A Review on Global Recovery Policy of Used Lubricating Oils and Their Effects on the Environment and Circular Economy

Abstract

1. Introduction

- (a)

- Acid/Clay Treatment. In acid/clay treatment, WLO is treated with an acid (e.g., sulfuric, acetic, phosphoric, or formic acid) to precipitate contaminants and degrade undesirable additives [16]. This method is attractive due to its simplicity and low capital cost, making it suitable for facilities with lower throughput.

- (b)

- Solvent Extraction. Solvent extraction separates the base oil from contaminants by exploiting differences in solubility [24]. Its near-ambient operating conditions reduce energy demands compared with thermal processes. On the other hand, it requires skilled operators and robust solvent recovery systems to minimize solvent losses and environmental emissions.

- (c)

- Vacuum Distillation (often as a downstream process). Following a primary treatment (such as solvent extraction), vacuum distillation is used to separate oil fractions based on their boiling points.

- (d)

- Hybrid and Emerging Methods (such as membrane filtration and pyrolysis). Recent advances have explored combining solvent extraction with vacuum distillation (or with other techniques) to optimize both recovery and quality [33].

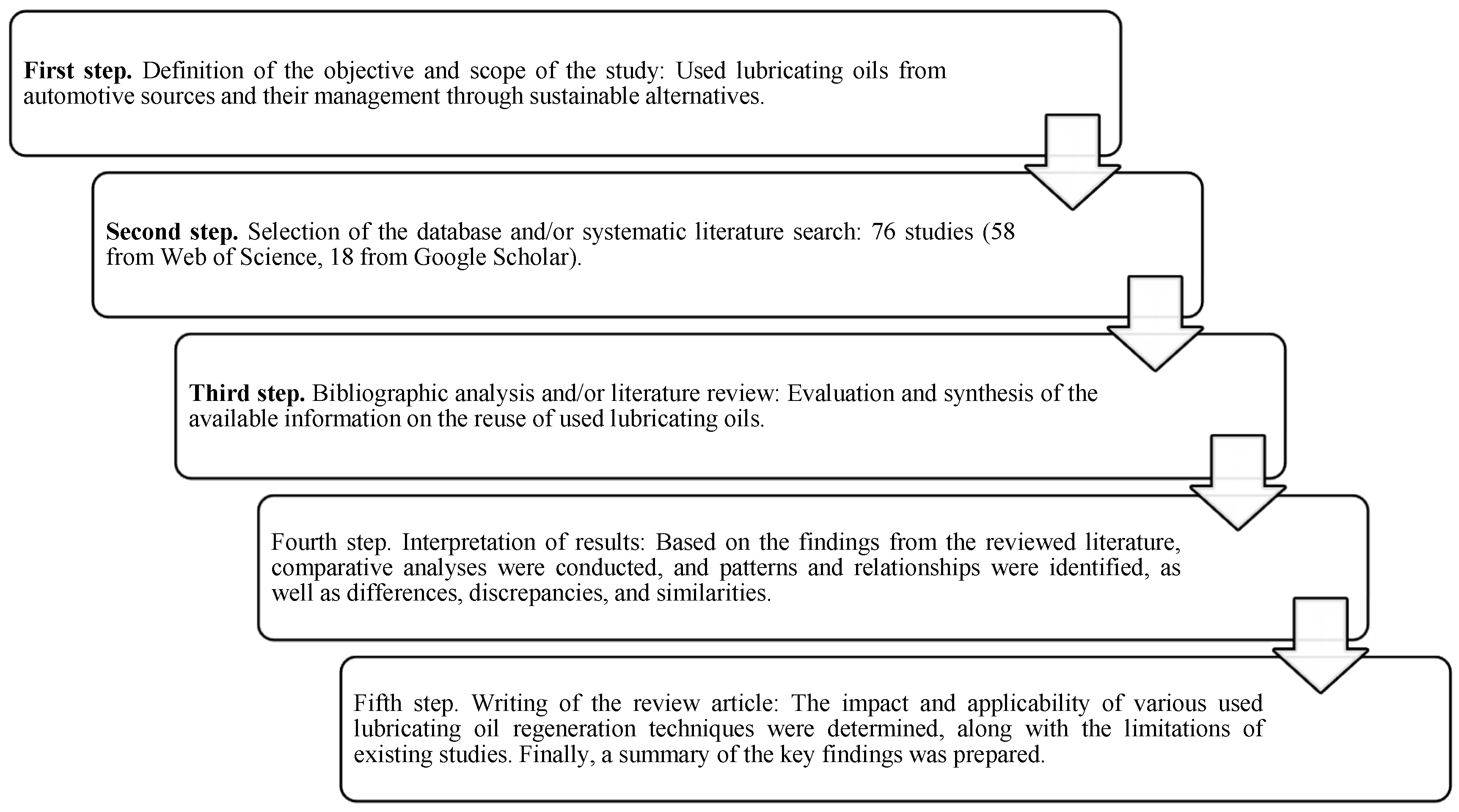

2. Methodology

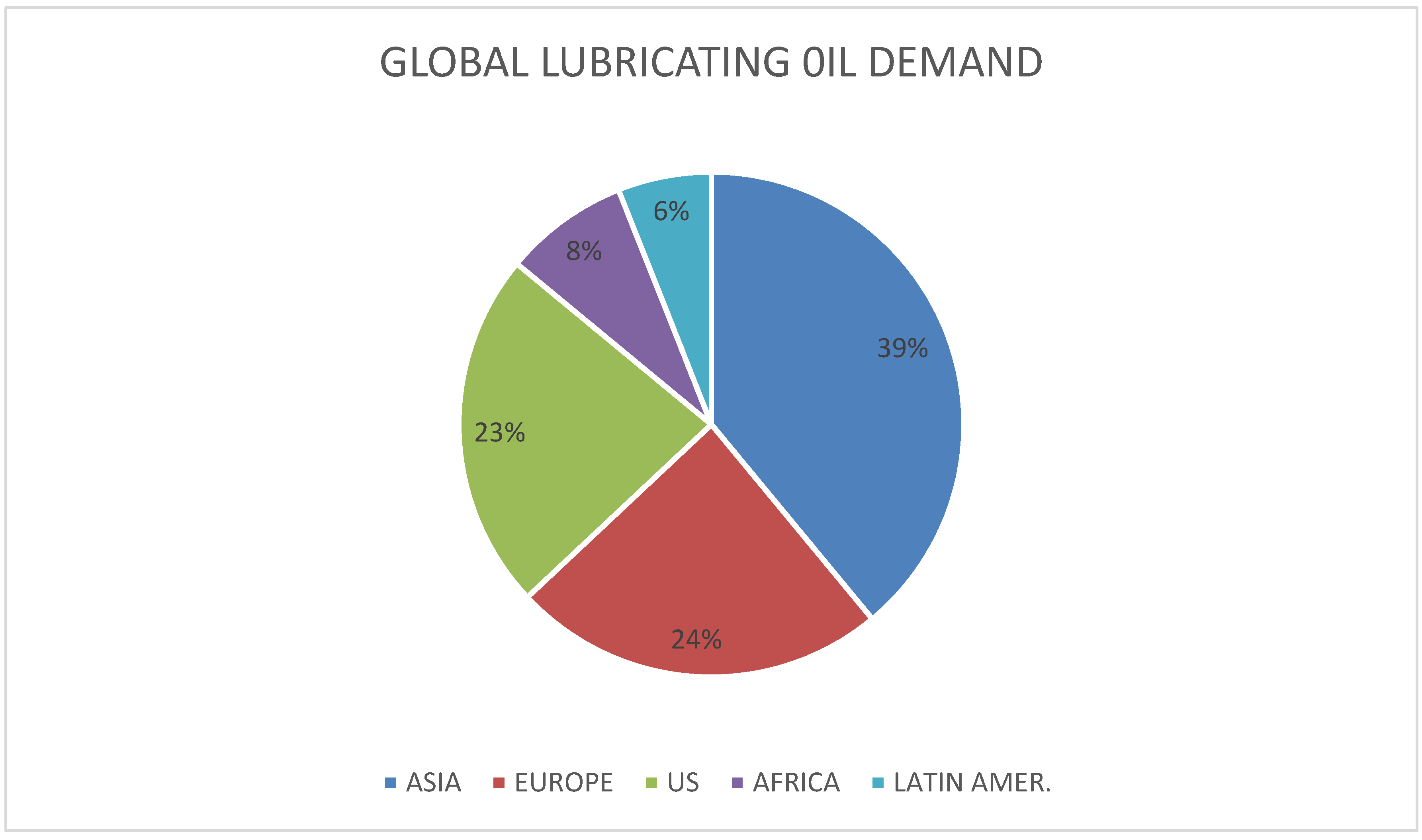

2.1. Current Global Status of Waste Oil Recycling

2.2. Global Political Feasibility in the Marketplace

2.3. Research Design

- Increased load leads to decreased brake-specific fuel consumption for all blends (10% to 40%).

- Blends of 10% and 20% exhibit lower fuel consumption than pure diesel at high loads.

- Blends of 30% and 40% have higher fuel consumption than pure diesel.

- The 10% blend displays higher brake thermal efficiency than pure diesel at high loads, while the 20% blend exhibits similar efficiency.

- Higher blends (30% and 40%) demonstrate lower thermal efficiency due to the lower calorific value of transformer oil.

3. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AFO | Alternative Fuel Oil |

| bTDC | Before Top Dead Center |

| BFO | By-product Fuel Oil |

| BSFC | Brake Specific Fuel Consumption |

| BTE | Brake Thermal Efficiency (BTE) |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| DFO | Destilate Fuel Oil |

| DIY | Do-It-Yourself Sources |

| DULO | Distilled Used Lubricating Oil |

| HFO | Heavy Fuel Oil |

| JB | Jatropha Biodiesel |

| JBDULO | Mixtures of JB and DULO |

| MDO | Marine Diesel Oil |

| NOx | Nitrogen Oxides |

| PSO | Product Stewardship for Oil |

| RFO | Residual Fuel Oil |

| RULO | Reprocessed Used Lubricating Oil |

| ULO | Used Lubricating Oil |

| WFD | Waste Framework Directive |

| WLO | Waste Lubricant Oil |

References

- Merai, Y.P. Re-refining of used lubricating oil. Int. J. Sci. Eng. Res. 2015, 6, 329–332. [Google Scholar]

- Study to Support the Commission in Gathering Structured Information and Defining of Reporting Obligations on Waste Oils and Other Hazardous Waste. 2020. Available online: https://op.europa.eu/en/publication-detail/-/publication/73a728bc-72f5-11eaa07e-01aa75ed71a1/language-en/format-PDF/source-123020647 (accessed on 12 November 2024).

- Waste Framework Directive. European Comision. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en (accessed on 5 September 2024).

- Speight, J.; Exall, D.I. Refining Used Lubricating Oils; CRC Press: Boca Raton, FL, USA, 2014; ISBN 9780429165252. [Google Scholar] [CrossRef]

- Klamerus-Iwan, A.; Błońska, E.; Lasota, J.; Kalandyk, A.; Waligórski, P. Influence of Oil Contamination on Physical and Biological Properties of Forest Soil After Chainsaw Use. Water Air Soil Pollut. 2015, 226, 389. [Google Scholar] [CrossRef] [PubMed]

- Morkunas, I.; Wo, A.; Mai, V.C.; Rucinska-Sobkowiak, R.; Jeandet, P. The Role of Heavy Metals in Plant Response to Biotic Stress. Molecules 2018, 23, 2320. [Google Scholar] [CrossRef]

- Vazquez-Duhalt, R. Environmental impact of used motor oil. Sci. Total Environ. 1989, 79, 1–23. [Google Scholar] [CrossRef]

- Basha, S.A.; Gopal, K.R.; Jebaraj, S. A review on biodiesel production, combustion, emissions and performance. Renew. Sustain. Energy Rev. 2009, 13, 1628–1634. [Google Scholar] [CrossRef]

- Belkhode, P.; Sakhale, C.; Bejalwar, A. Evaluation of the experimental data to determine the performance of a solar chimney power plant. Mater. Today Proc. 2020, 27, 102–106. [Google Scholar] [CrossRef]

- Dhande, H.K.; Shelare, S.D.; Khope, P.B. Developing a mixed solar drier for improved postharvest handling of food grains. Agric. Eng. Int. CIGR J. 2020, 22, 166–173. [Google Scholar]

- Nabi, M.N.; Rahman, M.M.; Akhter, M.S. Biodiesel from cotton seed oil and its effect on engine performance and exhaust emissions. Appl. Therm. Eng. 2009, 29, 2265–2270. [Google Scholar] [CrossRef]

- Report from the Commission to the European Parliament and the Council. Circularity of Mineral and Synthetic Lubrication and Industrial Waste Oil Management in the EU; European Comission: Brussels, Belgium, 2023.

- Shan, L.-l.; Tan, Z.; Chen, Y.; Wang, R.-s.; Zhang, M.; Pang, C.-l.; Cui, Y.-H.; Liao, Z.-m.; Ma, H.-q. Biodegradability enhancenment of waste lubricating oil regeneration watewater using electrocoagulation pretreatment. Environ. Sci. Pollut. Res. 2023, 30, 106421–106430. [Google Scholar] [CrossRef]

- Market Value of Lubricants Worldwide from 2018 to 2019, with a Forecast Until 2024, by Region (in Billion U.S. Dollars). Available online: https://www.statista.com/statistics/1073358/global-lubricants-market-size-by-region/ (accessed on 18 February 2025).

- Available online: https://eur-lex.europa.eu/ (accessed on 20 January 2025).

- Izza, H.; Abdessalam, S.B.; Bouida, M.; Haddad, A. Recycling of used motor oil as an alternative methiod for production feedstock for the conversion processes. Petrol. Sci. Technol. 2018, 36, 1511–1515. [Google Scholar] [CrossRef]

- Zgheib, N.K.; Takache, H. Recycling of used lubricating oil by solvent extraction: Experimental results, Aspen Plus simulation and feasibility study. Clean Technol. Environ. Policy 2021, 23, 65–76. [Google Scholar] [CrossRef]

- Mandloi, H.; Thakur, L.S. A Review on Recycle of Waste Lubricant Oil and its Properties Enhancement. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 4368–4371. [Google Scholar] [CrossRef]

- Al-Zahrani, S.; Putra, M.D. Used lubricating oil regeneration by various solvent extraction techniques. J. Ind. Eng. Chem. 2013, 19, 536–539. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, J.; Shen, W.; Song, Y. Regeneration of used lubricating oils by supercritical fluid extraction. Petrol. Sci. Technol. 2005, 23, 909–914. [Google Scholar] [CrossRef]

- Emam, E.A.; Shoaib, A.M. Re-refining of used lube oil, I- by solvent extraction and vacuum distillation followed by hydrotreating. Petrol. Coal. 2013, 55, 179–187. [Google Scholar]

- Saleem, H.J.; Karim, A.R. Re-refing of used lubricating oil by vacuum distillation/thin wiped film evaporation technique. Petrol. Sci. Technol. 2020, 38, 323–330. [Google Scholar] [CrossRef]

- Widodo, S.; Khoiruddin, K.; Ariono, D.; Subagjo, S.; Wenten, I.G. Re-refining of waste engine oil using ultra fitration membrane. J. Environ. Chem. Eng. 2020, 8, 103789. [Google Scholar] [CrossRef]

- Naima, K.; Liazid, A. Waste oils alternative fuel for diesel engine: A review. J. Petrol. Technol. Altern. Fuels 2013, 4, 30–43. [Google Scholar]

- Sánchez-Alvarracín, C.; Criollo-Bravo, J.; Albuja-Arias, D.; García-Ávila, F.; Pelaez-Samaniego, M.R. Characterization of Used Lubricant Oil in a Latin-American Medium-Size City and Analysis of Options for Its Regeneration. Recycling 2021, 6, 10. [Google Scholar] [CrossRef]

- Parekh, K.R.; Gaur, R.; Shahabuddin, S. Recent Advances in Reclamation of Used Lubricant Oil. In Tailored Functional Materials; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Alemu, N.A.; Nallamothu, R.B.; Lakew, G.A. Optimization, Characterization, and GC–MS Analysis of Recycled Used Engine Oil. Sci. Rep. 2025, 15, 517. [Google Scholar] [CrossRef]

- Pawlak, Z.; Urbaniak, W.; Kaldonski, T.; Styp-Rekowski, M. Energy conservation through recycling of used oil. Ecol. Eng. 2010, 36, 1761–1764. [Google Scholar] [CrossRef]

- Becthold, R.L.; Lestz, S.S. Combustion Characteristics of Diesel Fuel Blends Containing Used Lubrication Oil; SAE Paper no. 760132; SAE International: Warrendale, PA, USA, 1976. [Google Scholar]

- Tajima, H.; Takasaki, K.; Nakashima, M.; Yanagi, J.; Takaish, T.; Ishida, H.; Osafune, S.; Iwamoto, K. Combustion of Used Lubricating Oil in a Diesel Engine; SAE paper no. 2001-01-1930; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Arpa, O.; Yumrutas, R.; Argunhan, Z. Experimental investigation of the effects of diesel-like fuel obtained from waste lubrication oil on engine performance and exhaust emission. Fuel Process. Technol. 2010, 91, 1241–1249. [Google Scholar] [CrossRef]

- Wang, X.; Ni, P. Combustion and emission characteristics of diesel engine fueled with diesel-like fuel from waste lubrication oil. Energy Convers. Manag. 2017, 133, 275–283. [Google Scholar] [CrossRef]

- Garbina, G.; Martin, L.; Basurko, O.C.; Clemente, M.; Aldekoa, S.; Uriondo, Z. Waste oil-based alternative fuels for marine diesel engines. Fuel Process. Technol. 2016, 153, 28–36. [Google Scholar] [CrossRef]

- Singhabhandhu, A.; Tezuka, T. The waste-to-energy framework for integrated multiwaste utilization: Waste cooking oil, waste lubricating oil, and waste plastics. Energy 2010, 35, 2544–2551. [Google Scholar] [CrossRef]

- Breyer, S.; Mekhitarian, L.; Rimez, B.; Haut, B. Production of an alternative fuel by the co-pyrolysis of landfill recovered plastic wastes and used lubrication oils. Waste Manag. 2017, 60, 363–374. [Google Scholar] [CrossRef]

- Tambunan, B.H.; Simanjuntak, J.P.; Silaban, R.; Riduwan, R. Improving Quality of Used Lubricant Oil as an Alternative Fuel Through the Pyrolysis Process. In Proceedings of the 5th International Conference on Innovation in Education, Science, and Culture, ICIESC 2023, Medan, Indonesia, 24 October 2023. [Google Scholar] [CrossRef]

- Silaban, R.; Simanjuntak, J.P.; Firdaus, F.; Ginting, L. Experimental Study of Used Lubricant Oil Combustion as an Alternative Energy Source. In Proceedings of the 5th International Conference on Innovation in Education, Science, and Culture, ICIESC 2023, Medan, Indonesia, 24 October 2023. [Google Scholar] [CrossRef]

- Furqon, Z.; Anggoro, D.D.; Sutanto, H. Physical characterization of used lubricating oil as fuel production feedstock. E3S Web Conf. 2025, 605, 03050. [Google Scholar] [CrossRef]

- Kumar, P.; Mohan, R.; Prasad, J. Investigations on a Diesel Engine Run on used Lubricating Oil-Biodiesel Blend as an Alternative Fuel. Int. J. Trend Sci. Res. Dev. (IJTSRD) 2020, 4, 872–877, ISSN 2456-6470. [Google Scholar]

- International Environmental Technology Centre. Policy Brief on Waste Oil: What, Why and How. 2013. Available online: https://www.unep.org/ietc/ (accessed on 30 June 2020).

- Geir. Waste Framework Directive Revision: European Waste Oil Re-Refining Industry Position. 2016. Available online: https://www.geir-rerefining.org/wp-content/uploads/GEIRpositionpaperWFD_2016_FINAL.pdf (accessed on 30 June 2020).

- Used Oil Management and Beneficial Reuse Options to Address Section 1: Energy Savings from Lubricating Oil Public Law 115-345; Report to Congress; United States Department of Energy: Washington, DC, USA, 2020.

- National Catalogue of Hazardous Wastes; Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China, 2008.

- Aust Gov, Department of Climate Change, Energy, the Environment and Water. Product Stewardship for Oil Scheme. Available online: https://oia.pmc.gov.au/published-impact-analyses-and-reports/product-stewardship-oil-scheme (accessed on 5 December 2024).

- Waghmare, S.N.; Shelare, S.D.; Tembhurkar, C.K.; Jawalekar, S.B. Pyrolysis system for environment- friendly conversion of plastic waste into fuel. In Advances in Materials Processing; Lecture Notes in Mechanical, Engineering; Singh, S., Prakash, C., Ramakrishna, S., Krolczyk, G., Eds.; Springer: Singapore, 2020; pp. 131–138. [Google Scholar] [CrossRef]

- Groupement Européen de l’Industrie de la Régénération. Waste Framework Directive Revision: European Waste Oil Re-Refining Industry Position; GEIR: Brussels, Belgium, 2016. [Google Scholar]

- Abdalla, N.; Fehrenbach, H. Updating the Study Ecological and Energetic Assessment of Re-Refining Waste Oils to Base Oils Substitution of Primarily Produced Base Oils Including Semi-Synthetic and Synthetic Compounds. 2017. Ifeu–Institut fur Energie. Available online: https://bva-altoelrecycling.de/files/uploads/2017/10/oekobilanz_ifeu_2017.pdf (accessed on 6 January 2025).

- Giovanna, F.D. Lubricants Recycling–A Case Study: How Italy Managed to Become an Excellence and an Example for the Other EU’s Member States. In Global Risk-Based Management of Chemical Additives I; The Handbook of Environmental Chemistry (HEC, Volume 18); Bilitewski, B., Darbra, R., Barceló, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- EPR Registration Guide in India: All You Need to Know in 2025. Available online: https://recykal.com/blog/epr-registration-guide-in-india-all-you-need-to-know-in-2025/ (accessed on 12 January 2025).

- An Energy and Sustainability Road Map for the Middle East. Available online: https://www.atlanticcouncil.org/in-depth-research-reports/report/an-energy-and-sustainability-road-map-for-the-middle-east/ (accessed on 13 December 2024).

- Botas, J.A.; Moreno, J.; Espada, J.J.; Serrano, D.P.; Dufour, J. Recycling of used lubricating oil: Evaluation of environmental and energy performance by LCA. Resour. Conserv. Recycl. 2017, 125, 315–323. [Google Scholar] [CrossRef]

- Study to Analyse Lubricant and Industrial Oil EPR Systems and Waste Oil Collection Schemes in EU Member States to Support Measures to Increase Collection Rates. European Commission: Brussels, Belgium, 2023; Available online: https://op.europa.eu/en/publication-detail/-/publication/2d47e379-73a8-11ee-9220-01aa75ed71a1/language-en (accessed on 20 January 2025).

- Waste Framework Directive(2008/98/EC), Article 21(4). Available online: https://eur-lex.europa.eu/legal-content/EN-DA/TXT/?uri=CELEX:32008L0098&from=EN (accessed on 20 January 2025).

- Kim, H.H.; Park, Y.H.; Han, K.; Jang, J.H.; Park, H.Y.; Seo, Y.S. Combustion and emission characteristics of a reprocessed used lubricating oil as a renewable fuel for boiler cold start-up operation. Energy 2021, 222, 119784. [Google Scholar] [CrossRef]

- European Commission. Waste Oils. 2019. Available online: https://ec.europa.eu/environment/waste/oil_index.htm (accessed on 30 June 2020).

- Petroleum Service Company, Understanding Types of Lubricants: Base Oil Groups (18 January 2017). Available online: https://petroleumservicecompany.com/blog/understanding-types-of-lubricants-base-oil-groups/ (accessed on 10 January 2025).

- Kakati, J.; Gogoi, T.K. Biodiesel production from Kutkura (Meyna spinosa Roxb. Ex.) fruit seed oil: Its characterization and engine performance evaluation with 10% and 20% blends. Energy Convers. Manag. 2016, 121, 152–161. [Google Scholar] [CrossRef]

- Mowade, S.; Waghmare, S.; Shelare, S.; Tembhurkar, C. Mathematical Model for Convective Heat Transfer Coefficient During Solar Drying Process of Green Herbs. In Computing in Engineering and Technology; Advances in Intelligent Systems and Computing (AISC, Volume 1025); Springer: Singapore, 2020. [Google Scholar]

- Gopinath, S.; Devan, P.K.; Pitchandi, K. Production of pyrolytic oil from ULDP plastics using silica-alumina catalyst and used as fuel for DI diesel engine. RSC Adv. 2020, 10, 37266–37279. [Google Scholar] [CrossRef] [PubMed]

- Rajan, K.; Babu, A.M.; Paladi, R.; Nallusamy, S.; Kumar, K.R.S. Performance assessment of DI diesel engine using waste transformer oil with different compression ratios. Int. J. Ambient. Energy 2022, 43, 3536–3544. [Google Scholar] [CrossRef]

- Belkhode, P.N.; Ganvir, V.N.; Shende, A.C.; Shelare, S.D. Utilization of waste transformer oil as a fuel in diesel engine. Mater. Today Proc. 2022, 49, 262–268. [Google Scholar] [CrossRef]

- Gabiñaa, G.; Martinb, L.; Basurkoc, O.C.; Clemente, M.; Aldekoad, S.; Uriondo, Z. Performance of marine diesel engine in propulsion mode with a waste oilbased alternative fuel. Fuel 2019, 235, 259–268. [Google Scholar] [CrossRef]

- Sharma, A.; Gupta, G.; Agrawal, A. Utilization of Waste Lubricating Oil as a Diesel Engine Fuel. IOP Conf. Ser. Mater. Sci. Eng. 2020, 840, 012015. [Google Scholar] [CrossRef]

- Rathinam, S.; Baby, S.J.A.; Devarajan, Y. Influence of water on exhaust emissions on unmodified diesel engine propelled with biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 2511–2517. [Google Scholar] [CrossRef]

| Lubricants | ||

|---|---|---|

| Application | End User | |

| Manufacturing Companies | Automotive | Internal combustion engines. Lubrication of transmission, differentials, and gearboxes. Hydraulic systems for smooth operation. Wheel bearings and chassis lubrication. |

| Energy and Utilities | Oil and gas companies. Power generation plants (thermal, hydro, nuclear, wind). Renewable energy operators (e.g., wind farms with turbine gearboxes). Aerospace and marine industry. Agriculture and heavy equipment. | Lubrication systems for all equipment. Turbine oils, jet engines, turbines, and hydraulic systems. Ship engines, gear systems, and hydraulic equipment. Tractor and farm equipment oils. |

| Food Industry | Food-grade lubricants. Pharmaceutical. | Heat processing equipment (ovens and grills, fryers, steamers and boiling tanks). Raw material processing equipment, tablet press machines, and packaging and labeling equipment. |

| Electrical and Electronics | Transformer oils. Dielectric oils. | Transformers and circuit breakers for insulation and cooling. Insulation and cooling in high-voltage equipment. |

| Household and Consumer Goods | Lubricants for appliances. Penetrating oils. | Fans, sewing machines, and bicycles. Loosening rusted bolts and hinges. |

| Railways and Transport | Railway engine and bearing oils. Greases for tracks and axles. | Locomotives and railcars to reduce wear. Reduce friction in moving parts. |

| Process | Author | Application |

|---|---|---|

| Acid/clay | Izza, H. et al., 2018 [16] | Good quality lubrication stocks. |

| Solvent extraction process | Al-ZahraniIm and Putra MD., 2013 [19] | Re-refining WLO. |

| Super-critical fluid extraction | Liu Y et al., 2005 [20] | Re-refining WLO. |

| Hydrotreating | Emam EA et al., 2013 [21] | Re-refining WLO. |

| Thin wiped film evaporation | Saleem HJ et al., 2020 [22] | Re-refining WLO. |

| Membrane technology | Widodo S et al., 2020 [23] | Re-refining WLO. |

| Recycled waste oils | Naima K., 2013 [24] | Shipping industry. |

| Characterization of Used Lubricant Oil | Carlos Sánchez-Alvarracín et al., 2021 [25] | Analysis of options for its regeneration. |

| Solvent extraction | Nancy Kamil Zgheib and Hosni Takache, 2021 [17] | Simulation and feasibility study. |

| Recent Advances in Reclamation of Used Lubricant Oil | Krunal Rajeshkumar et al., 2022 [26] | Industry (included marine and aerospace). |

| Review on Recycle of Waste Lubricant | Harshit Mandloi et al., 2023 [18] | Industry (included marine and aerospace). |

| Analysis of Recycled Used Engine Oil | Negasa Abdena Alemu et al., 2025 [27] | Industry (included marine and aerospace). |

| Process | Author | Application |

|---|---|---|

| Reprocessed into fuel | Pawlak Z et al., 2010 [28] | Burning in engines |

| Reprocessed into fuel | Becthold RL., 1976 [29] | Combustion in diesel engines |

| Reprocessed into fuel | Tajima et al., 2001 [30] | Combustion in diesel engines (as Heavy Fuel, HFO) |

| Reprocessed by pyrolysis and catalytic cracking as diesel-like fuel | Arpa et al., 2010 [31] | Effects on engine performance and exhaust emissions |

| Reprocessed as diesel-like fuel | Wang and Ni, 2017 [32] | Analysis of combustion and emission performance |

| Pretreated used automobile lubricating oil and a distillate fuel oil | Garbina et al., 2016 [33] | Marine diesel engine performance |

| Recovery waste lube oils | Singhabhandhu A., 2010 [34] | Energy conversion plants |

| Recovered waste lubricating oils | Breyer S, et al., 2017 [35] | Alternative fuel in diesel engines |

| Pyrolysis Process | Bisrul Hapis Tambunan et al., 2023 [36] | Alternative fuel |

| Physical characterization | Robert Silaban et al., 2024 [37] | Experimental study |

| Physical characterization | Zami Furqon et al., 2025 [38] | Alternative fuel |

| Investigations on a Diesel Engine Run | Pranav Kumar et al., 2020 [39] | Use as biodiesel blend |

| Engine type | TV1, 4S, Diesel engine |

| Power (kW) | 3.5 kW |

| Bore × Stroke (mm × mm) | 87.5 × 110 |

| Compression ratio | 17.5:1 (Range 12:1–22:1) |

| Injection pressure | 200 bar |

| Injection timing | 23 bTDC |

| Type of Fuel | Brake Termal Efficiency (BTE, %). Full Load Condition | BSFC kg/kWh | CO Emissions g/kWh | NOx Emissions ppm | Smoke Opacity Full Load | |||

|---|---|---|---|---|---|---|---|---|

| Low Load | High Load | Low Load | High Load | Low Load | High Load | % | ||

| DIESEL | 30.60 | 0.391 | 0.263 | 4.96 | 3.61 | 91 | 460 | 65.0 |

| JBDULO10 | 29.13 | 0.413 | 0.266 | 5.12 | 3.85 | 120 | 583 | 55.2 |

| JBDULO20 | 29.40 | 0.423 | 0.278 | 5.49 | 3.92 | 117 | 570 | 57.4 |

| JBDULO30 | 28.42 | 0.441 | 0.291 | 5.84 | 4.16 | 115 | 561 | 60.4 |

| JBDULO40 | 28.10 | 0.541 | 0.391 | 6.84 | 5.16 | 64.9 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabrera-Escobar, C.; Moreno-Gutiérrez, J.; Rodríguez-Moreno, R.; Pájaro-Velázquez, E.; Calderay-Cayetano, F.; Durán-Grados, V. A Review on Global Recovery Policy of Used Lubricating Oils and Their Effects on the Environment and Circular Economy. Environments 2025, 12, 135. https://doi.org/10.3390/environments12050135

Cabrera-Escobar C, Moreno-Gutiérrez J, Rodríguez-Moreno R, Pájaro-Velázquez E, Calderay-Cayetano F, Durán-Grados V. A Review on Global Recovery Policy of Used Lubricating Oils and Their Effects on the Environment and Circular Economy. Environments. 2025; 12(5):135. https://doi.org/10.3390/environments12050135

Chicago/Turabian StyleCabrera-Escobar, Catherine, Juan Moreno-Gutiérrez, Rubén Rodríguez-Moreno, Emilio Pájaro-Velázquez, Fátima Calderay-Cayetano, and Vanesa Durán-Grados. 2025. "A Review on Global Recovery Policy of Used Lubricating Oils and Their Effects on the Environment and Circular Economy" Environments 12, no. 5: 135. https://doi.org/10.3390/environments12050135

APA StyleCabrera-Escobar, C., Moreno-Gutiérrez, J., Rodríguez-Moreno, R., Pájaro-Velázquez, E., Calderay-Cayetano, F., & Durán-Grados, V. (2025). A Review on Global Recovery Policy of Used Lubricating Oils and Their Effects on the Environment and Circular Economy. Environments, 12(5), 135. https://doi.org/10.3390/environments12050135