Mobile Robotics in Agricultural Operations: A Narrative Review on Planning Aspects

Abstract

:1. Introduction

- (i)

- the presence of biological entities governed by temporal changes in their properties (the product itself-i.e., the crop-throughout its life continuously changes in terms of physical-e.g., size and shape-and chemical properties-e.g., color and nutrients)

- (ii)

- the nature of agricultural environments as operational environments are typically non-static, non-certain in terms of robot awareness, and not defined a priori; and

- (iii)

- the technological and functional constraints of mobile robots.

- RQ#1-What is a basic and concise terminology required for planning mobile robotic autonomous operations?

- RQ#2-What attributes have to be included to enable a comprehensive locomotion panning in autonomous operations within agri-environments?

2. Materials and Methods

2.1. Theoretical Lens

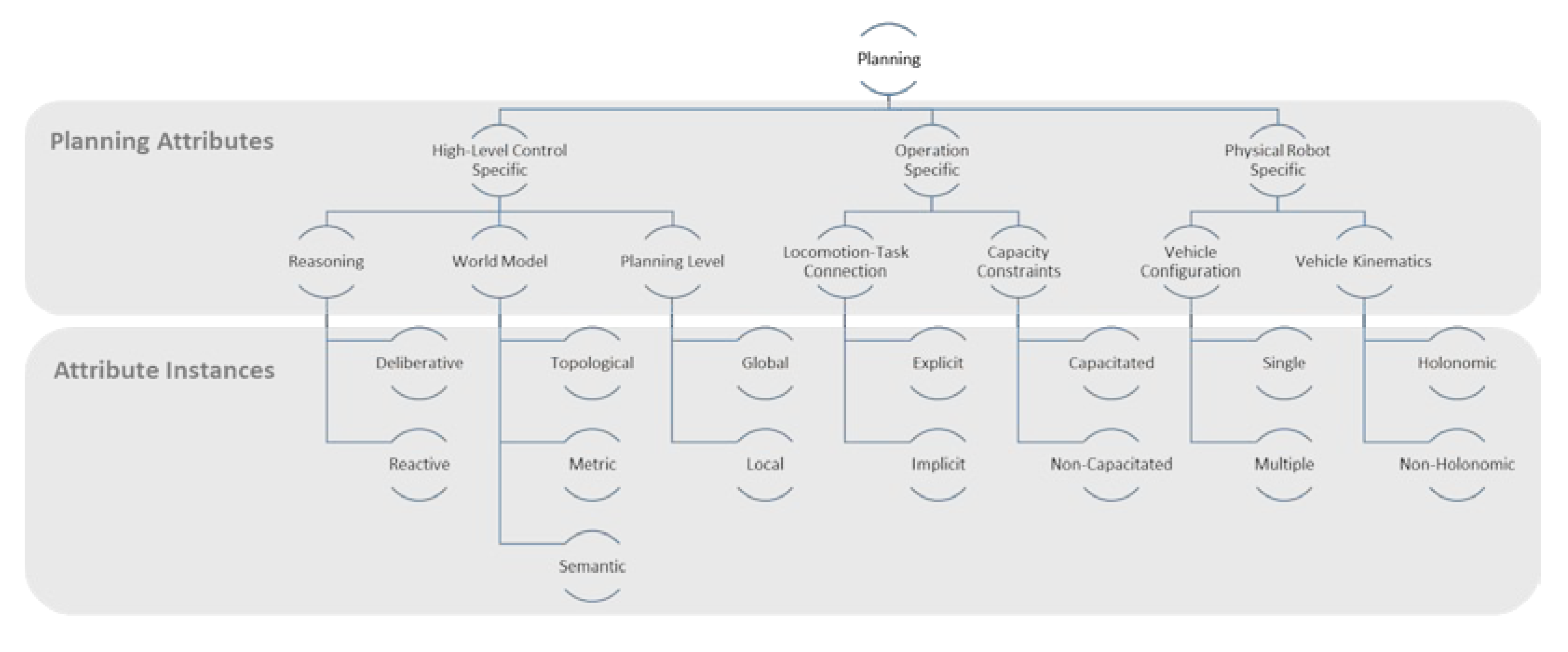

2.2. Definition of Planning Atributes

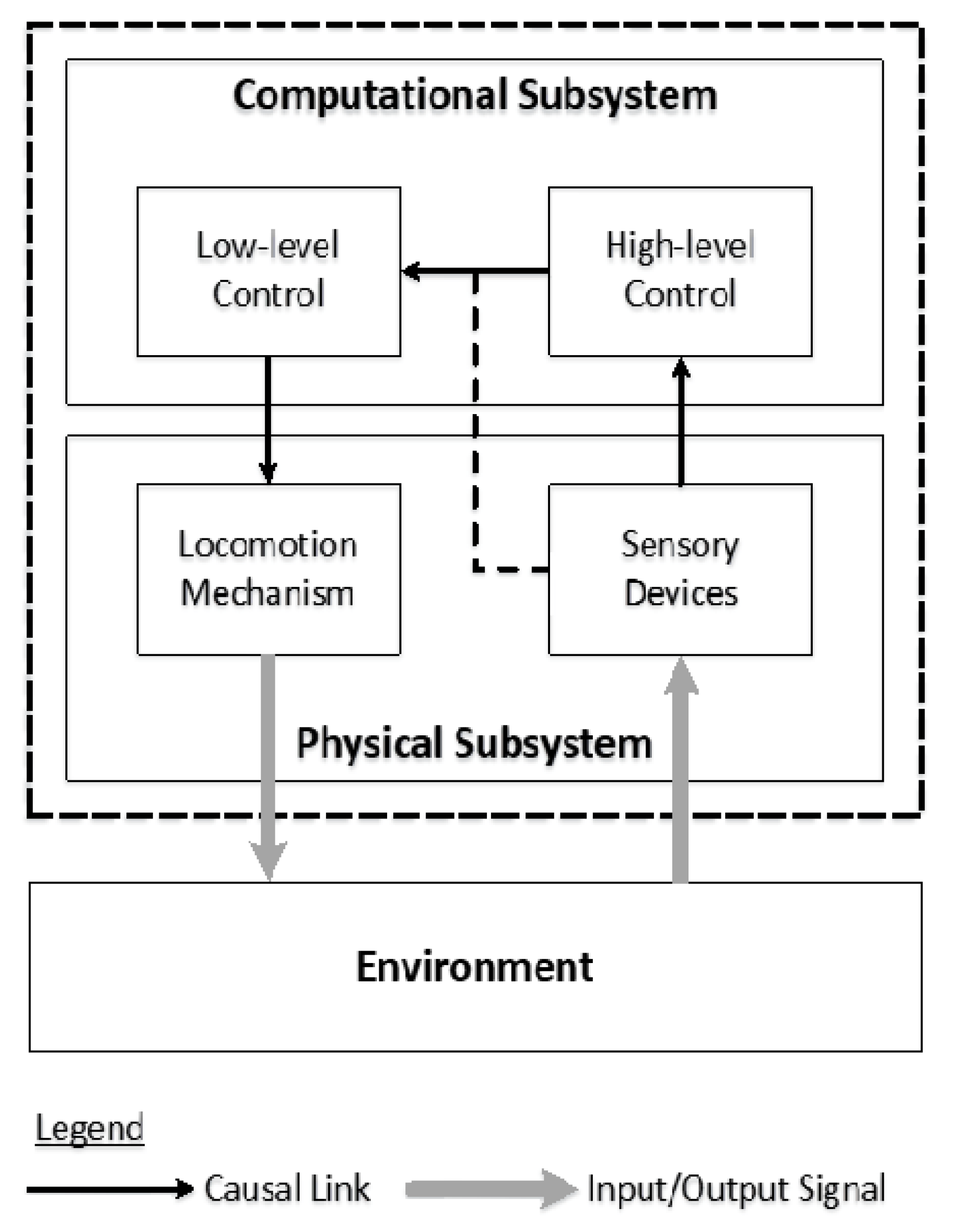

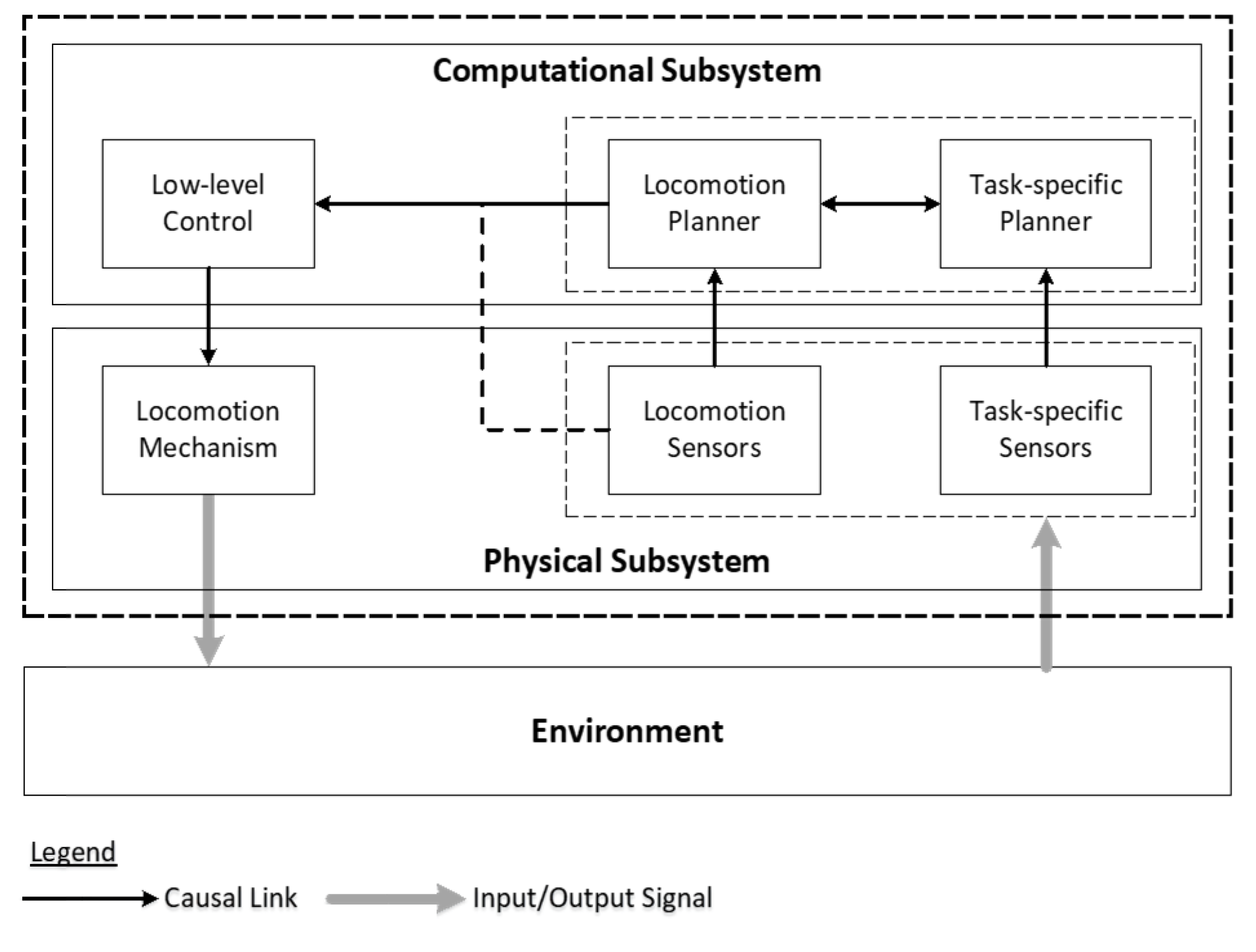

- 1.

- The physical sub-system that includes the locomotion mechanism, which enables the motion-transition of the robot between two subsequent configurations, along with the sensory devices, which enable interaction with the operating environment At the physical subsystem level, the locomotion mechanism includes physical steering systems (in the case of UGVs) or piloting systems (in the case of UAVs), the necessary control mechanisms and the underpinning kinematics;

- 2.

- The computational sub-system that includes the low- and high-level control layers and refers to all algorithms and models controlling the functionality and maneuverability of the robot.

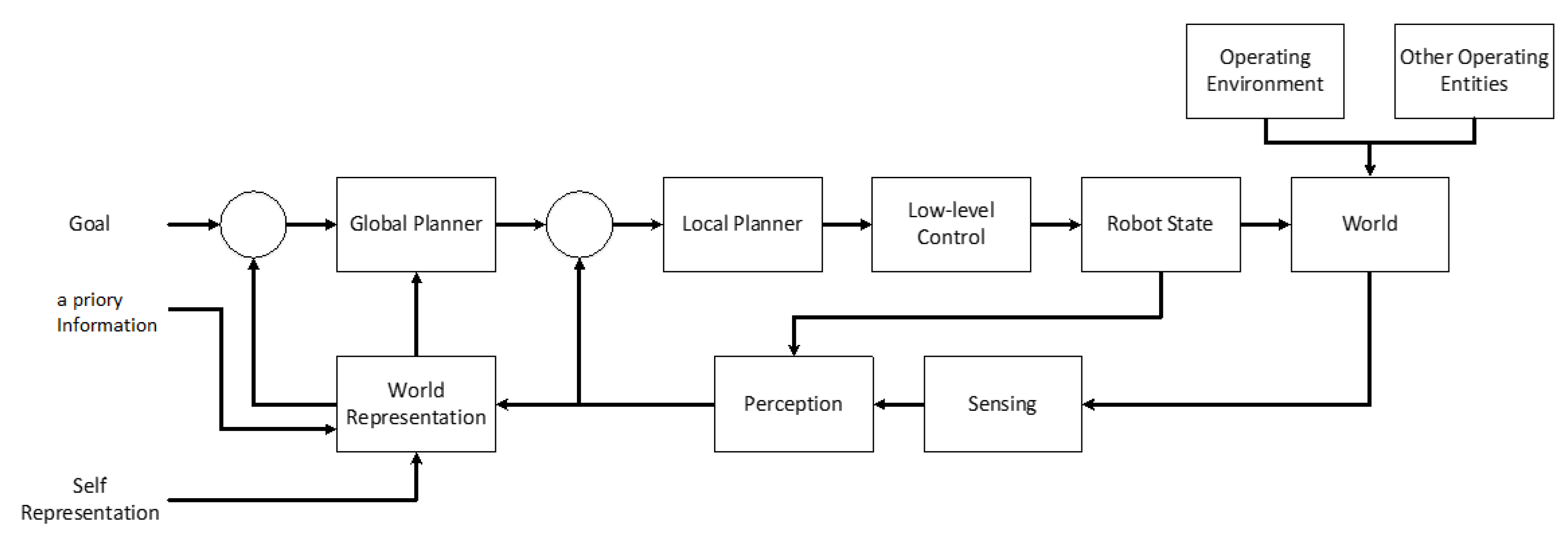

2.2.1 Reasoning Architecture

2.2.2. World Model

2.2.3. Locomotion–Task Connection

- Implicitly connected with the robot’s locomotion, i.e., the robot uses its mobility function in order to reach a set of distributed workstations to perform any required tasks. In this case, the way that the robot navigates is irrelevant to the task per se.

- Explicitly connected with the robot’s locomotion, i.e., the task is executed “on-the-go”. Notably, the way that the robot is moving affects the execution of the task.

2.2.4. Planning Level

2.2.5. Capacity Constraints

2.2.6. Vehicle Configuration

2.2.7. Vehicle Kinematics

2.3. Methodological Approach

- (i)

- Operational environment. Typically, three types of agricultural environments are recognized, including: (a) unstructured environments (arable farming, e.g., wheat and corn); (b) semi-structured environments (open-air horticulture, e.g., orchards and vineyards); and (c) structured environments (greenhouses).

- (ii)

- Operation. This regards physical agronomic operation, e.g., harvesting, spraying.

- (iii)

- Approach validation. This regards the validation means of the presented approach, namely, through simulation, lab experiments, or trials in a physical environment.

3. Review

4. Discussion

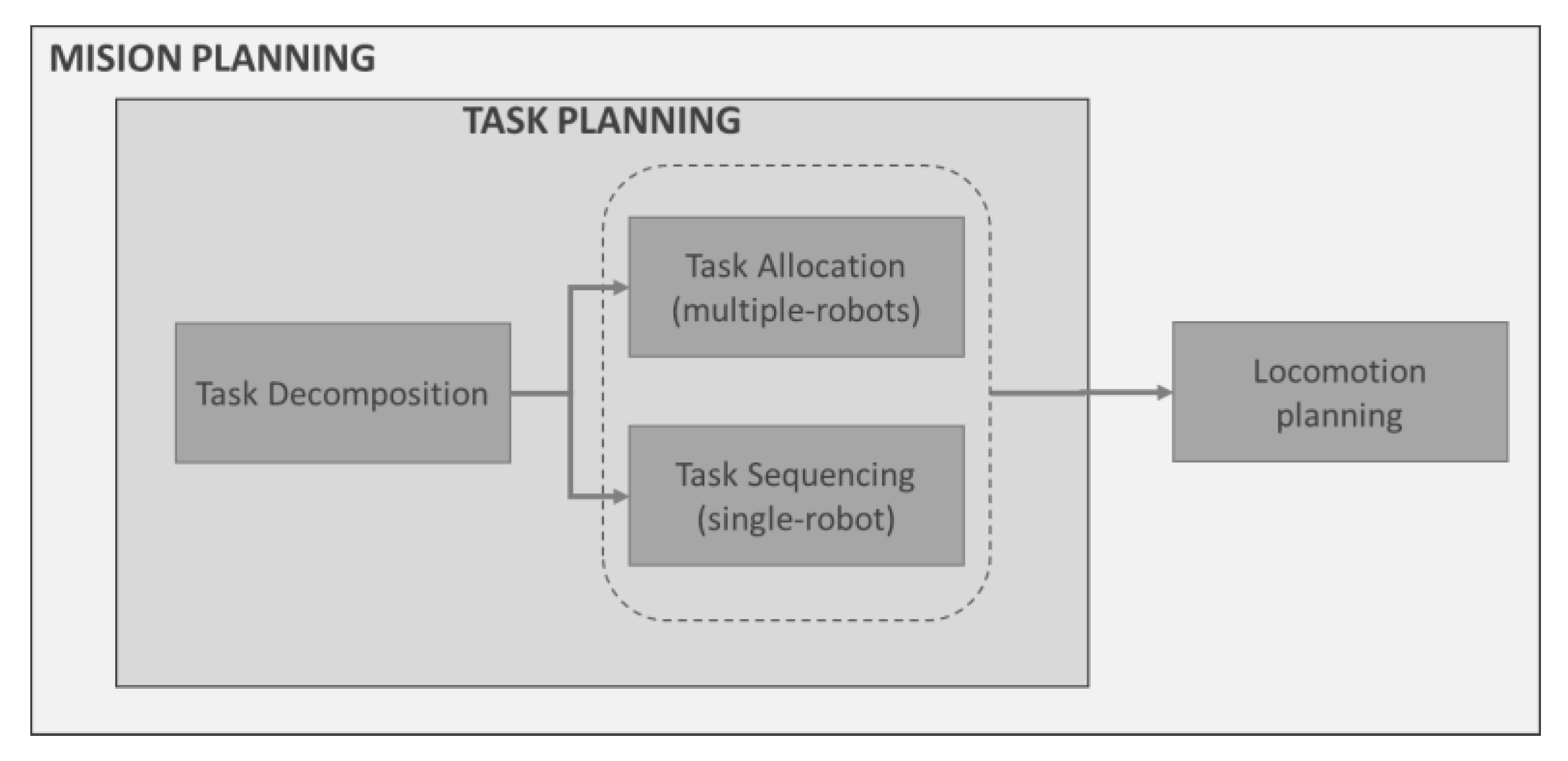

4.1. Locomotion Planning as Part of the Overall Mission Plannning

4.2. Limitations

4.3. Future Research

- Dynamic planning of autonomous operations, i.e., analyzing and analytically describing the process of efficiently updating a mobile robot’s plan, either when further knowledge of the working environment is gained or when the local obstacle avoidance system triggers an instantaneous and unplanned response; and

- Complete mission planning, i.e., a comprehensive planning system including both task and locomotion planning for the execution of a field operation.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Braña, F.J. A fourth industrial revolution? Digital transformation, labor and work organization: a view from Spain. J. Ind. Bus. Econ. 2019, 46, 415–430. [Google Scholar] [CrossRef]

- Sebastian, B.; Ben-Tzvi, P. Physics Based Path Planning for Autonomous Tracked Vehicle in Challenging Terrain. J. Intell. Robot. Syst. Theory Appl. 2019, 95, 511–526. [Google Scholar] [CrossRef]

- Mukherjee, U.K.; Sinha, K.K. Robot-assisted surgical care delivery at a hospital: Policies for maximizing clinical outcome benefits and minimizing costs. J. Oper. Manag. 2020, 66, 227–256. [Google Scholar] [CrossRef]

- Silvestri, P.; Zoppi, M.; Molfino, R. Dynamic investigation on a new robotized vehicle for urban freight transport. Simul. Model. Pract. Theory 2019, 96, 101938. [Google Scholar] [CrossRef]

- Sorensen, C.G.; Pesonen, L.; Fountas, S.; Suomi, P.; Bochtis, D.; Bildsøe, P.; Pedersen, S.M. A user-centric approach for information modelling in arable farming. Comput. Electron. Agric. 2010, 73, 44–55. [Google Scholar] [CrossRef]

- Siegwart, R.; Nourbakhsh, I.R.; Scaramuzza, D. Introduction to Autonomous Mobile Robots, 2nd ed.; MIT Press: Cambridge, MA, USA, 2011; ISBN 026219502X. [Google Scholar]

- Masoud, S.A.; Masoud, A.A. Motion planning in the presence of directional and regional avoidance constraints using nonlinear, anisotropic, harmonic potential fields: A physical metaphor. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2002, 32, 705–723. [Google Scholar] [CrossRef]

- Bruzzone, L.; Quaglia, G. Review article: Locomotion systems for ground mobile robots in unstructured environments. Mech. Sci. 2012, 3, 49–62. [Google Scholar] [CrossRef] [Green Version]

- Aravind, K.R.; Raja, P.; Pérez-Ruiz, M. Task-based agricultural mobile robots in arable farming: A review. Span. J. Agric. Res. 2017, 15, e02R01. [Google Scholar] [CrossRef]

- Ko, M.H.; Ryuh, B.S.; Kim, K.C.; Suprem, A.; Mahalik, N.P. Autonomous Greenhouse Mobile Robot Driving Strategies from System Integration Perspective: Review and Application. IEEE/ASME Trans. Mechatron. 2015, 20, 1705–1716. [Google Scholar] [CrossRef]

- Colomina, I.; Molina, P. Unmanned aerial systems for photogrammetry and remote sensing: A review. ISPRS J. Photogramm. Remote Sens. 2014, 92, 79–97. [Google Scholar] [CrossRef] [Green Version]

- Boukoberine, M.N.; Zhou, Z.; Benbouzid, M. A critical review on unmanned aerial vehicles power supply and energy management: Solutions, strategies, and prospects. Appl. Energy 2019, 255, 113823. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Milford, M.; Wyeth, G. Hybrid robot control and SLAM for persistent navigation and mapping. Robot. Auton. Syst. 2010, 58, 1096–1104. [Google Scholar] [CrossRef]

- Sontag, E.D. Mathematical Control Theory; Texts in Applied Mathematics; Springer: New York, NY, USA, 1998; Volume 6, ISBN 978-1-4612-6825-3. [Google Scholar]

- Song, S.; Zeng, X.; She, Y.; Wang, J.; Su, H.J. Modeling and control of inherently safe robots with variable stiffness links. Robot. Auton. Syst. 2019, 120, 103247. [Google Scholar] [CrossRef]

- Posadas, J.L.; Poza, J.L.; Simó, J.E.; Benet, G.; Blanes, F. Agent-based distributed architecture for mobile robot control. Eng. Appl. Artif. Intell. 2008, 21, 805–823. [Google Scholar] [CrossRef]

- Bechar, A.; Vigneault, C. Agricultural robots for field operations: Concepts and components. Biosyst. Eng. 2016, 149, 94–111. [Google Scholar] [CrossRef]

- Bechar, A.; Vigneault, C. Agricultural robots for field operations. Part 2: Operations and systems. Biosyst. Eng. 2017, 153, 110–128. [Google Scholar] [CrossRef]

- Asada, M.; Fukui, Y.; Tsuji, S. Representing Global World of a Mobile Robot with Relational Local Maps. IEEE Trans. Syst. Man Cybern. 1990, 20, 1456–1461. [Google Scholar] [CrossRef]

- Bochtis, D.D.; Sørensen, C.G. The vehicle routing problem in field logistics part I. Biosyst. Eng. 2009, 104, 447–457. [Google Scholar] [CrossRef]

- Bochtis, D.D.; Sørensen, C.G. The vehicle routing problem in field logistics: Part II. Biosyst. Eng. 2010, 105, 180–188. [Google Scholar] [CrossRef]

- Hirayama, M.; Guivant, J.; Katupitiya, J.; Whitty, M. Path planning for autonomous bulldozers. Mechatronics 2019, 58, 20–38. [Google Scholar] [CrossRef]

- Arkin, R.C. Integrating behavioral, perceptual, and world knowledge in reactive navigation. Robot. Auton. Syst. 1990, 6, 105–122. [Google Scholar] [CrossRef]

- Nilsson, N.J. Principles of Artificial Intelligence; Springer: Berlin, Germany, 1982; ISBN 9783540113409. [Google Scholar]

- Steels, L. Exploiting analogical representations. Robot. Auton. Syst. 1990, 6, 71–88. [Google Scholar] [CrossRef] [Green Version]

- Bochtis, D.D.; Sørensen, C.G.; Jørgensen, R.N.; Green, O. Modelling of material handling operations using controlled traffic. Biosyst. Eng. 2009, 103, 397–408. [Google Scholar] [CrossRef] [Green Version]

- Thrun, S. Learning metric-topological maps for indoor mobile robot navigation. Artif. Intell. 1998, 99, 21–71. [Google Scholar] [CrossRef] [Green Version]

- Kuipers, B.; Byun, Y.T. A robot exploration and mapping strategy based on a semantic hierarchy of spatial representations. Robot Auton. Syst. 1991, 8, 47–63. [Google Scholar] [CrossRef]

- Ruiz-Sarmiento, J.R.; Galindo, C.; Gonzalez-Jimenez, J. Building Multiversal Semantic Maps for Mobile Robot Operation. Knowl.-Based Syst. 2017, 119, 257–272. [Google Scholar] [CrossRef]

- Lueth, T.C.; Nassal, U.M.; Rembold, U. Reliability and integrated capabilities of locomotion and manipulation for autonomous robot assembly. Robot. Auton. Syst. 1995, 14, 185–198. [Google Scholar] [CrossRef]

- Low, E.S.; Ong, P.; Cheah, K.C. Solving the optimal path planning of a mobile robot using improved Q-learning. Robot. Auton. Syst. 2019, 115, 143–161. [Google Scholar] [CrossRef]

- Zhong, X.; Tian, J.; Hu, H.; Peng, X. Hybrid Path Planning Based on Safe A* Algorithm and Adaptive Window Approach for Mobile Robot in Large-Scale Dynamic Environment. J. Intell. Robot. Syst. Theory Appl. 2020, 1–13. [Google Scholar] [CrossRef]

- Jensen, M.F.; Bochtis, D.; Sørensen, C.G. Coverage planning for capacitated field operations, part II: Optimisation. Biosyst. Eng. 2015, 139, 149–164. [Google Scholar] [CrossRef]

- Baumeister, R.F.; Leary, M.R. Writing narrative literature reviews. Rev. Gen. Psychol. 1997, 1, 311–320. [Google Scholar] [CrossRef]

- Hammersley, M. On “Systematic” Reviews of Research Literatures: A “narrative” response to Evans & Benefield. Br. Educ. Res. J. 2001, 27, 543–554. [Google Scholar]

- Jones, O.; Gatrell, C. Editorial: The Future of Writing and Reviewing for IJMR. Int. J. Manag. Rev. 2014, 16, 249–264. [Google Scholar] [CrossRef]

- Mahmoudzadeh, S.; Powers, D.M.W.; Atyabi, A. UUV’s Hierarchical DE-Based Motion Planning in a Semi Dynamic Underwater Wireless Sensor Network. IEEE Trans. Cybern. 2019, 49, 2992–3005. [Google Scholar] [CrossRef] [PubMed]

- Linker, R.; Blass, T. Path-planning algorithm for vehicles operating in orchards. Biosyst. Eng. 2008, 101, 152–160. [Google Scholar] [CrossRef]

- Elbanhawi, M.; Simic, M. Randomised kinodynamic motion planning for an autonomous vehicle in semi-structured agricultural areas. Biosyst. Eng. 2014, 126, 30–44. [Google Scholar] [CrossRef]

- Cariou, C.; Gobor, Z.; Seiferth, B.; Berducat, M. Mobile Robot Trajectory Planning Under Kinematic and Dynamic Constraints for Partial and Full Field Coverage. J. Field Robot. 2017, 34, 1297–1312. [Google Scholar] [CrossRef]

- Li, Y.L.; Yi, S.P. Improving the efficiency of spatially selective operations for agricultural robotics in cropping field. Span. J. Agric. Res. 2013, 11, 56–64. [Google Scholar] [CrossRef] [Green Version]

- Bochtis, D.; Griepentrog, H.W.; Vougioukas, S.; Busato, P.; Berruto, R.; Zhou, K. Route planning for orchard operations. Comput. Electron. Agric. 2015, 113, 51–60. [Google Scholar] [CrossRef]

- Gonzalez-de-Soto, M.; Emmi, L.; Garcia, I.; Gonzalez-de-Santos, P. Reducing fuel consumption in weed and pest control using robotic tractors. Comput. Electron. Agric. 2015, 114, 96–113. [Google Scholar] [CrossRef]

- Conesa-Muñoz, J.; Bengochea-Guevara, J.M.; Andujar, D.; Ribeiro, A. Route planning for agricultural tasks: A general approach for fleets of autonomous vehicles in site-specific herbicide applications. Comput. Electron. Agric. 2016, 127, 204–220. [Google Scholar] [CrossRef]

- Mahmud, M.S.A.; Abidin, M.S.Z.; Mohamed, Z.; Rahman, M.K.I.A.; Iida, M. Multi-objective path planner for an agricultural mobile robot in a virtual greenhouse environment. Comput. Electron. Agric. 2019, 157, 488–499. [Google Scholar] [CrossRef]

- Di Franco, C.; Buttazzo, G. Coverage Path Planning for UAVs Photogrammetry with Energy and Resolution Constraints. J. Intell. Robot. Syst. 2016, 83, 445–462. [Google Scholar] [CrossRef]

- Moon, S.-W.; Shim, D.H.-C. Study on Path Planning Algorithms for Unmanned Agricultural Helicopters in Complex Environment. Int. J. Aeronaut. Sp. Sci. 2009, 10, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Valente, J.; Del Cerro, J.; Barrientos, A.; Sanz, D. Aerial coverage optimization in precision agriculture management: A musical harmony inspired approach. Comput. Electron. Agric. 2013, 99, 153–159. [Google Scholar] [CrossRef] [Green Version]

- Barrientos, A.; Colorado, J.; del Cerro, J.; Martinez, A.; Rossi, C.; Sanz, D.; Valente, J. Aerial remote sensing in agriculture: A practical approach to area coverage and path planning for fleets of mini aerial robots. J. Field Robot. 2011, 28, 667–689. [Google Scholar] [CrossRef] [Green Version]

- Vougioukas, S.; Blackmore, S.; Nielsen, J.; Fountas, S. A two-stage optimal motion planner for autonomous agricultural vehicles. Precis. Agric. 2006, 7, 361–377. [Google Scholar] [CrossRef]

- Ferentinos, K.P.; Arvanitis, K.G.; Sigrimis, N. Heuristic optimization methods for motion planning of autonomous agricultural vehicles. J. Glob. Optim. 2002, 23, 155–170. [Google Scholar] [CrossRef]

- Noguchi, N.; Terao, H. Path planning of an agricultural mobile robot by neural network and genetic algorithm. Comput. Electron. Agric. 1997, 18, 187–204. [Google Scholar] [CrossRef]

- Cao, Y.U.; Fukunaga, A.S.; Kahng, A. Cooperative Mobile Robotics: Antecedents and Directions. Auton. Robots 1997, 4, 7–27. [Google Scholar] [CrossRef]

- Hao, Y.; Agrawal, S.K. Formation Planning and Control of UGVs with Trailers. Auton. Robots 2005, 19, 257–270. [Google Scholar] [CrossRef] [Green Version]

- Vougioukas, S.G. A distributed control framework for motion coordination of teams of autonomous agricultural vehicles. Biosyst. Eng. 2012, 113, 284–297. [Google Scholar] [CrossRef]

- Oksanen, T.; Visala, A. Coverage path planning algorithms for agricultural field machines. J. Field Robot. 2009, 26, 651–668. [Google Scholar] [CrossRef]

- Hameed, I.A.; Bochtis, D.D.; Sørensen, C.G.; Jensen, A.L.; Larsen, R. Optimized driving direction based on a three-dimensional field representation. Comput. Electron. Agric. 2013, 91, 145–153. [Google Scholar] [CrossRef]

- Hameed, I.A.; la Cour-Harbo, A.; Osen, O.L. Side-to-side 3D coverage path planning approach for agricultural robots to minimize skip/overlap areas between swaths. Robot. Auton. Syst. 2016, 76, 36–45. [Google Scholar] [CrossRef]

- Parker, L.E. Current research in multirobot systems. Artif. Life Robot. 2003, 7, 1–5. [Google Scholar] [CrossRef]

- Bochtis, D.D.; Vougioukas, S.G.; Griepentrog, H.W. A Mission Planner for an Autonomous Tractor. Trans. ASABE 2009, 52, 1429–1440. [Google Scholar] [CrossRef]

- Ramdas, K. Managing Product Variety: An Integrative Review and Research Directions. SSRN Electron. J. 2001. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=290774 (accessed on 12 February 2020). [CrossRef]

- Marinoudi, V.; Sørensen, C.G.; Pearson, S.; Bochtis, D. Robotics and labour in agriculture. A context consideration. Biosyst. Eng. 2019, 184, 111–121. [Google Scholar] [CrossRef]

- Lampridi, M.G.; Kateris, D.; Vasileiadis, G.; Marinoudi, V.; Pearson, S.; Sørensen, C.G.; Balafoutis, A.; Bochtis, D. A Case-Based Economic Assessment of Robotics Employment in Precision Arable Farming. Agronomy 2019, 9, 175. [Google Scholar] [CrossRef] [Green Version]

- Tsarouchi, P.; Matthaiakis, A.S.; Makris, S.; Chryssolouris, G. On a human-robot collaboration in an assembly cell. Int. J. Comput. Integr. Manuf. 2017, 30, 580–589. [Google Scholar] [CrossRef] [Green Version]

- Bechtsis, D.; Tsolakis, N.; Vlachos, D.; Iakovou, E. Sustainable supply chain management in the digitalisation era: The impact of Automated Guided Vehicles. J. Clean. Prod. 2017, 142, 397–3984. [Google Scholar] [CrossRef] [Green Version]

- Tsolakis, N.; Bechtsis, D.; Srai, J.S. Intelligent autonomous vehicles in digital supply chains: From conceptualisation, to simulation modelling, to real-world operations. Bus. Process Manag. J. 2019, 25, 414–437. [Google Scholar] [CrossRef]

- Srai, J.S. Mapping industrial systems - A supply network perspective on enabling technologies, processes and actors. Int. J. Manuf. Technol. Manag. 2017, 31, 82–99. [Google Scholar] [CrossRef]

- Sørensen, C.G.; Bochtis, D.D. Conceptual model of fleet management in agriculture. Biosyst. Eng. 2010, 105, 41–50. [Google Scholar] [CrossRef]

| Article | Year | Agent | Planning Attributes | Application Features | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Planning Level | Reasoning Architecture | World Model | Vehicle Configuration | Capacity Constraints | Vehicle Kinematics | Locomotion–Task Connection | Operational Environment | Operation | Approach Validation | |||

| Barrientos et al. [50] | 2011 | UAV | Global | Deliberative | Topological | Multiple | Capacitated | Holonomic | Explicit | Semi-structured | Monitoring | Experiment |

| Simulation | ||||||||||||

| Bochtis et al. [43] | 2015 | UGV | Global | Deliberative | Metric | Single | Non-Capacitated | Non-Holonomic | Explicit | Semi-structured | Mowing | Experiment |

| Pesticides Spraying | Simulation | |||||||||||

| Bochtis et al. [21] | 2009 | UGV | Global | Deliberative | Metric | Single | Capacitated | Non-Holonomic | Explicit | Unstructured | Grass Cutting | Experiment |

| Spraying | ||||||||||||

| Cariou et al. [41] | 2017 | UGV | Global | Deliberative | Metric | Single | Non-Capacitated | Non-Holonomic | Explicit & Implicit | Unstructured | Scouting—Pasture Maintenance | Experiment |

| Conesa-Muñoz et al. [45] | 2016 | UGV | Global | Deliberative | Metric | Single | Non-Capacitated | Not Specified | Implicit | Semi-structured | Pesticides Spraying | Simulation |

| Di Franco and Buttazzo [47] | 2016 | UAV | Global | Deliberative | Topological & Metric | Single | Non-Capacitated | Non-Holonomic | Explicit | Not Specified | Monitoring | Experiment |

| Elbanhawi and Simic [40] | 2014 | UGV | Global | Deliberative | Metric | Single | Non-Capacitated | Non-Holonomic | Not Specified | Semi-structured | Not Specified | Experiment |

| Simulation | ||||||||||||

| Ferentinos et al. [52] | 2002 | UGV | Local | Deliberative | Metric | Single | Non-Capacitated | Non-Holonomic | Not Specified | Not Specified | Not Specified | Simulation |

| Gonzalez-de-Soto et al. [44] | 2015 | UGV | Global | Deliberative | Metric (3D) | Single | Non-Capacitated | Non-Holonomic | Explicit | Unstructured | Not Specified | Experiment |

| Hao et al. [55] | 2015 | UGV | Local | Reactive | Metric | Multiple | Non-Capacitated | Non-Holonomic | Implicit | Unstructured | Harvesting | Simulation & Lab Experiment |

| Li and Yi [42] | 2013 | UGV | Global | Deliberative | Metric | Single | Non-Capacitated | Non-Holonomic | Implicit | Unstructured | Spot Application (fertilizing, spraying) | Simulation |

| Linker and Blass [39] | 2008 | UGV | Global & Local | Deliberative | Topological | Single | Non-Capacitated | Non-Holonomic | Not Specified | Semi-structured | Not Specified | Simulation |

| Mahmud et al. [46] | 2019 | UGV | Global | Deliberative | Metric | Single | Capacitated | Non-Holonomic | Explicit | Structured | Pesticides Spraying | Experiment |

| Moon and Shim [48] | 2009 | UAV | Global | Deliberative | Metric | Single & Multiple | Non-Capacitated | Non-Holonomic | Explicit | Not Specified | Pesticides Spraying | Simulation |

| Noguchi and Terao [53] | 1997 | UGV | Global | Deliberative | Metric | Single | Non-Capacitated | Non-Holonomic | Explicit | Not Specified | Water Spraying | Experiment |

| Simulation | ||||||||||||

| Valente et al. [49] | 2013 | UAV | Global | Deliberative | Topological | Single & Multiple | Capacitated | Holonomic | Explicit | Semi-structured | Monitoring | Simulation |

| Vougioukas [56] | 2012 | UGV | Local | Reactive | Metric | Multiple | Non-Capacitated | Non-Holonomic | Implicit | Not Specified | Not Specified | Simulation |

| Vougioukas et al. [51] | 2006 | UGV | Local | Deliberative | Metric | Single | Non-Capacitated | Non-Holonomic | Explicit | Semi-structured | Weeding | Experiment |

| Simulation | ||||||||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moysiadis, V.; Tsolakis, N.; Katikaridis, D.; Sørensen, C.G.; Pearson, S.; Bochtis, D. Mobile Robotics in Agricultural Operations: A Narrative Review on Planning Aspects. Appl. Sci. 2020, 10, 3453. https://doi.org/10.3390/app10103453

Moysiadis V, Tsolakis N, Katikaridis D, Sørensen CG, Pearson S, Bochtis D. Mobile Robotics in Agricultural Operations: A Narrative Review on Planning Aspects. Applied Sciences. 2020; 10(10):3453. https://doi.org/10.3390/app10103453

Chicago/Turabian StyleMoysiadis, Vasileios, Naoum Tsolakis, Dimitris Katikaridis, Claus G. Sørensen, Simon Pearson, and Dionysis Bochtis. 2020. "Mobile Robotics in Agricultural Operations: A Narrative Review on Planning Aspects" Applied Sciences 10, no. 10: 3453. https://doi.org/10.3390/app10103453

APA StyleMoysiadis, V., Tsolakis, N., Katikaridis, D., Sørensen, C. G., Pearson, S., & Bochtis, D. (2020). Mobile Robotics in Agricultural Operations: A Narrative Review on Planning Aspects. Applied Sciences, 10(10), 3453. https://doi.org/10.3390/app10103453