Assessing Avoided Burden and Net Environmental Impact by Recycling and Repurposing of Retiring Wind Turbines

Abstract

1. Introduction

- To identify EOL disposal options available for wind power technology

- To evaluate these options by LCA, applied credits, and sensitivity analysis

- To analyze the results and provide recommendations

2. Materials and Methods

2.1. LCA Parameters

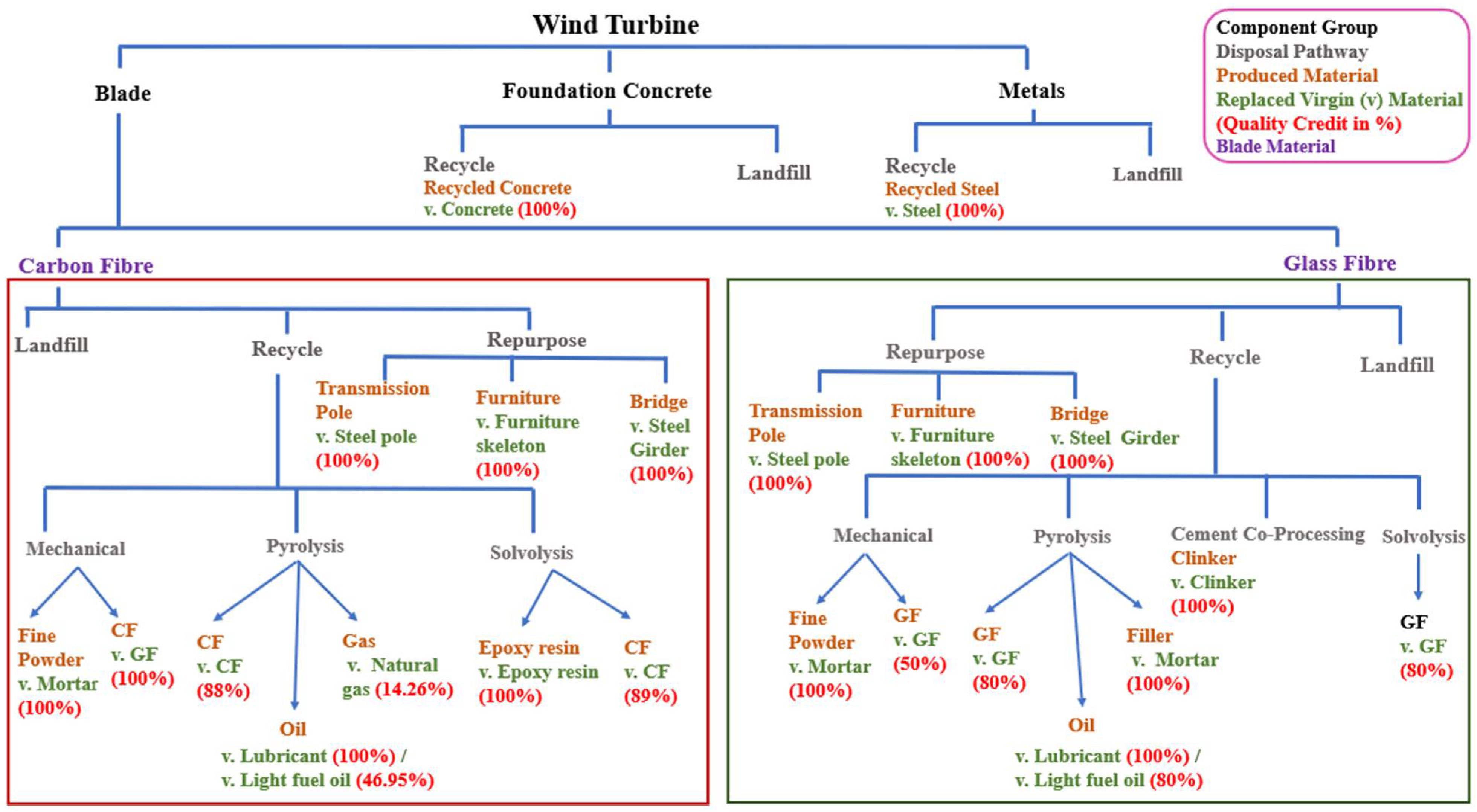

- Goal and Scope Definition: The goal was to assess the environmental impacts of recycling and landfilling each material group, and of repurposing blades. The scope was limited to the Permian Basin region of West Texas, USA, incorporating local transportation and energy grid data. The functional unit (FU) was defined as 1000 kg of wind turbine material at its EOL. The system boundary was consistent across all waste management pathways; it began when the turbine reached EOL and ended when the material was either landfilled, recycled, or repurposed. This system boundary includes dismantling, transporting, and treating the waste (Figure S1). Dismantling burdens were applied consistently across material groups, with adjustments for material-specific requirements. For blades, cutting energy was scaled by a ratio of tensile strength and density, resulting in CFRP requiring ~1.8× more energy than GFRP. Structural steel and foundation concrete followed separate dismantling processes. Landfill pathways were modeled with the same general dismantling as recycling, but with lower shredding energy and shorter transport distances. Repurposing scenarios assumed reduced dismantling effort, given that blade integrity was largely preserved. Full energy inventories are provided in the Supplementary Information.

- Life Cycle Inventory (LCI): Data was drawn from Ecoinvent 3.8.1 [33] (cutoff system model), with custom modifications based on the literature and consultations with industry and academia that reflect current best practices in wind blade recycling pathways. Full LCI details are available in the Supplementary Material.

- Life Cycle Impact Assessment (LCIA): Inventory data was mapped to the 16 selected impact categories using the ReCiPe 2016 (H) methodology [29].

- Interpretation: Key contributors to environmental impact were identified by material group and waste pathway. Reliability of data sources and assumptions regarding material quality and recovery rate were also assessed.

2.2. Avoided Burden Credit Assignment

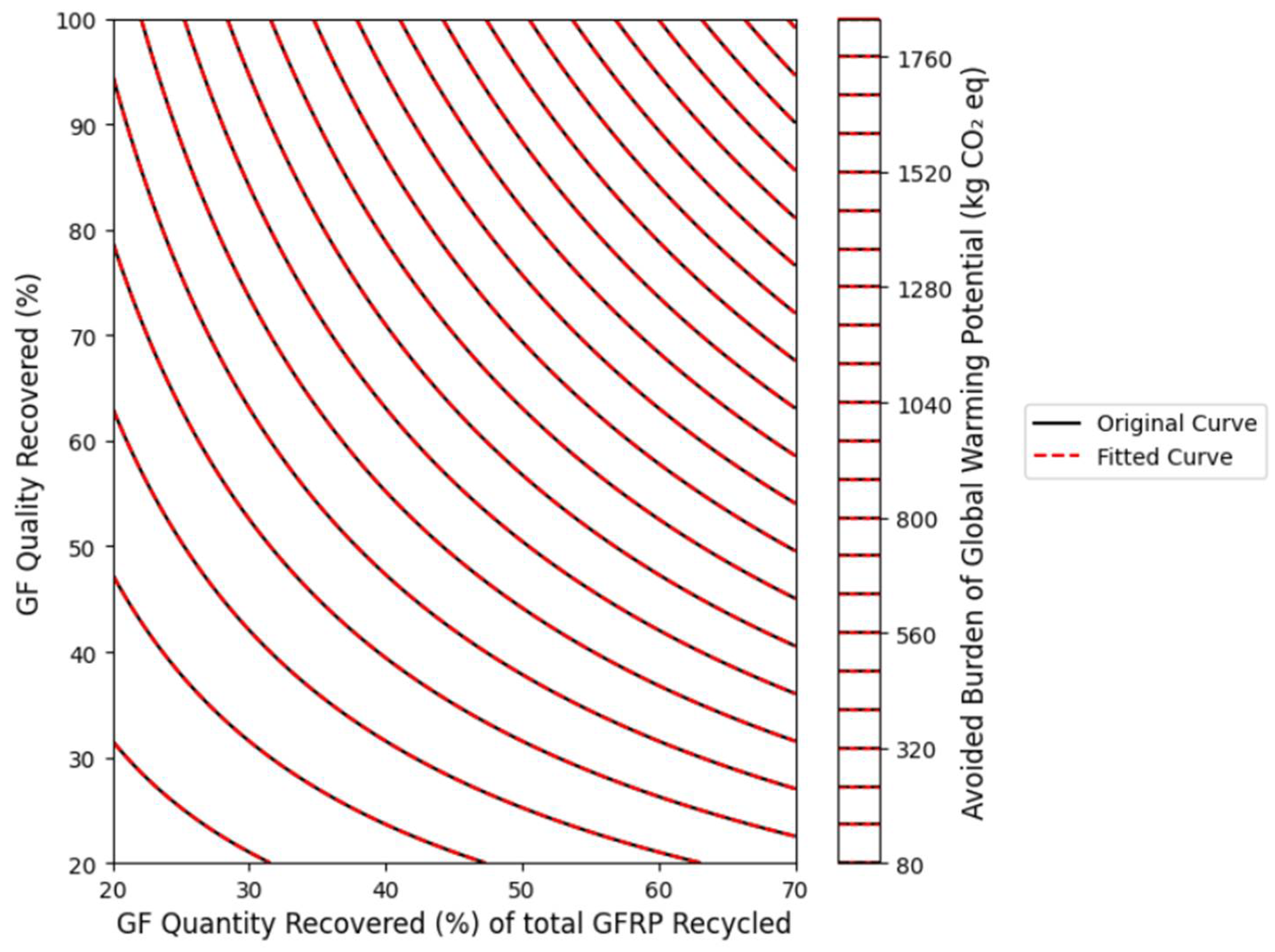

2.3. Sensitivity Analysis

- x represents the quantity of fiber recovered (as % of blade mass)

- y represents the quality of recovered fiber (relative to virgin material)

- z represents the avoided burden (per impact category)

- a–f represents fitted coefficients

3. Results

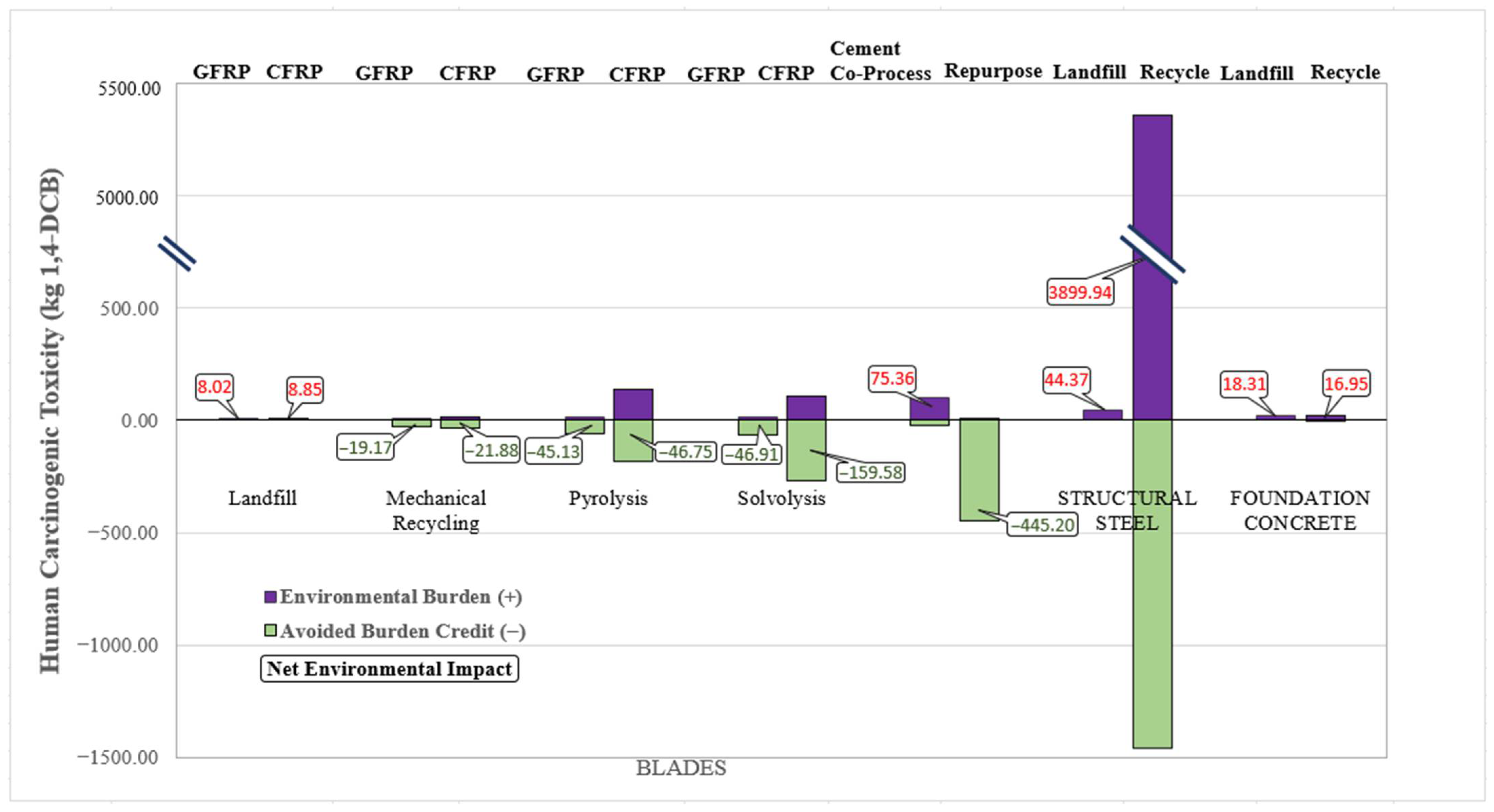

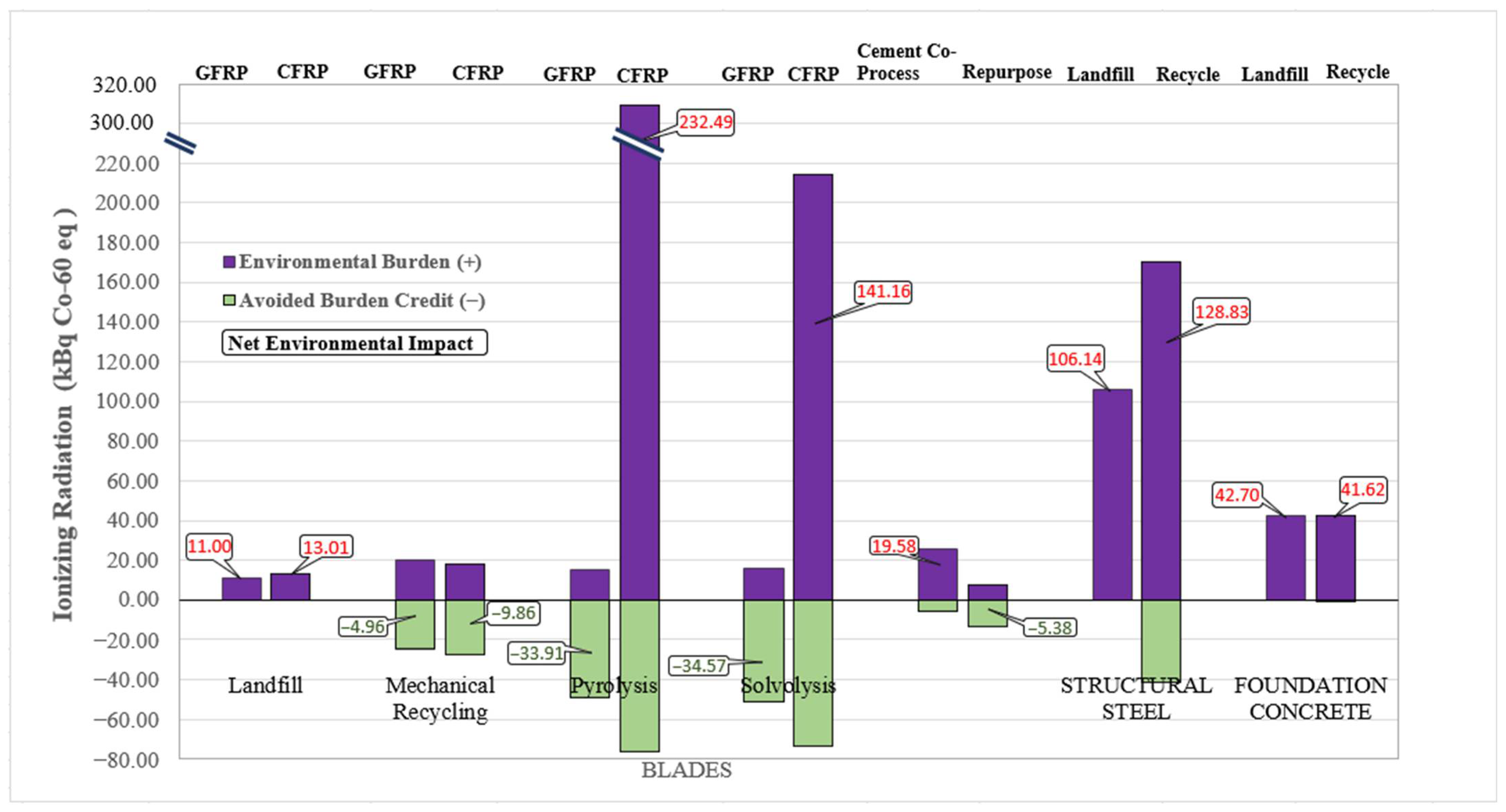

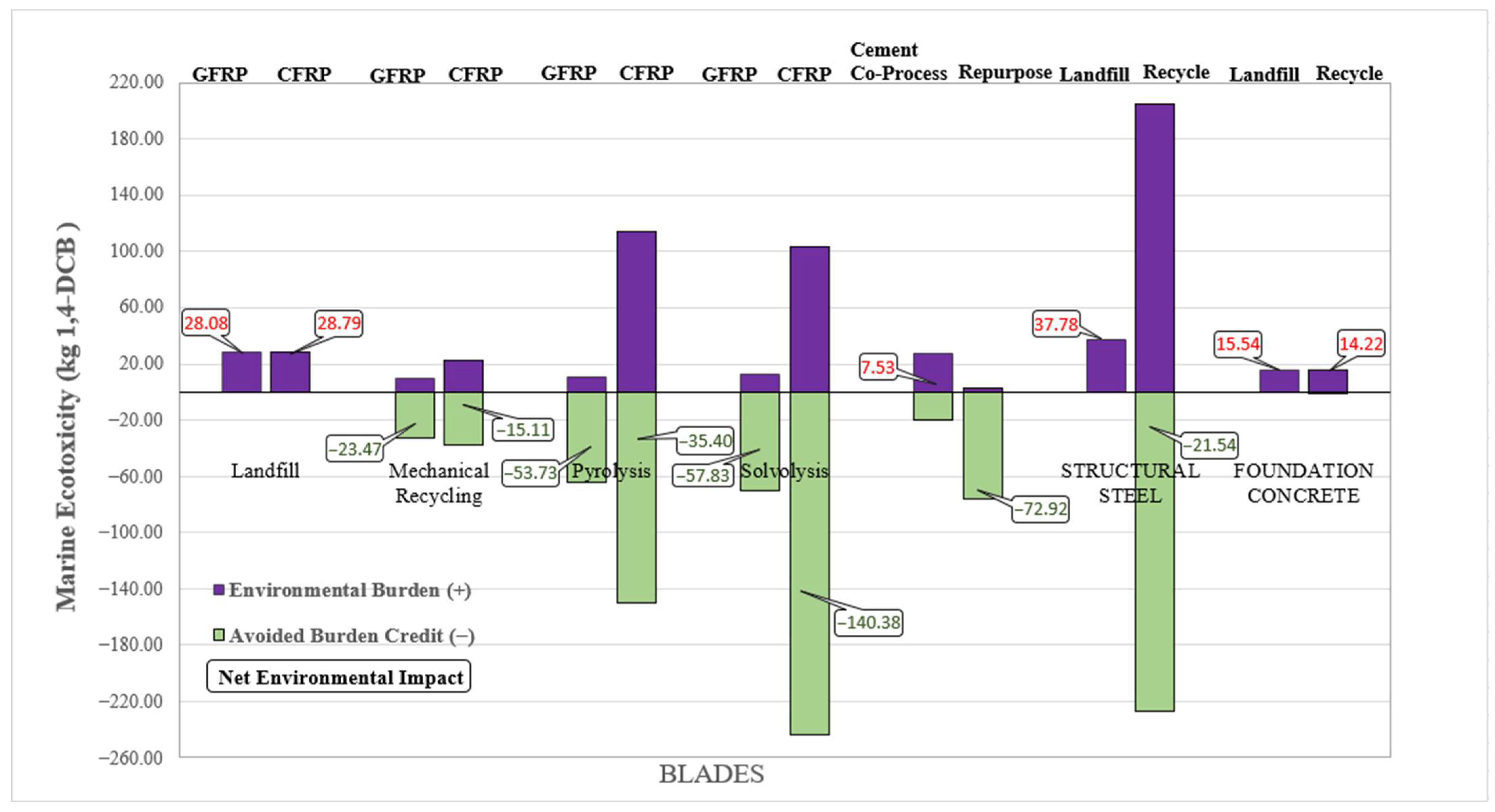

3.1. Net Environmental Impacts (NEI)

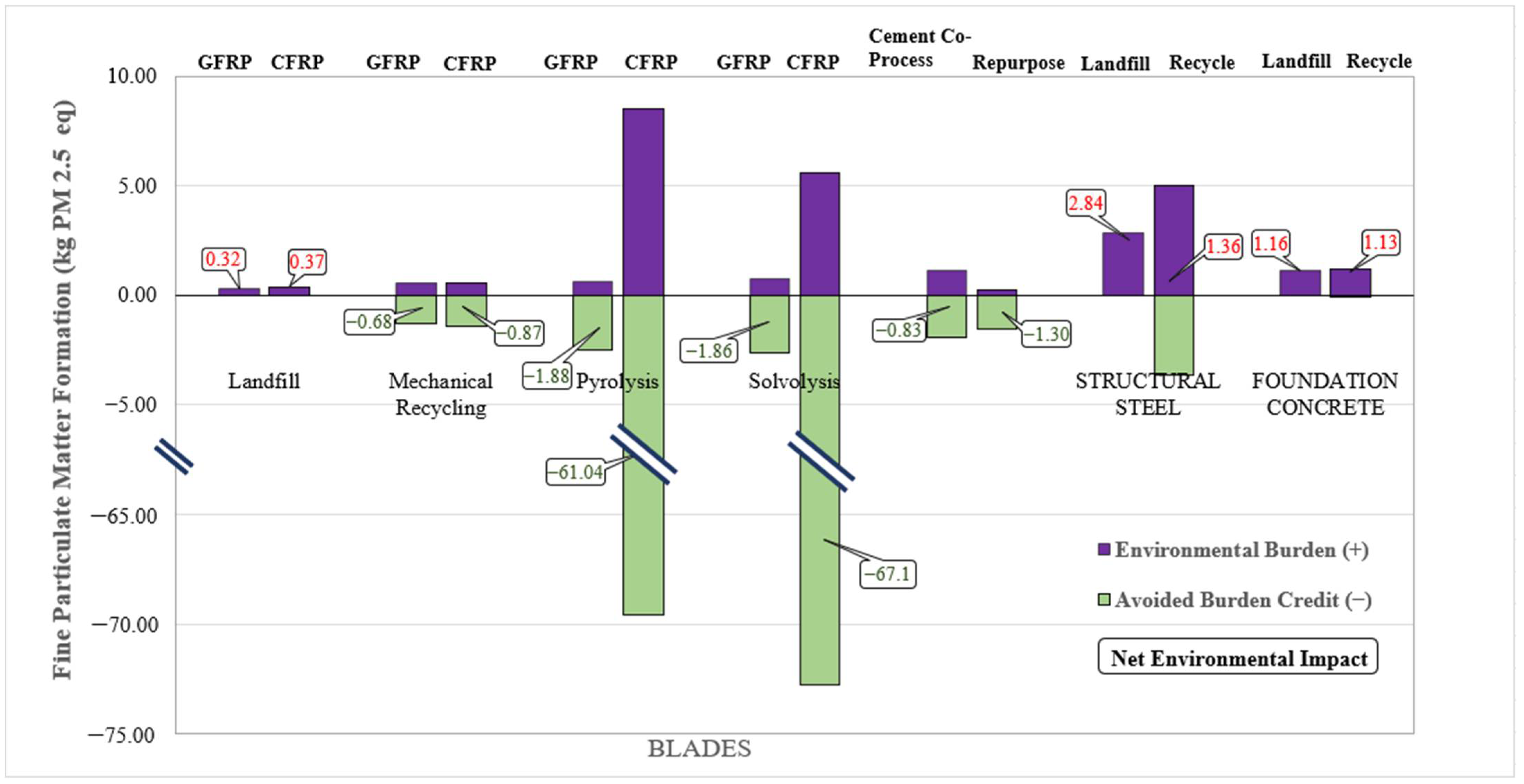

- Fine particulate matter formation (FPMF): reflects human health risks from airborne particles.

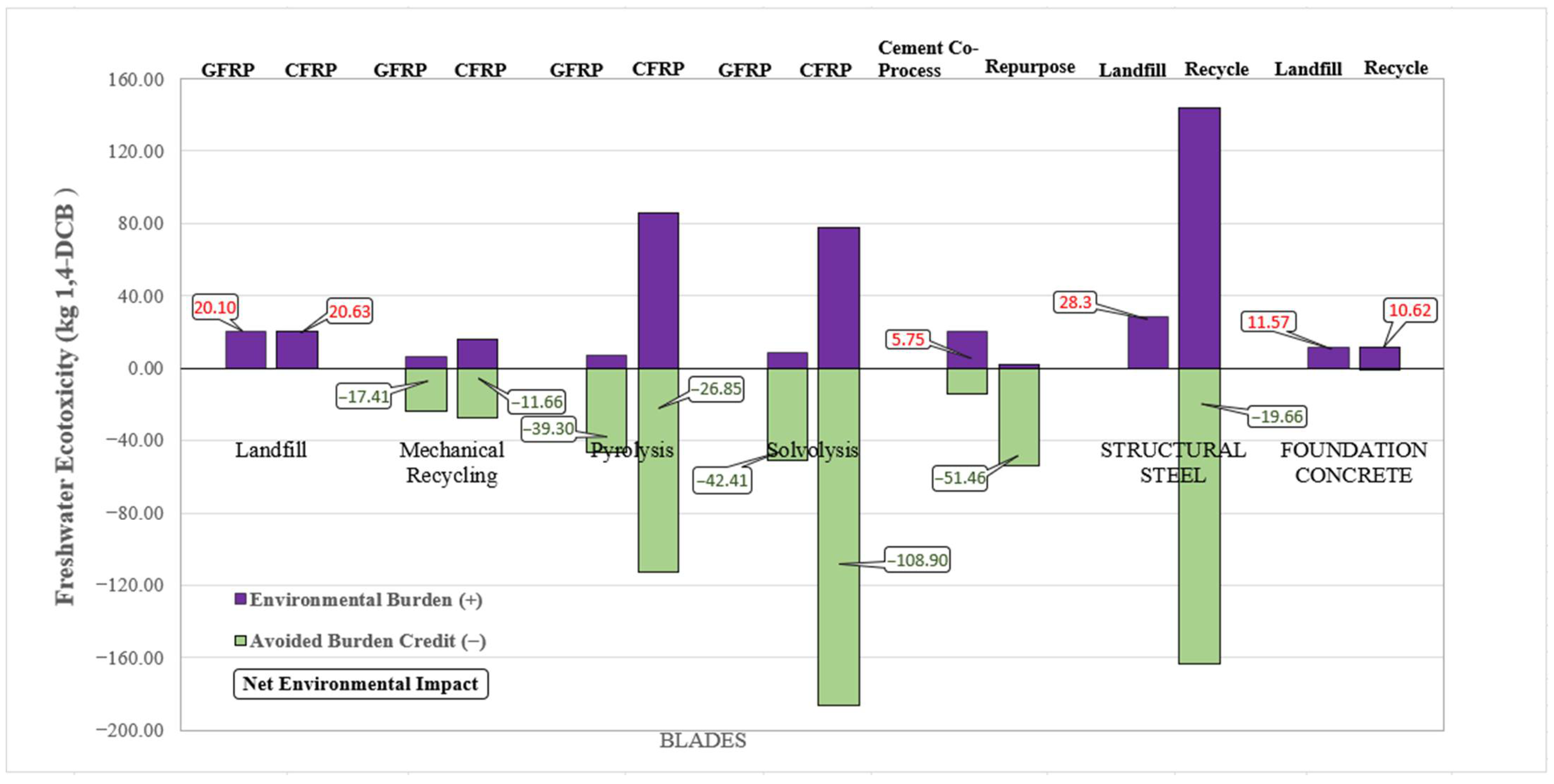

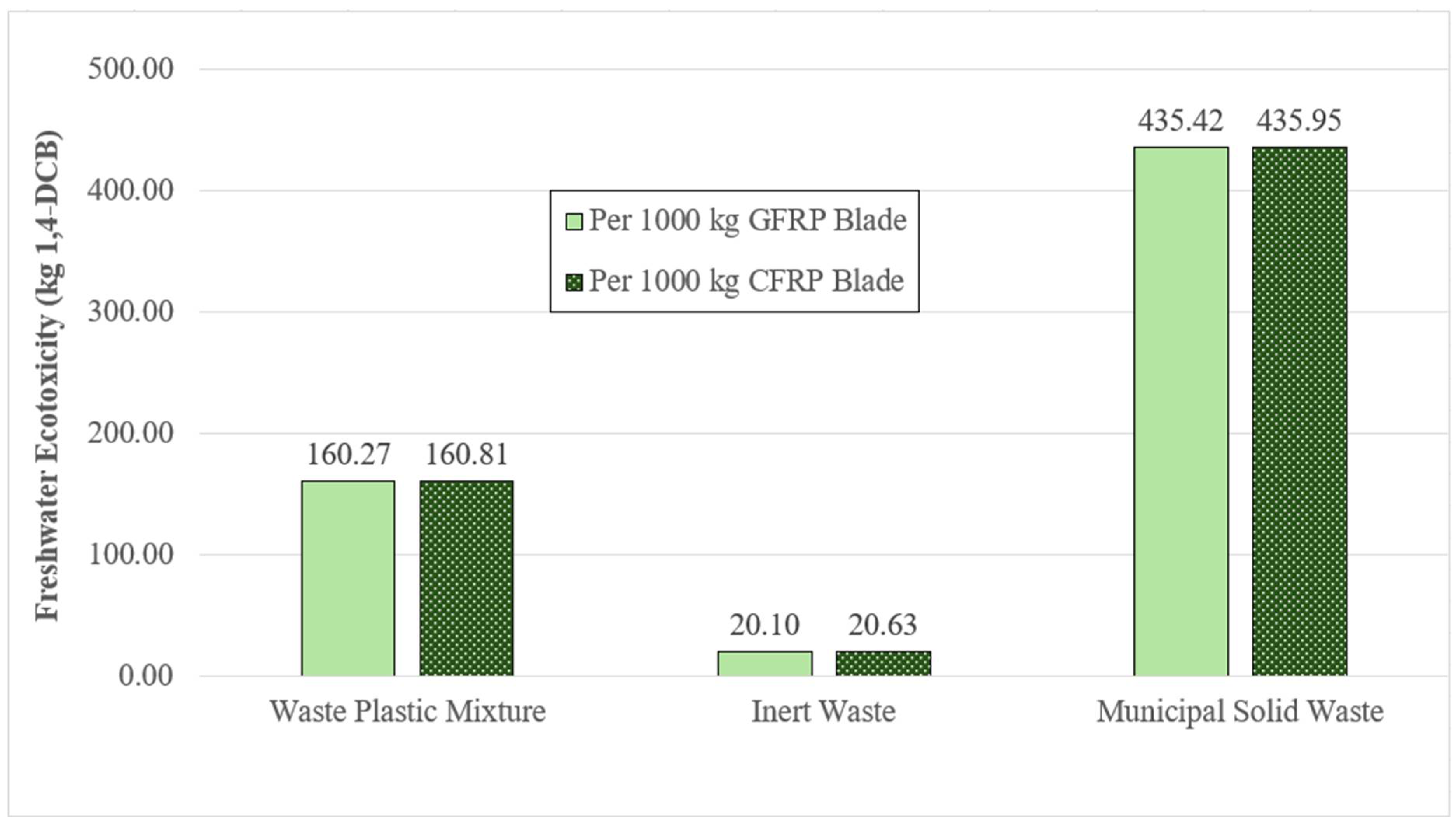

- Freshwater ecotoxicity: indicates toxicity to aquatic ecosystems and biodiversity.

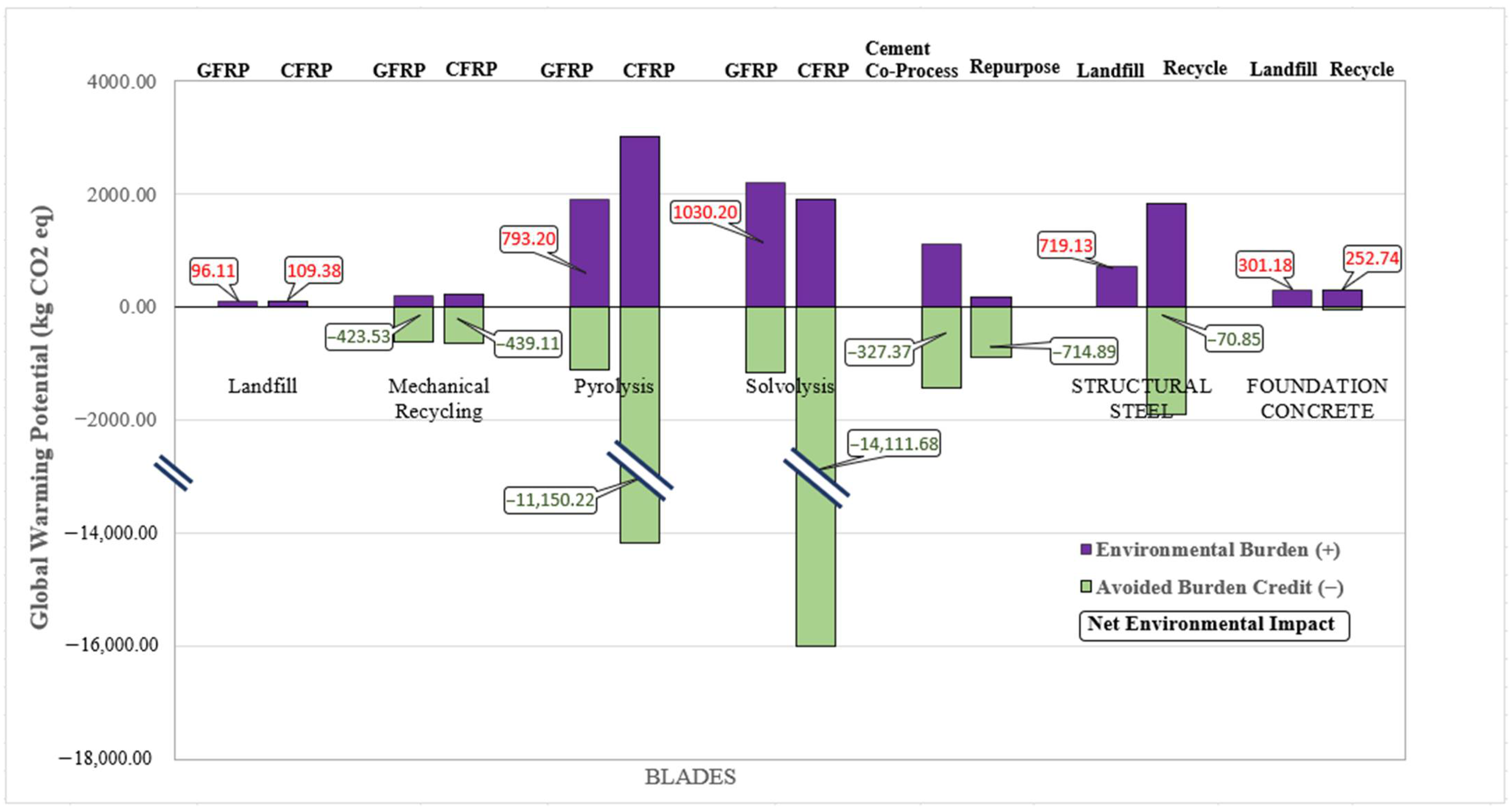

- Global warming potential (GWP): quantifies greenhouse gas emissions, linking directly to climate change.

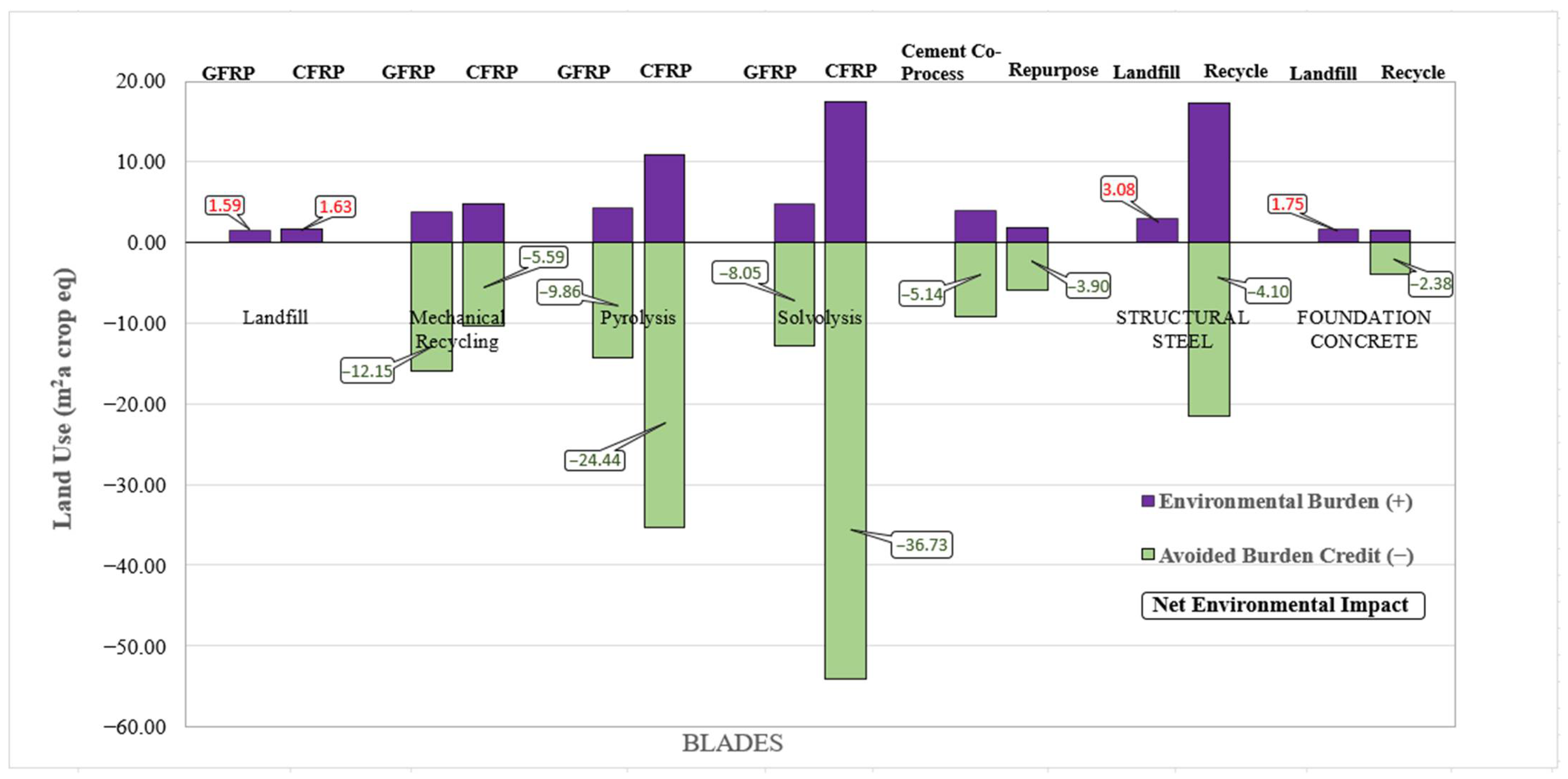

- Land use: measures land occupation and resource pressure.

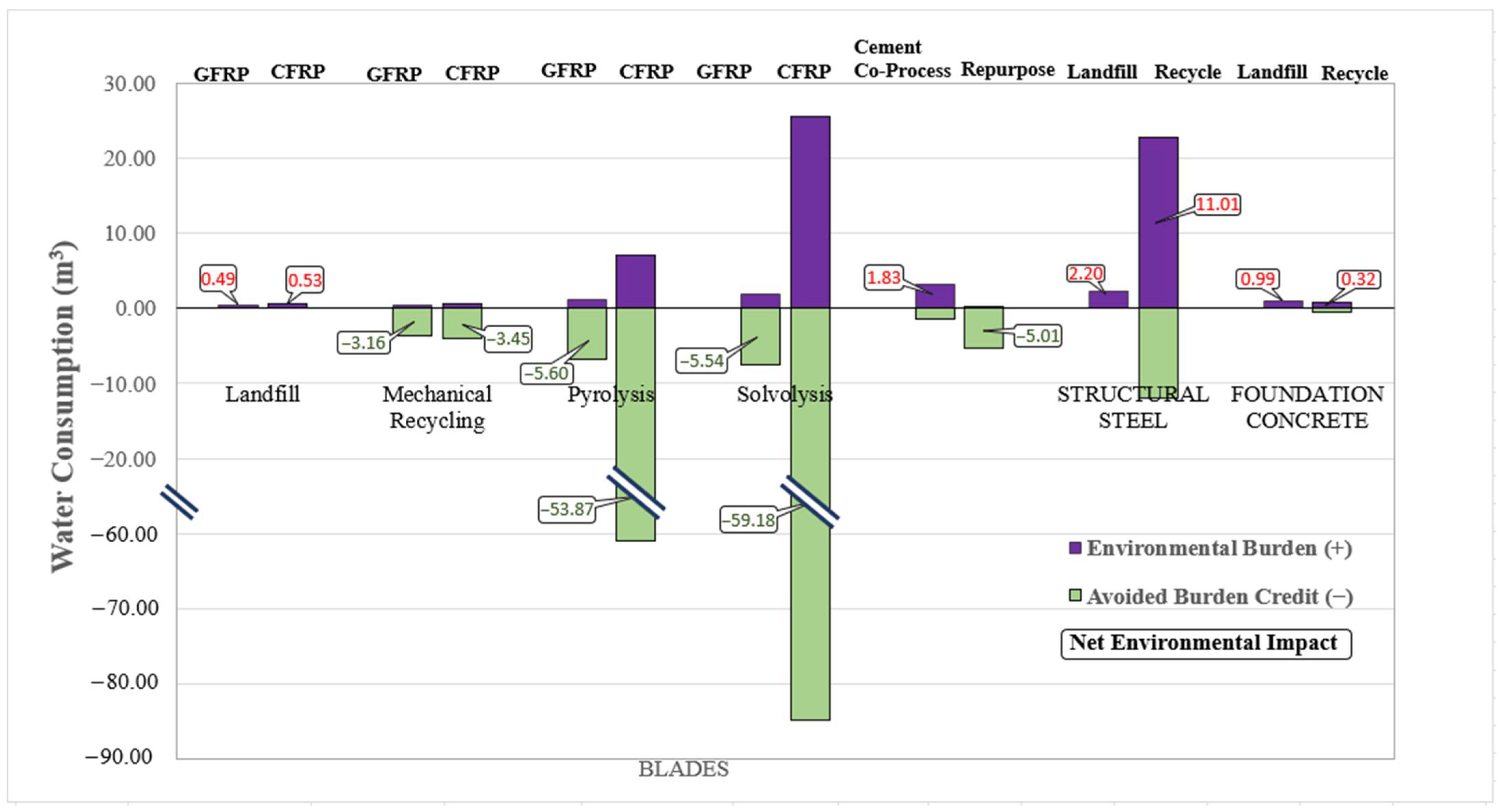

- Water consumption: highlights impact in water-stressed regions, such as Texas.

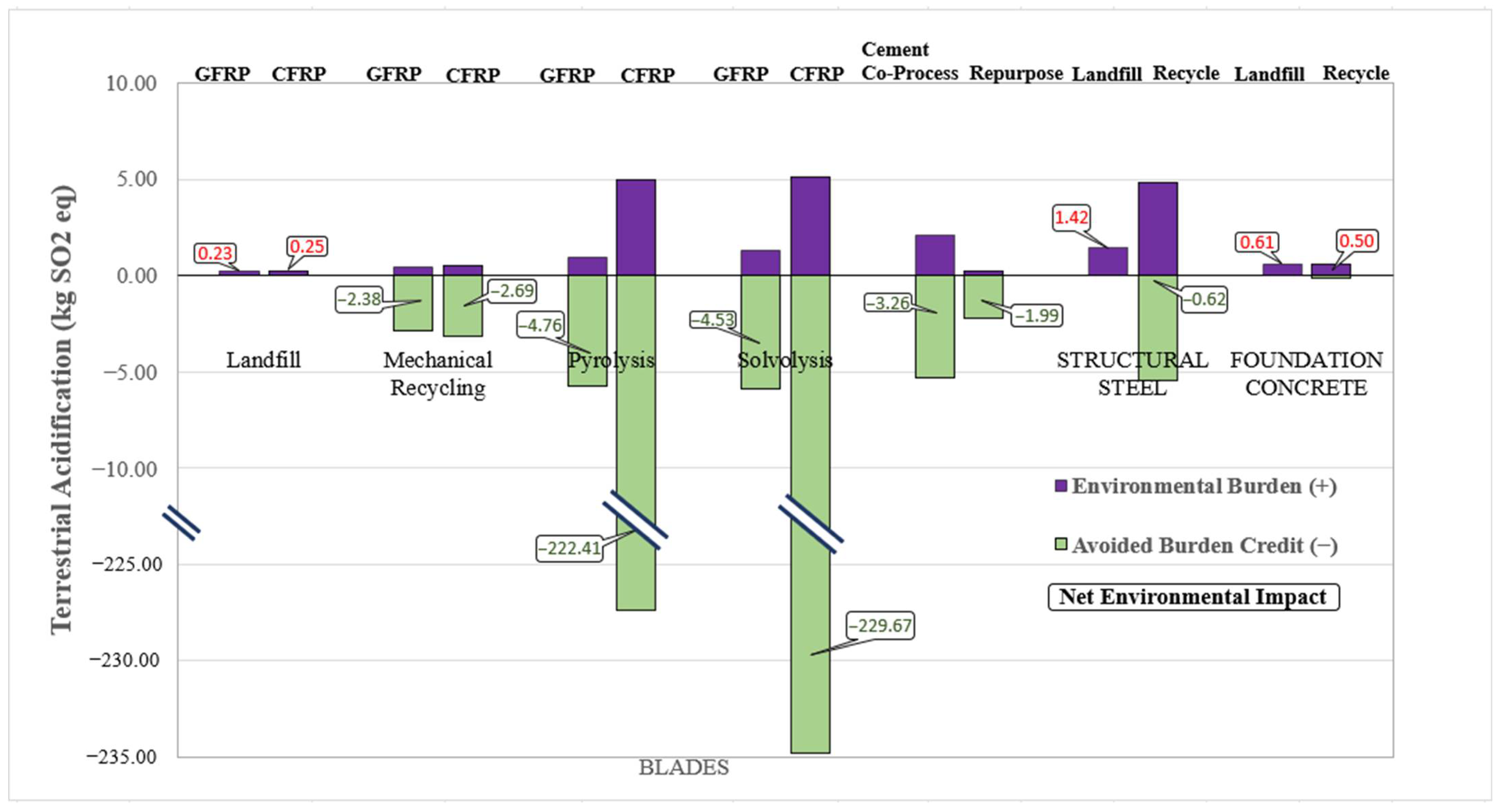

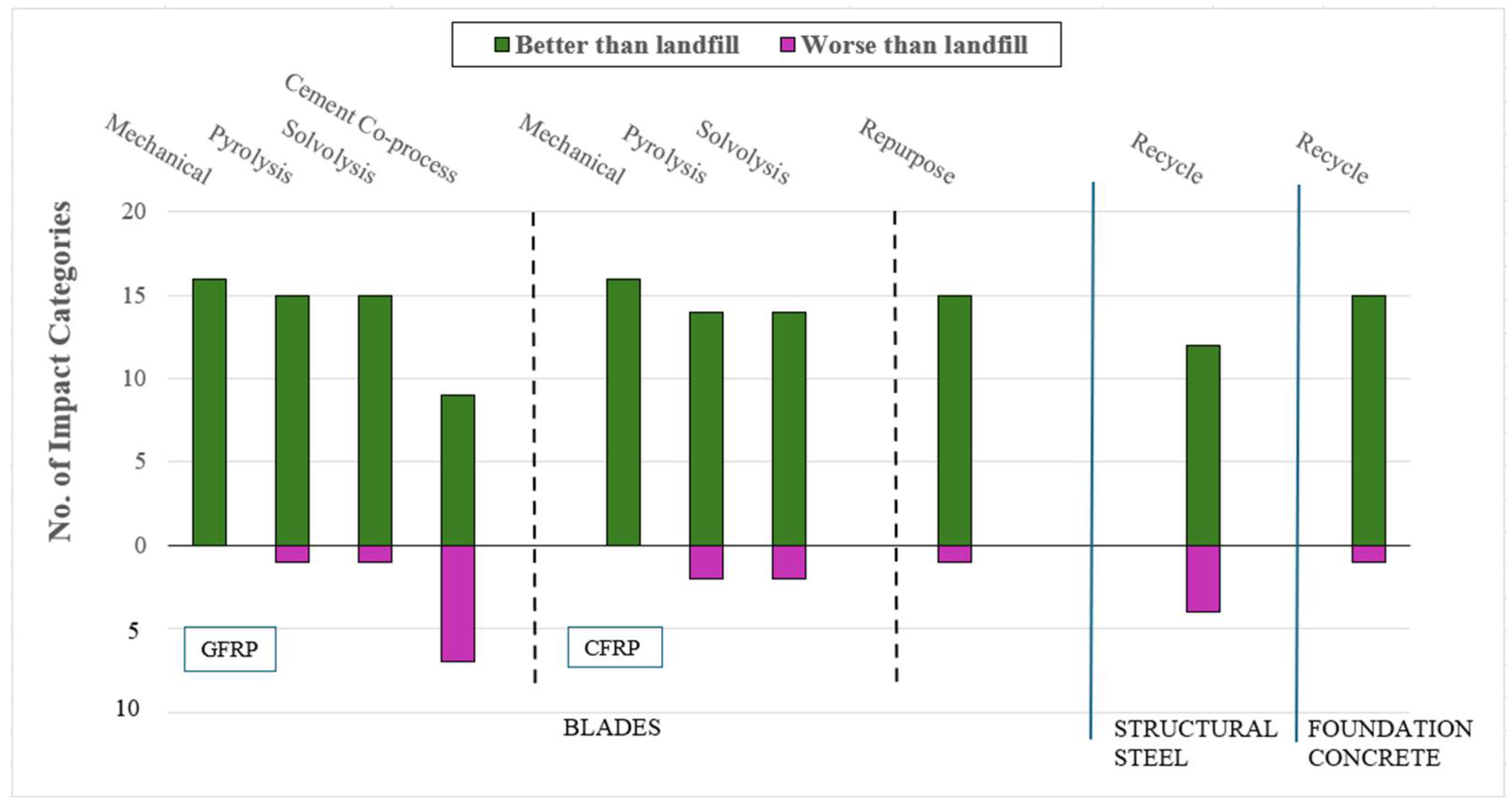

- Pyrolysis reduces net FPMF by ~6.9× compared to landfilling (Figure 2), as avoided burden credits outweigh process emissions. Landfilling has the highest FPMF, then mechanical recycling, cement co-processing, solvolysis, and pyrolysis.

- For freshwater ecotoxicity (Figure 3), all recycling pathways outperform landfilling. Cement co-processing achieves ~75% reduction, but only when avoided burden credits are applied, as kiln combustion can release heavy metals and pollutants.

- For GWP (Figure 4), pyrolysis and solvolysis emit 8–10× more CO2 eq than landfilling, even with solvent recovery for solvolysis, due to resin combustion and high energy demand (15,800 MJ for pyrolysis and 21,360 MJ for solvolysis). Cement co-processing leads to net-negative GWP, because blade materials substitute for coal/pet coke, although these credits may decline as cement decarbonizes.

- Mechanical recycling yields the greatest land-use savings (Figure 5), reducing NEI 8.6× compared to landfilling.

- All recycling options except cement co-processing reduce net water consumption (Figure 6).

3.2. Blade Characterization in Landfill

3.3. Sensitivity Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CF | Carbon Fiber |

| CFRP | Carbon Fiber-Reinforced Polymer |

| FU | Functional Unit |

| EOL | End-Of-Life |

| GF | Glass Fiber |

| GFRP | Glass Fiber-Reinforced Polymer |

| H | Heuristic |

| ISO | International Standardization Organization |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| NEI | Net Environmental Impact |

| UPR | Unsaturated Polyester Resin |

References

- Das, J.; Ur Rehman, A.; Verma, R.; Gulen, G.; Young, M.H. Comparative Life-Cycle Assessment of Electricity-Generation Technologies: West Texas Case Study. Energies 2024, 17, 992. [Google Scholar] [CrossRef]

- Namahoro, J.P.; Wu, Q.; Su, H. Wind energy, industrial-economic development and CO2 emissions nexus: Do droughts matter? Energy 2023, 278, 127869. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. Wind Energy. 2022. Available online: https://www.irena.org/Energy-Transition/Technology/Wind-energy (accessed on 9 March 2025).

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef]

- Bank, L.; Arias, F.; Yazdanbakhsh, A.; Gentry, T.; Al-Haddad, T.; Chen, J.-F.; Morrow, R. Concepts for Reusing Composite Materials from Decommissioned Wind Turbine Blades in Affordable Housing. Recycling 2018, 3, 3. [Google Scholar] [CrossRef]

- Majewski, P.; Florin, N.; Jit, J.; Stewart, R.A. End-of-life policy considerations for wind turbine blades. Renew. Sustain. Energy Rev. 2022, 164, 112538. [Google Scholar] [CrossRef]

- Gennitsaris, S.; Sagani, A.; Sofianopoulou, S.; Dedoussis, V. Integrated LCA and DEA approach for circular economy-driven performance evaluation of wind turbine end-of-life treatment options. Appl. Energy 2023, 339, 120951. [Google Scholar] [CrossRef]

- United States Geological Survey (USGS). What Materials Are Used to Make Wind Turbines? 2022. Available online: https://www.usgs.gov/faqs/what-materials-are-used-make-wind-turbines (accessed on 2 March 2025).

- Laurin, L. Handling Recycling in Life Cycle Assessment. 2019. Available online: https://earthshiftglobal.com/client_media/files/pdf/Handling_Recycling_in_Life_Cycle_Assessment_2019-11-15.pdf (accessed on 8 March 2025).

- Sproul, E.; Williams, M.; Rencheck, M.L.; Korey, M.; Ennis, B.L. Life cycle assessment of wind turbine blade recycling approaches in the United States. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1293, 012027. [Google Scholar] [CrossRef]

- Sproul, E.G.; Khalifa, S.A.; Ennis, B.L. Environmental and Economic Assessment of Wind Turbine Blade Recycling Approaches. ACS Sustain. Resour. Manag. 2024, 2, 39–49. [Google Scholar] [CrossRef]

- Meng, F.; Olivetti, E.A.; Zhao, Y.; Chang, J.C.; Pickering, S.J.; McKechnie, J. Comparing Life Cycle Energy and Global Warming Potential of Carbon Fiber Composite Recycling Technologies and Waste Management Options. ACS Sustain. Chem. Eng. 2018, 6, 9854–9865. [Google Scholar] [CrossRef]

- Upright Knowledge Base. Why Net Impact? February 2024. Available online: https://docs.uprightplatform.com/background/why-net-impact (accessed on 9 March 2025).

- European Parliament. Circular Economy: Definition, Importance and Benefits. European Parliament. May 2023. Available online: https://www.europarl.europa.eu/topics/en/article/20151201STO05603/circular-economy-definition-importance-and-benefits (accessed on 10 March 2025).

- United States Environmental Protection Agency (EPA). What Is a Circular Economy? November 2021. Available online: https://www.epa.gov/circulareconomy/what-circular-economy (accessed on 3 March 2025).

- International Resource Panel (IRP). Global Resources Outlook 2019: Natural Resources for the Future We Want. 2019. United Nations Programme. Available online: https://www.resourcepanel.org/reports/global-resources-outlook-2019 (accessed on 2 March 2025).

- Guezuraga, B.; Zauner, R.; Pölz, W. Life cycle assessment of two different 2 MW class wind turbines. Renew. Energy 2012, 37, 37–44. [Google Scholar] [CrossRef]

- Ghenai, C. Life Cycle Analysis of Wind Turbine. In Sustainable Development—Energy, Engineering and Technologies—Manufacturing and Environment; IntechOpen: London, UK, 2012. [Google Scholar]

- Alsaleh, A.; Ping, L.; Prabakar, S.; Shahandashti, M. Life Cycle Assessment of Greenhouse Gas Emissions, Traditional Air Pollutants, Water Depletion, and Cumulative Energy Demand from 2-MW Wind Turbine in Texas. 2017. Available online: https://rc.library.uta.edu/uta-ir/bitstream/handle/10106/26450/ALSALEH-DISSERTATION-2016.pdf?isAllowed=y&sequence=1 (accessed on 10 January 2025).

- Diez-Cañamero, B.; Mendoza, J.M.F. Circular economy performance and carbon footprint of wind turbine blade waste management alternatives. Waste Manag. 2023, 164, 94–105. [Google Scholar] [CrossRef] [PubMed]

- Rathore, N.; Panwar, N.L. Environmental impact and waste recycling technologies for modern wind turbines: An overview. Waste Manag. Res. J. A Sustain. Circ. Econ. 2022, 41, 0734242–2211355. [Google Scholar] [CrossRef]

- Paulsen, E.B.; Enevoldsen, P. A Multidisciplinary Review of Recycling Methods for End-of-Life Wind Turbine Blades. Energies 2021, 14, 4247. [Google Scholar] [CrossRef]

- Nagle, A.J.; Mullally, G.; Leahy, P.G.; Dunphy, N.P. Life cycle assessment of the use of decommissioned wind blades in second life applications. J. Environ. Manag. 2022, 302, 113994. [Google Scholar] [CrossRef]

- Nagle, A.J.; Ruane, K.; Gentry, T.R.; Bank, L.C.; Dunphy, N.; Mullally, G.; Leahy, P.G. Life Cycle Sustainability Assessment of a Pedestrian Bridge Made from Repurposed Wind Turbine Blades. In Civil Engineering Research in Ireland; CERI: Dublin, Ireland, 2022. [Google Scholar]

- Henao, Y.; Grubert, E.; Korey, M.; Bank, L.C.; Gentry, R. Life Cycle Assessment and Life Cycle Cost Analysis of Repurposing Decommissioned Wind Turbine Blades as High-Voltage Transmission Poles. J. Constr. Eng. Manag. 2024, 150, 05024004. [Google Scholar] [CrossRef]

- Ruane, K.; Soutsos, M.; Huynh, A.; Zhang, Z.; Nagle, A.; McDonald, K.; Gentry, T.R.; Leahy, P.; Bank, L.C. Construction and Cost Analysis of BladeBridges Made from Decommissioned FRP Wind Turbine Blades. Sustainability 2023, 15, 3366. [Google Scholar] [CrossRef]

- Tapper, R.J.; Longana, M.L.; Norton, A.; Potter, K.D.; Hamerton, I. An evaluation of life cycle assessment and its application to the closed-loop recycling of carbon fibre reinforced polymers. Compos. Part B Eng. 2020, 184, 107665. [Google Scholar] [CrossRef]

- Gopalraj, K.S.; Deviatkin, I.; Horttanainen, M.; Kärki, T. Life Cycle Assessment of a Thermal Recycling Process as an Alternative to Existing CFRP and GFRP Composite Wastes Management Options. Polymers 2021, 13, 4430. [Google Scholar] [CrossRef] [PubMed]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, August 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 13 March 2025).

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, August 2014. Available online: https://www.iso.org/standard/38498.html (accessed on 13 March 2025).

- OpenLCA (Version 2.3). 2024. GreenDelta. Available online: https://www.openlca.org (accessed on 4 July 2025).

- Ecoinvent Association. Ecoinvent Database (Version 3.8.1); Ecoinvent Association: Zurich, Switzerland, 2021; Available online: https://ecoinvent.org/ (accessed on 4 July 2025).

- Bowyer, D.; Bratkovich, S.; Fernholz, K.; Groot, H.; Howe, D. Understanding Steel Recovery and Recycling Rates and Limitations to Recycling. 2015. Available online: https://www.dovetailinc.org/upload/tmp/1579886221.pdf (accessed on 2 March 2025).

- Cappel, J. EAF Efficiency. Presented at the AIST Association for Iron & Steel Technology. 2021. Available online: https://www.aist.org/AIST/aist/AIST/Conferences_Exhibitions/MENA/Presentations/AIST_MENA_EAF-Efficiency_Cappel.pdf (accessed on 2 March 2025).

- Marie, I.; Quiasrawi, H. Closed-loop recycling of recycled concrete aggregates. J. Clean. Prod. 2012, 37, 243–248. [Google Scholar] [CrossRef]

- Climatiq. Emission Factor: Light Fuel Oil (Light Fuel Oil—Import from RoW). 2021. Available online: https://www.climatiq.io/data/emission-factor/9d8aac68-d68d-43fb-a1e8-17c6a0fac05a_b89dadb0-75e9-44fd-8d41-1ec8dcce23b6 (accessed on 25 March 2025).

- World Nuclear Association. Heat Values of Various Fuels—World Nuclear Association. November 2020. Available online: https://world-nuclear.org/information-library/facts-and-figures/heat-values-of-various-fuels (accessed on 25 March 2025).

- Yousef, S.; Eimontas, J.; Stasiulaitiene, I.; Zakarauskas, K.; Striūgas, N. Recovery of energy and carbon fibre from wind turbine blades waste (carbon fibre/unsaturated polyester resin) using pyrolysis process and its life-cycle assessment. Environ. Res. 2024, 245, 118016. [Google Scholar] [CrossRef]

- Spini, F.; Bettini, P. End-of-Life wind turbine blades: Review on recycling strategies. Compos. Part B Eng. 2024, 275, 111290. [Google Scholar] [CrossRef]

- Nagle, A.J.; Delaney, E.L.; Bank, L.C.; Leahy, P.G. A comparative life cycle assessment between landfilling and co-processing of waste from decommissioned Irish wind turbine blades. J. Clean. Prod. 2020, 277, 123321. [Google Scholar] [CrossRef]

- Cheng, G.; Yang, S.; Wang, X.; Guo, Z.; Cai, M. Study on the recycling of waste wind turbine blades. J. Eng. Res. 2023, 11, 100070. [Google Scholar] [CrossRef]

- Doka, G. Life Cycle Inventories of Waste Treatment Services (Ecoinvent Report No. 13); Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2003; Available online: https://www.doka.ch/13_III_Landfills.pdf (accessed on 30 July 2025).

- Kuindersma, C. What Does the Impact Category Human Toxicity (Cancer) Mean in an LCA Report? Hhc.earth; Hedgehog, March 2025. Available online: https://www.hhc.earth/knowledge-base/articles/what-does-the-impact-category-human-toxicity-cancer-mean-in-an-lca-report (accessed on 24 March 2025).

- Xia, W.; Geng, Y.; Zhao, C.; Tao, M.; Qiu, X. Towards Sustainable Minerals for Energy Transition: LCA Insights from an Open-Pit Molybdenum–Copper Mine. Sustainability 2025, 17, 4849. [Google Scholar] [CrossRef]

- Eurofins. Life Cycle Assessment Impact Categories Explained|Eurofins|BLC Leather Technology Centre Ltd. August 2024. Available online: https://www.blcleathertech.com/news/life-cycle-assessment-categories-explained (accessed on 25 March 2025).

- Prenzel, T.M.; Hohmann, A.; Prescher, T.; Angerer, K.; Wehner, D.; Ilg, R.; von Reden, T.; Drechsler, K.; Albrecht, S. Bringing Light into the Dark—Overview of Environmental Impacts of Carbon Fiber Production and Potential Levers for Reduction. Polymers 2024, 16, 12. [Google Scholar] [CrossRef]

- Dér, A.; Dilger, N.; Kaluza, A.; Creighton, C.; Kara, S.; Varley, R.; Herrmann, C.; Thiede, S. Modelling and analysis of the energy intensity in polyacrylonitrile (PAN) precursor and carbon fibre manufacturing. J. Clean. Prod. 2021, 303, 127105. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Losa, R. Public policies on circular economy: A systematic review. Ecol. Econ. 2025, 228, 108452. [Google Scholar] [CrossRef]

| Material | Process | Output | Quantity (%) ±10% † | Avoided Virgin Material | Quality-Basis | Reference |

|---|---|---|---|---|---|---|

| Steel | Recycling | Recycled Steel | 87% | Virgin Steel | Structural Equivalence | [34,35] |

| Concrete | Recycling | Recycled Concrete | 60% | Virgin Concrete (<20 MPa) | Structural Equivalence | [36] |

| Glass Fiber Reinforced Polymer (GFRP) | Mechanical Recycling | Recovered GF | 42% | Virgin GF | Tensile Strength | [10,11] and Cement Kiln Mass Balance |

| Fine Powder | 58% | Construction Mortar | Functional Equivalence | |||

| Pyrolysis | Recovered GF | 58% | Virgin GF | Tensile Strength | ||

| Fine Powder | 14% | Construction Mortar | ||||

| Oil | 16% | Lubricant/Light Fuel Oil | Functional Equivalence/Heating Value | |||

| Gas | 12% | None Used To Offset Thermal Energy Demand | N/A | |||

| Solvolysis | Recovered GF | 61% | Virgin GF | Tensile Strength | ||

| Cement Co-Processing | Clinker | 56% | Clinker Raw Materials | Functional and Structural Equivalence | ||

| Carbon Fiber Reinforced Polymer (CFRP) | Mechanical Recycling | Recovered CF | 24% | Virgin GF | Tensile Strength | [12,37,38,39] |

| Fine Powder | 19% | Construction Mortar | Functional Equivalence | |||

| Coarse Fraction | 57% | No Landfill Waste | N/A | |||

| Pyrolysis | Recovered CF | 55% | Virgin CF | Variable Fiber Content | ||

| Oil | 28% | Lubricant/Light Fuel Oil | Heating Value | |||

| Gas | 1% | Natural Gas | Heating Value | |||

| Char | 12% | No Waste | N/A | |||

| Water | 3% | No Waste | N/A | |||

| Solvolysis | Recovered CF | 55% | Virgin CF | Variable Fiber Content | ||

| Recovered Epoxy Resin | 35% | Virgin Epoxy Resin | Functional Equivalence |

| Impact Category | Unit | Solvolysis with Solvent Recovery | Solvolysis Without Solvent Recovery | Landfilling |

|---|---|---|---|---|

| Fine Particulate Matter Formation | kg PM2.5 eq | −1.86 | 8.26 | 0.32 |

| Freshwater Ecotoxicity | kg 1,4-DCB | −42.41 | 126.99 | 20.10 |

| Global Warming Potential | kg eq | 1030.20 | 9165.94 | 96.11 |

| Land Use | crop eq | −8.05 | 22.45 | 1.59 |

| Water Consumption | −5.54 | 84.20 | 0.49 | |

| Freshwater Eutrophication | kg P eq | −0.20 | 1.00 | 0.08 |

| Human Carcinogenic Toxicity | kg 1,4-DCB | −46.91 | 189.64 | 8.02 |

| Human Non-Carcinogenic Toxicity | kg 1,4-DCB | −2120.07 | 1493.78 | 960.77 |

| Ionizing Radiation | kBq Co-60 eq | −34.57 | 60.69 | 11.00 |

| Marine Ecotoxicity | kg 1,4-DCB | −57.83 | 166.62 | 28.08 |

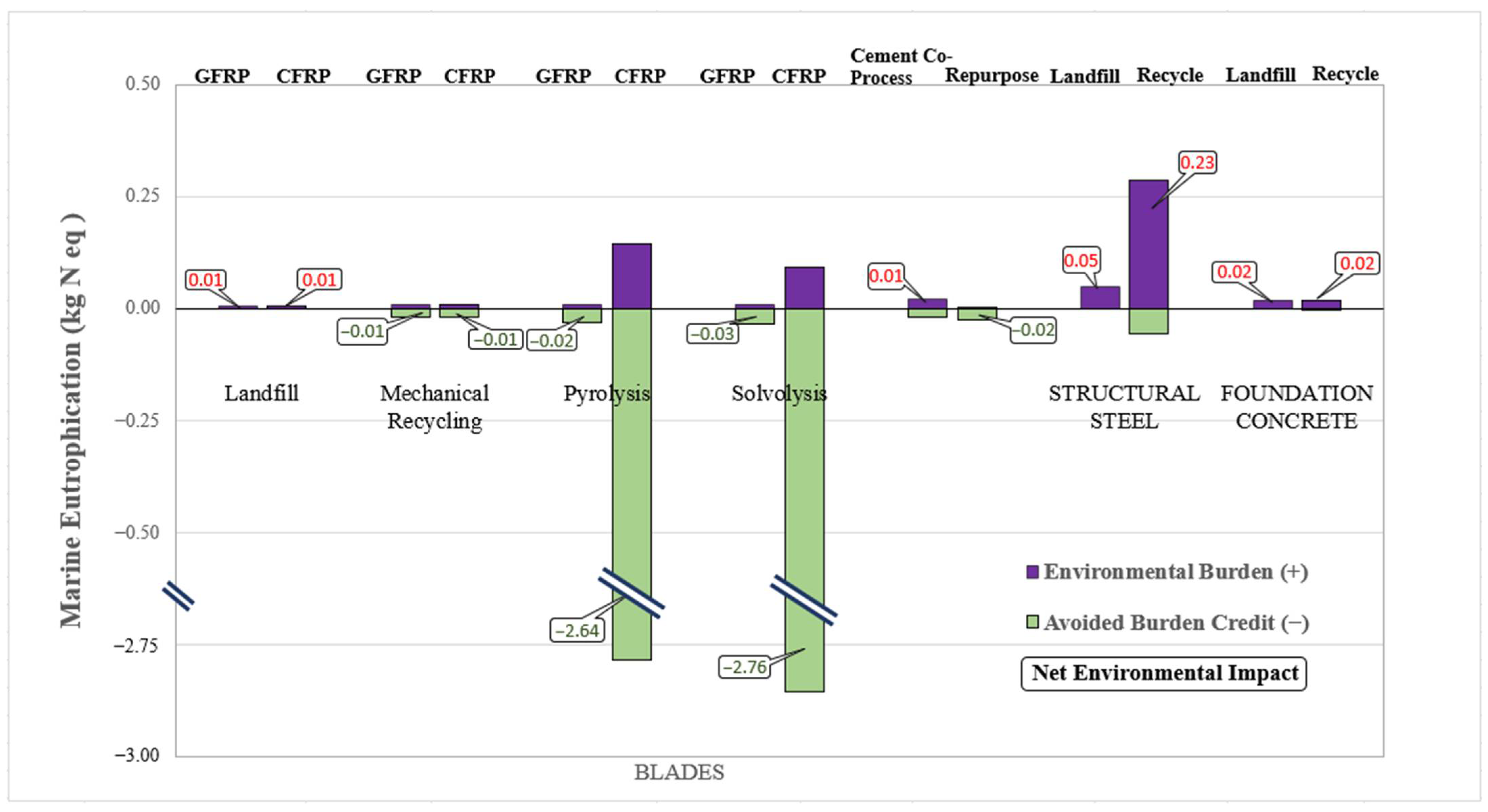

| Marine Eutrophication | kg N eq | −0.03 | 0.04 | 0.01 |

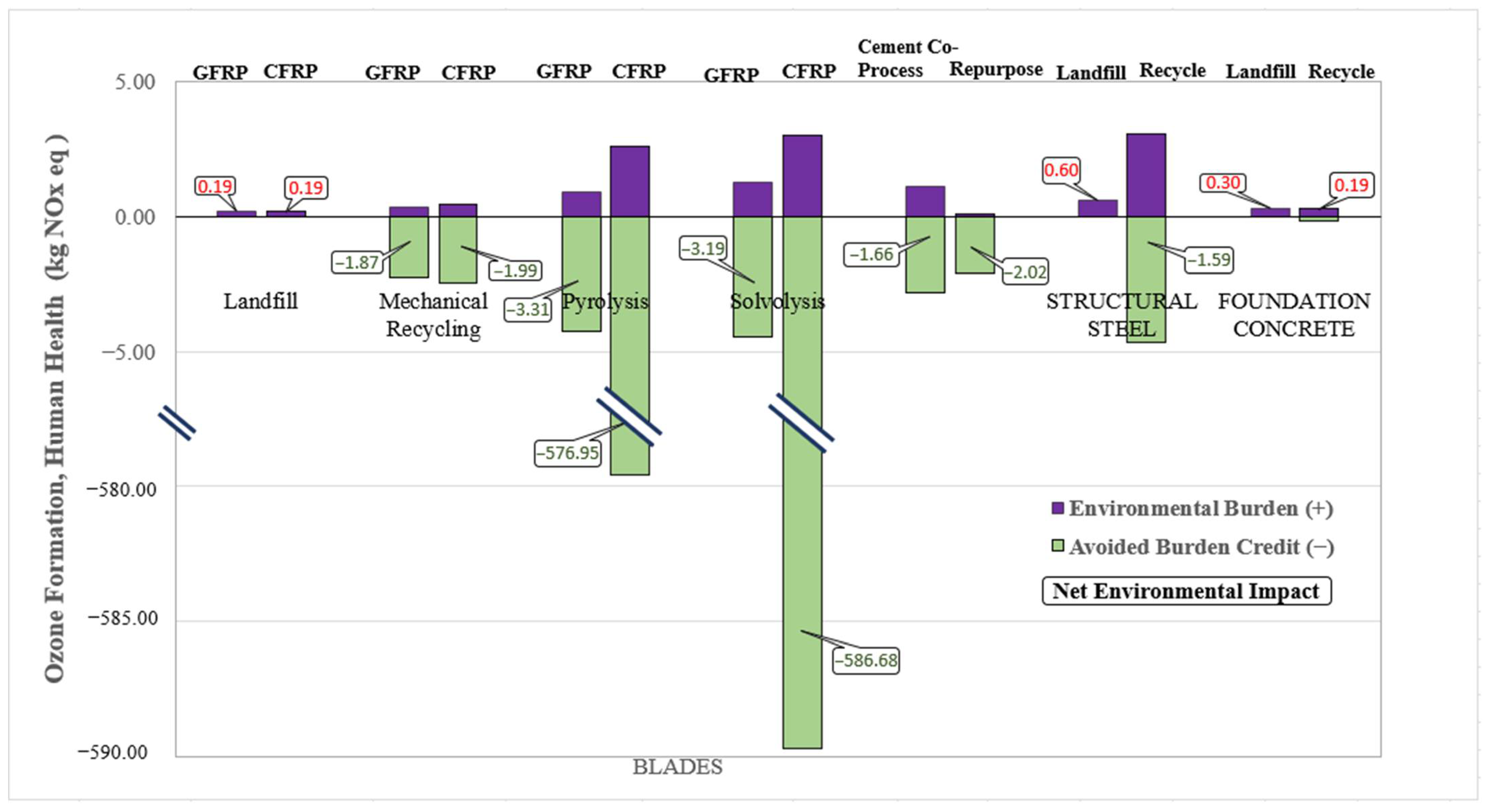

| Ozone Formation, Human Health | kg NOx eq | −3.19 | 18.00 | 0.19 |

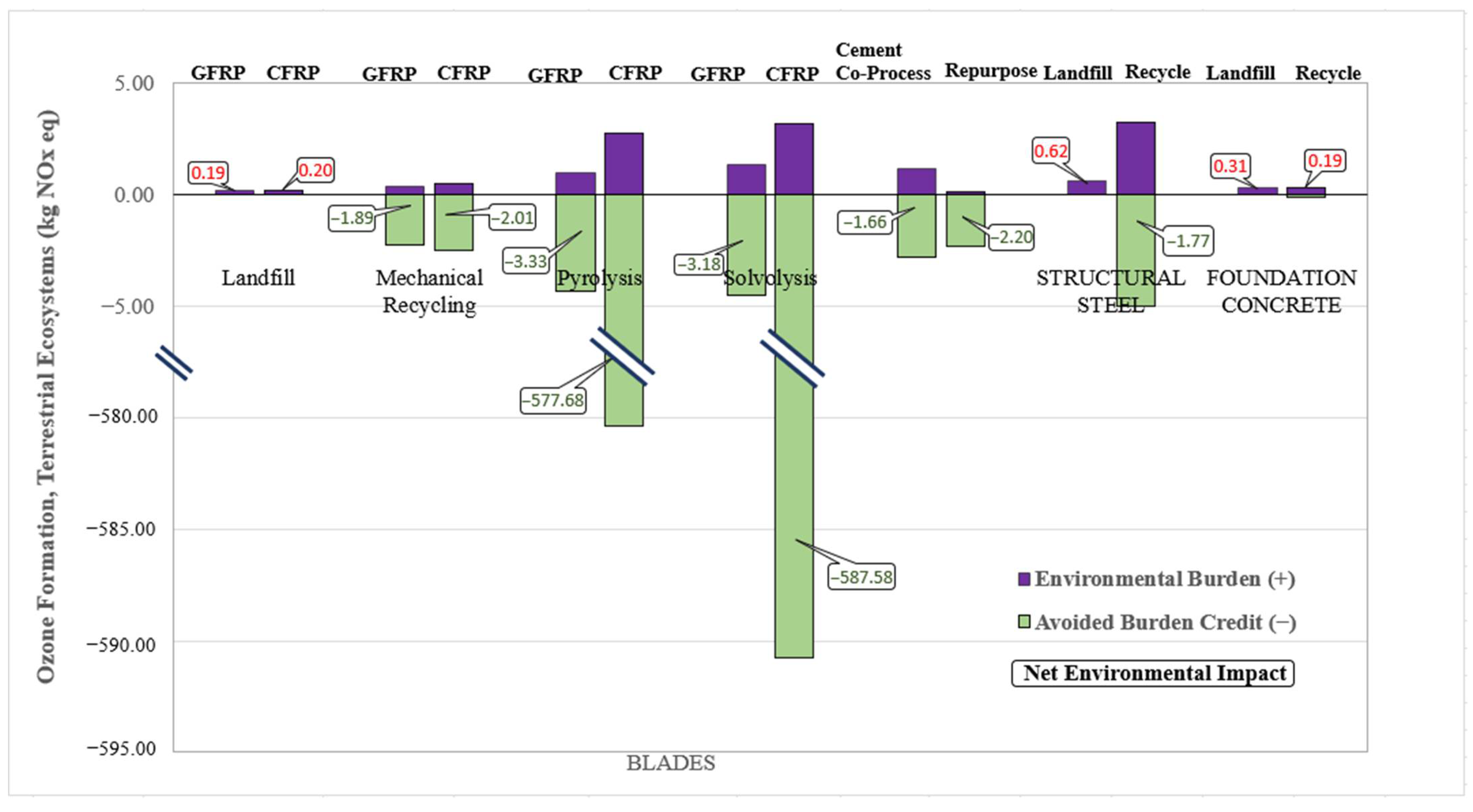

| Ozone Formation, Terrestrial Ecosystems | kg NOx eq | −3.18 | 21.06 | 0.19 |

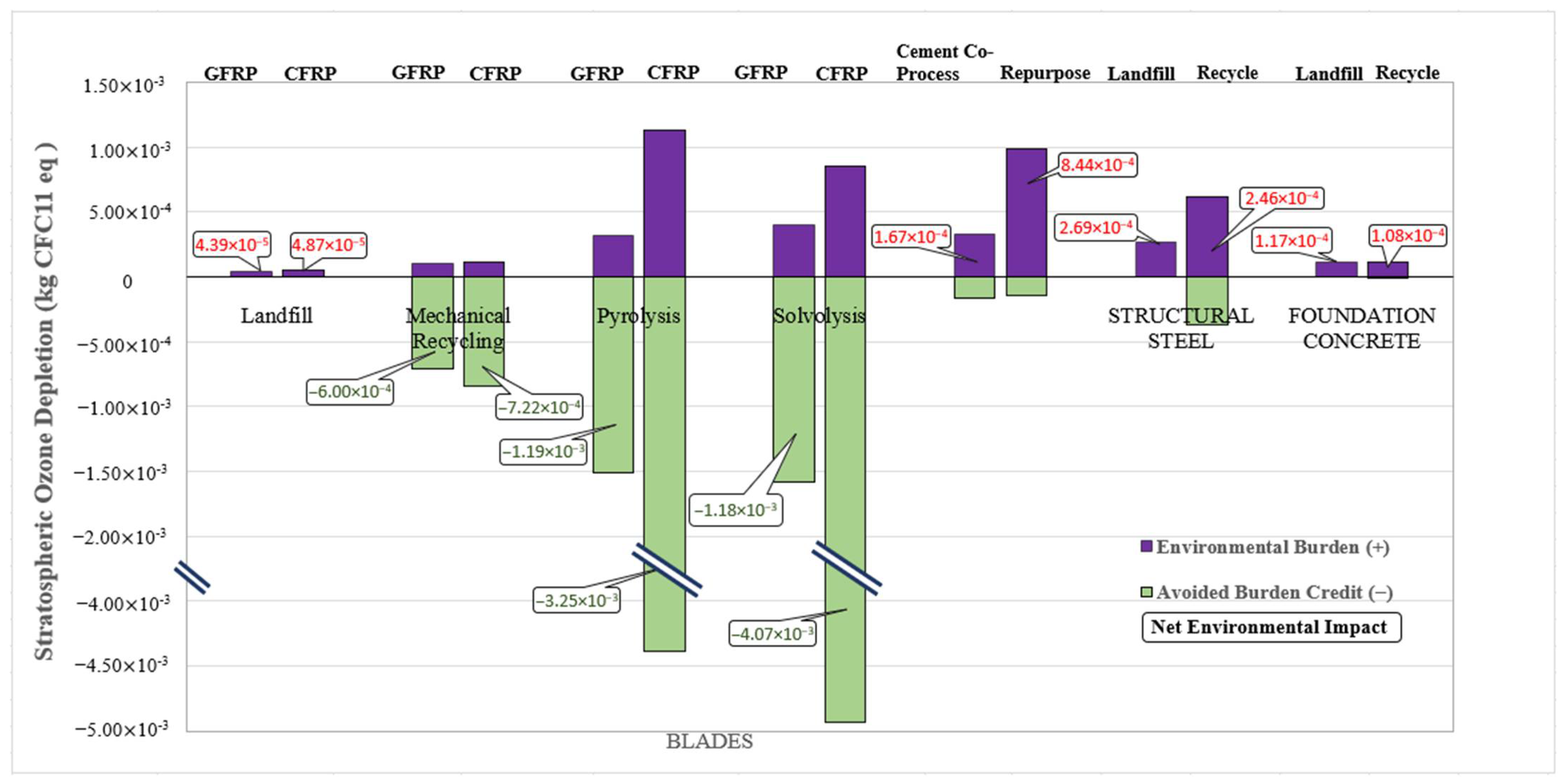

| Stratospheric Ozone Depletion | kg CFC11 eq | −1.18 × 10−3 | −4.43 × 10−4 | 4.39 × 10−5 |

| Terrestrial Acidification | kg SO2 eq | −4.53 | 23.46 | 0.23 |

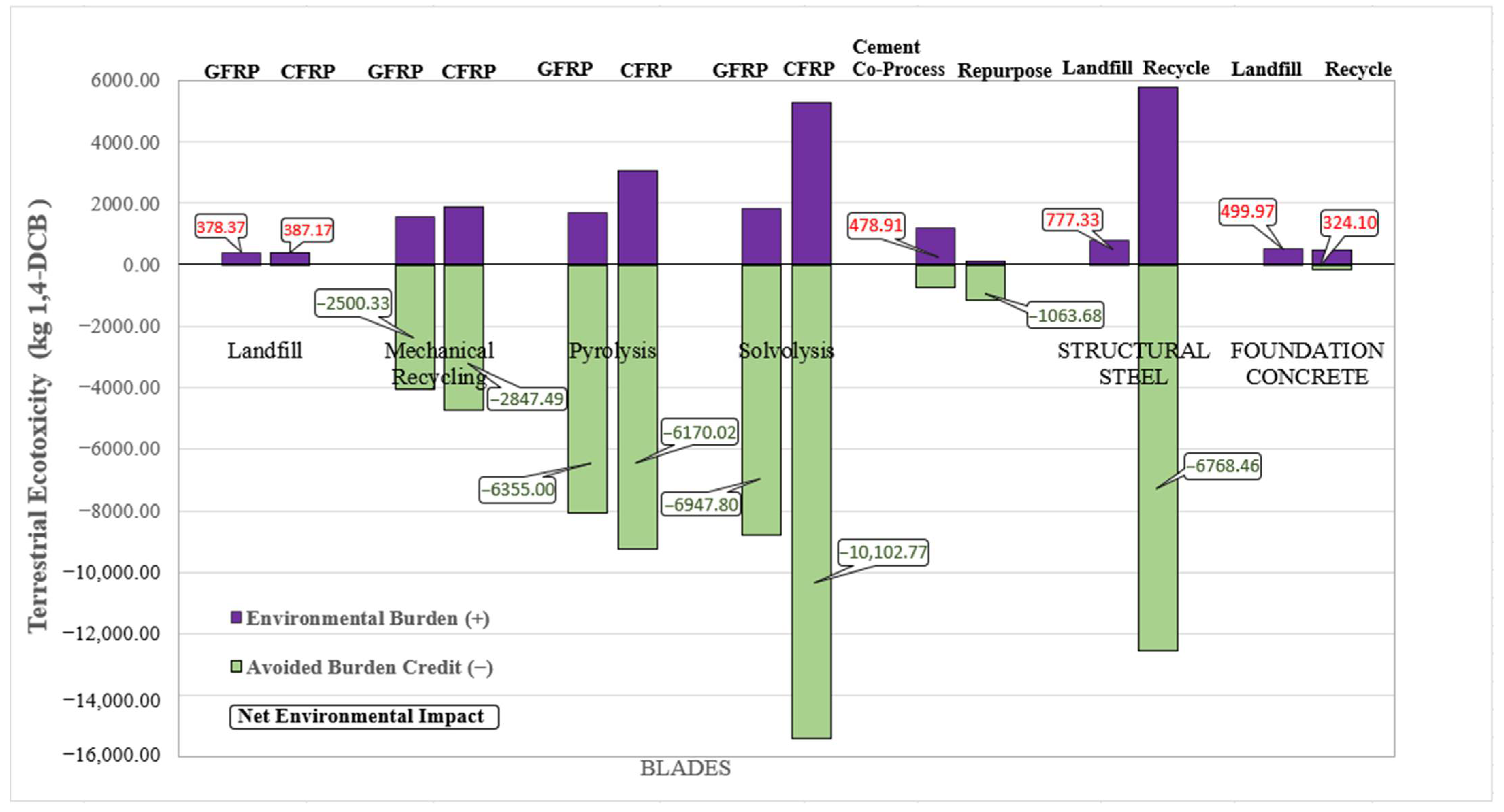

| Terrestrial Ecotoxicity | kg 1,4-DCB | −6947.80 | 11,183.19 | 378.37 |

| Impact Category | Unit | Net Impact for GF Blade | Net Impact for CF Blade | ||

|---|---|---|---|---|---|

| Use: Light Fuel Oil | Use: Lubricant | Use: Light Fuel Oil | Use: Lubricant | ||

| Fine particulate matter formation | kg PM2.5 eq | −1.88 | −2.12 | −61.04 | −61.65 |

| Freshwater ecotoxicity | kg 1,4-DCB | −39.30 | −47.60 | −26.85 | −43.78 |

| Global warming | kg eq | 793.20 | −651.00 | −11,150.22 | −11,475.28 |

| Land use | crop eq | −9.86 | −12.13 | −24.44 | −29.29 |

| Water consumption | −5.60 | −7.14 | −53.87 | −56.98 | |

| Freshwater eutrophication | kg P eq | −0.18 | −0.22 | 1.56 | 1.47 |

| Human carcinogenic toxicity | kg 1,4-DCB | −45.13 | −54.08 | −46.75 | −65.91 |

| Human non-carcinogenic toxicity | kg 1,4-DCB | −1,923.65 | −2092.67 | 130.97 | −219.07 |

| Ionizing radiation | kBq Co-60 eq | −33.91 | −41.67 | 232.49 | 214.29 |

| Marine ecotoxicity | kg 1,4-DCB | −53.73 | −64.69 | −35.40 | −57.95 |

| Marine eutrophication | kg N eq | −2.39 × 10−2 | −2.71 × 10−2 | −2.64 | −2.64 |

| Ozone formation, human health | kg NOx eq | −3.31 | −4.18 | −576.95 | −578.86 |

| Ozone formation, terrestrial ecosystems | kg NOx eq | −3.33 | −4.55 | −577.68 | −580.28 |

| Stratospheric ozone depletion | kg CFC11 eq | −1.19 × 10−3 | −1.24 × 10−3 | −3.25 × 10−3 | −3.43 × 10−3 |

| Terrestrial acidification | kg SO2 eq | −4.76 | −5.26 | −222.41 | −223.78 |

| Terrestrial ecotoxicity | kg 1,4-DCB | −6,355.00 | −7055.3 | −6170.02 | −7701.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kabir, M.; Young, M.H.; Gülen, G.; Singh, S. Assessing Avoided Burden and Net Environmental Impact by Recycling and Repurposing of Retiring Wind Turbines. Environments 2025, 12, 396. https://doi.org/10.3390/environments12110396

Kabir M, Young MH, Gülen G, Singh S. Assessing Avoided Burden and Net Environmental Impact by Recycling and Repurposing of Retiring Wind Turbines. Environments. 2025; 12(11):396. https://doi.org/10.3390/environments12110396

Chicago/Turabian StyleKabir, Mrittika, Michael H. Young, Gürcan Gülen, and Shweta Singh. 2025. "Assessing Avoided Burden and Net Environmental Impact by Recycling and Repurposing of Retiring Wind Turbines" Environments 12, no. 11: 396. https://doi.org/10.3390/environments12110396

APA StyleKabir, M., Young, M. H., Gülen, G., & Singh, S. (2025). Assessing Avoided Burden and Net Environmental Impact by Recycling and Repurposing of Retiring Wind Turbines. Environments, 12(11), 396. https://doi.org/10.3390/environments12110396