Dynamic Characteristics of Sandstone under Coupled Static-Dynamic Loads after Freeze-Thaw Cycles

Abstract

1. Introduction

2. Experimental and Rock Specimens

2.1. Rock Specimens and Preparation

2.2. Freeze-Thaw Treatment

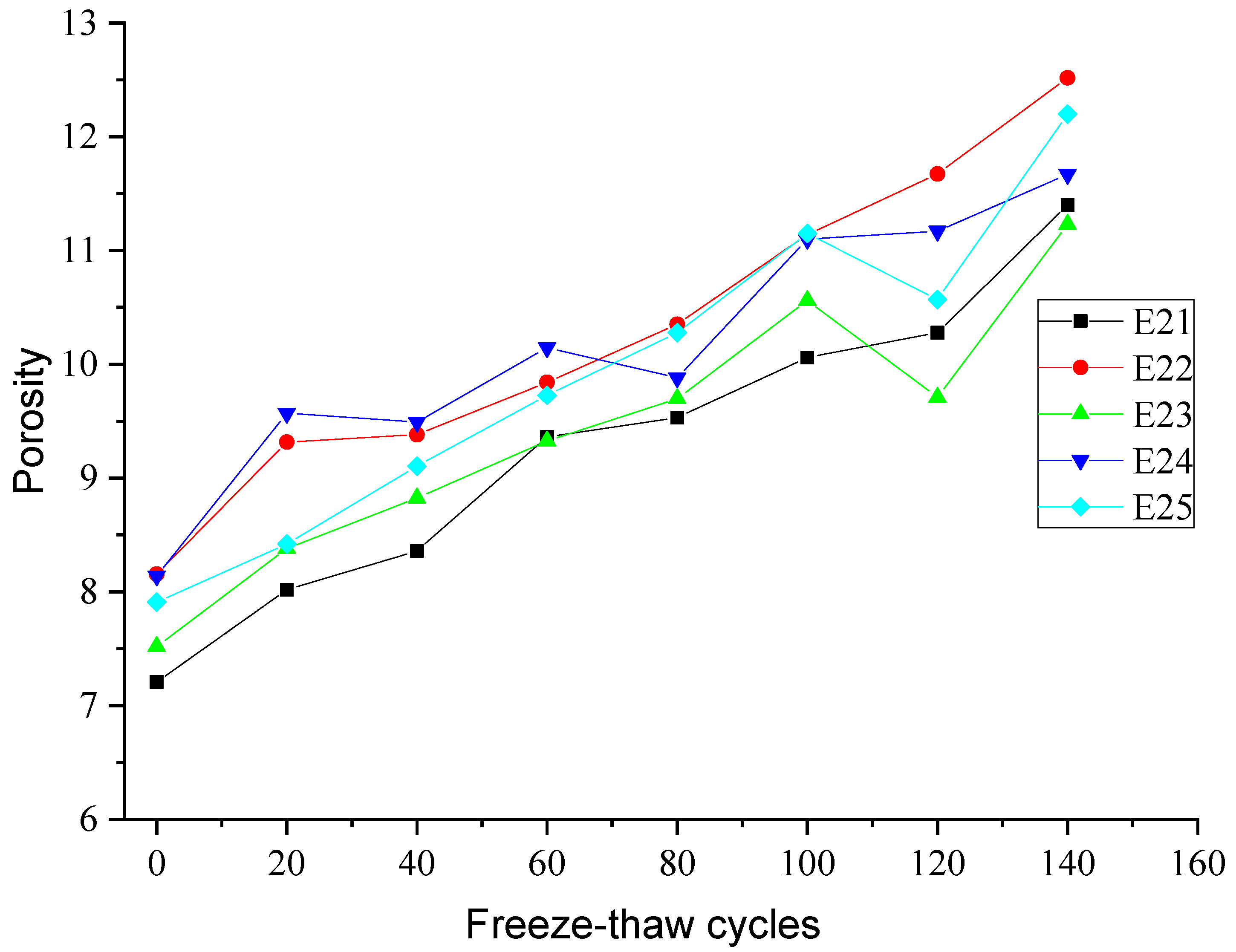

2.3. NMR Test

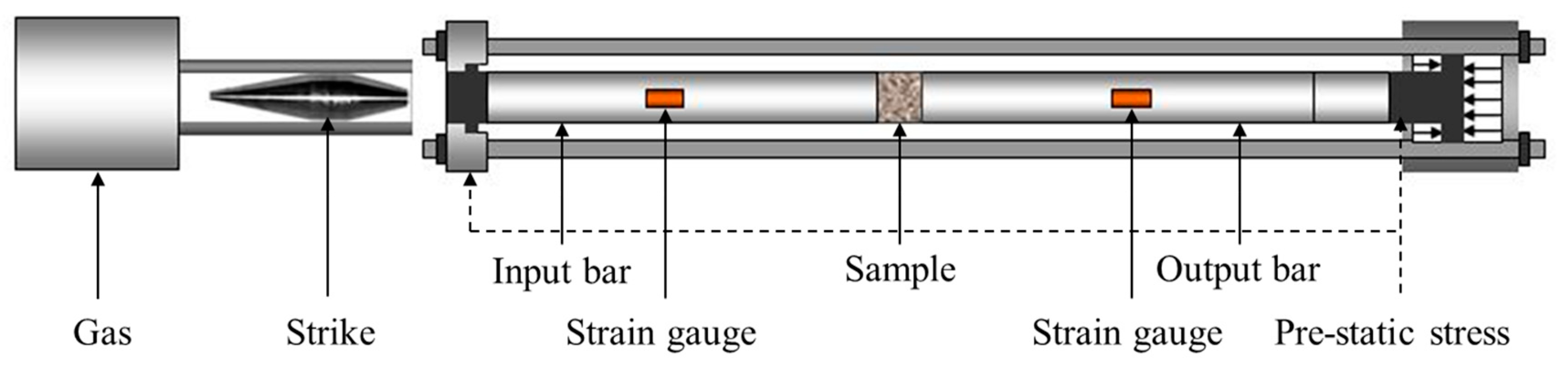

2.4. Testing Technique Simulating Coupling Static and Dynamic Loads

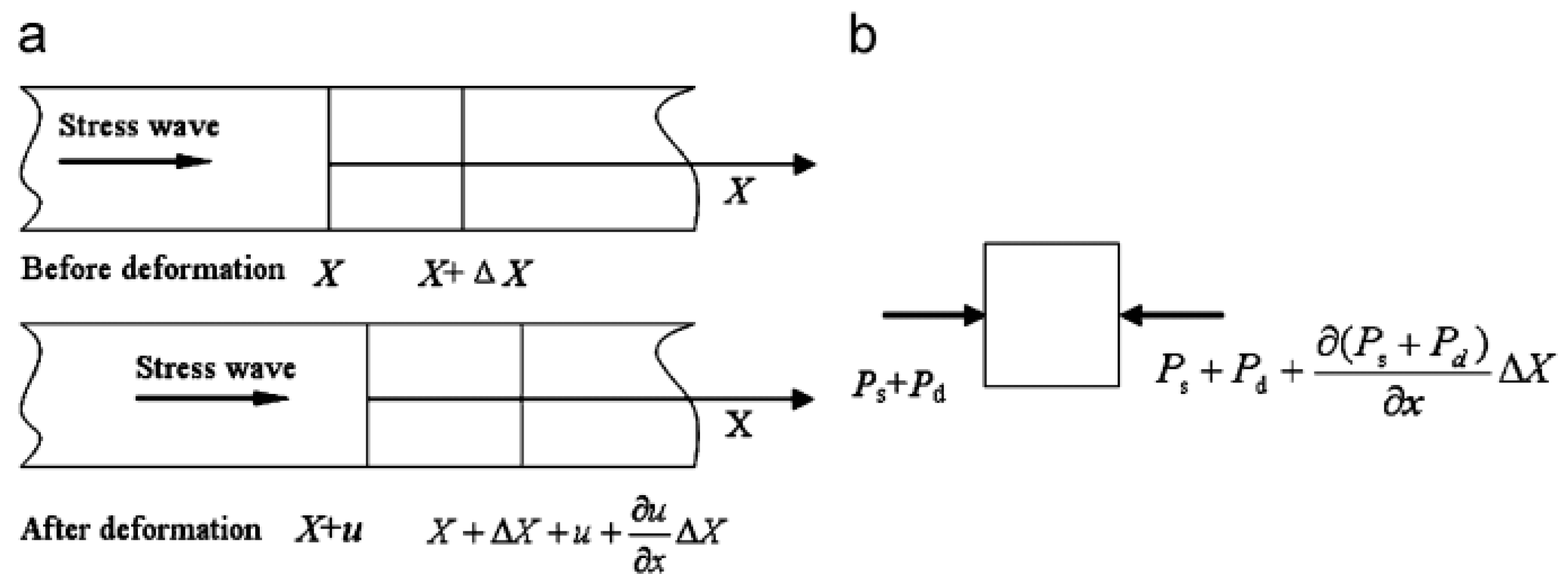

2.4.1. Theoretical Background

2.4.2. Test System and Equipment

3. Strength Characteristics of Sandstone under Freeze-Thaw Cycles and Axial Pre-Compression Stresses

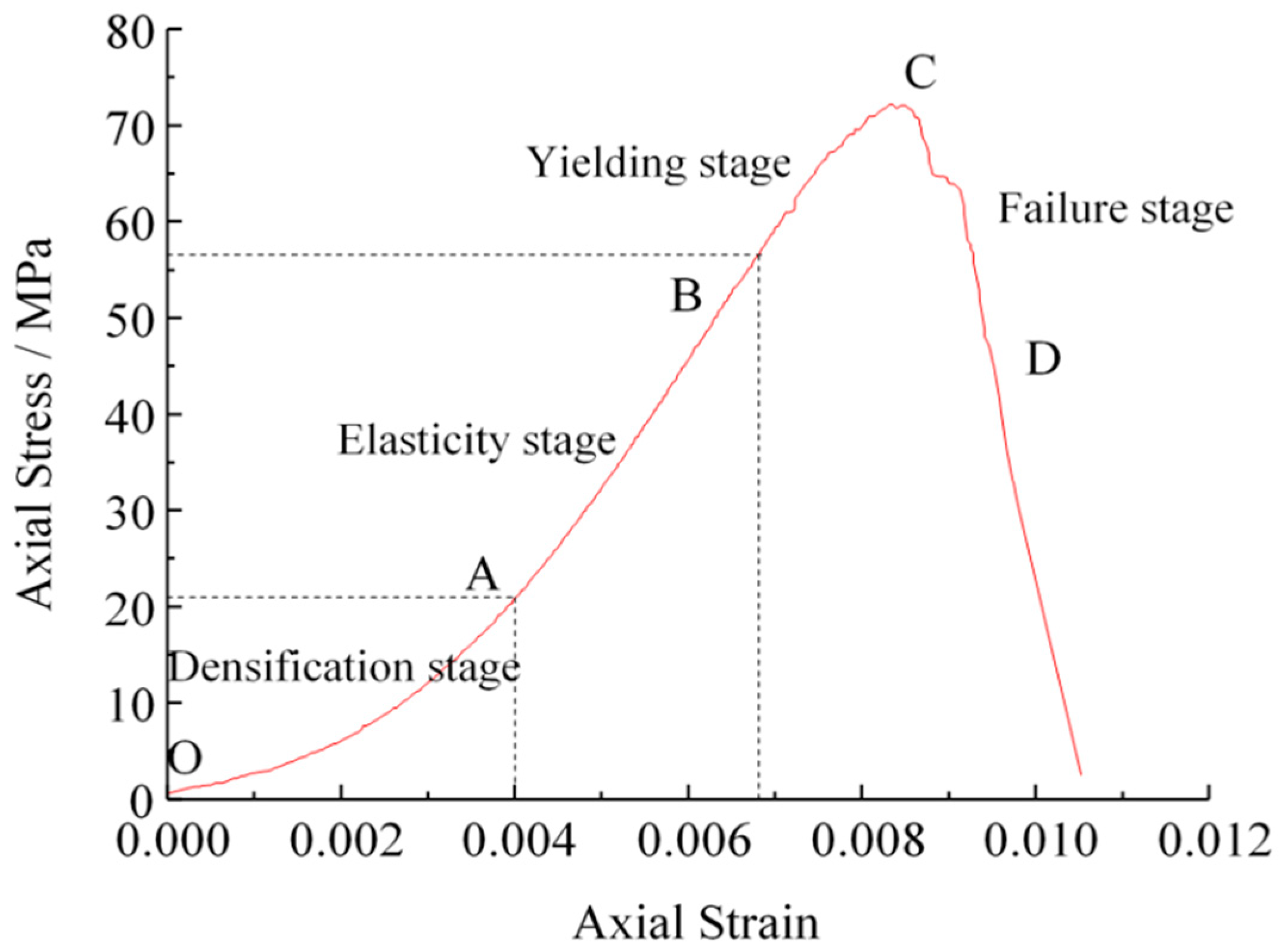

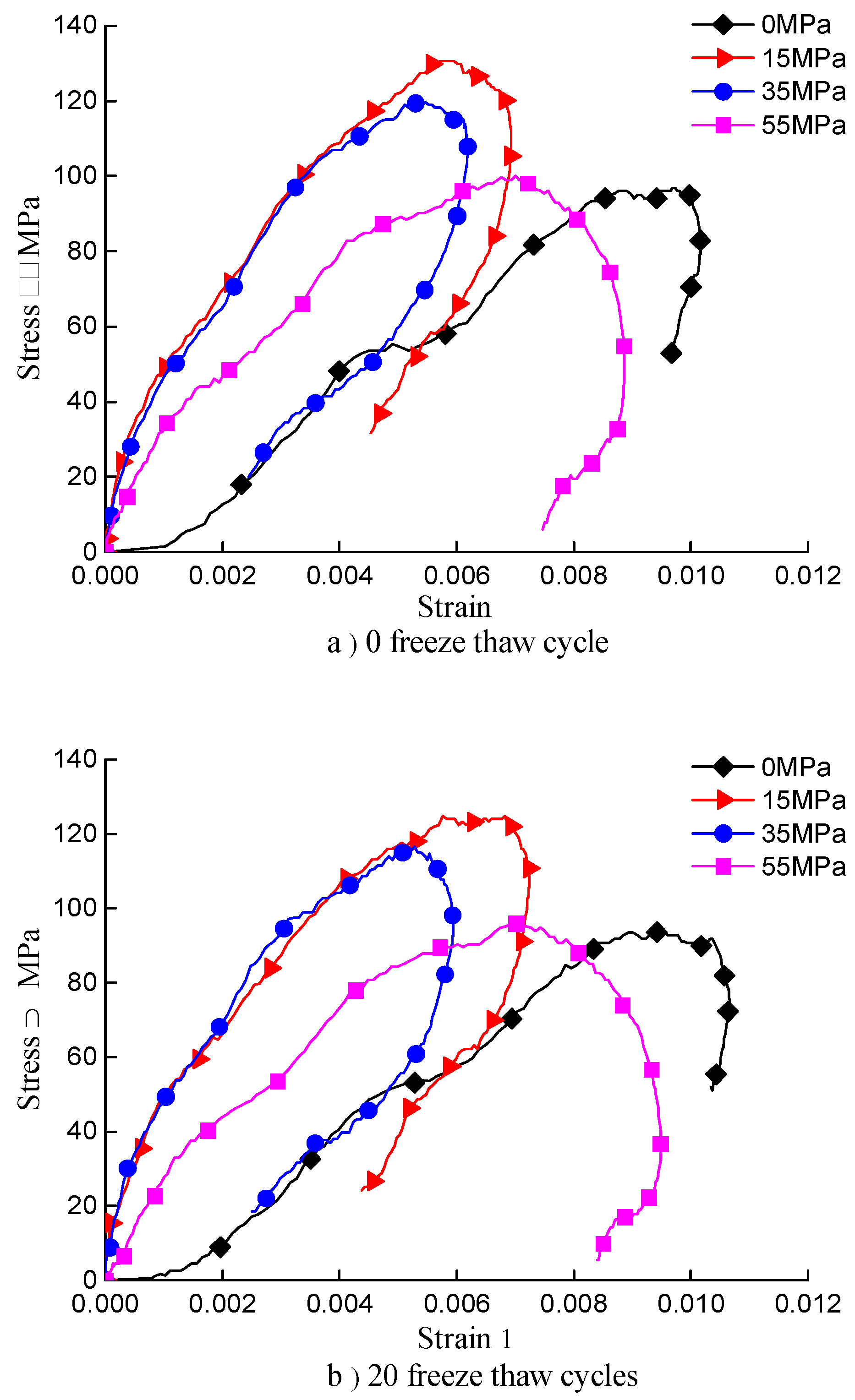

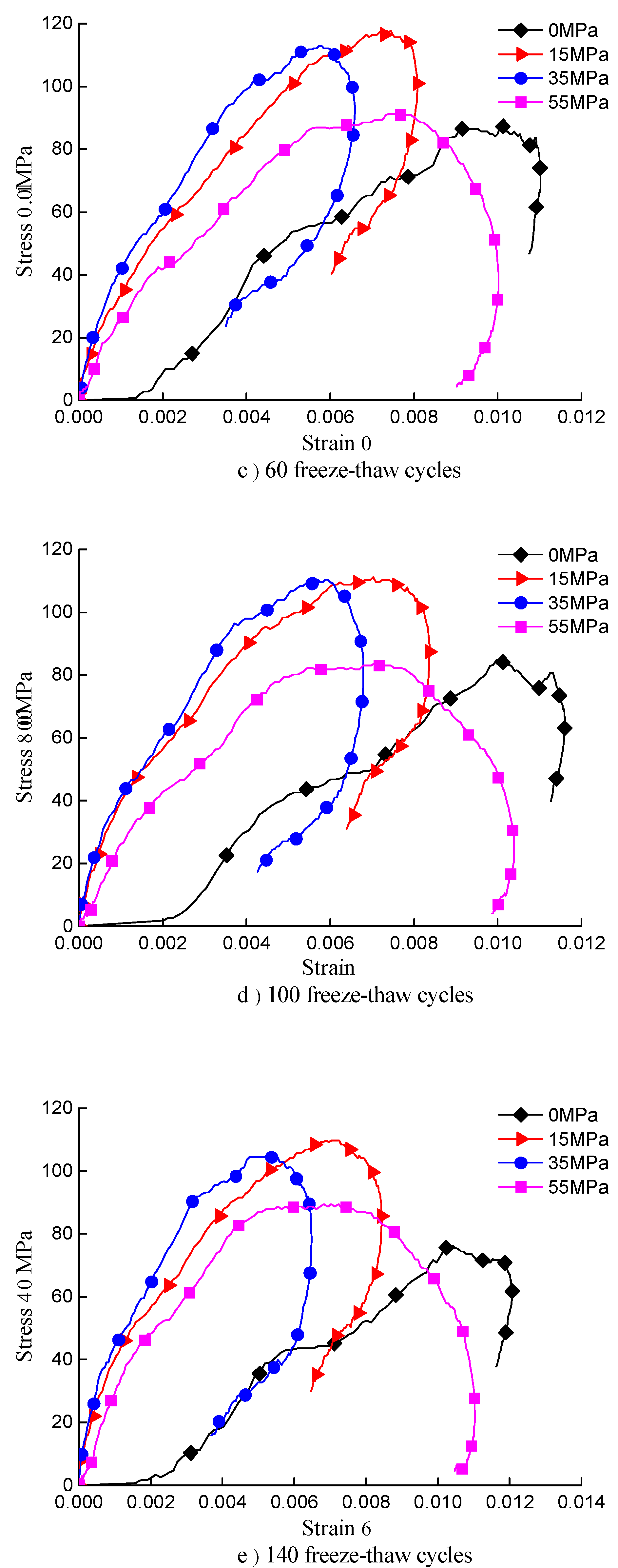

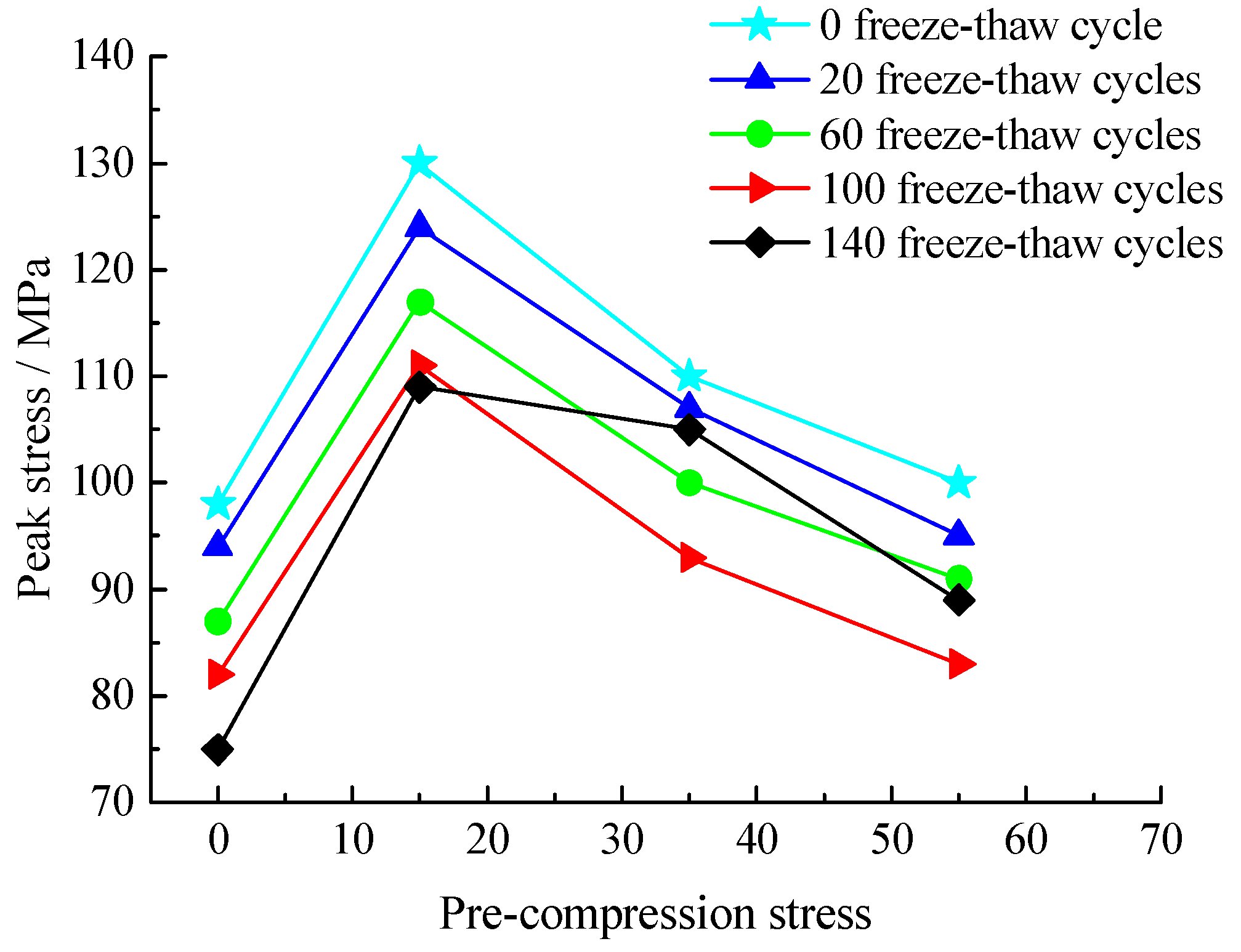

3.1. Strength Characteristics of Sandstone at Different Pre-Compression Stresses

3.2. Strength Degradation of Sandstone under Freeze-Thaw Cycles

4. Dynamic Failure Characteristics

4.1. Failure Mode

4.2. Energy Absorption Characteristics

5. Conclusions

- (1)

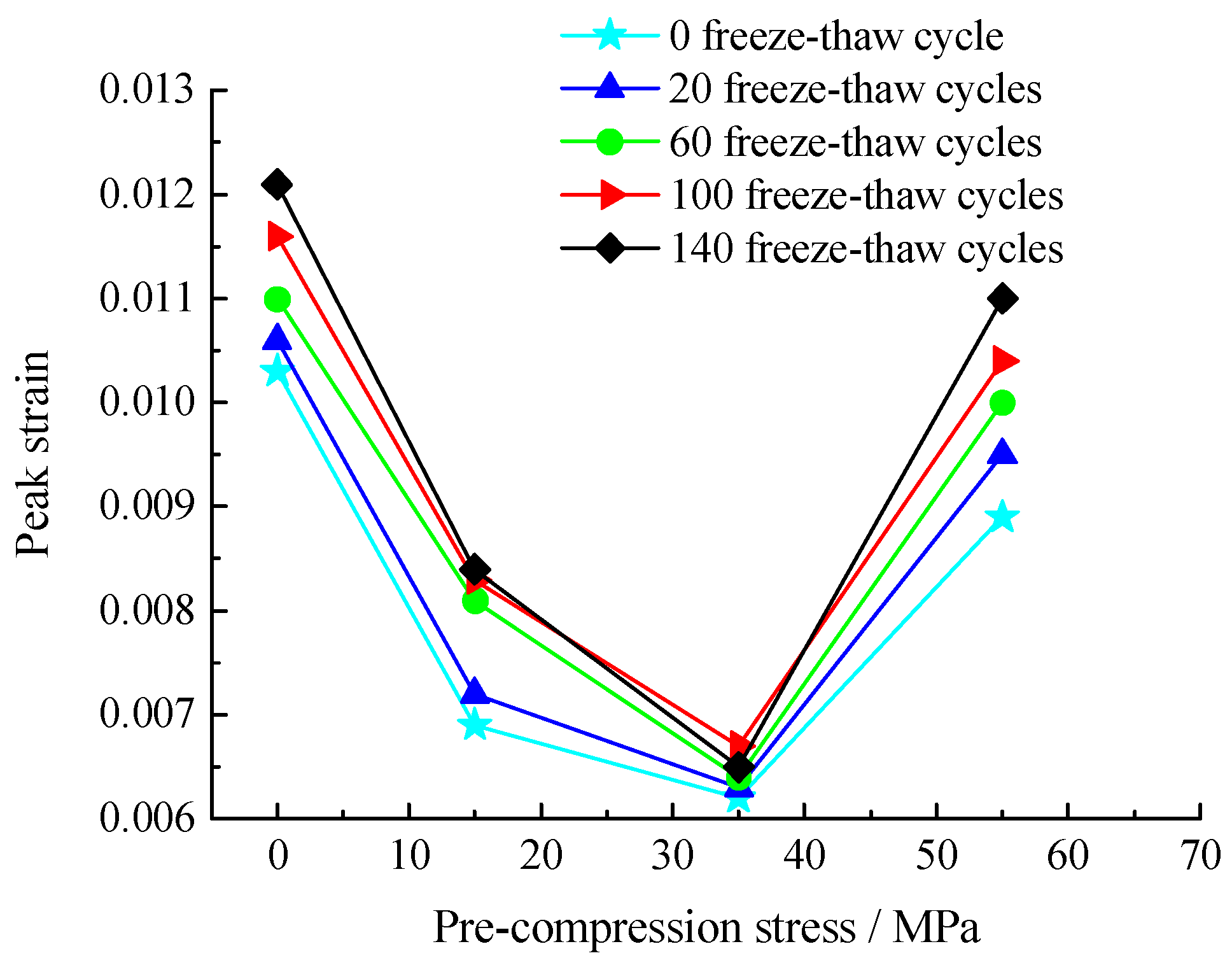

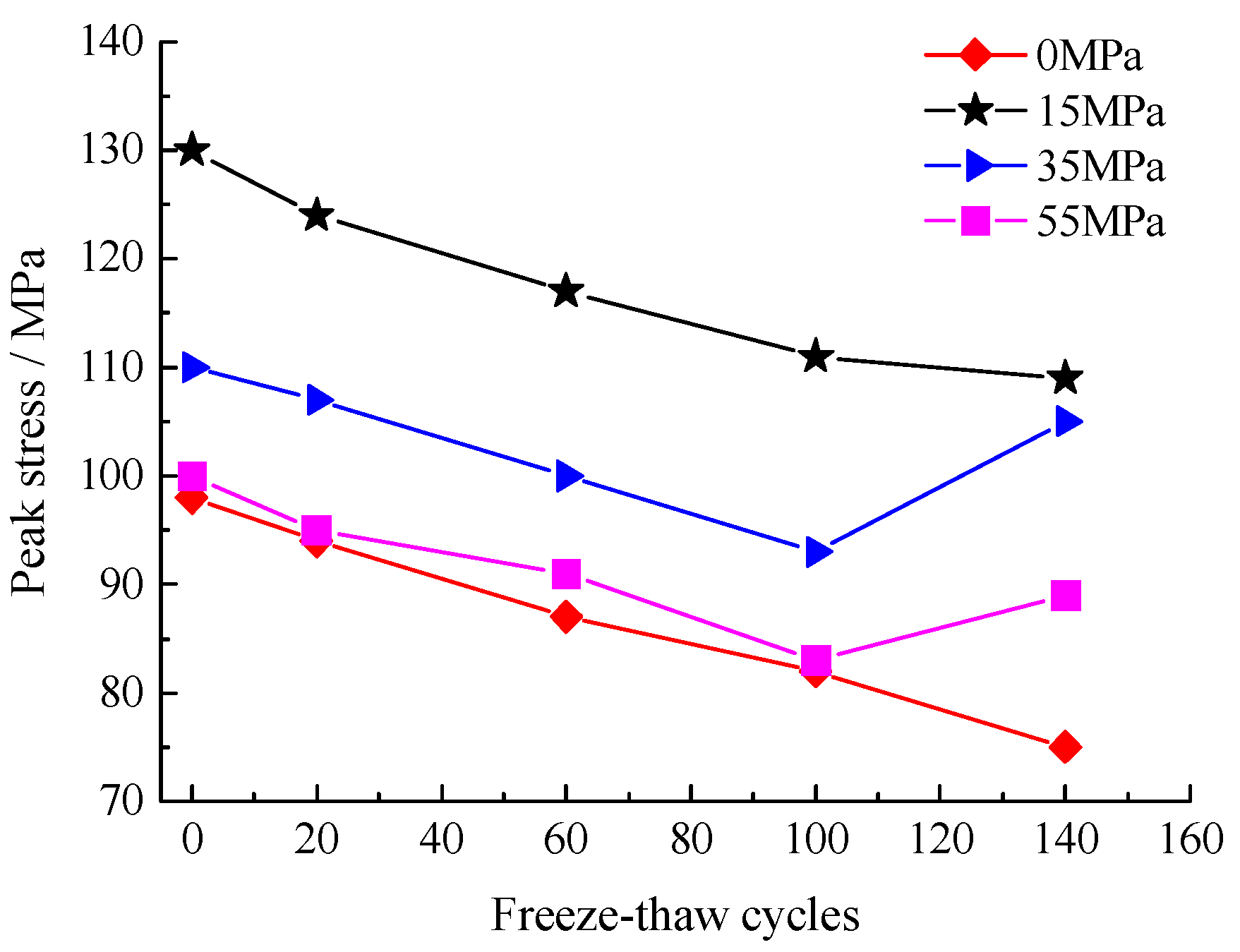

- The stress–strain curves of the sandstone can be divided into three stages under axial pre-compression stresses and do not exhibit a densification stage. With increasing axial pre-compression stress, the slope of the elastic stage and the peak strength first increase and then decrease. The dynamic peak strain, on the other hand, first decreases and then increases for the same number of freeze-thaw cycles. When the axial pre-compression stress is 15 MPa, with increasing number of freeze-thaw cycles, the peak stress decreases and the peak strain increases almost linearly. When the axial pre-compression stress is 30 MPa, the peak stress decreases and then increases while the peak strain decreases. The peak stress and strain both increase under a pre-compression stress of 55 MPa.

- (2)

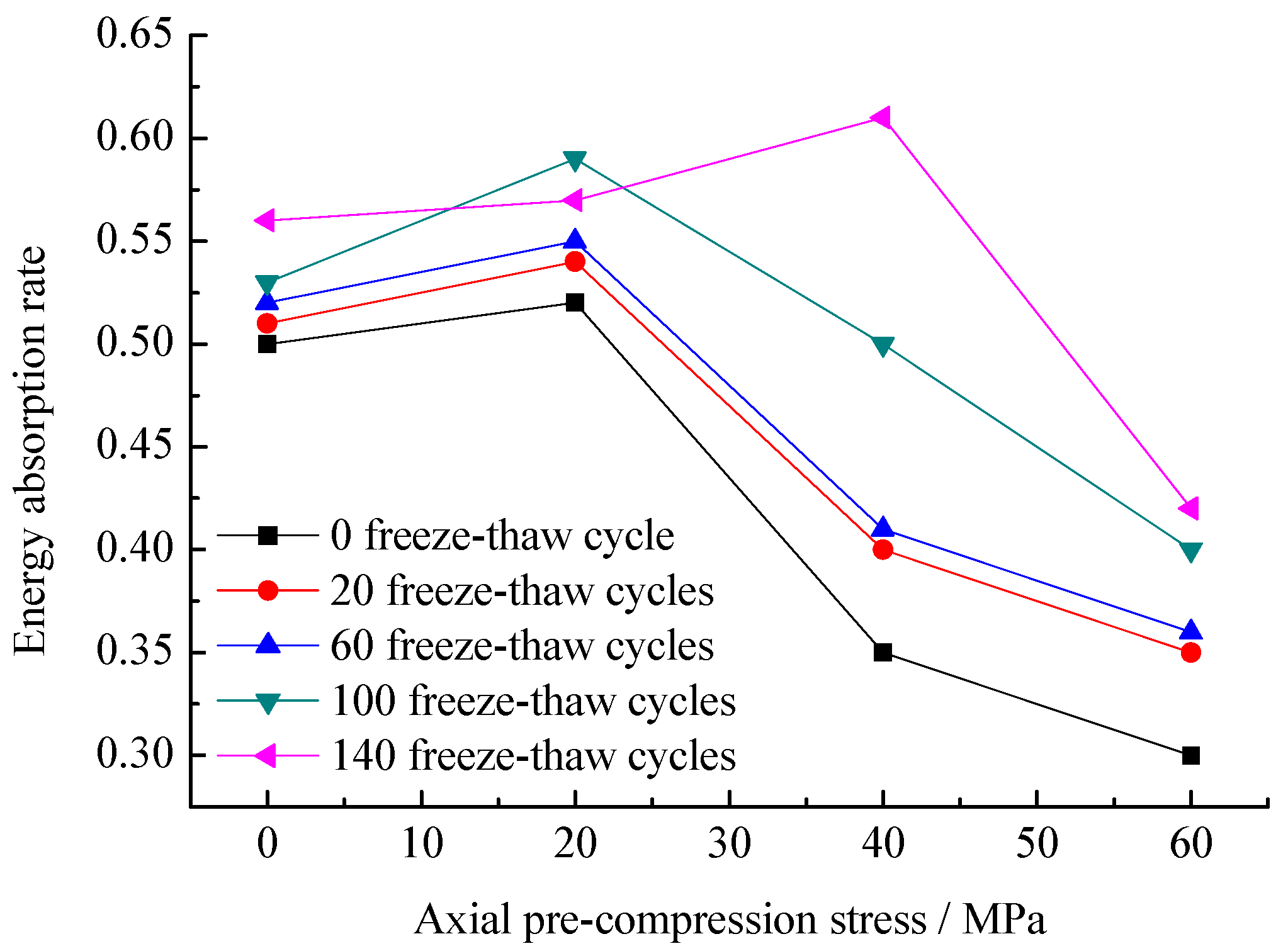

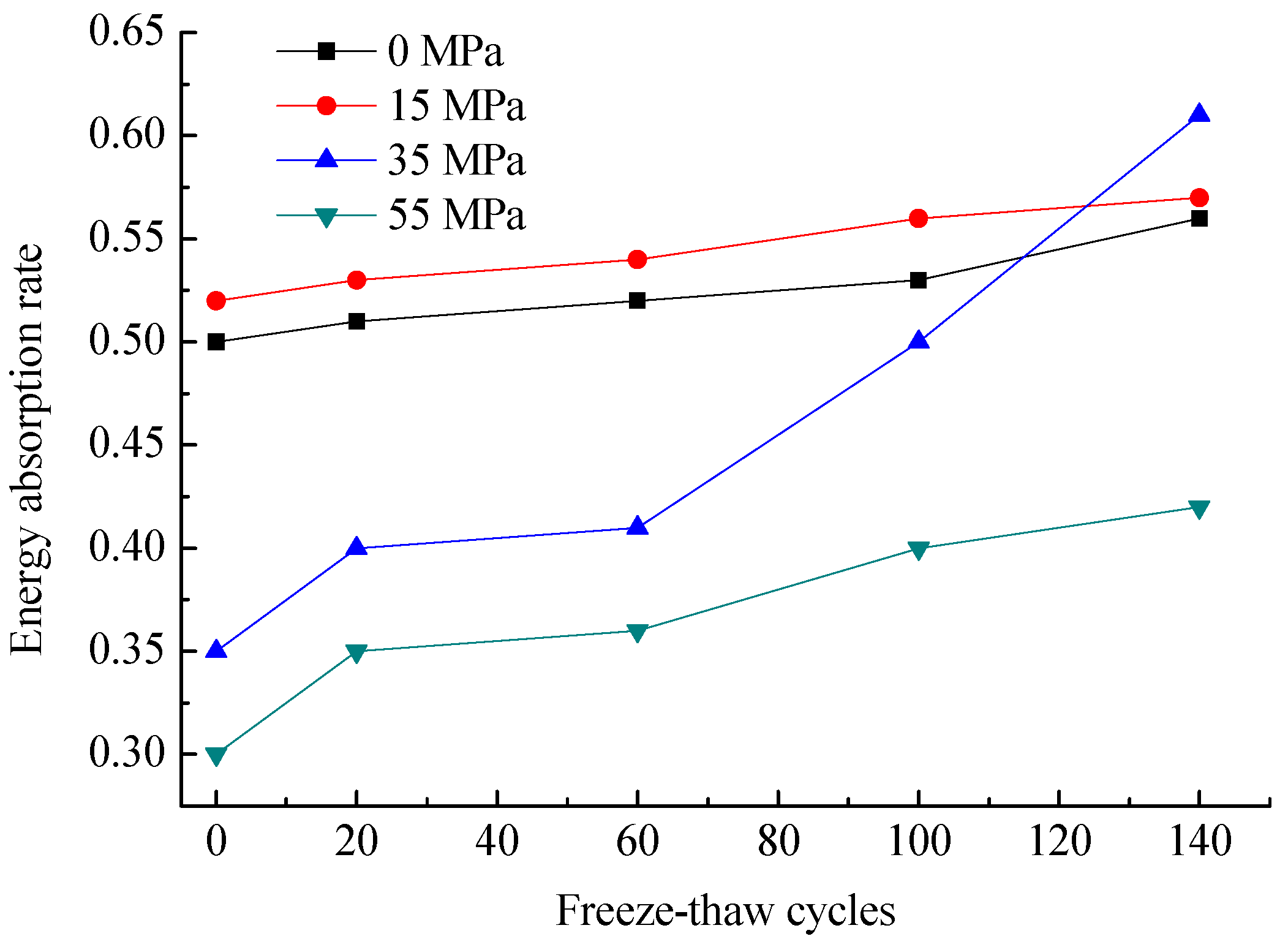

- The rock failure characteristics under different freeze-thaw processes and pre-compression stresses indicate that the number of fragments increases with both the increasing axial pre- compression stress and the increasing number of freeze-thaw cycles. The fragments become more uniform when more freeze-thaw cycles are applied due to the increasing internal damage within the rock. The failure modes change from splitting at 0 MPa axial pre-compression stress to shear failure at higher pre-compression stresses. The energy absorption rate of the sandstone specimen increases first and then decreases with increasing axial pre-compression stresses. With increasing number of freeze-thaw cycles, the energy absorption rates of the sandstone increase.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, T.C.; Yeung, M.R.; Mori, N. Effect of water saturation on deterioration of welded tuff due to freeze-thaw action. Cold Reg. Sci. Technol. 2004, 38, 127–136. [Google Scholar] [CrossRef]

- Ke, B.; Zhou, K.P.; Deng, H.W.; Bin, F. NMR Pore Structure and Dynamic Characteristics of Sandstone Caused by Ambient Freeze-Thaw Action. Shock Vib. 2017, 2017, 10. [Google Scholar] [CrossRef]

- Grossi, C.M.; Brimblecombe, P.; Harris, I. Predicting long term freeze-thaw risks on Europe built heritage and archaeological sites in a changing climate. Sci. Total Environ. 2007, 377, 273–281. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.J.; Lai, Y.M.; Zhang, X.F.; Pu, Y.B.; Yu, Y.B. Study on the damage propagation of surrounding rock from a cold-region tunnel under freeze-thaw cycle condition. Tunn. Undergr. Space Technol. 2004, 19, 295–302. [Google Scholar] [CrossRef]

- Beier, N.A.; Sego, D.C. Cyclic freeze-thaw to enhance the stability of coal tailings. Cold Reg. Sci. Technol. 2009, 55, 278–285. [Google Scholar] [CrossRef]

- Proskin, S.; Sego, D.; Alostaz, M. Freeze-thaw and consolidation tests on Suncor mature fine tailings (MET). Cold Reg. Sci. Technol. 2010, 63, 110–120. [Google Scholar] [CrossRef]

- Inada, Y.; Yokota, K. Some studies of low temperature rock strength. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1984, 21, 145–153. [Google Scholar] [CrossRef]

- Matsuoka, N. Mechanisms of rock breakdown by frost action: An experimental approach. Cold Reg. Sci. Technol. 1990, 17, 253–270. [Google Scholar] [CrossRef]

- Park, J.; Hyun, C.-U.; Park, H.-D. Changes in microstructure and physical properties of rocks caused by artificial freeze–thaw action. Bull. Eng. Geol. Environ. 2015, 74, 555–565. [Google Scholar] [CrossRef]

- De Argandona, V.G.R.; Rey, A.R.; Celorio, C.; del Rio, L.M.S.; Calleja, L.; Llavona, J. Characterization by computed X-ray tomography of the evolution of the pore structure of a dolomite rock during freeze-thaw cyclic tests. Phys. Chem. Earth Part a-Solid Earth Geod. 1999, 24, 633–637. [Google Scholar] [CrossRef]

- De Kock, T.; Boone, M.A.; De Schryver, T.; Van Stappen, J.; Derluyn, H.; Masschaele, B.; De Schutter, G.; Cnudde, V. A pore-scale study of fracture dynamics in rock using X-ray micro-CT under ambient freeze-thaw cycling. Environ. Sci. Technol. 2015, 49, 2867–2874. [Google Scholar] [CrossRef] [PubMed]

- Zhou, K.P.; Li, B.; Li, J.L.; Deng, H.W.; Bin, F. Microscopic damage and dynamic mechanical properties of rock under freeze–thaw environment. Trans. Nonferrous Metals Soc. China 2015, 25, 1254–1261. [Google Scholar] [CrossRef]

- Gao, F.; Wang, Q.L.; Deng, H.W.; Zhang, J.; Tian, W.G.; Ke, B. Coupled effects of chemical environments and freeze–thaw cycles on damage characteristics of red sandstone. Bull. Eng. Geol. Environ. 2017, 76, 1481–1490. [Google Scholar] [CrossRef]

- Li, J.L.; Zhou, K.P.; Liu, W.J.; Deng, H.W. NMR research on deterioration characteristics of microscopic structure of sandstones in freeze–thaw cycles. Trans. Nonferrous Metals Soc. China 2016, 26, 2997–3003. [Google Scholar] [CrossRef]

- Liu, C.; Deng, H.W.; Zhao, H.T.; Zhang, J. Effects of freeze-thaw treatment on the dynamic tensile strength of granite using the Brazilian test. Cold Reg. Sci. Technol. 2018, 155, 327–332. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.W.; Taheri, A.; Ke, B.; Liu, C.J.; Yang, X.R. Degradation of physical and mechanical properties of sandstone subjected to freeze-thaw cycles and chemical erosion. Cold Reg. Sci. Technol. 2018, 155, 37–46. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.W.; Taheri, A.; Ke, B.; Liu, C.J. Deterioration and strain energy development of sandstones under quasi-static and dynamic loading after freeze-thaw cycles. Cold Reg. Sci. Technol. 2019, 160, 252–264. [Google Scholar] [CrossRef]

- Nicholson, D.T.; Nicholson, F.H. Physical deterioration of sedimentary rocks subjected to experimental freeze–thaw weathering. Earth Surf. Process. Landf. 2000, 25, 1295–1307. [Google Scholar] [CrossRef]

- Tan, X.; Chen, W.Z.; Yang, J.P.; Cao, J.J. Laboratory investigations on the mechanical properties degradation of granite under freeze–thaw cycles. Cold Reg. Sci. Technol. 2011, 68, 130–138. [Google Scholar] [CrossRef]

- Wang, P.; Xu, J.Y.; Liu, S.; Liu, S.H.; Wang, H.Y. A prediction model for the dynamic mechanical degradation of sedimentary rock after a long-term freeze-thaw weathering: Considering the strain-rate effect. Cold Reg. Sci. Technol. 2016, 131, 16–23. [Google Scholar] [CrossRef]

- Ke, B.; Zhou, K.P.; Xu, C.S.; Deng, H.W.; Li, J.L.; Bin, F. Dynamic mechanical property deterioration model of sandstone caused by freeze–thaw weathering. Rock Mech. Rock Eng. 2018, 51, 2791–2804. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Xia, K.; Li, X.B.; Li, H.B.; Ma, G.W.; Zhao, J.; Zhou, Z.L.; Dai, F. Suggested Methods for Determining the Dynamic Strength Parameters and Mode-I Fracture Toughness of Rock Materials. In The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007–2014; Ulusay, R., Ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 35–44. [Google Scholar]

- Mohnke, O.; Hughes, B. Jointly deriving NMR surface relaxivity and pore size distributions by NMR relaxation experiments on partially desaturated rocks. Water Resour. Res. 2014, 50, 5309–5321. [Google Scholar] [CrossRef]

- Shang, J.; Hu, J.H.; Zhou, K.P.; Luo, X.W.; Aliyu, M.M. Porosity increment and strength degradation of low-porosity sedimentary rocks under different loading conditions. Int. J. Rock Mech. Min. Sci. 2015, 75, 216–223. [Google Scholar] [CrossRef]

- Li, X.; Zhou, Z.L.; Lok, T.S.; Hong, L.; Yin, T.B. Innovative testing technique of rock subjected to coupled static and dynamic loads. Int. J. Rock Mech. Min. Sci. 2008, 45, 739–748. [Google Scholar] [CrossRef]

- Li, X.B.; Lok, T.S.; Zhao, J.; Zhao, P.J. Oscillation elimination in the Hopkinson bar apparatus and resultant complete dynamic stress–strain curves for rocks. Int. J. Rock Mech. Min. Sci. 2000, 37, 1055–1060. [Google Scholar] [CrossRef]

- Lok, T.S.; Li, X.B.; Liu, D.; Zhao, P.J. Testing and response of large diameter brittle materials subjected to high strain rate. J. Mater. Civil Eng. 2002, 14, 262–269. [Google Scholar] [CrossRef]

- Gray, G.T., III. Classic split-Hopkinson pressure bar testing, in ASM Handbook, 8. In Mechanical Testing and Evaluation; Committee, A.H., Ed.; ASM International: Novelty, OH, USA, 2000; pp. 1027–1068. [Google Scholar]

- Lifshitz, J.M.; Leber, H. Data processing in the split Hopkinson pressure bar tests. Int. J. Impact Eng. 1994, 15, 723–733. [Google Scholar] [CrossRef]

- Li, X.B.; Lok, T.S.; Zhao, J. Dynamic characteristics of granite subjected to intermediate loading rate. Rock Mech. Rock Eng. 2005, 38, 21–39. [Google Scholar] [CrossRef]

| Density (kg/m3) | P-Wave Velocity (m/s) | UCS (Uniaxial Compressive Strength) (MPa) | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|---|

| 2360 | 3750 | 75.0 | 15.7 | 0.2 |

| Group Number | Mass of Saturated Samples after Different Freeze-Thaw Times in g | Change % | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 20 | 40 | 60 | 80 | 100 | 120 | 140 | |||

| Group B | B21 | 230.27 | 231.08 | 231.71 | 231.56 | 231.19 | 231.55 | 231.79 | 232.12 | 0.80 |

| B22 | 229.80 | 230.60 | 230.69 | 231.07 | 230.63 | 230.84 | 231.26 | 231.43 | 0.71 | |

| B23 | 229.08 | 229.93 | 230.06 | 230.38 | 229.80 | 229.76 | 230.32 | 230.52 | 0.63 | |

| B24 | 228.40 | 229.31 | 229.38 | 229.40 | 229.15 | 228.95 | 229.56 | 229.87 | 0.64 | |

| B25 | 231.26 | 232.19 | 232.35 | 232.26 | 232.11 | 232.17 | 232.44 | 232.90 | 0.71 | |

| Average | 229.76 | 230.62 | 230.84 | 230.93 | 230.58 | 230.65 | 231.07 | 231.37 | 0.70 | |

| Group C | C21 | 230.94 | 232.32 | 232.57 | 232.64 | 232.89 | 233.05 | 233.03 | 233.25 | 1.00 |

| C22 | 231.04 | 232.16 | 231.15 | 232.44 | 231.64 | 232.39 | 232.53 | 232.76 | 0.74 | |

| C23 | 229.56 | 230.72 | 231.13 | 231.00 | 230.59 | 231.27 | 231.36 | 230.87 | 0.57 | |

| C24 | 227.40 | 228.48 | 228.48 | 228.53 | 228.15 | 228.63 | 228.73 | 229.95 | 1.12 | |

| C25 | 229.69 | 230.83 | 230.98 | 231.15 | 230.64 | 231.34 | 231.51 | 230.80 | 0.48 | |

| Average | 229.73 | 230.90 | 230.86 | 231.15 | 230.78 | 231.34 | 231.43 | 231.53 | 0.78 | |

| Group D | D21 | 229.68 | 230.49 | 230.84 | 231.48 | 231.65 | 231.78 | 231.78 | 231.37 | 0.74 |

| D22 | 228.83 | 230.02 | 230.37 | 230.85 | 230.77 | 230.89 | 231.83 | 230.82 | 0.87 | |

| D23 | 229.51 | 230.09 | 230.46 | 231.07 | 231.15 | 231.29 | 231.09 | 230.98 | 0.64 | |

| D24 | 228.02 | 228.95 | 229.40 | 229.80 | 229.70 | 229.83 | 229.70 | 229.16 | 0.50 | |

| D25 | 229.57 | 230.20 | 230.76 | 231.29 | 231.25 | 231.27 | 230.83 | 230.18 | 0.27 | |

| Average | 229.12 | 229.95 | 230.37 | 230.90 | 230.90 | 231.01 | 231.05 | 231.50 | 0.60 | |

| Group E | E21 | 224.30 | 225.10 | 225.37 | 226.31 | 226.36 | 226.17 | 226.40 | 226.37 | 0.92 |

| E22 | 229.41 | 230.60 | 250.52 | 230.87 | 231.26 | 230.99 | 231.02 | 231.48 | 0.90 | |

| E23 | 228.95 | 229.84 | 230.18 | 230.60 | 230.86 | 230.14 | 230.39 | 231.22 | 0.99 | |

| E24 | 231.42 | 232.89 | 232.68 | 233.23 | 232.90 | 232.67 | 232.43 | 233.54 | 0.92 | |

| E25 | 230.13 | 230.60 | 231.18 | 231.81 | 232.25 | 232.26 | 231.79 | 232.62 | 1.08 | |

| Average | 228.84 | 229.81 | 229.99 | 230.56 | 230.73 | 230.45 | 230.41 | 231.05 | 0.96 | |

| Specimen | Saturated Rock Porosity After Different Freeze-Thaw Cycles % | Change Rate % | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 20 | 40 | 60 | 80 | 100 | 120 | 140 | ||

| E21 | 7.207 | 8.018 | 8.359 | 9.362 | 9.532 | 10.060 | 10.278 | 11.400 | 58.18 |

| E22 | 8.156 | 9.317 | 9.382 | 9.842 | 10.352 | 11.140 | 11.674 | 12.518 | 53.48 |

| E23 | 7.519 | 8.383 | 8.824 | 9.326 | 9.698 | 10.564 | 9.713 | 11.227 | 49.32 |

| E24 | 8.142 | 9.572 | 9.493 | 10.146 | 9.881 | 11.097 | 11.166 | 11.668 | 43.31 |

| E25 | 7.910 | 8.417 | 9.104 | 9.728 | 10.278 | 11.145 | 10.570 | 12.202 | 54.26 |

| Average Value | 7.787 | 8.741 | 9.032 | 9.681 | 9.948 | 10.801 | 10.680 | 11.803 | 51.71 |

| Axial Pre-Compression Stress (MPa) | Average Peak Stress at Different Numbers of Freeze-Thaw Cycles (MPa) | Average Peak Strain at Different Numbers of Freeze-Thaw Cycles | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 20 | 60 | 100 | 140 | 0 | 20 | 60 | 100 | 140 | |

| 0 | 96.21 | 92.31 | 88.54 | 82.81 | 76.37 | 0.0103 | 0.0106 | 0.011 | 0.0116 | 0.0121 |

| 15 | 129.58 | 124.8 | 119.67 | 113.08 | 109.24 | 0.0069 | 0.0072 | 0.0081 | 0.0083 | 0.0084 |

| 35 | 119.48 | 116.64 | 112.96 | 110.35 | 105.15 | 0.0062 | 0.0063 | 0.0064 | 0.0067 | 0.0065 |

| 55 | 100.11 | 95.95 | 91.29 | 83.80 | 89.41 | 0.0089 | 0.0095 | 0.0100 | 0.0104 | 0.0110 |

| Axial Stress | Numbers of Freeze-Thaw Cycles | ||||

|---|---|---|---|---|---|

| 0 | 20 | 60 | 100 | 140 | |

| 0 MPa |  |  |  |  |  |

| 15 MPa |  |  |  |  |  |

| 35 MPa |  |  |  |  |  |

| 55 MPa |  |  |  |  |  |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ke, B.; Zhang, J.; Deng, H.; Yang, X. Dynamic Characteristics of Sandstone under Coupled Static-Dynamic Loads after Freeze-Thaw Cycles. Appl. Sci. 2020, 10, 3351. https://doi.org/10.3390/app10103351

Ke B, Zhang J, Deng H, Yang X. Dynamic Characteristics of Sandstone under Coupled Static-Dynamic Loads after Freeze-Thaw Cycles. Applied Sciences. 2020; 10(10):3351. https://doi.org/10.3390/app10103351

Chicago/Turabian StyleKe, Bo, Jian Zhang, Hongwei Deng, and Xiangru Yang. 2020. "Dynamic Characteristics of Sandstone under Coupled Static-Dynamic Loads after Freeze-Thaw Cycles" Applied Sciences 10, no. 10: 3351. https://doi.org/10.3390/app10103351

APA StyleKe, B., Zhang, J., Deng, H., & Yang, X. (2020). Dynamic Characteristics of Sandstone under Coupled Static-Dynamic Loads after Freeze-Thaw Cycles. Applied Sciences, 10(10), 3351. https://doi.org/10.3390/app10103351