Assessing Energy-Based CO2 Emission and Workers’ Health Risks at the Shipbreaking Industries in Bangladesh

Abstract

:1. Introduction

2. Materials and Methods

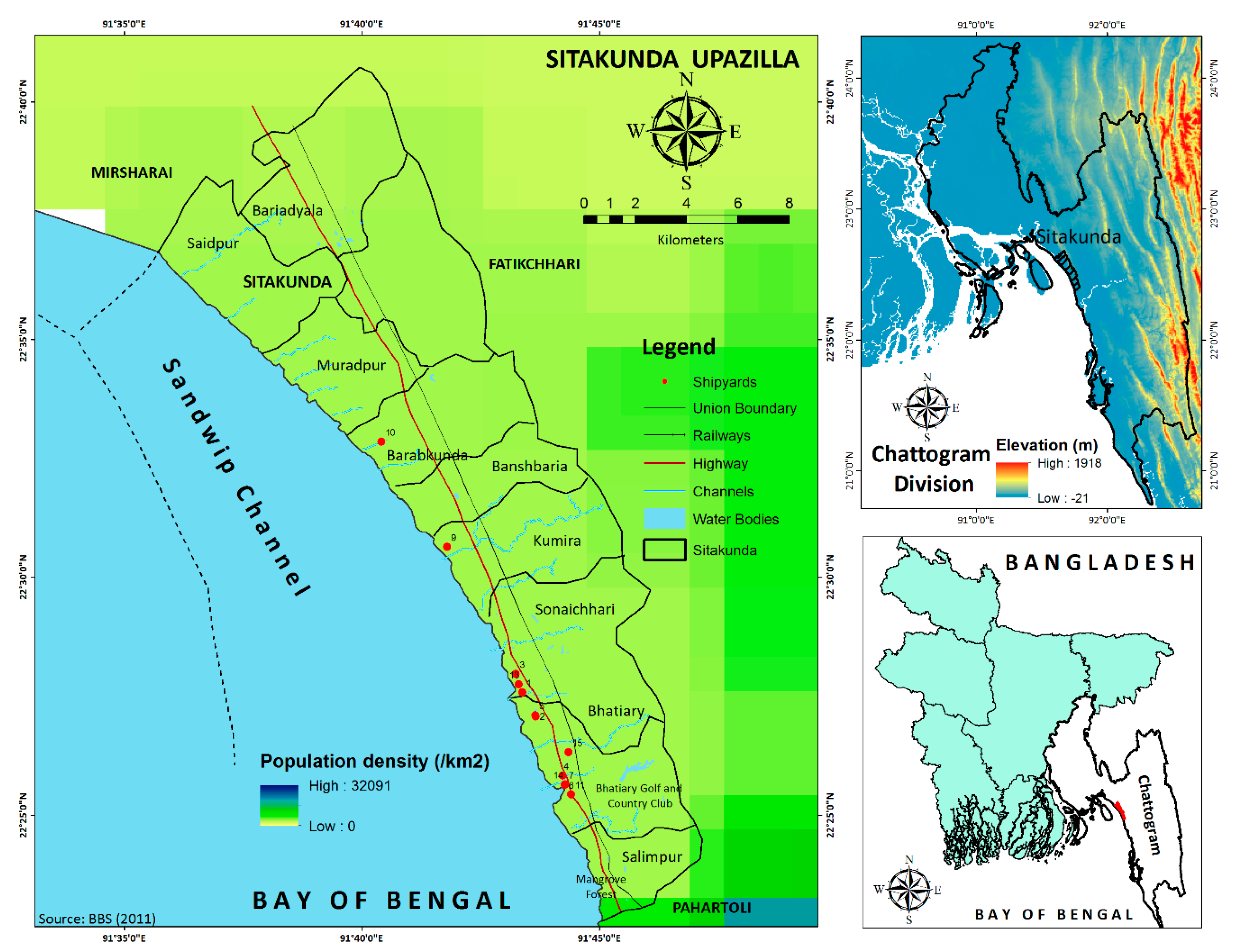

2.1. Study Area

2.2. Estimation of Energy-Based CO2 Emission

2.3. Geographic Weighted Regression (GWR) Model

2.4. Assessment of Workers’ Condition and Environmental Consequences

3. Results

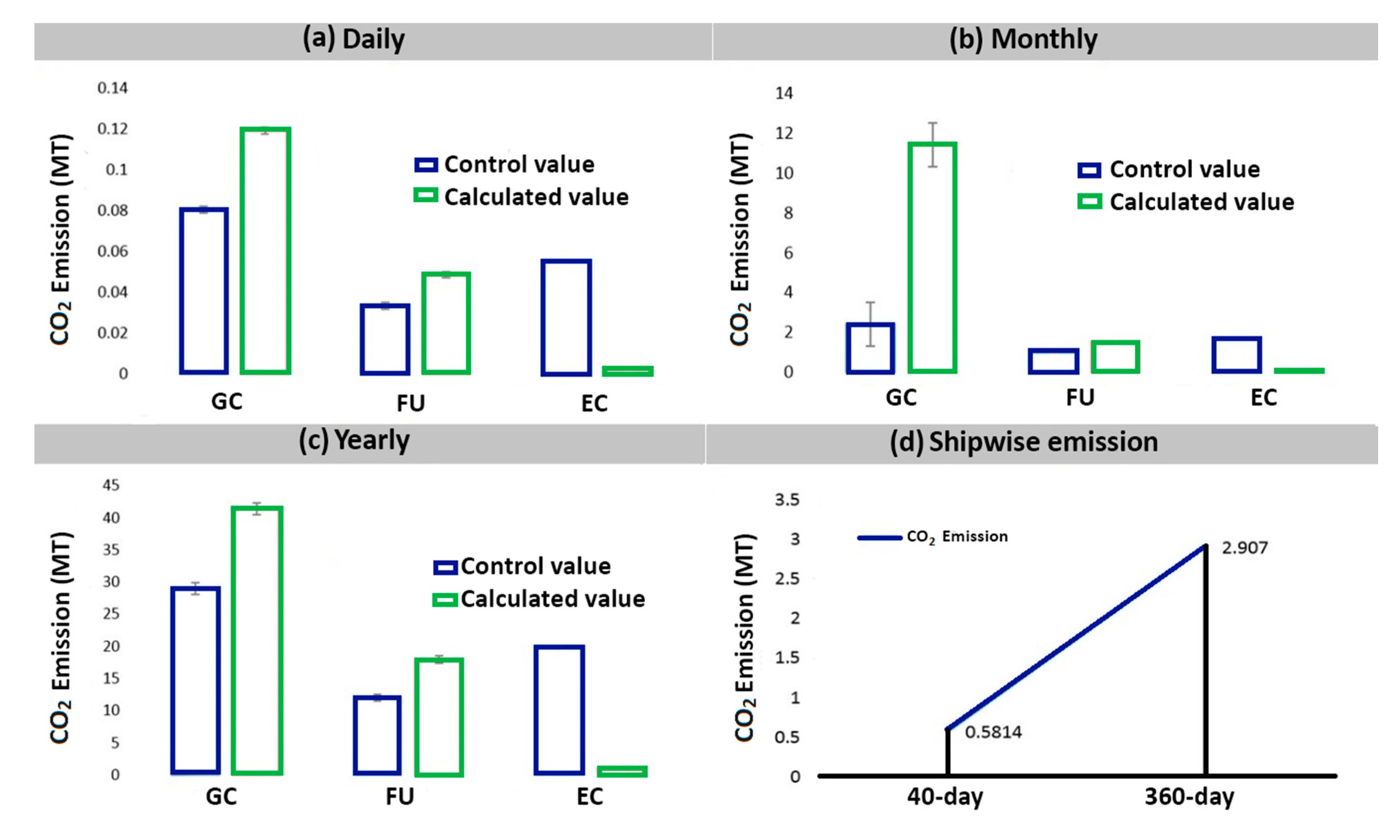

3.1. Calculation of Energy-Based CO2 Emission

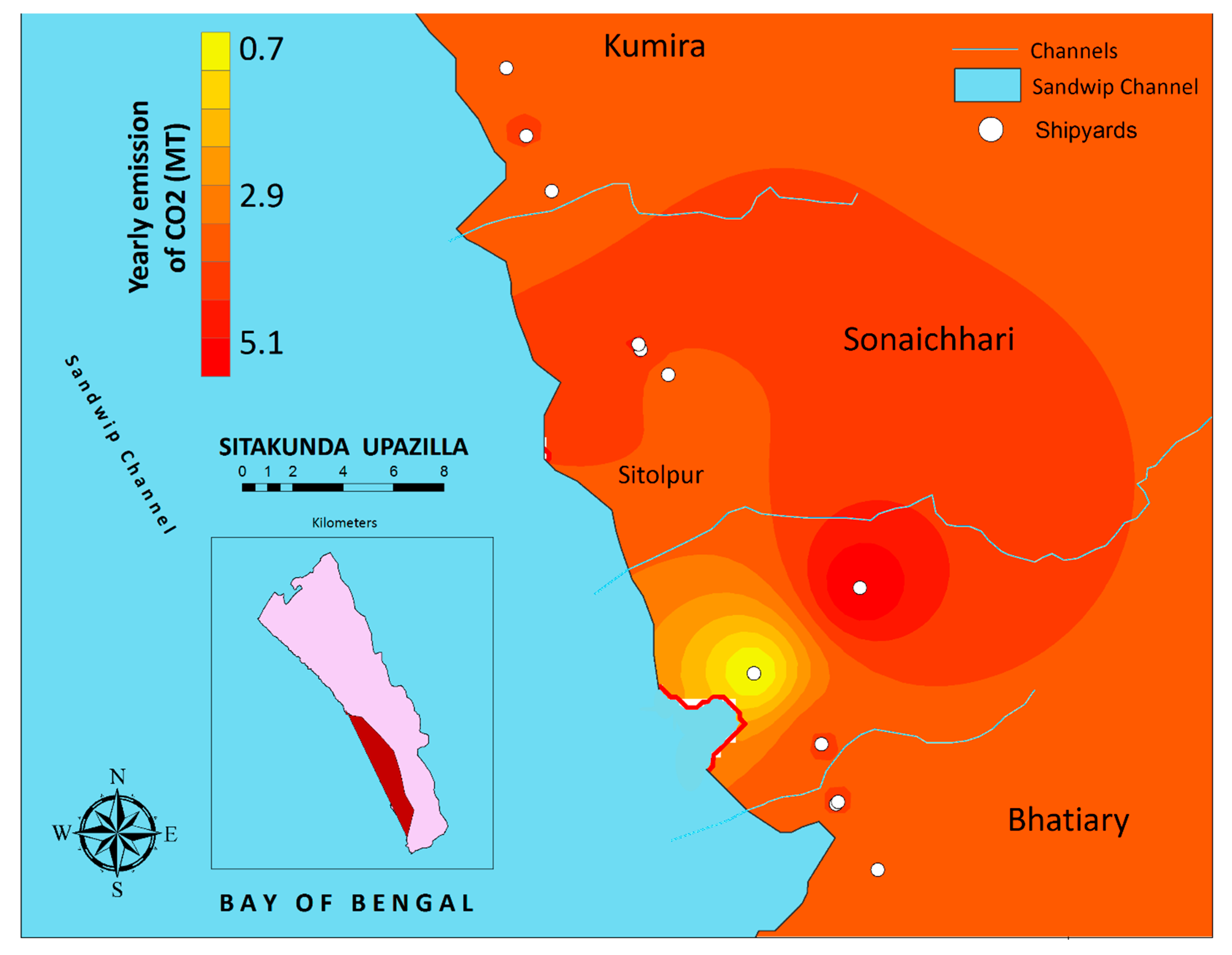

3.2. GWR Model

3.3. Assesment of Workers’ Condition

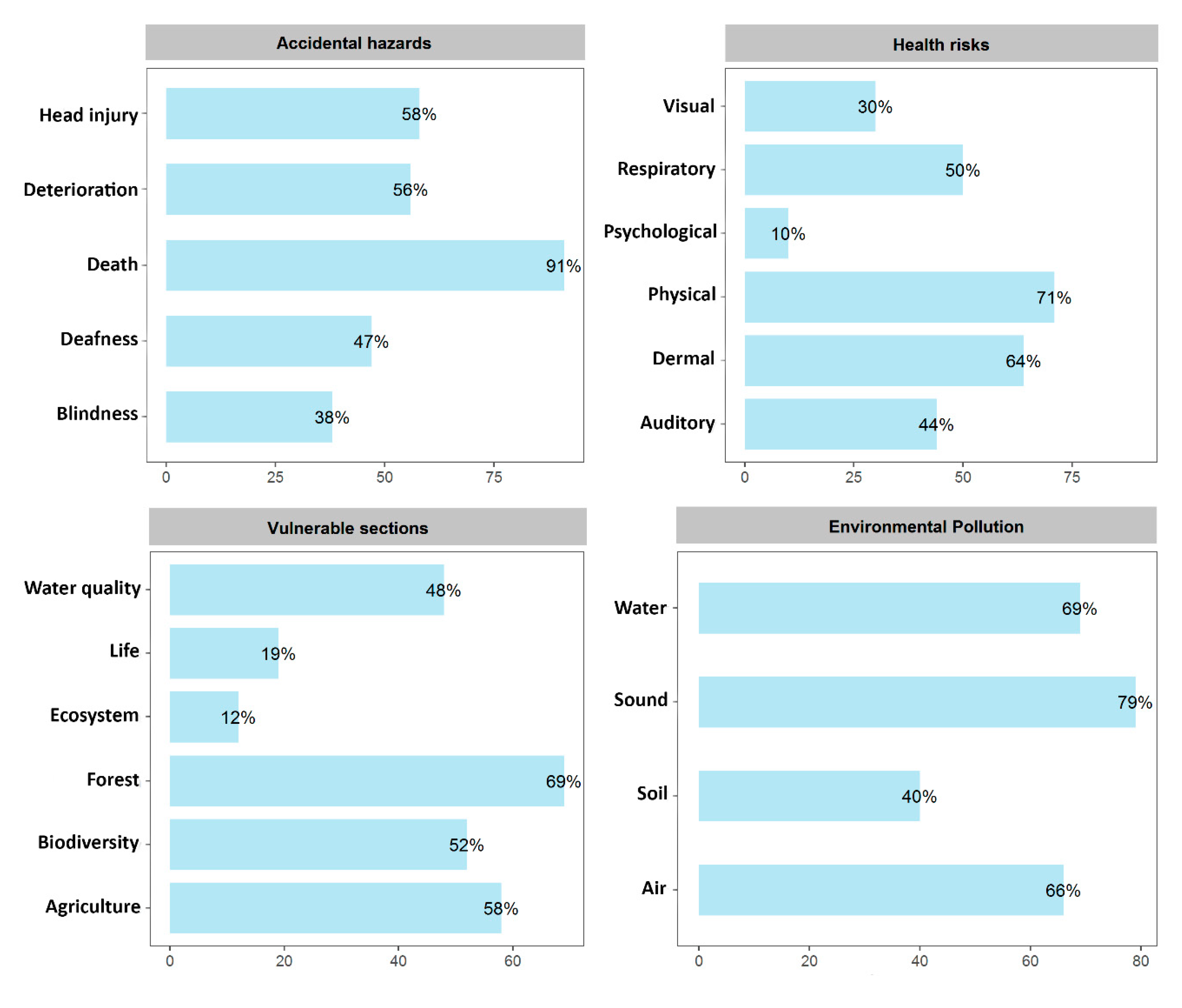

3.3.1. Accidental Hazards

3.3.2. Environmental Hazards

3.3.3. Health Hazards

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sarraf, M.; Stuer-Lauridsen, F.; Dyoulgerov, M.; Bloch, R.; Wingfield, S.; Watkinson, R. The Ship Breaking and Recycling Industry in Bangladesh and Pakistan; Report No. 58275-SAS; World Bank: Washington, DC, USA, 2010. [Google Scholar] [CrossRef]

- Azad, A.K.; Jensen, K.R.; Lin, C.K. Coastal aquaculture development in Bangladesh: Unsustainable and sustainable experiences. Environ. Manag. 2009, 44, 800–809. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.; Selvanathan, A. Population, poverty and CO2 emission in Asia: An overview. In Climate Change and Growth in Asia; Elgar, E., Ed.; Edward Elgar Publishing Limited: Cheltenham, UK, 2011; pp. 17–37. [Google Scholar]

- Abdullah, H.M.; Mahboob, M.G.; Banu, M.R.; Seker, D.Z. Monitoring the drastic growth of ship breaking yards in Sitakunda: A threat to the coastal environment of Bangladesh. Environ. Monit. Assess. 2012, 185, 3839–3851. [Google Scholar] [CrossRef] [PubMed]

- Hossain, K.A. Overview of ship recycling industry of Bangladesh. J. Environ. Anal. Toxicol. 2015, 5, 312. [Google Scholar] [CrossRef]

- Alam, S.; Faruque, A. Legal regulation of the shipbreaking industry in Bangladesh: The international regulatory framework and domestic implementation challenges. Mar. Policy 2014, 47, 46–56. [Google Scholar] [CrossRef]

- Iqbal, K.M.J.; Heidegger, P. Pakistan Shipbreaking Outlook: The Way Forward for A Green Ship Recycling Industry–Environmental, Health and Safety Conditions; Sustainable Development Policy Institute and NGO Shipbreaking Platform: Brussels, Belgium; Islamabad, Pakistan, 2013. [Google Scholar]

- Das, J.; Shahin, M.A. Ship Breaking and its Future in Bangladesh. J. Ocean Coast. Econ. 2019, 6, 9. [Google Scholar] [CrossRef] [Green Version]

- Hossain, M.M.M.; Islam, M.M. Ship Breaking Activities and Its Impact on the Coastal Zone of Chittagong, Bangladesh: Towards Sustainable Management; Advocacy & Publication Unit, Young Power in Social Action (YPSA): Chittagong, Bangladesh, 2006. [Google Scholar]

- Reddy, M.S.; Basha, S.; Kumar, V.S.; Joshi, H.V.; Ghosh, P.K. Quantification and classification of ship scraping waste at Alang–Sosiya, India. Mar. Pollut. Bull. 2003, 46, 1609–1614. [Google Scholar] [CrossRef]

- Zou, L.L.; Wei, Y.M. Driving factors for social vulnerability to coastal hazards in Southeast Asia: Results from the meta-analysis. Nat. Hazards 2010, 54, 901–929. [Google Scholar] [CrossRef]

- Islam, K.L.; Hossain, M.M. Effect of ship scrapping activities on the soil and sea environment in the coastal area of Chittagong, Bangladesh. Mar. Pollut. Bull. 1986, 17, 462–463. [Google Scholar] [CrossRef]

- Tewari, A.; Joshi, H.V.; Trivedi, R.H.; Sravankumar, V.G.; Raghunathan, C.; Khambhaty, Y.; Kotiwar, O.S.; Mandal, S.K. The effect of ship scrapping industry and its associated wastes on the biomass production and biodiversity of biota in in situ condition at Alang. Mar. Pollut. Bull. 2001, 42, 461–468. [Google Scholar] [CrossRef]

- Neşer, G.; Ünsalan, D.; Tekoğul, N.; Stuer-Lauridsen, F. The shipbreaking industry in Turkey: Environmental, safety and health issues. J. Clean. Prod. 2008, 16, 350–358. [Google Scholar] [CrossRef]

- Hossain, M.M.M.; Rahman, M.A. Ship breaking activities: Threats to coastal environment and fish biodiversity. In Ecosystem Health and Management of Pollution in the Bay of Bengal; Bangladesh Fisheries Research Institute: Mymensingh, Bangladesh, 2011; p. 23. [Google Scholar]

- Pasha, M.; Mahmood, A.H.; Rahman, I.; Hasnat, A. Assessment of Ship Breaking and Recycling Industries in Bangladesh - An Effective Step Towards The Achievement of Environmental Sustainability. In Proceedings of the International Conference on Agricultural, Environment and Biological Sciences (ICAEBS), Phuket, Thailand, 26–27 May 2012; pp. 43–47. [Google Scholar]

- Zakaria, N.G.; Ali, M.T.; Hossain, K.A. Underlying problems of ship recycling industries in Bangladesh and way forward. J. Nav. Arch. Mar. Eng. 2012, 9, 91–102. [Google Scholar] [CrossRef]

- Patwary, M.S.H.; Bartlett, D. Impacts of shipbreaking industry in Bangladesh: Search for a sustainable solution. Eur. J. Eng. Tech. 2019, 7, 64–79. [Google Scholar]

- Gunbeyaz, S.A.; Kurt, R.E.; Baumler, R. A study on evaluating the status of current occupational training in the ship recycling industry in Bangladesh. WMU J. Marit. Aff. 2019, 18, 41–59. [Google Scholar] [CrossRef] [Green Version]

- Siddiquee, N.A.; Parween, S.; Quddus, M.M.A.; Barua, P. Heavy metal pollution in sediments at ship breaking area of Bangladesh. In Coastal Environments: Focus on Asian Regions; Subramanian, V., Ed.; Springer: Dordrecht, The Netherlands, 2012; pp. 78–87. [Google Scholar]

- Hasan, A.B.; Kabir, S.; Reza, A.S.; Zaman, M.N.; Ahsan, A.; Rashid, M. Enrichment factor and geo-accumulation index of trace metals in sediments of the ship breaking area of Sitakund Upazilla (Bhatiary–Kumira), Chittagong, Bangladesh. J. Geochem. Explor. 2013, 125, 130–137. [Google Scholar] [CrossRef]

- Sujauddin, M.; Koide, R.; Komatsu, T.; Hossain, M.M.; Tokoro, C.; Murakami, S. Characterization of ship breaking industry in Bangladesh. J. Mater. Cycles Waste Manag. 2015, 17, 72–83. [Google Scholar] [CrossRef]

- Hossain, M.S.; Fakhruddin, A.N.M.; Chowdhury, M.A.Z.; Gan, S.H. Impact of ship-breaking activities on the coastal environment of Bangladesh and a management system for its sustainability. Environ. Sci. Policy 2016, 60, 84–94. [Google Scholar] [CrossRef]

- Khan, M.Z.H.; Hasan, M.R.; Khan, M.; Aktar, S.; Fatema, K. Distribution of heavy metals in surface sediments of the Bay of Bengal Coast. J. Toxicol. 2017, 2017, 1–7. [Google Scholar] [CrossRef]

- Rahman, M.S.; Hossain, M.B.; Babu, S.O.F.; Rahman, M.; Ahmed, A.S.; Jolly, Y.N.; Akter, S. Source of metal contamination in sediment, their ecological risk, and phytoremediation ability of the studied mangrove plants in ship breaking area, Bangladesh. Mar. Pollut. Bull. 2019, 141, 137–146. [Google Scholar] [CrossRef]

- Nøst, T.H.; Halse, A.K.; Randall, S.; Borgen, A.R.; Schlabach, M.; Paul, A.; Breivik, K. High concentrations of organic contaminants in air from ship breaking activities in Chittagong, Bangladesh. Environ. Sci. Technol. 2015, 49, 11372–11380. [Google Scholar] [CrossRef] [Green Version]

- Alam, I.; Barua, S.; Ishii, K.; Mizutani, S.; Hossain, M.M.; Rahman, I.M.; Hasegawa, H. Assessment of health risks associated with potentially toxic element contamination of soil by end-of-life ship dismantling in Bangladesh. Environ. Sci. Pollut. Res. 2019, 26, 24162. [Google Scholar] [CrossRef]

- Kibria, G.; Hossain, M.M.; Mallick, D.; Lau, T.C.; Wu, R. Trace/heavy metal pollution monitoring in estuary and coastal area of Bay of Bengal, Bangladesh and implicated impacts. Mar. Pollut. Bull. 2016, 105, 393–402. [Google Scholar] [CrossRef] [PubMed]

- Yılmaz, A.; Karacık, B.; Yakan, S.D.; Henkelmann, B.; Schramm, K.W.; Okay, O.S. Organic and heavy metal pollution in shipbreaking yards. Ocean Eng. 2016, 123, 452–457. [Google Scholar] [CrossRef]

- Liu, L.C.; Fan, Y.; Wu, G.; Wei, Y.M. Using LMDI method to analyze the change of China’s industrial CO2 emissions from final fuel use: An empirical analysis. Energy Policy 2007, 35, 5892–5900. [Google Scholar] [CrossRef]

- Deshpande, P.C.; Kalbar, P.P.; Tilwankar, A.K.; Asolekar, S.R. A novel approach to estimating resource consumption rates and emission factors for ship recycling yards in Alang, India. J. Clean. Prod. 2013, 59, 251–259. [Google Scholar] [CrossRef]

- Rahman, S.M.; Handler, R.M.; Mayer, A.L. Life cycle assessment of steel in the ship recycling industry in Bangladesh. J. Clean. Prod. 2016, 135, 963–971. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, L.; Cui, Y.; Xu, Y.; Wang, C.; Yu, J.; Streets, D.G.; Lin, B. Effects of urbanization on airport CO2 emissions: A geographically weighted approach using nighttime light data in China. Resour. Conserv. Recycl. 2019, 150, 104454. [Google Scholar] [CrossRef]

- Gilbert, P.; Wilson, P.; Walsh, C.; Hodgson, P. The role of material efficiency to reduce CO2 emissions during ship manufacture: A life cycle approach. Mar. Policy 2017, 75, 227–237. [Google Scholar] [CrossRef]

- Young Power in Social Action (YPSA). Workers in Ship Breaking Industries: A Base Line Survey of Chittagong (Bangladesh); Young Power in Social Action (YPSA): Chittagong, Bangladesh, 2005. [Google Scholar]

- The Daily New Age. Two Ship-breaking Yard Workers Burnt Dead in Sitakundu. Available online: http://www.newagebd.net/article/65300/two-ship-breaking-yard-workers-burnt-dead-in-sitakundu (accessed on 19 February 2019).

- Rabbi, H.R.; Rahman, A. Ship breaking and recycling industry of Bangladesh; issues and challenges. Procedia Eng. 2017, 194, 254–259. [Google Scholar] [CrossRef]

- Rahman, S.M.; Schelly, C.; Mayer, A.L.; Norman, E.S. Uncovering discursive framings of the Bangladesh shipbreaking industry. Soc. Sci. 2018, 7, 14. [Google Scholar] [CrossRef] [Green Version]

- Cairns, G. A critical scenario analysis of end-of-life ship disposal: The “bottom of the pyramid” as opportunity and graveyard. Crit. Persp. Int. Bus. 2014, 10, 172–189. [Google Scholar] [CrossRef]

- Iqbal, K.; Zakaria, N.M.; Hossain, K. Identifying and Analysing Underlying Problems of Shipbuilding Industries in Bangladesh. J. Mech. Eng. 2011, 41, 147–158. [Google Scholar] [CrossRef] [Green Version]

- Banglapedia. Available online: http://en.banglapedia.org/index.php?title=Sitakunda_Upazila (accessed on 13 November 2019).

- The Intergovernmental Panel on Climate Change (IPCC). Greenhouse Gas Inventory: IPCC Guidelines for National Greenhouse Gas Inventories; United Kingdom Meteorological Office: Bracknell, UK, 1995.

- United States Environmental Protection Agency (EPA). EGRID Summary Tables 2012. Available online: https://www.epa.gov/energy/egrid-summary-tables (accessed on 5 February 2019).

- Bartier, P.M.; Keller, C.P. Multivariate interpolation to incorporate thematic surface data using inverse distance weighting (IDW). Comput. Geosci. 1996, 22, 795–799. [Google Scholar] [CrossRef]

- Harman, B.I.; Koseoglu, H.; Yigit, C.O. Performance evaluation of IDW, Kriging and multiquadric interpolation methods in producing noise mapping: A case study at the city of Isparta, Turkey. Appl. Acoust. 2016, 112, 147–157. [Google Scholar] [CrossRef]

- Huang, F.; Liu, D.; Tan, X.; Wang, J.; Chen, Y.; He, B. Explorations of the implementation of a parallel IDW interpolation algorithm in a Linux cluster-based parallel GIS. Comput. Geosci. 2011, 37, 426–434. [Google Scholar] [CrossRef]

- Fotheringham, A.S.; Brunsdon, C.; Charlton, M. Geographically Weighted Regression: The Analysis of Spatially Varying Relationships; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Bivand, R.; Yu, D.; Nakaya, T.; Garcia-Lopez, M.A.; Bivand, M.R. Package ‘spgwr’. Available online: ftp://oss.ustc.edu.cn/CRAN/web/packages/spgwr/spgwr.pdf (accessed on 29 April 2020).

- Paradis, E.; Schliep, K. ape 50: An environment for modern phylogenetics and evolutionary analyses in R. Bioinformatics 2019, 35, 526–528. [Google Scholar] [CrossRef]

- Hasan, A.B.; Kabir, S.; Reza, A.S.; Zaman, M.N.; Ahsan, M.A.; Akbor, M.A.; Rashid, M.M. Trace metals pollution in seawater and groundwater in the ship breaking area of Sitakund Upazilla, Chittagong, Bangladesh. Mar. Pollut. Bull. 2013, 71, 317–324. [Google Scholar] [CrossRef] [PubMed]

- Barua, S.; Rahman, I.M.; Hossain, M.M.; Begum, Z.A.; Alam, I.; Sawai, H.; Maki, T.; Hasegawa, H. Environmental hazards associated with open-beach breaking of end-of-life ships: A review. Environ. Sci. Pollut. Res. 2018, 25, 30880–30893. [Google Scholar] [CrossRef]

- Wei, Y.M.; Liu, L.C.; Fan, Y.; Wu, G. The impact of lifestyle on energy use and CO2 emission: An empirical analysis of China’s residents. Energy Policy 2007, 35, 247–257. [Google Scholar] [CrossRef]

- Xu, B.; Lin, B. Factors affecting CO2 emissions in China’s agriculture sector: Evidence from geographically weighted regression model. Energy Policy 2017, 104, 404–414. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Kang, Y.; Chen, W.; Zhao, M.; Li, W. Analyzing the impact of urbanization quality on CO2 emissions: What can geographically weighted regression tell us? Renew. Sustain. Energy Rev. 2019, 104, 127–136. [Google Scholar] [CrossRef]

- Kutub, M.J.R.; Falgunee, N.; Nawfee, S.M.; Rabby, Y.W. Ship breaking industries and their impacts on the local people and environment of coastal areas of Bangladesh. Hum. Soc. Stud. 2017, 6, 35–58. [Google Scholar] [CrossRef] [Green Version]

- Choi, B.J.; Lee, S.; Lee, I.J.; Park, S.W.; Lee, S. Gastric and rectal cancers in workers exposed to asbestos: A case series. Ann. Occup. Environ. Med. 2020, 32, e4. [Google Scholar] [CrossRef]

- Rousmaniere, P.; Raj, N. Shipbreaking in the developing world: Problems and prospects. Int. J. Occup. Environ. Health 2007, 13, 359–368. [Google Scholar] [CrossRef] [PubMed]

- Rahman, S.M.; Kim, J. Circular economy, proximity, and shipbreaking: A material flow and environmental impact analysis. J. Clean. Prod. 2020, 259, 120681. [Google Scholar] [CrossRef]

- Sujauddin, M.; Koide, R.; Komatsu, T.; Hossain, M.M.; Tokoro, C.; Murakami, S. Ship breaking and the steel industry in Bangladesh: A material flow perspective. J. Ind. Ecol. 2017, 21, 191–203. [Google Scholar] [CrossRef]

| Fuel | EF (tC/TJ) *b | FCO | Fuel | EF (tC/TJ) | FCO |

|---|---|---|---|---|---|

| Coal | 25.8 | 0.98 | Aviation turbine fuel | 19.5 | 0.99 |

| Soft Coke | 25.8 | 0.98 | Diesel oil | 20.2 | 0.98 |

| Natural Gas | 15.3 | 0.995 | Light-speed oil | 20.2 | 0.99 |

| LPG | 17.2 | 0.995 | High-speed oil | 20.2 | 0.99 |

| Naptha | 20.0 | 0.99 | Fuel oil | 20.2 | 0.99 |

| Motor Gasoline | 18.9 | 0.99 | Other petroleum | 20.2 | 0.99 |

| YN | Calculated Energy-Based CO2 Emission in Shipyards (MT) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Daily | Monthly | Yearly | |||||||

| GC | FU | EC | GC | FU | EC | GC | FU | EC | |

| 1 | 0.0081 | 0.0012 | 0.0002 | 0.2423 | 0.0452 | 0.0071 | 2.907 | 0.5427 | 0.0853 |

| 2 | 0.0097 | 0.0030 | 0.0002 | 0.2907 | 0.0905 | 0.0059 | 3.488 | 1.0854 | 0.0711 |

| 3 | 0.0081 | 0.0030 | 0.0000 | 0.2423 | 0.0905 | 0.0000 | 2.907 | 1.0854 | 0.0000 |

| 4 | 0.0081 | 0.0030 | 0.0003 | 0.2423 | 0.0905 | 0.0089 | 2.907 | 1.0854 | 0.1000 |

| 5 | 0.0065 | 0.0060 | 0.0003 | 0.1938 | 0.1809 | 0.0089 | 2.326 | 2.1708 | 0.1000 |

| 6 | 0.0097 | 0.0012 | 0.0000 | 0.2907 | 0.0452 | 0.0000 | 3.488 | 0.5427 | 0.0000 |

| 7 | 0.0081 | 0.0030 | 0.0000 | 0.2423 | 0.0904 | 0.0000 | 2.907 | 1.0854 | 0.0000 |

| 8 | 0.0048 | 0.0012 | 0.0002 | 0.1454 | 0.0452 | 0.0059 | 0.116 | 0.5427 | 0.0711 |

| 9 | 0.0065 | 0.0060 | 0.0000 | 0.1938 | 0.1809 | 0.0000 | 2.326 | 2.1708 | 0.0000 |

| 10 | 0.0113 | 0.0030 | 0.0002 | 0.3392 | 0.0905 | 0.0071 | 4.069 | 1.0854 | 0.08532 |

| 11 | 0.0065 | 0.0030 | 0.0002 | 0.1938 | 0.0905 | 0.0059 | 2.326 | 1.0854 | 0.0711 |

| 12 | 0.0065 | 0.0030 | 0.0003 | 0.1938 | 0.0905 | 0.0089 | 2.326 | 1.0854 | 0.1000 |

| 13 | 0.0081 | 0.0030 | 0.0002 | 0.2423 | 0.0905 | 0.0059 | 2.907 | 1.0854 | 0.0711 |

| 14 | 0.0081 | 0.0030 | 0.0002 | 0.2423 | 0.0905 | 0.0059 | 2.907 | 1.0854 | 0.0711 |

| 15 | 0.0096 | 0.0060 | 0.0000 | 0.2907 | 0.1809 | 0.000 | 3.488 | 2.170 | 0.0000 |

| Variable | Minimum | Maximum | Median | 1st Quartile | 3rd Quartile | Global | p-value | R2 |

|---|---|---|---|---|---|---|---|---|

| Intercept | −5.11 | −4.71 | −5.07 | −5.07 | −5.02 | −5.10 | 0.59 | |

| GC | −0.01 | 0.03 | 0.02 | 0.02 | 0.03 | 0.03 | 0.01* | |

| FU | 0.001 | 0.04 | 0.004 | 0.002 | 0.04 | 0.002 | 0.08 | |

| EC | −0.01 | 0.002 | −0.004 | −0.003 | 0.002 | −0.003 | 0.78 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitra, N.; Shahriar, S.A.; Lovely, N.; Khan, M.S.; Rak, A.E.; Kar, S.P.; Khaleque, M.A.; Amin, M.F.M.; Kayes, I.; Salam, M.A. Assessing Energy-Based CO2 Emission and Workers’ Health Risks at the Shipbreaking Industries in Bangladesh. Environments 2020, 7, 35. https://doi.org/10.3390/environments7050035

Mitra N, Shahriar SA, Lovely N, Khan MS, Rak AE, Kar SP, Khaleque MA, Amin MFM, Kayes I, Salam MA. Assessing Energy-Based CO2 Emission and Workers’ Health Risks at the Shipbreaking Industries in Bangladesh. Environments. 2020; 7(5):35. https://doi.org/10.3390/environments7050035

Chicago/Turabian StyleMitra, Nandita, Shihab Ahmad Shahriar, Nurunnaher Lovely, Md Shohel Khan, Aweng Eh Rak, S. P. Kar, Md Abdul Khaleque, Mohamad Faiz Mohd Amin, Imrul Kayes, and Mohammed Abdus Salam. 2020. "Assessing Energy-Based CO2 Emission and Workers’ Health Risks at the Shipbreaking Industries in Bangladesh" Environments 7, no. 5: 35. https://doi.org/10.3390/environments7050035

APA StyleMitra, N., Shahriar, S. A., Lovely, N., Khan, M. S., Rak, A. E., Kar, S. P., Khaleque, M. A., Amin, M. F. M., Kayes, I., & Salam, M. A. (2020). Assessing Energy-Based CO2 Emission and Workers’ Health Risks at the Shipbreaking Industries in Bangladesh. Environments, 7(5), 35. https://doi.org/10.3390/environments7050035