Comparison of Greenhouse Gas Emission Assessments of Solar and Energy Efficiency Improvements at Small Water Resource Recovery Facilities

Abstract

1. Introduction

1.1. Energy Use at Small WRRFs

1.2. Energy Efficiency and Renewable Energy Options for Small WRRFs

1.3. Research Goal

- (1)

- To examine the greenhouse gas (GHG) impacts of energy efficiency (E2) improvements made at small WRRFs.

- (2)

- To evaluate the GHG profiles of three existing case study sites utilizing on-site solar energy.

- (3)

- To compare the net environmental tradeoffs and payback times of E2 and on-site solar improvements.

2. Literature Review

3. Methodology

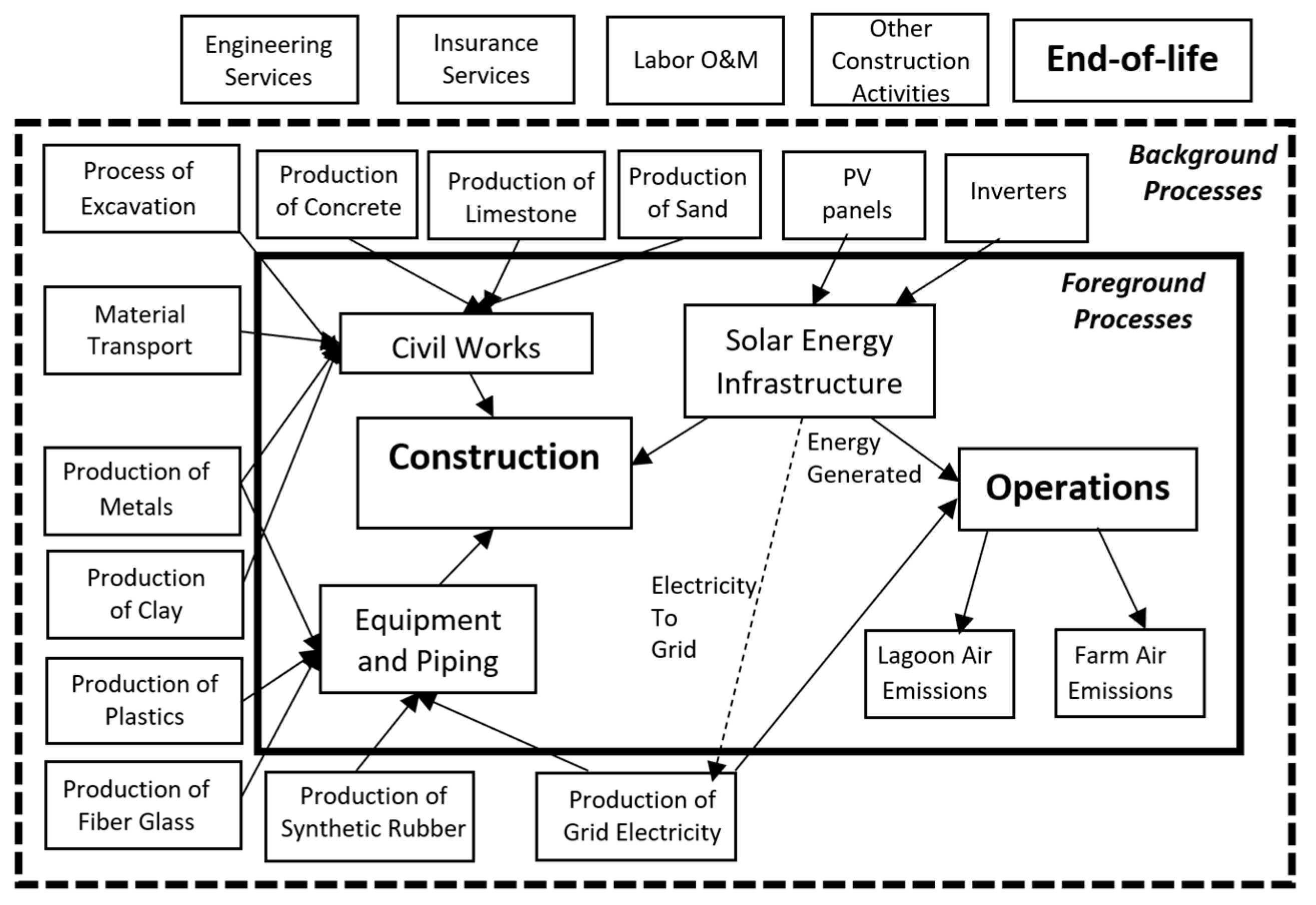

3.1. Life Cycle Assessment

| Data Type | Data Source |

|---|---|

| Construction inventory | Engineering design documents and contractor line item documents |

| Electricity usage and solar production data | Facility utility bills and utility providers |

| Flowrates, water quality, and biosolid characteristics | Nebraska Department of Environment and Energy (NDEE) Discharge Monitoring Reports |

| Air emissions from biological processes | Estimated based on the literature [36] |

| Background process data | Ecoinvent Database v3.6 |

| Carbon Intensity of Electricity | USEPA eGRID [34] and NREL [35] |

| Design life | 10 State Standards (Great Lakes-Upper Mississippi River Board’s Recommended Standards for Water Works) |

3.2. Evaluation of On-Site Solar Energy Generation

3.3. Evaluation of Energy Efficiency (E2) Improvements

4. Results and Discussion

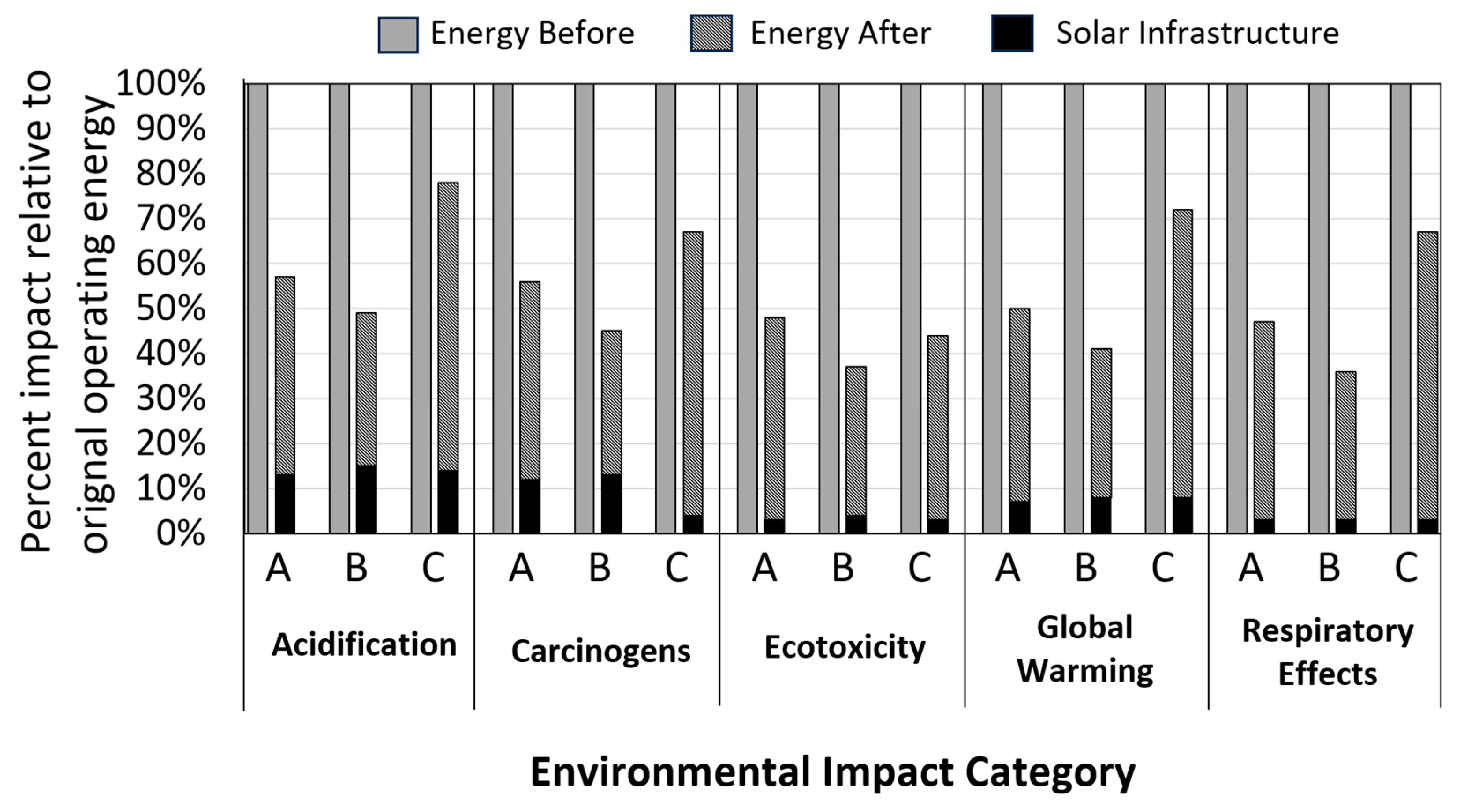

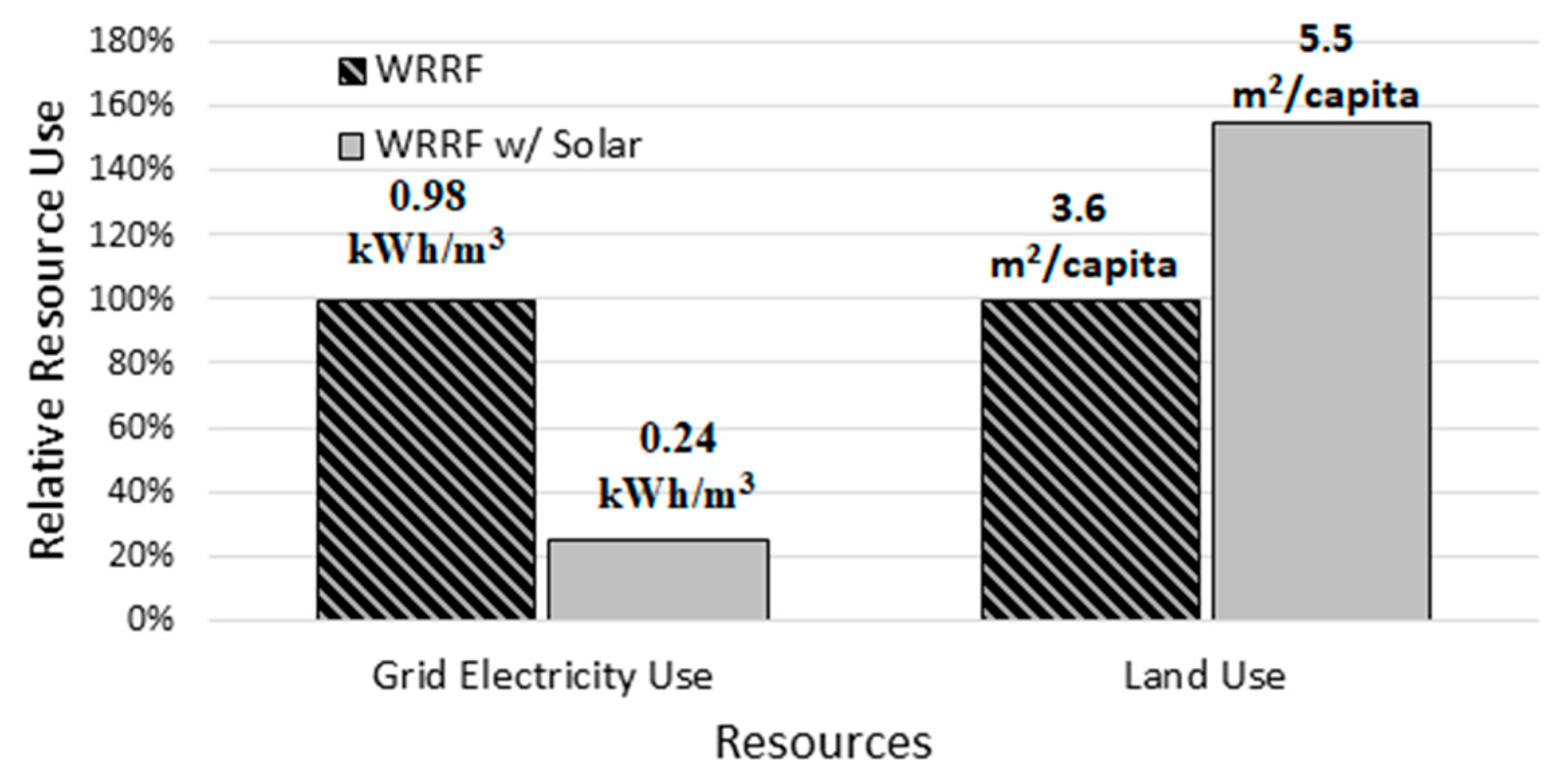

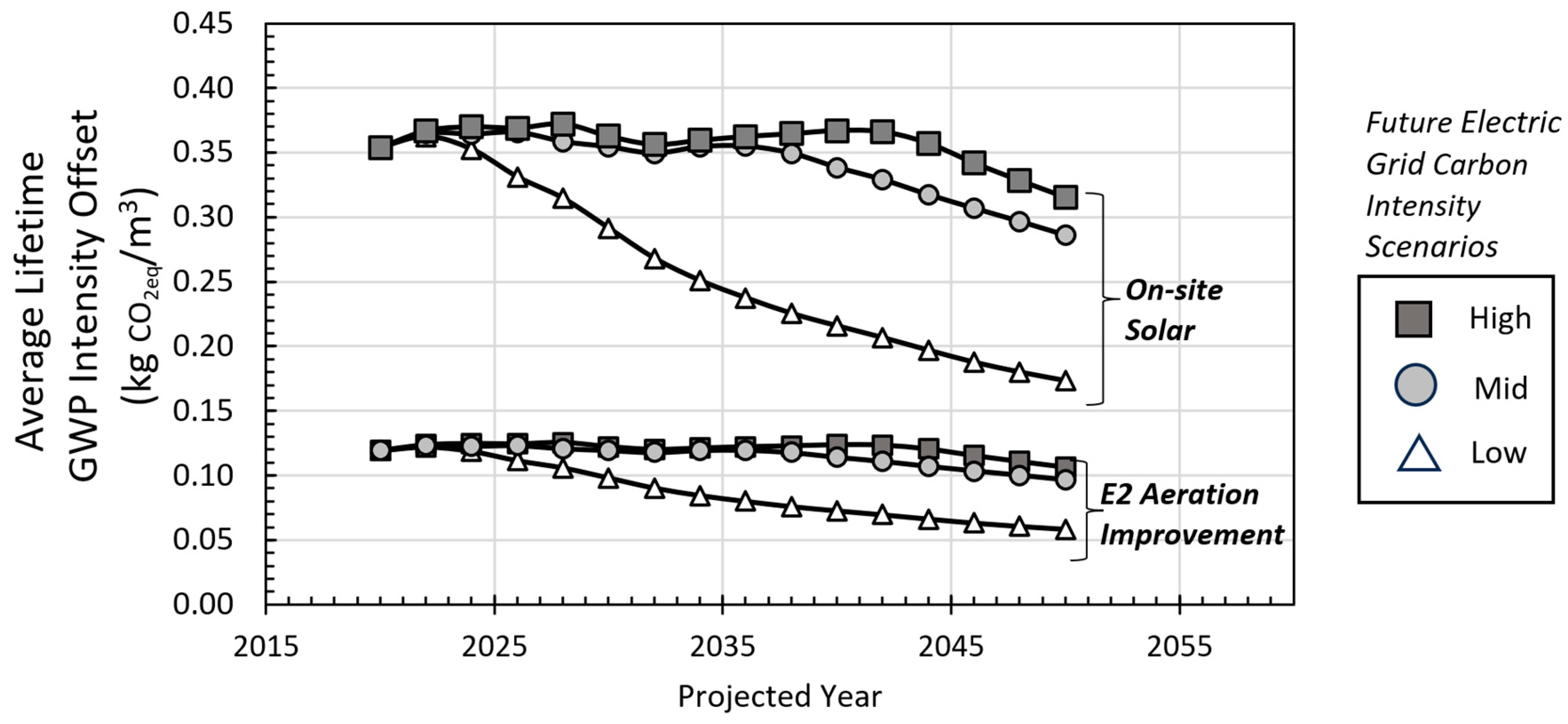

4.1. On-Site Solar Energy Improvements

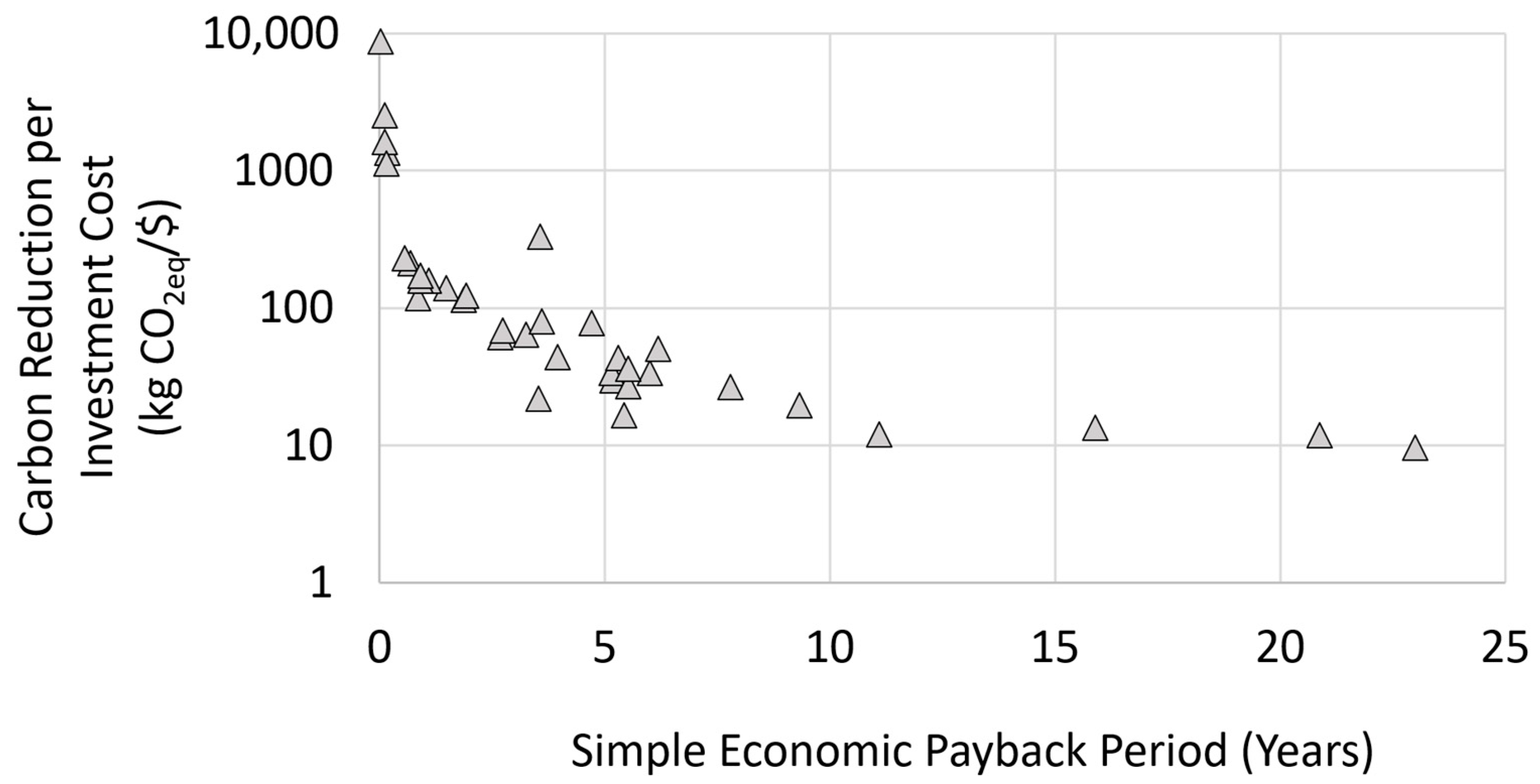

4.2. Energy Efficiency Improvements

4.3. Comparison of On-Site Solar and E2 Retrofits

4.4. Limitations and Uncertainties

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, J.; Tang, J.; Shan, R.; Li, G.; Rao, P.; Zhang, N. Spatiotemporal analysis of the future carbon footprint of solar electricity in the United States by a dynamic life cycle assessment. iScience 2023, 26, 106188. [Google Scholar] [CrossRef]

- US EPA. About Small Wastewater Systems. Available online: https://www.epa.gov/small-and-rural-wastewater-systems/about-small-wastewater-systems (accessed on 12 August 2023).

- Thompson, M.; Dahab, M.F.; Williams, R.E.; Dvorak, B. Improving Energy Efficiency of Small Water-Resource Recovery Facilities: Opportunities and Barriers. J. Environ. Eng. 2020, 146, 05020005. [Google Scholar] [CrossRef]

- Hanna, S.; Thompson, M.; Williams, R.; Dahab, M.; Dvorak, B. Benchmarking the Electric Intensity of Small Nebraska Wastewater Treatment Facilities. Water Environ. Res. 2018, 90, 738–747. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Robinson, Z.; Wang, X.; Wu, J.; Li, F. The feasibility and challenges of energy self-sufficient wastewater treatment plants. Appl. Energy 2017, 204, 1463–1475. [Google Scholar] [CrossRef]

- US EPA. Sustainable Water Infrastructure: Energy Efficiency for Water Utilities. Available online: https://www.epa.gov/sustainable-water-infrastructure/energy-efficiency-water-utilities (accessed on 10 February 2023).

- EPRI. Water and Wastewater Industries: Characteristics and Energy Management Opportunities. Electrical Power Research Institute. (EPRI/CR-106941, September 1996). Available online: https://www.epri.com/research/products/000000003002001433 (accessed on 21 May 2024).

- Pabi, S.; Amarnath, A.; Goldstein, R.; Reekie, L. Electricity Use and Management in the Municipal Water Supply and Wastewater Industries; Report No. 3002001433; Electric Power Research Institute: Palo Alto, CA, USA, 2013; Available online: https://www.sciencetheearth.com/uploads/2/4/6/5/24658156/electricity_use_and_management_in_the_municipal_water_supply_and_wastewater_industries.pdf (accessed on 21 May 2024).

- Balmér, P.; Hellström, D. Performance indicators for wastewater treatment plants. Water Sci. Technol. 2012, 65, 1304–1310. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.; Shen, Z.; Wang, H.; Xu, J.; Ai, Z.; Zheng, H.; Liu, R. Evaluating the energy efficiency of wastewater treatment plants in the Yangtze River Delta: Perspectives on regional discrepancies. Appl. Energy 2021, 297, 117087. [Google Scholar] [CrossRef]

- Sowby, R.; Thompson, M. Energy Profiles of Nine Water Treatment Plants in the Salt Lake City Area and Implications for Planning, Design, and Operation. J. Environ. Eng. 2021, 147, 04021018. [Google Scholar] [CrossRef]

- Daw, J.; Hallett, K.; DeWolfe, J.; Venner, I. Energy Efficiency Strategies for 503 Municipal Wastewater Treatment Facilities. 2012; [NREL/TP-7A30-53341]. Available online: https://www.nrel.gov/docs/fy12osti/53341.pdf (accessed on 21 May 2024).

- Foladori, P.; Vaccari, M.; Vitali, F. Energy audit in small wastewater treatment plants: Methodology, energy consumption indicators, and lessons learned. Water Sci. Technol. 2015, 72, 1007–1015. [Google Scholar] [CrossRef]

- Landis, A.E. The state of water/wastewater utility sustainability: A North American survey. J.-Am. Water Work. Assoc. 2015, 107, E464–E473. [Google Scholar] [CrossRef]

- US EPA. Clean Watersheds Needs Survey 2012; [EPA/830/R-15005]; United States Environmental Protection Agency: Washington, DC, USA, 2016. Available online: https://www.epa.gov/sites/default/files/2015-12/documents/cwns_2012_report_to_congress-508-opt.pdf (accessed on 21 May 2024).

- Doka, G. Part IV: Wastewater Treatment. In Life Cycle Inventories of Waste Treatment Services; Ecoinvent Report No. 13; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, December 2003; Available online: https://www.doka.ch/13_IV_WastewaterTreatment.pdf (accessed on 1 June 2021).

- Nguyen, T.K.L.; Ngo, H.H.; Guo, W.S.; Chang, S.W.; Nguyen, D.D.; Nghiem, L.D.; Nguyen, T.V. A critical review on life cycle assessment and plant-wide models towards emission control strategies for greenhouse gas from wastewater treatment plants. J. Environ. Manag. 2020, 264, 110440. [Google Scholar] [CrossRef]

- Thompson, M.; Moussavi, S.; Li, S.; Dvorak, B. Environmental Life Cycle Assessment of small water resource recovery facilities: Comparison of mechanical and lagoon systems. Water Res. 2022, 215, 118234. [Google Scholar] [CrossRef] [PubMed]

- de Haas, D.; Dancey, M. Wastewater Treatment Energy Efficiency. Water J. Aust. Water Assoc. 2015, 42, 53. [Google Scholar]

- US Congress. S.914—Drinking Water and Wastewater Infrastructure Act of 2021. 117th Congress (2021–2022). Available online: https://www.congress.gov/bill/117th-congress/senate-bill/914 (accessed on 21 May 2024).

- USDA. Water & Waste Disposal Loan & Grant Program. Available online: https://www.rd.usda.gov/programs-services/water-environmental-programs/water-waste-disposal-loan-grant-program (accessed on 10 February 2023).

- NDEE (Nebraska Department of Environment and Energy). Nebraska Climate Pollution Reduction Planning. Available online: https://dee.ne.gov/ndeqprog.nsf/onweb/cprg (accessed on 12 June 2023).

- Milani, S.; Bidhendi, G. Biogas and photovoltaic solar energy as renewable energy in wastewater treatment plants: A focus on energy recovery and greenhouse gas emission mitigation. Water Sci. Eng. 2023. [Google Scholar] [CrossRef]

- Algunaibet, I.; Guillén-Gosálbez, G. Life cycle burden-shifting in energy systems designed to minimize greenhouse gas emissions: Novel analytical method and application to the United States. J. Clean. Prod. 2019, 229, 886–901. [Google Scholar] [CrossRef]

- Lopsik, K. Life cycle assessment of small-scale constructed wetland and extended aeration activated sludge wastewater treatment system. Inter. J. Environ. Sci. Technol. 2013, 10, 1295–1308. [Google Scholar] [CrossRef]

- ISO (2006a). “Environmental Management—Life Cycle Assessment—Principles and Framework.” ISO 14040. Available online: https://wapsustainability.com/wp-content/uploads/2020/11/ISO-14040.pdf (accessed on 2 February 2023).

- ISO (2006b). “Eanvironmental Management—Life Cycle Assessment—Requirements and Guidelines.” ISO 14044. Available online: https://wapsustainability.com/wp-content/uploads/2020/11/ISO-14044.pdf (accessed on 2 February 2023).

- Garfí, M.; Flores, L.; Ferrer, I. Life Cycle Assessment of wastewater treatment systems for small communities: Activated sludge, constructed wetlands and high rate algal ponds. J. Clean. Prod. 2017, 161, 211–219. [Google Scholar] [CrossRef]

- Longo, S.; d’Antoni, B.; Bongards, M.; Chaparro, A.; Cronrath, A.; Fatone, F.; Lema, J.; Mauricio-Iglesias, M.; Soares, A.; Hospido, A. Monitoring and diagnosis of energy consumption in wastewater treatment plants. A state of the art and proposals for improvement. Appl. Energy 2016, 179, 1251–1268. [Google Scholar] [CrossRef]

- Corominas, L.; Byrne, D.; Guest, J.S.; Hospido, A.; Roux, P.; Shaw, A.; Short, M.D. The application of life cycle assessment (LCA) to wastewater treatment: A best practice guide and critical review. Water Res. 2020, 184, 116058. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Tang, W.Z.; Gu, L. Energy efficiency assessment of China wastewater treatment plants by unit energy consumption per kg COD removed. Environ. Technol. 2023, 44, 278–292. [Google Scholar] [CrossRef]

- Bare, J.C. The Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts. J. Ind. Ecol. 2002, 6, 49–78. [Google Scholar] [CrossRef]

- Ryberg, M.; Vieira, M.D.M.; Zgola, M.; Bare, J.; Rosenbaum, R.K. Updated US and Canadian normalization factors for TRACI 2.1. Clean Technol. Environ. Policy 2014, 16, 329–339. [Google Scholar] [CrossRef]

- US EPA. eGRID Data Explorer. Available online: https://www.epa.gov/egrid/data-explorer (accessed on 28 April 2024).

- Gagnon, P.; Cowiestoll, B.; Schwarz, M. Cambium 2022 Data. National Renewable Energy Laboratory. Available online: https://scenarioviewer.nrel.gov (accessed on 28 April 2024).

- Foley, J.; de Haas, D.; Hartley, K.; Lant, P. Comprehensive life cycle inventories of alternative wastewater treatment systems. Water Res. 2010, 44, 1654–1666. [Google Scholar] [CrossRef] [PubMed]

- Jordan, D.C.; Kurtz, S.R.; VanSant, K.; Newmiller, J. Compendium of photovoltaic degradation rates. Prog. Photovolt. Res. Appl. 2016, 24, 978–989. [Google Scholar] [CrossRef]

- Dvorak, B.I.; Stewart, B.A.; Hosni, A.; Hawkey, S.A.; Nelsen, V. Intensive Environmental Sustainability Education: Long-Term Impacts on Workplace Behavior. J. Prof. Issues Eng. Educ. 2011, 137, 113–120. [Google Scholar] [CrossRef]

- US EPA. Evaluation of Energy Conservation Measures for Wastewater Treatment Facilities [EPA/832/R-10/005]; United States Environmental Protection Agency: Washington, DC, USA, 2010. [Google Scholar]

- US EPA. Energy Efficiency in Water and Wastewater Facilities: A Guide to Developing and Implementing Greenhouse Reduction Programs [EPA/430/R-09/038]; United States Environmental Protection Agency: Washington, DC, USA, 2013. [Google Scholar]

- Grant, C.; Hicks, A. Effect of manufacturing and installation location on environmental impact payback time of solar power. Clean Technol. Environ. Policy 2020, 22, 187–196. [Google Scholar] [CrossRef]

- Krebs-Moberg, M.; Pitz, M.; Dorsette, T.; Gheewala, S. Third generation of photovoltaic panels: A life cycle assessment. Renew. Energy 2021, 164, 556–565. [Google Scholar] [CrossRef]

- Rashedi, A.; Khanam, T. Life cycle assessment of most widely adopted solar photovoltaic energy technologies by mid-point and end-point indicators of ReCiPe method. Environ. Sci. Pollut. Res. 2020, 27, 29075–29090. [Google Scholar] [CrossRef]

| Improvement Type | Area of Focus | Recommendation | # of Recommendations |

|---|---|---|---|

| Building | Building Envelope | Improve building insulation | 3 |

| Lighting | Install LED lightbulbs | 14 | |

| Lighting | Occupancy sensors | 1 | |

| Treatment Process | Secondary Treatment | Downsize aeration blower | 1 |

| Timer on secondary aeration | 1 | ||

| VFD on secondary aeration | 2 | ||

| Install premium efficiency motor | 1 | ||

| Biosolids Management | Improve BFP/aerobic digester operation | 2 | |

| Improve sludge blower operations | 2 | ||

| Install aerobic digester cover | 2 | ||

| Timer on aerobic digester blower | 4 | ||

| VFD on aerobic digestion | 1 | ||

| Pumping | Install premium-efficiency motor | 1 | |

| Aeration | 1 |

| On-Site Solar Power | E2 Improvements |

|---|---|

| Largest potential for net GHG reductions | Often shorter paybacks |

| Lower operational involvement | Large GHG reductions per unit cost |

| Longer paybacks | May require additional operational effort |

| Lowest GHG reduction per initial cost | Higher uncertainty and risks |

| Larger land use | Tend to have smaller overall net impact |

| Resiliency of on-site electricity source | Minimal additional spatial footprint |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thompson, M.; Dvorak, B. Comparison of Greenhouse Gas Emission Assessments of Solar and Energy Efficiency Improvements at Small Water Resource Recovery Facilities. Environments 2024, 11, 118. https://doi.org/10.3390/environments11060118

Thompson M, Dvorak B. Comparison of Greenhouse Gas Emission Assessments of Solar and Energy Efficiency Improvements at Small Water Resource Recovery Facilities. Environments. 2024; 11(6):118. https://doi.org/10.3390/environments11060118

Chicago/Turabian StyleThompson, Matthew, and Bruce Dvorak. 2024. "Comparison of Greenhouse Gas Emission Assessments of Solar and Energy Efficiency Improvements at Small Water Resource Recovery Facilities" Environments 11, no. 6: 118. https://doi.org/10.3390/environments11060118

APA StyleThompson, M., & Dvorak, B. (2024). Comparison of Greenhouse Gas Emission Assessments of Solar and Energy Efficiency Improvements at Small Water Resource Recovery Facilities. Environments, 11(6), 118. https://doi.org/10.3390/environments11060118