Fractional Order PI-Based Control Applied to the Traction System of an Electric Vehicle (EV)

Abstract

1. Introduction

2. Electric Car Model

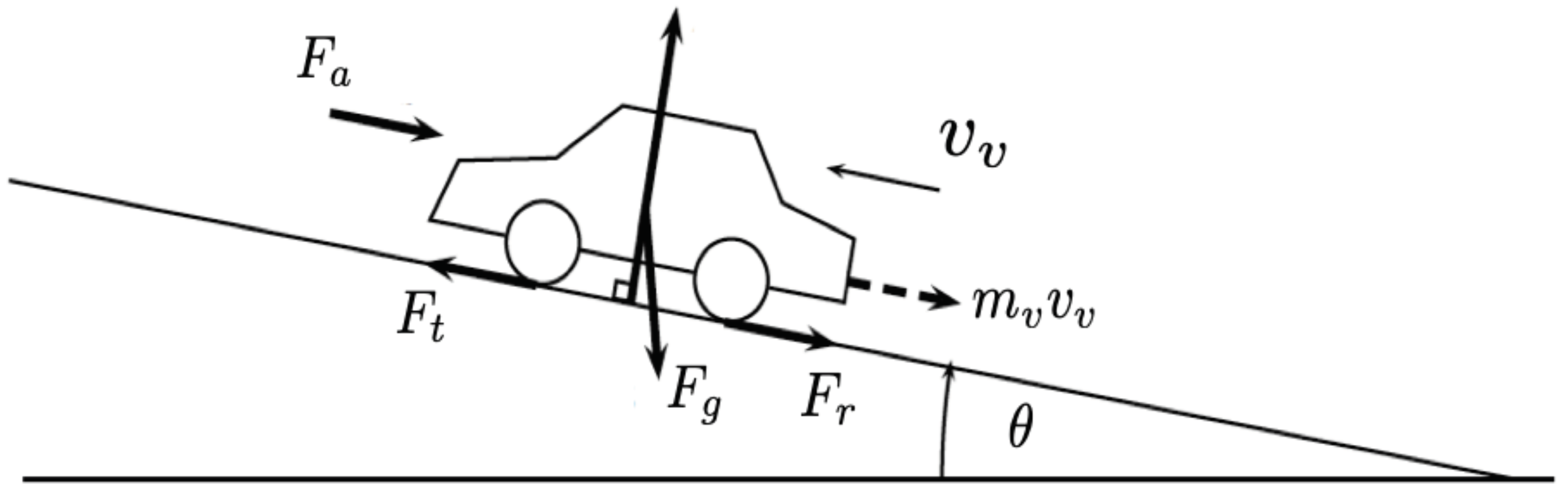

2.1. Mechanical Model

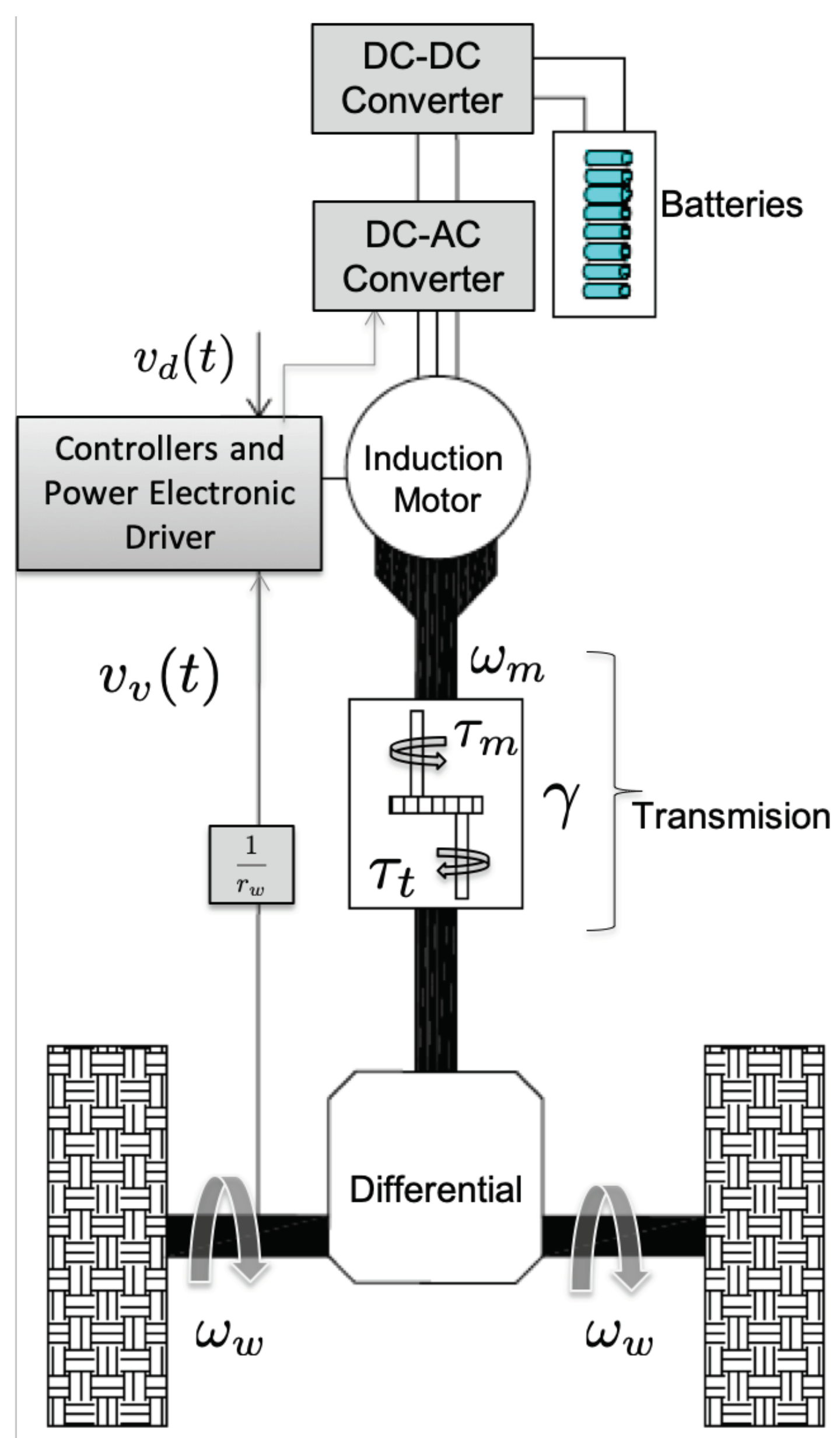

2.2. Traction System

2.3. Transmission

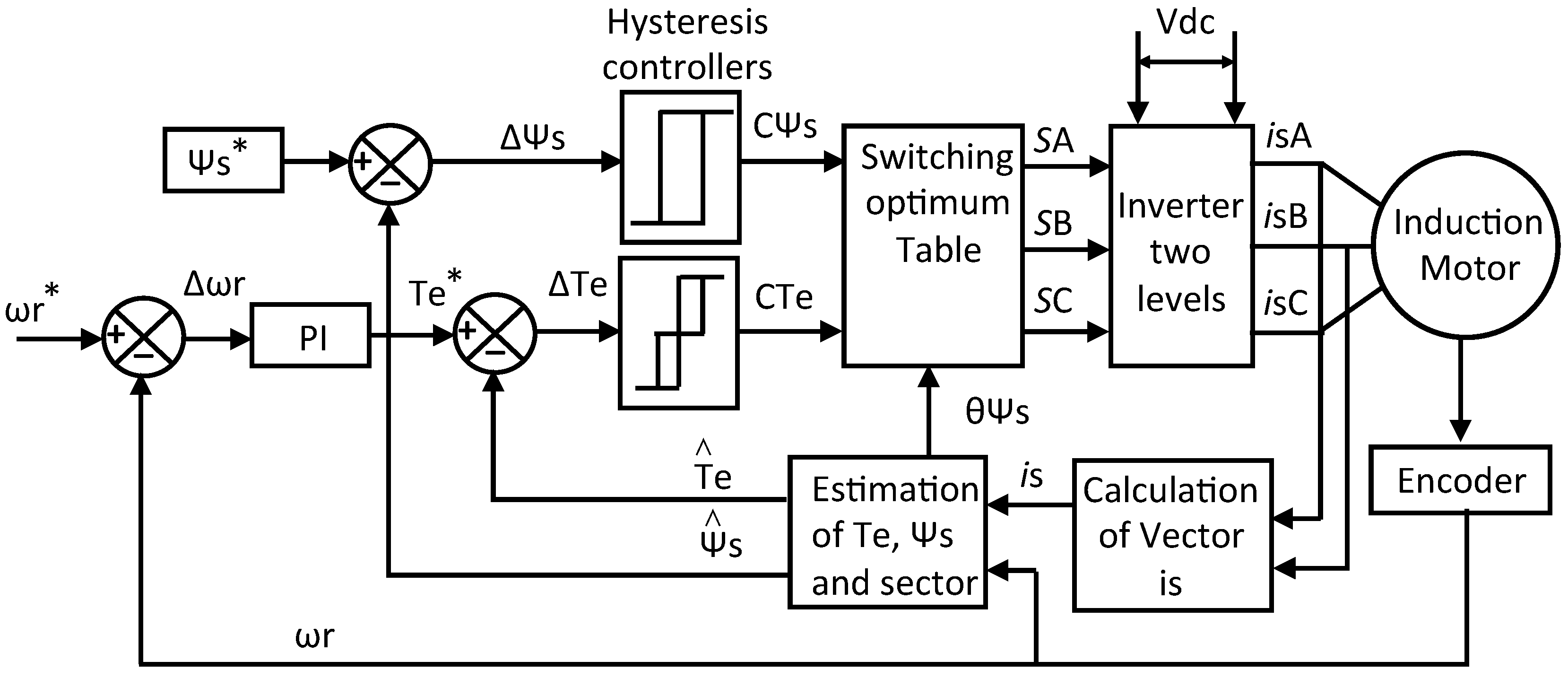

3. Direct Torque Control (DTC)

3.1. Direct Torque Control Strategy

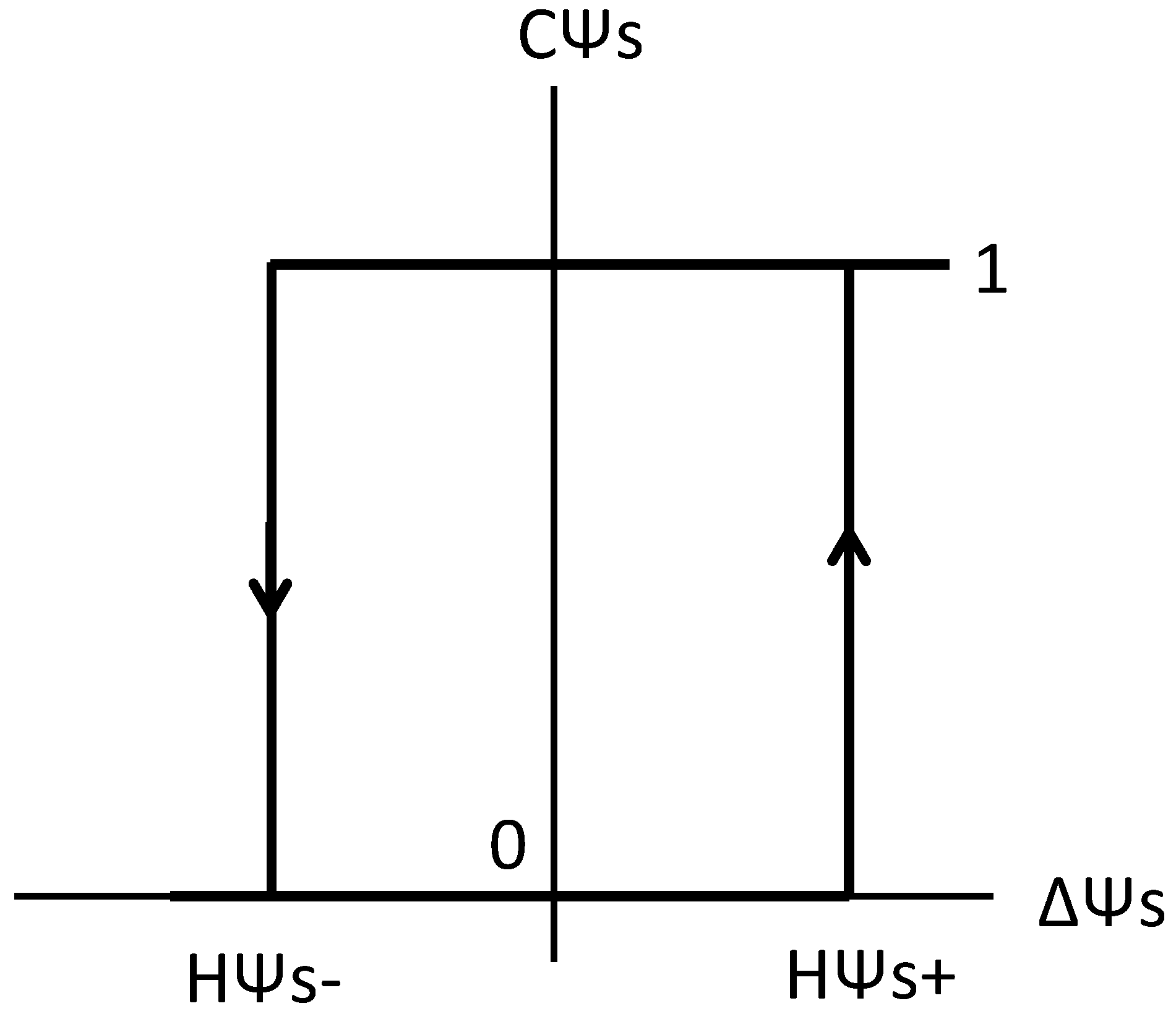

- Direct stator flux control and direct torque control

- Indirect regulation of stator currents and voltages

- Sinusoidal stator fluxes and stator currents approximation

- High dynamic performance even at locked rotor

- Absence of co-ordinate transform

- Absence of voltage modulator block

- Minimal response time, even better than the vector controllers

- The use of very fast digital control boards that allow the sampling frequency to be raised to high values (greater than 20 kHz).

- Instead of applying only one vector during the sampling period, a duty ratio control method can be used in which two vectors are applied, one active during a percentage of the sampling period and the other, the zero vector, which is applied during the rest of the period to reduce the torque ripple. Since there is no linear relationship that governs this operation, fuzzy logic can be applied to solve it [15].

- Inject a small but high frequency signal (>20 kHz) into the torque controller. A signal can also be injected into the flux controller to reduce the flux ripple. But the drawback of this method is that the switching frequency of the inverter must be increased, thereby increasing the switching losses. This method is suitable for a quasi-resonant type inverter [18].

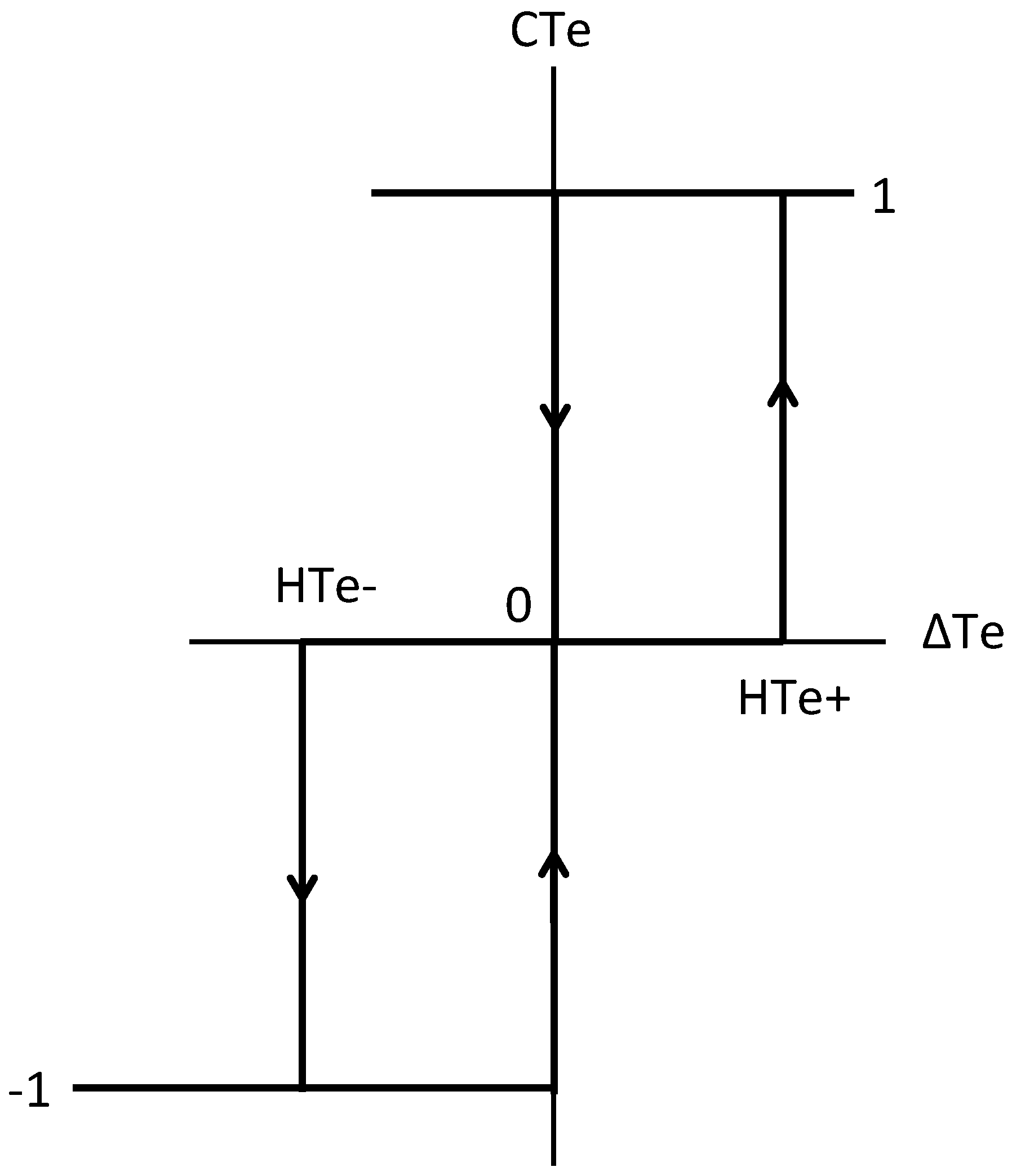

- Use a torque controller whose output is 1 or −1.

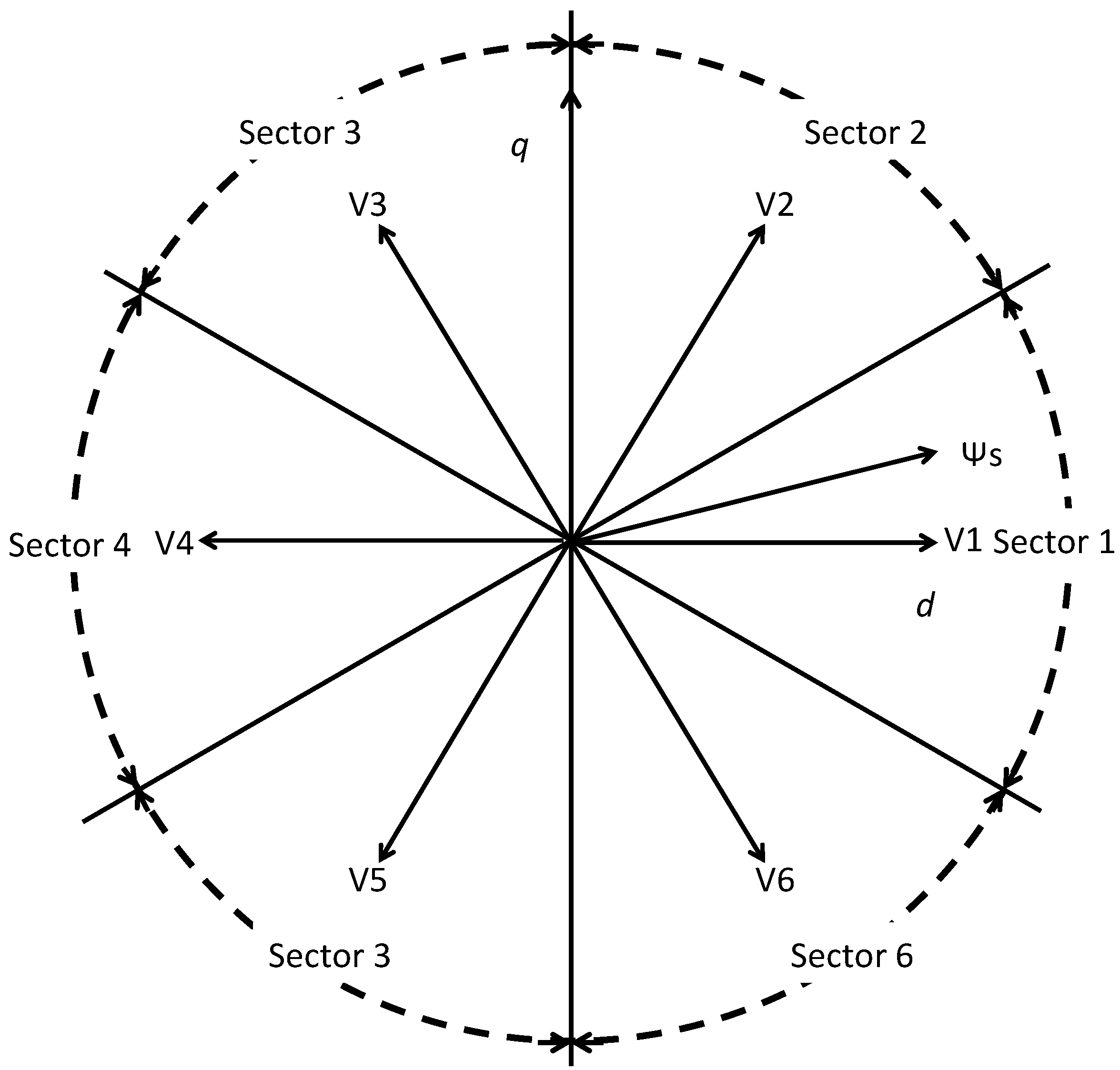

3.2. Sector Location

4. Fractional Order Control

- , real integral operator.

- , real differential operator.

- , proportional constant.

- , integration constant.

- , differentiation constant.

- is the pole of the lag compensator

- is the zero of the lag compensator

- is the pole of the lead compensator

- is the zero of the lead compensator

5. Statement of the Problem

6. Control Design

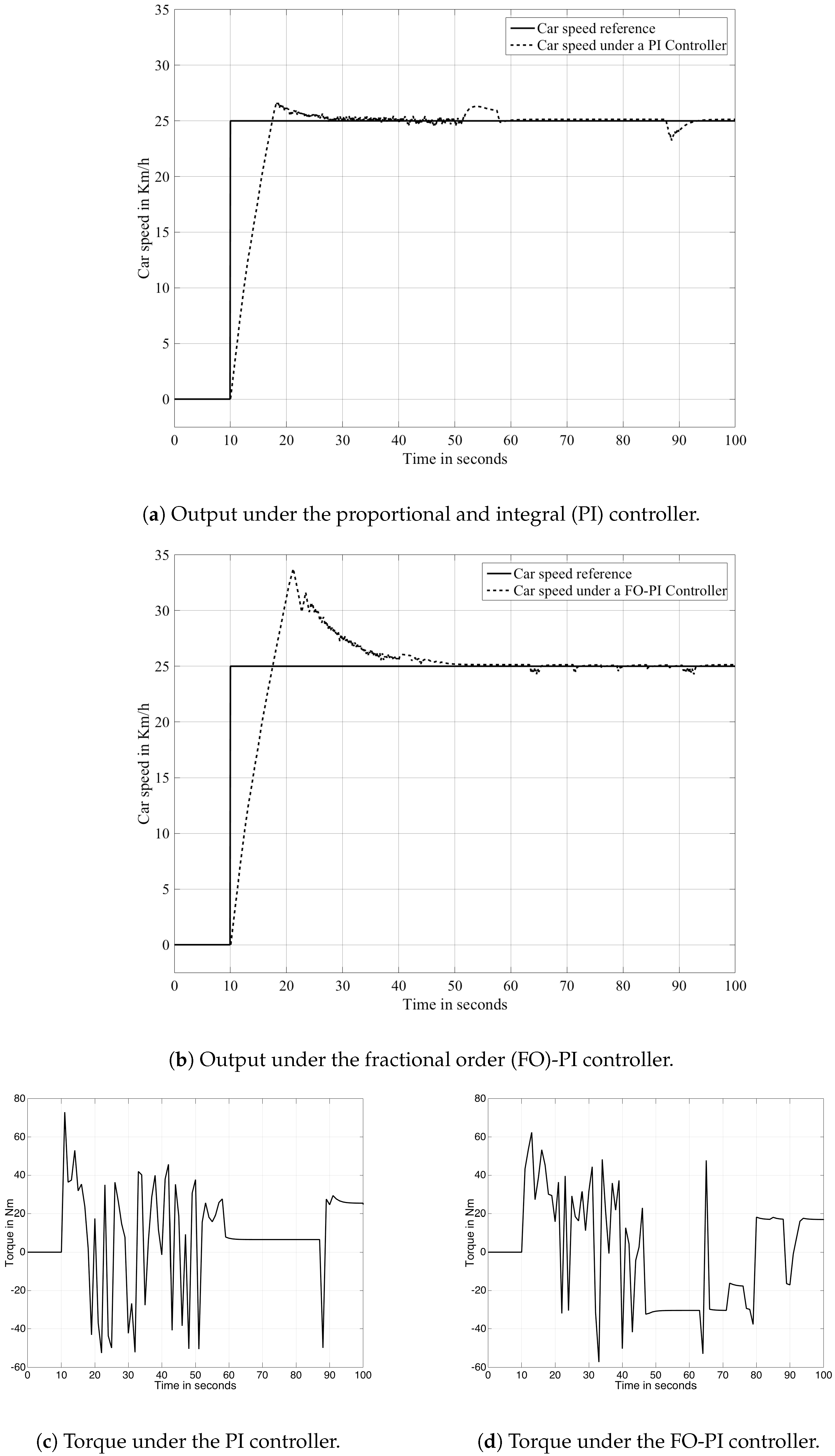

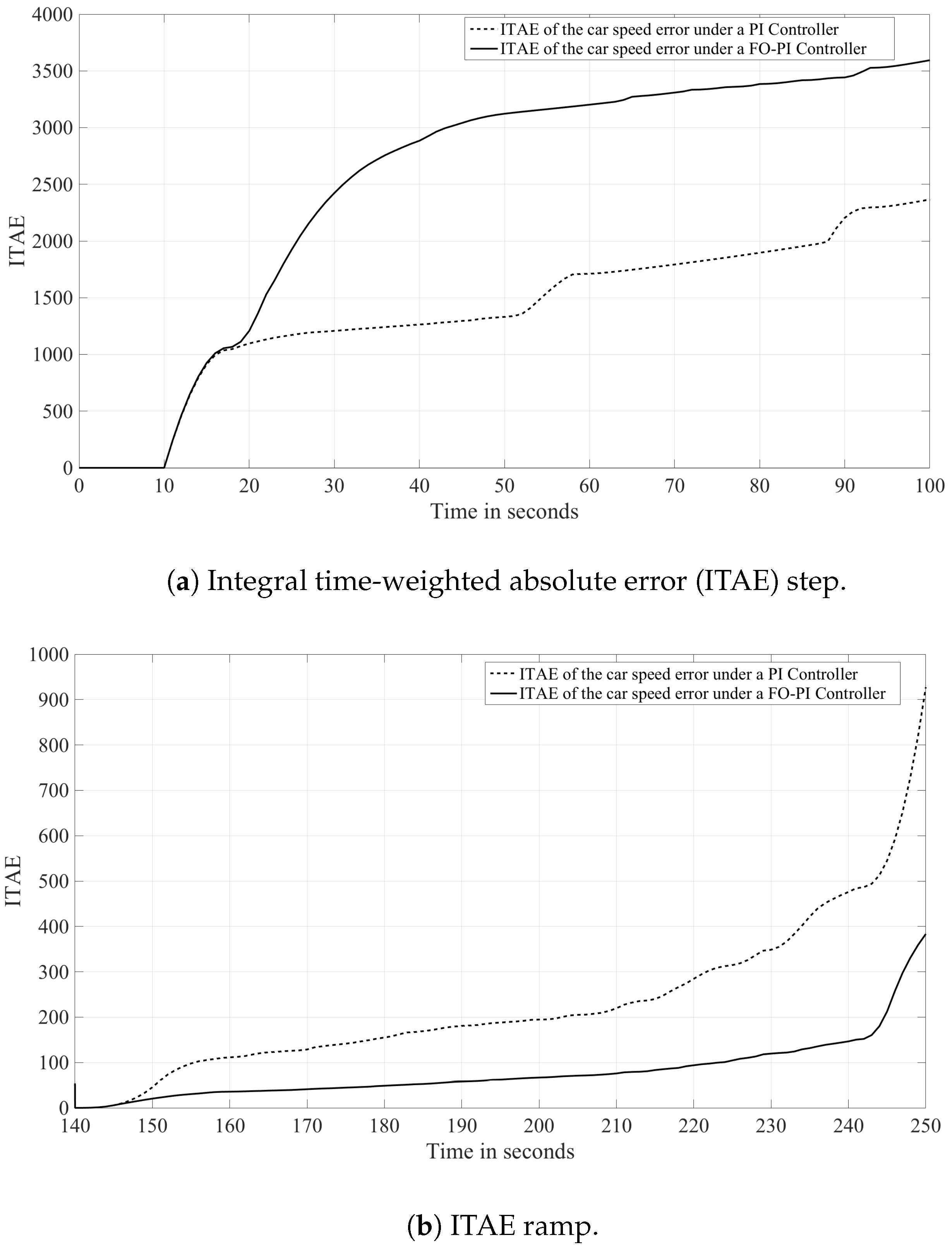

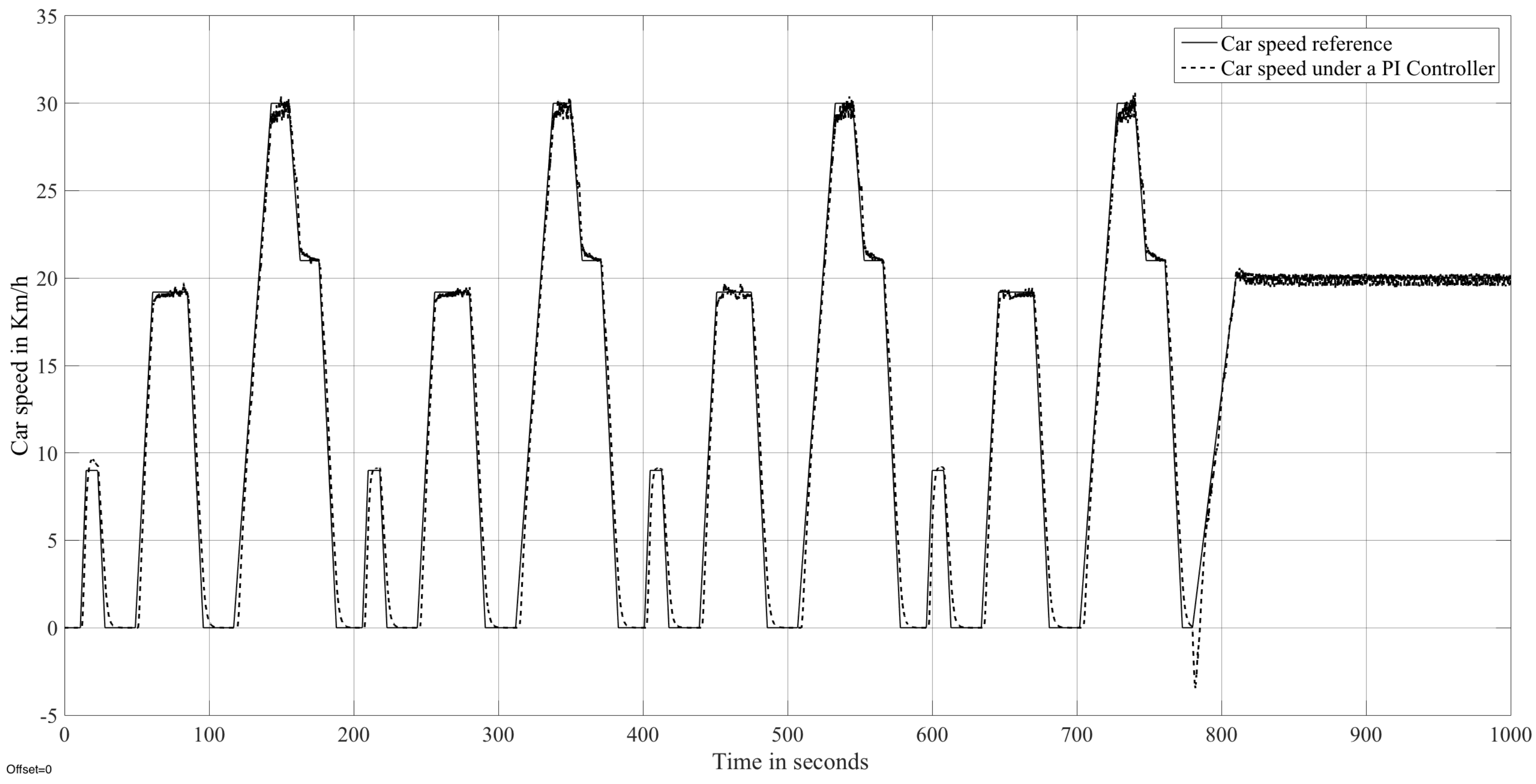

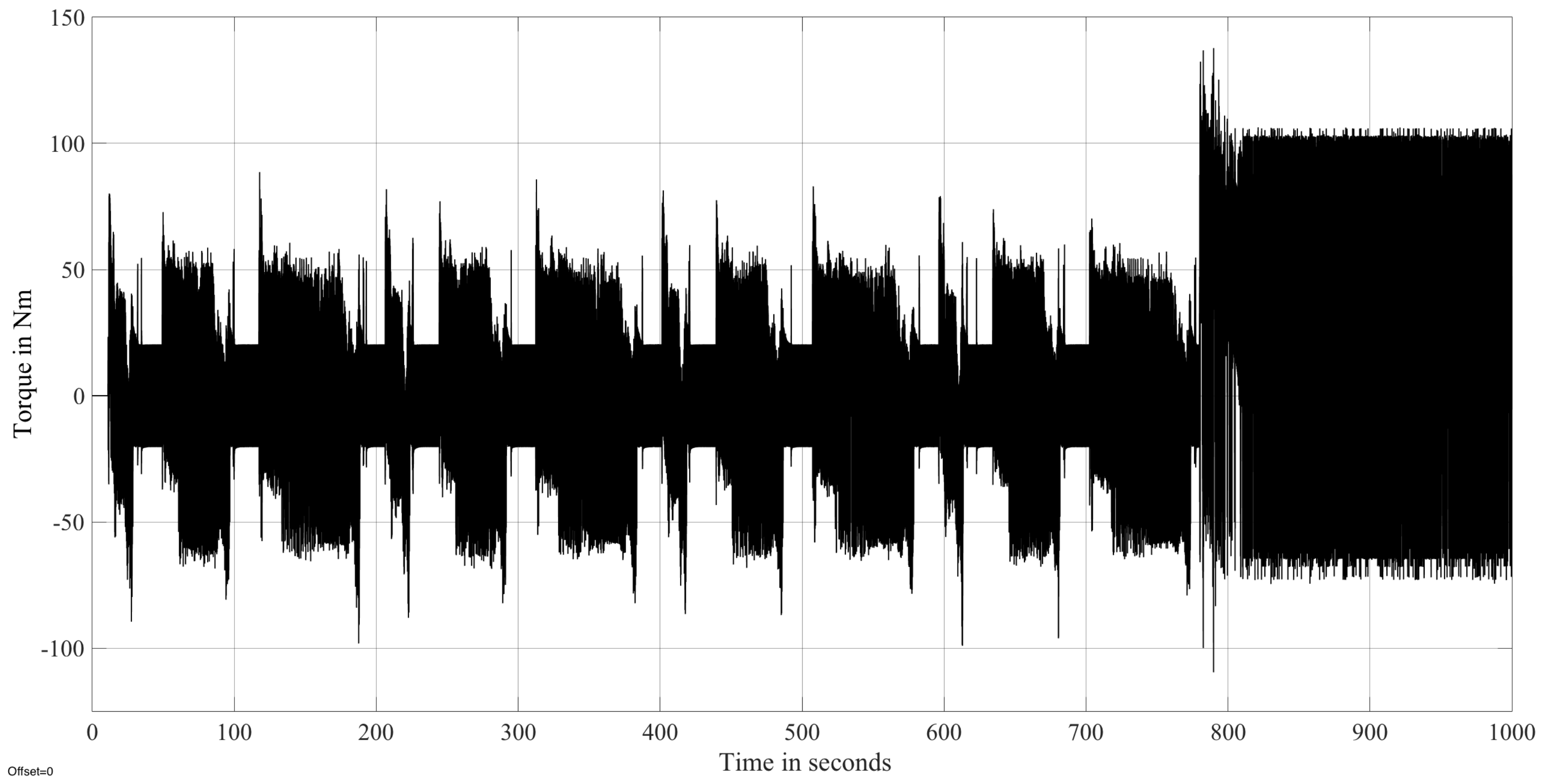

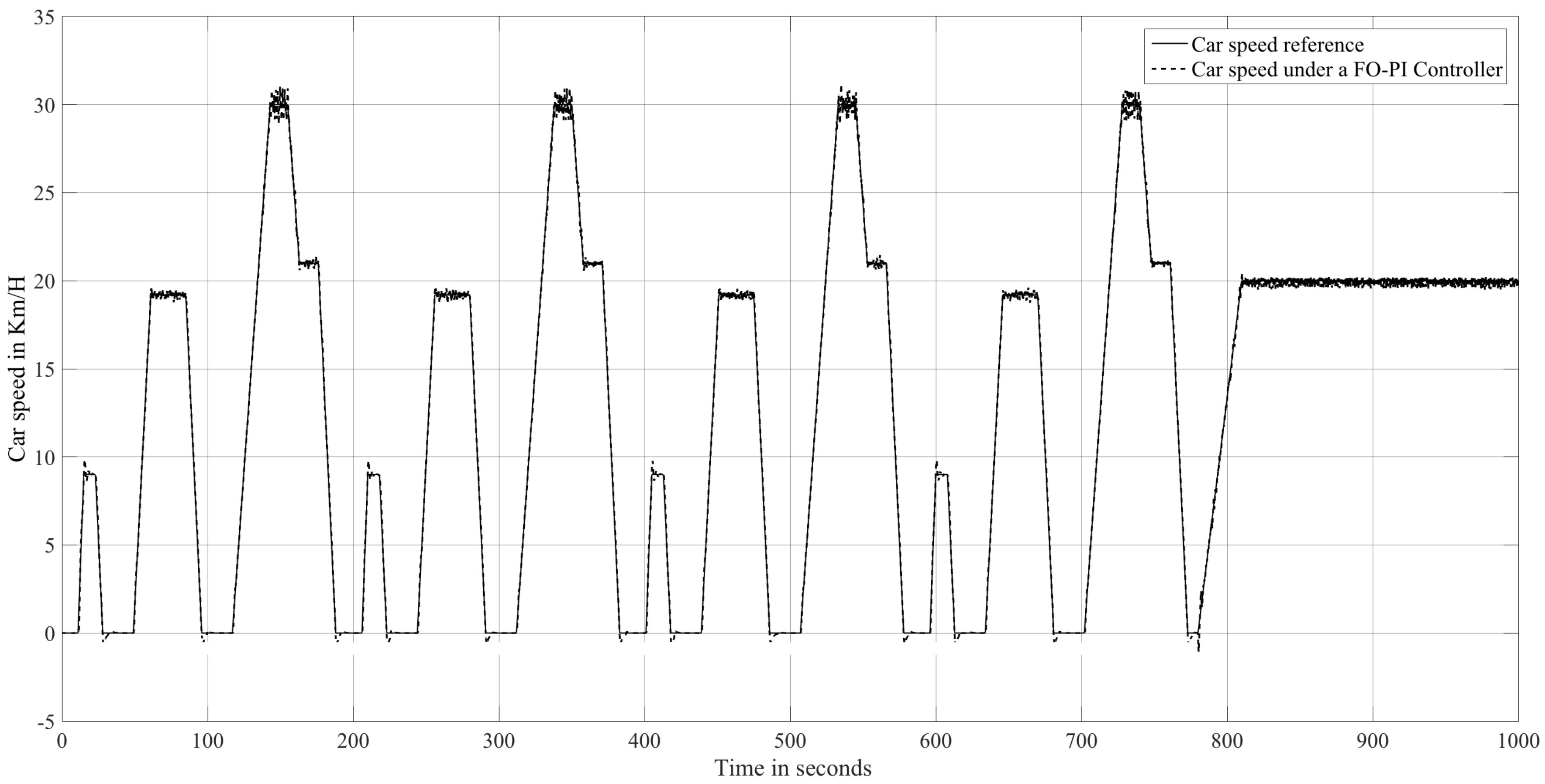

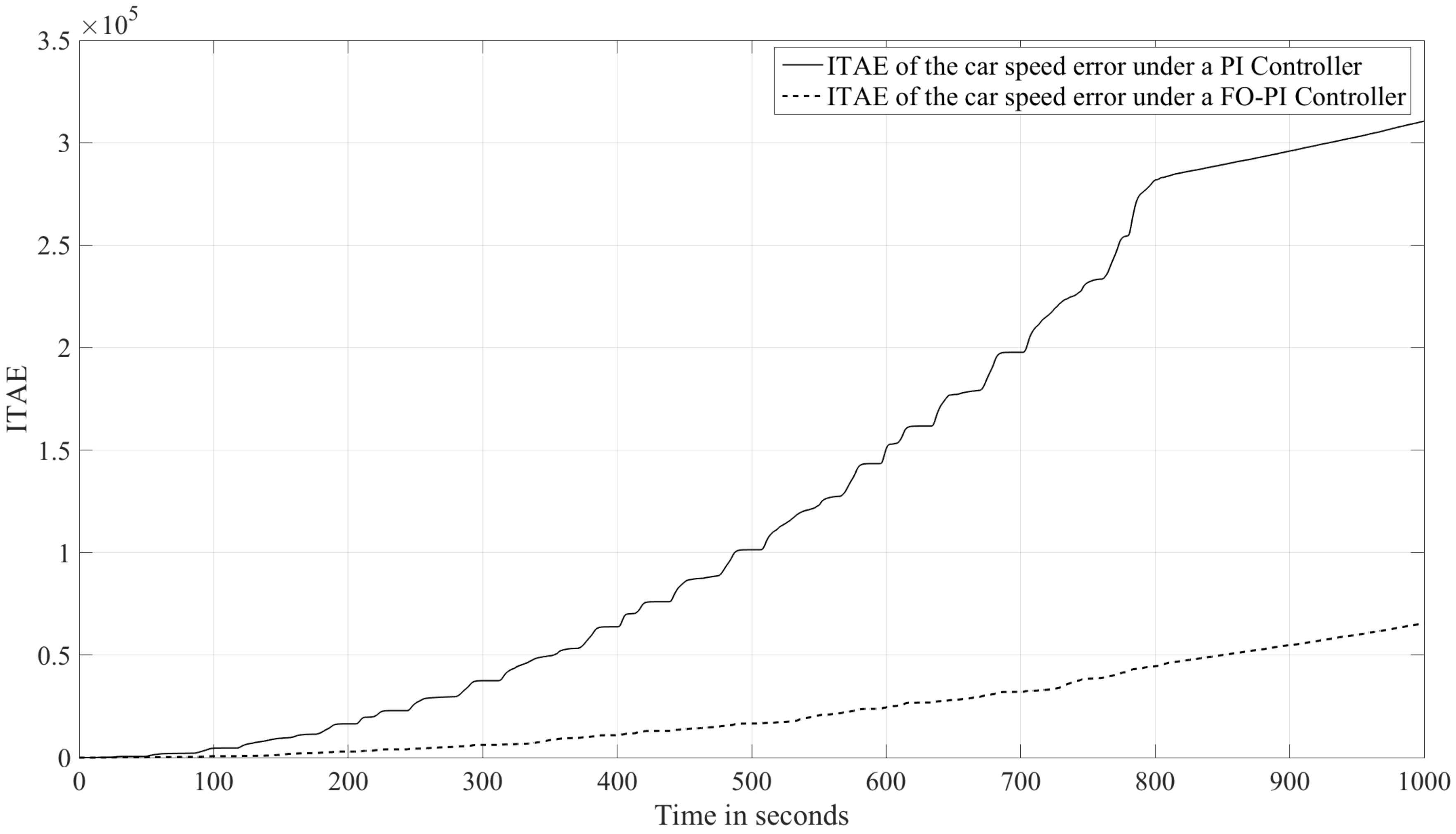

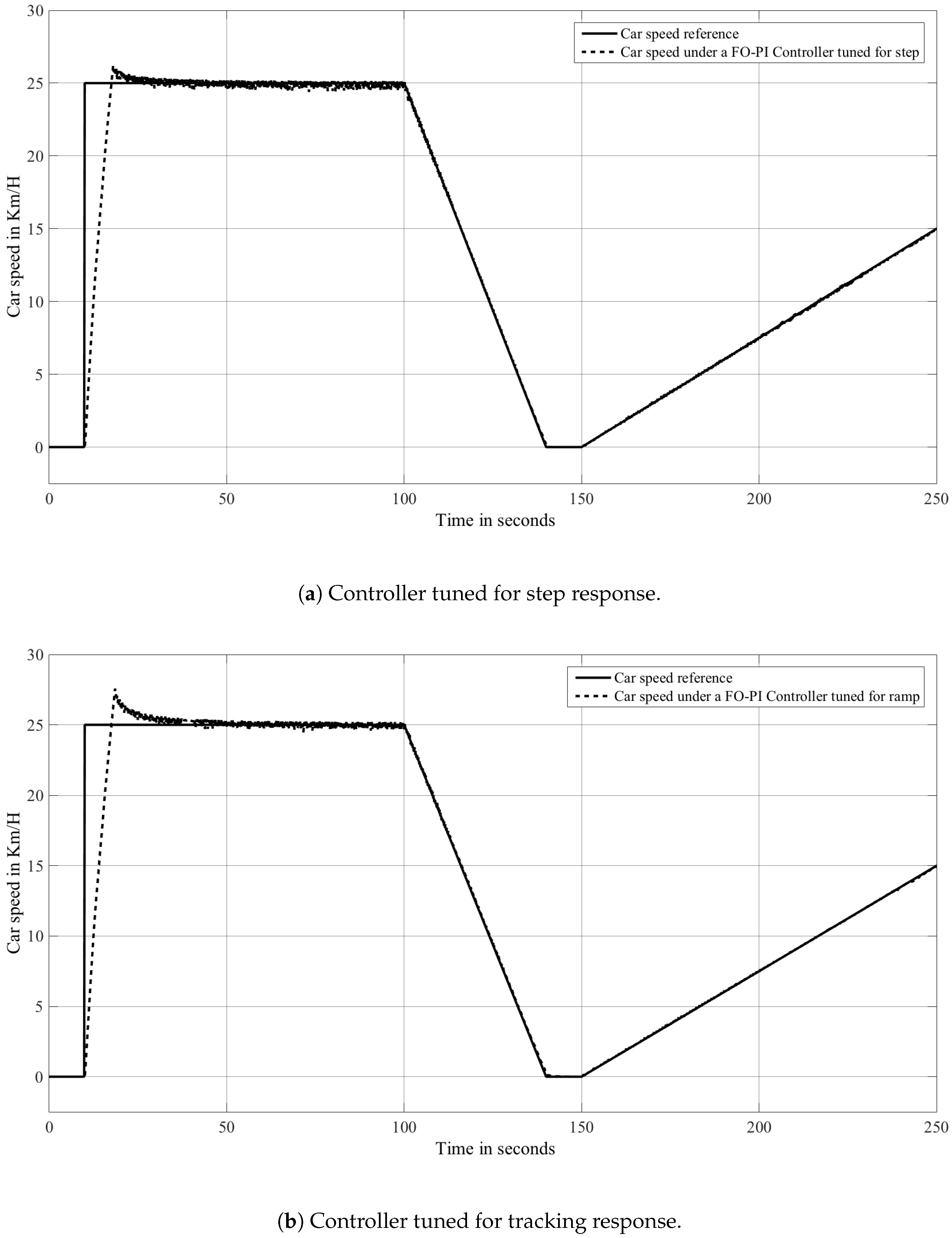

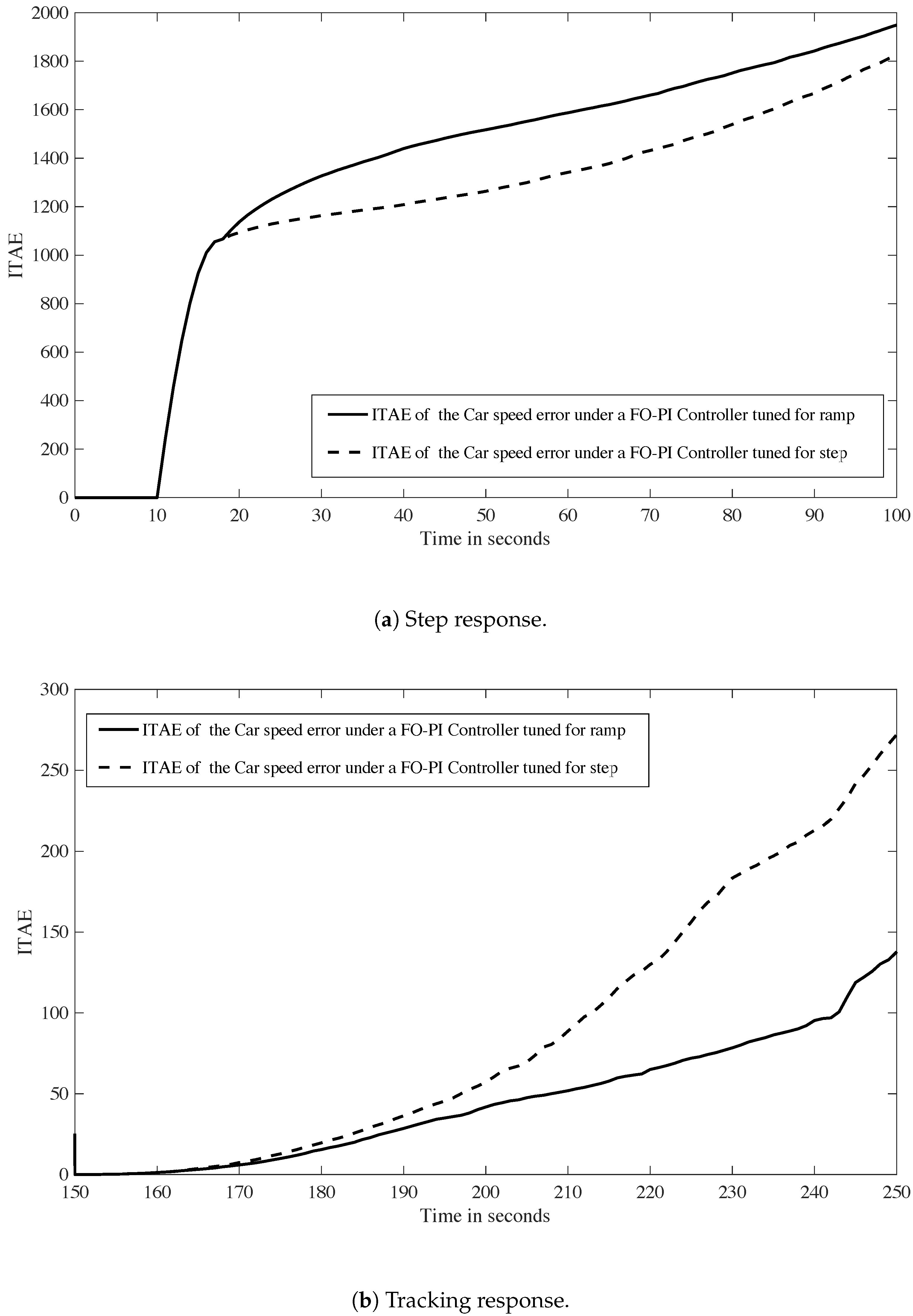

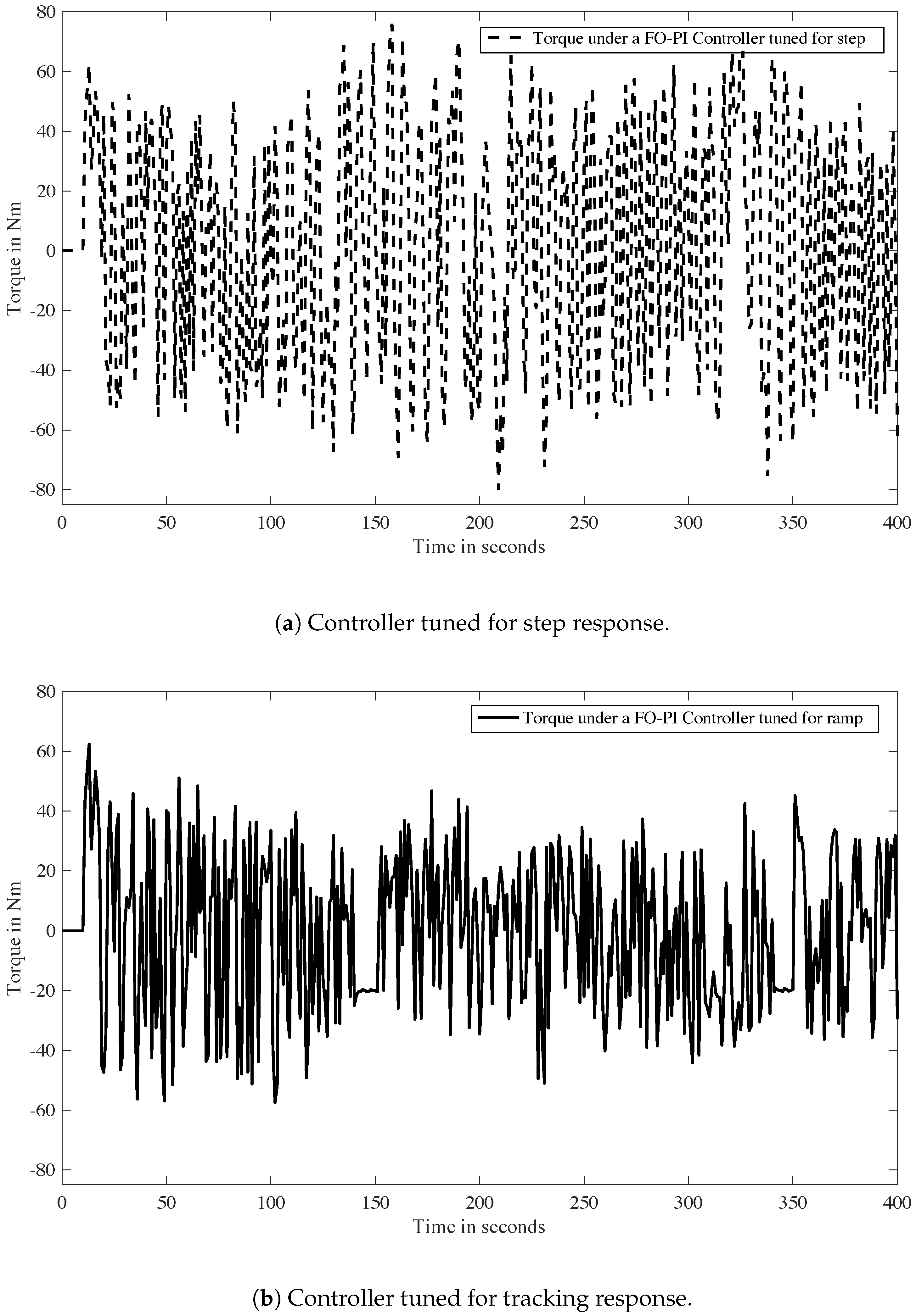

7. Results of the Simulation

- Average speed = 10 km/h

- Total time = 14 min

- Distance covered = 2 km 700 m

- Maximum speed reached = 30 km/h

8. Discussion

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| EV | Electrical vehicle |

| HEV | Hybrid electrical vehicle |

| ICE | Internal combustion engines |

| IM | Induction motor |

| DTC | Direct torque control |

| PID | Proportional, integral and derivative |

| FO-PI | Fractional order proportional and integral |

| NEDC | New Europe Drive Cycle |

| ITAE | Time-weighted absolute error |

| BUAP | Meritorious Autonomous University of Puebla |

References

- Kosow, I. Control de Máquinas Eléctricas (in Spanish); Reverte: Cartagena, Colombia, 1977. [Google Scholar]

- Ponce-Cruz, P.; Sampe-Lopez, J. Máquinas Eléctricas y Técnicas Modernas de Control (in Spanish); AlfaOmega: São Paulo, Brazil, 2008. [Google Scholar]

- De Almeida, A.T.; Ferreira, F.J.T.E.; Both, D. Technical and economical considerations in the application of variable-speed drives with electric motor systems. IEEE Trans. Ind. Appl. 2005, 41, 188–199. [Google Scholar] [CrossRef]

- Emadi, A. Handbook of Automotive Power and Electronics and Motor Drives; Taylor and Francis: Abingdon, UK, 2005. [Google Scholar]

- Chan, C.C.; Bouscayrol, A.; Chen, K. Electric, Hybrid, and Fuel-Cell Vehicles: Architectures and Modeling. IEEE Trans. Veh. Technol. 2010, 59, 589–598. [Google Scholar] [CrossRef]

- Lukic, S.; Emadi, A. Performance analysis of automotive power systems: Effects of power electronic intensive loads and electrically-assisted propulsion systems. In Proceedings of the IEEE Vehicular Techonology Conference (VTC), Vancouver, BC, Canada, 24–28 September 2002; pp. 1835–1839. [Google Scholar]

- Mapelli, F.L.; Tarsitano, D.; Mauri, M. Plug-In Hybrid Electric Vehicle: Modeling, Prototype Realization, and Inverter Losses Reduction Analysis. IEEE Trans. Ind. Electron. 2010, 57, 598–607. [Google Scholar] [CrossRef]

- Duran, M.; Aguilera, J.; Guerrero-Ramirez, G.; Claudio, A.; Vela, L.G.; Gudino-Lau, J. Modelado Del Sistema De Traccion Para Un Vehiculo Electrico (In Spanish). Congreso Anual De La Asociacion De Mexico De Control Automatico, 2010. Available online: http://amca.mx/memorias/amca2010/Art%C3%ADculos/Sistemas%20de%20Potencia/amca2010_submission_13.pdf (accessed on 27 December 2019).

- Hosseinnia, S.H.; Tejado, I.; Milanés, V.; Villagrá, J.; Vinagre, B.M. Experimental Application of Hybrid Fractional-Order Adaptive Cruise Control at Low Speed. IEEE Trans. Control Syst. Technol. 2014, 22, 2329–2336. [Google Scholar] [CrossRef]

- Kumar, V.; Rana, K.P.S.; Mishra, P. Robust speed control of hybrid electric vehicle using fractional order fuzzy PD and PI controllers in cascade control loop. J. Frankl. Inst. 2016, 353, 1713–1741. [Google Scholar] [CrossRef]

- Taymans, A.; Melchior, P.; Malti, R.; Aioun, F.; Guillemard, F.; Servel, A. Cruise control of an electric vehicle through fractional linear feedforward & prefiltering of an acceleration reference signal. In 20th IFAC World Congress; Elsevier: New York, NY, USA, 2017; pp. 12569–12574. [Google Scholar]

- Moreno Eguilaz, J.M. Aportaciones a La Optimizacion De Energia en Accionamientos Electricos De Motores De Induccion Mediante Logica Difusa (In Spanish); UPC: São Paulo, Brazil, 1997. [Google Scholar]

- Chapuis, Y.A.; Roye, D. DTC & current limitation method in start up of an induction machine. In Proceedings of the IEEE Conference on Power Electronics & Variable Speed Drives, London, UK, 21–23 September 1998; pp. 451–455. [Google Scholar]

- Azab, M.A.M. Estudio Y RealizacióN Del Control Directo Del Par (DTC) Para Accionamientos De Motores De InduccióN Con Inversores De Diferentes TopologíAs. Ph.D. Thesis, Universidad Politecnica de Cataluna, Electric Engeeniering Departament, Barcelona, Spain, 2002. [Google Scholar]

- Mir, S.A.; Elbuluk, M. Precision Torque Control in inverter fed induction machines. In Proceedings of the Record of IEEE IAS Annual Meeting 1995, Atlanta, GA, USA, 18–22 June 1995; pp. 394–401. [Google Scholar]

- Attaianese, C.; Nardt, V.A.; Tomasso, G. Vectorial torque control: A novel approach to torque and flux control of induction motor drives. IEEE Trans. Ind. Appl. 1999, 35, 1399–1405. [Google Scholar] [CrossRef]

- Chen, J.; Yongdong, L. Virtual vector based predictive control of torque and flux of induction motor and speed sensorless drives. In Proceedings of the Record of IEEE IAS Annual Meeting 1999, Phoenix, AZ, USA, 3–7 October 1999; pp. 2606–2613. [Google Scholar]

- Noguchi, T.; Takahashi, I. High frequency switching operation of PWM inverter for direct torque control of induction motor. In Proceedings of the Record of IEEE IAS Annual Meeting 1997, New Orleans, LA, USA, 5–9 October 1997; pp. 775–780. [Google Scholar]

- Monje, C.A.; Chen, Y.; Vinagre, B.M.; Xue, D.; Feliu, V. Fractional Order Systems and Controls: Fundamentals and Applications; Springer: New York, NY, USA, 2010. [Google Scholar]

- Podlubny, I.; Dorcak, L.; Kostial, I. On Fractional Derivatives, Fractional-Order Dynamic Systems and PIlDu Controllers. In Proceedings of the IEEE Conference on Decision and Control, San Diego, CA, USA, 12 December 1997; pp. 4985–4990. [Google Scholar]

- Podlubny, I. Fractional-order systems and PIλ Dμ-controllers. IEEE Trans. Autom. Control 1999, 44, 208–214. [Google Scholar] [CrossRef]

- Goodwin, G.C.; Graebe, S.F.; Salgado, M.E. Control System Design; Prentice Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Petras, I. Fractional-Order Nonlinear Systems: Modeling, Analysis and Simulation, 1st ed.; Springer: Berlin, Germany, 2011. [Google Scholar]

- Muniz-Montero, C.; Sanchez-Gaspariano, L.; Sanchez-Lopez, C.; Gonzalez-Diaz, V.; Tlelo-Cuautle, E. Fractional Order Control and Synchronization of Chaotic Systems. In Chapter on the Electronic Realizations of Fractional-Order Phase-Lead-Lag Compensators with OpAmps and FPAAs; Springer: Berlin, Germany, 2017. [Google Scholar]

- Awouda, A.; Mamat, R. Refine PID tuning rule using ITAE criteria. In Proceedings of the International Conference on Computer and Automation Engineering (ICCAE), Singapore, 26–28 Febuary 2000; pp. 171–176. [Google Scholar]

- Saynes-Torres, J. Técnicas de diseño de observadores de velocidad para el control de un motor de inducción (in Spanish). Master’s Thesis, Faculty of Electronic Sciences (FCE), Meritorious Autonomous University of Puebla (BUAP), Puebla, Mexico, 2011. [Google Scholar]

- Tzirakis, E.; Pitsas, K.; Zannikos, F.; Stournas, S. Vehicle emissions and driving cycles: Comparison of the Athens driving cycle (ADC) with ECE-15 and European driving cycle (EDC). Glob. Nest 2006, 8, 282–290. [Google Scholar]

| VSI State | |||

|---|---|---|---|

| V1 | 1 | 0 | 0 |

| V2 | 1 | 1 | 0 |

| V3 | 0 | 1 | 0 |

| V4 | 0 | 1 | 1 |

| V5 | 0 | 0 | 1 |

| V6 | 1 | 0 | 1 |

| V7 | 1 | 1 | 1 |

| V8 | 0 | 0 | 0 |

| C,CTE, | |||||||

|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | ||

| C | CTE = 1 | V2 | V3 | V4 | V5 | V6 | V1 |

| CTE = 0 | V7 | V8 | V7 | V8 | V7 | V8 | |

| CTE = −1 | V6 | V1 | V2 | V3 | V4 | V5 | |

| C | CTE = 1 | V3 | V4 | V5 | V6 | V1 | V2 |

| CTE = 0 | V8 | V7 | V8 | V7 | V8 | V7 | |

| CTE = −1 | V5 | V6 | V1 | V2 | V3 | V4 | |

| Parameters of the Motor | Value |

|---|---|

| Poles | 4 |

| Rated power | 1.1 kW (Y: 380 V/4.43 A) |

| Nominal speed | 1415 rpm = 148.17 rad/s |

| Nominal Flux | 0.96 Wb |

| Nominal torque | 7.4 Nm |

| Rs | 9.21 |

| Rr | 6.644 |

| Lm | 0.44415 H |

| Ls | 0.03207 |

| Lr | 0.00847 H |

| Parameters | Value |

|---|---|

| Vehicle mass | 200 Kg |

| Aerodynamic coefficient | 0.2 |

| Front Area | 1.5 m |

| Coefficient of friction | 0.015 |

| Transmission efficiency | 0.97 |

| Tire radius | 0.2 m |

| Transmission ratio | 6 |

| Response | Second-Order Model | Control Parameters | |||

|---|---|---|---|---|---|

| Step | 2.1314 | 6.0171 | 0.15 | 3 | 1.5 |

| Ramp | 4.1964 | 3.3135 | 0.25 | 2 | 1.25 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munoz-Hernandez, G.A.; Mino-Aguilar, G.; Guerrero-Castellanos, J.F.; Peralta-Sanchez, E. Fractional Order PI-Based Control Applied to the Traction System of an Electric Vehicle (EV). Appl. Sci. 2020, 10, 364. https://doi.org/10.3390/app10010364

Munoz-Hernandez GA, Mino-Aguilar G, Guerrero-Castellanos JF, Peralta-Sanchez E. Fractional Order PI-Based Control Applied to the Traction System of an Electric Vehicle (EV). Applied Sciences. 2020; 10(1):364. https://doi.org/10.3390/app10010364

Chicago/Turabian StyleMunoz-Hernandez, German Ardul, Gerardo Mino-Aguilar, Jose Fermi Guerrero-Castellanos, and Edgar Peralta-Sanchez. 2020. "Fractional Order PI-Based Control Applied to the Traction System of an Electric Vehicle (EV)" Applied Sciences 10, no. 1: 364. https://doi.org/10.3390/app10010364

APA StyleMunoz-Hernandez, G. A., Mino-Aguilar, G., Guerrero-Castellanos, J. F., & Peralta-Sanchez, E. (2020). Fractional Order PI-Based Control Applied to the Traction System of an Electric Vehicle (EV). Applied Sciences, 10(1), 364. https://doi.org/10.3390/app10010364