Development of Biomass Gasification Technology with Fluidized-Bed Reactors for Enhancing Hydrogen Generation: Part I, Hydrodynamic Characterization of Dual Fluidized-Bed Gasifiers

Abstract

Featured Application

Abstract

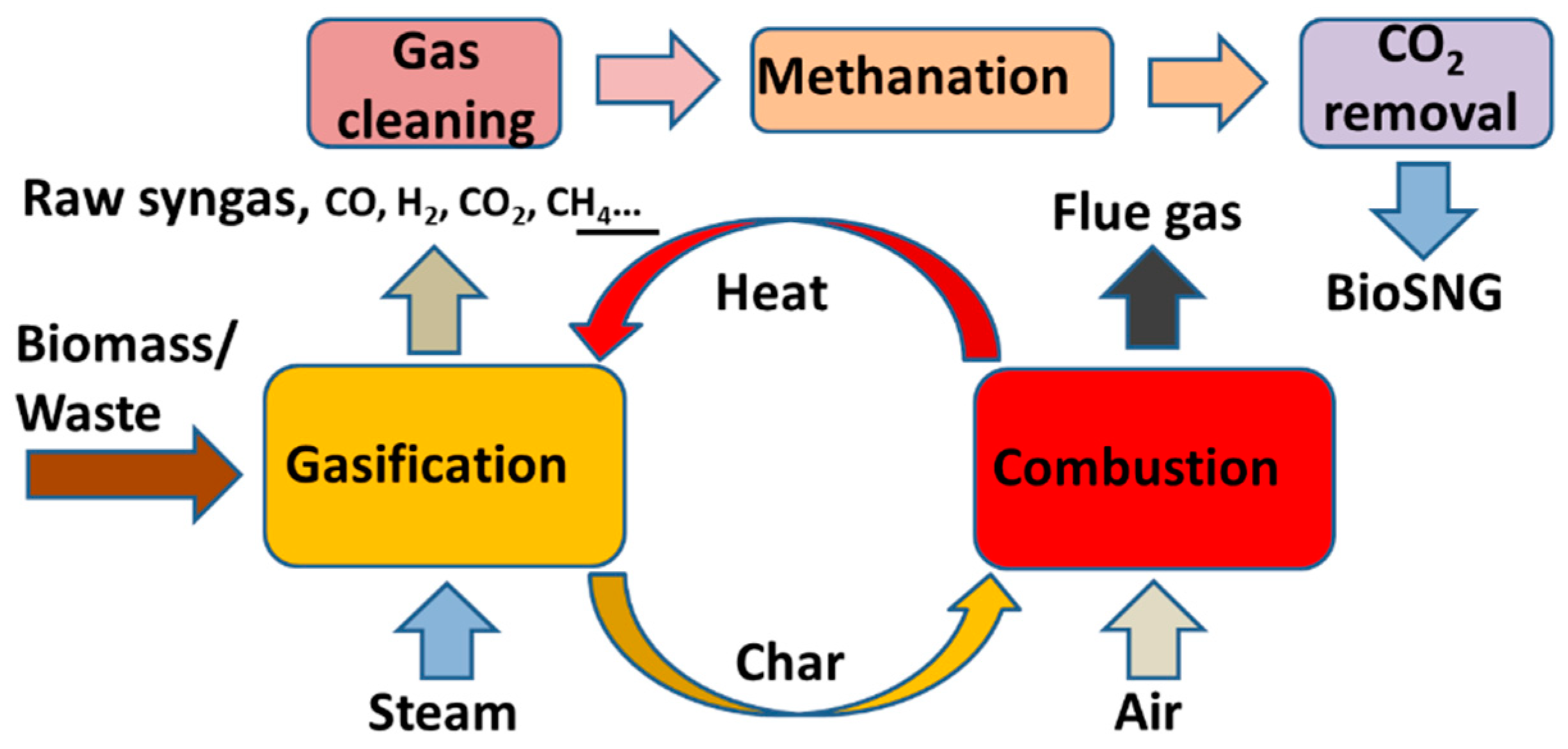

1. Introduction

2. Materials and Methods

2.1. Feedstock

2.2. Basic Platform, Solo Fluidized Bed

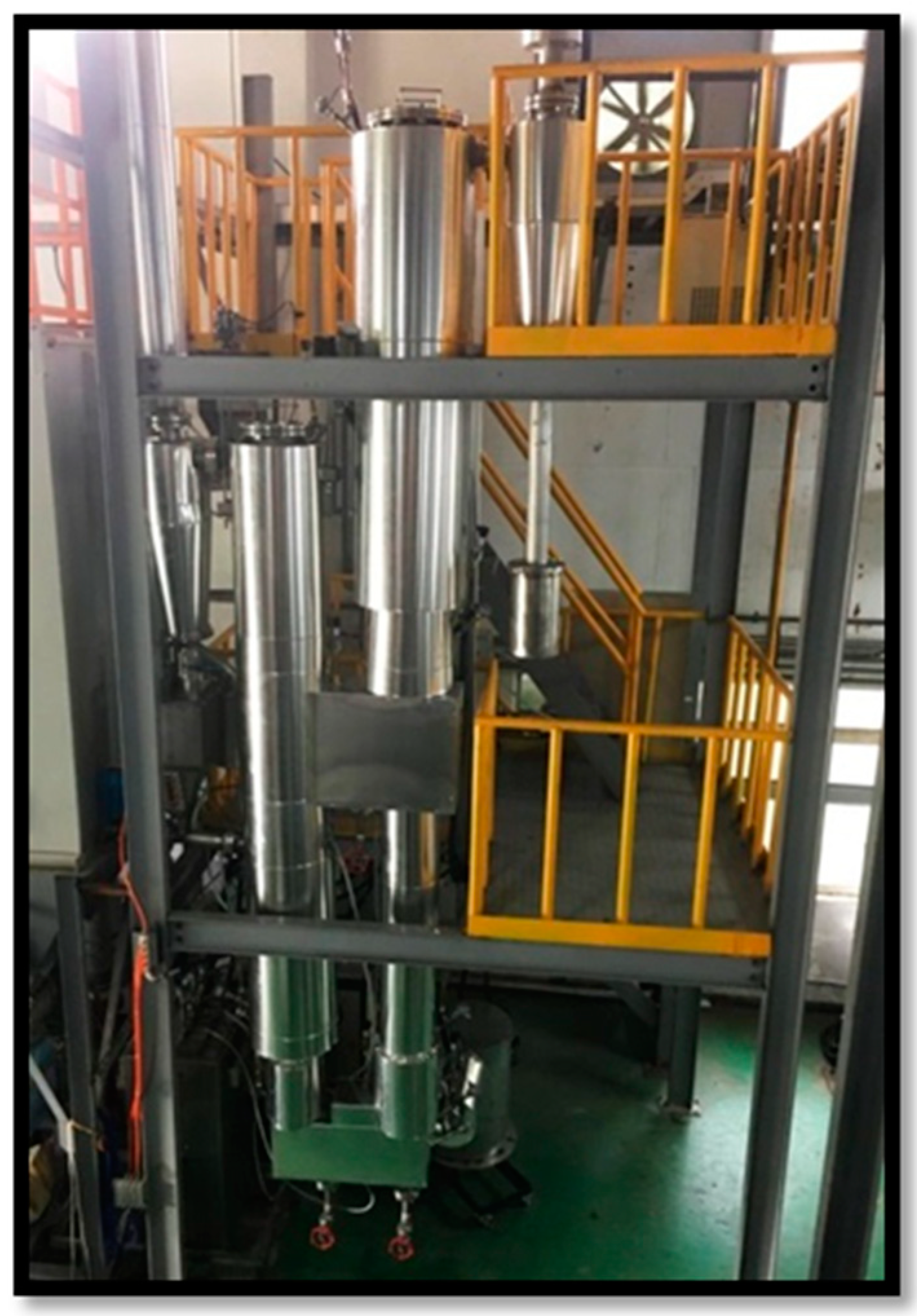

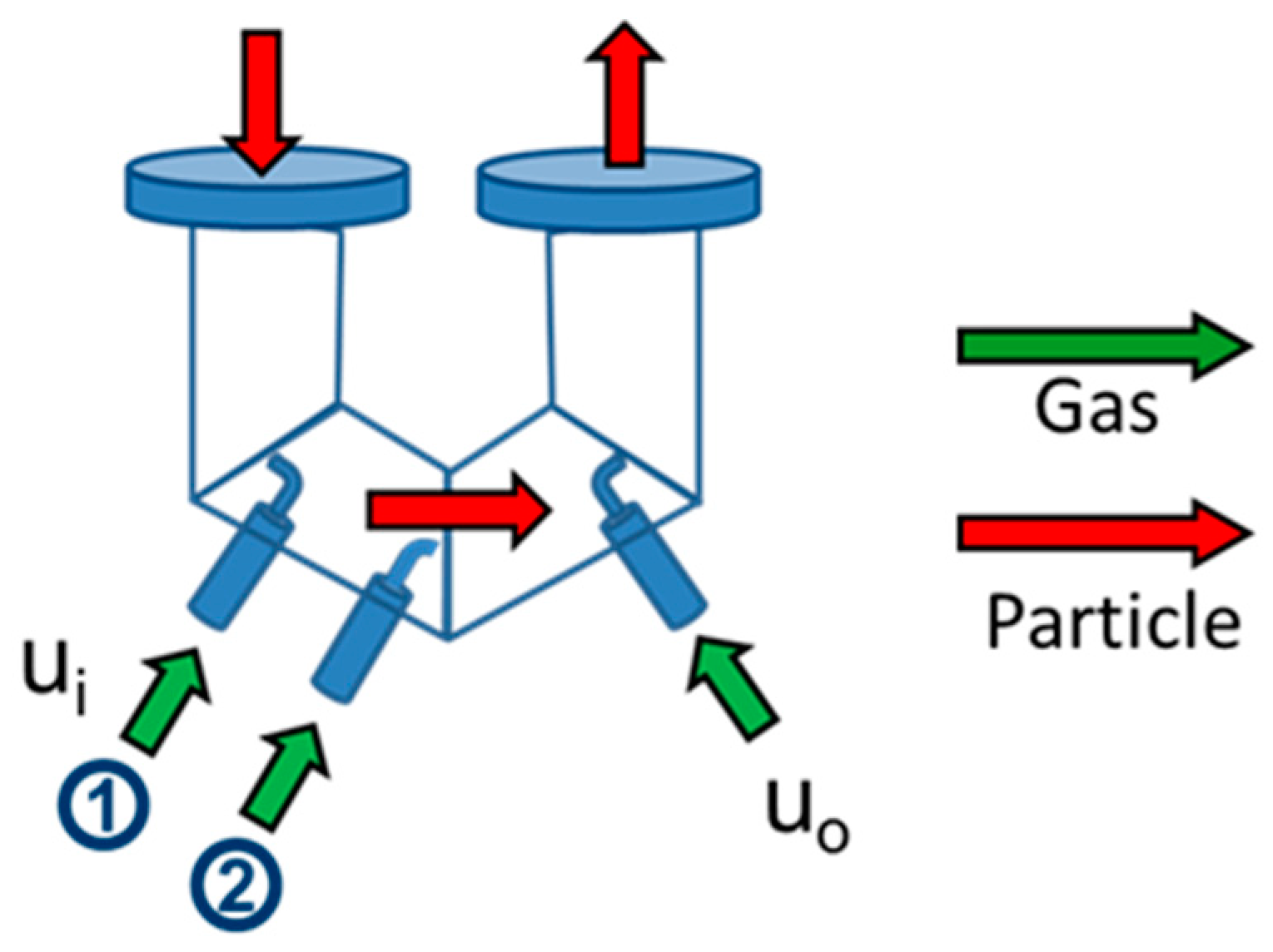

2.3. Dual Fluidized Beds

3. Results and Discussion

3.1. Baseline Performance Characteristics

3.1.1. Key Operating Parameters

3.1.2. Influence of Gasification Medium

3.2. Study of DFB for Indirect Gasification

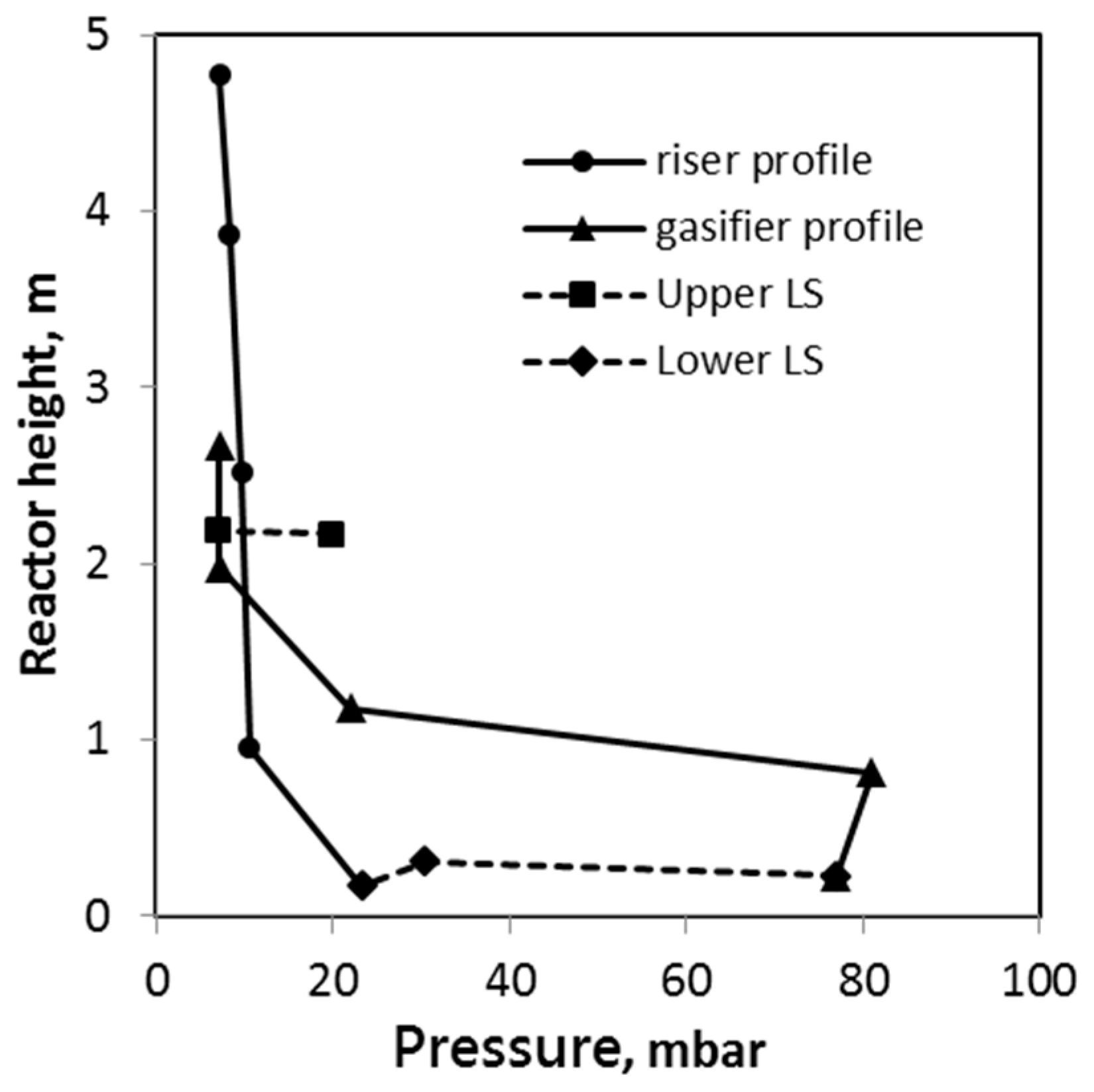

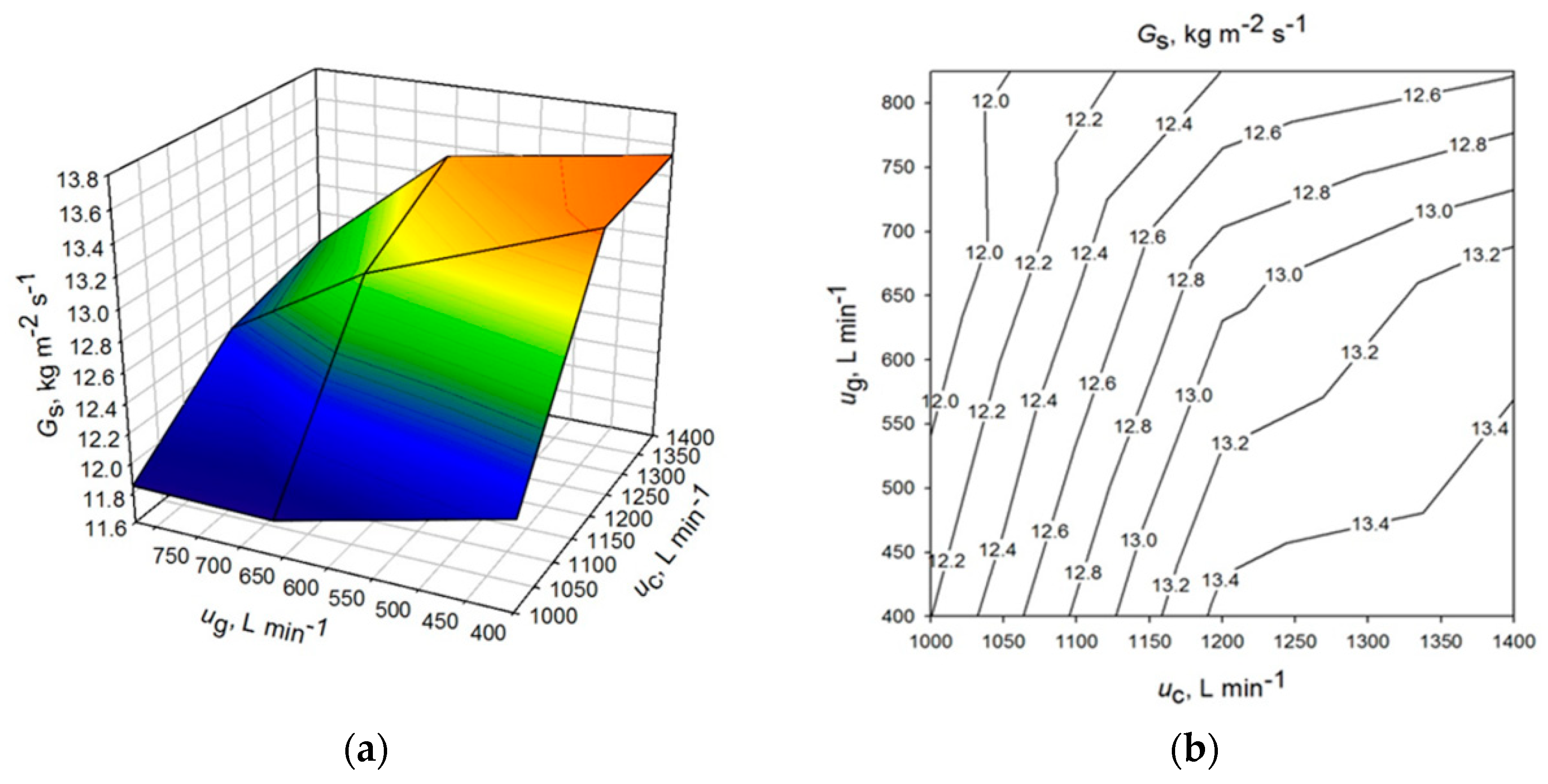

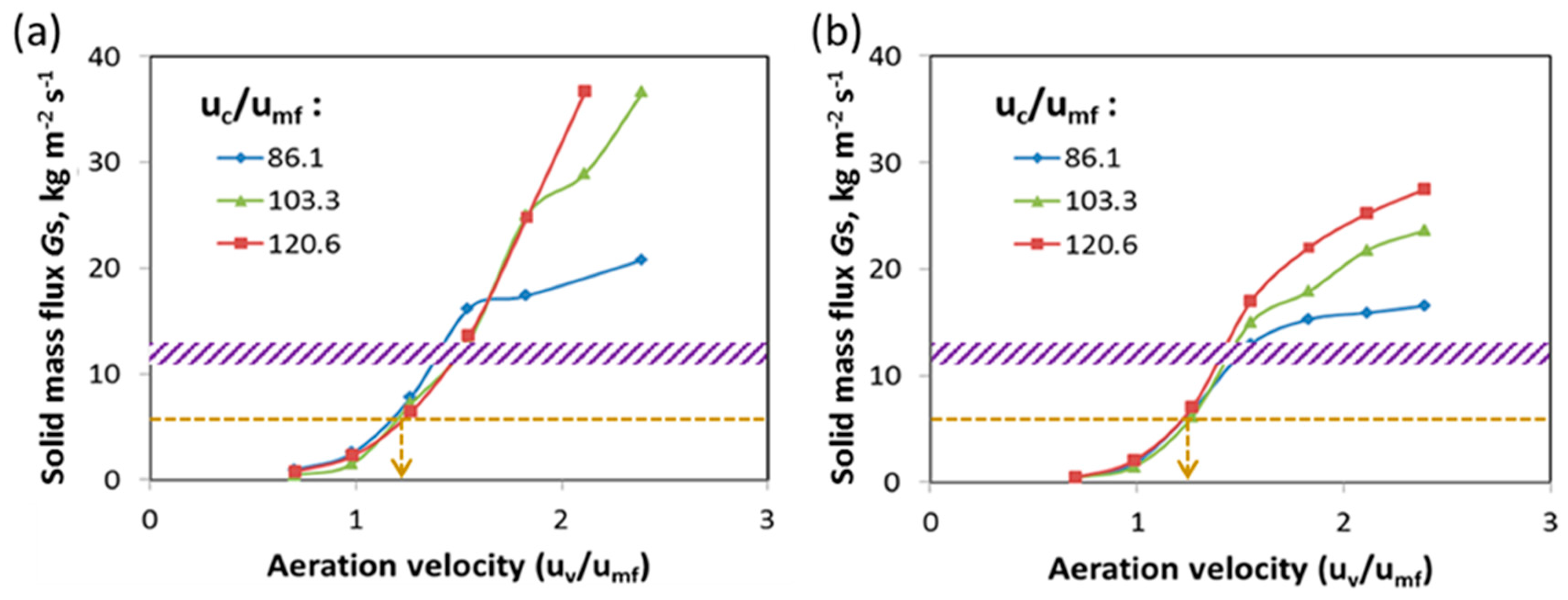

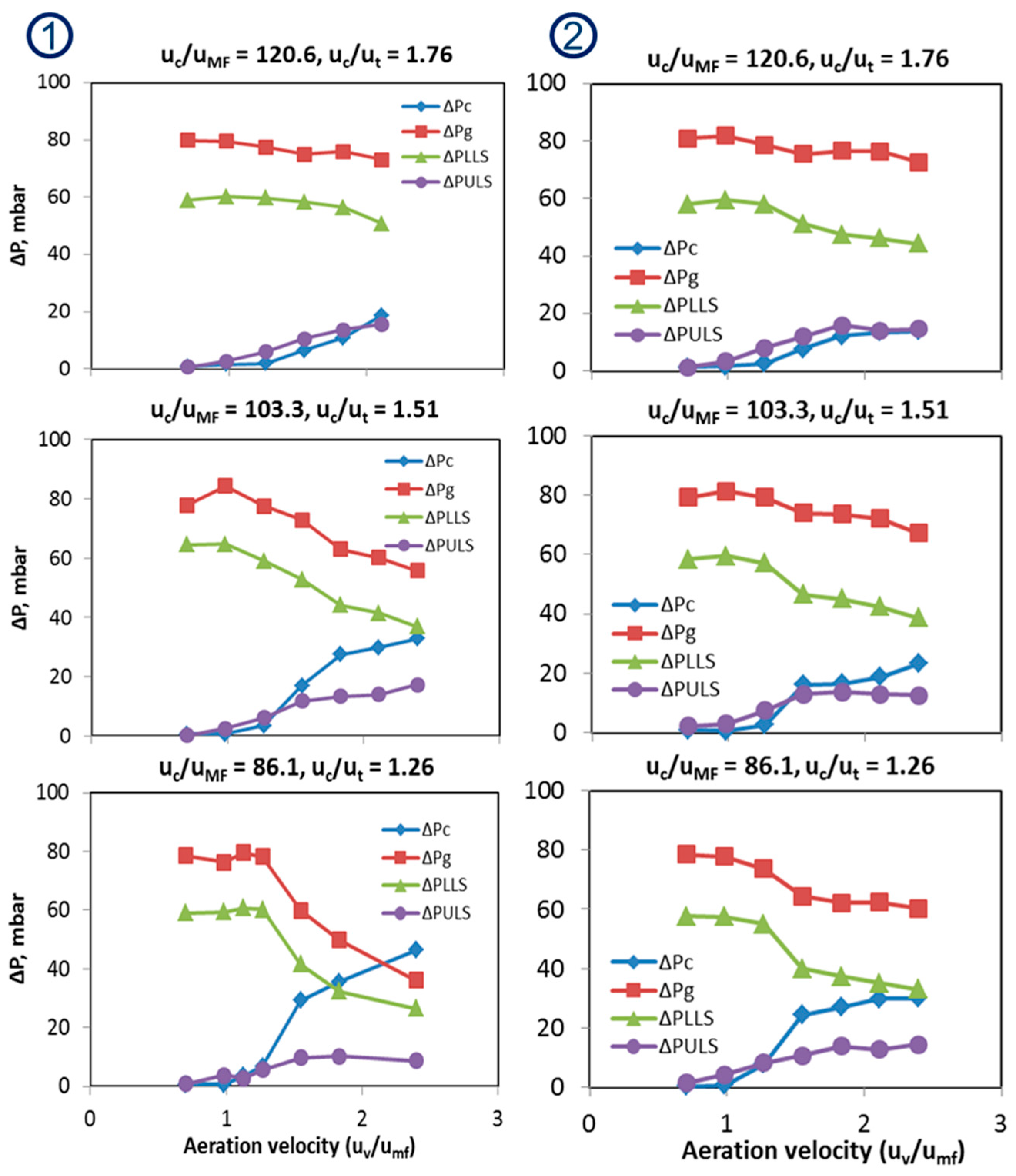

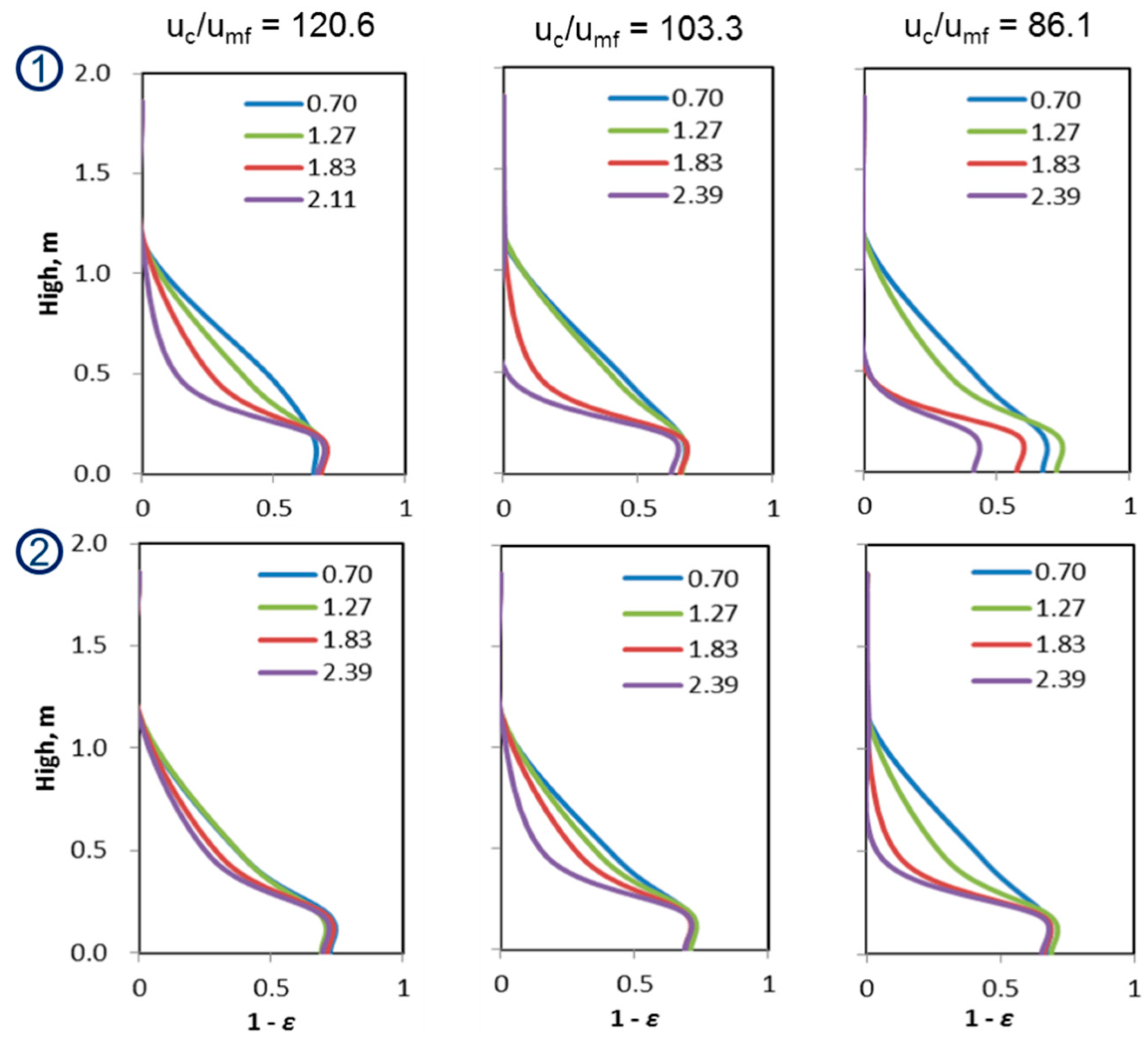

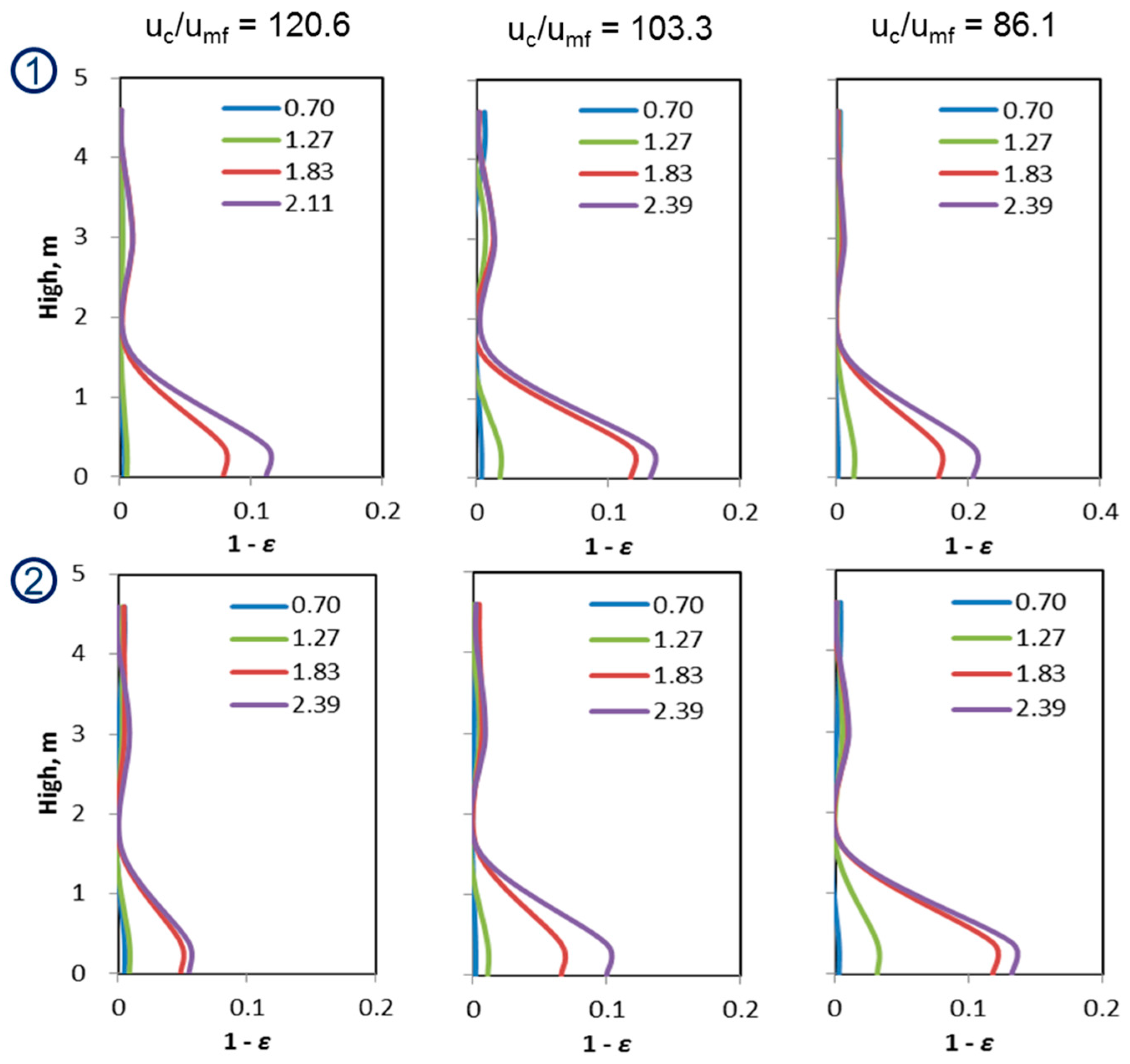

3.2.1. Hydrodynamic Properties of the DFB Cold Model

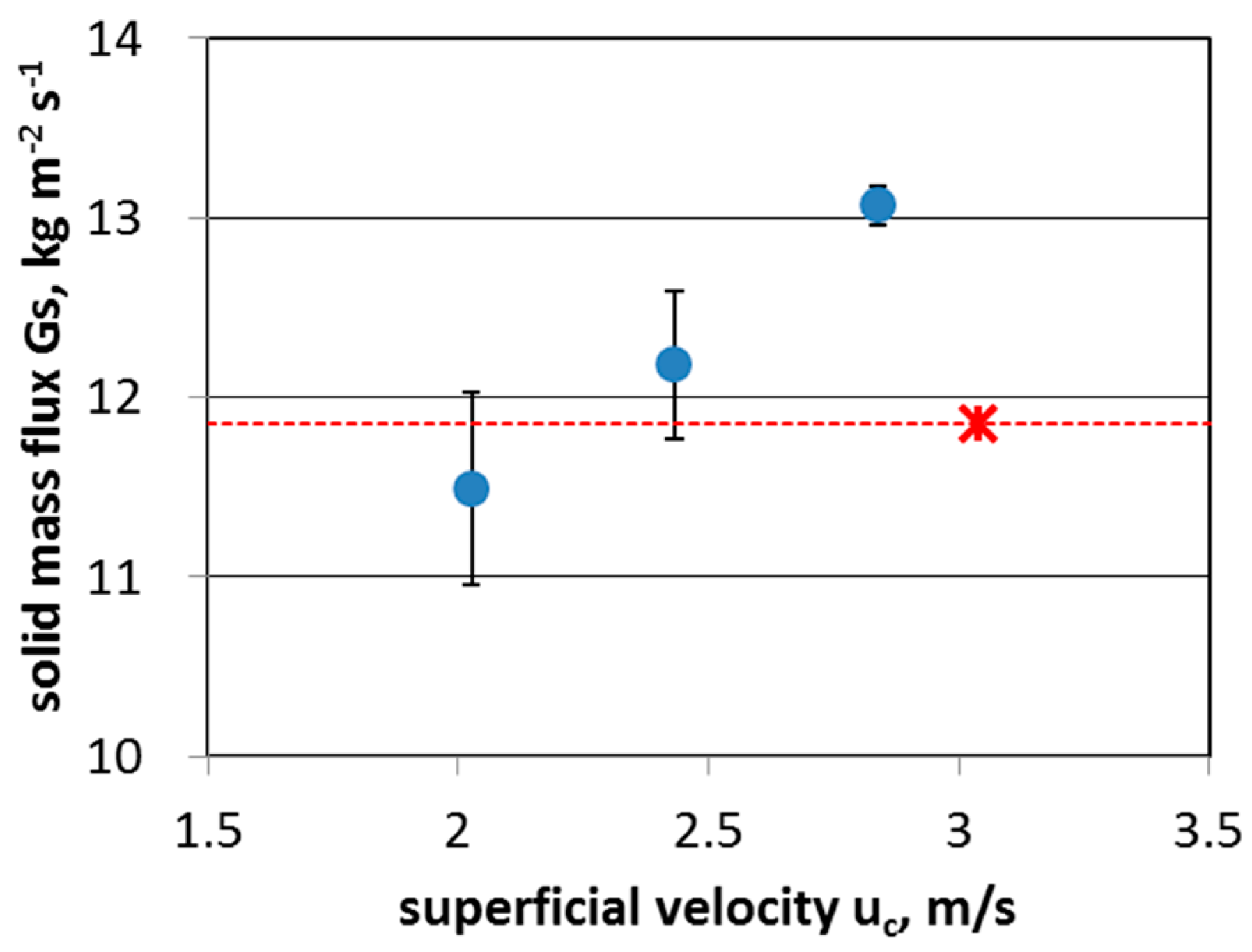

3.2.2. Operating the Cold Model by Loop Seals

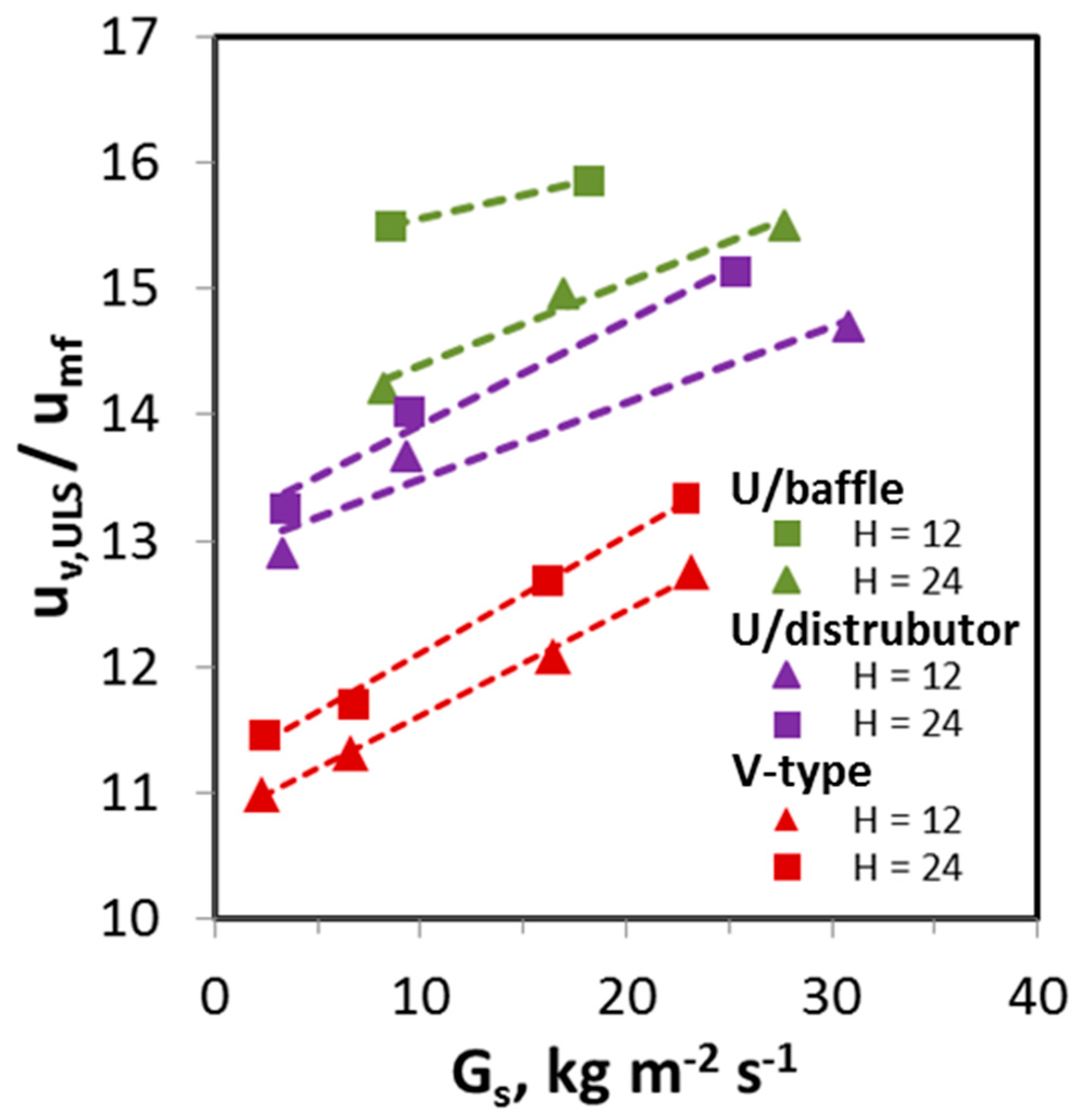

Upper Loop Seal

Lower Loop Seal

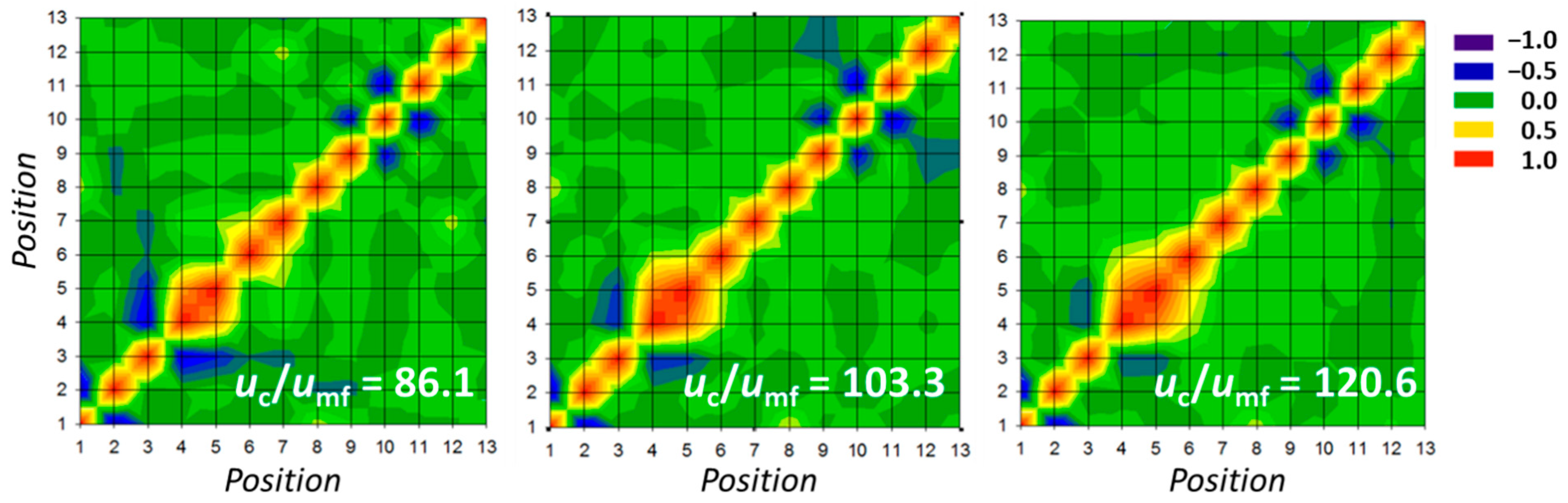

3.2.3. Advanced Dynamic Analysis on the Cold Model

3.2.4. Operating Condition and Suggestion of DFB

- (1)

- The circulation rate of the bed material was mainly controlled by the lower loop seal. To change the circulation rate of the bed material in operation, the first step was to set the new condition of the lower loop seal, then follow the flow direction of the bed material to change the conditions of the units.

- (2)

- The 110% loading operation was achievable by increasing the gas volume flow rates in the gasification and combustion reactors, as the upper and lower loop seals kept the same operating conditions.

- (3)

- For the case of partial loading of 50%, the major controlling unit was the lower loop seal, while the other units could adjust the needed GS with proper operating condition.

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| bed diameter (mm) | |

| dp | particle diameter (μm) |

| g | gravitational acceleration |

| GS | solid circulation flux (kg/m2/s) |

| h | bed high in inlet of loop seal (cm) |

| MW | mega-watts (power unit, 1000 kW) |

| ux | superficial velocity for x (m/s) |

| Greek letters | |

| ηg | gas viscosity (Pa/s) |

| ρg | gas density (kg/m3) |

| ρp | gas density (kg/m3) |

| Φ | shape factor (-) |

| Components with subscript i in notation | |

| c | combustor |

| C | cold model |

| g | gasifier |

| H | hat model |

| i | inlet side of loop seal |

| mf | minimum velocity |

| o | outlet side of loop seal |

| t | terminal velocity |

| th | thermal |

| v | over all in loop seal |

| Dimensionless groups | |

| Ar | |

| De | |

| Fl | |

| Fr | |

| U* | |

References

- Raizaiyan, J.; Cheremisinoff, N.P. Gasification Technologies; CRC Press: New York, NY, USA, 2005. [Google Scholar]

- Alauddin, Z.A.B.Z.; Lahijani, P.; Mohammadi, M.; Mohamed, A.R. Gasification of lignocellulosic biomass in fluidized beds for renewable energy development: A review. Renew. Sust. Energy Rev. 2010, 14, 2852–2862. [Google Scholar] [CrossRef]

- Basu, P. Combustion and Gasification in Fluidized Beds; CRC Press: New York, NY, USA, 2006. [Google Scholar]

- Bain, R.L. An overview of biomass gasification. In Proceedings of the 2004 AIChE Spring National Meeting, New Orleans, LA, USA, 25–29 April 2004; pp. 547–552. [Google Scholar]

- Thunman, H.; Lind, F.; Breitholtz, C.; Berguerand, N.; Seemann, M. Using an oxygen-carrier as bed material for combustion of biomass in a 12-MWth circulating fluidized-bed boiler. Fuel 2013, 113, 300–309. [Google Scholar] [CrossRef]

- Motta, I.L.; Miranda, N.T.; Filho, R.M.; Maciel, M.R.W. Biomass gasification in fluidized beds: A review of biomass moisture content and operating pressure effects. Renew. Sust. Energy Rev. 2018, 94, 998–1023. [Google Scholar] [CrossRef]

- Jeremiáš, M.; Pohořelý, M.; Svoboda, K.; Skoblia, S.; Beňoc, Z.; Šyc, M. CO2 gasification of biomass: The effect of lime concentration in a fluidised bed. Appl. Energy 2018, 217, 361–368. [Google Scholar] [CrossRef]

- Gómez-Barea, A.; Ollero, P.; Leckner, B. Optimization of char and tar conversion in fluidized bed biomass gasifiers. Fuel 2013, 103, 42–52. [Google Scholar] [CrossRef]

- Corella, J.; Toledo, J.M.; Molina, G. A review on dual fluidized-bed biomass gasifiers. Ind. Eng. Chem. Res. 2007, 46, 6831–6839. [Google Scholar] [CrossRef]

- Koppatz, S.; Pfeifer, C.; Hofbauer, H. Comparison of the performance behaviour of silica sand and olivine in a dual fluidised bed reactor system for steam gasification of biomass at pilot plant scale. Chem. Eng. J. 2011, 175, 468–483. [Google Scholar] [CrossRef]

- van der Drift, B. Commercialisation of WtE through gasification technology developed by ECN. Symposium on Renewable Energy and Products from Biomass and Waste. In Proceedings of the IEA TAsk 33 Workshop, Ponferrada, Spain, 11–13 May 2015. [Google Scholar]

- Kumagai, T. Fluidized bed gasification and combustion of biomass. In Proceedings of the 75th IEA-FBC Meeting 2017, Skive, Denmark, 23–25 October 2017; Available online: https://www.processeng.biz/iea-fbc.org/upload/75_06-Tomoyoshi%20Kumagai.pdf (accessed on 18 December 2019).

- Ohshita, T. Hydrogen production by gasification of biomass. Suiso. Enerugi. Shisutemum 2003, 28, 93–100. (In Japanese) [Google Scholar]

- Bengtsson, K. Twin-Bed Gasification Concepts for Bio-SNG Production; Lund University: Lund, Sweden, 2007. [Google Scholar]

- Kunii, D. Chemical reaction engineering and research and development of gas solid systems. Chem. Eng. Sci. 1980, 35, 1887–1911. [Google Scholar] [CrossRef]

- Korbee, R.; Schouten, J.C.; van den Bleek, C.M. Modelling interconnected fluidized bed systems. AICHE Symp. Ser. 1991, 87, 70–77. [Google Scholar]

- Korbee, R.; Snip, O.C.; Schouten, J.C.; van den Bleek, C.M. Rate of solids and gas transfer via an orifice between partially and completely fluidized beds. Chem. Eng. Sci. 1994, 49, 5819–5832. [Google Scholar] [CrossRef]

- Snip, O.C.; Korbee, R.; Schouten, J.C.; van den Bleek, C.M. The Influence of hydrodynamics on the performance of an interconnected fluidized bed system for regenerative desulfurization in coal conversion processes. AICHE Symp. Ser. 1995, 91, 82–92. [Google Scholar]

- Snip, O.C.; Woods, M.; Korbee, R.; Schouten, J.C.; van den Bleek, C.M. Regenerative removal of SO2 and NOx for a 150 MWe power plant in an interconnected fluidized bed facility. Chem. Eng. Sci. 1996, 51, 2021–2029. [Google Scholar] [CrossRef]

- Wu, K.T.; Wang, J.S.; Lee, H.F.; Hwang, S.J.; Lee, H.T. Gasification of refuse derived fuel in an interconnected fluidized bed gasifier. In Proceedings of the 9th Asian Conference on Fluidized-Bed and Three-Phase Reactors 2004, Taipei, Taiwan, 21–24 November 2004; pp. 97–102. [Google Scholar]

- Hsu, H.T.; Lin, S.C.; Chyou, Y.P. Gasification of solid fuels in a fluidized-bed reactor. In Proceedings of the 13th International Conference on Combustion & Energy Utilization 2016, Taipei, Taiwan, 2–5 October 2016; p. 260021. [Google Scholar]

- Chyou, Y.P.; Chang, W.C.; Tung, Y.C.; Chen, P.C.; Chein, R.Y.; Wu, K.T. Experimental study of syngas generated form biomass pellet in an interconnected fluidized-bed gasifier. In Proceedings of the 9th International Freiberg Conference on IGCC & XtL Technologies 2018, Berlin, Germany, 3–8 June 2018; pp. 22–24. [Google Scholar]

- Lim, M.T.; Saw, W.-L.; Pang, S. Effect of fluidizing velocity on gas bypass and solid fraction in a dual fluidized bed gasifier and a cold model. Particuology 2015, 18, 58–65. [Google Scholar] [CrossRef]

- Bidwe, A.R.; Hawthorne, C.; Xizhi, Y.; Dieter, H.; Scheffknecht, G. Cold model study of a dual fluidized bed system for the gasification of solid fuels. Fuel 2014, 127, 151–160. [Google Scholar] [CrossRef]

- Pröll, T.; Rupanovits, K.; Kolbitsch, P.; Bolhàr-Nordenkampf, J.; Hofbauer, H. Cold flow model study on a dual circulating fluidized bed system for chemical looping processes. Chem. Eng. Technol. 2009, 32, 418–424. [Google Scholar] [CrossRef]

- Farrel, P.A. Hydrodynamic Scaling and Solids Mixing in Pressurized Bubbling Fluidized Bed Combustors. Ph.D. Thesis, MIT, Cambridge, MA, USA, 1996. [Google Scholar]

- Grace, J.R. Contacting modes and behaviour classification of gas-solid and other two-phase suspensions. Can. J. Chem. Eng. 1986, 64, 353–363. [Google Scholar] [CrossRef]

- Lv, P.; Yuan, Z.L.; Ma, C.W.; Chen, Y.; Zhu, J. Hydrogen-rich gas production from biomass air and oxygen/steam gasification in a downdraft gasifier. Renew. Energy 2007, 32, 2173–2185. [Google Scholar] [CrossRef]

- Qin, K.; Lin, W.; Jensen, P.A.; Jensen, A.D. High-temperature entrained flow gasification of biomass. Fuel 2012, 93, 589–600. [Google Scholar] [CrossRef]

- Karmakar, M.K.; Datta, A.B. Generation of hydrogen rich gas through fluidized bed gasification of biomass. Bioresour. Technol. 2011, 102, 1907–1913. [Google Scholar] [CrossRef]

- Umeki, K.; Namioka, T.; Yoshikawa, K. The effect of steam on pyrolysis and char reactions behavior during rice straw gasification. Fuel Process. Technol. 2012, 94, 53–60. [Google Scholar] [CrossRef]

- Kantarelis, E.; Donaj, P.; Yang, W.; Zabaniotou, A. Sustainable valorization of plastic wastes for energy with environmental safety via High-Temperature Pyrolysis (HTP) and High-Temperature Steam Gasification (HTSG). J. Hazard. Mater. 2009, 7, 675–684. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-L.; Chou, J.-D.; Weng, W.-C. Partition of Cu and Pb in a two-stage fluidized-bed waste gasification system. Appl. Sci. 2019, 9, 1576. [Google Scholar] [CrossRef]

- Soni, C.G.; Wang, Z.; Dalai, A.K.; Pugsley, T.; Fonstad, T. Hydrogen production via gasification of meat and bone meal in two-stage fixed bed reactor system. Fuel 2009, 88, 920–925. [Google Scholar] [CrossRef]

| Units/Parts | #Gauge | Type of Fluidized-Bed |

|---|---|---|

| Gasifier | P1~P4 | Bubbling |

| Combustor | P7~P11 | Fast |

| Upper Loop Seal (ULS) | P12~P13 | |

| Lower Loop Seal (LLS) | P5~P6 |

| Bed Material | CRH | CRC | GRH | GRC |

|---|---|---|---|---|

| Olivine | Glass | Olivine | Glass | |

| ηG | 4.50 × 10−5 | 1.83 × 10−5 | 3.59 × 10−5 | 1.83 × 10−5 |

| ρG | 0.29 | 1.15 | 0.20 | 1.15 |

| ux | 9.20 | 3.06 | 0.66 | 0.19 |

| ρP | 2.85 | 2.42 | 2.85 | 2.42 |

| dP | 520.00 | 200.00 | 520.00 | 200.00 |

| Ф | 0.80 | 0.80 | 0.80 | 0.80 |

| D | 102.30 | 102.30 | 270 × 270 | 270 × 270 |

| GS | 42.24 | 11.85 | — | — |

| De | 9796.98 | 2095.53 | 14,103.04 | 2095.53 |

| Ar | 564.21 | 652.06 | 616.49 | 652.06 |

| Fl | 120.45 | 130.00 | 6.88 | 8.00 |

| GS* | 1.61 × 10−3 | 1.60 × 10−3 | — | — |

| Fr | 16,608.26 | 4780.76 | 85.32 | 18.10 |

| ReP | 30.93 | 38.58 | 1.93 | 2.37 |

| Ar1/3 | 8.26 | 8.67 | 8.51 | 8.67 |

| U* | 3.74 | 4.45 | 0.23 | 0.27 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chyou, Y.-P.; Chang, D.-M.; Chen, P.-C.; Chien, H.-Y.; Wu, K.-T.; Chein, R.-Y. Development of Biomass Gasification Technology with Fluidized-Bed Reactors for Enhancing Hydrogen Generation: Part I, Hydrodynamic Characterization of Dual Fluidized-Bed Gasifiers. Appl. Sci. 2020, 10, 2. https://doi.org/10.3390/app10010002

Chyou Y-P, Chang D-M, Chen P-C, Chien H-Y, Wu K-T, Chein R-Y. Development of Biomass Gasification Technology with Fluidized-Bed Reactors for Enhancing Hydrogen Generation: Part I, Hydrodynamic Characterization of Dual Fluidized-Bed Gasifiers. Applied Sciences. 2020; 10(1):2. https://doi.org/10.3390/app10010002

Chicago/Turabian StyleChyou, Yau-Pin, Der-Ming Chang, Po-Chuang Chen, Hsiu-Yun Chien, Keng-Tung Wu, and Rei-Yu Chein. 2020. "Development of Biomass Gasification Technology with Fluidized-Bed Reactors for Enhancing Hydrogen Generation: Part I, Hydrodynamic Characterization of Dual Fluidized-Bed Gasifiers" Applied Sciences 10, no. 1: 2. https://doi.org/10.3390/app10010002

APA StyleChyou, Y.-P., Chang, D.-M., Chen, P.-C., Chien, H.-Y., Wu, K.-T., & Chein, R.-Y. (2020). Development of Biomass Gasification Technology with Fluidized-Bed Reactors for Enhancing Hydrogen Generation: Part I, Hydrodynamic Characterization of Dual Fluidized-Bed Gasifiers. Applied Sciences, 10(1), 2. https://doi.org/10.3390/app10010002