Comparative Screening Life Cycle Assessments of Okara Valorisation Scenarios

Abstract

1. Introduction

2. Materials and Methods

2.1. Goal and Scope Definition

2.1.1. Functional Unit and Assumptions

2.1.2. System Boundaries

2.1.3. Scenarios

Disposal (Baseline S1–S3)

Biowaste Treatment (Valorisation S4–S6)

Biochemical Extraction (Valorisation S7–S9)

Animal Feed (Valorisation S10)

2.2. Life Cycle Inventory (LCI)

2.3. Life Cycle Impact Assessment (LCIA)

3. Results and Discussion

3.1. Characterised Results

3.1.1. Environmental Burdens

3.1.2. Avoided Burdens

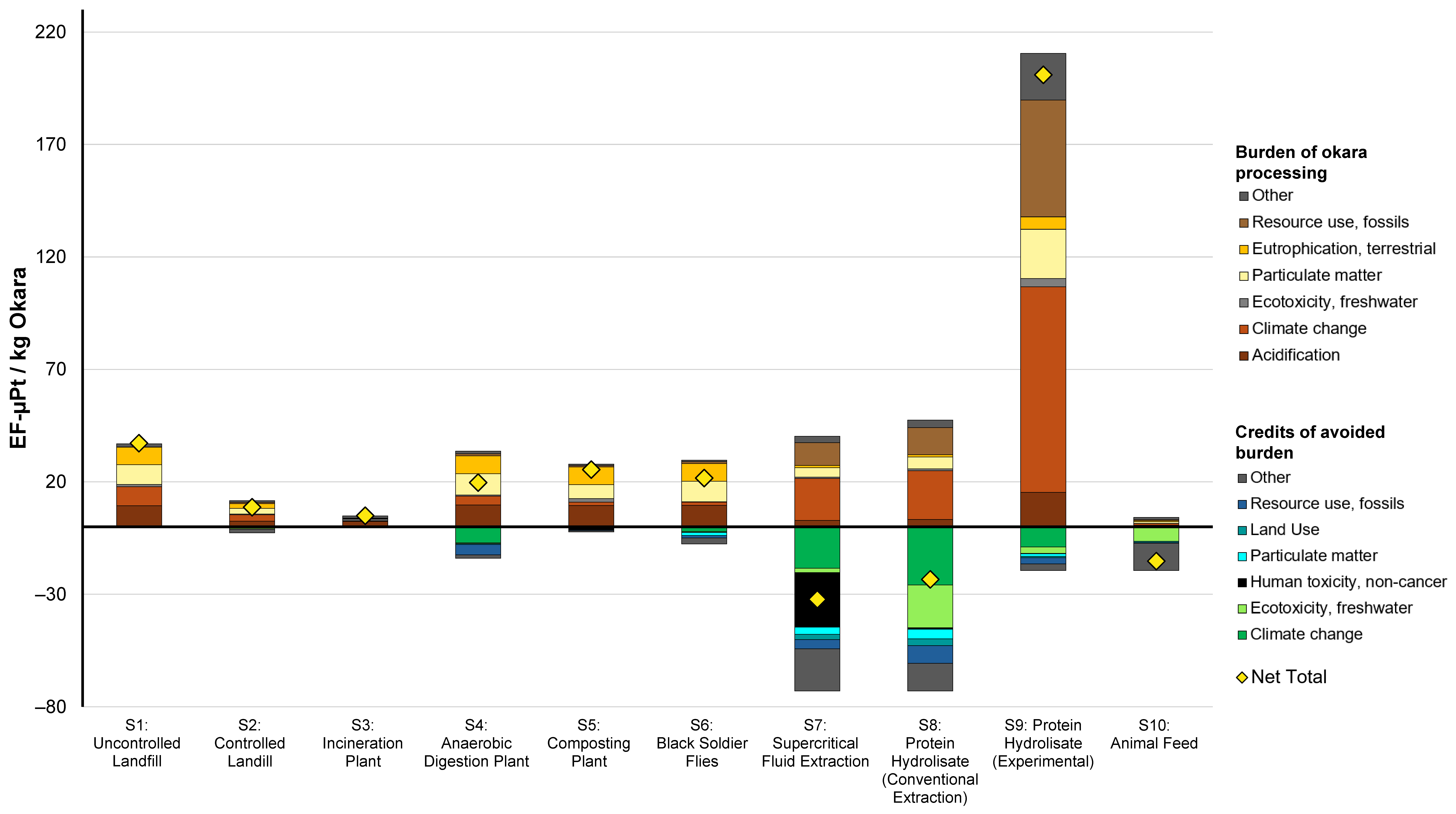

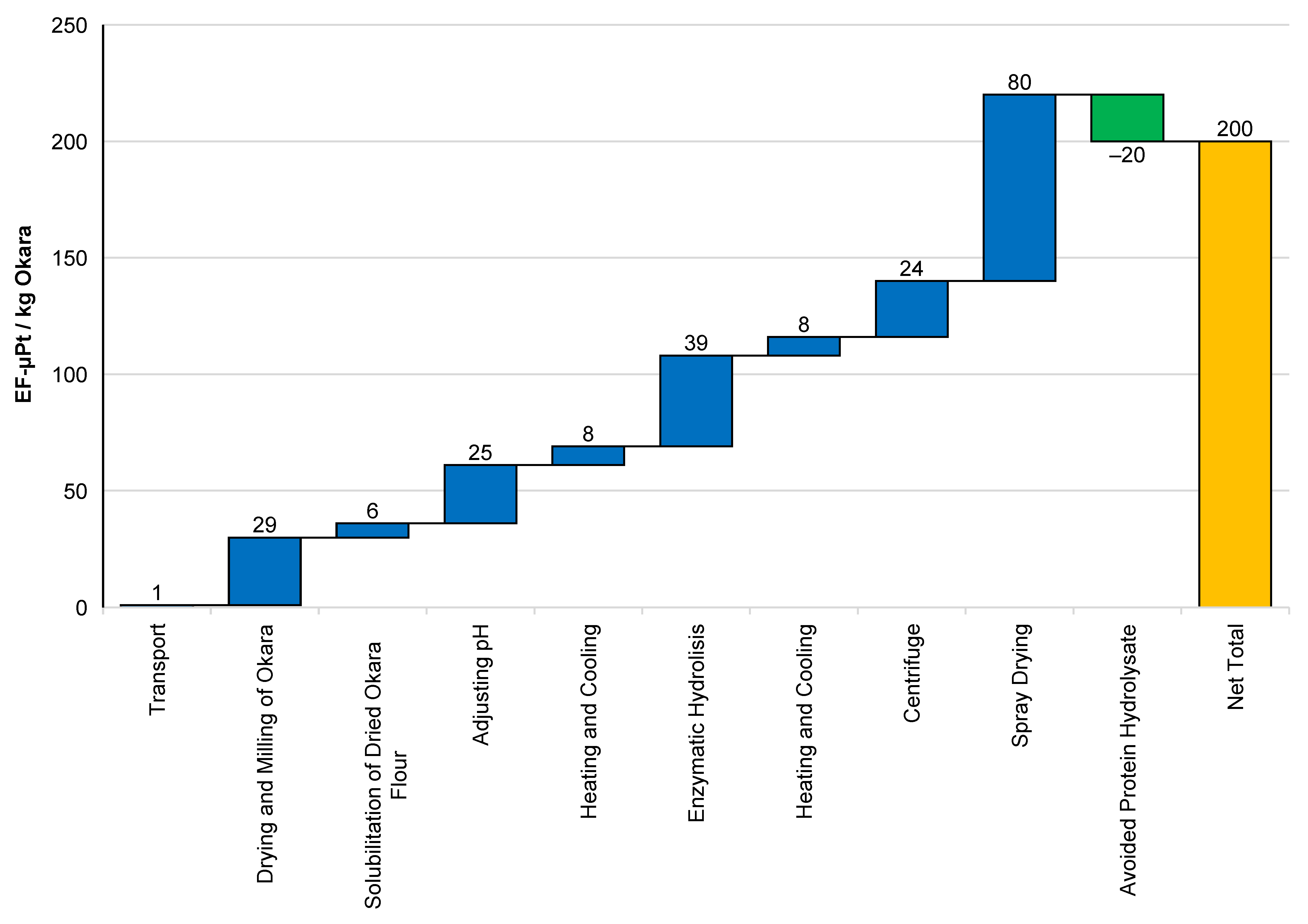

3.2. Weighted and Aggregated Results

3.3. Limitations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koptelova, A.; Ducrey, A.; Lunven, B.; Köller, L.; Nagornova, N.; Appenzeller, E.W.; Abitbol, T. Waste-to-Taste: Transforming Wet Byproducts of the Food Industry into New Nutritious Foods. CHIMIA 2024, 78, 824–830. [Google Scholar] [CrossRef]

- O’Toole, D.K. Soybean | Soymilk, Tofu, and Okara. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Swallah, M.S.; Fan, H.; Wang, S.; Yu, H.; Piao, C. Prebiotic Impacts of Soybean Residue (Okara) on Eubiosis/Dysbiosis Condition of the Gut and the Possible Effects on Liver and Kidney Functions. Molecules 2021, 26, 326. [Google Scholar] [CrossRef] [PubMed]

- Grand View Research. Tofu Market Size, Share & Trends Analysis Report by Product (Processed, Unprocessed), by Distribution Channel (Supermarkets & Hypermarkets, Grocery Stores, Online) by Region, and Segment Forecasts, 2025–2030. 2023. Available online: https://www.grandviewresearch.com/industry-analysis/tofu-market (accessed on 6 December 2024).

- Voss, G.B.; Sousa, V.; Rema, P.; Pintado, M.E.; Valente, L.M.P. Processed By-Products from Soy Beverage (Okara) as Sustainable Ingredients for Nile Tilapia (O. Niloticus) Juveniles: Effects on Nutrient Utilization and Muscle Quality. Animals 2021, 11, 590. [Google Scholar] [CrossRef] [PubMed]

- Vong, W.C.; Liu, S.-Q. Biovalorisation of Okara (Soybean Residue) for Food and Nutrition. Trends Food Sci. Technol. 2016, 52, 139–147. [Google Scholar] [CrossRef]

- Joo, K.H.; Kerr, W.L.; Cavender, G.A. The Effects of Okara Ratio and Particle Size on the Physical Properties and Consumer Acceptance of Tofu. Foods 2023, 12, 3004. [Google Scholar] [CrossRef]

- U.S. EPA. Quantifying Methane Emissions from Landfilled Food Waste; Food Waste Management; EPA-600-R-23-064; U.S. Environmental Protection Agency Office of Research and Development: Washington, DC, USA, 2023. Available online: https://www.epa.gov/system/files/documents/2023-10/food-waste-landfill-methane-10-8-23-final_508-compliant.pdf (accessed on 13 March 2025).

- Ellen McArthur Foundation. Urban Biocycles; Ellen MacArthur Foundation: Wight, UK, 2017; Available online: https://emf.thirdlight.com/file/24/MC1eXz-MW2hiiSMCEvuMcsrYg/Urban%20Biocycles.pdf (accessed on 22 January 2025).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Lin, L.; Xu, F.; Ge, X.; Li, Y. Improving the Sustainability of Organic Waste Management Practices in the Food-Energy-Water Nexus: A Comparative Review of Anaerobic Digestion and Composting. Renew. Sustain. Energy Rev. 2018, 89, 151–167. [Google Scholar] [CrossRef]

- Chiam, Z.; Lee, J.T.E.; Tan, J.K.N.; Song, S.; Arora, S.; Tong, Y.W.; Tan, H.T.W. Evaluating the Potential of Okara-Derived Black Soldier Fly Larval Frass as a Soil Amendment. J. Environ. Manag. 2021, 286, 112163. [Google Scholar] [CrossRef]

- Taylor’s Impact Labs. Taylor’s University. Using Black Soldier Fly Larvae to Combat Food Waste and Enhance Food Security. Available online: https://university.taylors.edu.my/en/discover-us/taylors-impact-labs/latest-at-impact-labs/food-security-and-nutrition/using-black-soldier-fly-larvae-to-combat-food-waste-and-enhance-food-security.html (accessed on 7 January 2025).

- Preece, K.E.; Hooshyar, N.; Zuidam, N.J. Whole Soybean Protein Extraction Processes: A Review. Innov. Food Sci. Emerg. Technol. 2017, 43, 163–172. [Google Scholar] [CrossRef]

- De Benedetti, S.; Girlando, V.; Pasquali, M.; Scarafoni, A. Valorization of Okara by Enzymatic Production of Anti-Fungal Compounds for Plant Protection. Molecules 2021, 26, 4858. [Google Scholar] [CrossRef]

- Aussanasuwannakul, A.; Boonbumrung, S.; Pantoa, T. Valorization of Soybean Residue (Okara) by Supercritical Carbon Dioxide Extraction: Compositional, Physicochemical, and Functional Properties of Oil and Defatted Powder. Foods 2023, 12, 2698. [Google Scholar] [CrossRef] [PubMed]

- Kantrong, H.; Aussanasuwannakul, A.; Rodkwan, N.; Chitisankul, W.T. Effect of Mechanical Treatment from Extrusion Process on Physicochemical Properties of Okara Cellulose Powder. Sci. Rep. 2024, 14, 22193. [Google Scholar] [CrossRef]

- Feng, J.-Y.; Wang, R.; Thakur, K.; Ni, Z.-J.; Zhu, Y.-Y.; Hu, F.; Zhang, J.-G.; Wei, Z.-J. Evolution of Okara from Waste to Value Added Food Ingredient: An Account of Its Bio-Valorization for Improved Nutritional and Functional Effects. Trends Food Sci. Technol. 2021, 116, 669–680. [Google Scholar] [CrossRef]

- Ningrum, A.; Wardani, D.W.; Vanidia, N.; Sarifudin, A.; Kumalasari, R.; Ekafitri, R.; Kristanti, D.; Setiaboma, W.; Munawaroh, H.S.H. In Silico Approach of Glycinin and Conglycinin Chains of Soybean By-Product (Okara) Using Papain and Bromelain. Molecules 2022, 27, 6855. [Google Scholar] [CrossRef] [PubMed]

- Kang, M.J.; Bae, I.Y.; Lee, H.G. Rice Noodle Enriched with Okara: Cooking Property, Texture, and in Vitro Starch Digestibility. Food Biosci. 2018, 22, 178–183. [Google Scholar] [CrossRef]

- Razavizadeh, S.; Alencikiene, G.; Salaseviciene, A.; Vaiciulyte-Funk, L.; Ertbjerg, P.; Zabulione, A. Impact of Fermentation of Okara on Physicochemical, Techno-Functional, and Sensory Properties of Meat Analogues. Eur. Food Res. Technol. 2021, 247, 2379–2389. [Google Scholar] [CrossRef]

- Asghar, A.; Afzaal, M.; Saeed, F.; Ahmed, A.; Ateeq, H.; Shah, Y.A.; Islam, F.; Hussain, M.; Akram, N.; Shah, M.A. Valorization and Food Applications of Okara (Soybean Residue): A Concurrent Review. Food Sci. Nutr. 2023, 11, 3631–3640. [Google Scholar] [CrossRef]

- Wu, C.; Jiang, N.; Wang, R.; Jiang, S.; Yuan, Z.; Luo, X.; Wu, J.; Shi, H.; Wu, R. Linoleic Acid Enrichment of Cheese by Okara Flour and Geotrichum Candidum Overexpressing Δ12 Fatty Acid Desaturase. J. Sci. Food Agric. 2023, 103, 2960–2969. [Google Scholar] [CrossRef]

- Aussanasuwannakul, A.; Puntaburt, K.; Pantoa, T. Enhancing Gluten-Free Crispy Waffles with Soybean Residue (Okara) Flour: Rheological, Nutritional, and Sensory Impacts. Foods 2024, 13, 2951. [Google Scholar] [CrossRef]

- Tian, Z.; Deng, D.; Cui, Y.; Chen, W.; Yu, M.; Ma, X. Diet Supplemented with Fermented Okara Improved Growth Performance, Meat Quality, and Amino Acid Profiles in Growing Pigs. Food Sci. Nutr. 2020, 8, 5650–5659. [Google Scholar] [CrossRef]

- Rahman, M.M.; Mat, K.; Ishigaki, G.; Akashi, R. A Review of Okara (Soybean Curd Residue) Utilization as Animal Feed: Nutritive Value and Animal Performance Aspects. Anim. Sci. J. 2021, 92, e13594. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Lee, J.J.L.; Chen, W.N. Eco-Friendly and Biodegradable Cellulose Hydrogels Produced from Low Cost Okara: Towards Non-Toxic Flexible Electronics. Sci. Rep. 2019, 9, 18166. [Google Scholar] [CrossRef]

- Prabsangob, N.; Hangsalad, S.; Udomrati, S. Surface Modification of Okara Cellulose Crystals with Phenolic Acids to Prepare Multifunction Emulsifier with Antioxidant Capacity and Lipolysis Retardation Effect. Foods 2024, 13, 184. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; McClements, D.; He, M.; Huang, Y.; Zhu, H.; Jiang, L.; Teng, F.; Li, Y. Okara Nanocellulose Fabricated Using Combined Chemical and Mechanical Treatments: Structure and Properties. J. Mol. Liq. 2021, 335, 116231. [Google Scholar] [CrossRef]

- Elginoz, N.; Khatami, K.; Owusu-Agyeman, I.; Cetecioglu, Z. Life Cycle Assessment of an Innovative Food Waste Management System. Front. Sustain. Food Syst. 2020, 4, 23. [Google Scholar] [CrossRef]

- Mondello, G.; Salomone, R.; Ioppolo, G.; Saija, G.; Sparacia, S.; Lucchetti, M.C. Comparative LCA of Alternative Scenarios for Waste Treatment: The Case of Food Waste Production by the Mass-Retail Sector. Sustainability 2017, 9, 827. [Google Scholar] [CrossRef]

- Trujillo Reyes, Á.; Jiménez Páez, E.; Serrano Moral, A.; Kassab, G.; Fermoso, F.G.; Alonso Fariñas, B. Comparative Life Cycle Environmental Impact Assessment of Fruit and Vegetable Waste Valorization by Anaerobic Digestion as an Alternative in a Mediterranean Market. Processes 2023, 11, 3397. [Google Scholar] [CrossRef]

- Di Maria, F.; Micale, C. Life Cycle Analysis of Incineration Compared to Anaerobic Digestion Followed by Composting for Managing Organic Waste: The Influence of System Components for an Italian District. Int. J. Life Cycle Assess. 2015, 20, 377–388. [Google Scholar] [CrossRef]

- Alonso-Fariñas, B.; Oliva, A.; Rodríguez-Galán, M.; Esposito, G.; García-Martín, J.F.; Rodríguez-Gutiérrez, G.; Serrano, A.; Fermoso, F.G. Environmental Assessment of Olive Mill Solid Waste Valorization via Anaerobic Digestion Versus Olive Pomace Oil Extraction. Processes 2020, 8, 626. [Google Scholar] [CrossRef]

- Drosou, F.; Kekes, T.; Boukouvalas, C.; Oikonomopoulou, V.; Krokida, M. Life Cycle Assessment of Innovative Methods for Treating Wastewater and Solid Wastes: A Case Study Focusing on Their Application within the Brewing Sector. Sustain. Food Technol. 2024, 2, 1476–1489. [Google Scholar] [CrossRef]

- Petit, G.; Korbel, E.; Jury, V.; Aider, M.; Rousselière, S.; Audebrand, L.; Turgeon, S.; Mikhaylin, S. Environmental Evaluation of New Brewer’s Spent Grain Preservation Pathways for Further Valorization in Human Nutrition. ACS Sustain. Chem. Eng. 2020, 8, 17335–17344. [Google Scholar] [CrossRef]

- Quintana, G.; Di Clemente, N.; Gómez-Zavaglia, A.; Gerbino, E. Quantification of the Environmental Impact Arising from the Utilization of Whole and Defatted Okara in Fermentative and Dehydration Processes. Food Res. Int. 2023, 174, 113645. [Google Scholar] [CrossRef]

- Lehmann, N.P.L. By-Product Valorisation for Sustainable Food Systems The Case of Oat Okara. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2024. Available online: https://www.diva-portal.org/smash/get/diva2:1898835/FULLTEXT01.pdf (accessed on 6 January 2025).

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. Interantional Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 30 January 2025).

- ISO 14040:2006(En); Environmental Management—Life Cycle Assessment—Principles and Framework. Interantional Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14040:ed-2:v1:en (accessed on 30 January 2025).

- Li, B.; Qiao, M.; Lu, F. Composition, Nutrition, and Utilization of Okara (Soybean Residue). Food Rev. Int. 2012, 28, 231–252. [Google Scholar] [CrossRef]

- Choy, S.Y.; Wang, K.; Qi, W.; Wang, B.; Chen, C.-L.; Wang, J.-Y. Co-Composting of Horticultural Waste with Fruit Peels, Food Waste, and Soybean Residues. Environ. Technol. 2015, 36, 1448–1456. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Circular Economy Systems Diagram (February 2019); Ellen MacArthur Foundation: Wight, UK; Available online: https://www.ellenmacarthurfoundation.org/circular-economy-diagram (accessed on 13 March 2025).

- Liu, C.; Nishiyama, T. CCET Guideline Series on Intermediate Municipal Solid Waste Treatment Technologies Waste-to-Energy Incineration; Institute for Global Environmental Strategies (IGES): Kanagawa, Japan, 2020. [Google Scholar]

- Amber van Veghel’s Internship Project. Revealing the Environmental Impact of Plant Proteins. Mérieux NutriSciences. Available online: https://blonksustainability.nl/news/revealing-the-environmental-impact-of-plant-proteins (accessed on 15 January 2025).

- Tsou, M.-J.; Kao, F.-J.; Tseng, C.-K.; Chiang, W.-D. Enhancing the Anti-Adipogenic Activity of Soy Protein by Limited Hydrolysis with Flavourzyme and Ultrafiltration. Food Chem. 2010, 122, 243–248. [Google Scholar] [CrossRef]

- Joint Research Centre—European Commission. Environmental Footprint Methodology for Life Cycle Assessment; European Commission: Brussel, Belgium, 2023; Available online: https://eplca.jrc.ec.europa.eu (accessed on 30 January 2025).

- Sala, S.; Cerutti, A.; Pant, R. Development of a Weighting Approach for the Environmental Footprint; Publications Office: Luxembourg, 2018. [Google Scholar]

- FOEN. Swiss Eco-Factors 2021 According to the Ecological Scarcity Method. Federal Office for the Environment. 2021. Available online: https://www.bafu.admin.ch/bafu/en/home/themen/thema-wirtschaft-und-konsum/wirtschaft-und-konsum--publikationen/publikationen-wirtschaft-und-konsum/oekofaktoren-schweiz.html (accessed on 30 January 2025).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Wang, Y.; Pan, S.; Yin, J.; Feng, H.; Wang, M.; Chen, T. Resource Potential and Global Warming Potential of Fruit and Vegetable Waste in China Based on Different Treatment Strategies. Waste Manag. 2022, 140, 225–232. [Google Scholar] [CrossRef]

- Martin, M.; Gani, R.; Mujtaba, I.M. Sustainable Process Synthesis, Design, and Analysis: Challenges and Opportunities. Sustain. Prod. Consum. 2022, 30, 686–705. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S.A.; Himanshu, H.; Stobernack, N. Economic and Environmental Life Cycle Assessment of Organic Waste Treatment by Means of Incineration and Biogasification. Is Source Segregation of Biowaste Justified in Germany? Sci. Total Environ. 2020, 721, 137731. [Google Scholar] [CrossRef]

| Parameter | Value * | Source |

|---|---|---|

| Dry matter | 20% | [2] |

| Lipids | 20%DM | [16] |

| Proteins | 26.90%DM | [41] |

| Nitrogen (N) | 4.55%DM | [42] |

| Phosphorus (P) | 0.29%DM | [42] |

| Potassium (K) | 0.84%DM | [42] |

| Unit | Scenario 1: Uncontrolled Landfill | Scenario 2: Controlled Landfill | Scenario 3: Incineration Plant | |

|---|---|---|---|---|

| Input * | ||||

| Okara | kg | 1.000 | 1.000 | 1.000 |

| Transport | tkm | 0.025 | 0.025 | 0.025 |

| Output | ||||

| Biomethane ** | kWh | 0.125 | ||

| Avoided Burden | ||||

| Natural gas ** | kWh | 0.125 |

| Unit | Scenario 4: Anaerobic Digestion | Scenario 5: Composting * | Scenario 6: Black Soldier Fly | |

|---|---|---|---|---|

| Input | ||||

| Okara | kg | 1.000 | 1.000 | 1.000 |

| Transport | tkm | 0.025 | 0.025 | 0.050 |

| Steam | kWh | 0.053 | ||

| Electricity | kWh | 0.028 | ||

| Water | kg | 0.002 | ||

| Young Larvae | kg | 0.002 | ||

| Output | ||||

| Biomethane ** | kWh | 0.897 | ||

| Biofertiliser | kg | 0.100 | 0.270 | 0.067 |

| Insect meal (indicated as 100% protein) | kg | 0.018 | ||

| Insectoil | kg | 0.017 | ||

| Avoided Burden | ||||

| Natural gas ** | kWh | 0.897 | ||

| Fishmeal (65% protein) | kg | 0.028 | ||

| Fish oil | kg | 0.017 | ||

| NPK Fertiliser | kg | 0.005 | 0.005 | 0.004 |

| Unit | Scenario 7: Oil (Supercritical Fluid Extraction) | Scenario 8: Protein Hydrolisate (Conventional Extraction) | Scenario 9: Protein Hydrolisate (Experimental) | |

|---|---|---|---|---|

| Input | ||||

| Okara | kg | 1.000 | 1.000 | 1.000 |

| Transport | tkm | 0.050 | 0.050 | 0.050 |

| Chemicals | kg | 0.003 | 0.160 | |

| Steam | kWh | 0.950 | 1.570 | 4.387 |

| Electricity | kWh | 0.267 | 0.167 | 1.114 |

| Liquid CO2 | kg | 0.020 | ||

| Output | ||||

| Defatted flour | kgDM | 0.160 | ||

| Oil | l | 0.040 | ||

| Feed (8% protein) | kgDM | 0.149 | ||

| Protein hydrolisate * | kg | 0.051 | 0.041 | |

| Process water | m3 | 0.002 | 0.001 | |

| Avoided Burden | ||||

| Crude sesameseed oil (solvent) | kg | 0.040 | ||

| Soybean meal | kgDM | 0.16 | ||

| Soybean protein hydrolisate 95% | kg | 0.043 | 0.015 | |

| Pea wet animal feed | kg | 0.68 |

| Unit | Scenario 10: Animal Feed | |

|---|---|---|

| Input | ||

| Okara | kg | 1.000 |

| Transport | tkm | 0.025 |

| Land Use | m2a | 5.2× 10–5 |

| Land Transformation | m2 | 2.0 × 10–6 |

| Silo storage | m3 | 8.5 × 10–6 |

| Water | kg | 0.056 |

| Electricity | kWh | 0.025 |

| Output | ||

| Feed (indicated as 100% protein) | kgDM | 0.027 |

| Avoided Burden | ||

| Soybean meal | kgDM | 0.066 |

| Acidification | Climate Change | Ecotoxicity, Freshwater | Particulate Matter | Eutrophication, Terrestrial | Photochemical Ozone Formation | Resource Use, Fossils | ||

|---|---|---|---|---|---|---|---|---|

| S1 | Uncontrolled landfilling | ● | ● | ● | ● | ● | ● | ● |

| S2 | Controlled landfilling | ● | ● | ● | ● | ● | ● | ● |

| S3 | Incineration plant | ● | ● | ● | ● | ● | ● | ● |

| S4 | Anaerobic digestion plant | ● * | ● | ● | ● * | ● * | ● | ● |

| S5 | Composting plant | ● | ● | ● * | ● | ● | ● | ● |

| S6 | Black soldier flies | ● | ● | ● | ● | ● | ● | ● |

| S7 | Supercritical fluid extraction | ● | ● | ● | ● | ● | ● | ● |

| S8 | Protein extraction (conventional) | ● | ● * | ● | ● | ● | ● * | ● * |

| S10 | Animal feed | ● | ● | ● | ● | ● | ● | ● |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rohrer, K.; Whitfield, F.; Aussanasuwannakul, A.; Ningrum, A.; Hugi, C.; Breitenmoser, L. Comparative Screening Life Cycle Assessments of Okara Valorisation Scenarios. Environments 2025, 12, 93. https://doi.org/10.3390/environments12030093

Rohrer K, Whitfield F, Aussanasuwannakul A, Ningrum A, Hugi C, Breitenmoser L. Comparative Screening Life Cycle Assessments of Okara Valorisation Scenarios. Environments. 2025; 12(3):93. https://doi.org/10.3390/environments12030093

Chicago/Turabian StyleRohrer, Karina, Fabian Whitfield, Aunchalee Aussanasuwannakul, Andriati Ningrum, Christoph Hugi, and Lena Breitenmoser. 2025. "Comparative Screening Life Cycle Assessments of Okara Valorisation Scenarios" Environments 12, no. 3: 93. https://doi.org/10.3390/environments12030093

APA StyleRohrer, K., Whitfield, F., Aussanasuwannakul, A., Ningrum, A., Hugi, C., & Breitenmoser, L. (2025). Comparative Screening Life Cycle Assessments of Okara Valorisation Scenarios. Environments, 12(3), 93. https://doi.org/10.3390/environments12030093