The Case for Carbon Capture and Storage Technologies

Abstract

1. Introduction

2. Materials and Methods

2.1. Carbon Capture Technologies

2.2. The Data

2.3. Methodology

3. Results

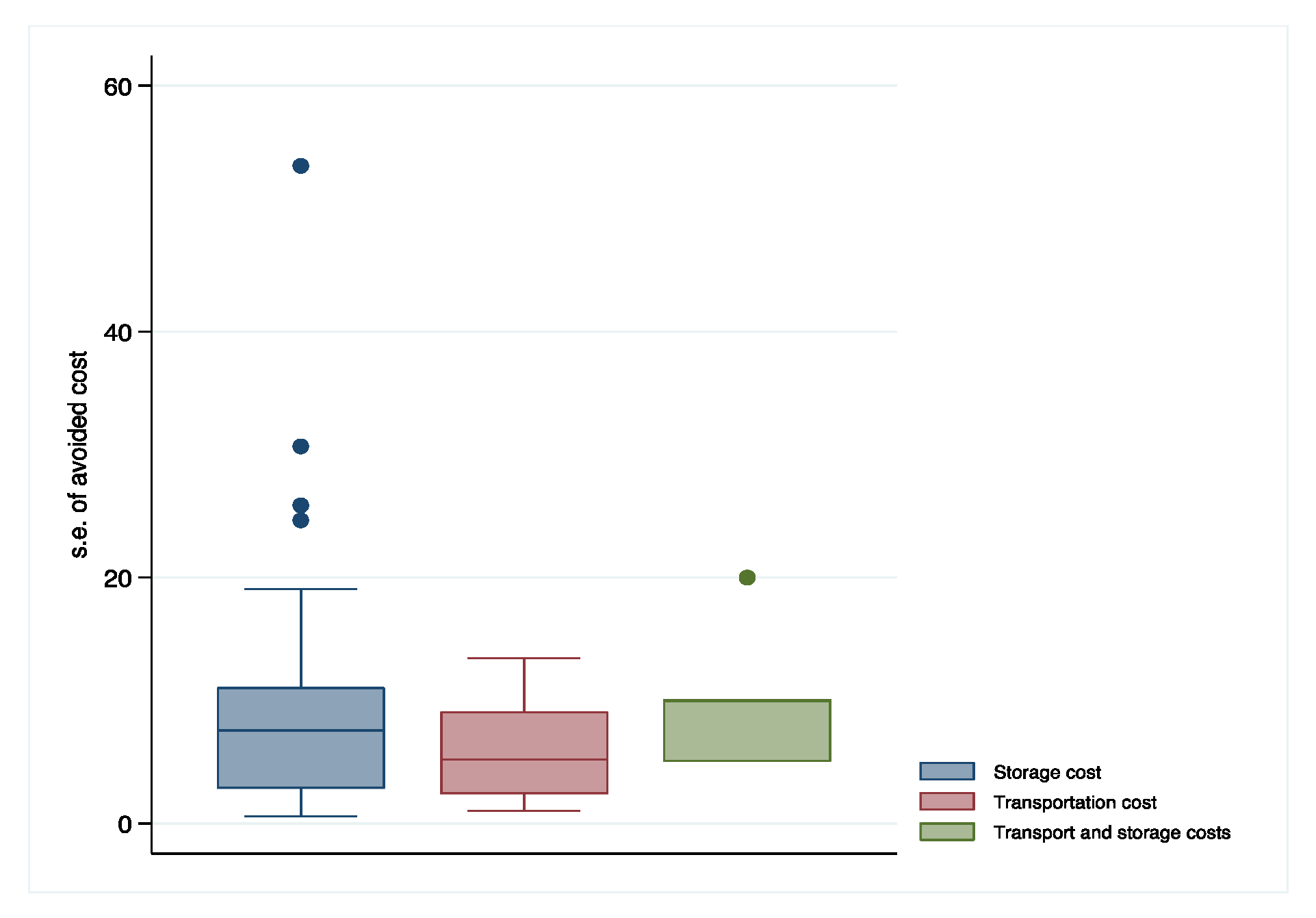

3.1. Summary Statistics

3.2. Meta-Analysis

3.2.1. Models

3.2.2. Small Sample Biases

3.2.3. The Estimated Effects

4. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nation, Climate Action COP28. Available online: https://www.un.org/en/climatechange/un-climate-conferences (accessed on 21 December 2023).

- United Nation, Climate Action COP27. Available online: https://www.un.org/en/climatechange/cop27 (accessed on 20 December 2023).

- IPCC. Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; Masson-Delmotte, V., Zhai, P., Pörtner, H.-O., Roberts, D., Skea, J., Shukla, P.R., Pirani, A., Moufouma-Okia, W., Péan, C., Pidcock, R., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2018; p. 616. [Google Scholar] [CrossRef]

- Lal, R. Enhancing crop yields in the developing countries through restoration of the soil organic carbon pool in agricultural lands. Land Degrad. Dev. 2006, 17, 197–209. [Google Scholar] [CrossRef]

- Ajayi, T.; Gomes, J.S.; Bera, A. A review of CO2 storage in geological formations emphasizing modeling, monitoring, and capacity estimation approaches. Pet. Sci. 2019, 16, 1028–1063. [Google Scholar] [CrossRef]

- Theo, W.L.; Lim, J.S.; Hashim, H.; Mustaffa, A.A.; Ho, W.S. Review of pre-combustion capture and ionic liquid in carbon capture and storage. Appl. Energy 2016, 183, 1633–1663. [Google Scholar] [CrossRef]

- Yadav, S.; Mondal, S.S. A review on the progress and prospects of oxy-fuel carbon capture and sequestration (CCS) technology. Fuel 2022, 308, 122057. [Google Scholar] [CrossRef]

- Chao, C.; Deng, Y.; Dewil, R.; Baeyens, J.; Fan, X. Post-combustion carbon capture. Renew. Sustain. Energy Rev. 2021, 138, 110490. [Google Scholar] [CrossRef]

- Munkejord, S.T.; Hammer, M.; Løvseth, S.W. CO2 transport: Data and models—A review. Appl. Energy 2016, 169, 499–523. [Google Scholar] [CrossRef]

- Benson, S.M.; Hepple, R.; Apps, J.; Tsang, C.F.; Lippmann, M. Lessons Learned from Natural and Industrial Analogues for Storage of Carbon Dioxide in Deep Geological Formations; No. LBNL-51170; Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 2002.

- Klara, S.; Beecy, D.; Kuuskraa, V.; DiPietro, P. Economic benefits of a technology strategy and R&D program in carbon sequestration. In Proceedings of the Greenhouse Gas Control Technologies—6th International Conference, Kyoto, Japan, 1–4 October 2002; pp. 1089–1094. [Google Scholar]

- Baines, S.J.; Worden, R.H. Geological Storage of Carbon Dioxide; Special Publications; Geological Society: London, UK, 2004; Volume 233, pp. 1–6. [Google Scholar]

- Gale, J. Why Do We Need to Consider Geological Storage of CO2; Special Publications; Geological Society: London, UK, 2004; Volume 233, pp. 7–15. [Google Scholar]

- Schmelz, W.J.; Hochman, G.; Miller, K.G. Total cost of carbon capture and storage implemented at a regional scale: Northeastern and midwestern United States. Interface Focus 2020, 10, 20190065. [Google Scholar] [CrossRef]

- Norhasyima, R.S.; Mahlia, T.M.I. Advances in CO2 utilization technology: A patent landscape review. J. CO2 Util. 2018, 26, 323–335. [Google Scholar] [CrossRef]

- Hepburn, C.; Adlen, E.; Beddington, J.; Carter, E.A.; Fuss, S.; Mac Dowell, N.; Minx, J.C.; Smith, P.; Williams, C.K. The technological and economic prospects for CO2 utilization and removal. Nature 2019, 575, 87–97. [Google Scholar] [CrossRef]

- Zhang, Z.; Pan, S.Y.; Li, H.; Cai, J.; Olabi, A.G.; Anthony, E.J.; Manovic, V. Recent advances in carbon dioxide utilization. Renew. Sustain. Energy Rev. 2020, 125, 109799. [Google Scholar] [CrossRef]

- Al Juaied, M.; Whitmore, A. Realistic Costs of Carbon Capture; No. ETP-DiscussionPaper-2009-08; Energy Technology Innovation Policy Research Group, Belfer Center for Science and International Affairs, Harvard Kennedy School of Government, Harvard University: Cambridge, MA, USA, 2009. [Google Scholar]

- Chen, C.; Tavoni, M. Direct air capture of CO2 and climate stabilization: A model-based assessment. Clim. Change 2013, 118, 59–72. [Google Scholar] [CrossRef]

- Azar, C.; Lindgren, K.; Larson, E.; Möllersten, K. Carbon capture and storage from fossil fuels and biomass-costs and potential role in stabilizing the atmosphere. Clim. Change 2006, 74, 47–79. [Google Scholar] [CrossRef]

- Bhave, A.; Taylor, R.H.; Fennell, P.; Livingston, W.R.; Shah, N.; Mac Dowell, N.; Dennis, J.; Kraft, M.; Pourkashanian, M.; Insa, M.; et al. Screening and techno-economic assessment of biomass-based power generation with CCS technologies to meet 2050 CO2 targets. Appl. Energy 2017, 190, 481–489. [Google Scholar] [CrossRef]

- Fuss, S.; Reuter, W.H.; Szolgayová, J.; Obersteiner, M. Optimal mitigation strategies with negative emission technologies and carbon sinks under uncertainty. Clim. Change 2013, 118, 73–87. [Google Scholar] [CrossRef]

- Bozzuto, C.R.; Nsakala, N.; Liljedahl, G.N.; Palkes, M.; Marion, J.L.; Vogel, D.; Gupta, J.C.; Fugate, M.; Guha, M.K. Engineering Feasibility and Economics of CO2 Capture on an Existing Coal-Fired Power Plant. Alstom Power Inc., Ohio Coal Development Office, and US DOE NETL (June 2001). Available online: https://discovery.researcher.life/download/article/95dde7604e043968a6c31a750aeb4701/full-text (accessed on 6 August 2022).

- Carbo, M.C.; Smit, R.; van der Drift, B.; Jansen, D. Bio energy with CCS (BECCS): Large potential for BioSNG at low CO2 avoidance cost. Energy Procedia 2011, 4, 2950–2954. [Google Scholar] [CrossRef]

- House, K.Z.; Baclig, A.C.; Ranjan, M.; Van Nierop, E.A.; Wilcox, J.; Herzog, H.J. Economic and energetic analysis of capturing CO2 from ambient air. Proc. Natl. Acad. Sci. USA 2011, 108, 20428–20433. [Google Scholar] [CrossRef] [PubMed]

- Christensen, N.P.; Holloway, S. Geological Storage of CO2 from Combustion of Fossil Fuel. European Union Fifth Framework Programme for Research and Development; Project No. ENK6-CT-1999-00010, Summary Report; Geological Survey of Norway: Trondheim, Norway, 2004.

- Edmonds, J.; Luckow, P.; Calvin, K.; Wise, M.; Dooley, J.; Kyle, P.; Kim, S.H.; Patel, P.; Clarke, L. Can radiative forcing be limited to 2.6 Wm−2 without negative emissions from bioenergy and CO2 capture and storage? Clim. Change 2013, 118, 29–43. [Google Scholar] [CrossRef]

- Keith, D.W.; Ha-Duong, M.; Stolaroff, J.K. Climate strategy with CO2 capture from the air. Clim. Change 2006, 74, 17–45. [Google Scholar] [CrossRef]

- Dooley, J.J.; Dahowski, R.T. Large-scale US unconventional fuels production and the role of carbon dioxide capture and storage technologies in reducing their greenhouse gas emissions. Energy Procedia 2009, 1, 4225–4232. [Google Scholar] [CrossRef][Green Version]

- McLaren, D. A comparative global assessment of potential negative emissions technologies. Process Saf. Environ. Prot. 2012, 90, 489–500. [Google Scholar] [CrossRef]

- Finkenrath, M. Cost and Performance of Carbon Dioxide Capture from Power Generation; International Energy Agency: Paris, France, 2011. [Google Scholar]

- Gough, C.; Upham, P. Biomass Energy with Carbon Capture and Storage (BECCS): A Review; Working Paper; Tyndall Centre for Climate Change Research: Norwich, UK, 2010; Volume 147. [Google Scholar]

- Pacala, S.; Al-Kaisi, M.; Barteau, M.; Belmont, E.; Benson, S.; Birdsey, R.; Boysen, D.; Duren, R.; Hopkinson, C.; Jones, C.; et al. Negative Emissions Technologies and Reliable Sequestration: A Research Agenda; National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2018. [Google Scholar]

- Fornell, R.; Berntsson, T.; Åsblad, A. Techno-economic analysis of a kraft pulp-mill-based biorefinery producing both ethanol and dimethyl ether. Energy 2013, 50, 83–92. [Google Scholar] [CrossRef]

- Katofsky, R.; Stanberry, M.; Frantzis, L. Achieving Climate Stabilization in an Insecure World: Does Renewable Energy Hold the Key? Final Report; U.S. Department of Energy Office of Scientific and Technical Information: Richland, WA, USA, 2010.

- Pielke, R.A., Jr. An idealized assessment of the economics of air capture of carbon dioxide in mitigation policy. Environ. Sci. Policy 2009, 12, 216–225. [Google Scholar] [CrossRef]

- Freund, P.; Ormerod, W.G. Progress toward storage of carbon dioxide. Energy Convers. Manag. 1997, 38, S199–S204. [Google Scholar] [CrossRef]

- Laude, A.; Ricci, O.; Bureau, G.; Royer-Adnot, J.; Fabbri, A. CO2 capture and storage from a bioethanol plant: Carbon and energy footprint and economic assessment. Int. J. Greenh. Gas Control. 2011, 5, 1220–1231. [Google Scholar] [CrossRef]

- Viebahn, P.; Daniel, V.; Samuel, H. Integrated assessment of carbon capture and storage (CCS) in the German power sector and comparison with the deployment of renewable energies. Appl. Energy 2012, 97, 238–248. [Google Scholar] [CrossRef]

- Gibbins, J.; Chalmers, H. Carbon capture and storage. Energy Policy 2008, 36, 4317–4322. [Google Scholar] [CrossRef]

- Luckow, P.; Wise, M.A.; Dooley, J.J.; Kim, S.H. Large-scale utilization of biomass energy and carbon dioxide capture and storage in the transport and electricity sectors under stringent CO2 concentration limit scenarios. Int. J. Greenh. Gas Control. 2010, 4, 865–877. [Google Scholar] [CrossRef]

- Hendriks, C.; Graus, W.; van Bergen, F. Global Carbon Dioxide Storage Potential and Costs; ECOFYS: Utrecht, The Netherlands, 2004; p. 64. Available online: https://www.researchgate.net/profile/Wina-Crijns-Graus/publication/260095614_Global_Carbon_Dioxide_Storage_Potential_and_Costs/links/02e7e52f8a006a9854000000/Global-Carbon-Dioxide-Storage-Potential-and-Costs.pdf (accessed on 13 January 2024).

- Herzog, H.J. Scaling up carbon dioxide capture and storage: From megatons to gigatons. Energy Econ. 2011, 33, 597–604. [Google Scholar] [CrossRef]

- Herzog, H.J.; Drake, E.M. Carbon dioxide recovery and disposal from large energy systems. Annu. Rev. Energy Environ. 1996, 21, 145–166. [Google Scholar] [CrossRef]

- Rhodes, J.S.; Keith, D.W. Engineering economic analysis of biomass IGCC with carbon capture and storage. Biomass Bioenergy 2005, 29, 440–450. [Google Scholar] [CrossRef]

- Schmidt, J.; Leduc, S.; Dotzauer, E.; Kindermann, G.; Schmid, E. Cost-effective CO2 emission reduction through heat, power, and biofuel production from woody biomass: A spatially explicit comparison of conversion technologies. Appl. Energy 2010, 87, 2128–2141. [Google Scholar] [CrossRef]

- Ramezan, M.; Skone, T.J.; Nsakala, N.Y.; Liljedahl, G.N.; Gearhart, L.E.; Hestermann, R.; Rederstorff, B. Carbon Dioxide Capture from Existing Coal-Fired Power Plants; DOE/NETL Report; National Energy Technology Laboratory: Morgantown, WV, USA, 2007; Volume 401, p. 110907. [Google Scholar]

- Socolow, R.; Desmond, M.; Aines, R.; Blackstock, J.; Bolland, O.; Kaarsberg, T.; Lewis, N.; Mazzotti, M.; Pfeffer, A.; Sawyer, K.; et al. Direct Air Capture of CO2 with Chemicals: A Technology Assessment for the APS Panel on Public Affairs (No. BOOK); American Physical Society: Washington, DC, USA, 2011. [Google Scholar]

- Riemer, P.W.; Ormerod, W.G. International perspectives and the results of carbon dioxide capture disposal and utilisation studies. Energy Convers. Manag. 1995, 36, 813–818. [Google Scholar] [CrossRef]

- Rubin, E.S.; Davison, J.E.; Herzog, H.J. The cost of CO2 capture and storage. Int. J. Greenh. Gas Control. 2015, 40, 378–400. [Google Scholar] [CrossRef]

- Rubin, E.S. Understanding the pitfalls of CCS cost estimates. Int. J. Greenh. Gas Control. 2012, 10, 181–190. [Google Scholar] [CrossRef]

- Hochman, G.; Zilberman, D. Corn Ethanol and US Biofuel Policy Ten Years Later: A Systematic Review and Meta-Analysis; No. 333-2016-14652; AAEA: Washington, DC, USA, 2016. [Google Scholar]

- Zellner, A. An efficient method of estimating seemingly unrelated regressions and tests for aggregation bias. J. Am. Stat. Assoc. 1962, 57, 348–368. [Google Scholar] [CrossRef]

- Way, R.; Ives, M.C.; Mealy, P.; Farmer, J.D. Empirically grounded technology forecasts and the energy transition. Joule 2022, 6, 2057–2082. [Google Scholar] [CrossRef]

- The IFPRI’s IMPACT Model. Available online: https://www.ifpri.org/project/ifpri-impact-model (accessed on 13 January 2024).

- The WITCH Model. Available online: https://www.witchmodel.org (accessed on 13 January 2024).

- De Luca, G.; Magnus, J.R. Bayesian model averaging and weighted-average least squares: Equivariance, stability, and numerical issues. Stata J. 2011, 11, 518–544. [Google Scholar] [CrossRef]

- Magnus, J.R.; Powell, O.; Prüfer, P. A comparison of two model averaging techniques with an application to growth empirics. J. Econom. 2010, 154, 139–153. [Google Scholar] [CrossRef]

- Kemper, J. Biomass and carbon dioxide capture and storage: A review. Int. J. Greenh. Gas Control. 2015, 40, 401–430. [Google Scholar] [CrossRef]

- Moioli, S.; De Guido, G.; Pellegrini, L.A.; Fasola, E.; Riva, E.R.; Alberti, D.; Carrara, A. Techno-economic assessment of the CO2 value chain with CCUS applied to a waste-to-energy Italian plant. Chem. Eng. Sci. 2024, 287, 119717. [Google Scholar] [CrossRef]

| Papers Used under the Alternative Technologies | ||

|---|---|---|

| CCS | BECCS | DAC |

| Al Juaied and Whitmore, 2009 [18] | Azar et al., 2006 [18] | Chen and Tavoni, 2013 [19] |

| Azar et al., 2006 [20] | Bhave et al., 2017 [21] | Fuss et al., 2013 [22] |

| Bozzuto et al., 2001 [23] | Carbo et al., 2011 [24] | House et al., 2011 [25] |

| Christensen and Holloway, 2004 [26] | Edmonds et al., 2013 [27] | Keith et al., 2006 [28] |

| Dooley and Dahowski, 2009 [29] | Fuss et al., 2013 [22] | McLaren, 2012 [30] |

| Finkenrath, 2011 [31] | Gough and Upham, 2010 [32] | Pacala et al., 2018 [33] |

| Fornell et al., 2013 [34] | Katofsky et al., 2010 [35] | Pielke Jr., 2009 [36] |

| Freund and Ormerod, 1997 [37] | Laude et al., 2011 [38] | Socolow et al., 2011 [39] |

| Gibbins and Chalmers, 2008 [40] | Luckow et al., 2010 [41] | |

| Hendriks et al., 2004 [42] | McLaren, 2012 [30] | |

| Herzog, 2011 [43] | Pacala et al., 2018 [33] | |

| Herzog and Drake, 1996 [44] | Rhodes and Keith, 2005 [45] | |

| Katofsky et al., 2010 [35] | Schmidt et al., 2010 [46] | |

| Ramezan et al., 2007 [47] | Schmelz et al., 2020 [48] | |

| Riemer and Ormerod, 1995 [49] | ||

| Rubin et al., 2015 [50] | ||

| Schmidt et al., 2010 [46] | ||

| Socolow et al., 2011 [39] | ||

| Viebahn et al., 2012 [51] | ||

| Transportation Costs | Sequestration Costs |

|---|---|

| Christensen and Holloway, 2004 [26] | Christensen and Holloway, 2004 [26] |

| Fornell et al., 2013 [34] | Freund and Ormerod, 1997 [37] |

| Herzog, 2011 [43] | Gibbins and Chalmers, 2008 [40] |

| Laude et al., 2011 [38] | Laude et al., 2011 [38] |

| Luckow et al., 2010 [41] |

| Capture Costs (USD per MT CO2) | Avoided Costs (USD per MT CO2) | |

|---|---|---|

| CCS | 53.21 | 55.26 |

| BECCS | 49.82 | 115.49 |

| DAC | 390.47 | 463.36 |

| Capture Costs | Avoided Costs | |||

|---|---|---|---|---|

| Variables | (1) | (2) | (3) | (4) |

| BMA model | WALS model | BMA model | WALS model | |

| Energy feedstock | 1.898 *** | 1.918 *** | 1.4038 *** | 1.3967 *** |

| (0.218) | (0.206) | (0.2907) | (0.2492) | |

| Capture technology | −0.142 | −0.348 ** | −0.3433 | −0.4346 ** |

| (0.220) | (0.173) | (0.3256) | (0.2075) | |

| Number of Authors | 0.015 | 0.101 | 2.9068 ** | 3.0339 ** |

| (0.049) | (0.080) | (1.1786) | (1.1664) | |

| Period of analysis | −5.728 *** | −5.919 *** | 0.2463 | 0.6783 |

| (0.852) | (0.867) | (0.4383) | (0.5341) | |

| Price of electricity (USD per kWh) | 657.037 *** | 614.623 *** | −2.3046 | −1.6405 |

| (79.592) | (78.256) | (11.6587) | (17.6569) | |

| Constant | 11,494.699 *** | 11,887.986 *** | −457.0317 | −1323.8800 |

| (1711.243) | (1740.940) | (882.1436) | (1075.4327) | |

| Observations | 67 | 67 | 128 | 128 |

| Studies | Effect Size | [95% Confidence Interval] | |

|---|---|---|---|

| Observed | 44.742 | 41.760 | 47.724 |

| Observed + imputed | 42.586 | 39.662 | 45.509 |

| Studies | Effect Size | [95% Confidence Interval] | |

|---|---|---|---|

| Observed | 51.633 | 49.450 | 53.816 |

| Observed + imputed | 49.041 | 46.601 | 51.481 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hochman, G.; Appasamy, V. The Case for Carbon Capture and Storage Technologies. Environments 2024, 11, 52. https://doi.org/10.3390/environments11030052

Hochman G, Appasamy V. The Case for Carbon Capture and Storage Technologies. Environments. 2024; 11(3):52. https://doi.org/10.3390/environments11030052

Chicago/Turabian StyleHochman, Gal, and Vijay Appasamy. 2024. "The Case for Carbon Capture and Storage Technologies" Environments 11, no. 3: 52. https://doi.org/10.3390/environments11030052

APA StyleHochman, G., & Appasamy, V. (2024). The Case for Carbon Capture and Storage Technologies. Environments, 11(3), 52. https://doi.org/10.3390/environments11030052