3.1. Nonlinear Evolution Characteristics of Seepage-Erosion Process

As the progress of water–sand inrush process, soil particles continue to erode away, which not only changes the soil skeleton, but also the flow pattern along with seepage-erosion process. The eroding ability of seepage flow is represented by sands erosion rate, namely the mass of eroded soil particles within a certain amount of time. The sands mass concentration of eroded sands in discharged fluid is also regarded as a crucial symptom herein, which can be obtained through equation below

where

mi is the weight of collected sands,

qi is the volume of discharged fluid,

ρf is water density,

i is the serial number of time per minute.

The test results of each group is calculated and shown in

Table 3,

Table 4 and

Table 5 and

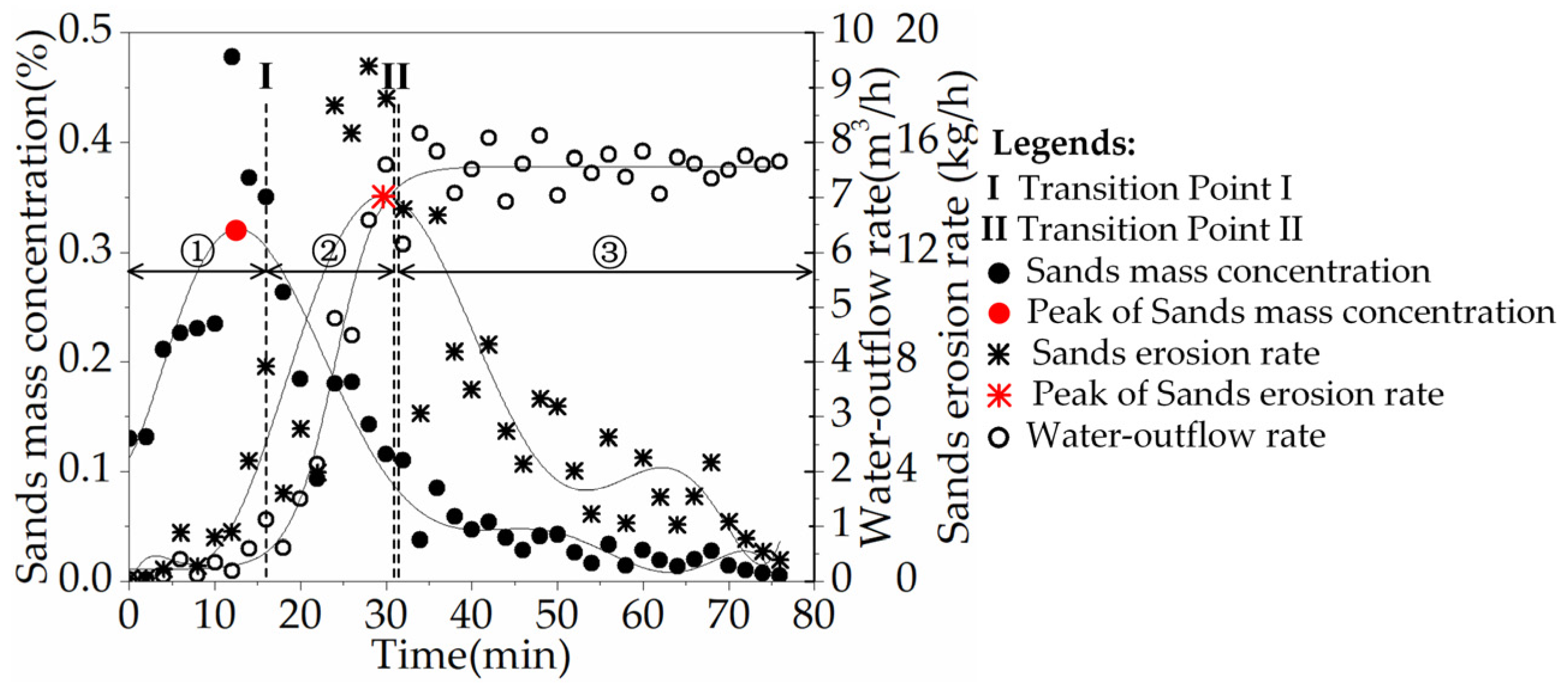

Figure 6. The variation of water-outflow rate is well fitted through Boltzmann equation, the variation of sands erosion rate and sands mass concentration with time are depicted by the 7th order polynomial equation. It can be observed that the test results exhibit obvious similarities among each group, the variation of water-outflow rate are all characterized with distinct non-linear feature, the variation of sands mass concentration and sands erosion rate are both in shape of wave with the existence of summit. In order to deeply analyze the experimental phenomena, the test result of group 2 is illustrated in detail in

Figure 7 and

Figure 8.

First, according to the variation curve of water-outflow rate, the water–sand inrush process is visually divided into three stages by Transition Point I, II, which are determined through the extremum analysis of water-outflow rate’s fitted curve. The property description of each seepage stage is detailed as following:

Stage ①: Up until the 16.8th min since beginning, water-outflow rate maintains less than 0.5 m

3/h; sands erosion rate starts rising after being below 2.0 kg/h within the first 12 mins, and then up to nearly 5.5 kg/h until the end of this stage; sands mass concentration increases instantly from the very beginning, and reaches the peak after 12.6 mins; as seen from the grain-size distribution of the eroded soil particles collected in this stage, shown in

Figure 8, the content of soil particles over 1 mm is only about 10%, while the particles smaller than 0.5 mm and 0.075 mm occupy about 70% and 32% of the total eroded mass, respectively, significantly less than the contents of the same grain-size particles of being about 26% and 5% in the original soil sample. At the initiation stage of the seepage-erosion process, soil particles compact densely with the soil skeleton maintaining stable, resulting in fairly small porosity and permeability, which ensures a small seepage rate through the soil sample. Subsequently, with the advancing of penetration process, the fine and unbounded soil particles start being activated and migrated into the seepage flow even under relatively small dragging force exerted by slow seepage flow. In this stage, with the existence of fine and unbounded particles, the migration rate of fluidized soil particles into the flow is greater than the conveyance rate, which manifests as the increase of sands mass concentration, resulting in a greater erosion ability of seepage flow because of the existence of more free particles and their surfaces. Based on the seepage characteristics obtained, this period can be named as “slow flow” stage.

Stage ②: After Transition Point I, water-outflow rate starts abruptly increasing, reaching Transition Point II of being about 8.0 m3/h after 32.0 mins totally; sands erosion rate also quickly rises to the peak right before Transition Point II, and sands mass concentration starts going down sharply; through observation of the grain-size distribution of soil particles collected in this stage, there are more coarser particles showing up than that in stage ①. The content of particles between 0.5 mm and 1 mm significantly rises to 57% from 20%, and the particles smaller than 0.075 mm are barely seen in this stage. As the fine particles kept losing, the microstructure of soil sample is changed accordingly. Due to the loss of significant fine particles, not only the interspaces and voids grows bigger, but also the lateral supports for soil skeleton reduce too, causing the coarser soil particles becoming less stable and easier being eroded away. This process will increase the porosity and permeability of soil sample, which in return accelerates the flowing rate, increases the eroding ability of the fluid, and further facilitates the formation of seepage channels. In this stage, the eroding ability of seepage flow increases with the rising of flowing rate, inducing a growing number of sands being eroded away. The water-outflow rate also climbs dramatically, resulting in a greater transfer rate than the generation rate of fluidized soil particles, so the variation of sands mass concentration in this stage declines rapidly all along. Considering the seepage characteristics and experimental phenomenon, this stage can be characterized as “transition flow” stage.

Stage ③: By the end of stage ②, water-outflow rate fluctuates around 7.6 m

3/h, and the acceleration of water-outflow rate suddenly drops to nearly zero; sands erosion rate starts declining soon after the summit of being 18.79 kg/h, at the meantime, sands mass concentration continues to drop consistently with a smaller gradient after Transition Point II. Through observation of the grain-size distribution of eroded soil particles, the content of particles between 0.5 mm and 1 mm remains approximately the same as the content of the same grain-size particles in stage ②, but for the coarse particles over 1 mm, its content occupies 27%, almost the twice of the content of those in stage ②. By the end of “transition flow” stage, around 56% soil particles have been eroded away, resulting in nearly penetrating-through of seepage channels, which promotes the flow pattern transforming into pipe flow from porous media flow [

26], hence the water-outflow rate maintains a relatively stable rate under specific hydraulic pressure. In this stage, the formation of penetration-through seepage channels partially decreases the lateral erosion ability of seepage flow, which not only results in a greater transferring rate than migration rate of soil particles, but also a slowly declining of sands mass concentration all along. It should be noted that, in real geo-conditions, karst cavity may be filled with abundant karst water, or even connected to underground river or surface water, the outflow discharge could suddenly and dramatically increase after the penetration through of seepage channels, resulting in the occurrence of water–sand inrush accidents. In consequence, this period can be named as “pipe flow” stage.

After introducing the nonlinear evolution characteristics of seepage-erosion process, the reason behind the existence of outliers in

Figure 7 should be discussed here. As we mentioned above, the mesh size of perforated plate II is set as 10.0 mm, ensuring at least 90% sand particles to pass through. While, the particle clogging will appear when the particles over 10.0 mm approaching perforated plate II. Moreover, with the existence of medium size particles, the clogging will still theoretically appear when 2, 4, or many of those particles approaching the open hole together, which would retard the erosion of soil particles. However, due to the dynamic evolution characteristics of seepage-erosion progress, the particle clogging has a possibility to collapse under the disturbance of dynamic flow, which abruptly increases the mass of eroded particles, resulting in a sharp growth of sands erosion rate, as well as the fluctuations of water-outflow rate and sands mass concentration.

3.3. Identification and Forecast of Seepage-Erosion’s Evolutionary Process

Based on the elaboration in last two sections, it’s reasonable to conclude that particle loss caused by seepage-erosion is the internal mechanism of water–sand inrush; the variation of water-outflow characteristics are external manifestations correspondingly. In other words, with the acquaintance of external manifestations’ variation features, the specific seepage stage where the water–sand inrush is located can be accurately identified, which could theoretically offer possibilities to forecast the occurrence of water–sand inrush.

As introduced in

Section 3.1, the whole seepage-erosion process is visually spit by Transition Point I, II, characterized with distinct non-linear features, thus the identification of seepage-erosion stage can be determined through the location of Transition Point I, II, which can be accessed through the extremum analysis of water-outflow rate. While considering the complexity of the geo-environment in practical geo-conditions, solely relying on the variation of water-outflow rate seems not adequate and reliable. Through further observation of the seepage test results in

Table 6 and

Figure 15, one crucial phenomenon should be noted, the occurrence of Transition Point I is closely behind the peak of sands mass concentration. For instance, as shown in

Figure 15a, the appearance time of Transition Point I is the 10.4th min, 16.8th min and 27.2th min, as the relative density increasing to 0.75 from 0.25, the peak of sands mass concentration appears at the 5.9th min, 12.6th min and 25.0th min correspondingly, with only 4.5 mins, 4.2 mins and 2.2 mins ahead; as for Transition Point II, it appears at the 22.4th min, 32.0th min and 52.4th min, and the peak of sands mass concentration shows up at the 18.2th min, 30.1th min and 45.9th min correspondingly when the relative density up to 0.75 from 0.25, respectively with only 4.2 mins, 1.9 mins and 6.5 mins in advance. This manifestation that the peak of sands mass concentration occurs slightly ahead of Transition Point I, the peak of sands erosion rate occurs slightly ahead of Transition Point II, which also applies to other groups under varying hydraulic pressure and confining pressure as shown in

Figure 15b,c.

It can be briefly summarized that the sequence between sands mass concentration’s peak, sands erosion rate’s peak, and transition points is confirmed. To be precise, the seepage stage can be theoretically determined through the identification of Transition Point I, II, and further verified by locating the peak of sands mass concentration and sands erosion rate, respectively. Therefore, with the monitoring data of flow characteristics in practical situation, the critical status of water–sand inrush can be near-real-time identified, which offers an early warning to respond in a timely manner and the basis for ultimately forecasting the occurrence of water–sand inrush. It should be emphasized that the employ of polynomial of 7th order is to precisely fit the variation of sands erosion rate and sands mass concentration, which cannot be employed to quantitatively predict their variation tendency even with extremely high correlation. The strict regression equation needs to be developed and validated through more experiment datasets.