Influence of Different Freezing Modes on the Base Slab Displacement of an Upper Structure

Abstract

1. Introduction

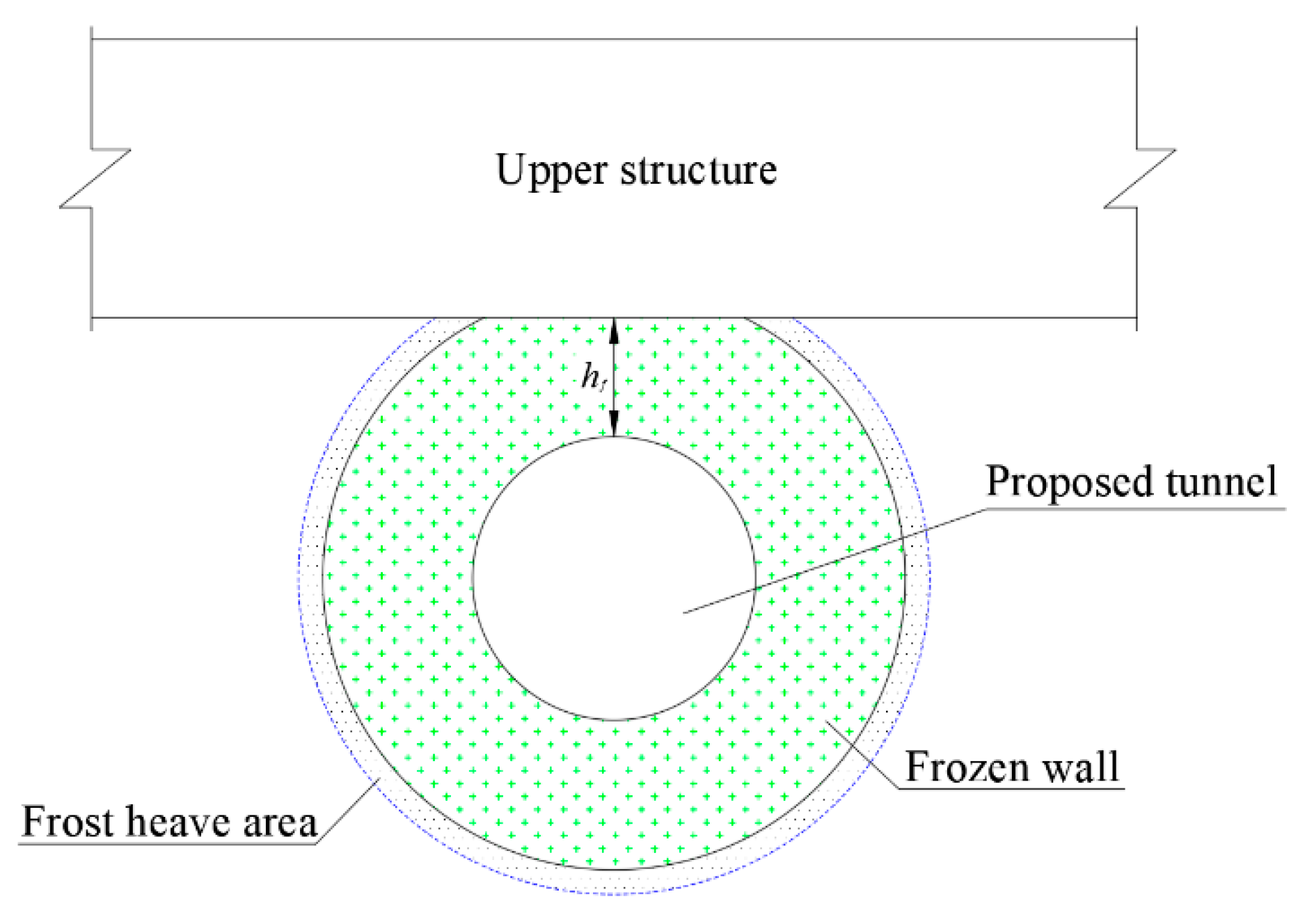

2. Similarity Simulation Experiment

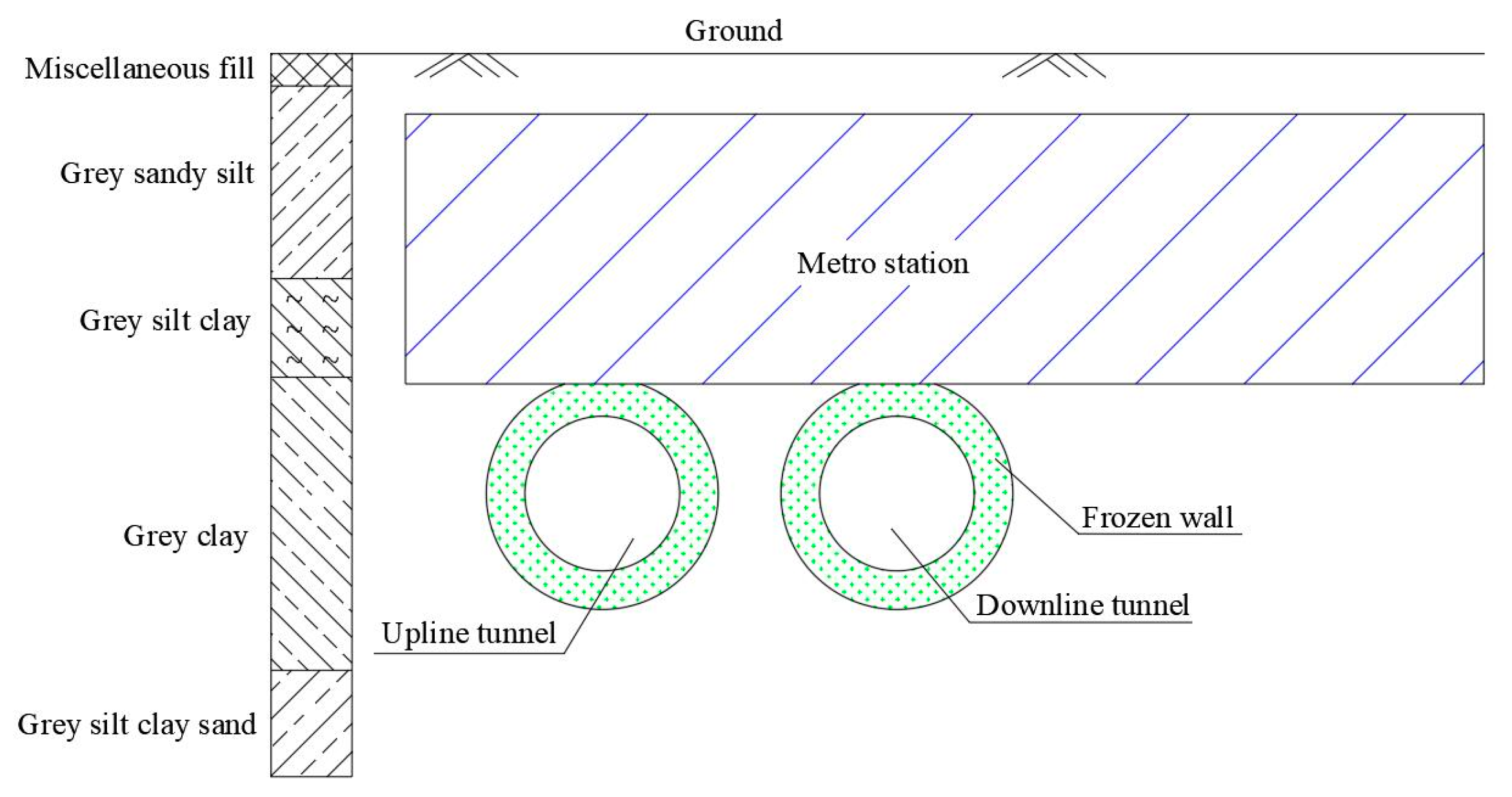

2.1. Engineering Background

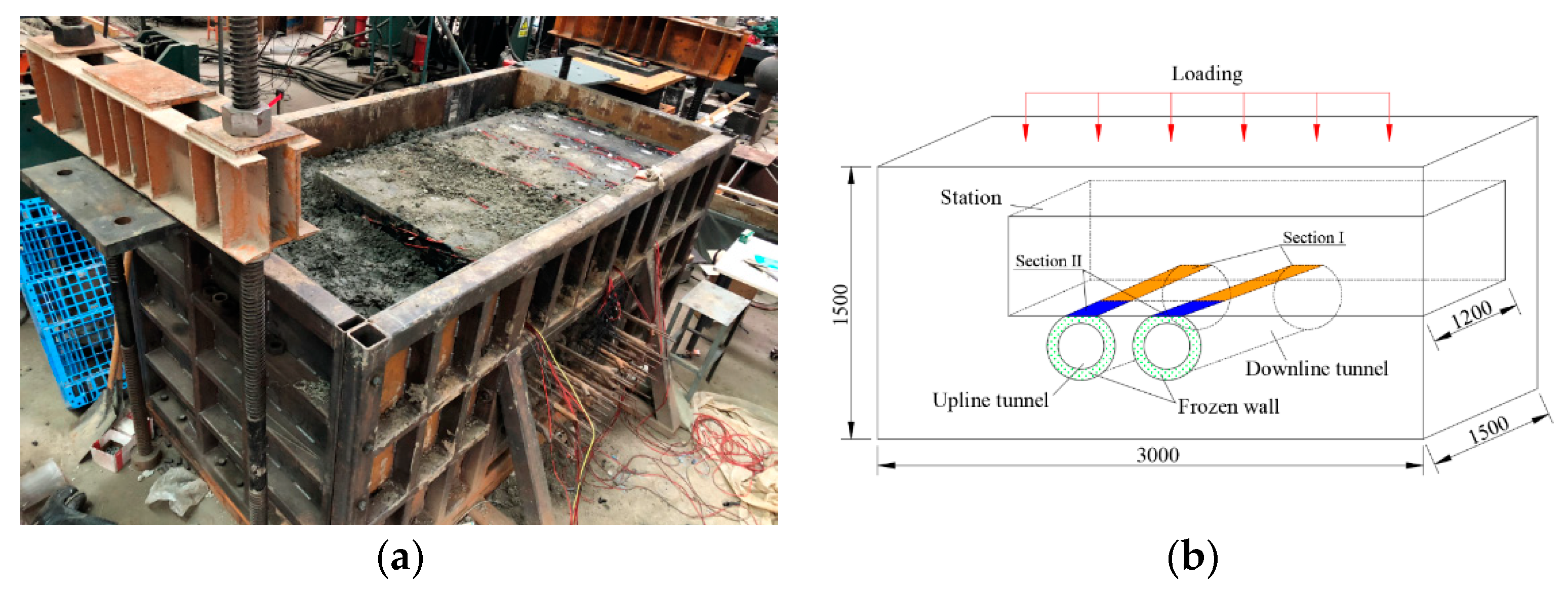

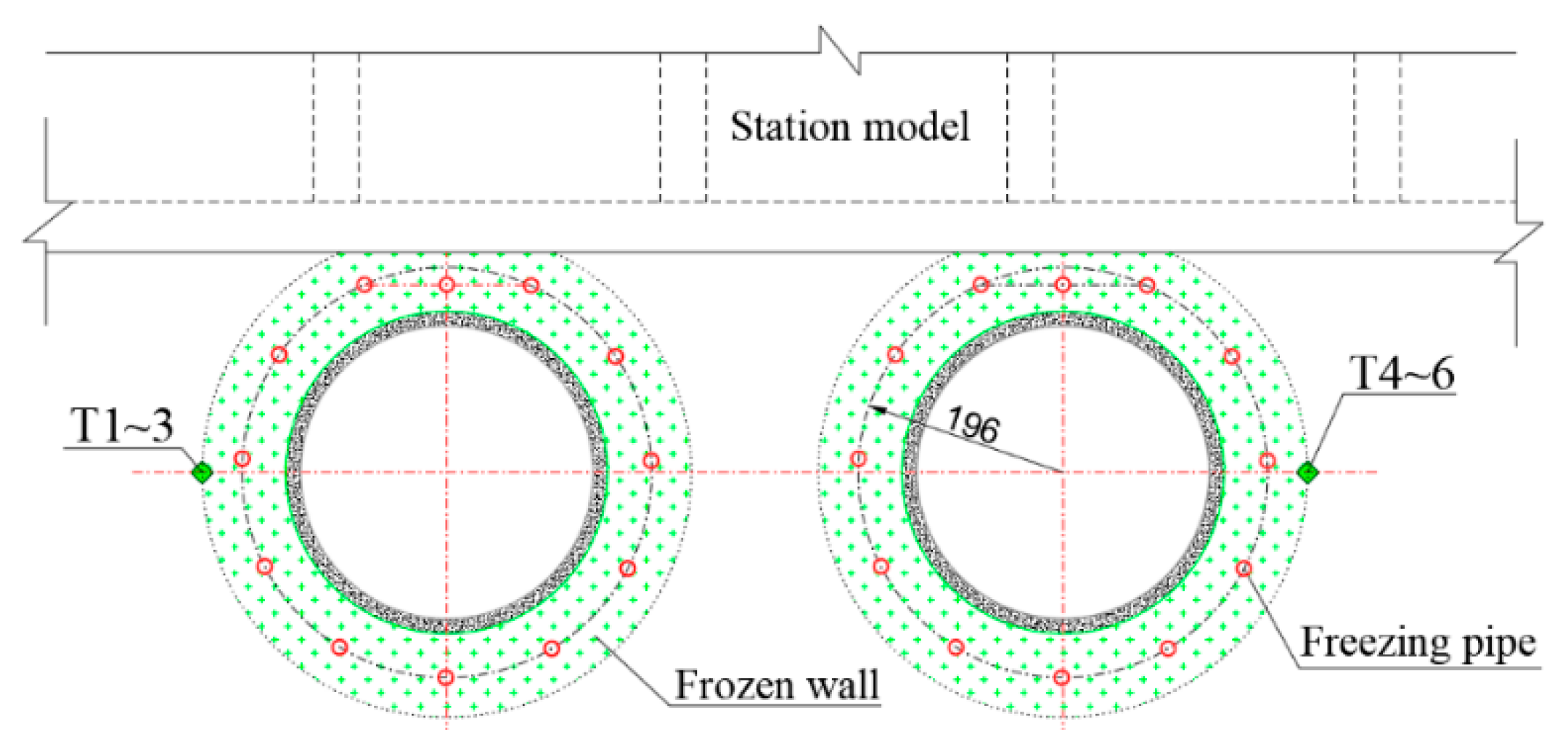

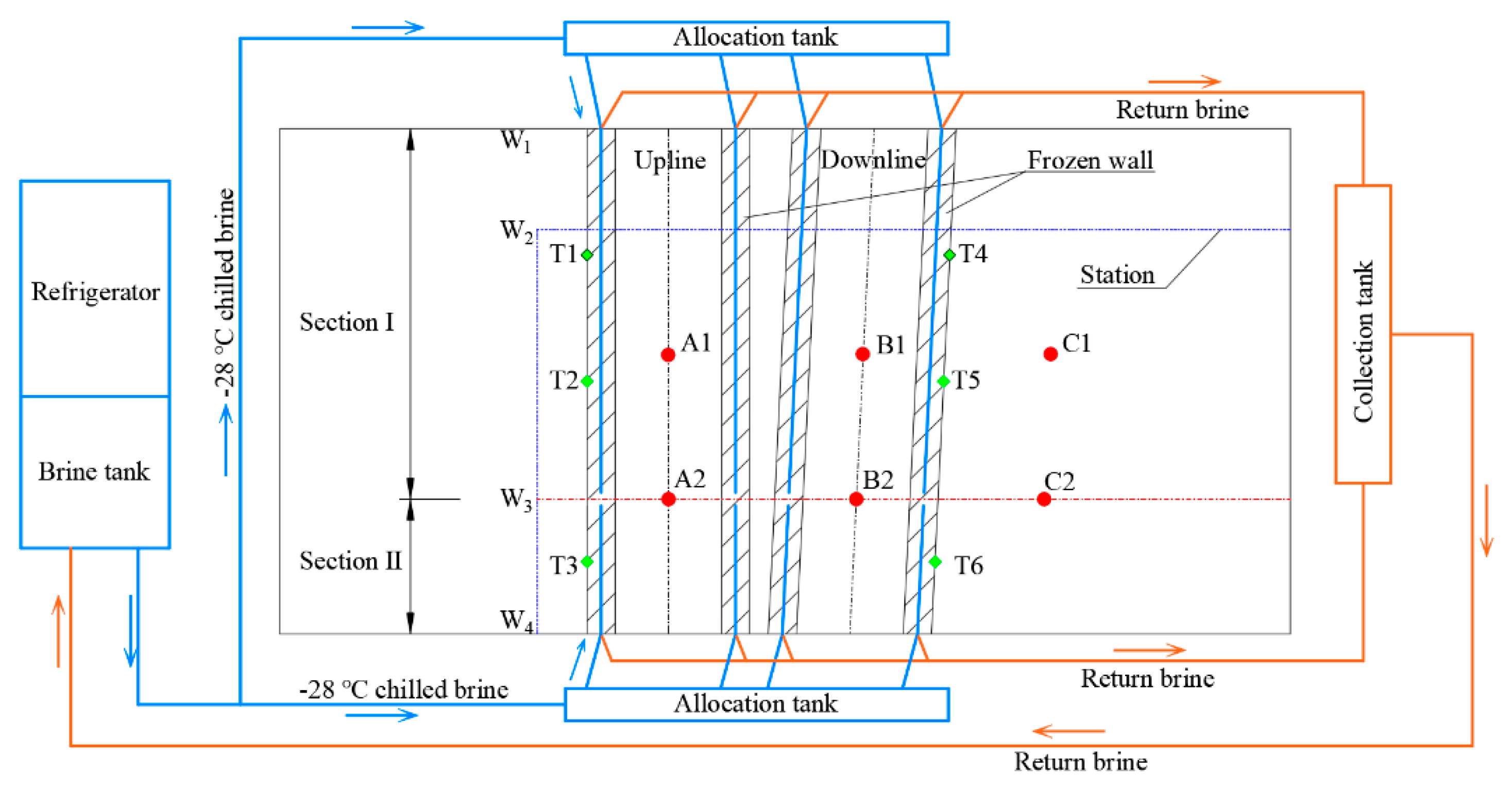

2.2. Modeling Test

Ct = n2,

CL = Cρ = Cd = n.

2.3. Construction Scheme

3. Testing Results and Discussion

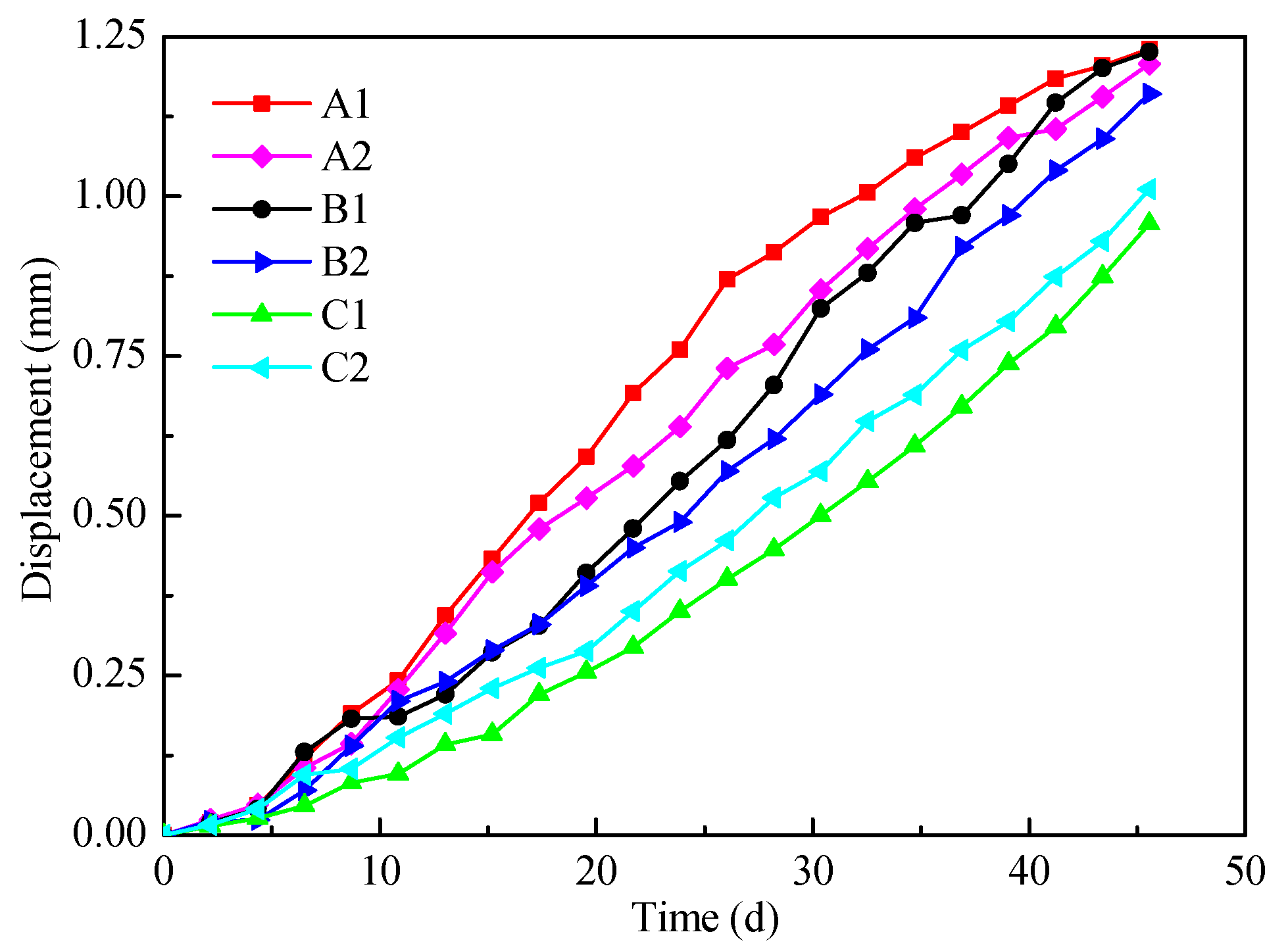

3.1. Displacement in Simultaneous Freezing Test

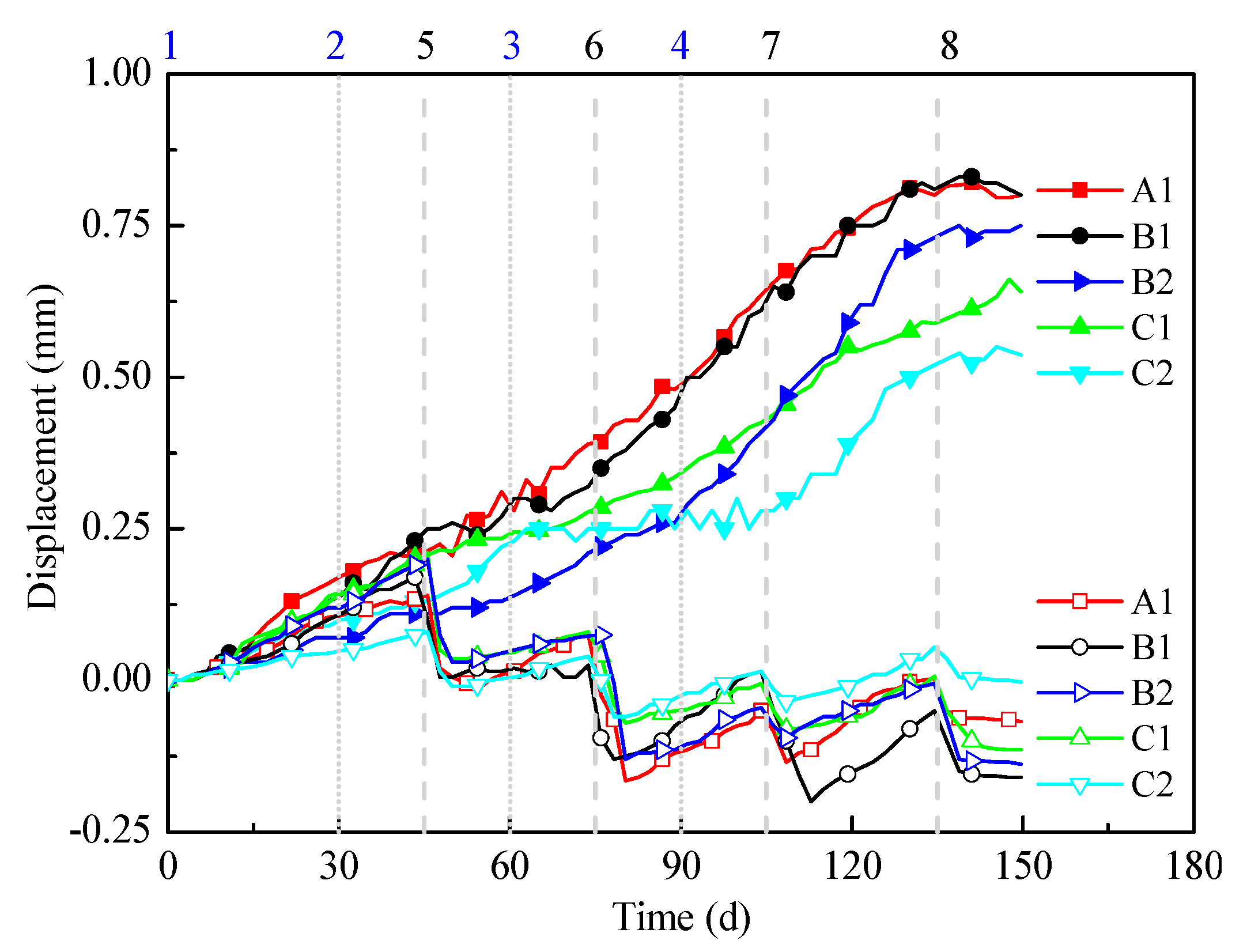

3.2. Displacement in Sequential Freezing Test

4. Conclusions

- (1)

- The experimental results show that, by the AFG method, both the maximum frost heave and the frost heaving increase velocity in a sequential freezing mode are less than that in a simultaneous freezing mode. The former can prevent and limit damage of frost heaving on sensitive and high-risk buildings.

- (2)

- The similarity simulation tests indicate that, by using the construction scheme of sequential freezing and excavation, deformation of base slab displays a zigzag shape under the dual action of frost heaving and excavation settlement. It implied that the sequential excavation of a tunnel can largely reduce frost heave.

- (3)

- Given that the frozen wall is uniformly spread in a closely underpassing projects, the maximum displacement of an upper-structure can be approximately estimated by the frost heave ratio of a soil sample.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Inose, K.; Kamegaya, I.; Ueda, A.; Imanaka, Y. Construction of the underground ventilation station while shield machines pass 1.5 m underneath. Tunn. Undergr. Sp. Technol. 2006, 21, 335–336. [Google Scholar] [CrossRef]

- Ercelebi, S.; Copur, H.; Ocak, I. Surface settlement predictions for Istanbul Metro tunnels excavated by EPB-TBM. Environ. Earth Sci. 2011, 62, 357–365. [Google Scholar] [CrossRef]

- Garner, C.D.; Coffman, R.A. Subway tunnel design using a ground surface settlement profile to characterize an acceptable configuration. Tunn. Undergr. Sp. Technol. 2013, 35, 219–226. [Google Scholar] [CrossRef]

- Ou, C.Y.; Teng, F.C.; Wang, I.W. Analysis and design of partial ground improvement in deep excavations. Comput. Geotech. 2008, 35, 576–584. [Google Scholar] [CrossRef]

- Ding, L.Y.; Yu, H.L.; Li, H.; Zhou, C.; Wu, X.G.; Yu, M.H. Safety risk identification system for metro construction on the basis of construction drawings. Automat. Constr. 2012, 27, 120–137. [Google Scholar] [CrossRef]

- Zhou, X.; Shen, S.; Xu, Y.; Zhou, A. Analysis of production safety in the construction industry of China in 2018. Sustainability 2019, 11, 4537. [Google Scholar] [CrossRef]

- Farrokh, E.; Rostami, J. Effect of adverse geological condition on TBM operation in Ghomroud tunnel conveyance project. Tunn. Undergr. Sp. Technol. 2009, 24, 436–446. [Google Scholar] [CrossRef]

- Nikbakhtan, B.; Osanloo, M. Effect of grout pressure and grout flow on soil physical and mechanical properties in jet grouting operations. Int. J. Rock Mech. Min. 2009, 46, 498–505. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, P.; Tian, S. Prevention and treatment technologies of railway tunnel water inrush and mud gushing in China. J. Rock Mech. Geotech. 2013, 5, 468–477. (In Chinese) [Google Scholar] [CrossRef]

- Russo, G.; Corbo, A.; Cavuoto, F.; Autuori, S. Artificial ground freezing to excavate a tunnel in sandy soil. Measurements and back analysis. Tunn. Undergr. Sp. Technol. 2015, 50, 226–238. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Li, Y.; Yao, K. Artificial ground freezing in tunnelling through aquifer soil layers: A case study in Nanjing Metro Line 2. KSCE J. Civ. Eng. 2018, 22, 4136–4142. [Google Scholar] [CrossRef]

- Yan, Q.; Xu, Y.; Yang, W.; Geng, P. Nonlinear transient analysis of temperature fields in an AGF project used for a cross-passage tunnel in the Suzhou Metro. KSCE J. Civ. Eng. 2018, 22, 1473–1483. [Google Scholar] [CrossRef]

- Hu, X.; Wang, J.; Yu, R. Uniaxial compressive and splitting tensile tests of artificially frozen soils in tunnel construction of Hong Kong. J. Shanghai Jiaotong Univ. 2013, 18, 688–692. [Google Scholar] [CrossRef]

- Zheng, H.; Kanie, S.; Niu, F.; Akagawa, S.; Li, A. Application of practical one-dimensional frost heave estimation method in two-dimensional situation. Soils Found. 2016, 56, 904–914. [Google Scholar] [CrossRef]

- Hu, X.; Deng, S. Ground freezing application of intake installing construction of an underwater tunnel. Procedia Eng. 2016, 165, 633–640. [Google Scholar] [CrossRef]

- Zhou, J.; Tang, Y. Practical model of deformation prediction in soft clay after artificial ground freezing under subway low-level cyclic loading. Tunn. Undergr. Sp. Technol. 2018, 76, 30–42. [Google Scholar] [CrossRef]

- Taber, S. The mechanics of frost heaving. J. Geol. 1930, 38, 303–317. [Google Scholar] [CrossRef]

- Ye, M.; Hufangfu, Y.; Mao, X. Freeze depth predicting of permafrost subgrade based on moisture and thermal coupling model. KSCE J. Civ. Eng. 2015, 19, 1707–1715. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, D.; Li, G.; Qin, L.; Luo, K.; Liu, J. Optimizing the grouting design for groundwater inrush control in completely weathered granite tunnel: An experimental and field investigation. Sustainability 2019, 11, 3636. [Google Scholar] [CrossRef]

- Addenbrooke, T.; Potts, D. Twin tunnel interaction: Surface and subsurface effects. Int. J. Geomech. 2001, 1, 249–271. [Google Scholar] [CrossRef]

- Cooper, M.L.; Chapman, D.N.; Rogers, C.D.; Hansmire, W. Prediction of settlement in existing tunnel caused by the second of twin tunnels. Transp. Res. Rec. 2002, 1814, 103–111. [Google Scholar] [CrossRef]

- Chen, R.P.; Zhu, J.; Liu, W.; Tang, X.W. Ground movement induced by parallel EPB tunnels in silty soils. Tunn. Undergr. Sp. Technol. 2011, 26, 163–171. [Google Scholar] [CrossRef]

- Cai, H.; Peng, L.; Zheng, T. A duration prediction model of surface frost heave induced by tunnelling with horizontal freezing method. Rock Soil Mech. 2012, 33, 1761–1768. (In Chinese) [Google Scholar] [CrossRef]

- Divall, S. Ground Movements Associated with Twin-Tunnel Construction in Clay. Ph.D. Thesis, City University of London, London, UK, 2013. [Google Scholar]

- Ocak, I. A new approach for estimating the transverse surface settlement curve for twin tunnels in shallow and soft soils. Environ. Earth Sci. 2014, 72, 2357–2367. [Google Scholar] [CrossRef]

- Zhou, X.; Lin, F.; Ren, X.; Yang, G. The freezing stress and displacement field and its control technique during the tunnel construction under the metro line. Chin. Q. Mech. 2005, 26, 438–443. (In Chinese) [Google Scholar] [CrossRef]

- Van Dorst, A. Artificial Ground Freezing as a Construction Method for Underground Spaces in Densely Built up Areas. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2013. [Google Scholar]

- Gioda, G.; Locatelli, L.; Gallavresi, F. A numerical and experimental study of the artificial freezing of sand. Can. Geotech. J. 1994, 31, 1–11. [Google Scholar] [CrossRef]

- Chen, H.; Yu, H.; Smith, M.J. Physical model tests and numerical simulation for assessing the stability of brick-lined tunnels. Tunn. Undergr. Sp. Technol. 2016, 53, 109–119. [Google Scholar] [CrossRef]

- Feng, Q.; Jiang, B.; Zhang, Q.; Wang, G. Reliability research on the 5-cm-thick insulation layer used in the Yuximolegai tunnel based on a physical model test. Cold Reg. Sci. Technol. 2016, 124, 54–66. [Google Scholar] [CrossRef]

- Sayles, F.; Baker, T.; Gallavres, F.; Jessberger, H.; Kinosita, S.; Sadovskiy, A.; Sego, D.; Vyalov, S. Classification and laboratory testing of artificially frozen ground. J. Cold Reg. Eng. 1987, 1, 22–48. [Google Scholar] [CrossRef]

- Yao, Z.; Cai, H.; Cheng, H. The model test study on frost heaving and melting sedimentation of subway tunnel construction with manual level freezing method. Adv. Mat. Res. 2011, 243, 3476–3483. [Google Scholar] [CrossRef]

- Alzoubi, M.A.; Nie-Rouquette, A.; Sasmito, A.P. Conjugate heat transfer in artificial ground freezing using enthalpy-porosity method: Experiments and model validation. Int. J. Heat Mass Transf. 2018, 126, 740–752. [Google Scholar] [CrossRef]

- Zhou, J.; Tang, Y. Centrifuge experimental study of thaw settlement characteristics of mucky clay after artificial ground freezing. Eng. Geol. 2015, 190, 98–108. [Google Scholar] [CrossRef]

- Matsuoka, N.; Abe, M.; Ijiri, M. Differential frost heave and sorted patterned ground: Field measurements and a laboratory experiment. Geomorphology 2003, 52, 73–85. [Google Scholar] [CrossRef]

- Eslami-nejad, P.; Bernier, M. Freezing of geothermal borehole surroundings: A numerical and experimental assessment with applications. Appl. Energy 2012, 98, 333–345. [Google Scholar] [CrossRef]

- Kurylyk, B.L.; McKenzie, J.M.; MacQuarrie, K.T.; Voss, C.I. Analytical solutions for benchmarking cold regions subsurface water flow and energy transport models: One-dimensional soil thaw with conduction and advection. Adv. Water Resour. 2014, 70, 172–184. [Google Scholar] [CrossRef]

- Hu, R.; Liu, Q.; Xing, Y. Case study of heat transfer during artificial ground freezing with groundwater flow. Water 2018, 10, 1322. [Google Scholar] [CrossRef]

- Pimentel, E.; Sres, A.; Anagnostou, G. Large-scale laboratory tests on artificial ground freezing under seepage-flow conditions. Geotechnique 2012, 62, 227. [Google Scholar] [CrossRef]

- Yang, X.; Ji, Z.; Zhang, P.; Qi, J. Model test and numerical simulation on the development of artificially freezing wall in sandy layers considering water seepage. Transp. Geotech. 2019, 21, 100293. [Google Scholar] [CrossRef]

- Hu, X.; Deng, S.; Ren, H. In situ test study on freezing scheme of freeze-sealing pipe roof applied to the Gongbei tunnel in the Hong Kong-Zhuhai-Macau bridge. Appl. Sci. 2017, 7, 27. [Google Scholar] [CrossRef]

- Hu, X.; Fang, T.; Chen, J.; Ren, H.; Guo, W. A large-scale physical model test on frozen status in freeze-sealing pipe roof method for tunnel construction. Tunn. Undergr. Sp. Technol. 2018, 72, 55–63. [Google Scholar] [CrossRef]

- Hu, X.; Wu, Y.; Li, X. A field study on the freezing characteristics of freeze-sealing pipe roof used in ultra-shallow buried tunnel. Appl. Sci. 2019, 9, 1532. [Google Scholar] [CrossRef]

- Taherdangkoo, R.; Abdideh, M. Application of wavelet transform to detect fractured zones using conventional well logs data (Case study: Southwest of Iran). Int. J. Pet. Eng. 2016, 2, 125–139. [Google Scholar] [CrossRef]

- Qiu, P.; Hu, R.; Hu, L.; Liu, Q.; Xing, Y.; Yang, H.; Qi, J.; Ptak, T. A numerical study on travel time based hydraulic tomography using the SIRT algorithm with Cimmino Iteration. Water 2019, 11, 909. [Google Scholar] [CrossRef]

- Taherdangkoo, R.; Abdideh, M. Fracture density estimation from well logs data using regression analysis: Validation based on image logs (Case study: South West Iran). Int. J. Pet. Eng. 2016, 2, 289–301. [Google Scholar] [CrossRef]

- Marwan, A.; Zhou, M.-M.; Abdelrehim, M.Z.; Meschke, G. Optimization of artificial ground freezing in tunneling in the presence of seepage flow. Comput. Geotech. 2016, 75, 112–125. [Google Scholar] [CrossRef]

- Cui, G. Simulation test theory of freezing method shaft sinking. J. China Univ. Min. Technol. 1989, 18, 59–68. (In Chinese) [Google Scholar]

- Cai, H.; Li, S.; Liang, Y.; Yao, Z.; Cheng, H. Model test and numerical simulation of frost heave during twin-tunnel construction using artificial ground-freezing technique. Comput. Geotech. 2019, 115, 1–11. [Google Scholar] [CrossRef]

- Liu, L.; Li, Z.; Liu, X.; Li, Y. Frost front research of a cold-region tunnel considering ventilation based on a physical model test. Tunn. Undergr. Sp. Technol. 2018, 77, 261–279. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, M.; Tao, L.; Yang, S. Model test and prototype observation on artifical ground freezing and tunneling of Beijing subway. Chin. J. Geotech. Eng. 2003, 25, 676–679. (In Chinese) [Google Scholar] [CrossRef]

- Harris, C.; Murton, J.; Davies, M.C. Soft-sediment deformation during thawing of ice-rich frozen soils: Results of scaled centrifuge modelling experiments. Sedimentology 2000, 47, 687–700. [Google Scholar] [CrossRef]

- Zhou, J.; Tang, Y. Artificial ground freezing of fully saturated mucky clay: Thawing problem by centrifuge modeling. Cold Reg. Sci. Technol. 2015, 117, 1–11. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, G.; Ma, W.; Wang, J.; Zhou, Y.; Ji, S. Experimental research on controlling frost heave of artificial frozen soil with intermission freezing method. J. China Univ. Min. Technol. 2006, 35, 708–712. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, Y.; Zhou, G. Intermittent freezing mode to reduce frost heave in freezing soils-experiments and mechanism analysis. Can. Geotech. J. 2012, 49, 686–693. [Google Scholar] [CrossRef]

- Cai, H.; Liu, Z.; Li, S.; Zheng, T. Improved analytical prediction of ground frost heave during tunnel construction using artificial ground freezing technique. Tunn. Undergr. Sp. Technol. 2019, 92, 103050. [Google Scholar] [CrossRef]

| Material | Density (g cm−³) | Water Content (%) | Saturation (%) | Freezing Temperature (°C) | Specific Heat Capacity (W·m−1·°C−1) |

|---|---|---|---|---|---|

| Clay | 1.78 | 38.5 | 97 | 0.1 | 1.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Wang, Y.; Li, F.; Liu, Z.; Lu, C. Influence of Different Freezing Modes on the Base Slab Displacement of an Upper Structure. Appl. Sci. 2020, 10, 27. https://doi.org/10.3390/app10010027

Wang L, Wang Y, Li F, Liu Z, Lu C. Influence of Different Freezing Modes on the Base Slab Displacement of an Upper Structure. Applied Sciences. 2020; 10(1):27. https://doi.org/10.3390/app10010027

Chicago/Turabian StyleWang, Lei, Yanting Wang, Fangzheng Li, Zhiqiang Liu, and Chunsheng Lu. 2020. "Influence of Different Freezing Modes on the Base Slab Displacement of an Upper Structure" Applied Sciences 10, no. 1: 27. https://doi.org/10.3390/app10010027

APA StyleWang, L., Wang, Y., Li, F., Liu, Z., & Lu, C. (2020). Influence of Different Freezing Modes on the Base Slab Displacement of an Upper Structure. Applied Sciences, 10(1), 27. https://doi.org/10.3390/app10010027