Abstract

Virgin polymers based on petrochemical feedstock are mainly preferred by most plastic goods manufacturers instead of recycled plastic feedstock. Major reason for this is the lack of reliable information about the quality, suitability, and availability of recycled plastics, which is partly due to lack of proper segregation techniques. In this paper, we present our ongoing efforts to segregate plastics based on its types and improve the reliability of information about recycled plastics using the first-of-its-kind blockchain smart contracts powered by multi-sensor data-fusion algorithms using artificial intelligence. We have demonstrated how different data-fusion modes can be employed to retrieve various physico-chemical parameters of plastic waste for accurate segregation. We have discussed how these smart tools help in efficiently segregating commingled plastics and can be reliably used in the circular economy of plastic. Using these tools, segregators, recyclers, and manufacturers can reliably share data, plan the supply chain, execute purchase orders, and hence, finally increase the use of recycled plastic feedstock.

1. Introduction

Today, plastic has become both a symbol of human ingenuity and absurdity. We created this remarkable material with different properties and capabilities. However, we did not pay proper attention in managing this resource after its use (Thompson et al. 2009). As a result, in 30 years, our oceans will contain more plastic by volume than fish (WEM 2016). Illicit oil-spills from ships (Bhatt et al. 2018; Sankaran and Fortuny-Guasch 2004) and massive oil-refinery accidents (Dean et al. 1990) in oceans often catch our attention and several studies have been reported to mitigate and manage these marine pollutions (Brekke and Solberg 2005; Fingas 2016; Sankaran 2019b, 2020). However, we do not take responsibility for our collective actions that are silently poisoning the entire marine ecosystem in a different way in the form of plastic pollution.

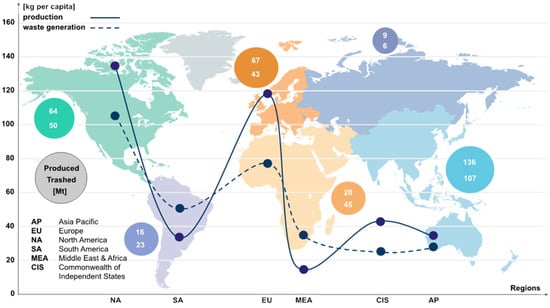

Worrying? Of course, this is not a sudden change. The historical data, in retrospect, tells us the dramatic development of this silent chaos. 15 million tonne [Mt] of plastic was globally produced in 1964, which grew to 311 Mt in 2014. This further grew to 359 Mt in 2018 (PlasticsEurope 2015, 2019; WEM 2016). Present estimates warn us that this figure will triple in the next three to four decades (Lebreton and Andrady 2019). Figure 1 illustrates annual virgin plastic production (figures on the top) and plastic trashed as waste (figures on the bottom) in million tonne [Mt] across different regions in year 2010 (PlasticsEurope 2011). Additionally, the per capita virgin plastic production (solid line) and waste generation (dotted line) are also plotted giving different regional perspectives.

Figure 1.

Annual virgin plastic produced (top) and trashed as waste (bottom) in million tonne [Mt] for different shaded regions in year 2010. Per capita virgin plastic production (solid) and waste generated (dotted) for different shaded regions.

In the case of Asia-Pacific (AP) region, the per capita plastic production and waste generation are low as seen in Figure 1. This is because the population of this region is the highest in the world with China and India together contributing to more than one third of the world’s population. It would be worth mentioning that in 2018 China alone contributed to about 23% of plastic production and 21% of waste generation in the world (PlasticsEurope 2019; Ritchie and Roser 2019).

Crazy as it may sound, there is no simple way to wish away this pervasive material. At least there is a common understanding on how plastic is polluting our water bodies, destroying wildlife, entering our food-chain, and ultimately damaging our well-being (Jambeck et al. 2015; Rochman et al. 2013). Most of the countries around the world are committing resources to collect and recycle this material (Giacovelli 2018; UNEP-AR 2018; UNEP-SP 2018). But this is far away from ideal scenario (Hook and Reed 2018).

Away from eyes away from mind best reflects our attitude about plastic wastes because most of it is still ending up in landfills. In 2015 globally, about 50–60% of the total plastic waste was discarded or dumped in landfills, 20–30% was incinerated, and about 10–20% was recycled (Geyer et al. 2017; Ritchie and Roser 2017). Considering only developing or underdeveloped countries, the amount of plastic waste sent to landfills is much higher than the global average. Various reckless dumping activities have contributed to land and marine pollution, which will take decades, if not centuries, to rehabilitate (Barnes et al. 2009). The next viable option to dumping is to incinerate plastic waste to produce energy, however, this approach has two drawbacks. Firstly, by burning the plastic waste, we are potentially destroying valuable feedstock. Secondly, by doing this, we are going to only increase the influx of virgin feedstock mainly derived from fossil fuel-based sources into our ecosystem. Hence, putting us on an ever-increasing Sisyphean task.

Moreover, only by efficiently recycling plastic waste we can fight marine and land pollution. In 2016, PlasticsEurope and the European Association of Plastics Recycling and Recovery Organisations (EPRO) commissioned a study across EU-28 countries plus Norway and Switzerland for monitoring plastics waste, recycling and recovery (European Commission 2018; PlasticsEurope 2017). This study reported that the collected annual post-consumer plastic waste reached 25.1 Mt. The recovery of feedstock through recycling reached 72.7%. This study further highlights that among all plastic waste, the packaging plastic materials have the highest recycling and recovery rates for Europe—42% (PlasticsEurope 2019). During this reporting period, for the first time, the amount of recycling for plastic waste was more than what went into landfills. These figures are consoling, however, they do not reveal the ground reality in many countries.

Producing plastic products is carbon- and energy-intensive. These processes emit huge amount of greenhouse gases, either directly or indirectly. If we take into account the complete supply chain of the source of various plastics and their respective disposal pathways, overall carbon footprint increases tremendously. Regardless of post-disposal pathways—landfilling, incinerating or recycling—we have to deal with resulting carbon emissions. In 2015, global carbon emission due to virgin (fossil fuel-based) plastic production was approximately 1.8 Gt. To put this into perspective, this amount corresponds to roughly 3.8% of the overall global carbon emission in that year due to various human activities. If we take into account all the emissions coming from the post-disposal and recycling processes, the carbon footprint of plastics during their entire life cycle will be much higher (Chaffee and Yoros 2007; Pilz et al. 2010; Zheng and Suh 2019).

In reality, even in Europe only about 10 countries have less than 10% of their plastic waste going to landfill. Among the 28-Member-States European Union (EU), this figure is disturbingly more than 50% for nearly 11 countries (Gourmelon 2015). Obviously, increasing the amount of recycling in terms of material recovery will reduce the fossil fuel consumption and related greenhouse gas (GHG) emissions (Zheng and Suh 2019). This will also spare us from not depleting valuable natural resources. But then, why are we not taking this logical next step seriously? Are there structural challenges in the pathways to plastic recycling? If then, what are recent technological developments that can help us in the battle against this human-induced absurdity?

We will address these points in this paper. In particular, we will discuss some of the ongoing efforts in Radical Innovations Group in domain of circular economy of plastic waste. In addition to the ongoing activities in circular economy of plastic waste, we also studied various other processes involving recycling of wastes and emissions (Patil and Sankaran 2020a, 2020b; Sankaran 2019a). We have developed first-of-its-kind blockchain smart contracts powered by multi-sensor artificial intelligence (AI) tools that are highly useful for the circular economy of plastic. We will discuss how these smart tools help segregators, recyclers, and manufacturers to reliably share data, plan the supply chain, execute purchase orders to increase the use of recycled plastic feedstock. In the following, we will first look at some of relevant recent developments and challenges in the circular economy of plastic.

2. Plastic Circular Economy—Recent Developments and Challenges

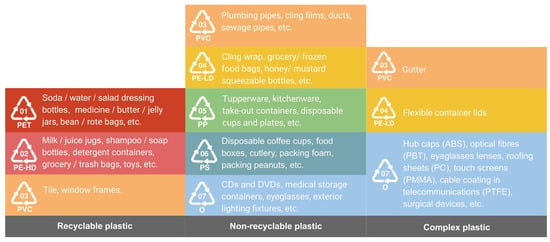

There are different classifications of the plastics based on their constituent components, reusability, synthesis process, etc. In this work on circular economy of plastic waste, we classify them in three types, namely, recyclable, non-recyclable, and complex or unknown. The types of plastics considered here are as per the European classification described in (European Commission 1997). The most commonly produced plastics under these types are shown in Figure 2.

Figure 2.

Different types of recyclable, non-recyclable, and complex plastics.

2.1. Recent Developments

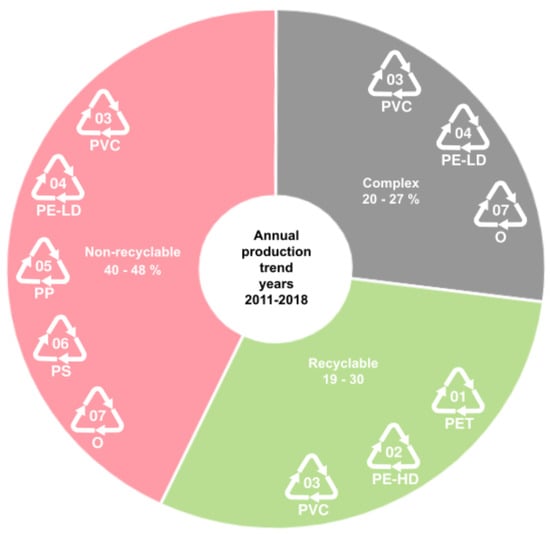

We analysed annual plastic production data available for years between 2011 and 2018 as shown in Figure 3. This data reveals that based on different types of plastics about 40–48% of annually produced plastics are non-recyclable. About 19–30% are potentially recyclable and nearly 20–27% fall under complex or unknown category (PlasticsEurope 2011, 2012, 2013, 2014, 2015, 2016, 2017, 2018, 2019). When we say potentially recyclable it only means there is a scope for recycling, however, whether we actually recycle them or not depends on how we handle them after their end-of-life. Likewise, most of the non-recycling plastic has the potential to be converted in waste-to-energy. But disturbingly they are often dumped in oceans and landfills (Bläsing and Amelung 2018; Derraik 2002; Haward 2018; Jambeck et al. 2015; Parker 2015; Wong et al. 1974).

Figure 3.

Potentially recyclable, non-recyclable, and complex plastics based on global annual production data for years between 2011 and 2018.

Cities and suburbs are main sources of plastic waste that ends up in landfills and water bodies. Various organised efforts in the form of waste collection are in place in many regions. For example, in cities and suburbs with high density of population, truck-based come $ collect schemes are becoming popular. Done on a weekly- or biweekly-basis in different neighbourhoods, they become commercially feasible following the economies of scale. However, in rural areas with less population density go & return schemes are economically-efficient (Hopewell et al. 2009).

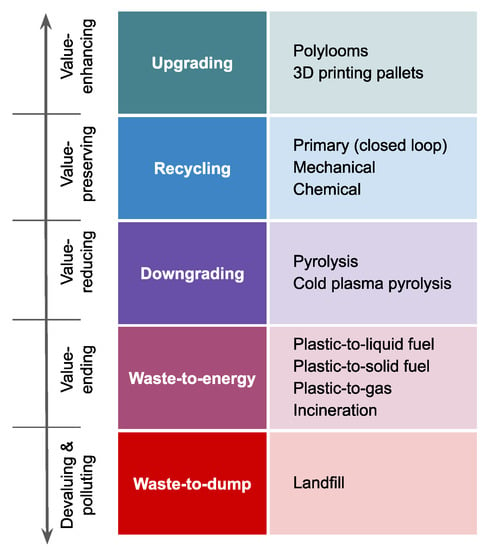

Different industrial processes to recycle various types of plastics are shown in Figure 4. These pathways differ in their underlying technologies. Each of these processes have their advantages and disadvantages, which need to be properly weighed before making a decision (Singh et al. 2017). Important industrial processes include pyrolysis (Adrados et al. 2012; Kaminsky 1992), plastic waste-to-energy (Kunwar et al. 2016; Miskolczi et al. 2004; Wong et al. 2015), chemical and mechanical recycling (Ragaert et al. 2017; Shen and Worrell 2014). Though we term them plastic waste, there is an inherent material value (cost per unit mass) to the original feedstock that is retrievable from the plastic waste. One can enhance, preserve, reduce, end, or dump this inherent material value depending on the steps we take to process them.

Figure 4.

Different pathways to process plastic waste.

2.2. Challenges

Before addressing the main challenges, we need to pay attention to key factors influencing plastic recycling. First, the price of the recycled plastic feedstock compared to virgin feedstock is a primary factor on which most plastic manufacturers base their purchase decisions. If the price is lower or comparable to that of virgin polymers, then the quantity and quality of the recycled plastic feedstock come into question. These three factors (price, quality, and quantity) are important drivers of the demand-side for recycled plastic polymers (Eriksen et al. 2018).

In addition to the above factors, the price of oil directly drives the price of virgin feedstock. In turn, the price of virgin polymers set the upper limit for the selling price of recycled plastic feedstock. Though increasing oil prices directly pushes the price of virgin polymers high, this increase makes recycled polymers more attractive (Ruhl 2019). That being said, there will be of course an indirect increase in the cost of plastic waste collection, processing, and distribution. This, however, will not be so dramatic as in the case of virgin polymers (Hopewell et al. 2009).

The next big challenge is the notion of polymer quality. Generally, manufacturers assume that the recycled polymers are poorer in quality compared to their virgin counterparts (Eriksen et al. 2018). Though there is a level of truth in this, exceptions are possible and needs to be supported by proper information.

Another fundamental challenge to overcome is the cost of recycling compared to alternative forms of plastic waste disposal. When reprocessing cost is very high compared to dumping or incineration and when the demand for recycled polymers is also low, there is low motivation to circular economy of plastics. In many poor and developing countries where land cost is low and poorly regulated, this is unfortunately the case (Dhokhikah and Trihadiningrum 2012; Driessen 2003). Hence, most of the potentially recyclable plastics end up being burnt or dumped in landfills. Recently, many developing countries are seriously regulating their plastic waste policies and shutting down illegal recycling, dumping, or incinerating activities (Brooks et al. 2018). We can overcome this challenge only when the demand for recycled plastic feedstock increase and cost of dumping becomes prohibitively high. Furthermore, when waste-to-energy becomes less commercially attractive or highly regulated, there is a positive drive for increased recycling.

Finally, it all boils down to increasing the demand for recycled polymers. Though price is an important driver, we cannot bring in big changes in this value-chain only by bringing the price of recycled plastics lower than that of their virgin counterparts. We need to also overcome a bigger challenge, which is the lack of reliable information about their availability, quantity, quality, and suitability for a specific application. Without such a reliable information, it will be difficult to motivate manufacturers to procure more recycled feedstock.

We will briefly address how we are able to help manufacturers get reliable information about the availability, quantity, and quality of recycled feedstock using advanced blockchain and AI technologies. Furthermore, if we are able to calibre and derive grades for different recycled polymers, we can assess the suitability of recycled polymers for various applications. This helps in transforming information to actionable intelligence and provides additional incentives to participate in the blockchain platform.

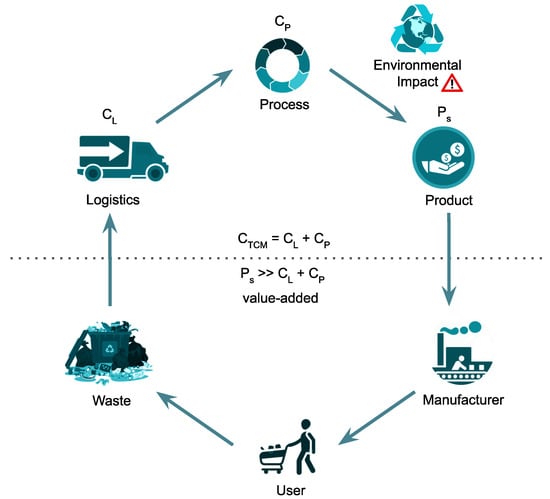

3. Value of Waste in Circular Economy

First step towards circular economy plastic is to understand the actual potential for creating value. For this, we have followed a process that we term as total costing method (TCM). In TCM, we account for cost incurred in each step of the circular economy starting from the waste collection point to the final destination. That is, the (waste) material starts its journey towards the final destination, which could be recycling plant, incineration plant or landfill. There are two stages which incur costs, namely, logistics and processing. Depending on how much the process adds (or removes) value, we have 5 types of processes, namely, upgrading, closed-loop recycling, downgrading, waste-to-energy, and dumping.

The cost of the material is going to step-by-step increase from the point of waste collection to their respective destination. Even if they are just going to be dumped, we have to take into account logistics and environmental costs. The latter is difficult to estimate as plastics take more than 400 years to degrade and most of it still exists in some form or the other after being dumped in land or ocean. According to the statistics for years between 2000 and 2015, roughly 15 to 25 % plastic wastes are incinerated and 10 to 20 % are recycled (Ritchie and Roser 2019). Hence, most of it still ends up in landfills and the cost of rehabilitation is considerably high.

The sum of logistics () and processing () costs is the total transactional cost of the processed material () after their respective processes as illustrated in Figure 5. The selling price of the material () should be more than the for any recycling process to be profitable. Here, we have not taken into account the cost of environmental degradation. To incorporate environmental cost, we need further investigation to carefully study the short-, medium-, and long-term impacts of the respective processes.

Figure 5.

Total carbon footprint for plastic waste recycling pathways.

In the next section, advanced tools developed to help manufacturers get reliable information about the availability, quantity, and quality of recycled feedstock are briefly discussed.

4. Multi-Sensor-Driven AI and Blockchain Tools

We would like to highlight the ongoing work in tool developments using blockchain and multi-sensor-driven AI system in Radical Innovations Group. We will shortly discuss multi-sensor-driven AI system before describing the blockchain platform.

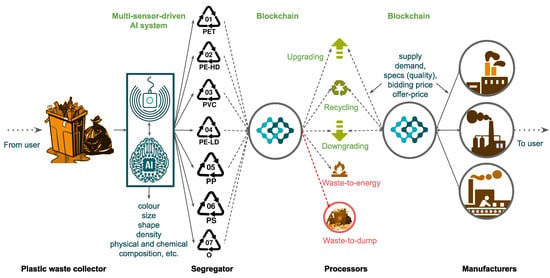

At the segregation stage as shown in Figure 6, we employ different type of sensors supported by AI. Multi-sensor data fusion has been very successful in training intelligent robots for various tasks (Luo et al. 1988; Masoumi et al. 2012; Mitchell 2007; Scott 1995). Some researchers have tried combining multi-sensor data fusion with neural network to identify and segregate plastic waste (Scott and Waterland 1995). The data about the shape, colour, and texture are retrieved from high-definition optical sensors (cameras). Using this, for example, we can separate certain shaped or coloured plastic bottles. We can also employ (near-infrared) laser diodes. The light absorption spectroscopy of plastics, particularly in the wavelength-range from 300 to 3000 nanometre [nm] showed new possibility of optical sensing of plastics. Near-infrared laser diodes are also increasingly used to study the resonant frequencies of different plastics. These laser sensors can differentiate six types of detectable plastics, namely, PET (polyethylene terephthalate), PE (polyethylene), PVC (polyvinyl chloride), PP (polypropylene), PS (polystyrene), and ABS (acrylonitrile butadiene styrene). Essentially, these sensors differentiate different grades of plastic based on the resonant frequency of each type of plastic. Those frequencies at which the absorption spectrum of the plastic has a peak, they are called as resonant frequencies. Different plastic molecules have different resonant frequencies. By scanning the plastic wastes using these laser detectors over a range of frequencies we can find their resonant frequency. Depending on their resonant frequency, we can identify the type of plastic. Recently, researchers have tried using advanced terahertz technologies for plastic identification (Hailu and Saeedkia 2017). These technologies can further help in accurate identification and segregation of plastic waste. For segregation based on colour, manual separation is not a good option for industrial scale operations. Taking into account both the speed and accuracy required for industrial scale set-ups, these technologies can yield nearly 99% accuracy for colour-based segregation and 95-98% accuracy for plastic type-based segregation (Inada et al. 2001; Scott and Waterland 1995; Zhu et al. 2019).

Figure 6.

Blockchain and multi-sensor-powered artificial intelligence interfaces for plastic waste recycling.

The role of AI in this multi-sensor platform is to minimize uncertainties and enable efficient and intelligent segregation. For example, AI can train the segregation system to recognize two bottles of same type even if one of them looked very different to the other (deformed or discoloured). In these instances, the AI can train the system to properly recognise and separate them accurately. The efficiency of the present multi-sensor-driven AI implementation for segregating plastic wastes is tested in various practical scenarios. Discussions regarding the outcomes of these studies are outside the scope of this present paper and will be presented elsewhere.

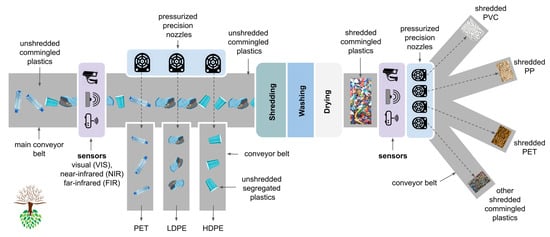

4.1. Multi-Sensor-Based Plastic Waste Segregation

Segregating commingled plastic waste is a challenging task. The amount of plastic recycling directly depends on the efficiency and accuracy of separating plastics into their respective categories based on colour (pigments), chemical composition (plastic type), and source of plastic waste. We have developed a multi-sensor-based segregation process that uses three types of sensors. They are classified based on their operating frequencies as visual (VIS), near-infrared (NIR), and far-infrared (FIR) sensors. These sensors retrieve different types of information (attributes) such as colour, physical and chemical compositions, shapes, etc., about the plastic waste. These attributes are used to segregate plastics into different types. One of segregation process flow models developed in Radical Innovations Group is illustrated in Figure 7.

Figure 7.

Segregation of commingled plastic waste into respective categories using multi-sensor data. © Radical Innovations Group.

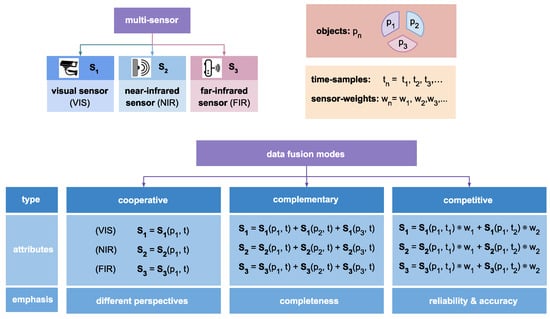

We will briefly describe three data-fusion modes employing three types of sensors. They are called cooperative, complementary, and competitive data-fusion modes and are illustrated in Figure 8. Consider an object with three different parts made of three types of plastics denoted as , , and . And let the data retrieved from VIS, NIR, and FIR sensors are respectively given by , , and . The cooperative mode is the most basic data-fusion mode where all three sensors—VIS, NIR, and FIR—are employed in parallel to get different information about the same object. In the case of VIS sensor data, we will get the visual image of as in the case of an optical camera. From NIR and FIR sensors, we can retrieve the absorption spectrum over a range wavelengths (typically in the range of 1–1000 m). The complementary mode of data-fusion helps us to retrieve the overall assessment of the complete object using different sensor data. Lastly, in the competitive data-fusion mode, data samples of the same object taken at different time steps are proportionately mixed using different weights.

Figure 8.

Multi-sensor cooperative, complementary, and competitive data-fusion modes.

4.2. Blockchain Smart Contracts

The blockchain technology serves as a trust-based platform between plastic waste segregators, recyclers, and recycled feedstock buyers (manufacturers). The blockchain network has distributed, but not copied, digital information (Adebiyi-Abiola et al. 2019; Crosby et al. 2016; Drescher 2017; Kouhizadeh and Sarkis 2018; Kouhizadeh et al. 2019; Mansfield-Devine 2017; Romano and Schmid 2017; Sekhri 2018; Wang and Qu 2019). This digital information is validated by various partners during each transaction. A transaction is an exchange of information between segregators, recyclers, and manufacturers. Information transacted contains data regarding supply, demand, specifications (quality), bidding- and offer-price as illustrated in Figure 6. A few use-case examples employing multi-sensor-driven AI for plastic waste segregation and blockchain platform for circular economy of plastic waste are currently under investigation in Radical Innovations Group.

In the original design of blockchain, one gets rewarded for participating in the validation process using digital currency. In our model, for simplicity, we have focused only on the backbone without the reward system to showcase the use of this technology for plastic circular economy. The security and transparency of the platform is derived from the fact that all the information is stored on a distributed blockchain ledger. The access to information powered by blockchain platform allows participants to exchange and validate information about supply, demand, specifications, bidding-, and offer-prices. In sum, the participants in the blockchain platform are rewarded by various actionable intelligence that allow for efficient planning of supply-chain, operations, and cashflow. This essentially will lead to an improved resource efficiency and a profitable model for the circular economy of plastic waste.

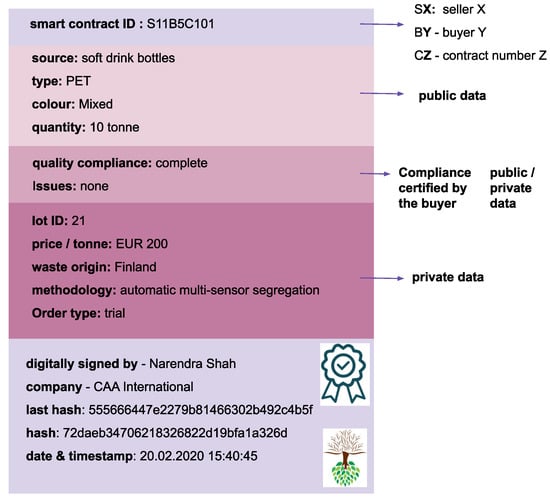

In the blockchain system currently being developed in Radical Innovations Group for modelling plastic circular economy we have developed two types of smart contracts depending on the stage of raw materials being transacted. In the first type, the smart contract is typically between a supplier of the segregated plastic waste (segregator) and a prospective buyer (example, closed-loop recycler). The second type of smart contract is typically between supplier of recycled plastic feedstock and prospective plastic goods manufacturer. Consider an example smart contract between segregator and closed-loop recycler shown in Figure 9. There are two types of data in this example smart contract, namely, public and private.

Figure 9.

Example blockchain smart contract between a plastic waste segregator and a closed-loop recycler. © Radical Innovations Group.

The public data is open for the validators to scrutinize and approve. The private data, however, is closed information only accessible to the seller and buyer involved in this contract. The validation of the private data is only possible through the buyer. Typically, information related to price, segregation methodology, origin of waste materials, order-type are contained in the private data. These information are hidden not to compromise the competitive-edge of each seller offering similar products. Most importantly, the buyers can validate and approve information related to quality compliance and issues related to purchased products. This information related to quality compliance and issues can be kept public or private depending on preferences set in the smart contract. Additionally, each smart contract will be digitally signed and timestamped through a validation protocol.

4.3. Remarks Related to Ongoing and Future Work

Our multi-sensor data-fusion algorithms and the blockchain interface are currently tested for various practical scenarios. Efficiency of multi-sensor data-fusion algorithms, implementations of different blockchain validation protocols and the overall supply-chain impact parameters such as segregation efficiency, accuracy, blockchain user-satisfaction, data integrity, transparency, and validation, etc., are currently being evaluated using those practical scenarios. Details of these assessments are outside the scope of current paper and will be presented elsewhere.

5. Conclusions

We addressed some of the structural challenges emerging due to the lack of improved technologies in plastic waste segregation and recycling processes, and the lack of reliable data about recycled plastics. We have showcased how multi-sensor data fusion tools using artificial intelligence help in accurate segregation of commingled plastic waste based on the physico-chemical parameters such as colour, polymer type, density, etc. Furthermore, we have demonstrated using a trust-based blockchain platform, how information about the suitability, quality compliance, bid- and offer-price, and availability of recycled plastic feedstock can be reliably shared between segregators, recyclers, and manufacturers. These blockchain smart contracts powered by multi-sensor data-fusion will encourage manufacturers to confidently procure more recycled plastic feedstock and, hence, reduce our increasing dependence on fossil-fuels. As a work in progress, we are currently testing these advanced tools with different early-stage adopters, to gain more real-time insights, and thereby increase impact of these tools in mainstream usage.

Author Contributions

K.S. wrote, reviewed, and edited the complete paper. K.S. is also responsible for developing the concept, tools, methodology, and investigation related to this work. A.C., P.B., D.K., M.Q. and M.K. worked directly under the supervision of K.S. as trainees and supported in data collection, preparing illustrations, and proofreading. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The paper is based on the ongoing work in the Radical Innovations Group, Finland.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| carbon dioxide | |

| GHG | greenhouse gas |

| CCS | carbon capture and storage |

| CCU | carbon capture and utilisation |

| CAGR | combined annual growth rate |

| methane | |

| methanol | |

| ammonia | |

| formic acid | |

| ROI | return on investment |

| PPP | public private partnership |

| CAPEX | capital expenditure |

| OPEX | operational expenditure |

| AI | artificial intelligence |

| Gt | giga tonne |

| Mt | million tonne |

| EU | European Union |

| EPRO | European Association of Plastics Recycling and Recovery Organisations |

| GHG | greenhouse gas |

| TCM | total costing method |

| cost of logistics | |

| cost of processing | |

| cost of environmental impact | |

| total transactional cost of processed material | |

| selling price of material | |

| PET | polyethylene terephthalate |

| PE | polyethylene |

| PVC | polyvinyl chloride |

| PP | polypropylene |

| PS | polystyrene |

| ABS | acrylonitrile butadiene styrene |

| nm | nanometre |

| specs | specifications |

References

- Adebiyi-Abiola, Bilikiss, Solomon Assefa, Kareem Sheikh, and Jeannette M. García. 2019. Cleaning up plastic pollution in Africa. Science 365: 1249–51. [Google Scholar] [CrossRef] [PubMed]

- Adrados, Aitziber, Isabel De Marco, Blanca Maria Caballero, A. López, M. Felisa Laresgoiti, and Amelia Torres. 2012. Pyrolysis of plastic packaging waste: A comparison of plastic residuals from material recovery facilities with simulated plastic waste. Waste Management 32: 826–32. [Google Scholar] [CrossRef]

- Barnes, David K. A., Francois Galgani, Richard C. Thompson, and Morton Barlaz. 2009. Accumulation and fragmentation of plastic debris in global environments. Philosophical Transactions of the Royal Society B: Biological Sciences 364: 1985–98. [Google Scholar] [CrossRef]

- Bhatt, Aditi, Aakash, and Krishnaswamy Sankaran. 2018. Spaceborne Ocean Monitors: Radar Imaging of Illicit Oil-Spills. In IEEE-INAE Workshop on Electromagnetics IIWE. Trivandrum: Indian National Academy of Engineering. [Google Scholar]

- Bläsing, Melanie, and Wulf Amelung. 2018. Plastics in soil: Analytical methods and possible sources. Science of The Total Environment 612: 422–35. [Google Scholar] [CrossRef]

- Brekke, Camilla, and Anne H. S. Solberg. 2005. Oil spill detection by satellite remote sensing. Remote Sensing of Environment 95: 1–13. [Google Scholar] [CrossRef]

- Brooks, Amy L., Shunli Wang, and Jenna R. Jambeck. 2018. The Chinese import ban and its impact on global plastic waste trade. Science Advances 4: 1–7. [Google Scholar] [CrossRef]

- Chaffee, Chet, and Bernard R. Yoros. 2007. Life Cycle Assessment for Three Types of Grocery Bags–Recyclable Plastics, Compostable, Biodegradable Plastic and Recyclable Paper. Boustead Consulting and Associates Limited. Available online: https://www.heartland.org/publications-resources/publications/life-cycle-assessment-for-three-types-of-grocery-bags—recyclable-plastic-compostable-biodegradable-plastic-and-recycled-recyclable-paper (accessed on 12 April 2020).

- Crosby, Michael, Nachiappan, Pradan Pattanayak, Sanjeev Verma, and Vignesh Kalyanaraman. 2016. Blockchain technology: Beyond bitcoin. Applied Innovation Review 2: 71. [Google Scholar]

- Dean, Kenneson G., William J. Stringer, Joanne E. Groves, Kristina Ahlinas, and Thomas C. Royer. 1990. The Exxon Valdez oil spill: Satellite analyses. In Oil Spills: Management and Legislative Implications. Reston: American Society of Civil Engineers, pp. 492–502. [Google Scholar]

- Derraik, José G. B. 2002. The pollution of the marine environment by plastic debris: A review. Marine Pollution Bulletin 44: 842–52. [Google Scholar] [CrossRef]

- Dhokhikah, Yeny, and Yulinah Trihadiningrum. 2012. Solid Waste Management in Asian Developing Countries: Challenges and Opportunities. Journal of Applied Environmental and Biological Sciences 2: 329–35. [Google Scholar]

- Drescher, Daniel. 2017. Blockchain Basics: A Non-technical Introduction in 25 Steps, 1st ed. Berkeley: Apress. [Google Scholar] [CrossRef]

- Driessen, Paul. 2003. Eco-Imperialism: Green Power, Black Death, 1st ed. Washington: Free Enterprise Press. [Google Scholar]

- Eriksen, Marie Kampmann, Anders Damgaard, Alessio Boldrin, and Thomas Fruergaard Astrup. 2018. Quality Assessment and Circularity Potential of Recovery Systems for Household Plastic Waste. Journal of Industrial Ecology 23: 156–68. [Google Scholar] [CrossRef]

- European Commission. 1997. Official Journal L 50 of the European Communities. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=OJ:L:1997:050:FULL&from=EN (accessed on 12 April 2020).

- European Commission. 2018. A European Strategy for Plastics in a Circular Economy. Technical Report. Available online: https://ec.europa.eu/environment/circular-economy/pdf/plastics-strategy-brochure.pdf (accessed on 12 April 2020).

- Fingas, Merv. 2016. Springer Handbook of Ocean Engineering. Volume Part D—Offshore Technologies, Chapter Oil Spills and Response. Cham: Springer, pp. 1067–94. [Google Scholar] [CrossRef]

- Geyer, Roland, Jenna R. Jambeck, and Kara Lavender Law. 2017. Production, use, and fate of all plastics ever made. Science Advances 3: e1700782. [Google Scholar] [CrossRef]

- Giacovelli, Claudia. 2018. Single-Use Plastics: A Roadmap for Sustainability. Technical Report. Nairobi: UNEP. [Google Scholar]

- Gourmelon, Gaelle. 2015. Global plastic production rises, recycling lags. In New Worldwatch Institute Analysis Explores Trends in Global Plastic Consumption and Recycling. Washington: Worldwatch Institute. Available online: http://www.plastic-resource-center.com/wp-content/uploads/2018/11/Global-Plastic-Production-RisesRecycling-Lags.pdf (accessed on 12 April 2020).

- Hailu, Daniel M., and Daryoosh Saeedkia. 2017. Applications of Terahertz Technology for Plastic Industry. Boca Raton: CRC Press, Chapter 5. pp. 107–17. [Google Scholar]

- Haward, Marcus. 2018. Plastic pollution of the world’s seas and oceans as a contemporary challenge in ocean governance. Nature Communications 9: 1–3. [Google Scholar] [CrossRef] [PubMed]

- Hook, Leslie, and John Reed. 2018. Why the World’s Recycling System Stopped Working. Financial Times, October 25. [Google Scholar]

- Hopewell, Jefferson, Robert Dvorak, and Edward Kosior. 2009. Plastics recycling: Challenges and opportunities. Biological Sciences 364: 2115–26. [Google Scholar] [CrossRef] [PubMed]

- Inada, Koji, Rina Matsuda, Chizuru Fujiwara, Mitsutoshi Nomura, Tatsumi Tamon, Ikkan Nishihara, Takeshi Takao, and Toshihiro Fujita. 2001. Identification of plastics by infrared absorption using InGaAsP laser diode. Resources, Conservation and Recycling 33: 131–46. [Google Scholar] [CrossRef]

- Jambeck, Jenna R., Roland Geyer, Chris Wilcox, Theodore R. Siegler, Miriam Perryman, Anthony Andrady, Ramani Narayan, and Kara Lavender Law. 2015. Plastic waste inputs from land into the ocean. Science 374: 768–71. [Google Scholar] [CrossRef]

- Kaminsky, Walter. 1992. Possibilities and limits of pyrolysis. Makromolekulare Chemie. Macromolecular Symposia 57: 145–60. [Google Scholar] [CrossRef]

- Kouhizadeh, Mahtab, and Joseph Sarkis. 2018. Blockchain practices, potentials, and perspectives in greening supply chains. Sustainability 10: 3652. [Google Scholar] [CrossRef]

- Kouhizadeh, Mahtab, Joseph Sarkis, and Qingyun Zhu. 2019. At the Nexus of Blockchain Technology, the Circular Economy, and Product Deletion. Applied Sciences 9: 1712. [Google Scholar] [CrossRef]

- Kunwar, Bidhya, H. N. Cheng, Sriram R. Chandrashekaran, and Brajendra K. Sharma. 2016. Plastics to fuel: A review. Renewable and Sustainable Energy Reviews 54: 421–28. [Google Scholar] [CrossRef]

- Lebreton, Laurent, and Anthony Andrady. 2019. Future scenarios of global plastic waste generation and disposal. Palgrave Communications 5: 1–11. [Google Scholar] [CrossRef]

- Luo, Ren C., M.-H. Lin, and Ralph S. Scherp. 1988. Dynamic multi-sensor data fusion system for intelligent robots. IEEE Journal on Robotics and Automation 4: 386–96. [Google Scholar] [CrossRef]

- Mansfield-Devine, Steve. 2017. Beyond Bitcoin: Using blockchain technology to provide assurance in the commercial world. Computer Fraud & Security 2017: 14–18. [Google Scholar] [CrossRef]

- Masoumi, Hamed, Seved Mohsen Safavi, and Zahra Khani. 2012. Identification and classification of plastic resins using near infrared reflectance. International Journal of Mechanical and Industrial Engineering 6: 213–20. [Google Scholar]

- Miskolczi, Norbert, Laszlo Bartha, Gy Deak, and Bela Jover. 2004. Thermal degradation of municipal plastic waste for production of fuel-like hydrocarbons. Polymer Degradation and Stability 86: 357–66. [Google Scholar] [CrossRef]

- Mitchell, Harvey B. 2007. Multi-Sensor Data Fusion: An Introduction, 1st ed. Berlin/Heidelberg: Springer. [Google Scholar] [CrossRef]

- Parker, Laura. 2015. Eight Million Tons of Plastic Dumped in Ocean Every Year. Available online: https://www.nationalgeographic.com/news/2015/2/150212-ocean-debris-plastic-garbage-patches-science/ (accessed on 12 April 2020).

- Patil, Aditya, and Krishnaswamy Sankaran. 2020a. Green Ammonia: What Feeds Our Crops Could Fuel Our Industries, Engineering Reports. In review.

- Patil, Aditya, and Krishnaswamy Sankaran. 2020b. Making Green from Black: Circular Economy of Carbon Emissions to Sustainable Fuels, Engineering Reports. In review.

- Pilz, Harald, Bernd Brandt, and Roland Fehringer. 2010. The Impact of Plastics on Life Cycle Energy Consumption and Greenhouse Gas Emissions in Europe; Summary Report June 2010. Vienna: PlasticEurope. Available online: https://www.plasticseurope.org/application/files/9015/1310/4686/september-2010-the-impact-of-plastic.pdf (accessed on 12 April 2020).

- PlasticsEurope. 2011. Plastics—The Facts 2011. Technical Report. Available online: https://www.plasticseurope.org/download_file/force/485/181 (accessed on 12 April 2020).

- PlasticsEurope. 2012. Plastics—The Facts 2012. Technical Report. Available online: https://www.plasticseurope.org/download_file/force/1687/181 (accessed on 12 April 2020).

- PlasticsEurope. 2013. Plastics—The Facts 2013. Technical Report. Available online: https://www.plasticseurope.org/download_file/force/930/181 (accessed on 12 April 2020).

- PlasticsEurope. 2014. Plastics—The Facts 2014. Technical Report. Available online: https://www.plasticseurope.org/download_file/force/840/181 (accessed on 12 April 2020).

- PlasticsEurope. 2015. Plastics—The Facts 2015. Technical Report. Available online: https://www.plasticseurope.org/download_file/force/835/181 (accessed on 12 April 2020).

- PlasticsEurope. 2016. Plastics—The Facts 2016. Technical Report. Available online: https://www.plasticseurope.org/download_file/force/6/181 (accessed on 12 April 2020).

- PlasticsEurope. 2017. Plastics—The Facts 2017. Technical Report. Available online: https://www.plasticseurope.org/download_file/force/1055/181 (accessed on 12 April 2020).

- PlasticsEurope. 2018. Plastics—The Facts 2018. Technical Report. Available online: https://www.plasticseurope.org/download_file/force/2367/181 (accessed on 12 April 2020).

- PlasticsEurope. 2019. The Circular Economy for Plastics—A European Overview. Technical Report. Available online: https://www.plasticseurope.org/en/resources/publications/1899-circular-economy-plastics-european-overview (accessed on 12 April 2020).

- Ragaert, Kim, Laurens Delva, and Kevin Van Geem. 2017. Mechanical and chemical recycling of solid plastic waste. Waste Management 69: 24–58. [Google Scholar] [CrossRef]

- Ritchie, Hannah, and Max Roser. 2017. CO2 and Greenhouse Gas Emissions. Our World in Data. Available online: https://ourworldindata.org/co2-and-other-greenhouse-gas-emissions (accessed on 12 April 2020).

- Ritchie, Hannah, and Max Roser. 2019. Plastic Pollution. Technical Report. Available online: https://ourworldindata.org/plastic-pollution (accessed on 12 April 2020).

- Rochman, Chelsea M., Mark Anthony Browne, Benjamin S. Halpern, Brian T. Hentschel, Eunha Hoh, Hrissi K. Karapanagioti, Lorena M. Rios-Mendoza, Hideshige Takada, Swee Teh, and Richard C. Thompson. 2013. Policy: Classify plastic waste as hazardous. Nature 494: 169. [Google Scholar] [CrossRef]

- Romano, Diego, and Giovanni Schmid. 2017. Beyond bitcoin: A critical look at Blockchain-based systems. Cryptography 1: 15. [Google Scholar] [CrossRef]

- Ruhl, Christof. 2019. The war on plastic will dent oil demand more than anticipated. Financial Times. Available online: https://www.ft.com/content/281addec-2ed9-11e9-80d2-7b637a9e1ba1 (accessed on 12 April 2020).

- Sankaran, Krishnaswamy. 2019a. Carbon Emission and Plastic Pollution: How Circular Economy, Blockchain, and Artificial Intelligence Support Energy Transition? Journal of Innovation Management 7. [Google Scholar] [CrossRef]

- Sankaran, Krishnaswamy. 2019b. Protecting Oceans from Illicit Oil Spills: Environment Control and Remote Sensing using Spaceborne Imaging Radars. Journal of Electromagnetic Waves and Applications 33: 2373–403. [Google Scholar] [CrossRef]

- Sankaran, Krishnaswamy. 2020. Spaceborne Radar Remote Sensing of Ocean Surfaces: Electromagnetic Modelling and Applications. Journal of Electromagnetic Waves and Applications 34: 1–34. [Google Scholar] [CrossRef]

- Sankaran, Krishnaswamy, and Joaquim Fortuny-Guasch. 2004. Radar remote sensing for oil spill classification (optimization for enhanced classification). Paper presented at the 12th IEEE Mediterranean Electrotechnical Conference, Dubrovnik, Croatia, May 12–15; pp. 511–514. [Google Scholar] [CrossRef]

- Scott, David M. 1995. A two-colour near-infrared sensor for sorting recycled plastic waste. Measurement Science and Technology 6: 156. [Google Scholar] [CrossRef]

- Scott, David M., and Robert L. Waterland. 1995. Identification of plastic waste using spectroscopy and neural networks. Polymer Engineering & Science 35: 1011–15. [Google Scholar]

- Sekhri, Prerna. 2018. Harvesting the Plastic We Have Sowed: Costs and Challenges In, and a Novel Application of Blockchain for Implementing Extended Producer Responsibility in Chile. Ph.D. thesis, Massachusetts Institute of Technology, Cambridge, MA, USA. [Google Scholar]

- Shen, Li, and Ernst Worrell. 2014. Plastic recycling. In Handbook of Recycling. Amsterdam: Elsevier, pp. 179–90. [Google Scholar] [CrossRef]

- Singh, Narinder, David Hui, Rupinder Singh, I. P. S. Ahuja, Luciano Feo, and Fernando Fraternali. 2017. Recycling of plastic solid waste: A state of art review and future applications. Composites Part B: Engineering 115: 409–22. [Google Scholar] [CrossRef]

- Thompson, Richard C., Shanna H. Swan, Charles J. Moore, and Frederick S. Vom Saal. 2009. Our plastic age. Biological Sciences. [Google Scholar] [CrossRef]

- UNEP-AR. 2018. Putting the Environment at the Heart of People’s Lives—Annual Report 2018. Nairobi: United Nation Environment Programme. [Google Scholar]

- UNEP-SP. 2018. The State of Plastics: World Environment Day Outlook 2018. Nairobi: United Nation Environment Programme. [Google Scholar]

- Wang, Shuaian, and Xiaobo Qu. 2019. Blockchain Applications in Shipping, Transportation, Logistics, and Supply Chain. In Smart Transportation Systems 2019. Singapore: Springer, pp. 225–231. [Google Scholar] [CrossRef]

- WEM. 2016. The New Plastics Economy—Rethinking the Future of Plastics; Technical Report. Geneva: World Economic Forum. Available online: http://www3.weforum.org/docs/WEF_The_New_Plastics_Economy.pdf (accessed on 12 April 2020).

- Wong, C. S., David R. Green, and Walter J. Cretney. 1974. Quantitative tar and plastic waste distributions in the Pacific Ocean. Nature 247: 30–32. [Google Scholar] [CrossRef]

- Wong, Syieluing, Norzita Ngadi, Tuan Amran Tuan Abdullah, and Ibrahim M. Inuwa. 2015. Current state and future prospects of plastic waste as source of fuel: A review. Renewable and Sustainable Energy Reviews 50: 1167–80. [Google Scholar] [CrossRef]

- Zheng, Jiajia, and Sangwon Suh. 2019. Strategies to reduce the global carbon footprint of plastics. Nature Climate Change 9: 374–78. [Google Scholar] [CrossRef]

- Zhu, Shichao, Honghui Chen, Mengmeng Wang, Xuemei Guo, Yu Lei, and Gang Jin. 2019. Plastic solid waste identification system based on near infrared spectroscopy in combination with support vector machine. Advanced Industrial and Engineering Polymer Research 2: 77–81. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).