Environmental Decay of Single Use Surgical Face Masks as an Agent of Plastic Micro-Fiber Pollution

Abstract

:1. Introduction

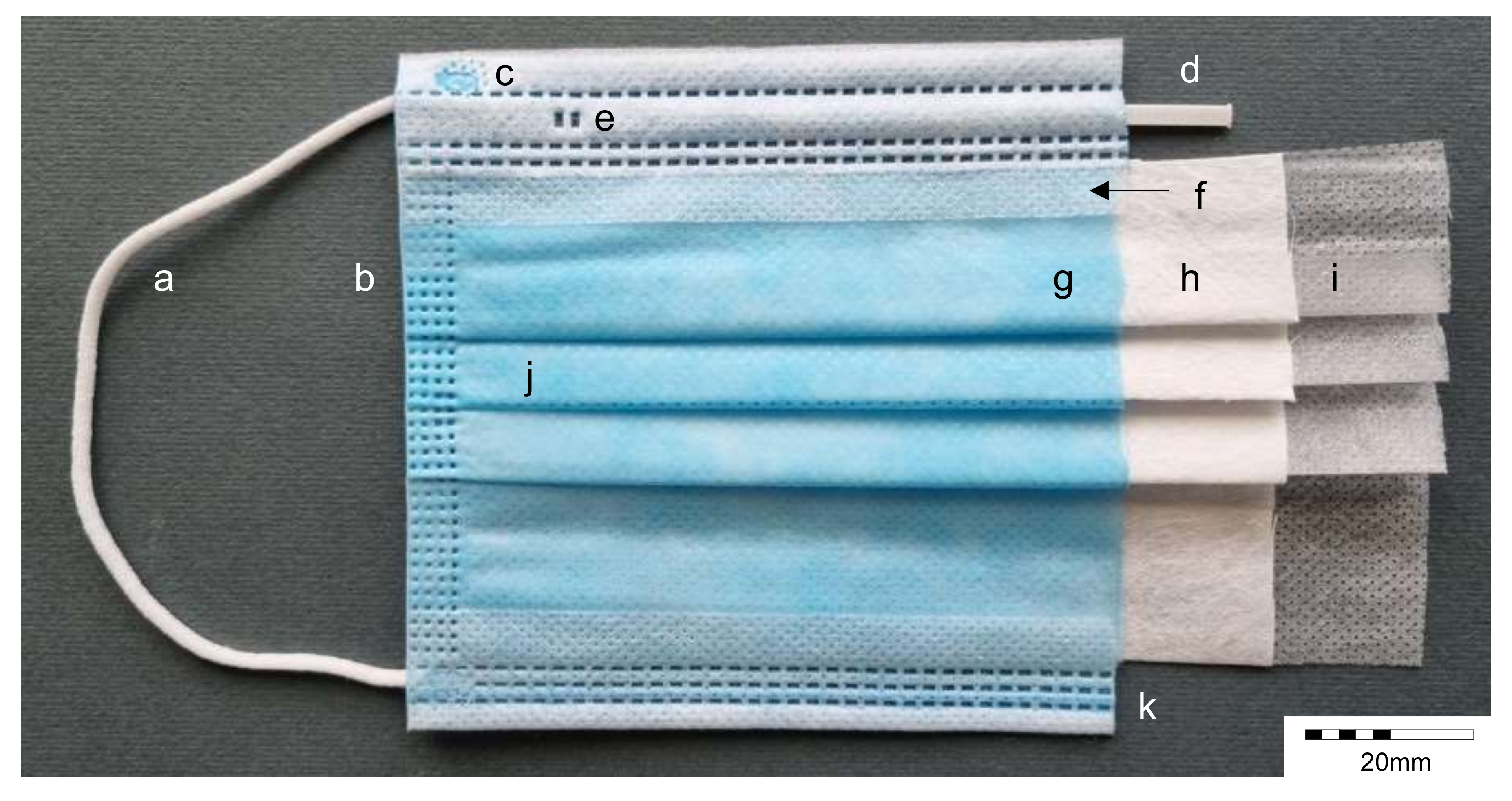

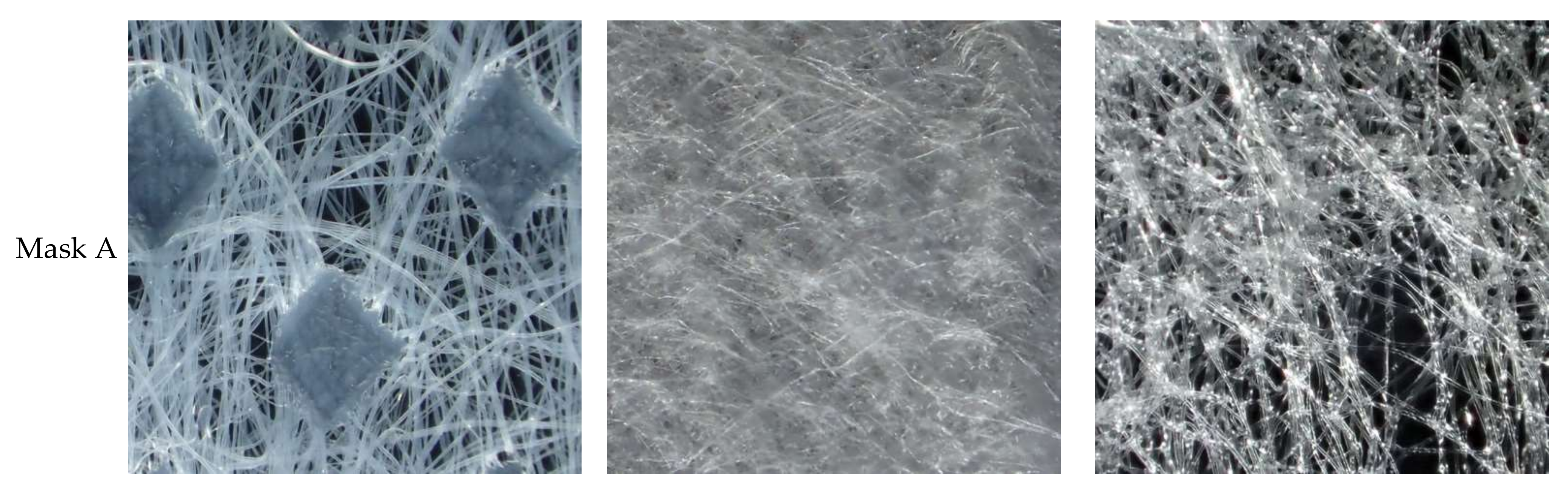

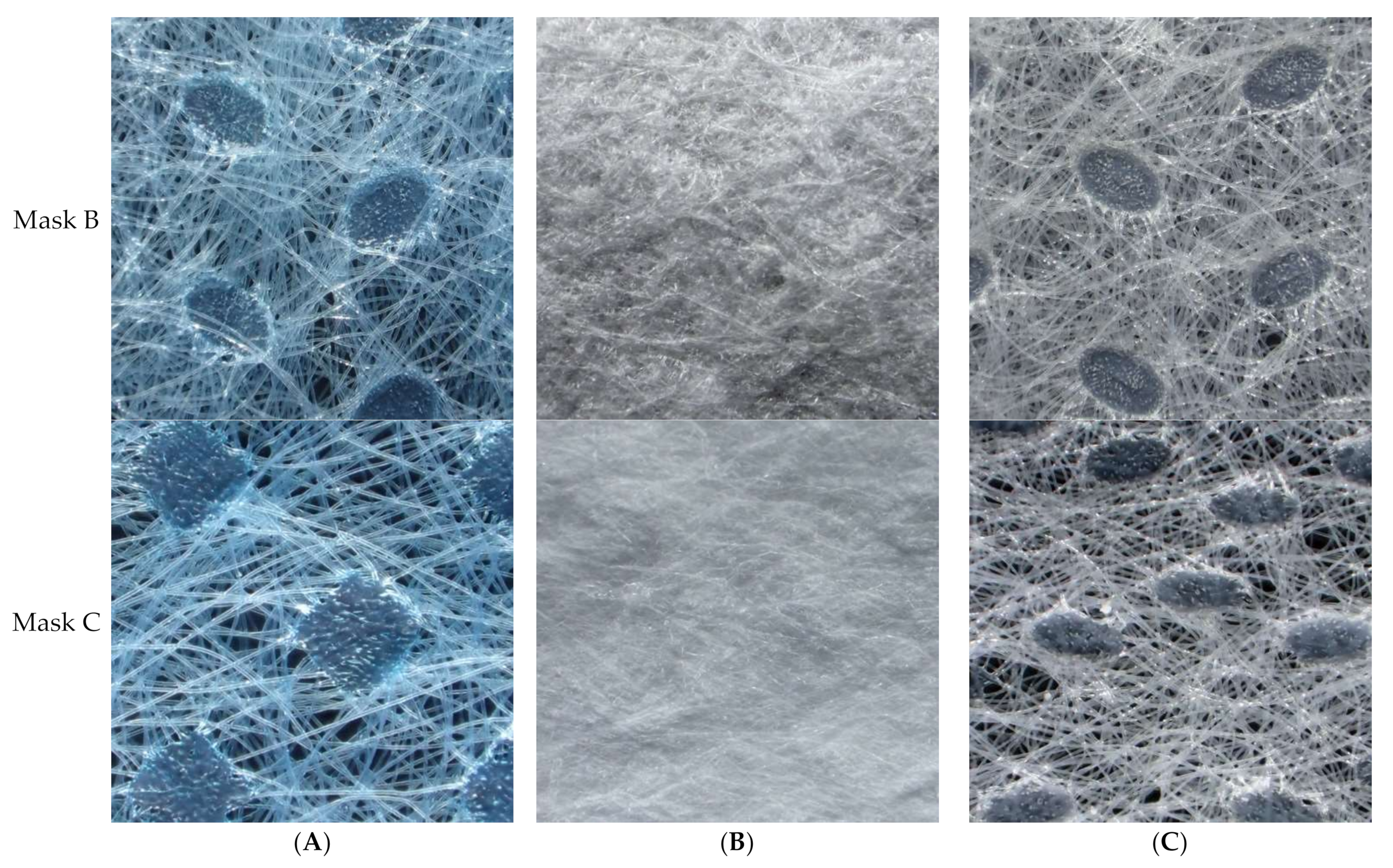

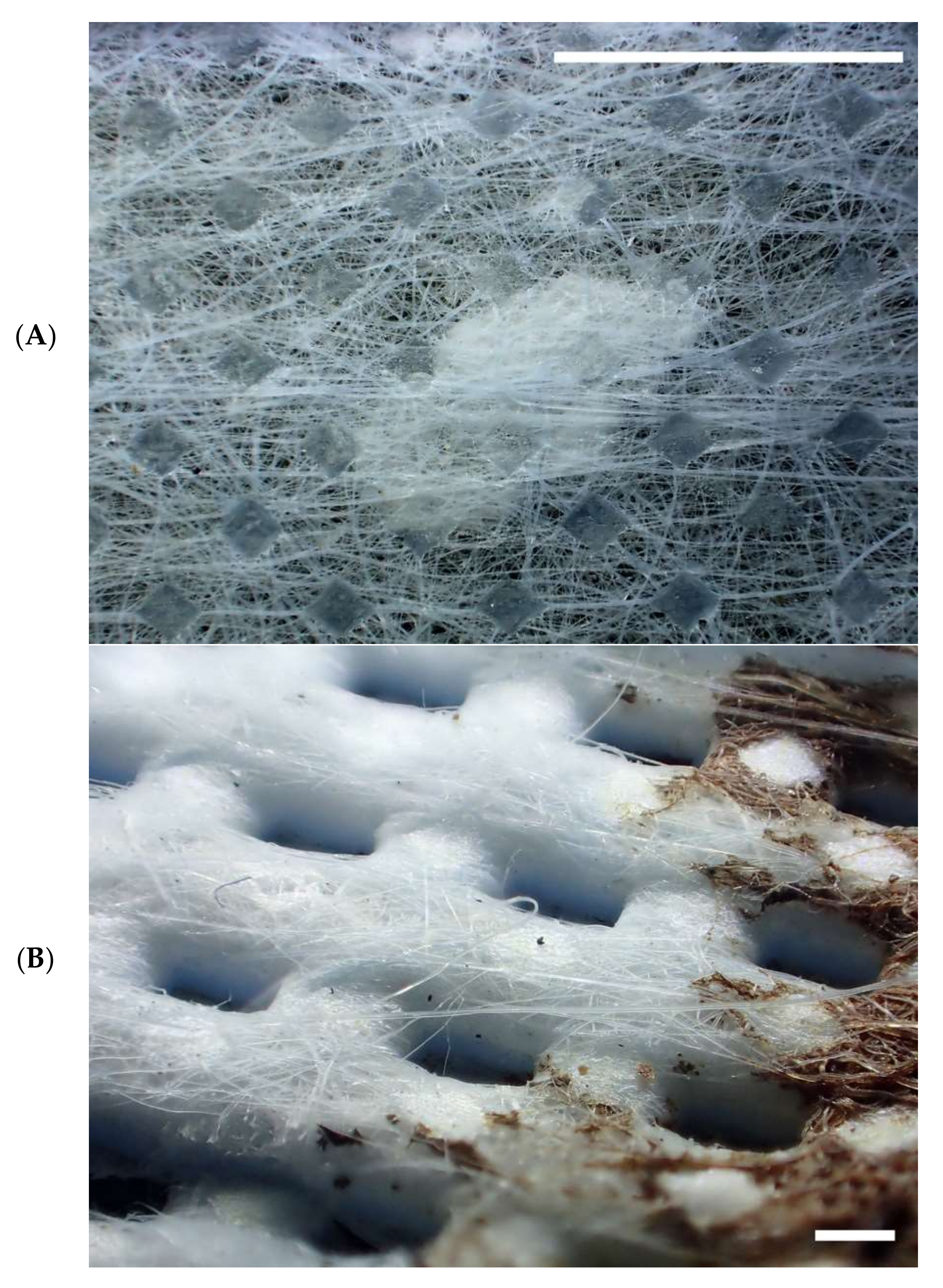

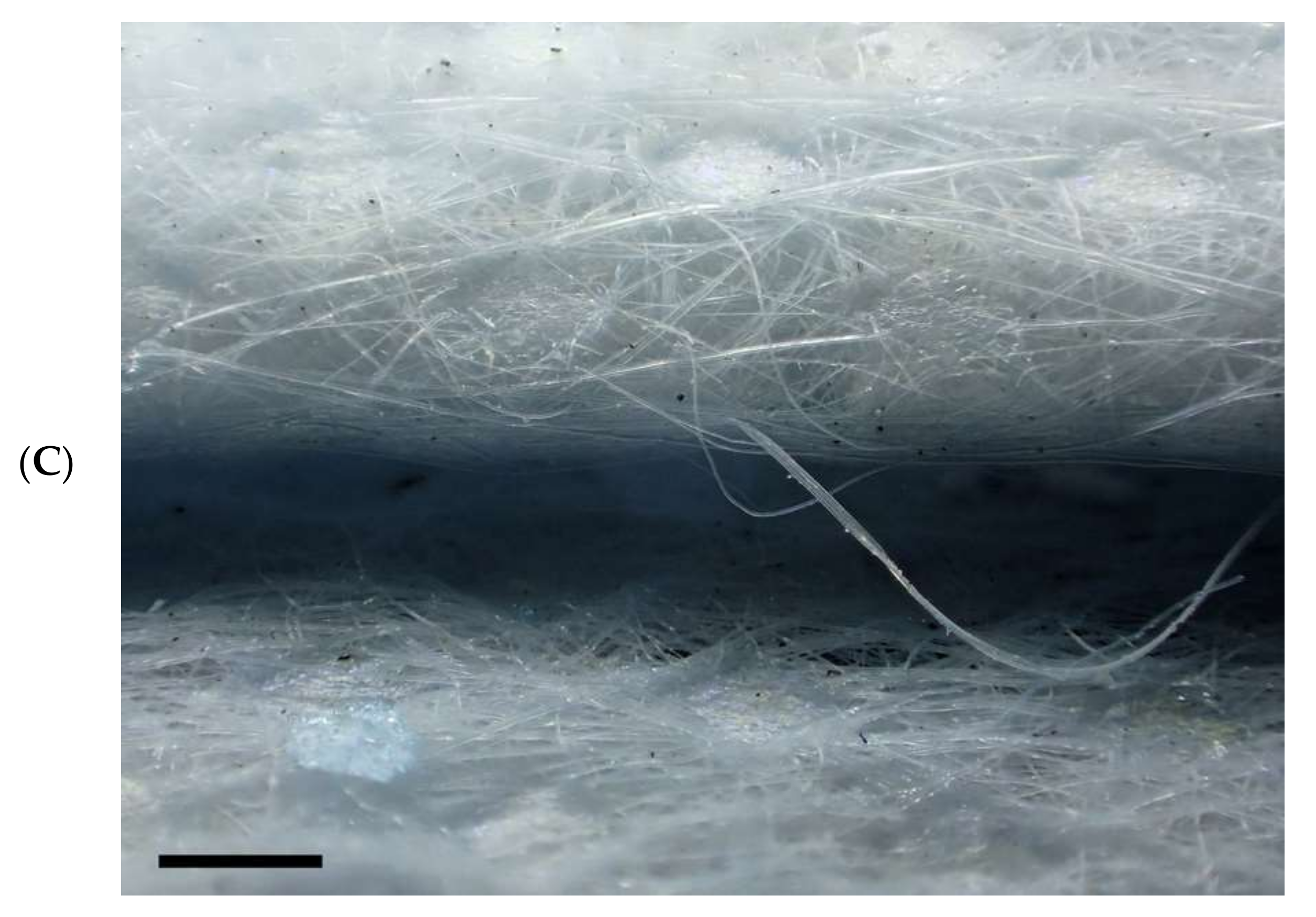

1.1. Mode of Manufacture of Surgical Face Masks

1.2. Environmental Decay Processes

2. Materials and Methods

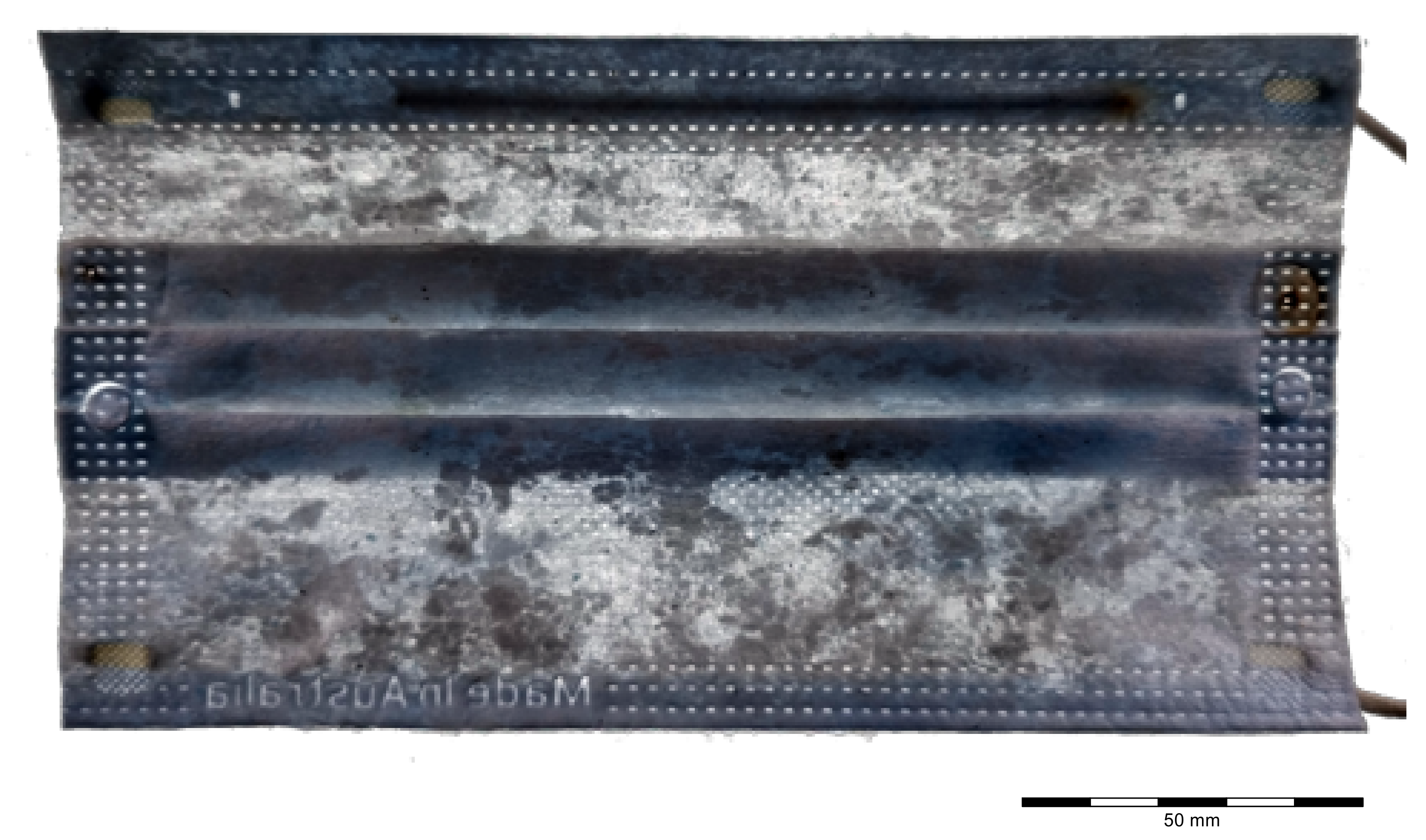

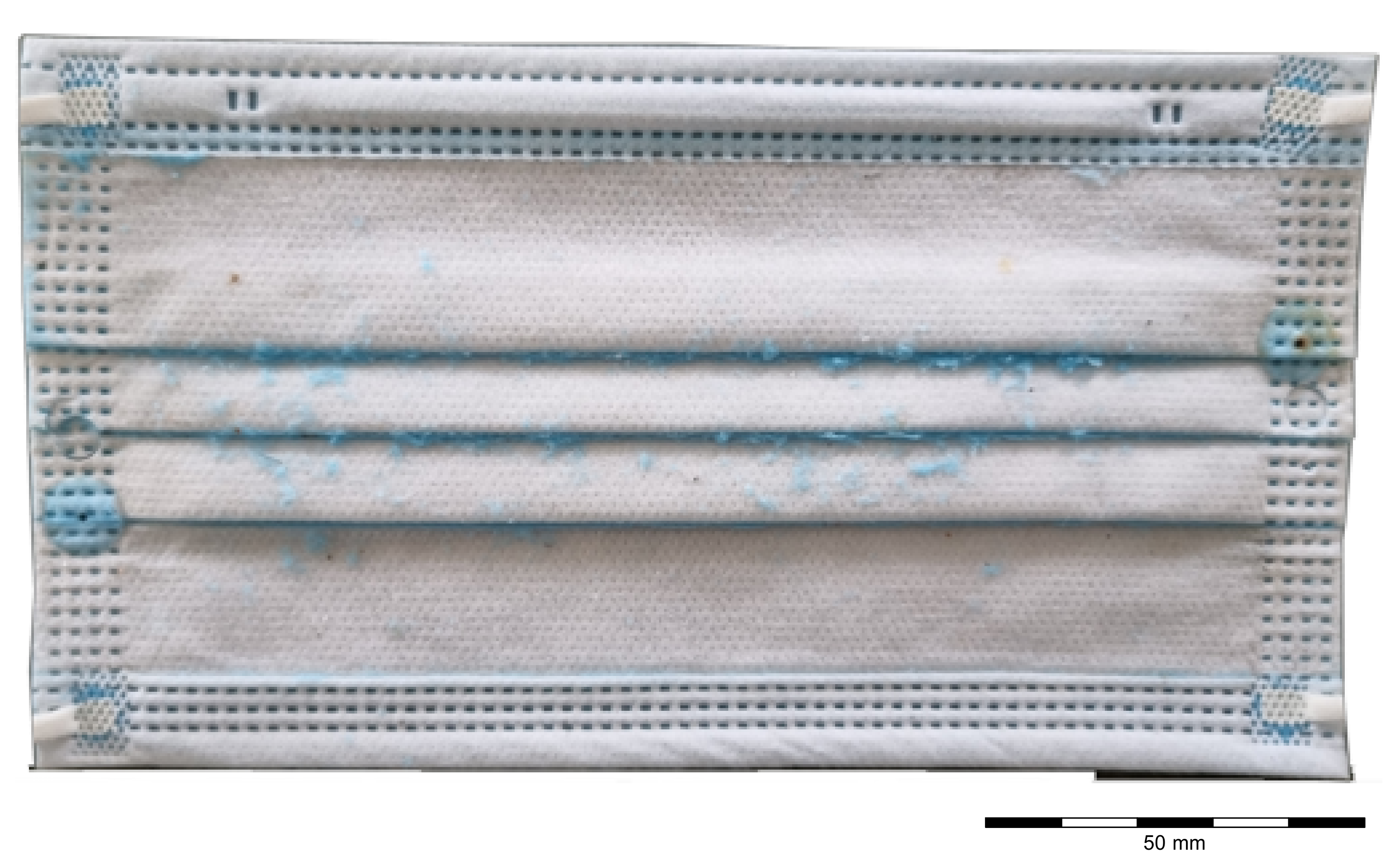

2.1. Masks Used for Experimentation

2.2. Experimental Layout

2.3. Documentation

2.3.1. Calculation of Material Loss

2.3.2. Nomenclatorial Conventions

2.4. Climatic Conditions

Thermal Expansion Calculations

3. Results

3.1. Mask A

3.1.1. Recto Side Exposed to the Elements

Final State (Day 69)

Diachronic Trajectory

3.1.2. Verso Side Exposed to the Elements

Final State (Day 69)

Diachronic Trajectory

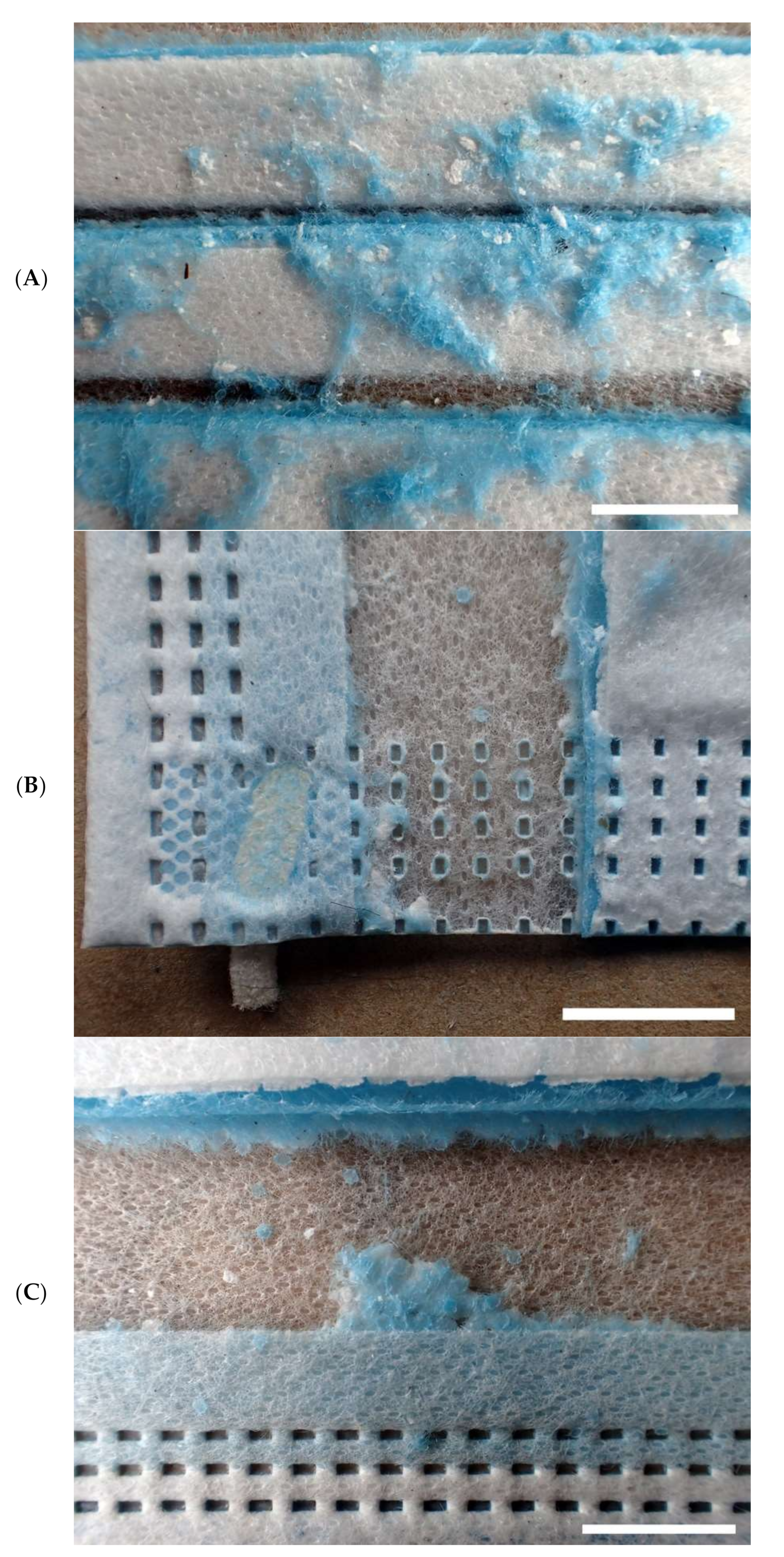

3.2. Mask B

3.2.1. Recto Side Exposed to the Elements

3.2.2. Verso Side Exposed to the Elements

Final State (Day 69)

Diachronic Trajectory

3.3. Mask C

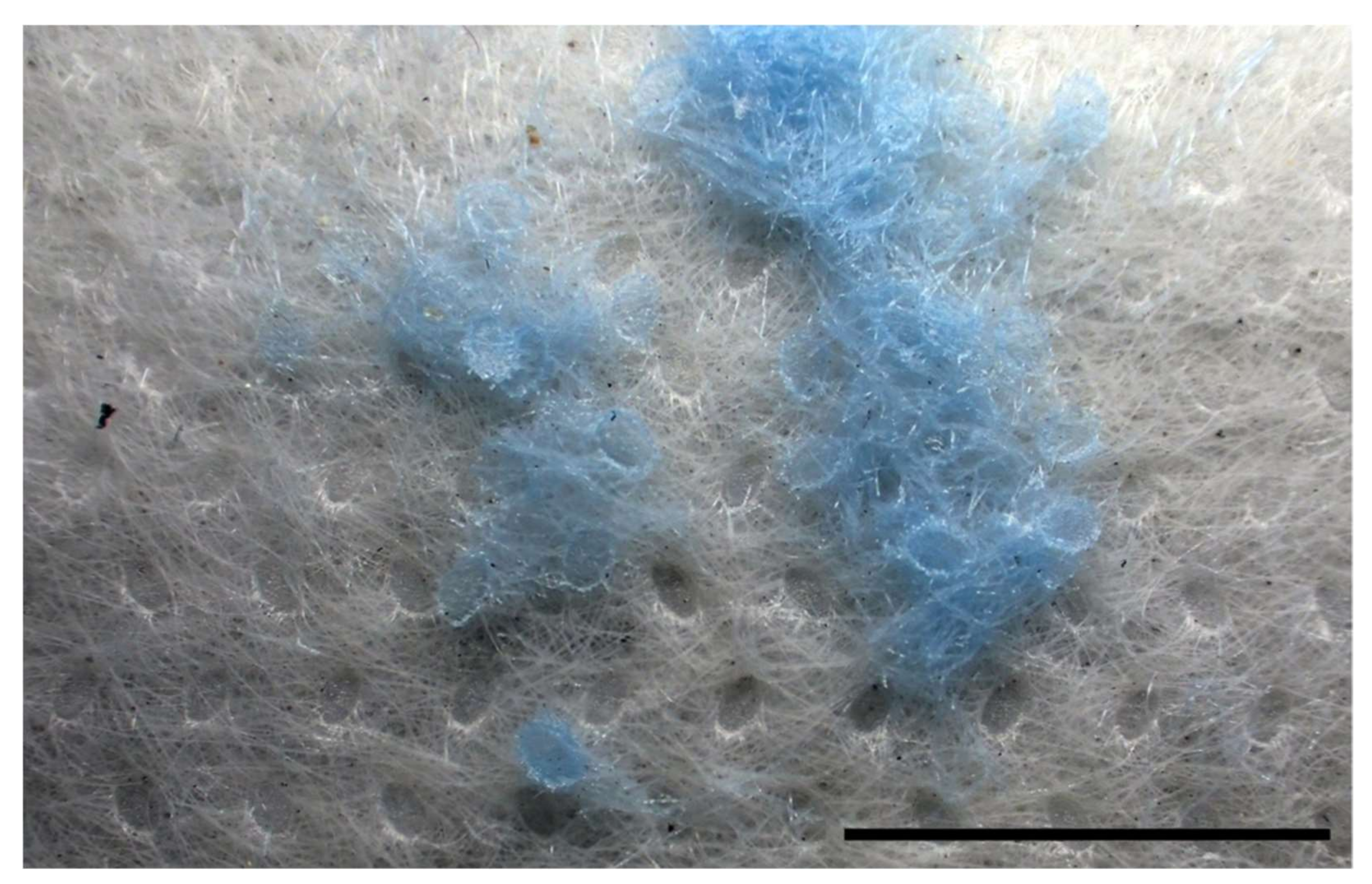

3.3.1. Recto Side Exposed to the Elements

Final State (Day 69)

Diachronic Trajectory

3.3.2. Verso Side Exposed to the Elements

Final State (Day 69)

Diachronic Trajectory

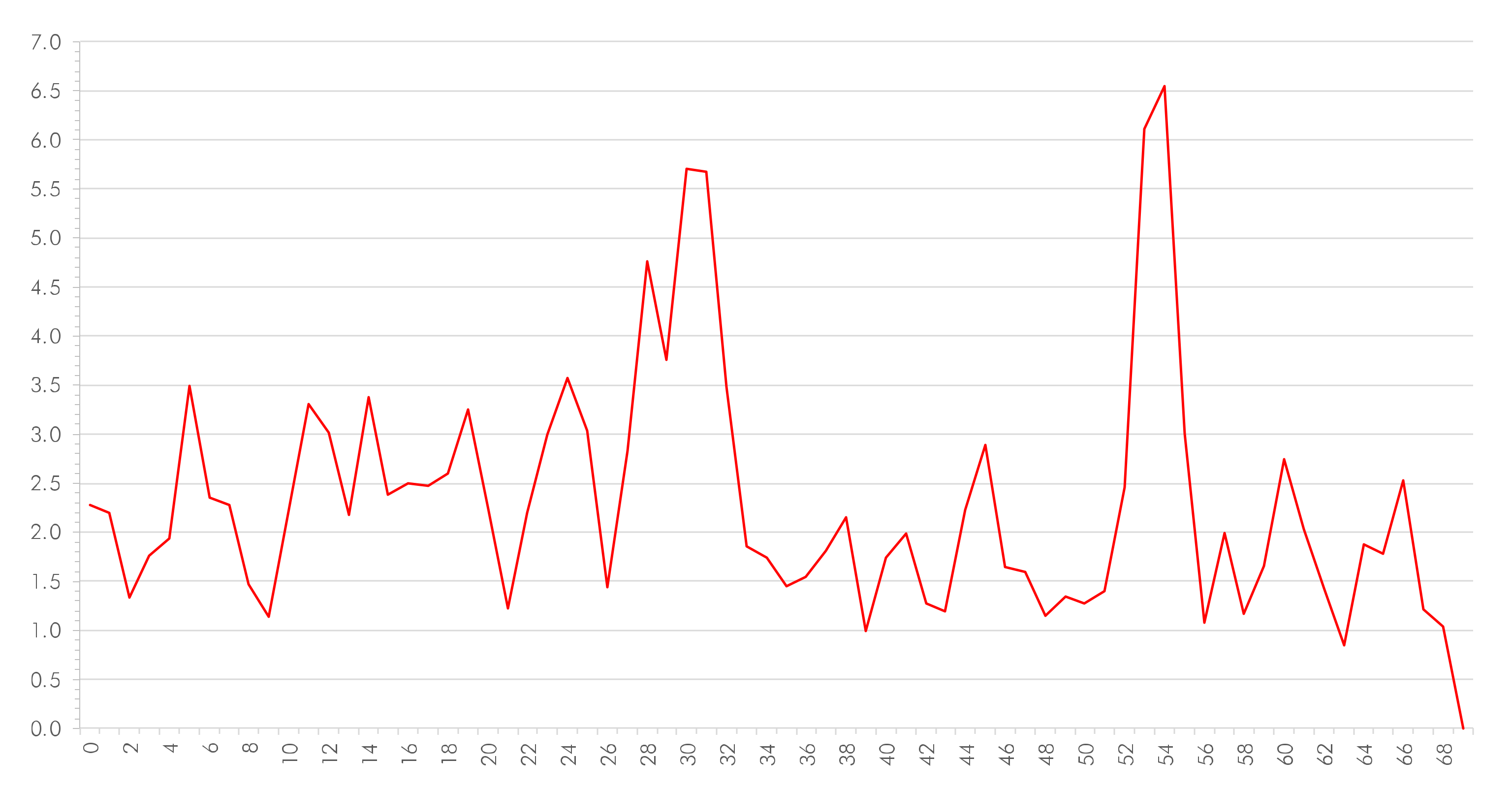

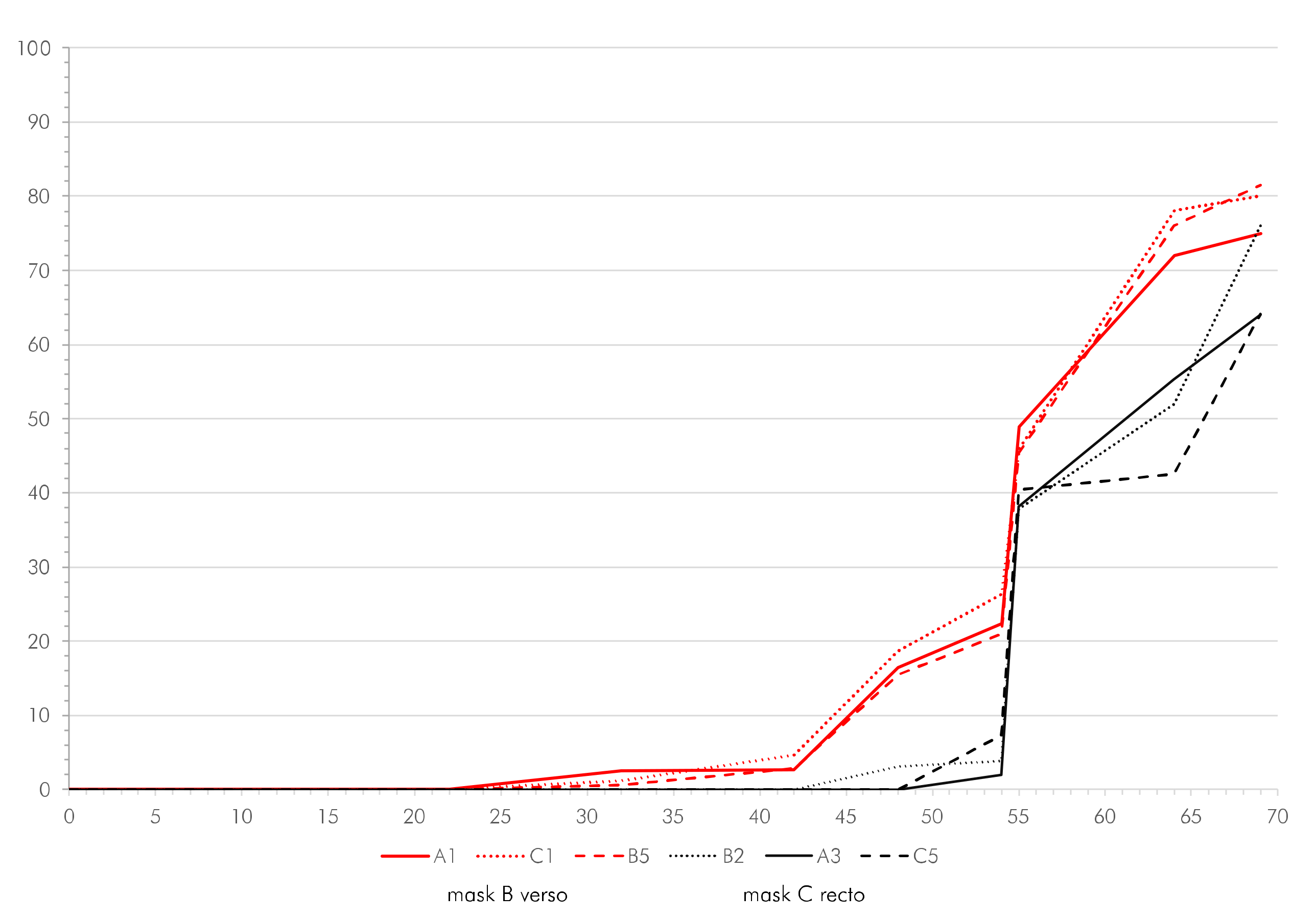

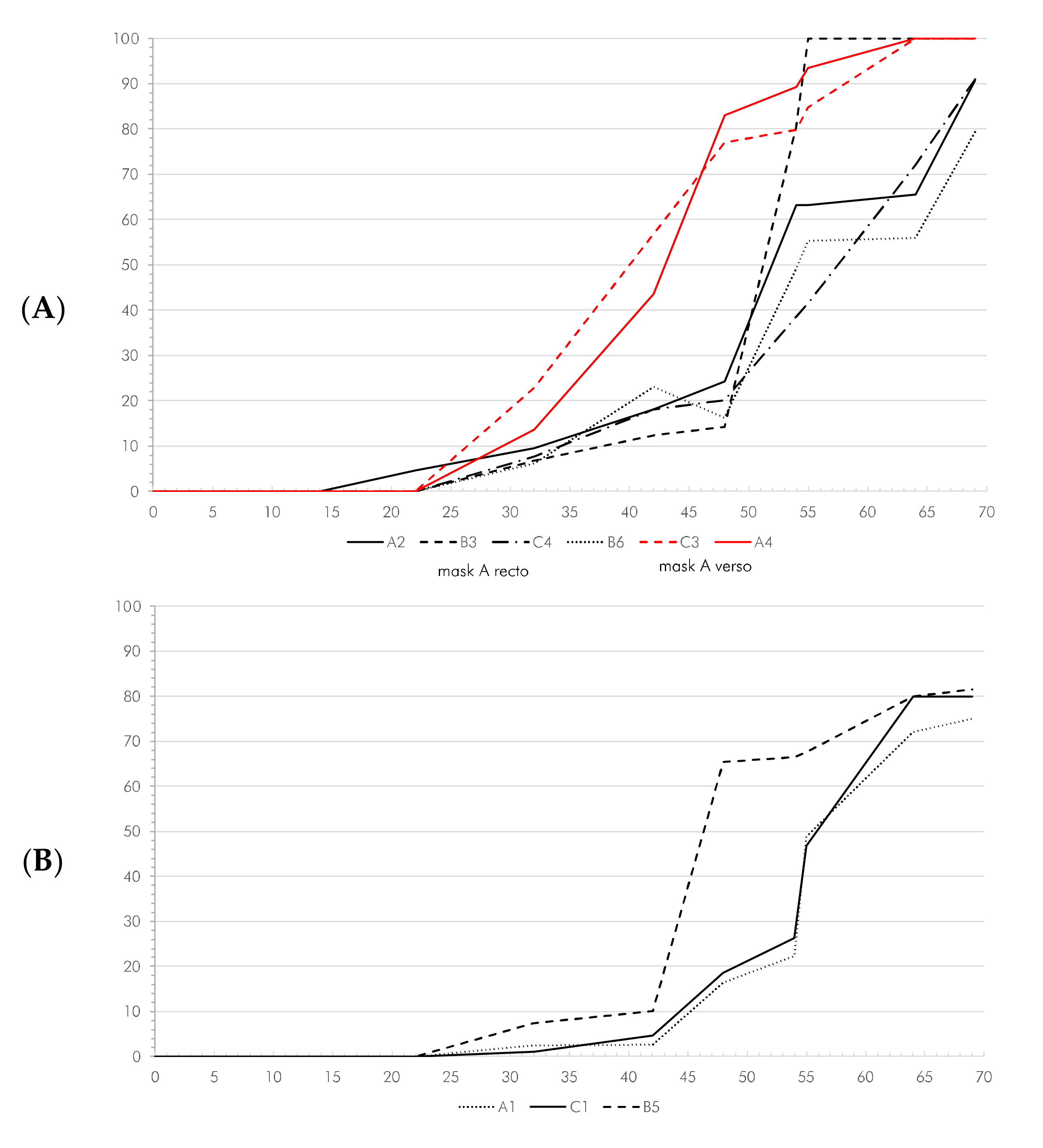

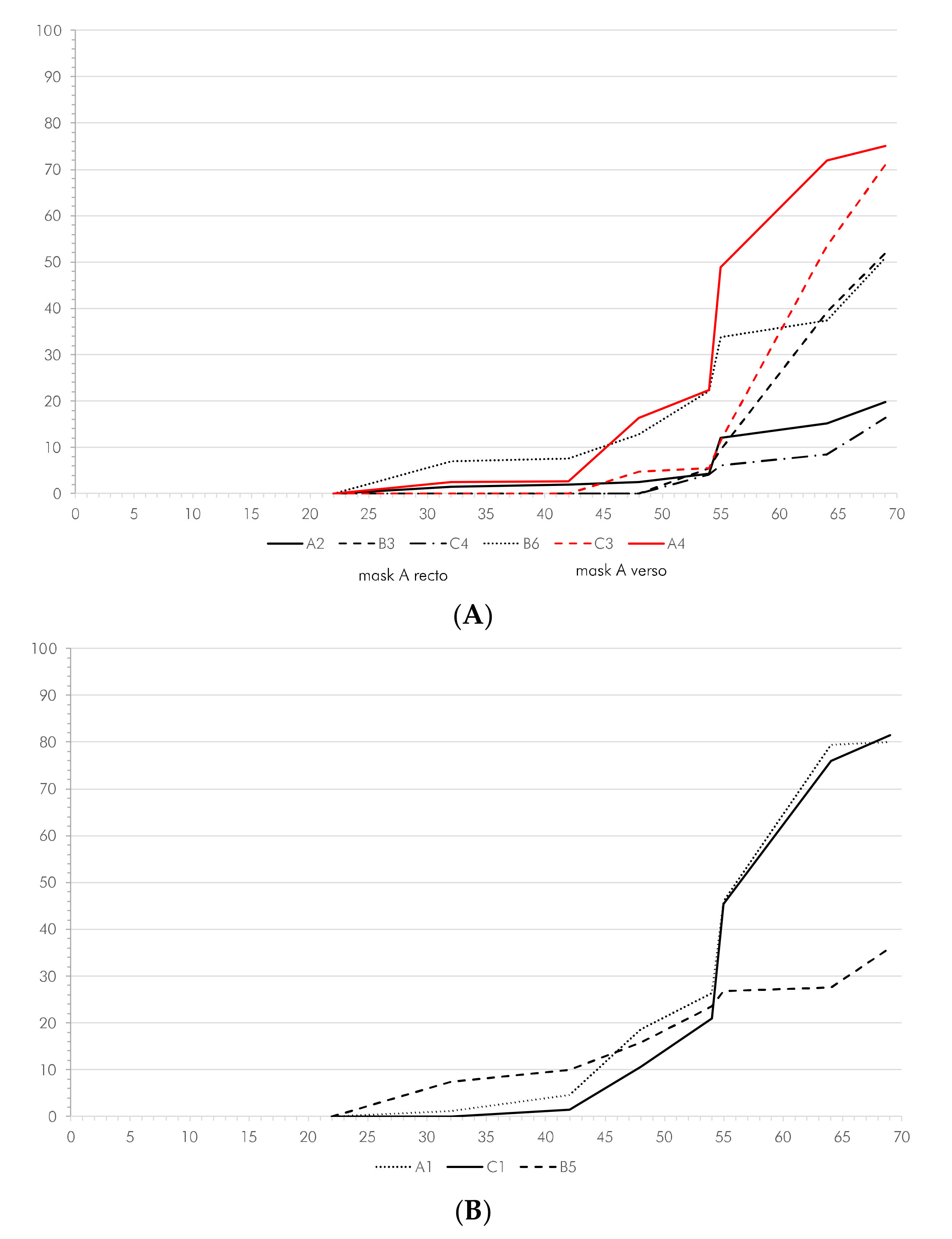

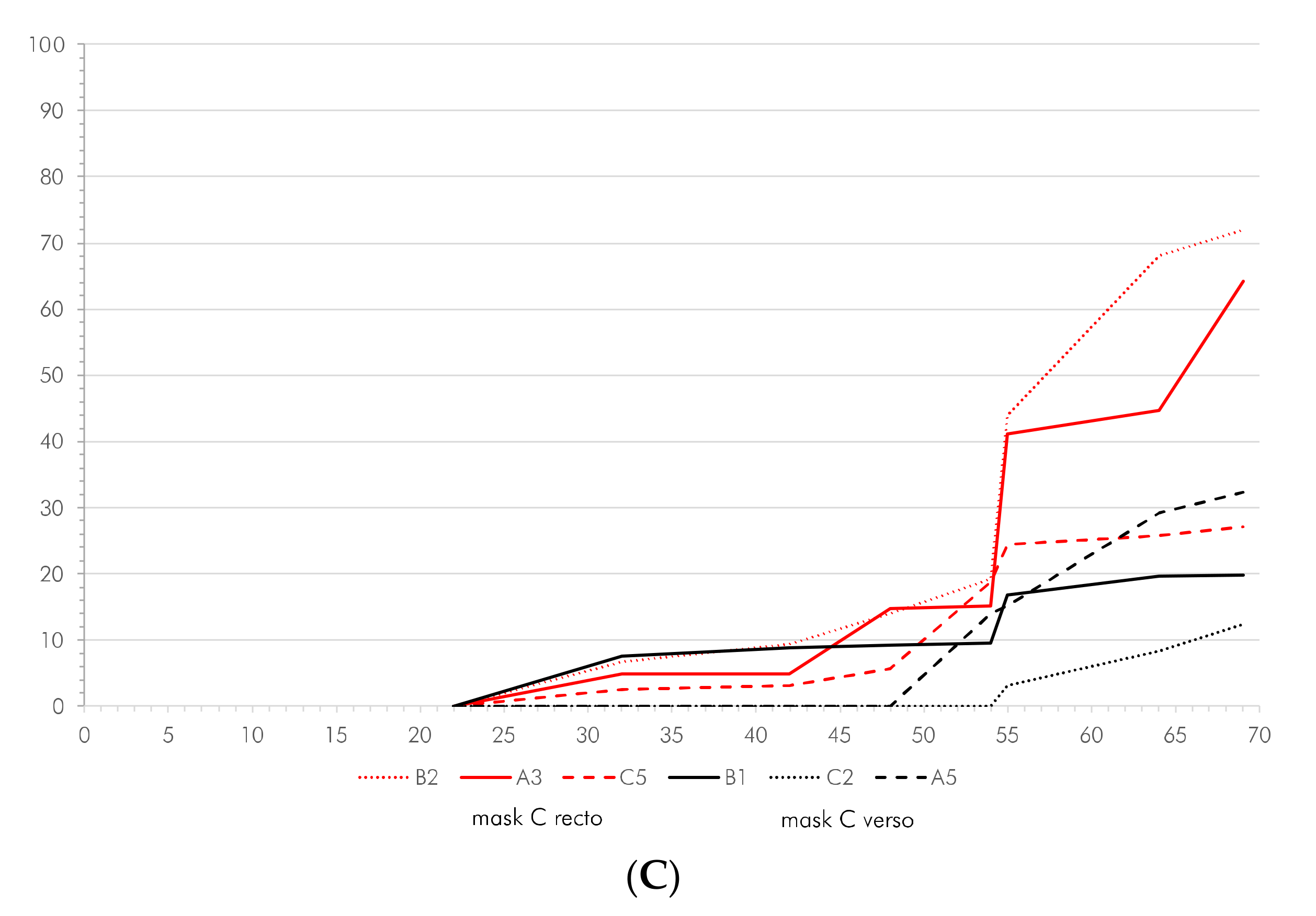

3.4. Comparative Progress of Decay over Time

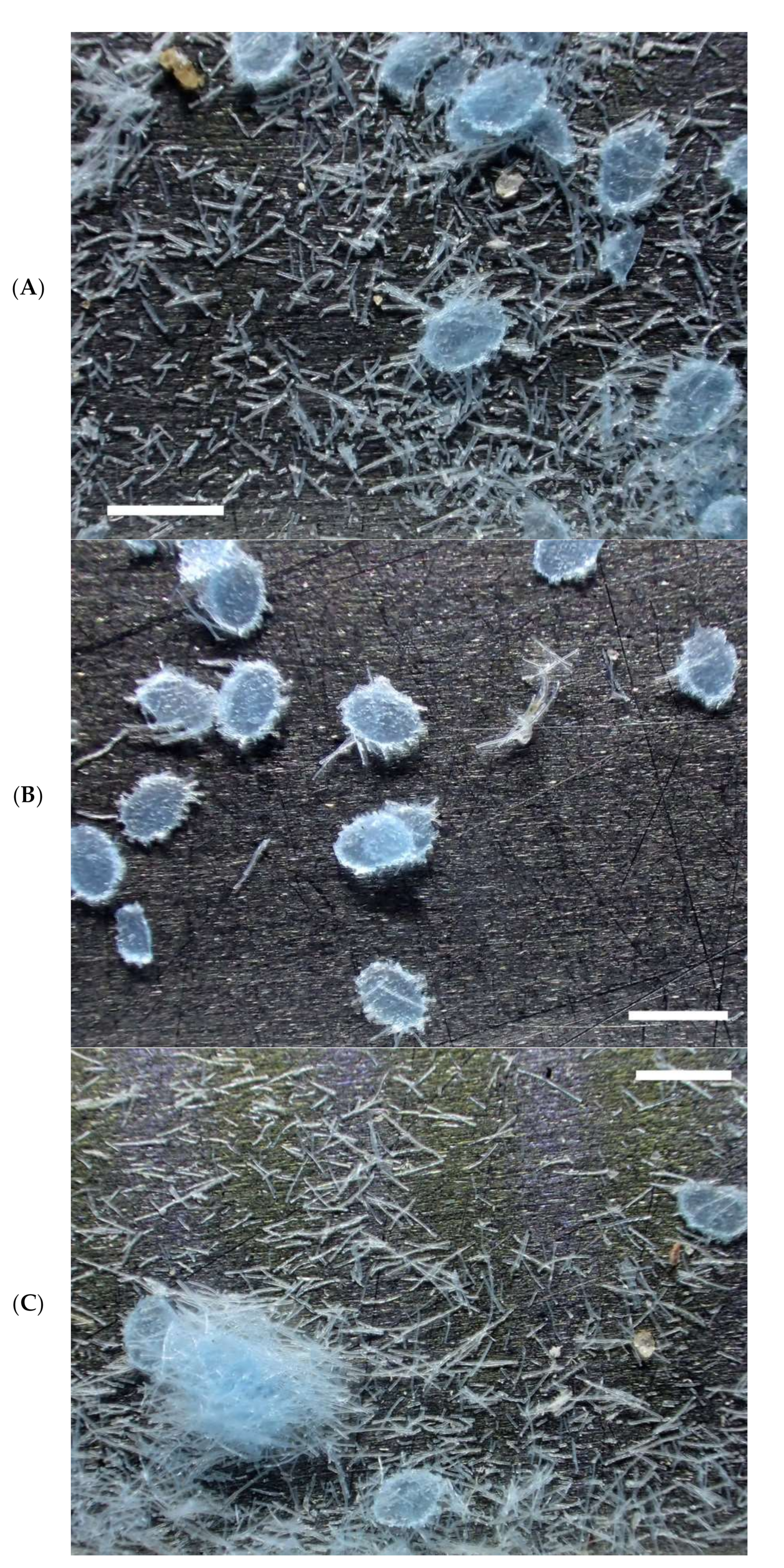

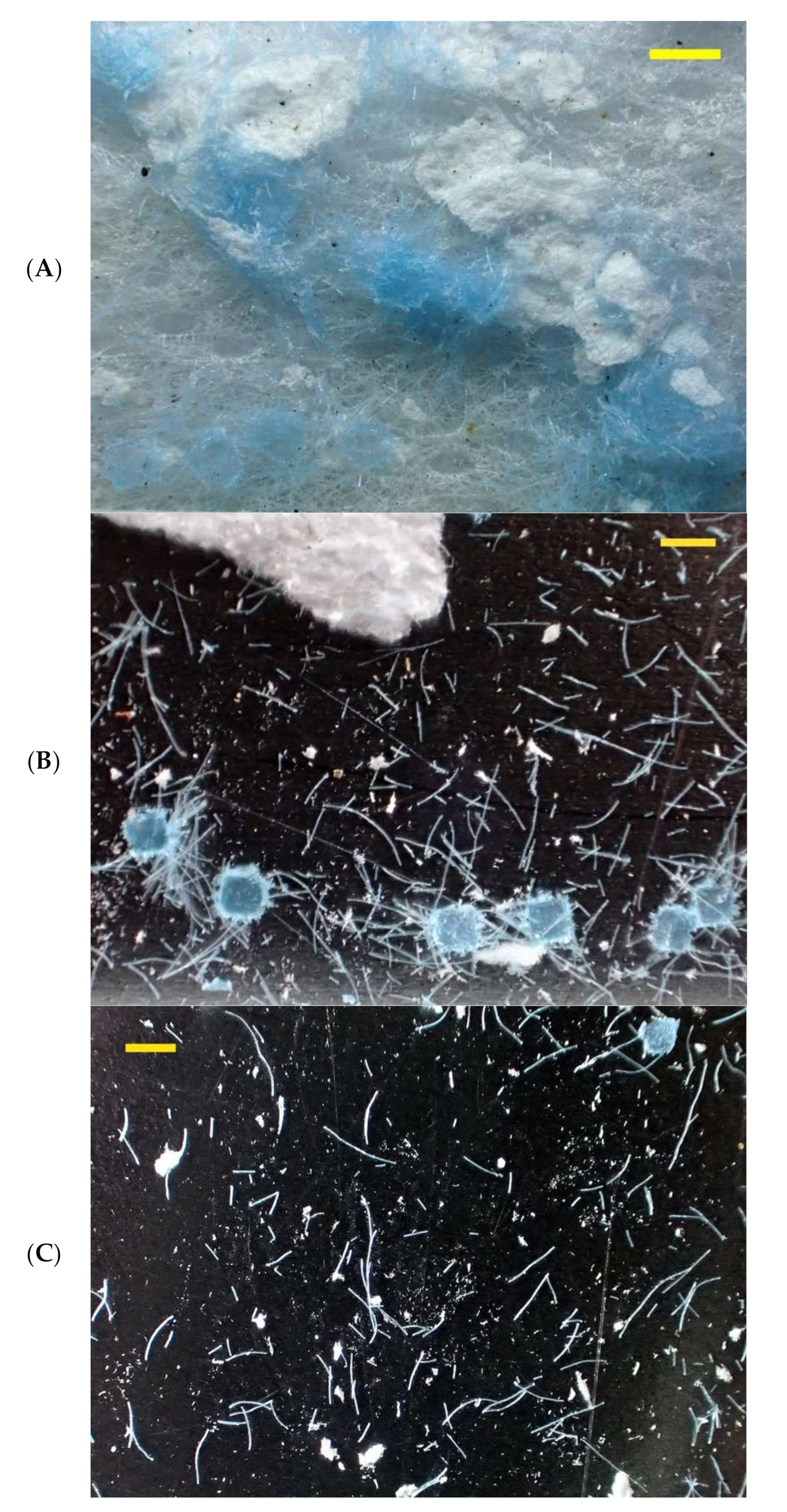

3.4.1. Spunbonded Fabric

3.4.2. Melt Blown Fabric

4. Discussion

4.1. Processes of Observed Decay: Thermal Expansion and Contraction

The Effects of Color

4.2. Spunbond vs. Melt-Blown Fabric

4.3. Duration of Exposure

4.4. Limitations

4.5. Surgical-Type Face Masks as Contributors to the Microplastics Problem

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Side | Day | ||||||||||

| Mask | Face-Up | Color | 22 | 32 | 42 | 48 | 54 | 55 | 64 | 69 | |

| A | recto | white | A2 | — | — | — | — | — | — | — | — |

| A | recto | white | B3 | — | — | — | — | — | — | — | — |

| A | recto | white | C4 | — | — | — | — | — | — | — | — |

| A | recto | white | B6 | — | — | — | — | — | — | — | — |

| A | verso | white | C3 | — | — | — | — | — | — | — | — |

| A | verso | white | A4 | — | — | — | — | — | — | — | — |

| B | recto | white | A6 | — | — | — | — | — | — | — | — |

| B | recto | white | B4 | — | — | — | — | — | — | — | — |

| B | recto | white | C6 | — | — | — | — | — | — | — | — |

| B | verso | blue | A1 | — | 2.50 | 2.63 | 16.38 | 22.38 | 48.88 | 72.00 | 75.00 |

| B | verso | blue | C1 | — | 1.13 | 4.63 | 18.63 | 26.38 | 46.00 | 78.13 | 80.00 |

| B | verso | blue | B5 | — | 0.63 | 2.88 | 15.50 | 21.00 | 45.38 | 76.00 | 81.50 |

| C | recto | blue | B2 | — | — | — | 3.13 | 3.88 | 37.88 | 52.00 | 76.00 |

| C | recto | blue | A3 | — | — | — | — | 2.00 | 38.25 | 55.25 | 64.00 |

| C | recto | blue | C5 | — | — | — | — | 7.25 | 40.38 | 42.50 | 64.13 |

| C | verso | white | B1 | — | — | — | — | — | — | — | — |

| C | verso | white | C2 | — | — | — | — | — | — | — | — |

| C | verso | white | A5 | — | — | — | — | — | — | — | — |

Appendix B

| Side | Day | ||||||||||

| Mask | Face-Up | Color | 22 | 32 | 42 | 48 | 54 | 55 | 64 | 69 | |

| A | recto | white | A2 | 4.63 | 9.63 | 18.13 | 24.38 | 63.25 | 63.25 | 65.50 | 90.63 |

| A | recto | white | B3 | — | 6.88 | 12.38 | 14.25 | 80.50 | 100.00 | 100.00 | 100.00 |

| A | recto | white | C4 | — | 7.75 | 18.13 | 20.13 | 38.50 | 41.50 | 72.00 | 91.00 |

| A | recto | white | B6 | — | 6.25 | 23.13 | 16.25 | 49.13 | 55.25 | 56.00 | 79.38 |

| A | verso | white | C3 | — | 22.88 | 56.88 | 77.00 | 79.75 | 84.75 | 100.00 | 100.00 |

| A | verso | white | A4 | — | 13.63 | 43.50 | 83.00 | 89.25 | 93.50 | 100.00 | 100.00 |

| B | recto | white | A6 | — | — | — | — | — | — | — | — |

| B | recto | white | B4 | — | — | — | — | — | — | — | — |

| B | recto | white | C6 | — | — | — | — | — | — | — | — |

| B | verso | blue | A1 | — | 2.50 | 2.63 | 16.38 | 22.38 | 48.88 | 72.00 | 75.00 |

| B | verso | blue | C1 | — | 1.13 | 4.63 | 18.63 | 26.38 | 46.75 | 80.00 | 80.00 |

| B | verso | blue | B5 | — | 7.38 | 10.00 | 65.38 | 66.50 | 67.50 | 80.00 | 81.50 |

| C | recto | blue | B2 | 10.63 | 51.00 | 52.50 | 65.63 | 73.00 | 76.00 | 91.75 | 100.00 |

| C | recto | blue | A3 | 11.25 | 58.75 | 59.75 | 61.50 | 68.25 | 76.00 | 80.00 | 97.00 |

| C | recto | blue | C5 | 5.63 | 52.50 | 59.50 | 66.50 | 67.50 | 87.50 | 100.00 | 100.00 |

| C | verso | white | B1 | 2.88 | 27.50 | 63.00 | 76.13 | 79.88 | 83.38 | 100.00 | 100.00 |

| C | verso | white | C2 | — | 19.63 | 28.25 | 44.00 | 61.75 | 65.25 | 100.00 | 100.00 |

| C | verso | white | A5 | — | 4.63 | 22.50 | 60.50 | 63.00 | 64.13 | 64.38 | 80.50 |

Appendix C

| Side | Day | ||||||||||

| Mask | Face-Up | Color | 22 | 32 | 42 | 48 | 54 | 55 | 64 | 69 | |

| A | recto | white | A2 | — | 1.50 | 1.88 | 2.50 | 4.25 | 12.13 | 15.25 | 19.75 |

| A | recto | white | B3 | — | — | — | — | 5.50 | 9.50 | 39.13 | 52.00 |

| A | recto | white | C4 | — | — | — | — | 4.13 | 6.13 | 8.50 | 16.38 |

| A | recto | white | B6 | — | 7.00 | 7.63 | 12.75 | 22.25 | 33.75 | 37.38 | 50.88 |

| A | verso | white | C3 | — | — | — | 4.75 | 5.50 | 11.50 | 53.50 | 71.13 |

| A | verso | white | A4 | — | 2.50 | 2.63 | 16.38 | 22.38 | 48.88 | 72.00 | 75.00 |

| B | recto | white | A6 | — | — | — | — | — | — | — | — |

| B | recto | white | B4 | — | — | — | — | — | — | — | — |

| B | recto | white | C6 | — | — | — | — | — | — | — | — |

| B | verso | blue | A1 | — | 1.13 | 4.63 | 18.63 | 26.38 | 46.00 | 79.38 | 80.00 |

| B | verso | blue | C1 | — | — | 1.50 | 10.63 | 21.00 | 45.38 | 76.00 | 81.50 |

| B | verso | blue | B5 | — | 7.38 | 10.00 | 15.75 | 23.50 | 26.75 | 27.50 | 36.00 |

| C | recto | blue | B2 | — | 6.63 | 9.38 | 14.00 | 19.25 | 43.88 | 68.00 | 72.00 |

| C | recto | blue | A3 | — | 4.88 | 4.88 | 14.75 | 15.25 | 41.13 | 44.75 | 64.13 |

| C | recto | blue | C5 | — | 2.50 | 3.13 | 5.63 | 18.75 | 24.38 | 25.75 | 27.13 |

| C | verso | white | B1 | — | 7.63 | 8.75 | 9.25 | 9.50 | 16.88 | 19.63 | 19.88 |

| C | verso | white | C2 | — | — | — | — | — | 3.13 | 8.38 | 12.38 |

| C | verso | white | A5 | — | — | — | — | 14.00 | 15.13 | 29.25 | 32.38 |

References

- Storen, R.; Corrigan, N. COVID-19: A Chronology of State and Territory Government Announcements (up Until 30 June 2020); Parliamentary Library, Commonwealth of Australia: Canberra, ACT, Australia, 2020.

- Spennemann, D.H.R. Collecting COVID-19 Ephemera: A Photographic Documentation of Examples from Regional Australia; Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, Australia, 2021. [Google Scholar]

- Spennemann, D.H.R. Facing COVID-19: Quantifying the use of reusable vs disposable facemasks. Hygiene 2021, 1, 120–128. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. A Rapid Observational Survey of Face Mask Use in a Major Shopping Centre in Melbourne (Victoria); Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, Australia, 2021. [Google Scholar]

- Spennemann, D.H.R. A Rapid Observational Survey of Face Mask Use in a Major Shopping Centre in Sydney (New South Wales); Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, Australia, 2022. [Google Scholar]

- MedicalXpress. China exported more than 220 Billion Masks in 2020: Government. Available online: https://medicalxpress.com/news/2021-01-china-exported-billion-masks.html (accessed on 15 May 2022).

- Spennemann, D.H.R. COVID face masks: Policy shift results in increased littering. Sustainability 2021, 13, 9875. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. Patterns of a Pandemic. A Documentation of COVID-19 Masks Sold, Lost and Discarded in a Regional Australian city; Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, Australia, 2021; p. 164. [Google Scholar]

- Spennemann, D.H.R. COVID-19 Face Masks as a Long-Term Source of Microplastics in Recycled Urban Green Waste. Sustainability 2022, 14, 207. [Google Scholar] [CrossRef]

- Forouzandeh, P.; O’Dowd, K.; Pillai, S.C. Face masks and respirators in the fight against the COVID-19 pandemic: An overview of the standards and testing methods. Saf. Sci. 2021, 133, 104995. [Google Scholar] [CrossRef] [PubMed]

- Liao, M.; Liu, H.; Wang, X.; Hu, X.; Huang, Y.; Liu, X.; Brenan, K.; Mecha, J.; Nirmalan, M.; Lu, J.R. A technical review of face mask wearing in preventing respiratory COVID-19 transmission. Curr. Opin. Colloid Interface Sci. 2021, 52, 101417. [Google Scholar] [CrossRef] [PubMed]

- Kellie, G. Advances in Technical Nonwovens; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Essa, W.K.; Yasin, S.A.; Saeed, I.A.; Ali, G.A. Nanofiber-based face masks and respirators as COVID-19 protection: A review. Membranes 2021, 11, 250. [Google Scholar] [CrossRef] [PubMed]

- Sessler, G.M. Physical principles of electrets. In Electrets; Sessler, G.M., Ed.; Topics in Applied Physics; Springer: Berlin/Heidelberg, Germany, 1980; Volume 33, pp. 13–80. [Google Scholar]

- Wu, P.; Li, J.; Lu, X.; Tang, Y.; Cai, Z. Release of tens of thousands of microfibers from discarded face masks under simulated environmental conditions. Sci. Total Environ. 2022, 806, 150458. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. The Material Culture of the COVID-19 Pandemic. A Photographic Documentation of the Mechanical Degradation of Single-Use Surgical Face Masks on Road Surfaces; SAEVS, Charles Sturt University: Albury, NSW, Australia, 2022. [Google Scholar]

- Spennemann, D.H.R. The Material Culture of the COVID-19 Pandemic. A Photographic Documentation of the Mechanical Degradation of Single-Use Surgical Face Masks embedded in Bitumen Patches on Road Surfaces; SAEVS, Charles Sturt University: Albury, NSW, Australia, 2022. [Google Scholar]

- Saliu, F.; Veronelli, M.; Raguso, C.; Barana, D.; Galli, P.; Lasagni, M. The release process of microfibers: From surgical face masks into the marine environment. Environ. Adv. 2021, 4, 100042. [Google Scholar] [CrossRef]

- Shen, M.; Zeng, Z.; Song, B.; Yi, H.; Hu, T.; Zhang, Y.; Zeng, G.; Xiao, R. Neglected microplastics pollution in global COVID-19: Disposable surgical masks. Sci. Total Environ. 2021, 790, 148130. [Google Scholar] [CrossRef]

- Liang, H.; Ji, Y.; Ge, W.; Wu, J.; Song, N.; Yin, Z.; Chai, C. Release kinetics of microplastics from disposable face masks into the aqueous environment. Sci. Total Environ. 2022, 816, 151650. [Google Scholar] [CrossRef]

- Pizarro-Ortega, C.I.; Dioses-Salinas, D.C.; Severini, M.D.F.; López, A.F.; Rimondino, G.N.; Benson, N.U.; Dobaradaran, S.; De-la-Torre, G.E. Degradation of plastics associated with the COVID-19 pandemic. Mar. Pollut. Bull. 2022, 176, 113474. [Google Scholar] [CrossRef] [PubMed]

- Rathinamoorthy, R.; Balasaraswathi, S.R. Disposable tri-layer masks and microfiber pollution–an experimental analysis on dry and wet state emission. Sci. Total Environ. 2022, 816, 151562. [Google Scholar] [CrossRef] [PubMed]

- Spennemann, D.H.R. The Material Culture of the COVID-19 Pandemic. The impact of Freeze-Thaw Action on the Structural Integrity of Single-Use-Use SURGICAL Face Masks; SAEVS, Charles Sturt University: Albury, NSW, Australia, 2022. [Google Scholar]

- Sales, E.; Mulatier, N.; Wittmann, L.; Fernandes, A.; Vacher, B.; Penuelas, J. Effect of dry heat treatment between room temperature and 160 °C on surgical mask. Mater. Lett. 2021, 308, 131270. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Sun, B.-C.; Wang, J.-X.; Zhou, Y.-Y.; Chen, Z.-W.; Fang, Y.; Yue, W.-H.; Liu, S.-M.; Liu, K.-Y.; Zeng, X.-F. Can masks be reused after hot water decontamination during the COVID-19 pandemic? Engineering 2020, 6, 1115–1121. [Google Scholar] [CrossRef]

- Rajakumar, K.; Sarasvathy, V.; Chelvan, A.T.; Chitra, R.; Vijayakumar, C. Natural weathering studies of polypropylene. J. Polym. Environ. 2009, 17, 191–202. [Google Scholar] [CrossRef]

- Feldman, D. Polymer Weathering: Photo-Oxidation. J. Polym. Environ. 2002, 10, 163–173. [Google Scholar] [CrossRef]

- Shimizu, K.; Tokuta, Y.; Oishi, A.; Kuriyama, T.; Kunioka, M. Weatherability of polypropylene by accelerated weathering tests and outdoor exposure tests in Japan. J. Polym. 2016, 2016, 6539567. [Google Scholar] [CrossRef]

- Yang, X.; Ding, X. Prediction of outdoor weathering performance of polypropylene filaments by accelerated weathering tests. Geotext. Geomembr. 2006, 24, 103–109. [Google Scholar] [CrossRef]

- Lv, Y.; Huang, Y.; Kong, M.; Yang, Q.; Li, G. Multivariate correlation analysis of outdoor weathering behavior of polypropylene under diverse climate scenarios. Polym. Test. 2017, 64, 65–76. [Google Scholar] [CrossRef]

- Cheng, F.; Zhang, T.; Liu, Y.; Zhang, Y.; Qu, J. Non-Negligible Effects of UV Irradiation on Transformation and Environmental Risks of Microplastics in the Water Environment. J. Xenobiot. 2021, 12, 1–12. [Google Scholar] [CrossRef]

- Song, Y.K.; Hong, S.H.; Jang, M.; Han, G.M.; Jung, S.W.; Shim, W.J. Combined effects of UV exposure duration and mechanical abrasion on microplastic fragmentation by polymer type. Environ. Sci. Technol. 2017, 51, 4368–4376. [Google Scholar] [CrossRef] [PubMed]

- Andrady, A.; Pegram, J.; Tropsha, Y. Changes in carbonyl index and average molecular weight on embrittlement of enhanced-photodegradable polyethylenes. J. Environ. Polym. Degrad. 1993, 1, 171–179. [Google Scholar] [CrossRef]

- Richaud, E.; Farcas, F.; Divet, L.; Benneton, J.P. Accelerated ageing of polypropylene geotextiles, the effect of temperature, oxygen pressure and aqueous media on fibers—Methodological aspects. Geotext. Geomembr. 2008, 26, 71–81. [Google Scholar] [CrossRef]

- Valentin, C.A.; Kobelnik, M.; Franco, Y.B.; Lavoie, F.L.; Silva, J.L.d.; Luz, M.P.d. Study of the ultraviolet effect and thermal analysis on polypropylene nonwoven geotextile. Materials 2021, 14, 1080. [Google Scholar] [CrossRef] [PubMed]

- Rabello, M.; White, J. The role of physical structure and morphology in the photodegradation behaviour of polypropylene. Polym. Degrad. Stab. 1997, 56, 55–73. [Google Scholar] [CrossRef]

- Zhang, G.; Xiao, Y.; Yan, J.; Xie, N.; Liu, R.; Zhang, Y. Ultraviolet Light-degradation Behavior and Antibacterial Activity of Polypropylene/ZnO Nanoparticles Fibers. Polymers 2019, 11, 1841. [Google Scholar] [CrossRef] [Green Version]

- Spennemann, D.H.R. The Material Culture of the COVID-19 Pandemic. A Photographic Documentation of UV Degradation of Discarded Single-Use Surgical Face Masks; SAEVS, Charles Sturt University: Albury, NSW, Australia, 2022. [Google Scholar]

- Fadare, O.O.; Okoffo, E.D. COVID-19 face masks: A potential source of microplastic fibers in the environment. Sci. Total Environ. 2020, 737, 140279. [Google Scholar] [CrossRef]

- Carneiro, J.R.; Almeida, P.J.; de Lurdes Lopes, M. Evaluation of the resistance of a polypropylene geotextile against ultraviolet radiation. Microsc. Microanal. 2019, 25, 196–202. [Google Scholar] [CrossRef]

- Aparicio-Ardila, M.A.; Pedroso, G.O.M.; Kobelnik, M.; Valentin, C.A.; da Luz, M.P.; Lins da Silva, J. Evaluating the Degradation of a Nonwoven Polypropylene Geotextile Exposed to Natural Weathering for 3 Years. Int. J. Geosynth. Ground Eng. 2021, 7, 69. [Google Scholar] [CrossRef]

- Guimarães, M.; de Mattos Vidal, D.; de Carvalho Urashima, D.; Castro, C. Degradation of polypropylene woven geotextile: Tensile creep and weathering. Geosynth. Int. 2017, 24, 213–223. [Google Scholar] [CrossRef]

- Rivaton, A.; Gardette, J.L.; Mailhot, B.; Morlat-Therlas, S. Basic aspects of polymer degradation. In Macromolecular Symposia; WILEY-VCH: Weinheim, Germany, 2005; pp. 129–146. [Google Scholar]

- Rabek, J.F. Polymer Photodegradation: Mechanisms and Experimental Methods; Springer Science & Business Media: Berlin, Germany, 1994. [Google Scholar]

- Zhao, Z.; Zhang, Z.; Lanzarini-Lopes, M.; Sinha, S.; Rho, H.; Herckes, P.; Westerhoff, P. Germicidal Ultraviolet Light Does Not Damage or Impede Performance of N95 Masks Upon Multiple Uses. Environ. Sci. Technol. Lett. 2020, 7, 600–605. [Google Scholar] [CrossRef]

- Nicolau, T.; Filho, N.G.; Zille, A. Ultraviolet-C as a Viable Reprocessing Method for Disposable Masks and Filtering Facepiece Respirators. Polymers 2021, 13, 801. [Google Scholar] [CrossRef] [PubMed]

- Purschke, M.; Elsamaloty, M.; Wilde, J.P.; Starr, N.; Anderson, R.R.; Farinelli, W.A.; Sakamoto, F.H.; Tung, M.; Tam, J.; Hesselink, L. Construction and validation of UV-C decontamination cabinets for filtering facepiece respirators. Appl. Opt. 2020, 59, 7585–7595. [Google Scholar] [CrossRef] [PubMed]

- Spennemann, D.H.R. The archaeological signature of single-use surgical face masks, the most ubiquitous artefact of the COVID-19 pandemic. Heritage 2021, 4, 2140–2162. [Google Scholar] [CrossRef]

- Färginstitutet. Natural Colour System Index; Skandinaviska Färginstitutet AG: Stockholm, Sweden, 1985. [Google Scholar]

- Alpine MDF. Alpine MDF Premium Panels; Alpine MDF Industries Pty Ltd.: North Wangaratta, VIC, Australia, 2011. [Google Scholar]

- Australian Building Codes Board. Climate Zone Map Australia Wide. Available online: https://www.abcb.gov.au/Resources/Tools-Calculators/Climate-Zone-Map-Australia-Wide (accessed on 15 May 2022).

- Bureau of Meteorology. Map of Climate Zones of Australia. Available online: http://www.bom.gov.au/climate/how/newproducts/images/zones.shtml (accessed on 15 May 2022).

- Bureau of Meterology. Evapotranspiration Calculations. Albury Airport. Available online: http://www.bom.gov.au/watl/eto/tables/nsw/albury_airport/albury_airport.html (accessed on 15 May 2022).

- Ineos Olefins & Polymers. Typical Engineering Properties of Polypropylene; INEOS: League City, TX, USA, 2014. [Google Scholar]

- Bureau of Meteorology. Climate statistics for Australian locations. Monthly Climate Statistics. Albury Airport (Station nº 072146). Available online: http://www.bom.gov.au/climate/averages/tables/cw_072146.shtml (accessed on 15 May 2022).

- Emmanuel, P.; Hassan, S. Potentials of Polypropylene Sheets in Trapping Solar Heat for the Management of Callosobruchus maculatus (Fab.) Infestation. J. Appl. Sci. 2019, 19, 349–354. [Google Scholar] [CrossRef] [Green Version]

- Hossain, E.; Bhadra, S.; Jain, H.; Das, S.; Bhattacharya, A.; Ghosh, S.; Levine, D. Recharging and rejuvenation of decontaminated N95 masks. Phys. Fluids 2020, 32, 093304. [Google Scholar] [CrossRef]

- Xiao, H.; Song, Y.; Chen, G. Correlation between charge decay and solvent effect for melt-blown polypropylene electret filter fabrics. J. Electrost. 2014, 72, 311–314. [Google Scholar] [CrossRef]

- Mirjalili, F.; Moradian, S.; Ameri, F. Enhancing the dyeability of polypropylene fibers by melt blending with polyethylene terephthalate. Sci. World J. 2013, 2013, 468542. [Google Scholar] [CrossRef] [Green Version]

- Lee, L.Y.-K.; Chan, I.C.-W.; Wong, O.P.-M.; Ng, Y.H.-Y.; Ng, C.K.-Y.; Chan, M.H.-W.; Ng, J.K.-C.; Koo, H.H.-T.; Lam, S.-T.; Chu, A.C.-W. Reuse of face masks among adults in Hong Kong during the COVID-19 pandemic. BMC Public Health 2021, 21, 1267. [Google Scholar] [CrossRef]

- Tan, M.; Wang, Y.; Luo, L.; Hu, J. How the public used face masks in China during the coronavirus disease pandemic: A survey study. Int. J. Nurs. Stud. 2021, 115, 103853. [Google Scholar] [CrossRef]

- Tam, V.C.; Tam, S.Y.; Poon, W.K.; Law, H.K.W.; Lee, S.W. A reality check on the use of face masks during the COVID-19 outbreak in Hong Kong. EClinicalMedicine 2020, 22, 100356. [Google Scholar] [CrossRef] [PubMed]

- Pereira-Ávila, F.M.V.; Lam, S.C.; Góes, F.G.B.; Gir, E.; Pereira-Caldeira, N.M.V.; Teles, S.A.; Caetano, K.A.A.; Goulart, M.D.C.; Bazilio, T.R.; Silva, A.C.D.O. Factors associated with the use and reuse of face masks among Brazilian individuals during the COVID-19 pandemic. Rev. Lat -Am. De Enferm. 2020, 28. [Google Scholar] [CrossRef] [PubMed]

- Suen, C.Y.; Leung, H.H.; Lam, K.W.; Hung, K.; Chan, M.Y.; Kwan, J.K. Feasibility of reusing surgical mask under different disinfection treatments. MedRxiv 2020. [Google Scholar] [CrossRef]

- Teo, J.Y.; Kng, J.; Periaswamy, B.; Liu, S.; Lim, P.C.; Lee, C.E.; Tan, B.H.; Loh, X.J.; Ni, X.; Tiang, D. Exploring Reusability of Disposable Face Masks: Effects of Disinfection Methods on Filtration Efficiency, Breathability, and Fluid Resistance. Glob. Chall. 2021, 5, 2100030. [Google Scholar] [CrossRef] [PubMed]

- European Chemicals Agency. Annex XV Restriction Report. Proposal for a Restriction. Substance Name(s): Intentionally Added Microplastics, 1.2nd ed.; European Chemicals Agency: Helsinki, Finland, 2019. [Google Scholar]

- Andrady, A.L. The plastic in microplastics: A review. Mar. Pollut. Bull. 2017, 119, 12–22. [Google Scholar] [CrossRef] [PubMed]

- Cole, M.; Lindeque, P.; Halsband, C.; Galloway, T.S. Microplastics as contaminants in the marine environment: A review. Mar. Pollut. Bull. 2011, 62, 2588–2597. [Google Scholar] [CrossRef] [PubMed]

- Silva, A.B.; Bastos, A.S.; Justino, C.I.; da Costa, J.P.; Duarte, A.C.; Rocha-Santos, T.A. Microplastics in the environment: Challenges in analytical chemistry—A review. Anal. Chim. Acta 2018, 1017, 1–19. [Google Scholar] [CrossRef]

- de Souza Machado, A.A.; Lau, C.W.; Till, J.; Kloas, W.; Lehmann, A.; Becker, R.; Rillig, M.C. Impacts of microplastics on the soil biophysical environment. Environ. Sci. Technol. 2018, 52, 9656–9665. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Liu, X.; Li, Y.; Powell, T.; Wang, X.; Wang, G.; Zhang, P. Microplastics as contaminants in the soil environment: A mini-review. Sci. Total Environ. 2019, 691, 848–857. [Google Scholar] [CrossRef]

- Senathirajah, K.; Attwood, S.; Bhagwat, G.; Carbery, M.; Wilson, S.; Palanisami, T. Estimation of the mass of microplastics ingested–A pivotal first step towards human health risk assessment. J. Hazard. Mater. 2021, 404, 124004. [Google Scholar] [CrossRef]

- Smith, M.; Love, D.C.; Rochman, C.M.; Neff, R.A. Microplastics in seafood and the implications for human health. Curr. Environ. Health Rep. 2018, 5, 375–386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carbery, M.; O’Connor, W.; Palanisami, T. Trophic transfer of microplastics and mixed contaminants in the marine food web and implications for human health. Environ. Int. 2018, 115, 400–409. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hunt, C.F.; Lin, W.H.; Voulvoulis, N. Evaluating alternatives to plastic microbeads in cosmetics. Nat. Sustain. 2021, 4, 366–372. [Google Scholar] [CrossRef]

- Sun, Q.; Ren, S.-Y.; Ni, H.-G. Incidence of microplastics in personal care products: An appreciable part of plastic pollution. Sci. Total Environ. 2020, 742, 140218. [Google Scholar] [CrossRef] [PubMed]

| Exposed Face | Color | Control | Sample | Weight | |||||

|---|---|---|---|---|---|---|---|---|---|

| Mask | #1 | #2 | #3 | #4 | Loss% | p | |||

| A | recto | white | 2.9663 | 2.8737 | 2.8269 | 2.9187 | 2.8639 | −3.22 | 0.0149 |

| A | verso | white | 2.9663 | 2.8764 | 2.9906 | — | — | −1.11 | |

| B | recto | white | 3.6424 | 3.8252 | 3.6944 | 3.8548 | — | 4.09 | |

| B | verso | blue | 3.6424 | 3.4377 | 3.5168 | 3.4226 | — | −5.03 | 0.0244 |

| C | recto | blue | 2.5287 | 2.2917 | 2.3130 | 2.4357 | — | −7.19 | |

| C | verso | white | 2.5287 | 2.8502 | 2.8662 | 2.8452 | — | 12.86 | 0.0004 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spennemann, D.H.R. Environmental Decay of Single Use Surgical Face Masks as an Agent of Plastic Micro-Fiber Pollution. Environments 2022, 9, 94. https://doi.org/10.3390/environments9070094

Spennemann DHR. Environmental Decay of Single Use Surgical Face Masks as an Agent of Plastic Micro-Fiber Pollution. Environments. 2022; 9(7):94. https://doi.org/10.3390/environments9070094

Chicago/Turabian StyleSpennemann, Dirk H. R. 2022. "Environmental Decay of Single Use Surgical Face Masks as an Agent of Plastic Micro-Fiber Pollution" Environments 9, no. 7: 94. https://doi.org/10.3390/environments9070094

APA StyleSpennemann, D. H. R. (2022). Environmental Decay of Single Use Surgical Face Masks as an Agent of Plastic Micro-Fiber Pollution. Environments, 9(7), 94. https://doi.org/10.3390/environments9070094