Reducing Methane, Carbon Dioxide, and Ammonia Emissions from Stored Pig Slurry Using Bacillus-Biological Additives and Aeration

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Biological Additive

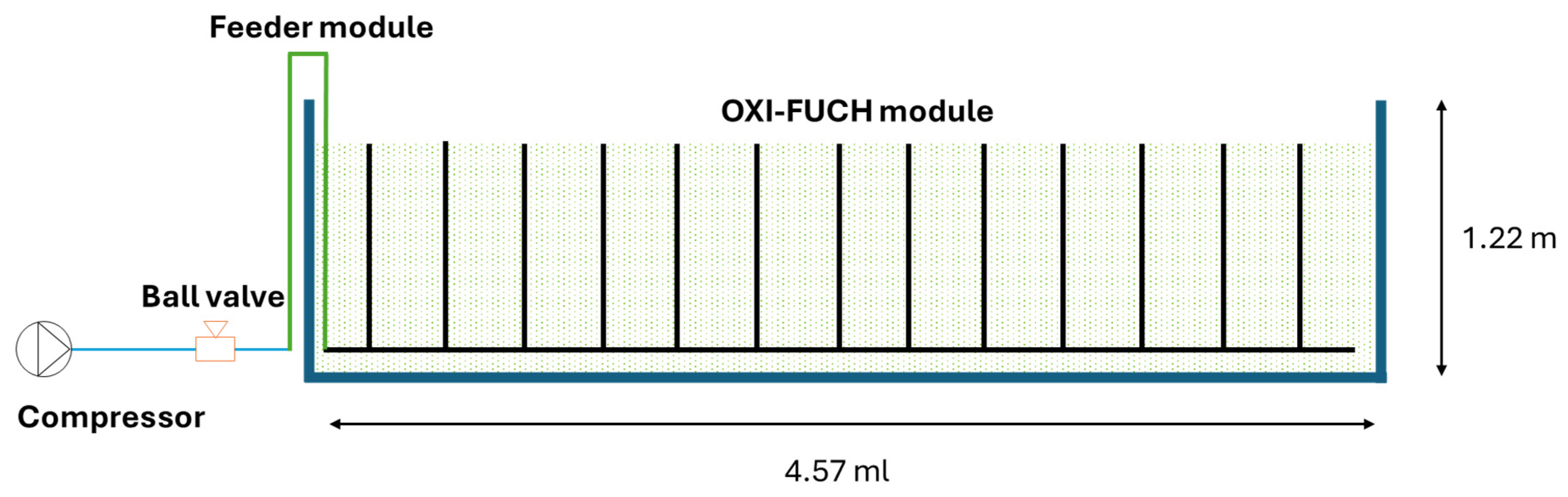

2.3. OXI-FUCH Aeration System

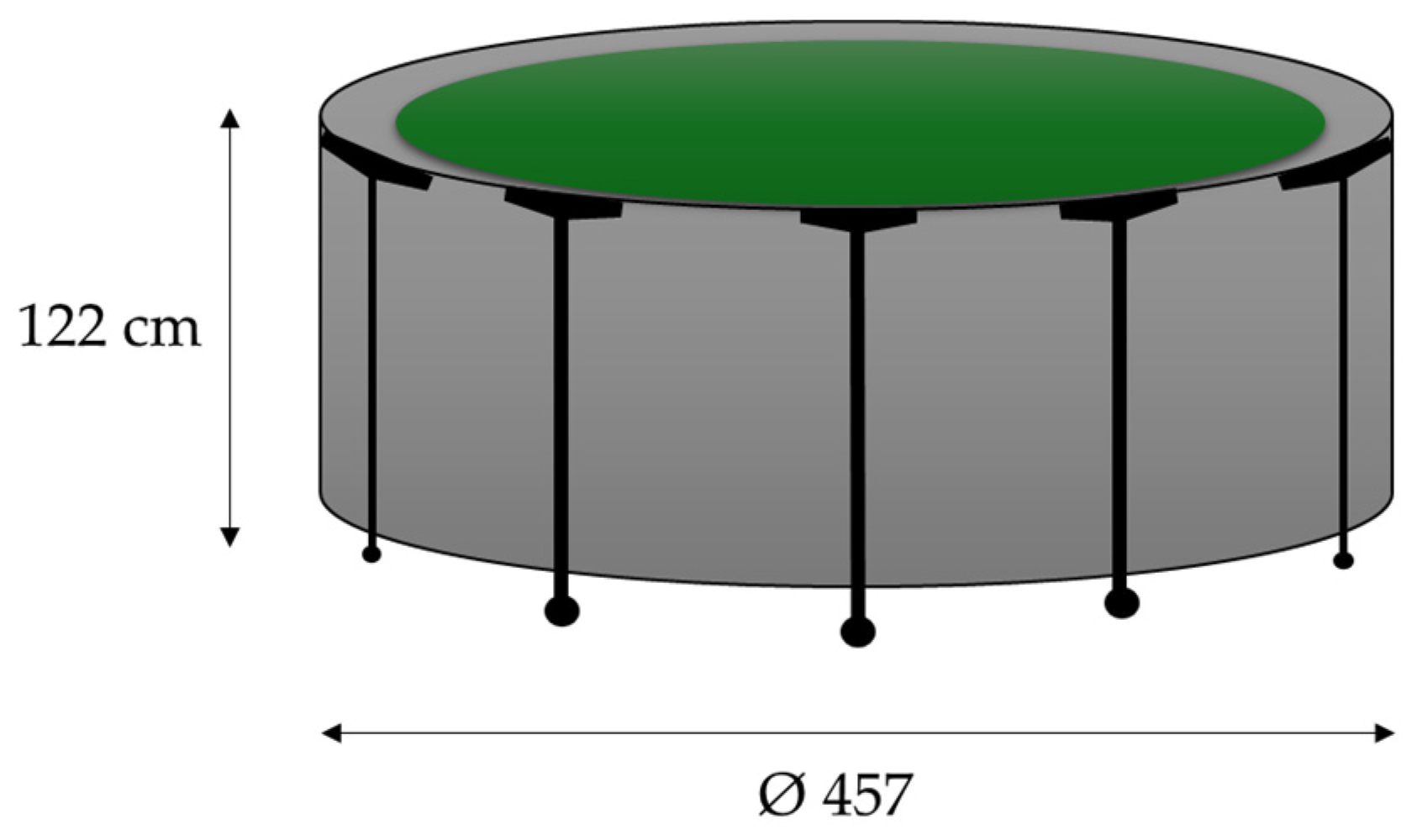

2.4. Dynamic Chamber

2.5. Gases Sampling Frequency

2.6. Liquid Pig Slurry Sampling and Analysis

2.7. Statistical Analysis

3. Results

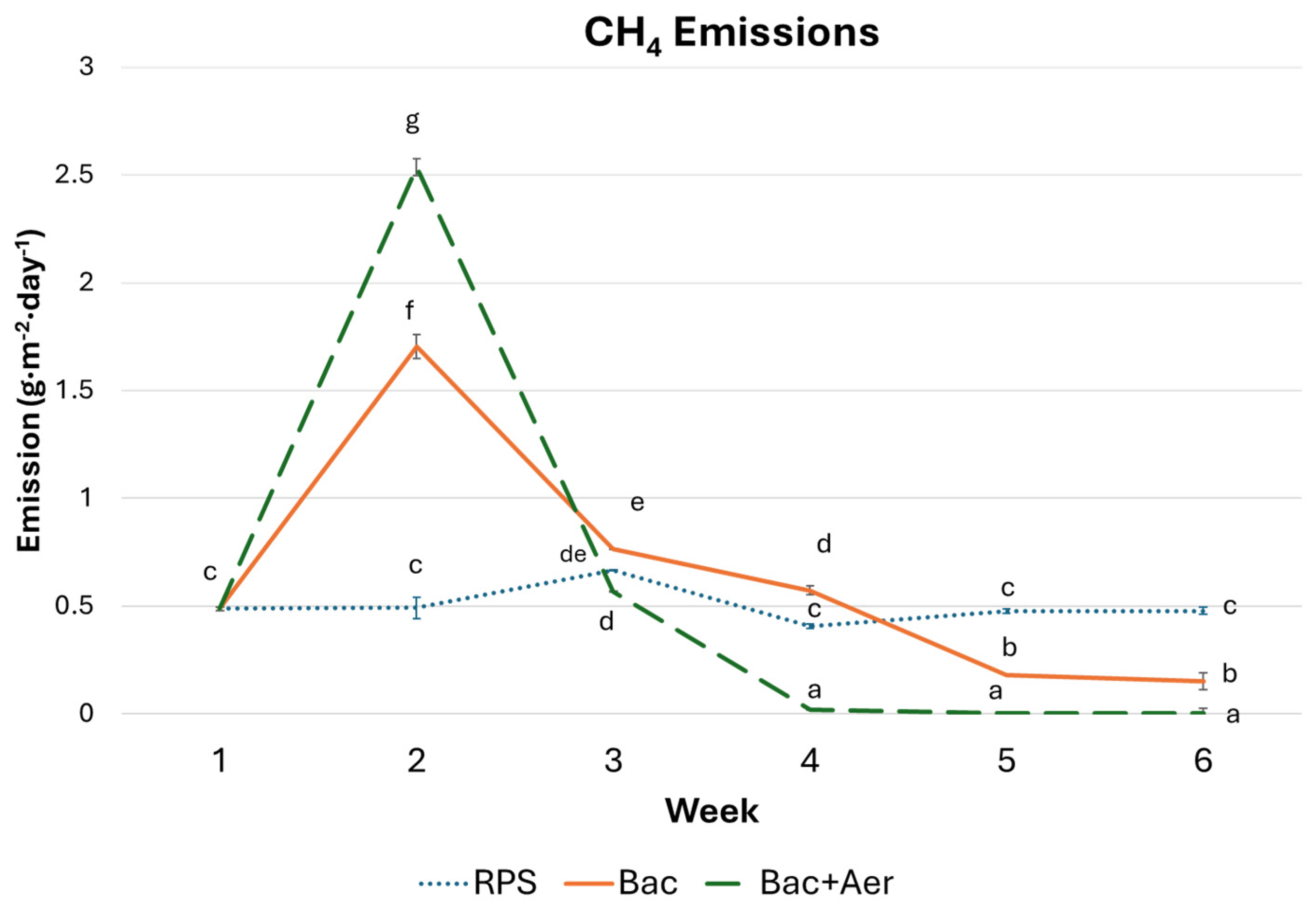

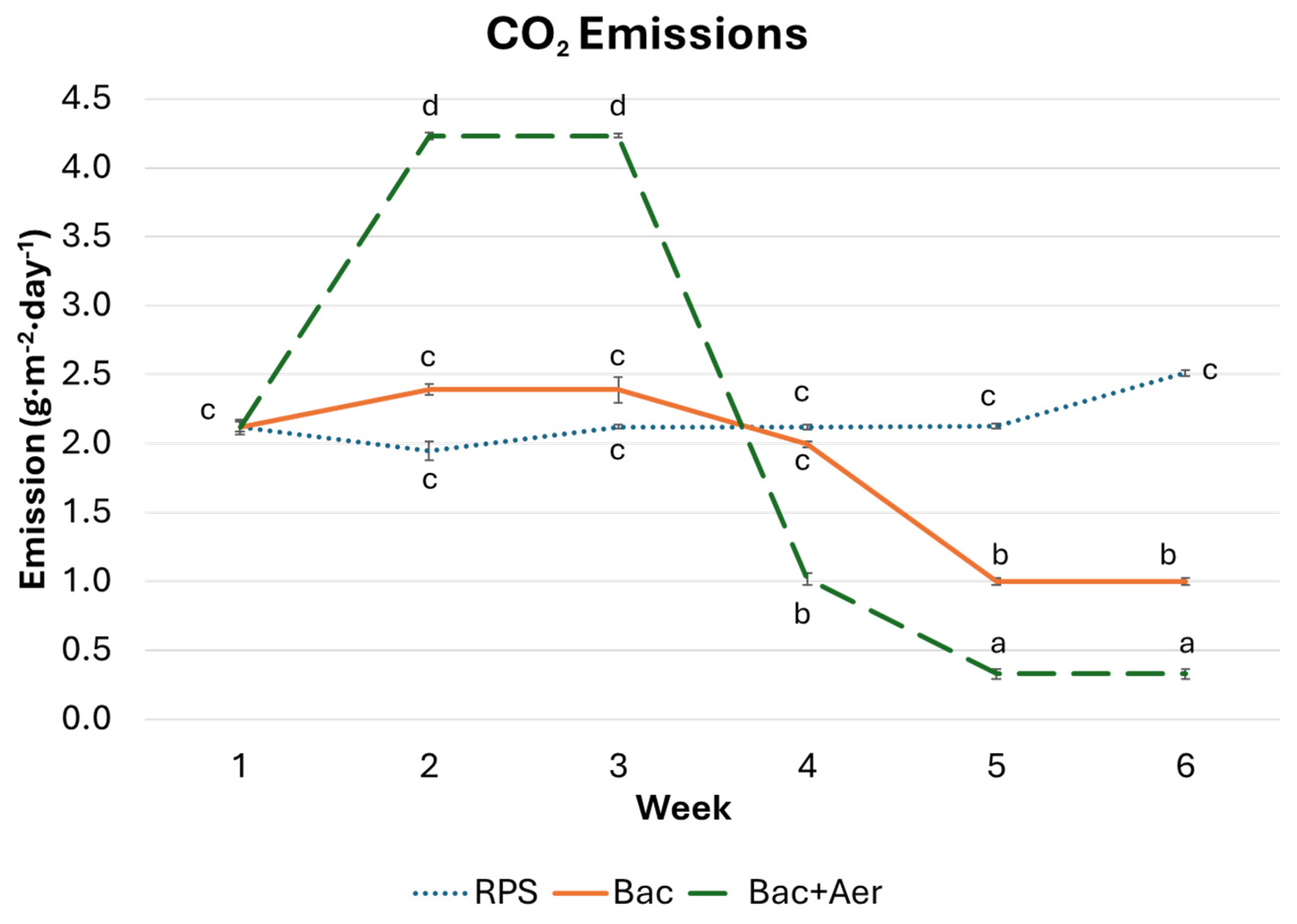

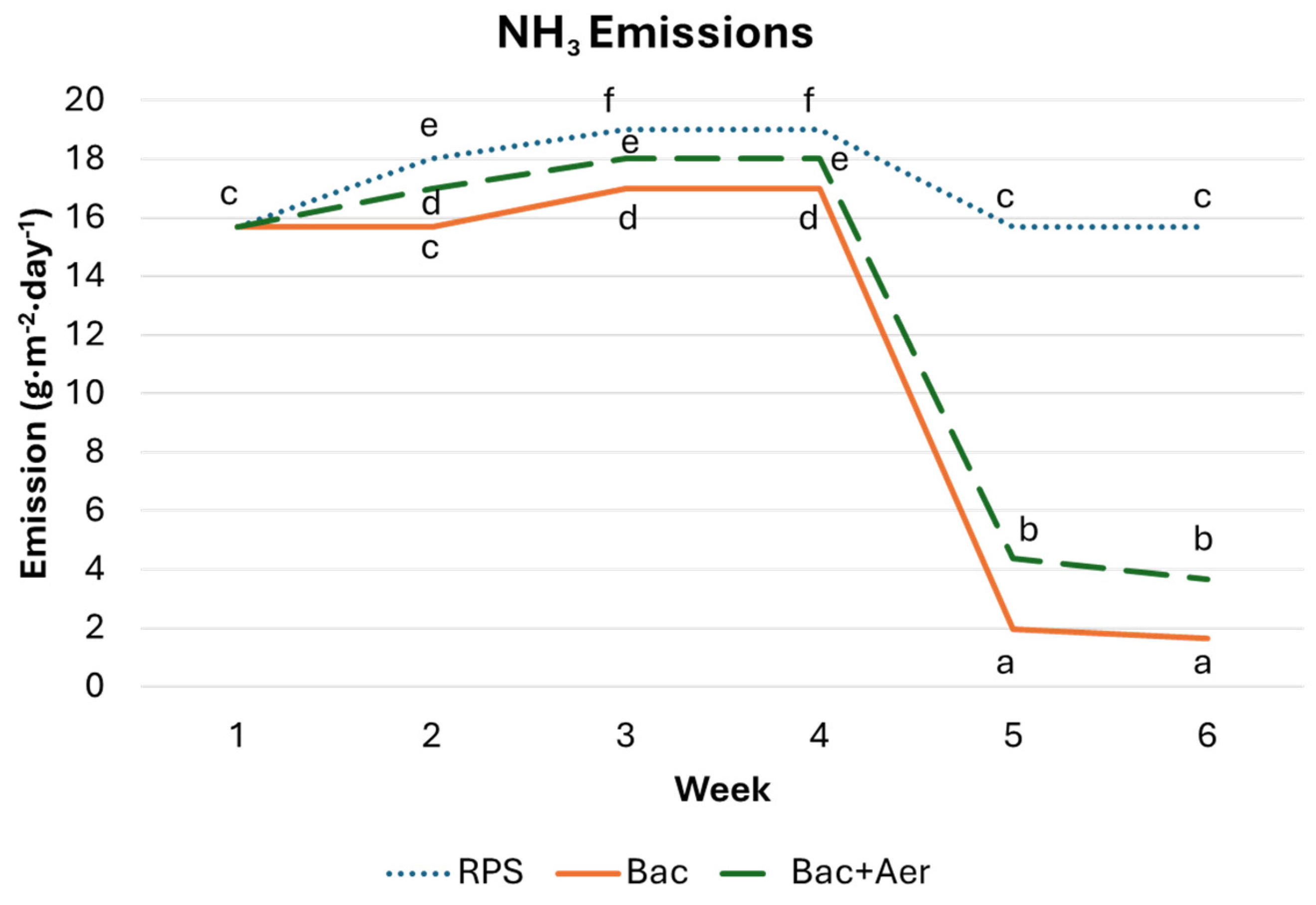

3.1. Greenhouse Gas Emissions and Ammonia

3.2. Untreated and Treated Pig Slurry Analysis

4. Discussion

4.1. Methane (CH4) Emissions

4.2. Carbon Dioxide (CO2) Emissions

4.3. Ammonia (NH3) Emissions

4.4. Compositions of the Treated and Control Raw Pig Slurry

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bayo, J.; Gómez-López, M.D.; Faz, A.; Caballero, A. Environmental Assessment of Pig Slurry Management after Local Characterization and Normalization. J. Clean. Prod. 2012, 32, 227–235. [Google Scholar] [CrossRef]

- Ministerio de Agricultura, Pesca y Alimentación. “Estadística de Ganado Porcino. Resultados” Edita: © Ministerio de Agricultura, Pesca y Alimentación; NIPO: 003230290, Resultados de las Encuestas de Ganado Porcino; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2023.

- Dennehy, C.; Lawlor, P.G.; Jiang, Y.; Gardiner, G.E.; Xie, S.; Nghiem, L.D.; Zhan, X. Greenhouse Gas Emissions from Different Pig Manure Management Techniques: A Critical Analysis. Front. Environ. Sci. Eng. 2017, 11, 11. [Google Scholar] [CrossRef]

- Varma, V.S.; Parajuli, R.; Scott, E.; Canter, T.; Lim, T.T.; Popp, J.; Thoma, G. Dairy and Swine Manure Management—Challenges and Perspectives for Sustainable Treatment Technology. Sci. Total Environ. 2021, 778, 146319. [Google Scholar] [CrossRef]

- Kerr, B.J.; Trabue, S.L.; Andersen, D.S.; Van Weelden, M.B.; Pepple, L.M. Dietary Composition and Particle Size Effects on Swine Manure Characteristics and Gas Emissions. J. Environ. Qual. 2020, 49, 1384–1395. [Google Scholar] [CrossRef] [PubMed]

- Antezana, W.; De Blas, C.; García-Rebollar, P.; Rodríguez, C.; Beccaccia, A.; Ferrer, P.; Cerisuelo, A.; Moset, V.; Estellés, F.; Cambra-López, M.; et al. Composition, Potential Emissions and Agricultural Value of Pig Slurry from Spanish Commercial Farms. Nutr. Cycl. Agroecosystems 2016, 104, 159–173. [Google Scholar] [CrossRef]

- U.S Foreign Agricultural Service. Department of agriculture Production—Pork /Top Producing Countries; U.S Foreign Agricultural Service: Washington, DC, USA, 2024.

- Provolo, G.; Manuli, G.; Finzi, A.; Lucchini, G.; Riva, E.; Sacchi, G.A. Effect of Pig and Cattle Slurry Application on Heavy Metal Composition of Maize Grown on Different Soils. Sustainability 2018, 10, 2684. [Google Scholar] [CrossRef]

- El Bied, O.; García-Valero, A.; Fechtali, T.; Faz, Á.; Acosta, J.A. Purification Performance of Filtration Process for Pig Slurry Using Marine Sands, Silty Loam Soils, Fly Ash and Zeolite. Agronomy 2021, 11, 1608. [Google Scholar] [CrossRef]

- Chojnacka, K.; Moustakas, K.; Witek-Krowiak, A. Bio-Based Fertilizers: A Practical Approach towards Circular Economy. Bioresour. Technol. 2020, 295, 122223. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Y.; Wang, S.; Wang, Z.; Liu, Y.; Hu, Z.; Zhan, X. Environmental Sustainability Assessment of Pig Manure Mono- and Co-Digestion and Dynamic Land Application of the Digestate. Renew. Sustain. Energy Rev. 2021, 137, 110476. [Google Scholar] [CrossRef]

- Antoneli, V.; Mosele, A.C.; Bednarz, J.A.; Pulido-Fernández, M.; Lozano-Parra, J.; Keesstra, S.D.; Rodrigo-Comino, J. Effects of Applying Liquid Swine Manure on Soil Quality and Yield Production in Tropical Soybean Crops (Paraná, Brazil). Sustainability 2019, 11, 3898. [Google Scholar] [CrossRef]

- Houghton, J.T.; Ding, Y.D.J.G.; Griggs, D.J. Climate Change 2001: The Scientific Basis; Cambridge University Press: Cambridge, UK, 2001. [Google Scholar]

- Degré, A.; Verhève, D.; Debouche, C. Émissions Gazeuses En Élevage Porcin et Modes de Réduction: Revue Bibliographique. Biotechnol. Agron. Soc. Environ. 2001, 5, 135–143. [Google Scholar]

- Directive 91/676/EEC. Concerning the Protection of Waters against Pollution Caused by Nitrates from Agricultural Sources. Off. J. Eur. Communities L 1991, 375, 1–8. [Google Scholar]

- Water Framework Directive (2000/60/EC) Water Framework Directive (2000/60/EC). Available online: https://eur-lex.europa.eu/eli/dir/2000/60/oj (accessed on 23 May 2024).

- Guía de Mejores Técnicas Disponibles del Sector Porcino 2017. pp. 1–146. Available online: https://www.mapa.gob.es/es/ganaderia/publicaciones/guiamtdssectorporcino_tcm30-105316.pdf (accessed on 23 May 2024).

- Company, E.; Farrés, M.; Colprim, J.; Magrí, A. Exploring the Recovery of Potassium-Rich Struvite after a Nitrification-Denitrification Process in Pig Slurry Treatment. Sci. Total Environ. 2022, 847, 157574. [Google Scholar] [CrossRef] [PubMed]

- Schott, C.; Cunha, J.R.; van der Weijden, R.D.; Buisman, C. Phosphorus Recovery from Pig Manure: Dissolution of Struvite and Formation of Calcium Phosphate Granules during Anaerobic Digestion with Calcium Addition. Chem. Eng. J. 2022, 437, 135406. [Google Scholar] [CrossRef]

- El, O.; Kessler, M.; Ang, M.; Fechtali, T.; Cano, A.F.; Acosta, J.A. Turbidity and Chemical Oxygen Demand Reduction from Pig Slurry through a Coagulation Flocculation Process. Agronomy 2021, 11, 2158. [Google Scholar] [CrossRef]

- Goldfarb, J.L.; Hubble, A.H.; Ma, Q.; Volpe, M.; Severini, G.; Andreottola, G.; Fiori, L. Valorization of Cow Manure via Hydrothermal Carbonization for Phosphorus Recovery and Adsorbents for Water Treatment. J. Environ. Manag. 2022, 308, 114561. [Google Scholar] [CrossRef] [PubMed]

- El bied, O.; Turbí, M.A.T.; García-Valero, A.; Cano, Á.F.; Acosta, J.A. Mitigating Ammonia, Methane, and Carbon Dioxide Emissions from Stored Pig Slurry Using Chemical and Biological Additives. Water 2023, 15, 4185. [Google Scholar] [CrossRef]

- Fangueiro, D.; Hjorth, M.; Gioelli, F. Acidification of Animal Slurry—A Review. J. Environ. Manag. 2015, 149, 46–56. [Google Scholar] [CrossRef] [PubMed]

- Hjorth, M.; Christensen, K.V.; Christensen, M.L.; Sommer, S.G. Solid—Liquid Separation of Animal Slurry in Theory and Practice. A Review. Agron. Sustain. Dev. 2010, 30, 153–180. [Google Scholar] [CrossRef]

- Møller, H.B.; Lund, I.; Sommer, S.G. Solid-Liquid Separation of Livestock Slurry: Efficiency and Cost. Bioresour. Technol. 2000, 74, 223–229. [Google Scholar] [CrossRef]

- Loyon, L.; Guiziou, F.; Béline, F.; Peu, P. Gaseous Emissions (NH3, N2O, CH4, CO2) during Pig Slurry Biological Aerobic Treatment and Treatment by-Product Storages. Int. Congr. Ser. 2006, 1293, 299–302. [Google Scholar] [CrossRef]

- Möller, K.; Müller, T. Effects of Anaerobic Digestion on Digestate Nutrient Availability and Crop Growth: A Review. Eng. Life Sci. 2012, 12, 242–257. [Google Scholar] [CrossRef]

- Lymperatou, A.; Rasmussen, N.B.; Gavala, H.N.; Skiadas, I.V. Improving the Anaerobic Digestion of Swine Manure through an Optimized Ammonia Treatment: Process Performance, Digestate and Techno-Economic Aspects. Energies 2021, 14, 787. [Google Scholar] [CrossRef]

- Petersen, S.O.; Sommer, S.G.; Beline, F.; Burton, C.; Dach, J.; Dourmad, J.Y.; Leip, A.; Misselbrook, T.H.; Nicholson, F.; Poulsen, H.D.; et al. Recycling of livestock manure in a whole-farm perspective. Livest. Sci. 2007, 112, 180–191. [Google Scholar] [CrossRef]

- Rajasulochana, P.; Preethy, V. Comparison on Efficiency of Various Techniques in Treatment of Waste and Sewage Water—A Comprehensive Review. Resour. Effic. Technol. 2016, 2, 175–184. [Google Scholar] [CrossRef]

- Provolo, G.; Finzi, A.; Perazzolo, F.; Mattachini, G.; Riva, E. Effect of a Biological Additive on Nitrogen Losses from Pig Slurry during Storage. J. Environ. Qual. 2016, 45, 1460–1465. [Google Scholar] [CrossRef]

- Petersen, S.O.; Blanchard, M.; Chadwick, D.; Del Prado, A.; Edouard, N.; Mosquera, J.; Sommer, S.G. Manure Management for Greenhouse Gas Mitigation. Animal 2013, 7, 266–282. [Google Scholar] [CrossRef] [PubMed]

- VERA. Verification of Environmental Technologies for Agricultural Production Vera Test Protocol Covers and Other Mitigation Technologies for Reduction of Gaseous Emissions from Stored Manure; VERA: Brondby, Denmark, 2018. [Google Scholar]

- Akkale, C. Production, Optimization and Partial Characterization of Alkaline Protease from Bacillus subtilis spp. subtilis NRRL B-3384 and B-3387. Hittite J. Sci. Eng. 2023, 10, 135–144. [Google Scholar] [CrossRef]

- Sekhon, A.; Dahiya, N.; Tiwari, R.; Hoondal, G. Production of Extracellular Lipase by Bacillus Megaterium AKG-1 in Submerged Fermentation. Indian J. Biotechnol. 2006, 5, 179–183. [Google Scholar]

- Jellouli, K.; Ghorbel-Bellaaj, O.; Ayed, H.B.; Manni, L.; Agrebi, R.; Nasri, M. Alkaline-Protease from Bacillus Licheniformis MP1: Purification, Characterization and Potential Application as a Detergent Additive and for Shrimp Waste Deproteinization. Process Biochem. 2011, 46, 1248–1256. [Google Scholar] [CrossRef]

- Guleria, S.; Walia, A.; Chauhan, A.; Shirkot, C.K. Molecular Characterization of Alkaline Protease of Bacillus Amyloliquefaciens SP1 Involved in Biocontrol of Fusarium oxysporum. Int. J. Food Microbiol. 2016, 232, 134–143. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Kan, X.; Yan, H.; Wang, D. Characterization of Extracellular Cellulose-Degrading Enzymes from Bacillus thuringiensis Strains. Electron. J. Biotechnol. 2012, 15, 2. [Google Scholar] [CrossRef]

- Awwa, W. APHA, Standard Methods for the Examination of Water and Wastewater, American Public Health Association; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Nemali, K.; University, P. Ji-Qin Ni and Albert Heber-Purdue Agricultural and Biological Engineering. 2018. Available online: https://www.extension.purdue.edu/extmedia/ABE/ABE-161-W.pdf (accessed on 23 May 2024).

- Wheeler, E.F.; Adviento-Borbe, M.A.A.; Brandt, R.C.; Topper, P.A.; Topper, D.A.; Elliot, H.A.; Graves, R.E.; Hristov, A.N.; Ishler, V.A.; Bruns, M.A. Amendments for Short-and Medium-Term Mitigation of Odor Emissions from Dairy Manure; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2001. [Google Scholar]

- Bastami, M.S.B.; Jones, D.L.; Chadwick, D.R. Reduction of Methane Emission during Slurry Storage by the Addition of Effective Microorganisms and Excessive Carbon Source from Brewing Sugar. J. Environ. Qual. 2016, 45, 2016–2022. [Google Scholar] [CrossRef] [PubMed]

- Kavanagh, I.; Fenton, O.; Healy, M.G.; Burchill, W.; Lanigan, G.J.; Krol, D.J. Mitigating Ammonia and Greenhouse Gas Emissions from Stored Cattle Slurry Using Agricultural Waste, Commercially Available Products and a Chemical Acidifier. J. Clean. Prod. 2021, 294, 126251. [Google Scholar] [CrossRef]

- Owusu-Twum, M.Y.; Polastre, A.; Subedi, R.; Santos, A.S.; Mendes Ferreira, L.M.; Coutinho, J.; Trindade, H. Gaseous Emissions and Modification of Slurry Composition during Storage and after Field Application: Effect of Slurry Additives and Mechanical Separation. J. Environ. Manag. 2017, 200, 416–422. [Google Scholar] [CrossRef]

- Amon, B.; Kryvoruchko, V.; Amon, T.; Zechmeister-Boltenstern, S. Methane, Nitrous Oxide and Ammonia Emissions during Storage and after Application of Dairy Cattle Slurry and Influence of Slurry Treatment. Agric. Ecosyst. Environ. 2006, 112, 153–162. [Google Scholar] [CrossRef]

- Husted, S.; Jensen, L.S.; Jørgensen, S.S. Reducing Ammonia Loss from Cattle Slurry by the Use of Acidifying Additives: The Role of the Buffer System. J. Sci. Food Agric. 1991, 57, 335–349. [Google Scholar] [CrossRef]

- Hamood, A.; Mao, X.; Jaworski, A.J. Two-Stage Thermoacoustic Electricity Generator for Waste Heat Recovery. In World Congress on Engineering; International Association of Engineers: Hongkong, China, 2006. [Google Scholar]

- Ishak, M.A.M.; Ani, A.Y.; Syed Ismail, S.N.A.; Ali, M.L.M.; Ahmad, R. Conversion of Biomass to Biofuels. In Value-Chain of Biofuels: Fundamentals, Technology, and Standardization; Elsevier: Amsterdam, The Netherlands, 2021; pp. 49–67. ISBN 9780128243886. [Google Scholar]

- Okoro, O.V.; Sun, Z.; Birch, J. Meat Processing Waste as a Potential Feedstock for Biochemicals and Biofuels—A Review of Possible Conversion Technologies. J. Clean. Prod. 2017, 142, 1583–1608. [Google Scholar] [CrossRef]

- Calvet, S.; Hunt, J.; Misselbrook, T.H. Low Frequency Aeration of Pig Slurry Affects Slurry Characteristics and Emissions of Greenhouse Gases and Ammonia. Biosyst. Eng. 2017, 159, 121–132. [Google Scholar] [CrossRef]

- Mostafa, E.; Selders, A.; Buescher, W. Aeration of Pig Slurry Affects Ammonia and Greenhouse Gases Emissions. Int. J. Environ. Sci. Technol. 2019, 16, 7327–7338. [Google Scholar] [CrossRef]

- Dettmer, A.; Coelho Cavalheiro, J.; Cavalli, E.; Misturini Rossi, D.; De Souza Gusatti, C.; Záchia Ayub, M.A.; Gutterres, M. Optimization of the Biotechnological Process for Hide Unhairing in Substitution of Toxic Sulfides. Chem. Eng. Technol. 2012, 35, 803–810. [Google Scholar] [CrossRef]

- Franke-Whittle, I.H.; Confalonieri, A.; Insam, H.; Schlegelmilch, M.; Körner, I. Changes in the Microbial Communities during Co-Composting of Digestates. Waste Manag. 2014, 34, 632–641. [Google Scholar] [CrossRef] [PubMed]

- Merlin Christy, P.; Gopinath, L.R.; Divya, D. A Review on Anaerobic Decomposition and Enhancement of Biogas Production through Enzymes and Microorganisms. Renew. Sustain. Energy Rev. 2014, 34, 167–173. [Google Scholar] [CrossRef]

- Alam, M.J.; Islam, M.; Jeon, C.O.; Lee, K.C.; Kim, S.H.; Yang, C.J.; Kabir, M.E.; Lee, S.S. In Vitro Assessment of Probiotic Potential of Selected Bacteria Isolated from Pig Faeces with Potential Application of Odour Reduction. Int. J. Vet. Sci. Med. 2021, 9, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Prenafeta-Boldú, F.X.; Fernández, B.; Viñas, M.; Lizardo, R.; Brufau, J.; Owusu-Asiedu, A.; Walsh, M.C.; Awati, A. Effect of Bacillus Spp. Direct-Fed Microbial on Slurry Characteristics and Gaseous Emissions in Growing Pigs Fed with High Fibre-Based Diets. Animal 2017, 11, 209–218. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.R.; Han, J.K.; Choi, Y.J.; Nam, K. Reduction of Ammonia and Hydrogen Sulfide Emission from Swine Manure Using Aqueous Foams Amended with Microorganisms and Chemical Additives. Clean 2007, 35, 230–234. [Google Scholar] [CrossRef]

- Blanes-Vidal, V.; Guàrdia, M.; Dai, X.R.; Nadimi, E.S. Emissions of NH3, CO2 and H2S during Swine Wastewater Management: Characterization of Transient Emissions after Air-Liquid Interface Disturbances. Atmos. Environ. 2012, 54, 408–418. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Zhu, J. Characteristics of Solids, BOD5 and VFAs in Liquid Swine Manure Treated by Short-Term Low-Intensity Aeration for Long-Term Storage. Bioresour. Technol. 2006, 97, 140–149. [Google Scholar] [CrossRef]

- Martinez, J.; Guiziou, F.; Peu, P.; Gueutier, V. Influence of Treatment Techniques for Pig Slurry on Methane Emissions during Subsequent Storage. Biosyst. Eng. 2003, 85, 347–354. [Google Scholar] [CrossRef]

- Dai, X.R.; Blanes-Vidal, V. Emissions of Ammonia, Carbon Dioxide, and Hydrogen Sulfide from Swine Wastewater during and after Acidification Treatment: Effect of PH, Mixing and Aeration. J. Environ. Manag. 2013, 115, 147–154. [Google Scholar] [CrossRef]

- Ni, J.-Q.; Hendriks, J.; Vinckier, C.; Coenegrachts, J. A New Concept. of Carbon. Dioxide Accelerated Ammonia Release from Liquid Manure in Pig House. Environ. Int. 2000, 26, 97–104. [Google Scholar] [CrossRef] [PubMed]

- Petersen, V.; Markfoged, R.; Hafner, S.D.; Sommer, S.G. A New Slurry PH Model Accounting for Effects of Ammonia and Carbon Dioxide Volatilization on Solution Speciation. Nutr. Cycl. Agroecosystems 2014, 100, 189–204. [Google Scholar] [CrossRef]

- Ma, S.; Xiong, J.; Cui, R.; Sun, X.; Han, L.; Xu, Y.; Kan, Z.; Gong, X.; Huang, G. Effects of Intermittent Aeration on Greenhouse Gas Emissions and Bacterial Community Succession during Large-Scale Membrane-Covered Aerobic Composting. J. Clean. Prod. 2020, 266, 121551. [Google Scholar] [CrossRef]

- Loyon, L.; Guiziou, F.; Béline, F.; Peu, P. Gaseous Emissions (NH3, N2O, CH4, CO2) from A Biological Aerobic Treatment Unit of Pig Slurry. Available online: http://ramiran.uvlf.sk/doc04/Proceedings%2004/Loyon.pdf (accessed on 23 May 2024).

- Marszałek, M.; Kowalski, Z.; Makara, A. Emission of Greenhouse Gases and Odorants from Pig Slurry—Effect on the Environment and Methods of Its Reduction. Ecol. Chem. Eng. S 2018, 25, 383–394. [Google Scholar] [CrossRef]

- Heinonen-Tanski, H.; Leinonen, P.; Niskanen, E.M.; Mielonen, M.M.; Räsänen, H.; Valta, T.; Rinne, K.; Joki-Tokola, E. Aeration Improves the Hygiene of Cattle Slurry and the Quality of Grass Forage and Silage. Acta Agric. Scand. B Soil Plant Sci. 1998, 48, 212–221. [Google Scholar] [CrossRef]

- Kupper, T.; Häni, C.; Neftel, A.; Kincaid, C.; Bühler, M.; Amon, B.; VanderZaag, A. Ammonia and Greenhouse Gas Emissions from Slurry Storage—A Review. Agric. Ecosyst. Environ. 2020, 300, 106963. [Google Scholar] [CrossRef]

- Clemens, J.; Ahlgrimm, H.-J. Greenhouse Gases from Animal Husbandry: Mitigation Options. Nutr. Cycl. Agroecosystems 2001, 60, 287–300. [Google Scholar] [CrossRef]

- El bied, O.; Angélica Terrero Turbí, M.; García-Valero, A.; Faz Cano, Á.; Alberto, J. Mitigating ammonia and greenhouse gas emissions from stored pig slurry using chemical additives and biochars. Agronomy 2023, 15, 2744. [Google Scholar]

- Chai, C.; Zhang, D.; Yu, Y.; Feng, Y.; Wong, M.S. Carbon Footprint Analyses of Mainstream Wastewater Treatment Technologies under Different Sludge Treatment Scenarios in China. Water 2015, 7, 918–938. [Google Scholar] [CrossRef]

- Ranieri, E.; D’Onghia, G.; Lopopolo, L.; Gikas, P.; Ranieri, F.; Gika, E.; Spagnolo, V.; Ranieri, A.C. Evaluation of Greenhouse Gas Emissions from Aerobic and Anaerobic Wastewater Treatment Plants in Southeast of Italy. J. Environ. Manag. 2023, 337, 117767. [Google Scholar] [CrossRef]

- Guarino, M.; Fabbri, C.; Brambilla, M.; Valli, L.; Navarotto, P. Evaluation of simplified covering systems to reduce gaseous emissions from livestock manure storage. Trans. ASABE 2006, 49, 737–747. [Google Scholar] [CrossRef]

- Berg, W.; Pazsiczki, I. Mitigation of Methane Emissions during Manure Storage. Int. Congr. Ser. 2006, 1293, 213–216. [Google Scholar] [CrossRef]

- Calvet, S.; Estellés, F.; Cartanyà Ferré, J.; Babot Gaspa, D. Guía Para La Minimización de Las Emisiones de Gases En Las Granjas Porcinas; Edicions de la Universitat de Lleida: Lleida, Spain, 2020. [Google Scholar]

- Shen, W.; Dai, H.; Gu, S.; Guo, F.; Li, T.; Rajasekar, A. Isolation and Application of PH- and Salt-Resistant Bacillus Strains to Reduce Ammonia Emission from Pig Manure during the Storage Period. J. Appl. Microbiol. 2023, 134, lxad134. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Bi, L.; Liao, Y.; Lu, D.; Zhang, H.; Liao, X.; Liang, J.B.; Wu, Y. Influence and Characteristics of Bacillus stearothermophilus in Ammonia Reduction during Layer Manure Composting. Ecotoxicol. Environ. Saf. 2019, 180, 80–87. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Yu, Y.; Li, X.; Jia, H.; Ma, X.; Opoku, P.A. Research Progress of Anaerobic Ammonium Oxidation (Anammox) Process Based on Integrated Fixed-Film Activated Sludge (IFAS). Environ. Microbiol. Rep. 2024, 16, e13235. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Fu, G.; Zeng, A.; Cheng, B.; Song, Z.; Hu, Z. Effects of Different Aeration Strategies and Ammonia-Nitrogen Loads on Nitrification Performance and Microbial Community Succession of Mangrove Constructed Wetlands for Saline Wastewater Treatment. Chemosphere 2023, 339, 139685. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.; Zhan, Y.; Chen, W.; Xu, S.; Wang, Z.; Tao, Y.; Shi, X.; Sun, B.; Ding, G.; Li, J.; et al. Impact of Aeration Rate on Phosphorus Conversion and Bacterial Community Dynamics in Phosphorus-Enriched Composting. Bioresour. Technol. 2022, 364, 128016. [Google Scholar] [CrossRef] [PubMed]

- Sørensen, P.; Eriksen, J. Effects of Slurry Acidification with Sulphuric Acid Combined with Aeration on the Turnover and Plant Availability of Nitrogen. Agric. Ecosyst. Environ. 2009, 131, 240–246. [Google Scholar] [CrossRef]

- Zhu, K.; El-Din, M.G.; Moawad, A.K.; Bromley, D. Physical and Chemical Processes for Removing Suspended Solids and Phosphorus from Liquid Swine Manure. Environ. Technol. 2004, 25, 1177–1187. [Google Scholar] [CrossRef]

- Paz Pérez-Sangrador, M.; Cristina León-Cófreces, M.; Acítores-Benavente, M.; Cruz García-González, M. Solids and Nutrient Removal from Flushed Swine Manure Using Polyacrylamides. J. Environ. Manag. 2012, 93, 67–70. [Google Scholar] [CrossRef]

- Doyle, Y.; de la Noüe, J. Aerobic Treatment of Swine Manure: Physico-Chemical Aspects. Biol. Wastes 1987, 22, 187–208. [Google Scholar] [CrossRef]

- O’Keefe, M.; McDonald, S.A.; Yan, M.; Davis, R.; Watts, P.; McGahan, E.; Tucker, R. Sludge Handling and Management. 2014, Project No. 2012/1029, Australian Pork Limited, Canberra, Australia, January 2014. Available online: https://extension.okstate.edu/fact-sheets/print-publications/pss/aerobic-treatment-system-pss-2275.pdf (accessed on 23 May 2024).

- Abit, S.M.; William, J.; Graduate, J.; Associate, R. Oklahoma Cooperative Extension Service Extension Specialist for Soils under Non-Agricultural Uses. Available online: https://extension.okstate.edu/fact-sheets/aerobic-treatment-system.html (accessed on 23 May 2024).

- Umweltbundesamt GmbH Final Report: Framework Service Contract. ENV.D2/FRA/2012/0013 Support. to the Implementation of the UWWTD: COD Substitution Scoping Study. 2017. Available online: https://circabc.europa.eu/sd/a/33c4c452-868e-4851-be02-56923cf75abb/COD_Study_Draft_Final_8Mar17_230517.pdf (accessed on 23 May 2024).

- BOD; TSS. The Biology and Troubleshooting of Facultative Lagoons; Wiley: Hoboken, NJ, USA, 2015; pp. 195–198. [Google Scholar]

- Alexander, R.T.; Cordat, E.; Chambrey, R.; Dimke, H.; Eladari, D. Acidosis and Urinary Calcium Excretion: Insights from Genetic Disorders. J. Am. Soc. Nephrol. 2016, 27, 3511–3520. [Google Scholar] [CrossRef] [PubMed]

- Duan, M.; Zhang, Y.; Zhou, B.; Qin, Z.; Wu, J.; Wang, Q.; Yin, Y. Effects of Bacillus subtilis on Carbon Components and Microbial Functional Metabolism during Cow Manure–Straw Composting. Bioresour. Technol. 2020, 303, 122868. [Google Scholar] [CrossRef] [PubMed]

- Shao, M.; Zhao, X.; Rehman, K.U.; Cai, M.; Zheng, L.; Huang, F.; Zhang, J. Synergistic Bioconversion of Organic Waste by Black Soldier Fly (Hermetia illucens) Larvae and Thermophilic Cellulose-Degrading Bacteria. Front. Microbiol. 2023, 14, 1288227. [Google Scholar] [CrossRef] [PubMed]

- Hwang, O.; Yun, Y.M.; Trabue, S. Impact of Bacillus subtilis on Manure Solids, Odor, and Microbiome. J. Environ. Manag. 2023, 333, 117390. [Google Scholar] [CrossRef] [PubMed]

- Xu, N.; Liao, M.; Liang, Y.; Guo, J.; Zhang, Y.; Xie, X.; Fan, Q.; Zhu, Y. Biological Nitrogen Removal Capability and Pathways Analysis of a Novel Low C/N Ratio Heterotrophic Nitrifying and Aerobic Denitrifying Bacterium (Bacillus thuringiensis Strain WXN-23). Environ. Res. 2021, 195, 110797. [Google Scholar] [CrossRef] [PubMed]

- Saeid, A.; Prochownik, E.; Dobrowolska-Iwanek, J. Phosphorus Solubilization by Bacillus Species. Molecules 2018, 23, 2897. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; An, Y.; Chen, H.; Zhang, J.; Zhang, H.; Zhu, G.; Chen, J.; Li, W.; Wang, J.; Xu, H.J.; et al. Effects of Earthworms and Phosphate-Solubilizing Bacteria on Carbon Sequestration in Soils Amended with Manure and Slurry: A 4-Year Field Study. Agronomy 2022, 12, 2064. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, C.; Zhou, Z.; Cao, X.; Zhou, Y. Coupling between Nitrification and Denitrification as Well as Its Effect on Phosphorus Release in Sediments of Chinese Shallow Lakes. Water 2019, 11, 1809. [Google Scholar] [CrossRef]

- Li, B.; Yang, Y.; Chen, J.; Wu, Z.; Liu, Y.; Xie, S. Nitrifying Activity and Ammonia-Oxidizing Microorganisms in a Constructed Wetland Treating Polluted Surface Water. Sci. Total Environ. 2018, 628–629, 310–318. [Google Scholar] [CrossRef]

- Wu, R.; Yao, F.; Li, X.; Shi, C.; Zang, X.; Shu, X.; Liu, H.; Zhang, W. Manganese Pollution and Its Remediation: A Review of Biological Removal and Promising Combination Strategies. Microorganisms 2022, 10, 2411. [Google Scholar] [CrossRef] [PubMed]

- Therdkiattikul, N.; Ratpukdi, T.; Kidkhunthod, P.; Chanlek, N.; Siripattanakul-Ratpukdi, S. Manganese-Contaminated Groundwater Treatment by Novel Bacterial Isolates: Kinetic Study and Mechanism Analysis Using Synchrotron-Based Techniques. Sci. Rep. 2020, 10, 13391. [Google Scholar] [CrossRef]

- Katsoyiannis, I.A.; Zouboulis, A.I. Biological Treatment of Mn(II) and Fe(II) Containing Groundwater: Kinetic Considerations and Product Characterization. Water Res. 2004, 38, 1922–1932. [Google Scholar] [CrossRef]

- Bloem, E.; Albihn, A.; Elving, J.; Hermann, L.; Lehmann, L.; Sarvi, M.; Schaaf, T.; Schick, J.; Turtola, E.; Ylivainio, K. Contamination of Organic Nutrient Sources with Potentially Toxic Elements, Antibiotics and Pathogen Microorganisms in Relation to P Fertilizer Potential and Treatment Options for the Production of Sustainable Fertilizers: A Review. Sci. Total Environ. 2017, 607–608, 225–242. [Google Scholar] [CrossRef]

- Moral, R.; Perez-Murcia, M.D.; Perez-Espinosa, A.; Moreno-Caselles, J.; Paredes, C. Estimation of Nutrient Values of Pig Slurries in Southeast Spain Using Easily Determined Properties. Waste Manag. 2005, 25, 719–725. [Google Scholar] [CrossRef]

- Dourmad, J.Y.; Jondreville, C. Impact of Nutrition on Nitrogen, Phosphorus, Cu and Zn in Pig Manure, and on Emissions of Ammonia and Odours. Livest. Sci. 2007, 112, 192–198. [Google Scholar] [CrossRef]

- Kerkaert, H.R.; Woodworth, J.C.; Derouchey, J.M.; Dritz, S.S.; Tokach, M.D.; Goodband, R.D.; Manzke, N.E. Determining the Effects of Manganese Source and Level on Growth Performance and Carcass Characteristics of Growing-Finishing Pigs. Transl. Anim. Sci. 2021, 5, txab067. [Google Scholar] [CrossRef] [PubMed]

- Hatfield, J.L.; Brumm, M.C.; Melvin, S.W. Chapter 4 Swine Manure Management. Agric. Uses Munic. Anim. Ind. Byprod. 1998, 44, 78–90. [Google Scholar]

- Clemente, R.; Sáez-Tovar, J.A.; Bernal, M.P. Extractability, Distribution Among Different Particle Size Fractions, and Phytotoxicity of Cu and Zn in Composts Made with the Separated Solid Fraction of Pig Slurry. Front. Sustain. Food Syst. 2020, 4, 2. [Google Scholar] [CrossRef]

- Choia, H.L. Changes of Physico-Chemical Properties of Pig Slurry During Storage. Media Peternak. 2011, 34, 179–183. [Google Scholar] [CrossRef]

| Weeks | 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|---|

| Ta (°C) | RPS | 18.05 ± 0.49 a | 17.92 ± 0.59 a | 21.61 ± 0.15 c | 19.94 ± 0.01 b | 23.1 ± 0.14 d | 22.96 ± 0.06 d |

| BAC | 17.36 ± 0.45 a | 18.12 ± 0.04 b | 23.79 ± 0.07 e | 18.71 ± 0.02 c | 22.06 ± 0.22 d | 23.42 ± 0.8 e | |

| BAC + AER | 18.79 ± 0.11 b | 17.54 ± 0.13 a | 23.53 ± 0.04 d | 19.89 ± 0.01 c | 24.06 ± 0.04 e | 24.91 ± 0.51 e | |

| pH | RPS | 7.32 ± 0.01 a | 7.68 ± 0.02 b | 7.71 ± 0.02 b | 7.71 ± 0.02 b | 7.33 ± 0.01 a | 7.35 ± 0.03 a |

| BAC | 7.32 ± 0.03 a | 7.75 ± 0.06 b | 7.73 ± 0.01 b | 8.00 ± 0.02 d | 7.96 ± 0.04 c | 7.97 ± 0.08 c | |

| BAC + AER | 7.32 ± 0.01 a | 7.3 ± 0.01 a | 7.69 ± 0.03 b | 8.3 ± 0.2 d | 8.26 ± 0.01 d | 8.46 ± 0.01 d | |

| EC (dS m−1) | RPS | 22.09 ± 0.02 a | 24.81 ± 0.12 c | 25.74 ± 0.23 d | 26.78 ± 0.01 e | 23.55 ± 0.06 b | 24.04 ± 0.09 b |

| BAC | 22.45 ± 0.56 bc | 23.87 ± 0.02 c | 24.56 ± 0.32 d | 24.98 ± 0.1 d | 19.38 ± 1.12 a | 21.76 ± 1.15 b | |

| BAC + AER | 23.54 ± 0.26 b | 22.26 ± 0.67 b | 22.38 ± 0.4 b | 22.47 ± 0.02 b | 16.16 ± 2.25 a | 20.45 ± 1.63 a | |

| TSSs (g L−1) | RPS | 26.57 ± 1.25 d | 11.67 ± 0.15 a | 22.2 ± 0.66 c | 22.4 ± 2.15 c | 15.53 ± 1.19 b | 14.5 ± 0.86 ab |

| BAC | 26.97 ± 1.55 d | 26.43 ± 0.35 c | 17.37 ± 0.71 ab | 15.5 ± 0.46 a | 15.3 ± 1.35 a | 19.03 ± 2.36 b | |

| BAC + AER | 26.77 ± 1.02 d | 21.23 ± 1.59 d | 17.93 ± 0.57 a | 25.97 ± 0.35 c | 21.03 ± 0.55 b | 24.07 ± 2.07 c | |

| COD (gL−1) | RPS | 32.5 ± 0.5 e | 21 ± 0.01 c | 26 ± 0.02 d | 17.5 ± 0.5 b | 10.9 ± 0.2 a | 10.75 ± 0.12 a |

| BAC | 32.5 ± 0.5 e | 24 ± 1.2 d | 17.5 ± 0.5 c | 12.5 ± 0.5 b | 9.4 ± 0.01 a | 10.5 ± 0.92 a | |

| BAC + AER | 32.5 ± 0.5 e | 28 ± 1.9 c | 26.5 ± 1.5 bc | 22 ± 1.2 a | 21.3 ± 0.2 a | 19.85 ± 1.68 c | |

| BOD5 (g O2L−1) | RPS | 12 ± 0.36 c | 11.68 ± 0.08 c | 12.98 ± 0.03 d | 9.41 ± 0.26 b | 2.54 ± 0.09 a | 2 ± 0.36 a |

| BAC | 9.94 ± 0.04 d | 10.32 ± 0.54 d | 7.09 ± 0.12 c | 3.09 ± 0.56 b | 2.01 ± 0.03 a | 2.59 ± 0.23 a | |

| BAC + AER | 11.9 ± 0.36 c | 13.76 ± 0.65 e | 10.62 ± 0.13 d | 10.54 ± 0.14 d | 6.92 ± 0.53b | 3.77 ± 1,18 a |

| Weeks | 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|---|

| N total (g L−1) | RPS | 2.66 ± 0.11 c | 2.33 ± 0.07 c | 2.33 ± 0.06 c | 2.7 ± 0.21 c | 1.93 ± 0.06 b | 2.11 ± 0.16 b |

| BAC | 2.66 ± 0.14 c | 2.68 ± 0.04 c | 2.56 ± 0.05 c | 2.29 ± 0.08 c | 1.87 ± 0.12 b | 1.47 ± 0.22 a | |

| BAC + AER | 2.63 ± 0.12 c | 2.65 ± 0.37 c | 2.67 ± 0.04 c | 2.37 ± 0.13 c | 1.72 ± 0.11 b | 1.52 ± 0.06 a | |

| Na+ (mg L−1) | RPS | 1504 ± 48 a | 1724 ± 54.95 b | 1923 ± 21.88 c | 1987 ± 41 c | 2060 ± 86.1 c | 2324 ± 155 d |

| BAC | 1492 ± 40 a | 1670 ± 41.11 b | 1822 ± 21.06 c | 2031 ± 25 d | 1980 ± 64.01 d | 2198 ± 122 e | |

| BAC + AER | 1495 ± 51 a | 1665 ± 48 b | 1780 ± 75 bc | 1979 ± 37 d | 1866 ± 29 cd | 2136 ± 128 e | |

| K+ (mg L−1) | RPS | 2096 ± 31 a | 2451 ± 51 b | 2772 ± 52 c | 2975 ± 57 d | 3096 ±137 d | 3441 ± 210 e |

| BAC | 2103 ± 52 a | 2297 ± 64 b | 2608 ± 56 c | 2966 ± 37 e | 2753 ± 11 d | 3173 ± 219 f | |

| BAC + AER | 2082 ± 78 a | 2319 ± 79 b | 2580 ± 125 c | 2925 ± 51 de | 2724 ± 42 cd | 3091 ± 184 e | |

| Ca2+ (mg L−1) | RPS | 372 ± 49 bc | 398 ± 11 c | 430 ± 30 c | 352 ± 2 bc | 305 ± 11 ab | 255 ± 22 a |

| BAC | 383 ± 41 cd | 428.73 ± 16 d | 348 ± 13 bc | 302 ± 12 ab | 240 ± 21 a | 268 ± 20 a | |

| BAC + AER | 365 ± 12 bc | 411.8 ± 15 c | 278 ± 43 a | 296 ± 41 ab | 301 ± 33 ab | 299 ± 28 ab | |

| Mg2+ (mg L−1) | RPS | 396 ± 22 c | 224 ±15 a | 248 ± 11 ab | 272 ± 11 b | 239 ± 13 ab | 233 ± 1 ab |

| BAC | 348 ± 72 c | 311 ± 11 bc | 263 ± 26 ab | 244 ± 6 ab | 201 ± 10 a | 227 ± 14 ab | |

| BAC + AER | 341 ± 68 b | 242 ±5 a | 195 ± 6 a | 193 ± 2 a | 263 ± 19 ab | 229 ± 34 a | |

| P (mg L−1) | RPS | 296 ± 46 b | 139 ±14 ab | 113 ± 6 ab | 93 ±1.81 a | 98 ±1.58 a | 96.6 ± 2.05 a |

| BAC | 231 ± 97 b | 70.2 ± 1.26 a | 96 ±1.58 a | 63.9 ± 1.58 a | 64.8 ± 1.27 c | 53.4 ± 1.43 c | |

| BAC + AER | 225 ± 106 b | 61.8 ± 2.04 a | 82.7 ± 1.85 a | 54.7 ± 0.73 c | 59.4 ± 0.73 c | 43.2 ± 1.59 c |

| Weeks | 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|---|

| Cu (mg L−1) | RPS | 0.49 ± 0.05 a | 0.82 ± 0.28 ab | 1.45 ± 0.07 b | 0.6 ± 0.15 a | 1.41 ± 0.27 b | 2.29 ± 0.58 c |

| BAC | 0.48 ± 0.05 a | 0.76 ± 0.03 ab | 1.36 ± 0.17 b | 0.67 ± 0.19 ab | 2.49 ± 0.18 c | 2.44 ± 0.11 c | |

| BAC + AER | 0.47 ± 0.07 ab | 0.78 ± 0.01 b | 1.49 ± 0.28 c | 0.34 ± 0.06 a | 1.43 ± 0.22 c | 1.96 ± 0.37 d | |

| Zn (mg L−1) | RPS | 1.28 ± 0.06 a | 2.12 ± 0.1 b | 2.15 ± 0.14 b | 2.3 ± 0.18 b | 4.08 ± 0.67 c | 5.28 ± 0.48 d |

| BAC | 1.39 ± 0.11 a | 2.23 ± 0.09 b | 2.53 ± 0.18 bc | 2.98 ± 0.32 c | 5.42 ± 0.48 d | 5.17 ± 0.4 d | |

| BAC + AER | 1.42 ± 0.05 a | 2.45 ± 0.06 b | 3.61 ± 0.31 cd | 3.04 ± 0.23 bc | 4.28 ± 0.64 de | 4.52 ± 0.66 e | |

| Fe (mg L−1) | RPS | 2.8 ± 0.22 a | 3.27 ± 0.28 ab | 4.72 ± 0.18 de | 3.69 ± 0.15 bc | 4.2 ± 0.17 cd | 5.46 ± 0.85 e |

| BAC | 3.31 ± 0.51 a | 4.45 ± 0.26 c | 4.7 ± 0.55 c | 3.63 ± 0.28 b | 5.38 ± 0.38 d | 5.34 ± 0.23 d | |

| BAC + AER | 3.36 ± 0.46 a | 4.17 ± 0.11 a | 6.62 ± 0.52 bc | 5.53 ± 0.23 b | 7.79 ± 0.76 cd | 8.23 ± 0.52 d | |

| Mn (mg L−1) | RPS | 7.02 ± 0.61 c | 4.68 ± 0.16 b | 4.58 ± 0.15 b | 4.21 ± 0.06 b | 4.31 ± 0.54 b | 4.91 ± 0.54 bc |

| BAC | 6.85 ± 0.57 c | 5.71 ± 0.19 c | 4.31 ± 0.54 b | 2.75 ± 0.1 a | 2.31 ± 0.06 a | 2.61 ± 0.17 a | |

| BAC + AER | 6.93 ± 1.18 d | 4.43 ± 0.2 c | 2.81 ± 0.15 ab | 2.04 ± 0.07 a | 3.41 ± 0.14 bc | 1.98 ± 0.83 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El bied, O.; Turbí, M.A.T.; Garrido, M.G.; Cano, Á.F.; Acosta, J.A. Reducing Methane, Carbon Dioxide, and Ammonia Emissions from Stored Pig Slurry Using Bacillus-Biological Additives and Aeration. Environments 2024, 11, 171. https://doi.org/10.3390/environments11080171

El bied O, Turbí MAT, Garrido MG, Cano ÁF, Acosta JA. Reducing Methane, Carbon Dioxide, and Ammonia Emissions from Stored Pig Slurry Using Bacillus-Biological Additives and Aeration. Environments. 2024; 11(8):171. https://doi.org/10.3390/environments11080171

Chicago/Turabian StyleEl bied, Oumaima, Martire Angélica Terrero Turbí, Melisa Gómez Garrido, Ángel Faz Cano, and José Alberto Acosta. 2024. "Reducing Methane, Carbon Dioxide, and Ammonia Emissions from Stored Pig Slurry Using Bacillus-Biological Additives and Aeration" Environments 11, no. 8: 171. https://doi.org/10.3390/environments11080171

APA StyleEl bied, O., Turbí, M. A. T., Garrido, M. G., Cano, Á. F., & Acosta, J. A. (2024). Reducing Methane, Carbon Dioxide, and Ammonia Emissions from Stored Pig Slurry Using Bacillus-Biological Additives and Aeration. Environments, 11(8), 171. https://doi.org/10.3390/environments11080171