, H.Y.; Gao, S.; Li, S.Z.; Song, C.; Wang, G.Y.; Pan, F. Resistive switching with self-rectifying behavior in Cu/SiOx/Si structure fabricated by plasma-oxidation. J. Appl. Phys. 2013, 113, 244502. [Google Scholar] [CrossRef]

- Heo, S.; Lee, J.; Kim, S.H.; Yun, D.-J.; Park, J.-B.; Kim, K.; Kim, N.; Kim, Y.; Lee, D.; Kim, K.-S.; et al. Device performance enhancement via a Si-rich silicon oxynitride buffer layer for the organic photodetecting device. Sci. Rep. 2017, 7. [Google Scholar] [CrossRef] [PubMed]

- Kapoor, V.; Bailey, R.S.; Smith, S.R. Impurities-related memory traps in silicon nitride thin films. J. Vac. Sci. Technol. 1981, 18, 305–308. [Google Scholar] [CrossRef]

- Chen, D.; Huang, S.; He, L. Effect of oxygen concentration on resistive switching behavior in silicon oxynitride film. J. Semicond. 2017, 38, 043002. [Google Scholar] [CrossRef]

- Yang, P.-C.; Chang, T.-C.; Chen, S.-C.; Lin, Y.-S.; Huang, H.-C.; Gan, D.-S. Influence of bias-induced copper diffusion on the resistive switching characteristics of a SiON thin film. Electrochem. Solid -State Lett. 2011, 14. [Google Scholar] [CrossRef]

- Yang, J.J.; Pickett, M.D.; Li, X.; Ohlberg, D.A.A.; Stewart, D.R.; Williams, R.S. Memristive switching mechanism for metal/oxide/metal nanodevices. Nat. Nanotechnol. 2008, 3, 429–433. [Google Scholar] [CrossRef]

- Wong, H.-S.P.; Lee, H.-Y.; Yu, S.; Chen, Y.-S.; Wu, Y.; Chen, P.-S.; Lee, B.; Chen, F.T.; Tsai, M.-J. Metal−Oxide RRAM. In Proceedings of the 2012 IEEE International Conference on Information Science and Technology, Wuhan, China, 23–25 March 2012; Volume 100, pp. 1951–1970. [Google Scholar]

- Münstermann, R.; Yang, J.J.; Strachan, J.P.; Medeiros-Ribeiro, G.; Dittmann, R.; Waser, R. Morphological and electrical changes in TiO2 memristive devices induced by electroforming and switching. Phys. Status Solidi (RRL) -Rapid Res. Lett. 2010, 4, 16–18. [Google Scholar] [CrossRef]

- Lee, D.; Seong, D.-J.; Choi, H.J.; Jo, I.; Dong, R.; Xiang, W.; Oh, S.; Pyun, M.; Seo, S.-O.; Heo, S.; et al. Excellent uniformity and reproducible resistance switching characteristics of doped binary metal oxides for non-volatile resistance memory applications. In Proceedings of the 2006 International Electron Devices Meeting, San Francisco, CA, USA, 11–13 December 2006. [Google Scholar]

- Kwon, D.-H.; Kim, K.M.; Jang, J.H.; Jeon, J.M.; Lee, M.H.; Kim, G.H.; Li, X.-S.; Park, G.-S.; Lee, B.; Han, S.; et al. Atomic structure of conducting nanofilaments in TiO2 resistive switching memory. Nat. Nanotechnol. 2010, 5, 148–153. [Google Scholar] [CrossRef]

- Fang, Z.; Yu, H.Y.; Li, X.; Singh, N.; Lo, G.Q.; Kwong, D.L. HfOx/TiOx/HfOx/TiOx multilayer-based forming-free RRAM devices with excellent uniformity. IEEE Electron Device Lett. 2011, 32, 566–568. [Google Scholar] [CrossRef]

- Wan, Z.; Darling, R.B.; Majumdar, A.; Anantram, M.P. A forming-free bipolar resistive switching behavior based on ITO/V2O5/ITO structure. Appl. Phys. Lett. 2017, 111, 041601. [Google Scholar] [CrossRef]

- Chien, W.; Chen, Y.; Chen, Y.; Chuang, A.T.; Lee, F.; Lin, Y.; Lai, E.; Shih, Y.; Hsieh, K.; Lu, C.-Y. A forming-free WOx resistive memory using a novel self-aligned field enhancement feature with excellent reliability and scalability. In Proceedings of the 2010 International Electron Devices Meeting, San Francisco, CA, USA, 6–8 December 2010. [Google Scholar]

- Kawai, M.; Ito, K.; Ichikawa, N.; Shimakawa, Y. Thermally formed conducting filaments in a single-crystalline NiO thin film. Appl. Phys. Lett. 2010, 96, 072106. [Google Scholar] [CrossRef]

- Chen, Y.-S.; Lee, H.-Y.; Chen, P.-S.; Wu, T.-Y.; Wang, C.-C.; Tzeng, P.-J.; Chen, F.; Tsai, M.-J.; Lien, C. An ultrathin forming-free HfOx resistance memory with excellent electrical performance. IEEE Electron Device Lett. 2010, 31, 1473–1475. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Gao, X.; Yu, W.; Liu, X.; Zhang, Y.; Chen, L.; Cheng, X. Forming-free colossal resistive switching effect in rare-earth-oxide Gd2O3 films for memristor applications. J. Appl. Phys. 2009, 106, 073723. [Google Scholar] [CrossRef]

- Shams, Q.A. Physical and electrical properties of memory quality PECVD silicon oxynitride. J. Electrochem. Soc. 1990, 137, 1244. [Google Scholar] [CrossRef]

- Criado, D.; Alayo, M.; Pereyra, I.; Fantini, M. Structural analysis of silicon oxynitride films deposited by PECVD. Mater. Sci. Eng. B 2004, 112, 123–127. [Google Scholar] [CrossRef]

- Ay, F.; Aydinli, A. Comparative investigation of hydrogen bonding in silicon based PECVD grown dielectrics for optical waveguides. Opt. Mater. 2004, 26, 33–46. [Google Scholar] [CrossRef]

- Hitchman, M.L.; Jensen, K.F. Chemical Vapor Deposition: Principles and Applications; Academic Press: London, UK, 1993. [Google Scholar]

- Shi, Y.; He, L.; Guang, F.; Li, L.; Xin, Z.; Liu, R. A Review: Preparation, performance, and applications of silicon oxynitride film. Micromachines 2019, 10, 552. [Google Scholar] [CrossRef]

- Kim, H.-D.; An, H.-M.; Kim, K.C.; Seo, Y.; Nam, K.-H.; Chung, H.-B.; Lee, E.B.; Kim, T.G. Large resistive-switching phenomena observed in Ag/Si3N4/Al memory cells. Semicond. Sci. Technol. 2010, 25, 065002. [Google Scholar] [CrossRef][Green Version]

- Park, J.H.; Kim, H.-D.; Hong, S.M.; Yun, M.J.; Jeon, D.S.; Kim, T.G. Improved resistive switching phenomena observed in SiNx-based resistive switching memory through oxygen doping process. Phys. Status Solidi (RRL) -Rapid Res. Lett. 2013, 8, 239–242. [Google Scholar] [CrossRef]

- Xu, N.; Gao, B.; Liu, L.; Sun, B.; Liu, X.; Han, R.; Kang, J.; Yu, B. A unified physical model of switching behavior in oxide-based RRAM. In Proceedings of the 2008 Symposium on VLSI Technology, Honolulu, HI, USA, 17–19 June 2008. [Google Scholar]

- Ielmini, D.; Spiga, S.; Nardi, F.; Cagli, C.; Lamperti, A.; Cianci, E.; Fanciulli, M. Scaling analysis of submicrometer nickel-oxide-based resistive switching memory devices. J. Appl. Phys. 2011, 109, 034506. [Google Scholar] [CrossRef]

- Rebib, F.; Tomasella, E.; Dubois, M.; Cellier, J.; Sauvage, T.; Jacquet, M. Structural and optical investigations of SiOxNy thin films deposited by R.F. sputtering. Surf. Coat. Technol. 2005, 200, 330–333. [Google Scholar] [CrossRef]

- Chen, W.S.; Chen, Y.S.; Hsu, Y.Y.; Yang, S.Y.; Liu, W.H.; Lee, H.Y.; Gu, P.Y.; Tsai, C.H.; Wang, S.M.; Chen, P.S.; et al. IC process compatible anodic electrode structures for unipolar HfOx-based RRAM. In Proceedings of the 2011 International Symposium on VLSI Technology, Systems and Applications, Taiwan, China, 25–27 April 2011. [Google Scholar]

- Li, L.; Yang, X.; Lei, Y.; Yu, H.; Yang, Z.; Zheng, Z.; Wang, D. Ultrathin Fe-NiO nanosheets as catalytic charge reservoirs for a planar Mo-doped BiVO4 photoanode. Chem. Sci. 2018, 9, 8860–8870. [Google Scholar] [CrossRef]

- Wu, H.; Wang, L.-S. A study of nickel monoxide (NiO), nickel dioxide (ONiO), and Ni(O2) complex by anion photoelectron spectroscopy. J. Chem. Phys. 1997, 107, 16–21. [Google Scholar] [CrossRef]

- Available online: http://www2.ucdsb.on.ca/tiss/stretton/database/inorganic_thermo.htm (accessed on 25 April 2020).

- Available online: http://www.colby.edu/chemistry/PChem/Hartree.html (accessed on 25 April 2020).

- Kim, K.M.; Choi, B.J.; Koo, B.W.; Choi, S.; Jeong, D.S.; Hwang, C.S. Resistive switching in Pt/Al2O3/TiO2/Ru stacked structures. Electrochem. Solid -State Lett. 2006, 9, G343–G346. [Google Scholar] [CrossRef]

- Wu, X.; Zhou, P.; Li, J.; Chen, L.Y.; Lv, H.B.; Lin, Y.Y.; Tang, T.A. Reproducible unipolar resistance switching in stoichiometric ZrO2 films. Appl. Phys. Lett. 2007, 90, 183507. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Wu, C.-Y.; Wu, C.-Y.; Tseng, T.-Y.; Hu, C. Modified resistive switching behavior of ZrO2 memory films based on the interface layer formed by using Ti top electrode. J. Appl. Phys. 2007, 102, 094101. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Wang, S.-Y.; Lee, D.-Y.; Tseng, T.-Y. Electrical properties and fatigue behaviors of ZrO2 resistive switching thin films. J. Electrochem. Soc. 2008, 155. [Google Scholar] [CrossRef]

- Yuan, X.-C.; Tang, J.-L.; Zeng, H.-Z.; Wei, X.-H. Abnormal coexistence of unipolar, bipolar, and threshold resistive switching in an Al/NiO/ITO structure. Nanoscale Res. Lett. 2014, 9, 268. [Google Scholar] [CrossRef]

- Tran, X.A.; Zhu, W.; Liu, W.J.; Yeo, Y.C.; Nguyen, B.Y.; Yu, H.Y. Self-selection unipolar HfOx-based RRAM. IEEE Trans. Electron Devices 2013, 60, 391–395. [Google Scholar] [CrossRef]

- Ielmini, D.; Nardi, F.; Cagli, C. Physical models of size-dependent nanofilament formation and rupture in NiO resistive switching memories. Nanotechnology 2011, 22, 254022. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.J.; Strukov, D.B.; Stewart, D.R. Memristive devices for computing. Nat. Nanotechnol. 2012, 8, 13–24. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.; Liu, L.; Xu, N.; Gao, B.; Wang, Y.; Han, D.; Liu, X.; Han, R.; Kang, J. The effect of current compliance on the resistive switching behaviors in TiN/ZrO2/Pt memory device. Jpn. J. Appl. Phys. 2009, 48, 04C061. [Google Scholar] [CrossRef]

- Sun, H.; Liu, Q.; Li, C.; Long, S.; Lv, H.; Bi, C.; Huo, Z.; Li, L.; Liu, M. Direct observation of conversion between threshold switching and memory switching induced by conductive filament morphology. Adv. Funct. Mater. 2014, 24, 5679–5686. [Google Scholar] [CrossRef]

- Tendulkar, M.; Gopal, V.; Hashim, I.; Higuchi, R.J.; Minvielle, T.; Wang, Y.; Yamaguchi, T. Bilayered oxide structures for ReRAM cells. U.S. Patent No. 20,140,175,360A1, 26 June 2014. [Google Scholar]

- Yoshida, M.; Tohyama, D.; Maeguchi, K.; Kanzaki, K. Increase of resistance to hot carriers in thin oxide MOSFETS. In Proceedings of the 1985 International Electron Devices Meeting, Washington, DC, USA, 1–4 December 1985. [Google Scholar]

- Rehman, S.; Khan, M.F.; Aftab, S.; Kim, H.; Eom, J.; Kim, D.-K. Thickness-dependent resistive switching in black phosphorus CBRAM. J. Mater. Chem. C 2019, 7, 725–732. [Google Scholar] [CrossRef]

- Nakajima, R.; Azuma, A.; Yoshida, H.; Shimizu, T.; Ito, T.; Shingubara, S. Hf layer thickness dependence of resistive switching characteristics of Ti/Hf/HfO2/Au resistive random access memory device. Jpn. J. Appl. Phys. 2018, 57, 06HD06. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, N.C.; Oh, S.-I.; Rani, J.R.; Hong, S.-M.; Jang, J.-H. Multilevel Bipolar Electroforming-Free Resistive Switching Memory Based on Silicon Oxynitride. Appl. Sci. 2020, 10, 3506. https://doi.org/10.3390/app10103506

Das NC, Oh S-I, Rani JR, Hong S-M, Jang J-H. Multilevel Bipolar Electroforming-Free Resistive Switching Memory Based on Silicon Oxynitride. Applied Sciences. 2020; 10(10):3506. https://doi.org/10.3390/app10103506

Chicago/Turabian StyleDas, Nayan C., Se-I Oh, Jarnardhanan R. Rani, Sung-Min Hong, and Jae-Hyung Jang. 2020. "Multilevel Bipolar Electroforming-Free Resistive Switching Memory Based on Silicon Oxynitride" Applied Sciences 10, no. 10: 3506. https://doi.org/10.3390/app10103506

APA StyleDas, N. C., Oh, S.-I., Rani, J. R., Hong, S.-M., & Jang, J.-H. (2020). Multilevel Bipolar Electroforming-Free Resistive Switching Memory Based on Silicon Oxynitride. Applied Sciences, 10(10), 3506. https://doi.org/10.3390/app10103506