Abstract

As coal resources trapped under surface buildings in the Wangtaipu coal mine area impede the efficient mining of coal seams and constrain the sustainable development of coal mines, a super-high-water roadway backfill mining technique for preventing building damage was adopted. According to the control principle and theoretical calculations, an engineering design was established including the reasonable width of segment coal pillars in the working face and technical parameter design. The monitoring results after the implementation of the scheme showed that building deformation was controlled within grade I, protecting the surface buildings. A reasonable roadway design parameter was achieved, with a surface subsidence of 27 mm and horizontal deformation of 0.3 mm/m, indicating that it can ensure the safety of surface buildings from the State Bureau of Coal Industry. The practical trial can provide a reference for the extraction of coal resources under similar conditions and is vital for the sustainable development of the mining industry and economic growth.

1. Introduction

China is the largest coal producer in the world due to progressive expansion of various energy-based programs. Based on the importance of coal in China’s energy resources, long-term rapid technological and economic development can be guaranteed [1]. Meanwhile, combined with national policies, the intention is to build coal mines that are in line with modernization, green, safe, and ecologically stable. However, as is well-known, coal exploitation will lead to many serious eco-environmental problems, such as surface building damage, destruction of groundwater resources, and exhaust emissions, which are a global problem [2,3,4,5]. At the same time, there is an estimated 13.7 billion tons of coal reserves trapped under surface buildings, water bodies, and railways (hereinafter referred to as “under-three”) in China, among which coal resources under surface buildings account for 9.5 billion tons [6,7]. At present, according to the present situation of coal trapped under surface buildings in the Wangtaipu coal mine, the total amount has reached 30 million tons, which not only affects the succession of subsequent mining, but also wastes coal resources and is not conducive to sustainable development of the coalmine. Therefore, under the premise of protecting surface buildings, it is important to liberate coal resources under surface buildings and other structures.

Recently, many different types of mining methods have been successfully applied to control overburden and surface damage when mining under buildings or other structures, such as strip mining [8,9], harmonic mining [10], room mining [11], grout injection [12] and backfill mining [13,14,15]. This is because the remaining coal pillar can usually support the overburden load, allowing slight surface movement and deformation. Although the strip mining or room mining method has reduced surface subsidence or damage to a certain extent, the mining rate is low due to the coal pillars. Because the harmonic mining is limited by many factors, such as construction organization, geological conditions, and subsidence factor, it is difficult to realize. Meanwhile, grouting injection technology has been successfully applied to reduce surface subsidence and building damage in populated areas. Alehossein [16] studied shear behaviour of the slurry through field and laboratory testing, and derived formulas for minimum pump pressure and local pressure, and the results are consistent with each other. Shen and Poulsen [17] used numerical modeling to study the evolution of horizontal fractures at bed separations during longwall mining. By analyzing the influence of filling ratio and maximum subsidence on the grouting effect, Xuan and Xu [18] obtained the supporting width that was formed at the center of the gob. Subsequently, the stiffness and distribution of the grouting mass were investigated through field borehole, and the mechanism of grouting to restrain the overburden deformation was revealed [19]. Considering the long-term stability of overburden, the effect of harmonic mining and grouting injection on overburden damage reduction is poor. In fact, the essential problem of “under-three” mining is controlling the movement and deformation of the overlying strata. By contrast, backfill mining has been widely used and is becoming an effective technique for reducing the degree of overburden failure in the green mining technical system, and has been developed to solve the global problems described above, especially for “under-three” mining [20,21,22,23]. In essence, backfill mining reduces the overburden movement by replacing the coal with backfill material. Meanwhile, its basic principle states that the maximum limited thickness should be controlled according to the specifications for “under-three” mining, so as to guarantee the mining influence is within the allowable range.

However, according to the study conducted by Szczepanska and Twardowska [24], heavy metal pollution caused by mining waste in the backfill mining area has resulted in groundwater pollution lasting for decades, with an increase in pollution intensity with respect to time. This is also noted by Chinese scholars [21,25]. Moreover, backfill material contains toxic metals and inorganic salts that will dissolve and spread in water, which can pose the risk of secondary pollution to the groundwater environment [26,27]. In order to avoid secondary pollution, reduce mining costs, and save the backfill material, a super-high-water material has been tested in the laboratory and applied in the field [28], and these tests indicated that this material can protect against geo-environmental hazards common with the solid backfill mining method. In addition to prevention of secondary pollution, other collateral benefits are also available, including reduced surface subsidence, water resources, and protection of the ecological environment. Therefore, it is necessary to study roadway backfill mining with super-high-water materials, which not only liberates coal resources, but also protects surface buildings.

In this paper, in order to determine the scope of the working face, the reasonable width of a coal pillar in the working face was analyzed and obtained through theoretical analysis. Then, the location of key strata (KS) in the overburden were identified based on KS theory, and its integrity is the essence of building protection. This was followed by the design of the technical parameters including the layout and support design of the roadway, the roadway backfill mining system, and determination of the backfill rate. In addition, in order to study surface subsidence characteristics and verify the effect of protecting surface buildings, a real-time monitoring of surface movement and deformation was carried out. The purpose of this study is not only to prolong the service life of a coal mine, but also to protect the surface buildings. Moreover, it is consistent with sustainable production and protection of the eco-environment.

2. Method and Geological Conditions

2.1. Key Strata (KS) Theory

The overburden is composed of different strata with delamination differences, thus the mining effects on each stratum are different. Hard and thick strata may have a stronger bearing capacity, supporting those weak and thin strata that only act as loads. Based on this difference, KS theory was proposed by Qian [29]. According to the theory, the hard and thick stratum is named KS, and the overburden has at least one KS. If there are more than two KS, the top KS is named the primary KS (PKS), as it bears the entire load from roof to ground surface. Correspondingly, the other KS are named the sub-key strata (SKS) that control partial overburden.

In general, the overburden is composed of strata with varied thicknesses and different lithology. In the mining process, the gob is under gravity without support and starts to bend when bed separation occurs. It also occurs between the upper hard strata and lower soft strata. The combination of roof movement can be determined by the bed separation position with theoretical analysis, and the calculation formula of the loads on the movement combination layer is given in Equation (1). If the first layer is the KS and its control reaches the nth layer, then the (n + 1)th layer becomes the second KS, which must meet the Equation (2).

where (qn)1 is the load formed by the effect of n layers on the first SKS, Pa; En is the nth layer’s elastic modulus, Pa; γn is the nth layer’s volumetric weight, N/m3; and hn is the nth layer’s thickness, m.

At present, much research is based on the KS theory, such as the influence of KS position on the height of water-conducting fracture zones [30], the influence of KS structures on the mine pressure [31], and the induced effect of KS-breaking on rock burst and disasters [32,33]. Therefore, based on the KS theory, combined with the distribution of KS position, backfill mining is used to control the overburden movement, so as to protect the surface buildings.

2.2. Geological Conditions

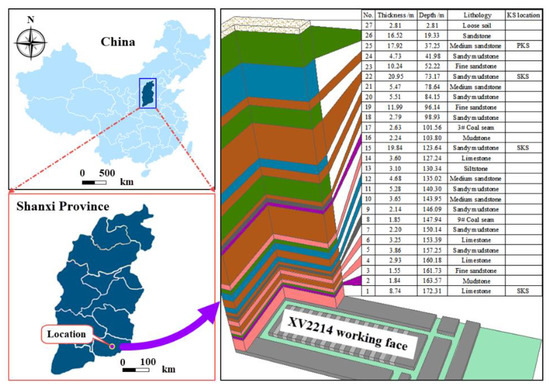

Wangtaipu coal deposit formed during the Carboniferous period and is located in Jincheng city, Shanxi Province, China. It covers a field area of 33.7 km2. There are fourteen layers of coal, and at present, No. 15 coal, which has a stable and simple structure, is being mined at 1.8 to 3.5 m and an average of 2.5 m. The geological conditions of the XV2214 working face (trial area) are as follows: the average buried depth is 175 m, with a dip angle of 1–3°. The average inclination length is about 280 m, and average trend length, 70 m. The surface buildings above are brick-concrete structures. They all require grade III protection (based on Specification Requirements). Based on the KS theory and borehole columnar section, the parameters of overburden are shown in Table 1.

Table 1.

Mechanical parameters of overlying strata and KS location.

According to Equations (1) and (2), the KS location could be calculated as follows:

It can be seen from the above that there are four KS in the overburden: namely, the first layer (limestone), 15th layer (sandy mudstone), 22th layer (sandy mudstone), and 25th layer (medium sandstone). A schematic diagram of the coalmine and the KS locations are shown in Figure 1.

Figure 1.

Schematic diagram of the Wangtaipu coalmine location and the key strata (KS).

3. Design for Roadway Backfill Mining under Surface Buildings

3.1. Reasonable Width of Segment Coal Pillar in the Working Face

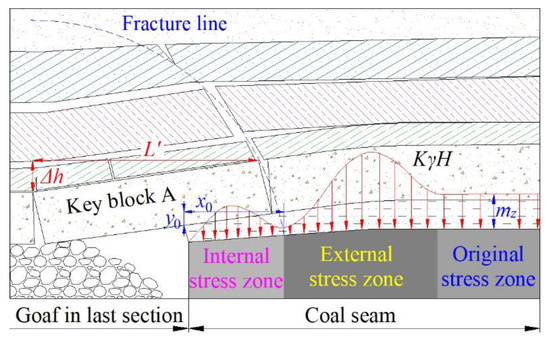

Reasonable coal pillar width should not only ensure the stability of the roadway during excavation, but also ensure the safety of the working face during the mining process. During mining progress at the adjacent working face, the basic roof breaks into the key block at the edge of the goaf and forms an articulated structure with the adjacent rock blocks. The abutment pressure of the overburden transferred to the coal is divided into two parts according to the fracture line, i.e., the internal stress field between the fracture line and coal and the external stress zone in the deep region (it becomes the original stress zone beyond a certain point). Additionally, the stress in the internal stress zone is determined by the weight and movement of the overburden under the fracture line, and the whole surrounding rock is in low stress, which is beneficial to roadway maintenance, as shown in Figure 2.

Figure 2.

Basic roof broken structure model of gob-side entry.

The study shows that the abutment pressure σy from the position of coal wall x in the relief stress zone is given by Equation (3) [34]:

where Gx is the stiffness of coal from the coal wall x, Pa; and yx is the compression of coal layer at x, m.

Stressing the development from the goaf to the internal stress field, the horizontal stress in the coal increases gradually and is positively correlated with the coal stiffness, and negatively correlated with the coal compression.

In order to simplify the analysis, the linearization of the Gx and yx distribution can be obtained from Equation (4):

where G0 is the maximum coal stiffness in the internal stress field, Pa; y0 is the coal compression at the edge of goaf, m; and x0 is the width of internal stress field, m.

Then, according to Equations (3) and (4), the abutment pressure in the internal stress field can be obtained as follows in Equation (5):

Based on the theory of the internal and external stress field, the abutment pressure in the internal stress field on the coal seam around the stope is equal to the self-weight of the basic roof stratum during the initial pressure of the working face. Accordingly, the following equation can be obtained:

where L is the panel length, m; C0 is the first roof weighting pace of the adjacent working face, m; M and γ are the basic roof strata thickness and bulk density, respectively. Therefore, the geometric relationship between y0 and x0 is as follows:

where h is the coal seam thickness, m; mz is the immediate roof thickness, m; Δh is the maximum subsidence of basic roof stratum, m; Kc is the residual expansion coefficient; and L’ is the suspension span of the rock beam, approximated to the periodic weighting step of the fully mechanized caving mining face, m.

According to the inclusion theory [35], the expression of coal stiffness G0 in the plastic state is:

where E is the elastic modulus of coal, Pa; ν is Poisson’s ratio; and ξ is the influence coefficient, which is related to the development of fissures in coal.

Therefore, the distribution range of internal stress field x0 can be obtained by combining Equations (6) to (8):

From the geological conditions of the working face, it can be found that L = 175 m, h = 2.52 m, M = 8.74 m, mz = 0 m, E = 2.6 GPa, γ = 27 kN/m3, and ν = 0.29. According to the experimental and field measurements, the value of Kc is 1.10, C0 = 45.76 m, L’ = 17.8 m, and ξ = 0.8. Thus, the range of internal stress field x0 is 7.97 m by parameter substitution in Equation (8), i.e., the breaking distance of the basic roof is 7.97 m away from the coal at the edge of the goaf.

Due to the fracture of basic roof strata causing severe strata behavior phenomenon, according to the actual situation, the roadway width should be at least 6 m to meet the requirements of the transportation equipment. Meanwhile, in order to support the coal pillar and prevent the spontaneous combustion of coal caused by air leakage, the coal pillar width must be at least 4 m. According to the empirical formula and theoretical analysis, the distance between the support pressure peak and the edge of the coal pillar was 3 m to 20 m. Consequently, to avoid the dynamic pressure influence of basic roof breaking on the roadway, the coal pillar width should be greater than 35 m. Therefore, 35 m coal pillars are kept on both sides of the working face.

3.2. Design of the Technical Parameters

The super-high-water backfill material is composed of two main ingredients (A mainly contains bauxite; B mainly contains gypsum) and other additives. These two mixed grouts (the water content of grout B can exceed 95%) are solidified after half an hour and reach final strength after 60 days. Meanwhile, many field tests proved that surface subsidence can be effectively controlled [36]. Based on the geological conditions and analysis above, the critical problem for successful implementation is finding the optimal design for the layout and support of the roadway, the roadway backfill mining system, and the filling rate. Citing security concerns, controlling the ground movement under buildings is the essence of backfill-mining technology. Therefore, the major design criterion under buildings is that the first SKS does not break.

3.2.1. Layout and Support Design of Roadway

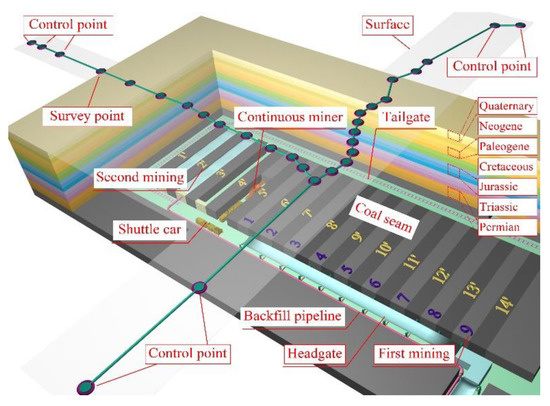

This mining process includes roadway mining and backfilling. Due to the advantages of flexible and appropriate, an intermittent transportation mode was adopted during roadway mining. This mode involves a continuous miner, shuttle car, individual roof bolter, anti-explosive diesel scraper, and continuous haulage, which includes five steps: cutting, loading, transporting, cleaning and mechanical operation. Similarly, during the backfilling process, two roadways were mined successively in the first stage, and followed by backfilling within these excavated roadways using the super-high water material. When the strength of the backfill body becomes stable, and no seepage of the backfill body occurs in the coal pillar, the next cycle can begin.

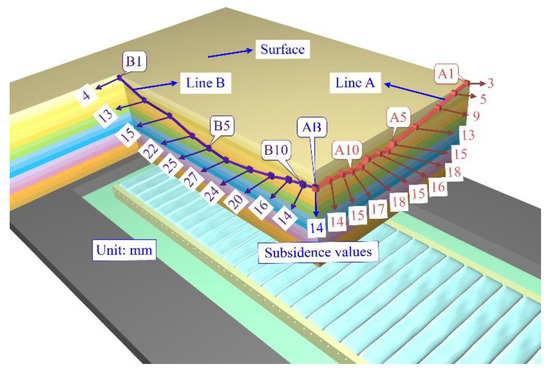

Based on the geological conditions, relevant regulations and other factors, the two observation lines (along the strike and inclination) were set up above the XV2214 working face. The Global Navigation Satellite System (GNSS) and Real-time kinematic (RTK) method, a method of GPS measurement, was used for monitoring the surface subsidence, with horizontal accuracy of 3 mm and vertical accuracy of 5 mm after static state. A schematic diagram indicating the backfilling process and layout of the observation lines is shown in Figure 3.

Figure 3.

A schematic diagram of the backfilling mining process and the observation station layout.

3.2.2. Support Design of Roadway

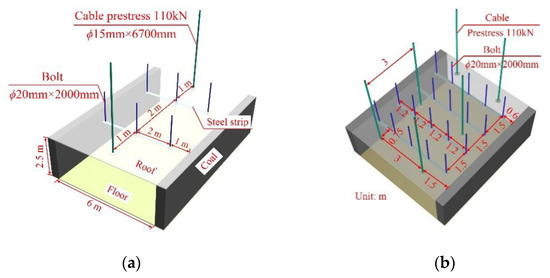

Based on the KS theory and geological conditions, the break distance of the first SKS is 36.93 m. Considering the factors of the buildings, geological conditions and equipment specifications, a scheme of “mining 6 m, leaving 6 m” is adopted. In order to facilitate the continuous mining machine, the pillar width is 6 m, and the roadway height is 2.5 m with a width of 6 m.

Due to the continuous mining machine used, the roadway was rectangular, supported by the roof and cable bolts, but its two sides were not supported. The parameters of the roof bolts are as follows: 0.1 m in radius by 2 m long with 1 m row spacing. Each row had 3 bolts. The cable was 0.15 m in diameter and 6.7 m long. The cable row spacing along the center line of the roadway roof is 4 m (Figure 4a). If the limestone thickness of the roadway roof in the working face is below 0.5 m or the roof meets the structure, destruction and instability, the roadway shall be strengthened, as shown in Figure 4b.

Figure 4.

Sketch map of roadway support: (a) roadway support; (b) roadway reinforcement support.

In order to study the roadway deformation, the observation points are arranged in the roadway for monitoring the convergence of two sides and roof-floor. Five observation stations are arranged in the same roadway, and the number of observation stations increases with the distance from the opening. During the excavation of the roadway, observation occurred once a day until the roadway closed.

3.2.3. Determination of Filling Rate

As a key index of the filling effect, the filling rate is directly related to the quality of surface subsidence control. Under the same conditions, with a higher filling rate, the larger gob space is occupied by filling materials and the smaller activity space of rock deformation, then there is a better control effect. Conversely, the control effect is poor. Therefore, the reasonable filling rate is particularly important. According to the definition of limited coal height mining, the calculation of the filling rate is shown as follows in Equation (9):

where η is the filling rate; m is the coal seam thickness, 2.5 m; b is the displacement factor, 0.28; q is the subsidence factor, 0.79; tanβ is the tangent of the major influence angle, 2.17; α is the dip angle of the coal seam, 2°; [ε] is the maximum allowable horizontal deformation of ground structures, 2 mm/m; and H is the mining depth, 175 m.

Therefore, the filling rate η ≥ 80.8%. However, in order to protect the surface buildings better, the filling rate should be improved as much as possible.

In order to verify the reliability of filling rate and ensure the control effect of backfill mining on the surface, assuming that the filling rate is 80% when SKS 1 is broken, it can be predicted that the separation will develop to the bottom of SKS 2 based on the KS theory. According to the Equivalent Mining Height (EMH) theory, the mining height h = 2.5 × (1 − 80%) = 0.5 m. Meanwhile, it can be seen from Figure 1 that the strata height controlled by SKS 1 is 39.93 m, assuming that the bulking coefficient of overlying strata controlled by SKS 1 is 1.002, the separation height under SKS 2 is h1 = 0.5 − 39.93 × 0.002 = 0.42 m. Then, according to the calculation of the above subsidence factor q, the surface subsidence value is s = 0.42 × 0.79 = 0.33 m. Considering the deformation resistance of the building itself and the mining experience of other working faces, the buildings are less affected by mining. Therefore, the filling rate can effectively control the overburden movement, and can achieve the purpose of protecting surface buildings.

4. Engineering Application

4.1. Pressure Observation in Roadway

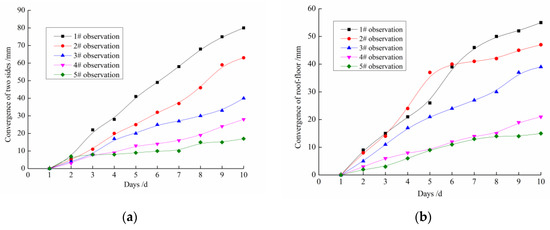

Dynamic monitoring was conducted during roadway mining. Processing of the monitoring data yielded the final curves shown in Figure 5. According to the monitoring data, the maximum convergence of the two sides and roof-floor reached 83 mm and 55 mm, respectively. The increasing trend in the later period was lower than that in the early stage due to the existence of a gap in the backfill body. In the case where the gap was reduced by a certain extent, the displacement of the two sides and roof-floor reached a stable state. At this time, the backfill body reached close packing, which can support the overburden strata more effectively.

Figure 5.

Curve results of roadway deformation: (a) convergence of the two sides; (b) convergence of roof-floor.

4.2. Analysis of Surface Subsidence

The mining of the working face lasted for half a year, and the result of monitoring after three months of mining ended were taken as the final surface subsidence (Figure 6). Based on the data analysis and calculation, the accumulated maximum subsidence is 27 mm after roadway backfill mining. However, the maximum horizontal deformation and surface slope only reach 0.3 mm/m and 0.7 mm/m respectively, lower than the critical value shown in Table 2. From the field observation, no obvious cracks were found on the surface and buildings after the implementation of roadway backfill mining. This proves that this mining method can effectively protect surface buildings and the eco-environment, as do other similar cases [37,38].

Figure 6.

Sketch of measured subsidence of observation lines.

Table 2.

Allowable surface deformation value for safe use of brick-concrete structural buildings.

5. Conclusions

As the exhaustion of coal resources in coalmines continues, “under-three” mining has long exhibited crucial issues that need to be further and continuously addressed, especially under surface buildings. Based on the KS theory, the design and implementation of roadway backfill mining with a super-high-water material was carried out under surface buildings. The conclusions are as follows:

- (1)

- According to the control principle and theoretical calculation, an engineering design was established, including the width of coal pillars in the working face, layout and supporting parameters of the roadway, and the filling rate.

- (2)

- According to the measured data of the underground roadway, the combination of roof bolts and cable bolts can effectively suppress roadway deformation, and ensure safe production at the working face. Meanwhile, the deformation decreases with the distance from the opening in the same roadway.

- (3)

- By using the roadway backfill mining method with a super-high-water material, the ground surface subsidence has been effectively reduced, and surface buildings and the ecological environment well protected. Meanwhile, the recovery ratio of coal resources has also been improved. Moreover, this approach provides a reference for the extraction of coal resources under similar conditions and is vital for the sustainable development of the mining industry and economic growth.

Author Contributions

Conceptualization, E.B., W.G. and Y.T.; data curation, E.B. and Y.T.; formal analysis, E.B. and M.G.; funding acquisition, W.G. and Y.T.; investigation, G.H., M.G. and Z.M.; methodology, W.G. and Y.T.; project administration, W.G.; supervision, W.G.; writing—original draft, E.B. and G.H.; writing—review & editing, W.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (51774111), Key Project of the National Natural Science Foundation of China (U1810203), Open Fund of State Key Laboratory of Water Resource Protection and Utilization in Coal Mining (GJNY-18-76.13) and Innovation and Outstanding Talent Project of Henan Province Science and Technology (184200510003).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lin, B.Q.; Liu, J.H. Estimating coal production peak and trends of coal imports in China. Energy Policy 2010, 38, 512–519. [Google Scholar] [CrossRef]

- Bai, E.H.; Guo, W.B.; Tan, Y. Negative externalities of high-intensity mining and disaster prevention technology in China. Bull. Eng. Geol. Environ. 2019, 78, 5219–5235. [Google Scholar] [CrossRef]

- Hsieh, C.S.; Shih, T.; Hu, J.C.; Tung, H.; Huang, M.H.; Angelier, J. Using differential SAR interferometry to map land subsidence: A case study in the Pingtung Plain of SW Taiwan. Nat. Hazards 2011, 58, 1311–1332. [Google Scholar] [CrossRef]

- Xu, Y.S.; Shen, S.L.; Cai, Z.Y.; Zhou, G.Y. The state of land subsidence and prediction approaches due to groundwater withdrawal in China. Nat. Hazards 2008, 45, 123–135. [Google Scholar] [CrossRef]

- Bai, E.H.; Guo, W.B.; Zhang, D.S.; Tan, Y.; Guo, M.J.; Zhao, G.B. Using the magnetotelluric method for detecting aquifer failure characteristics under high-intensity mining of thick coal seams. Energies 2019, 12, 4397. [Google Scholar] [CrossRef]

- Guo, W.B.; Xu, F.Y. Numerical simulation of overburden and surface movements for Wongawilli strip pillar mining. Int. J. Min. Sci. Technol. 2016, 26, 71–76. [Google Scholar] [CrossRef]

- Bai, E.H.; Guo, W.B.; Guo, M.J.; Lou, G.Z.; Tan, Y. Analysis and application of backfill mining in thin coal seams for preventing building damage. Sains Malays. 2019, 48, 1823–1832. [Google Scholar] [CrossRef]

- Guo, W.J.; Wang, H.L.; Chen, S.J. Coal pillar safety and surface deformation characteristics of wide strip pillar mining in deep mine. Arab. J. Geosci. 2016, 9, 137. [Google Scholar] [CrossRef]

- Esterhuizen, G.S.; Dolinar, D.R.; Ellenberger, J.L. Pillar strength in underground stone mines in the United States. Int. J. Rock Mech. Min. Sci. 2011, 48, 42–50. [Google Scholar] [CrossRef]

- Guo, W.B.; Tan, Y.; Bai, E.H. Top coal caving mining technique in thick coal seam beneath the earth dam. Int. J. Min. Sci. Technol. 2017, 27, 165–170. [Google Scholar] [CrossRef]

- Ghasemi, E.; Shahriar, K. A new coal pillars design method in order to enhance safety of the retreat mining in room and pillar mines. Saf. Sci. 2012, 50, 579–585. [Google Scholar] [CrossRef]

- Jiang, B.; Oh, K.H.; Kim, S.Y. Technical evaluation method for physical property changes due to environmental degradation of grout-injection repair materials for water-leakage cracks. Appl. Sci. 2019, 9, 1740. [Google Scholar] [CrossRef]

- Zhang, J.X.; Zhang, Q.; Sun, Q.; Gao, R.; Germain, D.; Abro, S. Surface subsidence control theory and application to backfill coal mining technology. Environ. Earth Sci. 2015, 74, 1439–1448. [Google Scholar] [CrossRef]

- Bai, E.H.; Guo, W.B.; Tan, Y.; Yang, D.M. Green coordinated mining technology of strip mining roadway backfilling method. J. China Coal Soc. 2018, 43, 21–27. [Google Scholar]

- Muhammad, Z.E.; Hani, M.; Cecile, K. State-of-the-art review of backfill practices for sublevel stoping system. Int. J. Min. Reclam. Environ. 2015, 29, 544–556. [Google Scholar]

- Alehossein, H. Viscous, cohesive, non-Newtonian, depositing, radial slurry flow. Int. J. Miner. Process 2009, 93, 11–19. [Google Scholar] [CrossRef]

- Shen, B.T.; Poulsen, B. Investigation of overburden behaviour for grout injection to control mine subsidence. Int. J. Min. Sci. Technol. 2014, 24, 317–323. [Google Scholar] [CrossRef]

- Xuan, D.; Xu, J.L. Grout injection into bed separation to control surface subsidence during longwall mining under villages: Case study of Liudian coal mine, China. Nat. Hazards 2014, 73, 883–906. [Google Scholar] [CrossRef]

- Xuan, D.Y.; Xu, J.L.; Wang, B.L.; Teng, H. Borehole investigation of the effectiveness of grout injection technology on coal mine subsidence control. Rock Mech. Rock Eng. 2015, 48, 2435–2445. [Google Scholar] [CrossRef]

- Bell, F.G.; Genske, D.D. The influence of subsidence attributable to coal mining on the environment, development and restoration: Some examples from western Europe and South Africa. Environ. Eng. Geosci. 2001, 7, 81–99. [Google Scholar] [CrossRef]

- Bian, Z.F.; Miao, X.X.; Lei, S.G.; Chen, S.E.; Wang, W.F.; Struthers, S. The challenges of reusing mining and mineral-processing wastes. Science 2012, 337, 702–703. [Google Scholar] [CrossRef] [PubMed]

- Kostecki, T.; Spearing, A.J.S. Influence of backfill on coal pillar strength and floor bearing capacity in weak floor conditions in the Illinois Basin. Int. J. Rock Mech. Min. Sci. 2015, 76, 55–67. [Google Scholar] [CrossRef]

- Bai, E.H.; Guo, W.B.; Tan, Y.; Yang, D.M. The analysis and application of granular backfill material to reduce surface subsidence in China’s northwest coal mining area. PLoS ONE 2018, 13, e0201112. [Google Scholar] [CrossRef] [PubMed]

- Szczepanska, J.; Twardowska, I. Distribution and environmental impact of coal mining wastes in Upper Silesia, Poland. Environ. Geol. 1999, 38, 249–258. [Google Scholar] [CrossRef]

- Jiao, H.Z.; Wu, A.X.; Wang, H.J.; Yang, S.K.; Li, R.; Xiao, Y.T. The influence of cemented paste backfill on groundwater quality. Procedia Earth Planet. Sci. 2011, 2, 183–188. [Google Scholar] [CrossRef]

- Li, P.; Qian, H.; Howard, K.W.F.; Wu, J.; Lyu, X. Anthropogenic pollution and variability of manganese in alluvial sediments of the yellow river, Ningxia, northwest China. Environ. Monit. Assess. 2014, 186, 1385–1398. [Google Scholar] [CrossRef]

- Qi, W.Y.; Huang, Y.L.; He, H.; Zhang, J.X.; Li, J.M.; Qiao, M. Potential pollution of groundwater by dissolution and release of contaminants due to using gangue for backfilling. Mine Water Environ. 2019, 38, 281–293. [Google Scholar] [CrossRef]

- Feng, G.M. Research on the Super-High Water Packing Material and Filling Mining Technology and Their Application. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2009. [Google Scholar]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Key strata theory in strata control. J. China Coal Soc. 1996, 21, 225–230. [Google Scholar]

- Li, P.; Wang, X.F.; Cao, W.H.; Zhang, D.S.; Qin, D.D.; Wang, H.Z. Influence of spatial relationships between key strata on the height of mining-induced fracture zone: A case study of thick coal seam mining. Energies 2018, 11, 102. [Google Scholar] [CrossRef]

- Xie, J.L.; Xu, J.L. Effect of key stratum on the mining abutment pressure of a coal seam. Geosci. J. 2017, 21, 267–276. [Google Scholar] [CrossRef]

- Dou, L.M.; He, X.Q.; He, H.; He, J.; Fan, J. Spatial structure evolution of overlying strata and inducing mechanism of rockburst in coal mine. Trans. Nonferrous Met. Soc. China 2014, 24, 1255–1261. [Google Scholar] [CrossRef]

- Zhou, D.W.; Wu, K.; Bai, Z.H.; Hu, Z.Q.; Li, L.; Xu, Y.K.; Diao, X.P. Formation and development mechanism of ground crack caused by coal mining: Effects of overlying key strata. Bull. Eng. Geol. Environ. 2019, 78, 1025–1044. [Google Scholar]

- Zhang, G.C.; He, F.L.; Lai, Y.H.; Song, J.W.; Xiao, P. Reasonable width and control technique of segment coal pillar with high-intensity fully-mechanized caving mining. J. China Coal Soc. 2016, 41, 2188–2194. [Google Scholar]

- Song, Z.P.; Yin, X.C.; Mei, S.R. Theoretical analysis of the spatio-temporal evolution of the bulk-strain field based on a rheologic inclusion model. Acta Seismol. Sin. 2000, 13, 525–535. [Google Scholar] [CrossRef]

- Wang, A.L.; Ma, L.Q.; Wang, Z.W.; Zhang, D.S.; Li, K.; Zhang, Y.; Yi, X.J. Soil and water conservation in mining area based on ground surface subsidence control: Development of a high-water swelling material and its application in backfilling mining. Environ. Earth Sci. 2016, 75, 779. [Google Scholar] [CrossRef]

- Wang, X.F.; Zhang, D.S.; Sun, C.D.; Wang, Y. Surface subsidence control during bag filling mining of super high-water content material in the Handan mining area. Int. J. Oil Gas Coal Technol. 2016, 13, 87. [Google Scholar] [CrossRef]

- Cao, W.H.; Wang, X.F.; Li, P.; Zhang, D.S.; Sun, C.D.; Qin, D.D. Wide strip backfill mining for surface subsidence control and its application in critical mining conditions of a coal mine. Sustainability 2018, 10, 700. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).