A Novel Fault Diagnosis Method for High-Temperature Superconducting Field Coil of Superconducting Rotating Machine

Abstract

1. Introduction

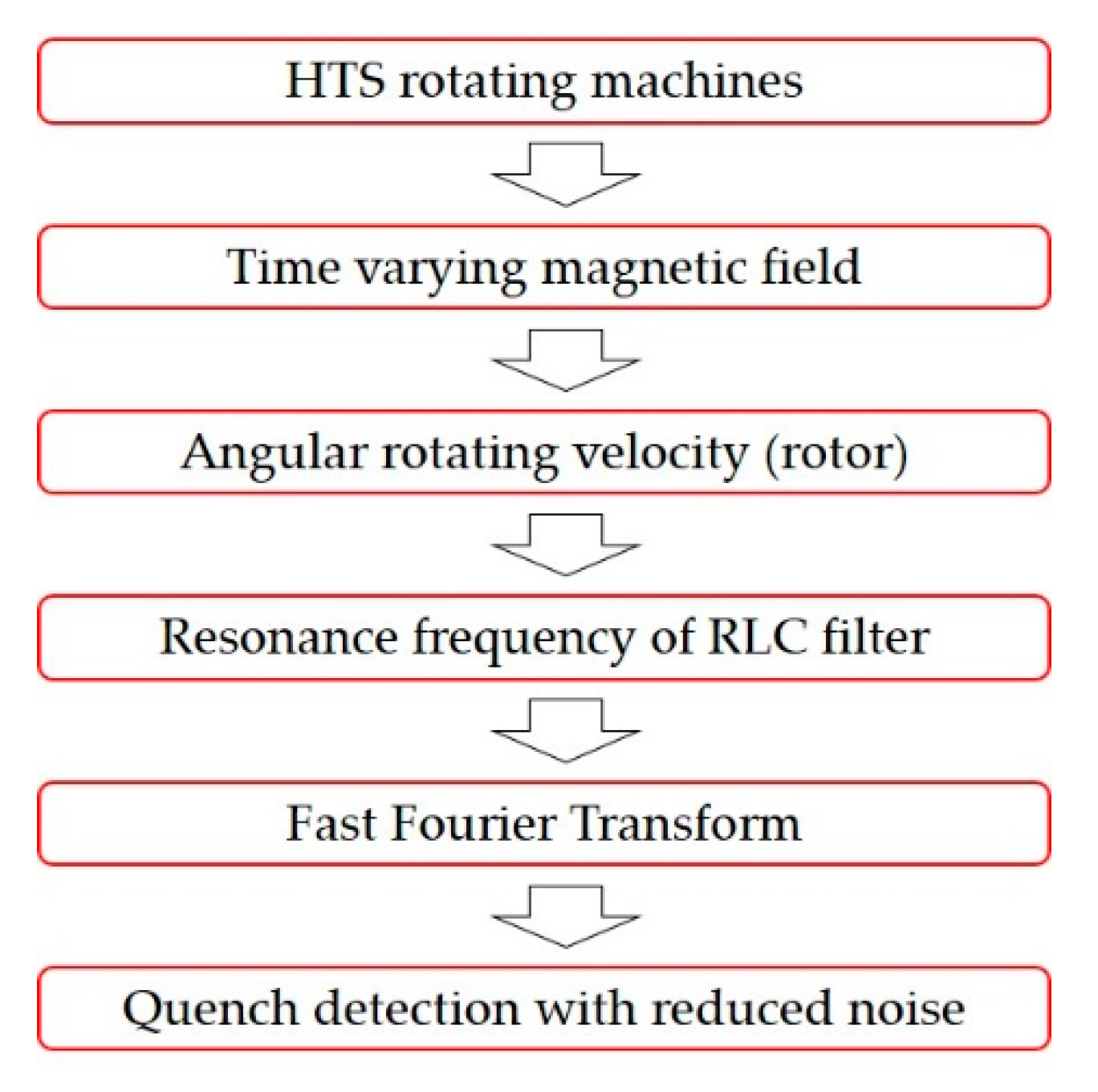

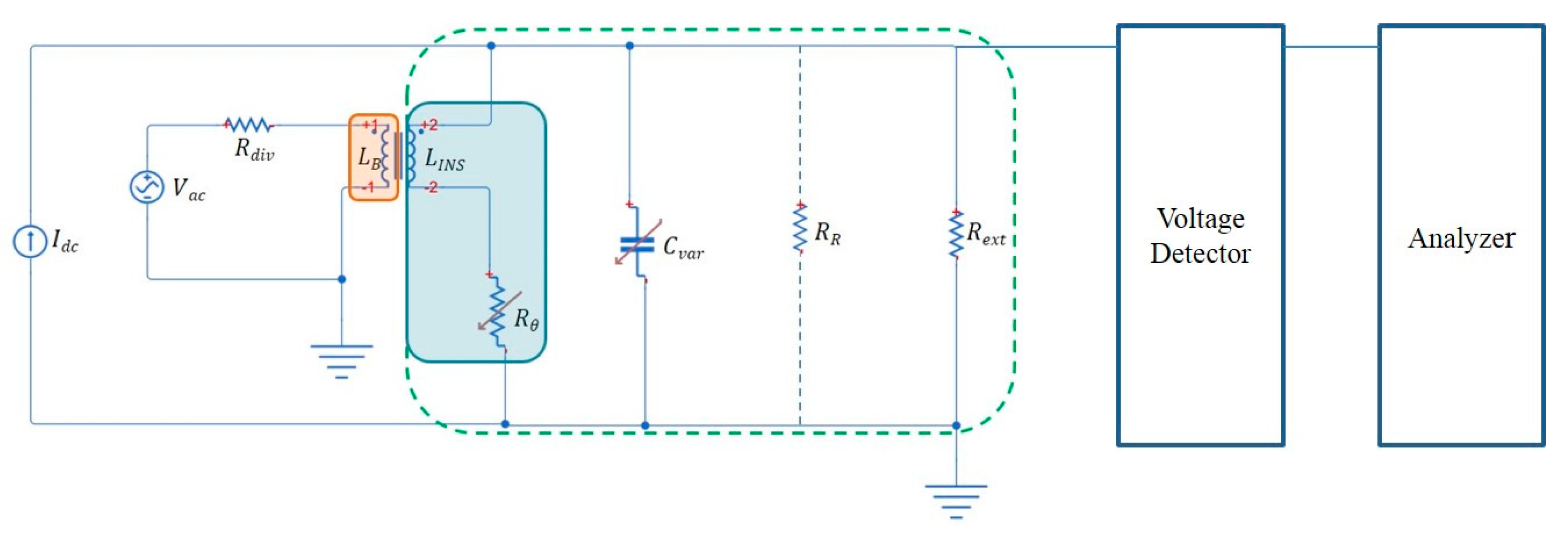

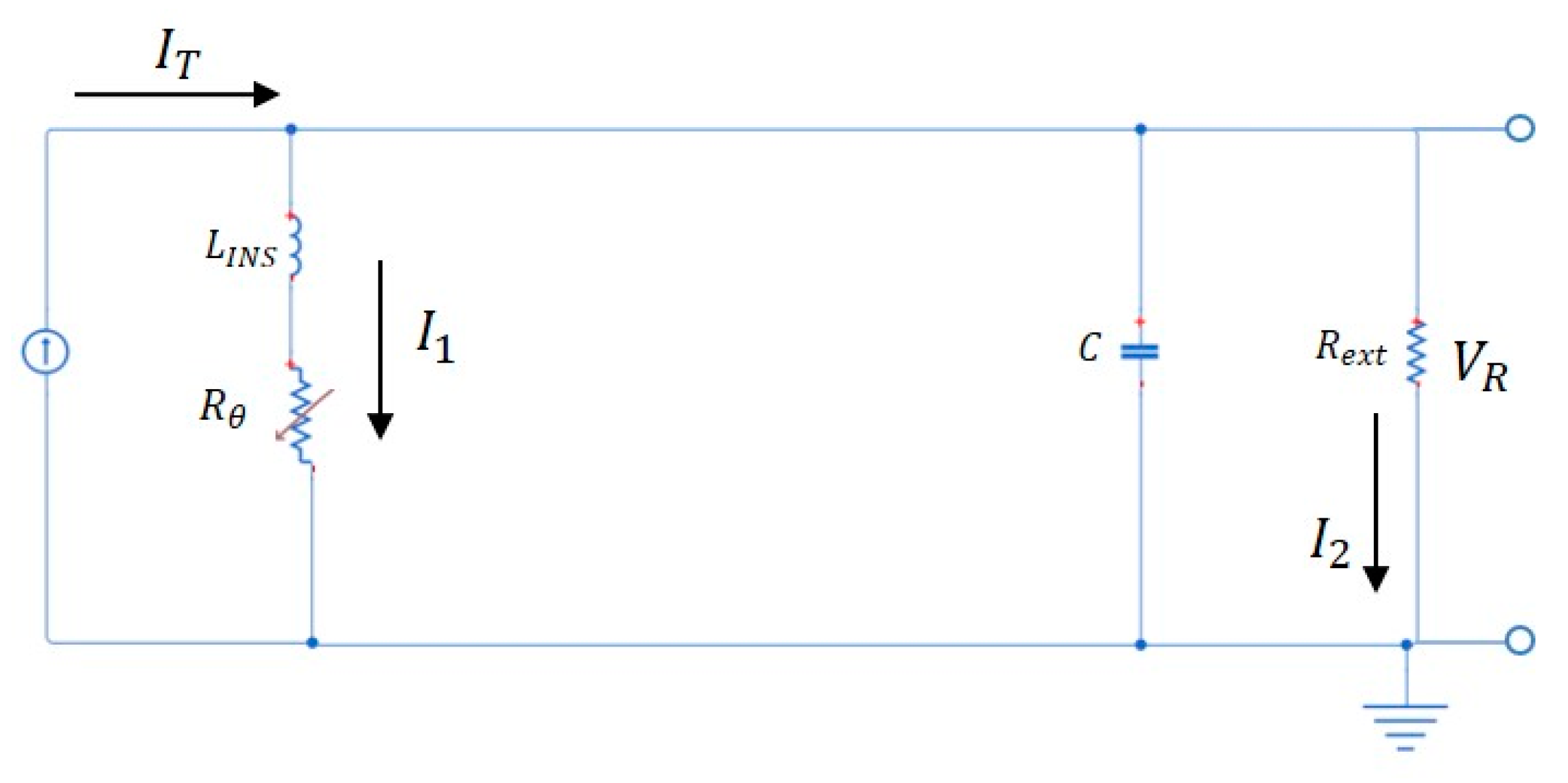

2. Analysis of a New Active Quench Detection Method for High-Temperature Superconducting Magnets

2.1. Concept of the Proposed Method

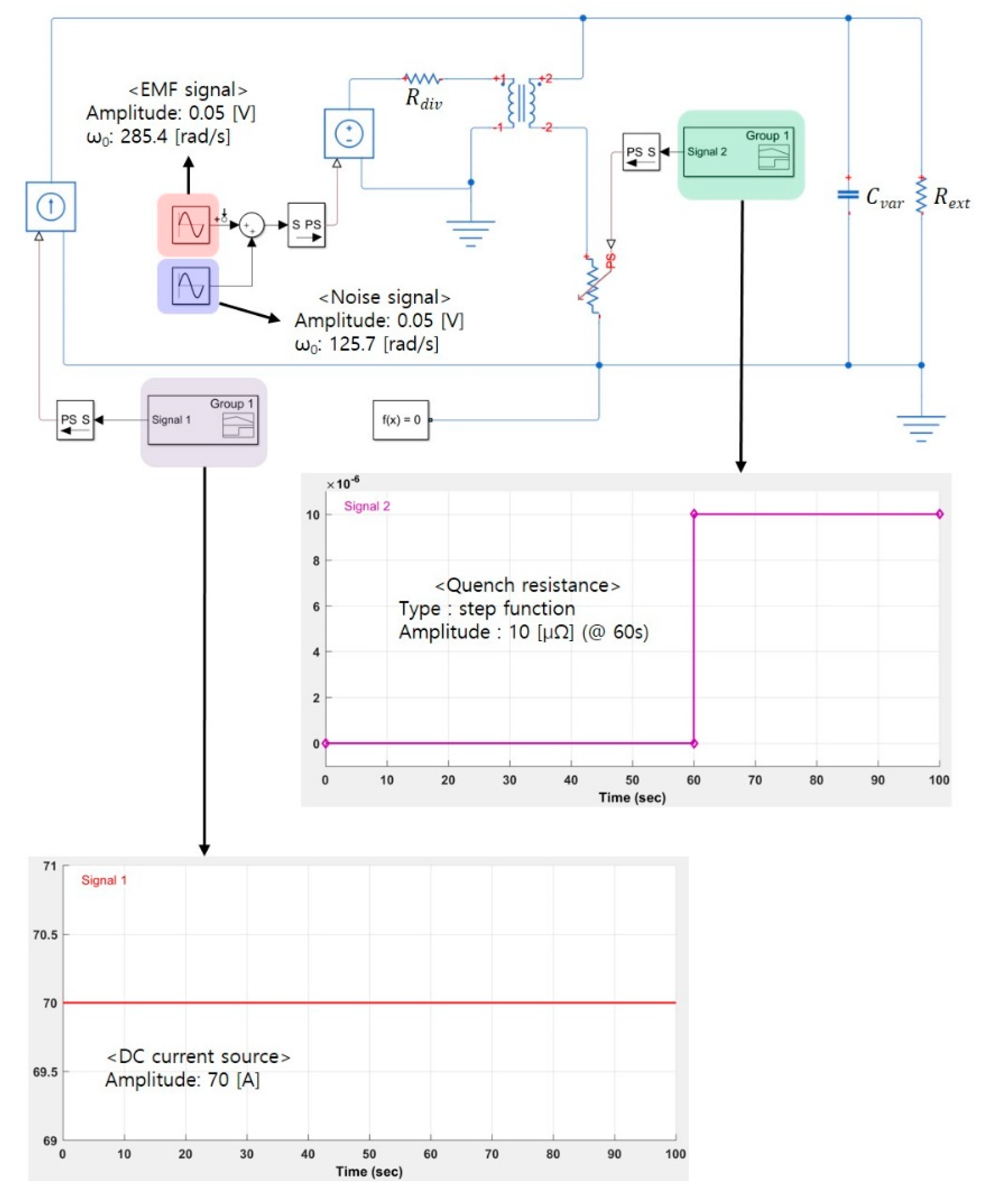

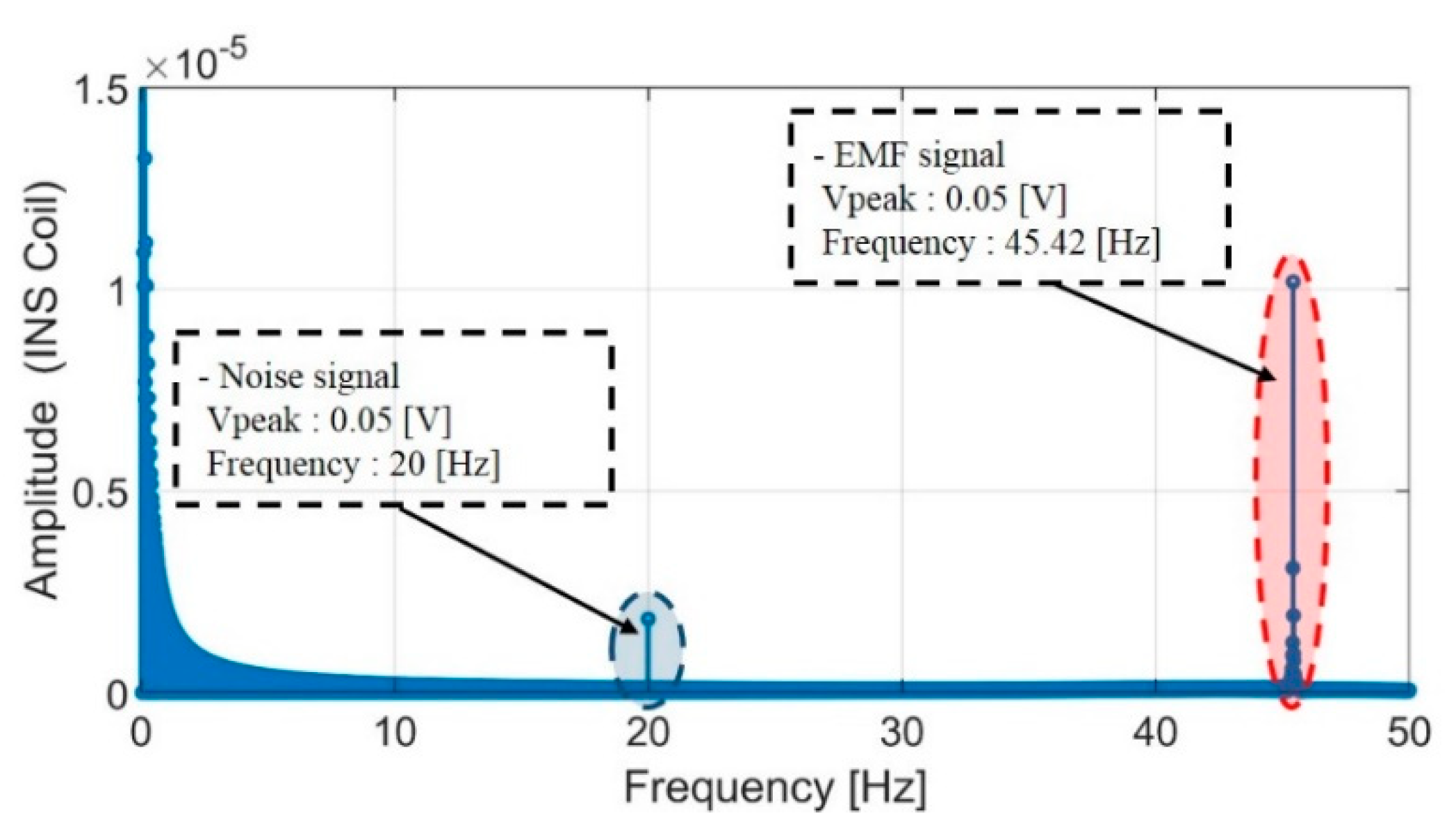

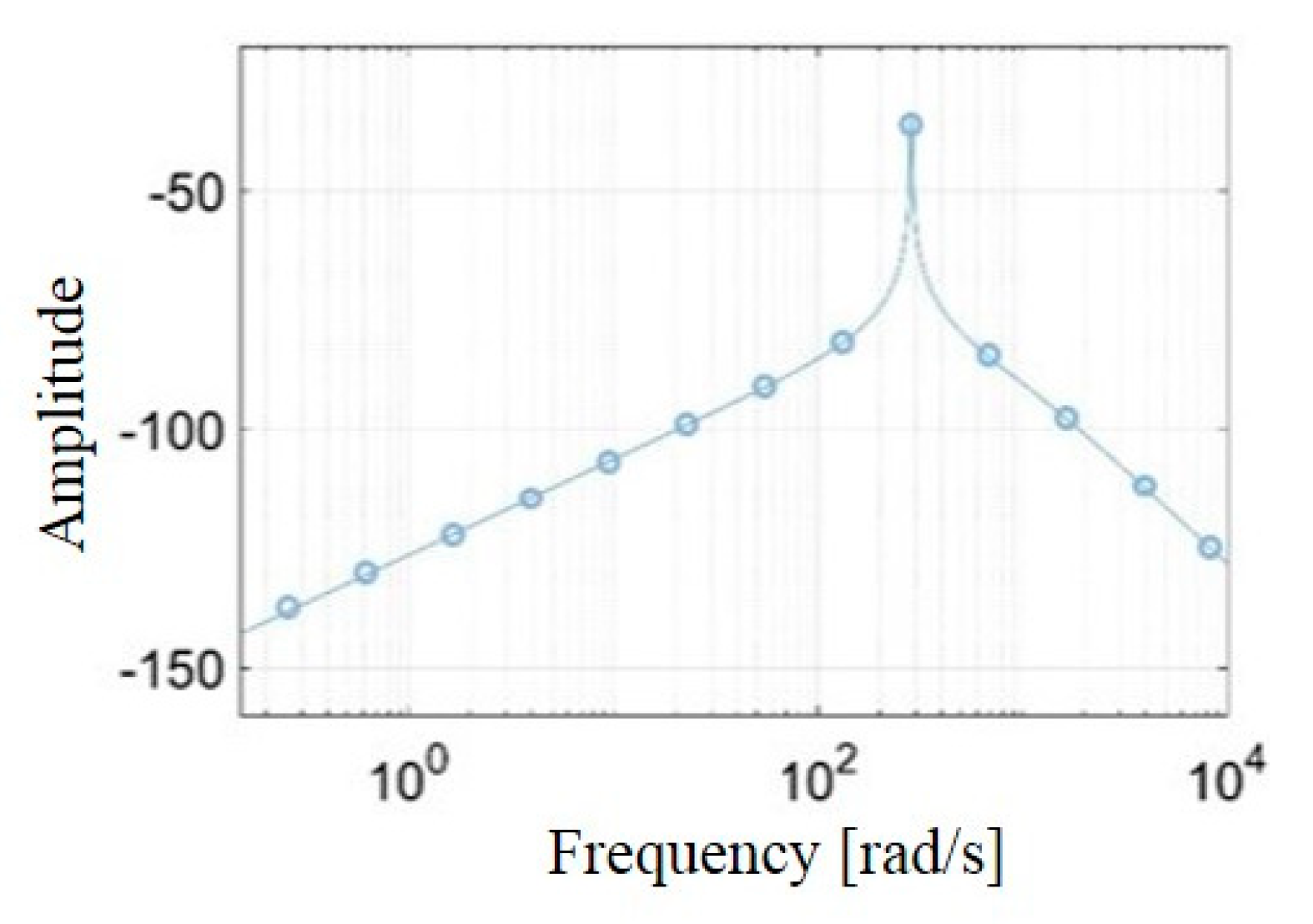

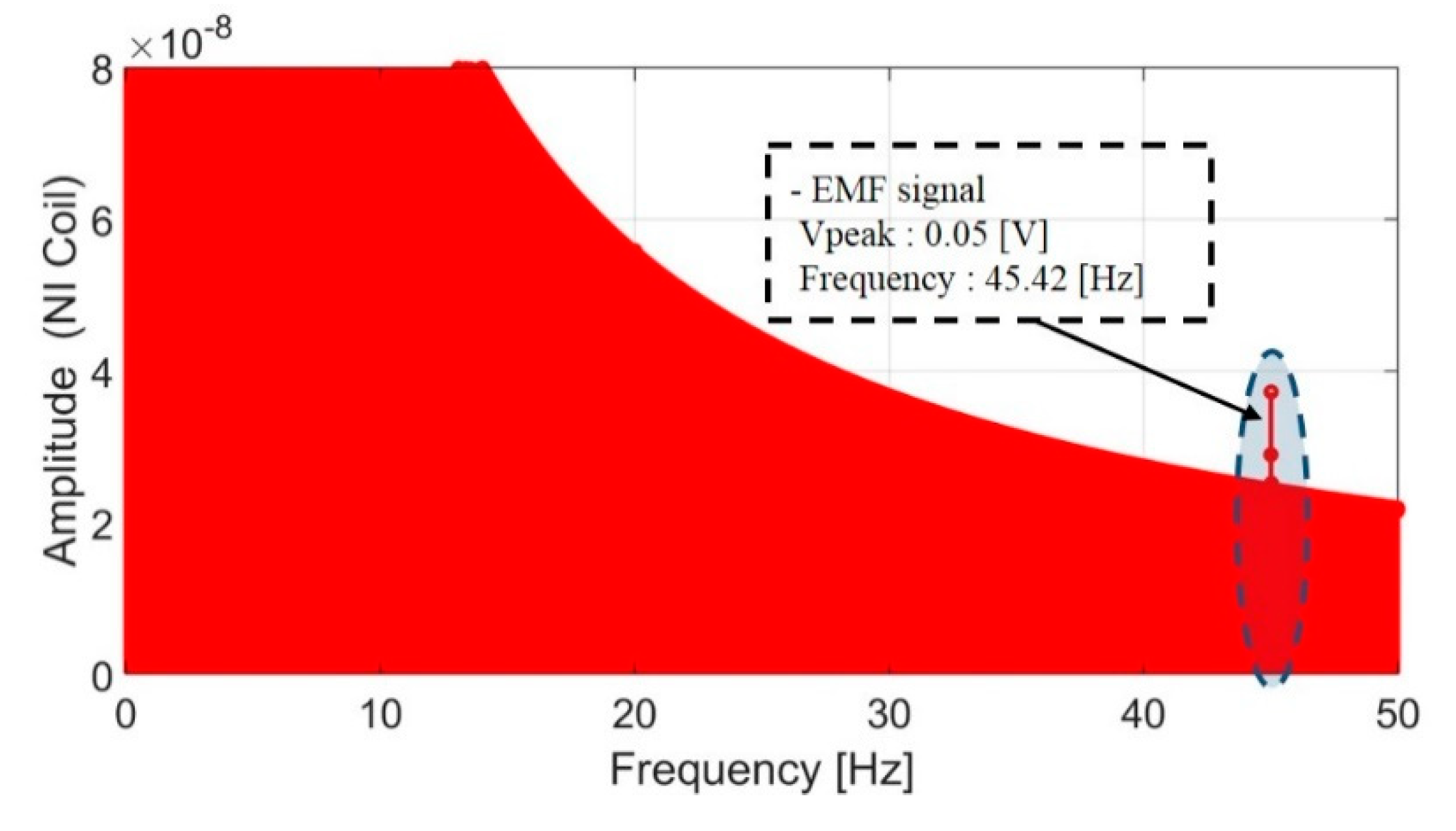

2.2. Simulation Results

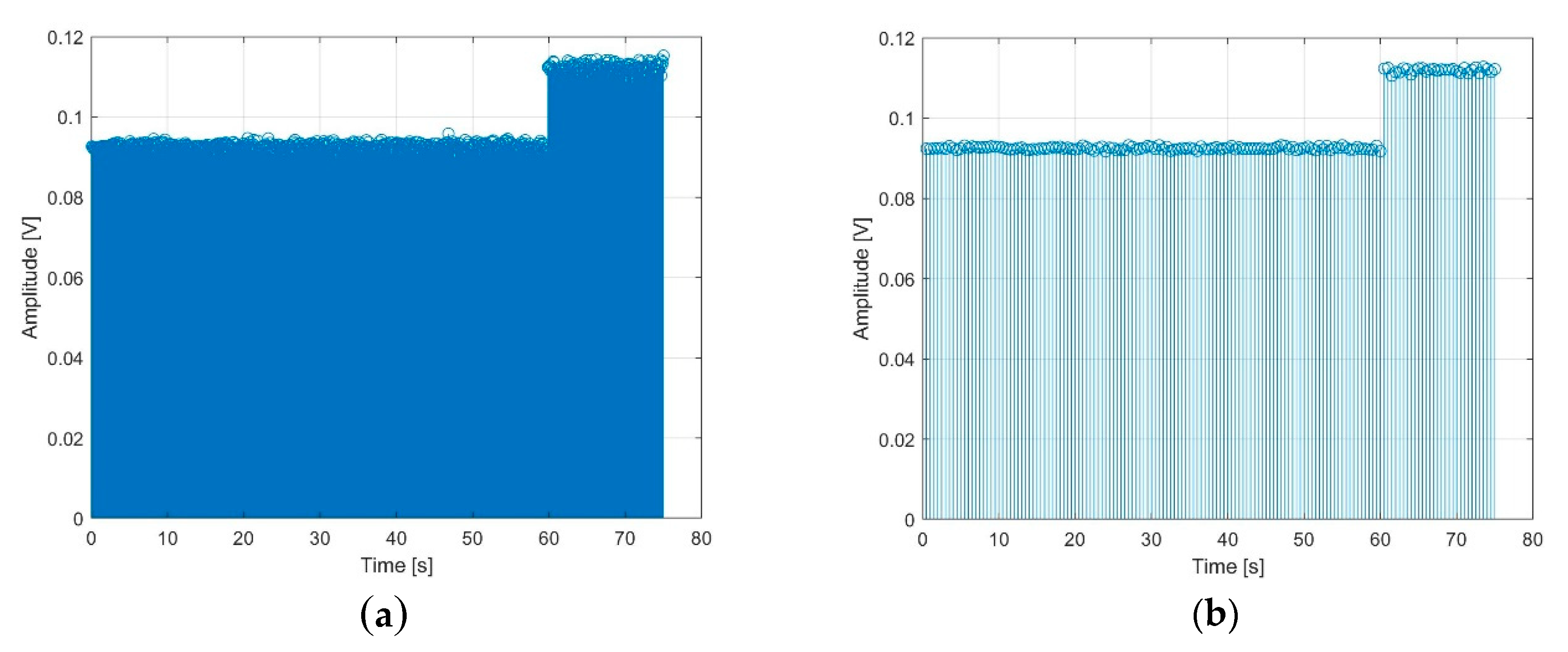

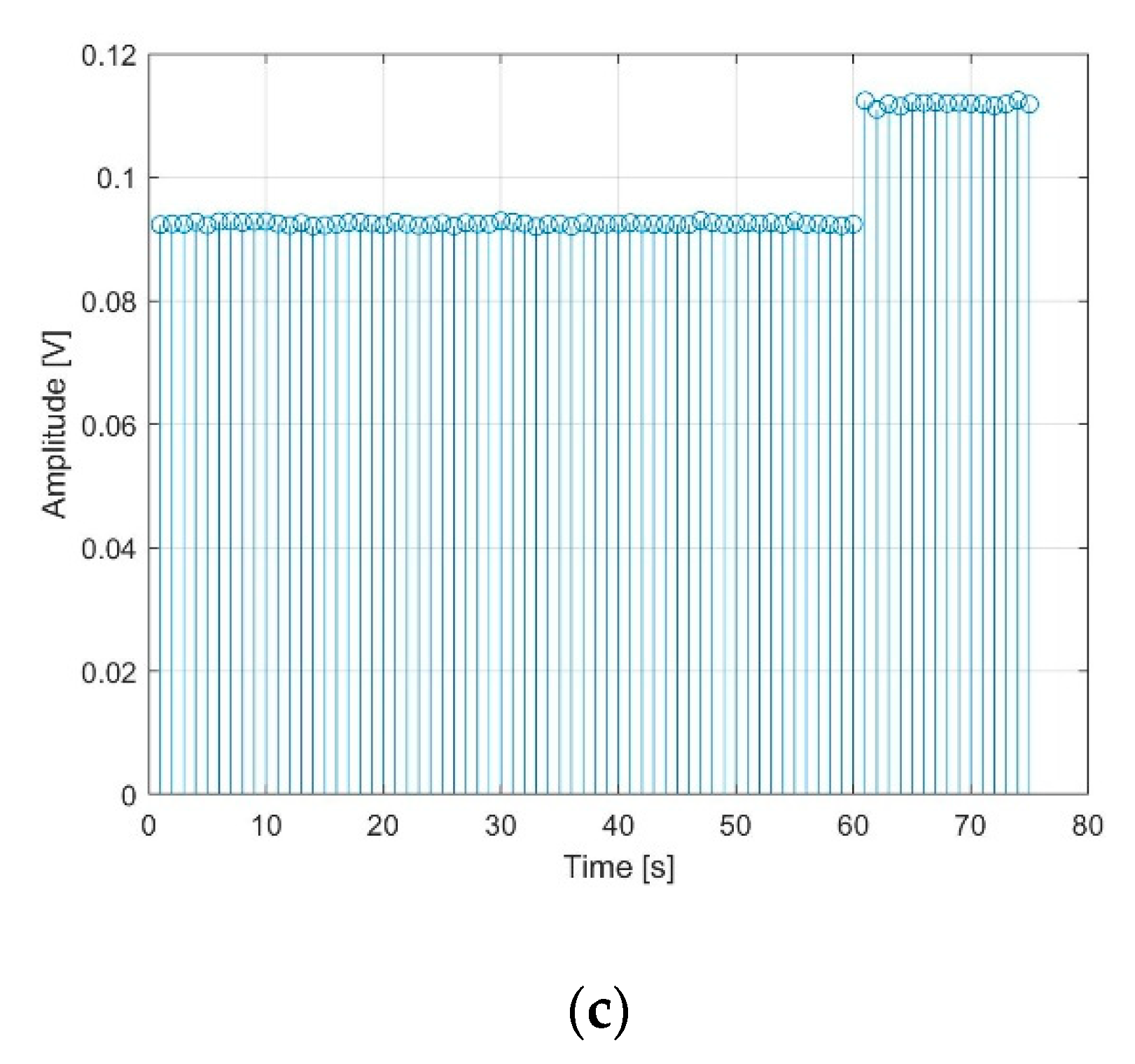

3. Experimental Results

4. Discussion and Outlooks

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ravaioli, E.; Davis, D.; Marchevsky, M.; Sabbi, G.; Shen, T.; Verweij, A.; Zhang, K. A new quench detection method for HTS magnets: Stray-capacitance change monitoring. Phys. Scr. 2019, 95, 015002. [Google Scholar] [CrossRef]

- Marchevsky, M.; Gourlay, S.A. Acoustic thermometry for detecting quenches in superconducting coils and conductor stacks. Appl. Phys. Lett. 2017, 110, 012601. [Google Scholar] [CrossRef]

- Makoto, T. An Acoustic Quench Detection Method for CICC Conductor Operating in Gas or Liquid. IEEE Trans. Appl. Supercond. 2019, 29, 4702305. [Google Scholar]

- Ryan, D.T.; Laskaris, E.T.; Huang, X. Quench Monitoring and Control System and Method of Operating Same. U.S. Patent 7,053,509,B2, 30 May 2006. [Google Scholar]

- Wang, X.; Guan, M.; Ma, L. Strain-based quench detection for a solenoid superconducting magnet. Supercond. Sci. Technol. 2012, 25, 095009. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, X.; Guan, M.; Wu, B. Strain responses of superconducting magnets based on embedded polymer-FBG and cryogenic resistance strain gauge measurements. IEEE Trans. Appl. Supercond. 2018, 29, 8400207. [Google Scholar] [CrossRef]

- Nanato, N.; Yanagishita, M.; Nakamura, K. Quench detection of Bi-2223 HTS coil by partial active power detecting method. IEEE Trans. Appl. Supercond. 2001, 11, 2391–2393. [Google Scholar] [CrossRef]

- Wei, B.; Yang, Y.; Qiu, M.; Zhang, H.; Zhu, J.; Chen, P.; Zhu, D.; Lai, X. The quench detection system for YBCO superconducting magnets. IEEE Trans. Appl. Supercond. 2010, 20, 1369–1372. [Google Scholar]

- Nanato, N.; Nakamura, K. Quench detection method without a central voltage tap by calculating active power. Cryogenics 2004, 44, 1–5. [Google Scholar] [CrossRef]

- Hasegawa, S.; Ito, S.; Nishijima, G.; Hashizume, H. Fundamental Evaluations of Applicability of LTS Quench Detectors to REBCO Pancake Coil. IEEE Trans. Appl. Supercond. 2019, 29, 9001305. [Google Scholar] [CrossRef]

- Collier, K.A.; Sengupta, S.; Espinosa, C.A.; Kelly, J.E.; Kelz, J.I.; Martin, R.W. Design and construction of a quadruple-resonance MAS NMR probe for investigation of extensively deuterated biomolecules. J. Magn. Reson. 2017, 285, 8–17. [Google Scholar] [CrossRef]

- Gan, Z.; Hung, I.; Wang, X.; Paulino, J.; Wu, G.; Litvak, I.M.; Gor’kov, P.L.; Brey, W.W.; Lendi, P.; Schiano, J.L.; et al. NMR spectroscopy up to 35.2 T using a series-connected hybrid magnet. J. Magn. Reson. 2017, 284, 125–136. [Google Scholar] [CrossRef] [PubMed]

- Hwang, Y.J.; Ahn, M.C.; Lee, T.S.; Lee, W.S.; Ko, T.K. Experimental study of the effect of alternating fields on HTS coils According to the winding insulation conditions. Supercond. Sci. Technol. 2013, 26, 085021. [Google Scholar] [CrossRef]

- Song, S.; Choi, Y.; Lee, W.S.; Sim, K.; Hwang, Y.J.; Jang, J.Y. Analytic Study of the Active Quench Detection Method for High-Temperature Superconducting Magnet Using Resonance Circuit. IEEE Trans. Appl. Supercond. 2018, 28, 4701304. [Google Scholar] [CrossRef]

- Hahn, S.; Kim, Y.; Voccio, J.L.; Park, D.K.; Bascuñán, J.; Lee, H.S. Yukikazu Iwasa No-Insulation Coil Under Time-Varying Condition: Magnetic Coupling with External Coil. IEEE Trans. Appl. Supercond. 2013, 23, 4601705. [Google Scholar] [CrossRef]

- Prommee, P.; Thongdit, P.; Angkeaw, K. Log-domain high-order low-pass and band-pass filters. Int. J. Electron. Commun. 2017, 79, 234–242. [Google Scholar] [CrossRef]

- Huang, Q.; Rajashekara, K. Virtual RLC active damping for grid-connected inverters with LCL filters. IEEE Appl. Power Electron. Conf. Expo. (APEC) 2017, 424–429. [Google Scholar] [CrossRef]

- Murta-Pina, J.; Vilhena, N.; Arsénio, P.; Pronto, A.; Álvarez, A. Preliminary Design and Test of Low-Resistance High Temperature Superconducting Short-Circuited Coils. IEEE Trans. Appl. Supercond. 2018, 28, 4604105. [Google Scholar] [CrossRef]

- Xie, Y.; Quyang, Z.; Shi, L.; Kuang, Z.; Meng, M. Experimental studies of diffusion welding of YBCO to copper using solder layers. IOP Conf. Ser. Mater. Sci. Eng. 2017, 171, 012155. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, W.S.; Song, S.; Jeon, H.; Ko, T.K. A New Quench Protection System Using Dual-Capacitor Switching for Fast Energy Extraction from HTS Magnets. IEEE Trans. Appl. Supercond. 2019, 29, 4702905. [Google Scholar] [CrossRef]

- Lee, J.; Ko, T.K. Estimation of the Engineering Critical Current Criteria for HTS Wire Carrying an Alternating Current. IEEE Trans. Appl. Supercond. 2014, 24, 9001705. [Google Scholar]

- Claeys, T.; Vanoost, D.; Peuteman, J.; Vandenbosch, G.A.E.; Pissoort, D. An iterative interpolated dft to remove spectral leakage in time-domain near-field scanning. IEEE Trans. Electromagn. Compat. 2017, 60, 202–210. [Google Scholar] [CrossRef]

- Hasegawa, S.; Ito, S.; Hashizume, H. Numerical and Experimental Evaluations of the Quench Detection Performance of an YBCO/Nb–Ti d Tape. IEEE Trans. Appl. Supercond. 2018, 28, 4700605. [Google Scholar] [CrossRef]

- Ahn, M.C.; Yang, H.; Kim, K.; Jang, J.Y.; Lee, S.; Hahn, S. Optimal design methodology of multiwidth HTS magnet for minimum wire consumption. IEEE Trans. Appl. Supercond. 2018, 28, 4602905. [Google Scholar] [CrossRef]

- Jang, J.; Yoon, S.; Hahn, S.; Hwang, Y.J.; Kim, J.; Shin, K.H.; Cheon, K.; Kim, K.; In, S.; Hong, Y.; et al. Design, construction and 13 K conduction-cooled operation of a 3 T 100 mm stainless steel cladding all-REBCO magnet. Supercond. Sci. Technol. 2017, 30, 105012. [Google Scholar] [CrossRef]

| Parameters | Values | ||

|---|---|---|---|

| VAC | EMF | Peak [Vpeak] | 0.5 |

| Frequency [Hz] | 45.42 | ||

| Noise | Peak [Vpeak] | 0.5 | |

| Frequency [Hz] | 20 | ||

| Rdiv [kΩ] | 1 | ||

| RR [mΩ] | 0.4 | ||

| Rext [Ω] | 5 | ||

| Idc [A] | 70 | ||

| Rθ [μΩ] | 10 | ||

| LB [mH] | 11.4 | ||

| LINS [mH] | 0.123 | ||

| LNI [mH] | 0.125 | ||

| Mutual inductance | 0.04 | ||

| Stator Coil | Rotor Coil | |||

|---|---|---|---|---|

| NI Coil | INS Coil | |||

| IC (@ 77K, Self) [A] | <80 | <65 | - | |

| Coil Type | Single Pancake | Solenoid | ||

| Turns | 30 | - | ||

| I.D. [mm] | 65 | 100 | ||

| O.D. [mm] | 80 | 83 | 120 | |

| Inductance [mH] | 0.125 | 0.123 | 11.4 | |

| Time Constant [ms] | 70 | 400 | - | |

| Insulation Material/Thickness [mm] | - | Kapton/0.05 | ||

| HTS Tape | Type | SuNAM 2G HTS Tape | ||

| Width [mm] | 4 | 12 | ||

| Thickness [mm] | 0.25 | |||

| Condition Positive | Condition Negative | |

|---|---|---|

| Predicted Condition Positive | True Positive (=153) | False Positive (=27) |

| True Positive Rate (=1) | False Positive Rate (=0.045) | |

| Predicted Condition Negative | False Negative (=0) | True negative (=573) |

| False Negative Rate (=0) | True negative Rate (=0.955) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, S.; Ko, T.K.; Choi, Y.; Lee, S. A Novel Fault Diagnosis Method for High-Temperature Superconducting Field Coil of Superconducting Rotating Machine. Appl. Sci. 2020, 10, 223. https://doi.org/10.3390/app10010223

Song S, Ko TK, Choi Y, Lee S. A Novel Fault Diagnosis Method for High-Temperature Superconducting Field Coil of Superconducting Rotating Machine. Applied Sciences. 2020; 10(1):223. https://doi.org/10.3390/app10010223

Chicago/Turabian StyleSong, Seunghyun, Tae Kuk Ko, Yojong Choi, and SangGap Lee. 2020. "A Novel Fault Diagnosis Method for High-Temperature Superconducting Field Coil of Superconducting Rotating Machine" Applied Sciences 10, no. 1: 223. https://doi.org/10.3390/app10010223

APA StyleSong, S., Ko, T. K., Choi, Y., & Lee, S. (2020). A Novel Fault Diagnosis Method for High-Temperature Superconducting Field Coil of Superconducting Rotating Machine. Applied Sciences, 10(1), 223. https://doi.org/10.3390/app10010223