Predicting the Impact of Utility Lighting Rebate Programs on Promoting Industrial Energy Efficiency: A Machine Learning Approach

Abstract

:1. Introduction

2. Literature Reviews

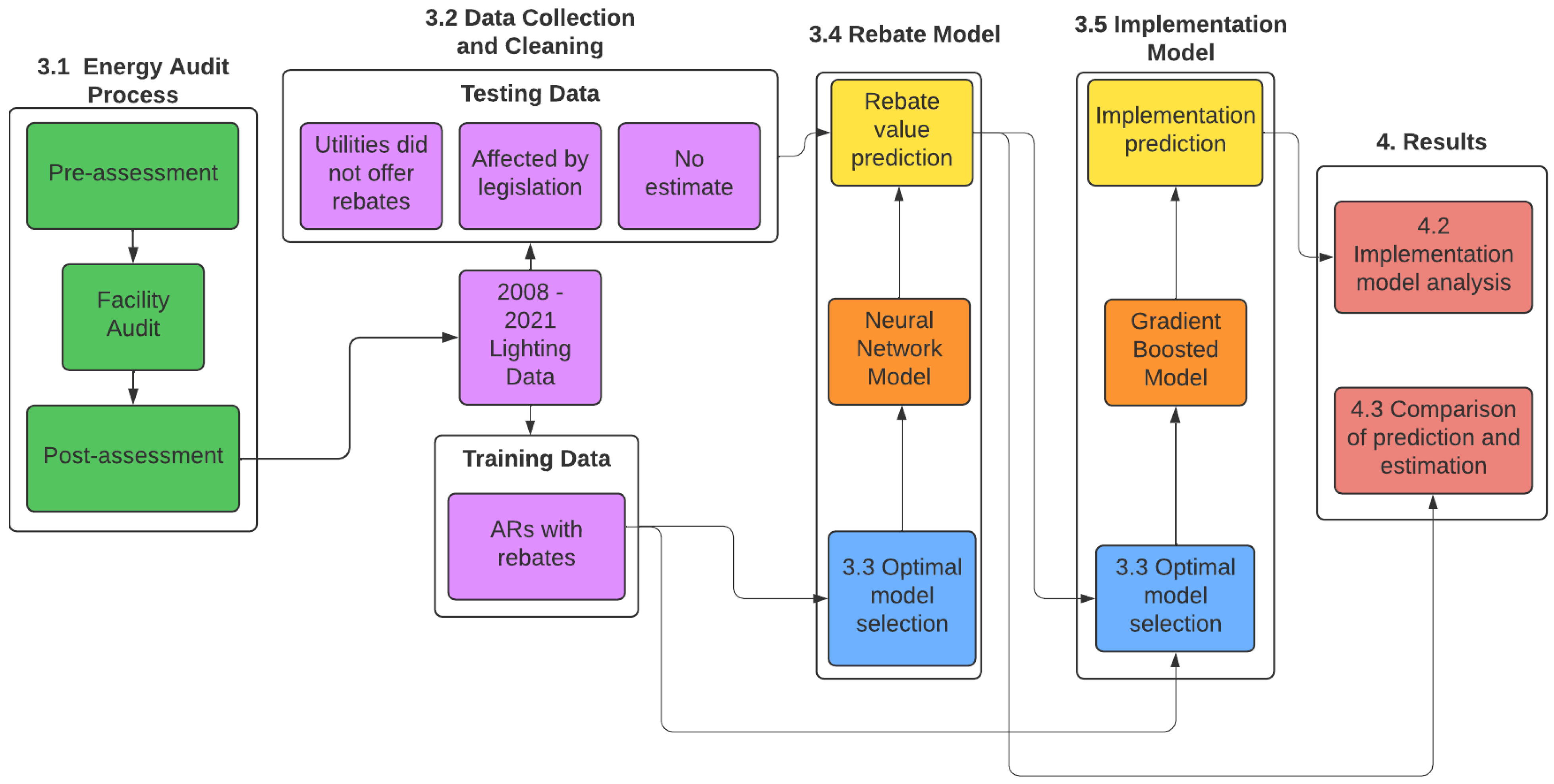

3. Methodology

3.1. Energy Audit Process

3.2. Data Collection and Cleaning

3.3. Optimal Model Selection

3.4. Rebate ML Model

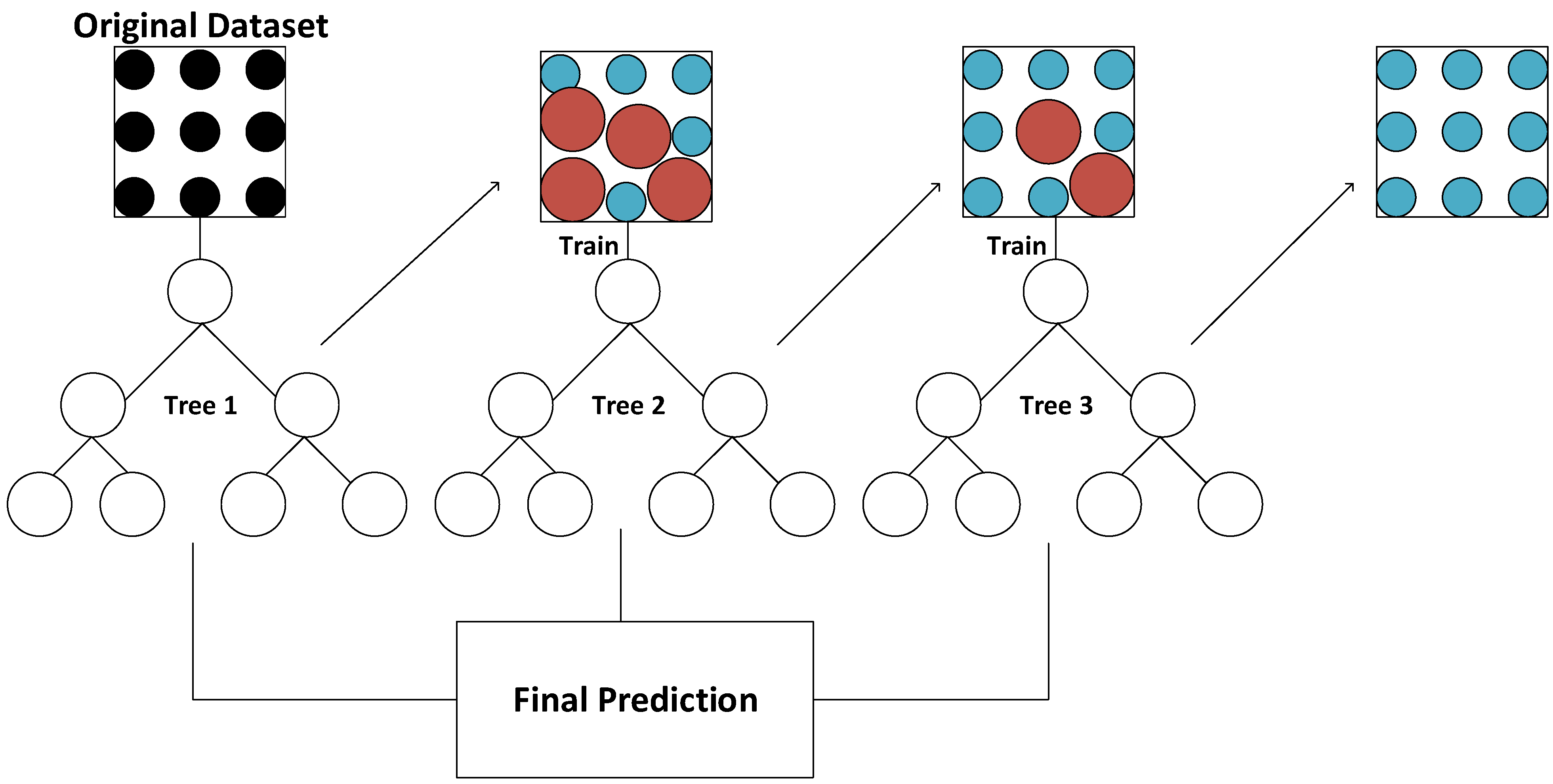

3.5. Implementation ML Model

4. Results

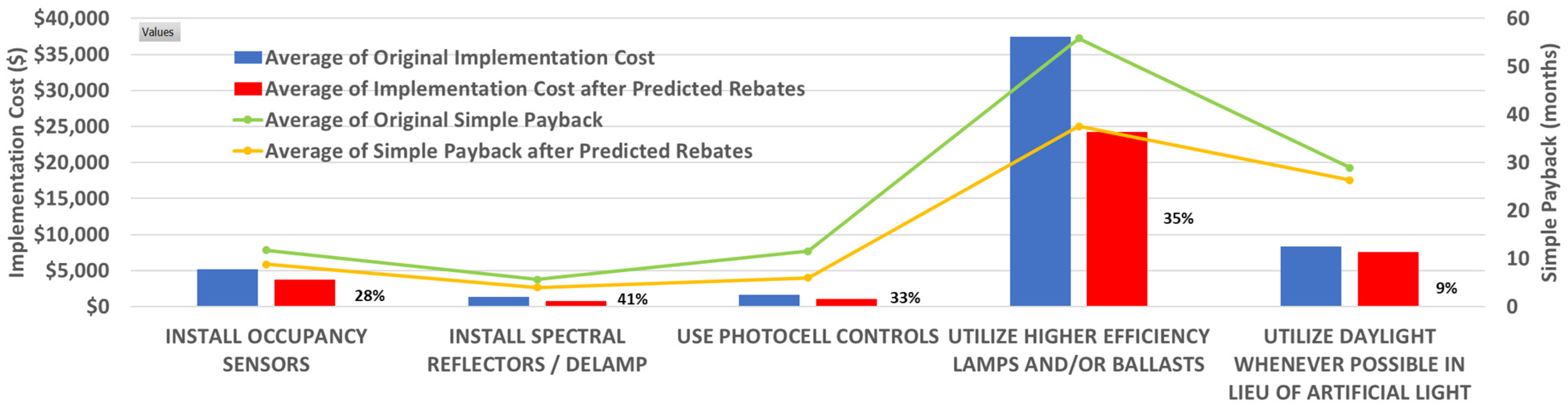

4.1. Results of the Rebate ML Model

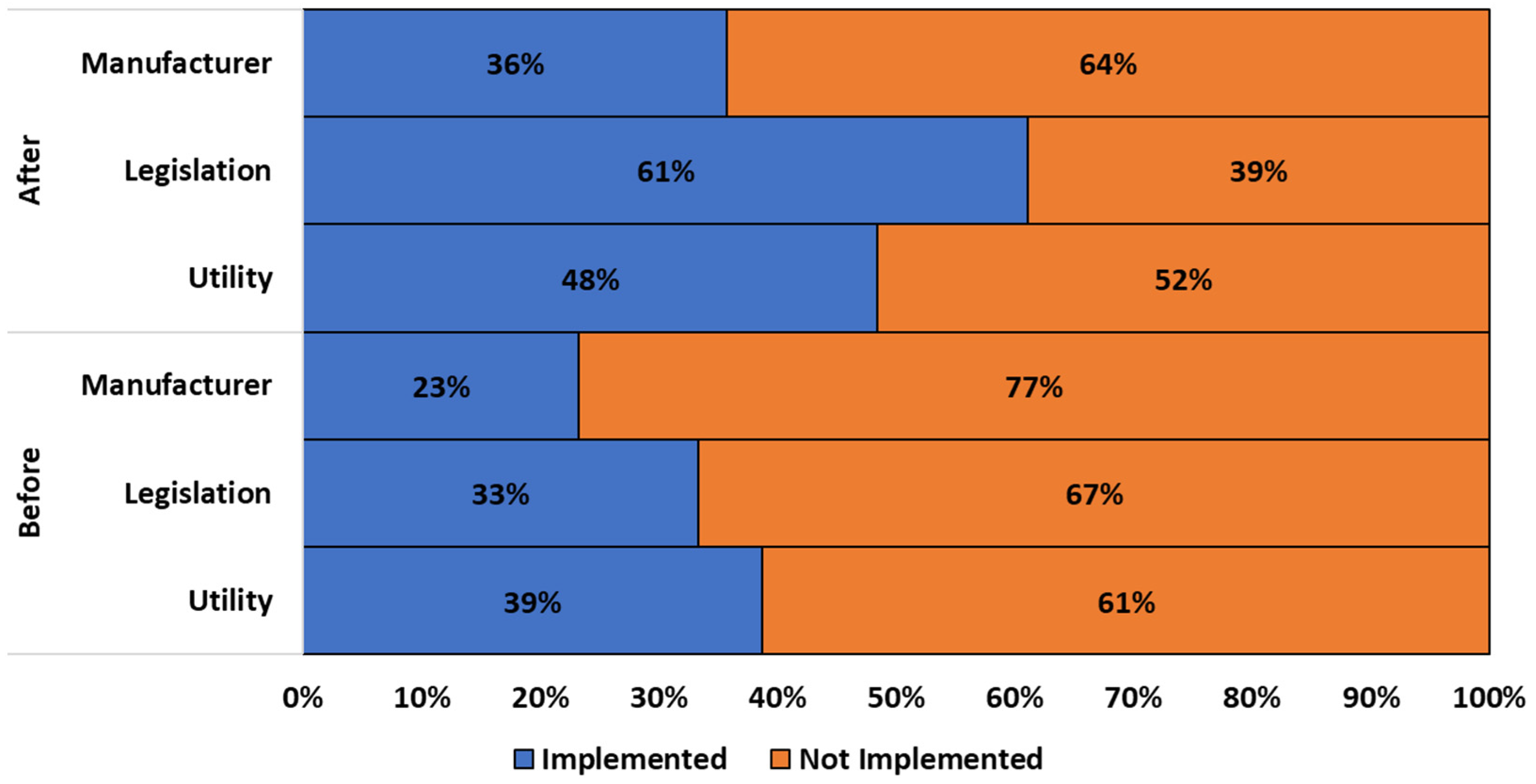

4.2. Results of the Implementation ML Model

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- EIA, U.S. Table F33: Total Energy Consumption, Price, and Expenditure Estimates; EIA, U.S.: Washington, DC, USA, 2019. [Google Scholar]

- EIA, U.S. How Much Electricity Is Used for Lighting in the United States? EIA, U.S.: Washington, DC, USA, 2021. [Google Scholar]

- Jovanović, B.; Filipović, J. ISO 50001 standard-based energy management maturity model—Proposal and validation in industry. J. Clean. Prod. 2016, 112, 2744–2755. [Google Scholar] [CrossRef]

- McKane, A. Thinking Globally: How ISO 50001—Energy Management Can Make Industrial Energy Efficiency Standard Practice; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2009. Available online: https://www.osti.gov/servlets/purl/983191 (accessed on 19 June 2022).

- Dalzell, N.M.; Boyd, G.A.; Reiter, J.P. Creating linked datasets for SME energy-assessment evidence-building: Results from the U.S. Industrial Assessment Center Program. Energy Policy 2017, 111, 95–101. [Google Scholar] [CrossRef]

- Choi, J.-K.; Schuessler, R.; Ising, M.; Kelley, D.; Kissock, K. A Pathway Towards Sustainable Manufacturing for Mid-size Manufacturers. Procedia CIRP 2018, 69, 230–235. [Google Scholar] [CrossRef]

- Juslén, H.; Tenner, A. Mechanisms involved in enhancing human performance by changing the lighting in the industrial workplace. Int. J. Ind. Ergon. 2005, 35, 843–855. [Google Scholar] [CrossRef]

- Jhunjhunwala, A.; Vasudevan, K.; Kaur, P.; Ramamurthi, B.; Kumaravel; Bitra, S.; Uppal, K. Energy efficiency in lighting: AC vs DC LED lights. In Proceedings of the 2016 First International Conference on Sustainable Green Buildings and Communities (SGBC), Chennai, India, 18–20 December 2016; pp. 1–4. [Google Scholar]

- Lundberg, D.C.; Tang, J.A.; Attari, S.Z. Easy but not effective: Why “turning off the lights” remains a salient energy conserving behaviour in the United States. Energy Res. Soc. Sci. 2019, 58, 101257. [Google Scholar] [CrossRef]

- Pandharipande, A.; Newsham, G.R. Lighting controls: Evolution and revolution. Lighting Res. Technol. 2018, 50, 115–128. [Google Scholar] [CrossRef]

- Delaney, D.; Ruzzelli, A.; O’Hare, G. Evaluation of Energy-Efficiency in Lighting Systems Using Sensor Networks. In Proceedings of the First ACM Workshop on Embedded Sensing Systems for Energy-Efficiency in Buildings, Berkeley, CA, USA, 3 November 2009. [Google Scholar] [CrossRef] [Green Version]

- Charles, A.G.; Elizabeth, S.; Ian, M.H.; Merrian, C.F.; Megan, A.B. Interactions between Energy Efficiency Programs Funded under the Recovery Act and Utility Customer-Funded Energy Efficiency Programs; LBNL: Berkeley, CA, USA, 2011; p. 73. [Google Scholar]

- Hoffman, I.M.; Goldman, C.A.; Rybka, G.; Leventis, G.; Schwartz, L.; Sanstad, A.H.; Schiller, S. Estimating the cost of saving electricity through U.S. utility customer-funded energy efficiency programs. Energy Policy 2017, 104, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Ohio General Assembly, SB 221, 127th General Assembly. 2008. Available online: http://archives.legislature.state.oh.us/bills.cfm?ID=127_SB_221 (accessed on 19 June 2022).

- Ohio State Government, House Bill 6. 2019. Available online: https://www.ohiocitizen.org/house_bill_6 (accessed on 18 June 2022).

- NC Clean Energy, DSIRE (Database of State Incentives for Renewables & Efficiency). Programs. 2021. Available online: https://www.dsireusa.org/ (accessed on 19 June 2022).

- Errigo, A.; Choi, J.-K.; Kissock, K. Techno-economic-environmental impacts of industrial energy assessment: Sustainable industrial motor systems of small and medium-sized enterprises. Sustain. Energy Technol. Assess. 2022, 49, 101694. [Google Scholar] [CrossRef]

- McLaughlin, E.; Choi, J.-K.; Kissock, K. Techno-Economic Impact Assessments of Energy Efficiency Improvements in the Industrial Combustion Systems. J. Energy Resour. Technol. 2021, 144, 082109. [Google Scholar] [CrossRef]

- Kapp, S.; Choi, J.-K.; Kissock, K. Toward energy-efficient industrial thermal systems for regional manufacturing facilities. Energy Rep. 2022, 8, 1377–1387. [Google Scholar] [CrossRef]

- Houde, S.; Aldy, J.E. Consumers’ Response to State Energy Efficient Appliance Rebate Programs. Am. Econ. J. Econ. Policy 2017, 9, 227–255. [Google Scholar] [CrossRef] [Green Version]

- Huh, S.-Y.; Jo, M.; Shin, J.; Yoo, S.-H. Impact of rebate program for energy-efficient household appliances on consumer purchasing decisions: The case of electric rice cookers in South Korea. Energy Policy 2019, 129, 1394–1403. [Google Scholar] [CrossRef]

- Datta, S.; Filippini, M. Analysing the impact of ENERGY STAR rebate policies in the US. Energy Effic. 2016, 9, 677–698. [Google Scholar] [CrossRef] [Green Version]

- Choi, J.-K.; Eom, J.; McClory, E. Economic and environmental impacts of local utility-delivered industrial energy-efficiency rebate programs. Energy Policy 2018, 123, 289–298. [Google Scholar] [CrossRef]

- Galarraga, I.; Abadie, L.M.; Ansuategi, A. Efficiency, effectiveness and implementation feasibility of energy efficiency rebates: The “Renove” plan in Spain. Energy Econ. 2013, 40, S98–S107. [Google Scholar] [CrossRef]

- Naji, A.; Al Tarhuni, B.; Choi, J.K.; Alshatshati, S.; Ajena, S. Ajena Toward cost-effective residential energy reduction and community impacts: A data-based machine learning approach. Energy AI 2021, 4, 100068. [Google Scholar] [CrossRef]

- Curtis, J.; Devitt, N.; Whelan, A. Estimating Building Energy Ratings for the Residential Building Stock: Location and Occupancy; ESRI WP489; Economic and Social Research Institute (ESRI): Dublin, Ireland, 2014.

- Chen, C.; Liu, Y.; Kumar, M.; Qin, J.; Ren, Y. Energy consumption modelling using deep learning embedded semi-supervised learning. Comput. Ind. Eng. 2019, 135, 757–765. [Google Scholar] [CrossRef]

- Violatto, G.; Pandharipande, A.; Li, S.; Schenato, L. Classification of Occupancy Sensor Anomalies in Connected Indoor Lighting Systems. IEEE Internet Things J. 2019, 6, 7175–7182. [Google Scholar] [CrossRef]

- Sharp, M.; Ak, R.; Hedberg, T., Jr. A Survey of the Advancing Use and Development of Machine Learning in Smart Manufacturing. J. Manuf. Syst. 2018, 48 Pt C, 170–179. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef] [Green Version]

- Ishwaran, H.; Lu, M. Standard errors and confidence intervals for variable importance in random forest regression, classification, and survival. Stat. Med. 2019, 38, 558–582. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, Y.; Zeng, R.; Srinivasan, R.S.; Ahrentzen, S. Random Forest based hourly building energy prediction. Energy Build. 2018, 171, 11–25. [Google Scholar] [CrossRef]

- Nelder, J.A.; Wedderburn, R.W.M. Generalized Linear Models. J. R. Stat. Soc. Ser. A 1972, 135, 370–384. [Google Scholar] [CrossRef]

- Apergis, N.; Aye, G.C.; Barros, C.P.; Gupta, R.; Wanke, P. Energy efficiency of selected OECD countries: A slacks based model with undesirable outputs. Energy Econ. 2015, 51, 45–53. [Google Scholar] [CrossRef] [Green Version]

- Iyit, N. Modelling world energy security data from multinomial distribution by generalized linear model under different cumulative link functions. Open Chem. 2018, 16, 377–385. [Google Scholar] [CrossRef]

- Ayyadevara, V.K. Gradient Boosting Machine. In Pro Machine Learning Algorithms: A Hands-On Approach to Implementing Algorithms in Python and R; Apress: Berkeley, CA, USA, 2018; pp. 117–134. [Google Scholar] [CrossRef]

- Friedman, J.H. Greedy Function Approximation: A Gradient Boosting Machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Touzani, S.; Granderson, J.; Fernandes, S. Gradient boosting machine for modeling the energy consumption of commercial buildings. Energy Build. 2018, 158, 1533–1543. [Google Scholar] [CrossRef] [Green Version]

- Nie, P.; Roccotelli, M.; Fanti, M.P.; Ming, Z.; Li, Z. Prediction of home energy consumption based on gradient boosting regression tree. Energy Rep. 2021, 7, 1246–1255. [Google Scholar] [CrossRef]

- Jain, A.K.; Jianchang, M.; Mohiuddin, K.M. Artificial neural networks: A tutorial. Computer 1996, 29, 31–44. [Google Scholar] [CrossRef] [Green Version]

- Ekici, B.B.; Aksoy, U.T. Prediction of building energy consumption by using artificial neural networks. Adv. Eng. Softw. 2009, 40, 356–362. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Applications of artificial neural-networks for energy systems. Appl. Energy 2000, 67, 17–35. [Google Scholar] [CrossRef]

- Ahmad, M.W.; Mourshed, M.; Rezgui, Y. Trees vs Neurons: Comparison between random forest and ANN for high-resolution prediction of building energy consumption. Energy Build. 2017, 147, 77–89. [Google Scholar] [CrossRef]

- Gallagher, C.V.; Bruton, K.; Leahy, K.; O’Sullivan, D.T. The suitability of machine learning to minimise uncertainty in the measurement and verification of energy savings. Energy Build. 2018, 158, 647–655. [Google Scholar] [CrossRef]

- Haricha, K.; Khiat, A.; Issaoui, Y.; Bahnasse, A.; Ouajji, H. Towards smart manufacturing: Implementation and benefits. J. Ubiquitous Syst. Pervasive Netw. 2021, 15, 25–31. [Google Scholar] [CrossRef]

- Nikolic, B.; Ignjatic, J.; Suzic, N.; Stevanov, B.; Rikalovic, A. Predictive manufacturing systems in industry 4.0: Trends, benefits, and challenges. Ann. DAAM Proc. 2017, 28. Available online: https://www.researchgate.net/profile/Aleksandar-Rikalovic/publication/321659440_Predictive_Manufacturing_Systems_in_Industry_40_Trends_Benefits_and_Challenges/links/5a2bbd8faca2728e05deb10b/Predictive-Manufacturing-Systems-in-Industry-40-Trends-Benefits-and-Challenges.pdf (accessed on 18 June 2022).

- Ayvaz, S.; Alpay, K. Predictive maintenance system for production lines in manufacturing: A machine learning approach using IoT data in real-time. Expert Syst. Appl. 2021, 173, 114598. [Google Scholar] [CrossRef]

- Kalantzis, F.; Revoltella, D. Do energy audits help SMEs to realize energy-efficiency opportunities? Energy Econ. 2019, 83, 229–239. [Google Scholar] [CrossRef]

- Marasco, D.E.; Kontokosta, C.E. Applications of machine learning methods to identifying and predicting building retrofit opportunities. Energy Build. 2016, 128, 431–441. [Google Scholar] [CrossRef] [Green Version]

- U.S. Department of Energy, Energy Efficiency and Renewable Energy (EERE), Advanced Manufacturing Office. Ind. Assess. Cent. (IAC) Program 2022. Available online: https://www.energy.gov/eere/amo/industrial-assessment-centers-iacs (accessed on 18 June 2022).

| Category | Description of Assessment Recommendations (ARs) |

|---|---|

| Controls | Install occupancy sensors Add area lighting switches Install timers on light switches in little-used areas Use photocell controls |

| Hardware | Utilize more efficient lamps and ballasts Install skylights Lower light fixtures in high ceiling areas Install spectral reflectors/delamping |

| Operation | Utilize daylight instead of artificial light whenever possible Make a practice of turning off lights when not needed Keep lamps and reflectors clean Disconnect ballasts |

| Levels | Reduce illumination to minimum necessary levels |

| Term | Warehouse | Manufacturing | Units |

|---|---|---|---|

| Operating hours | 2200 | 4400 | h |

| Electrical peak demand | 16.0 | 55.2 | kW |

| Electrical consumption | 35,284 | 243,065 | kWh/year |

| CO2 emissions | 25 | 172 | tons/year |

| Total electricity cost | USD4641 | USD20,908 | /year |

| Total relamping cost | USD218 | USD1500 | /year |

| Total operating cost | USD4859 | USD22,408 | /year |

| Number of “Rebates Applied” ARs (Training Data) | Number of “Rebate Omitted” ARs (Testing Data) | |||

|---|---|---|---|---|

| Lighting AR Type | Cause of missing the rebate opportunity | |||

| Legislation | Utility | Manufacturer | ||

| Install occupancy sensors | 45 | 6 | 7 | 13 |

| Install spectral reflectors/delamping | 2 | 0 | 1 | 5 |

| Utilize daylight whenever possible | 7 | 0 | 5 | 7 |

| Use photocell controls | 7 | 0 | 0 | 2 |

| Utilize more efficient lamps | 142 | 11 | 18 | 29 |

| Total | 203 | 104 | ||

| Type of ML Model | Validation Metrics | ||

|---|---|---|---|

| R2 | MSE (USD) | RMSE (USD) | |

| ANN (selected) | 0.99 | 284 | 418 |

| GBM | 0.99 | 318 | 566 |

| RF | 0.95 | 1036 | 2172 |

| GLM | 0.00 | 5830 | 9576 |

| Type of ML Model | Validation Metrics | ||

|---|---|---|---|

| R2 | MSE | RMSE | |

| GBM (selected) | 0.91 | 0.02 | 0.15 |

| RF | 0.88 | 0.03 | 0.17 |

| ANN | 0.83 | 0.04 | 0.07 |

| GLM | 0.23 | 0.19 | 0.43 |

| Energy-Efficient Lighting ARs | Predicted Rebate per Unit of Energy Saved (USD/kWh) |

|---|---|

| Install occupancy sensors | USD0.020 |

| Install spectral reflectors/delamping | USD0.014 |

| Utilize daylight whenever possible | USD0.016 |

| Use photocell controls | USD0.030 |

| Utilize more efficient lamps | USD0.043 |

| Number of Rebate-Omitted ARs | If Predicted Rebate Rates Were Applied | |||

|---|---|---|---|---|

| Energy-Efficient Lighting ARs | Not Implemented | Implemented | Not Implemented | Implemented |

| Install occupancy sensors | 19 | 7 | 18 | 8 |

| Install spectral reflectors/delamping | 4 | 2 | 3 | 3 |

| Utilize daylight whenever possible | 6 | 6 | 4 | 8 |

| Use photocell controls | 1 | 1 | 1 | 1 |

| Utilize more efficient lamps | 43 | 15 | 24 | 34 |

| Total | 73 | 31 | 50 | 54 |

| Percentile | 70% | 30% | 48% | 52% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shook, P.; Choi, J.-K. Predicting the Impact of Utility Lighting Rebate Programs on Promoting Industrial Energy Efficiency: A Machine Learning Approach. Environments 2022, 9, 100. https://doi.org/10.3390/environments9080100

Shook P, Choi J-K. Predicting the Impact of Utility Lighting Rebate Programs on Promoting Industrial Energy Efficiency: A Machine Learning Approach. Environments. 2022; 9(8):100. https://doi.org/10.3390/environments9080100

Chicago/Turabian StyleShook, Phillip, and Jun-Ki Choi. 2022. "Predicting the Impact of Utility Lighting Rebate Programs on Promoting Industrial Energy Efficiency: A Machine Learning Approach" Environments 9, no. 8: 100. https://doi.org/10.3390/environments9080100

APA StyleShook, P., & Choi, J.-K. (2022). Predicting the Impact of Utility Lighting Rebate Programs on Promoting Industrial Energy Efficiency: A Machine Learning Approach. Environments, 9(8), 100. https://doi.org/10.3390/environments9080100