Environmental Impact of Wind Farms

Abstract

1. Introduction

2. Materials and Methods

- Impacts on the global ecosystem, which includes analysing CO2 emissions and water consumption (water footprint);

- Impact on people, including the impact on human health, the emission of toxic substances, the impact of noise, the impact of shadows and flashes, the risk of ice flying off the blades, the risk of parts of the blade flying off and the impact on radio waves and air traffic;

- Impacts on the local ecosystem, including land take, habitat destruction, collisions of animals with the wind farm, noise and vibration impacts;

- Impacts on the environment in the “end-of-life” phase.

3. Results and Discussion

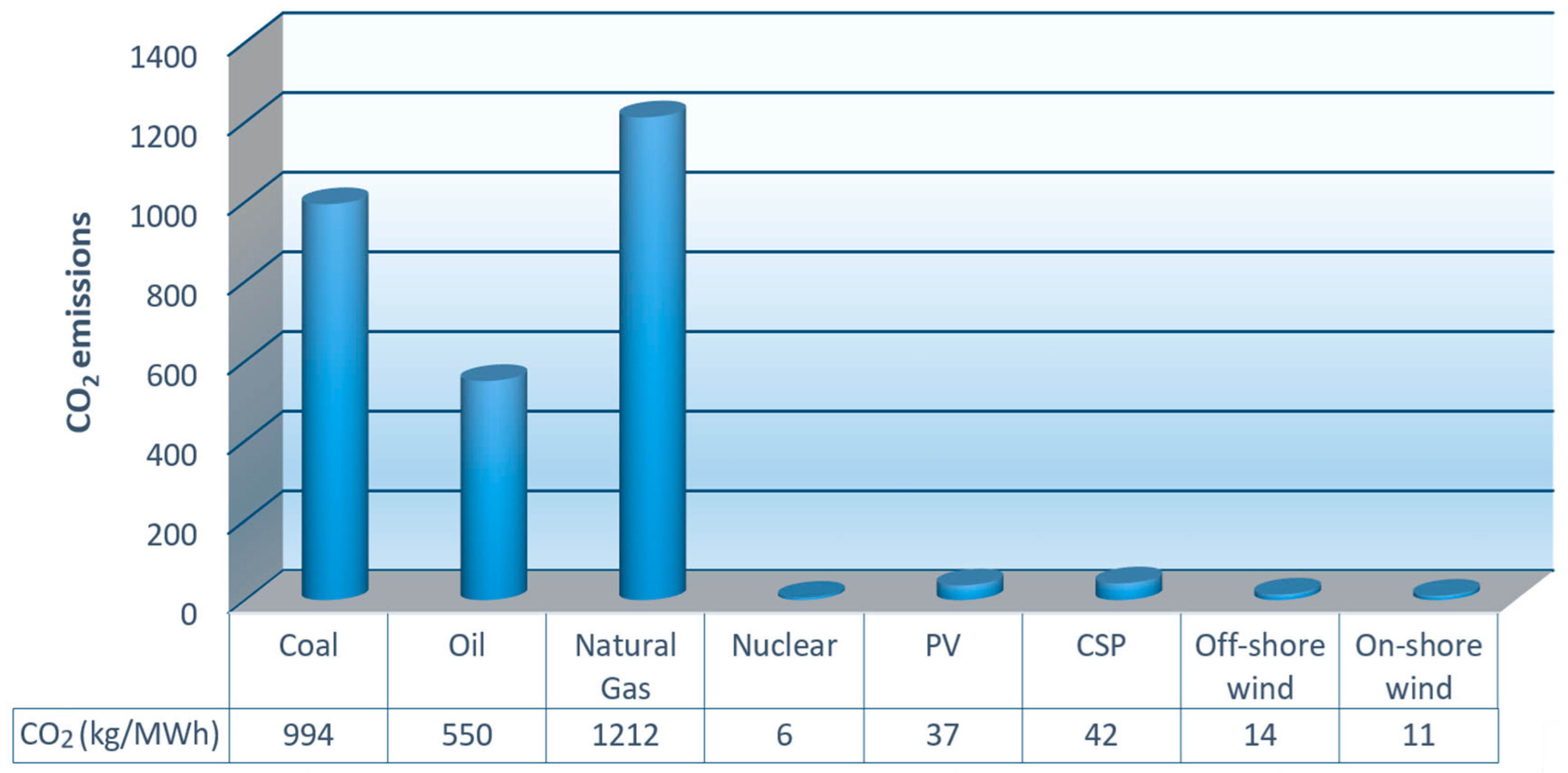

3.1. Emission of Greenhouse Gases

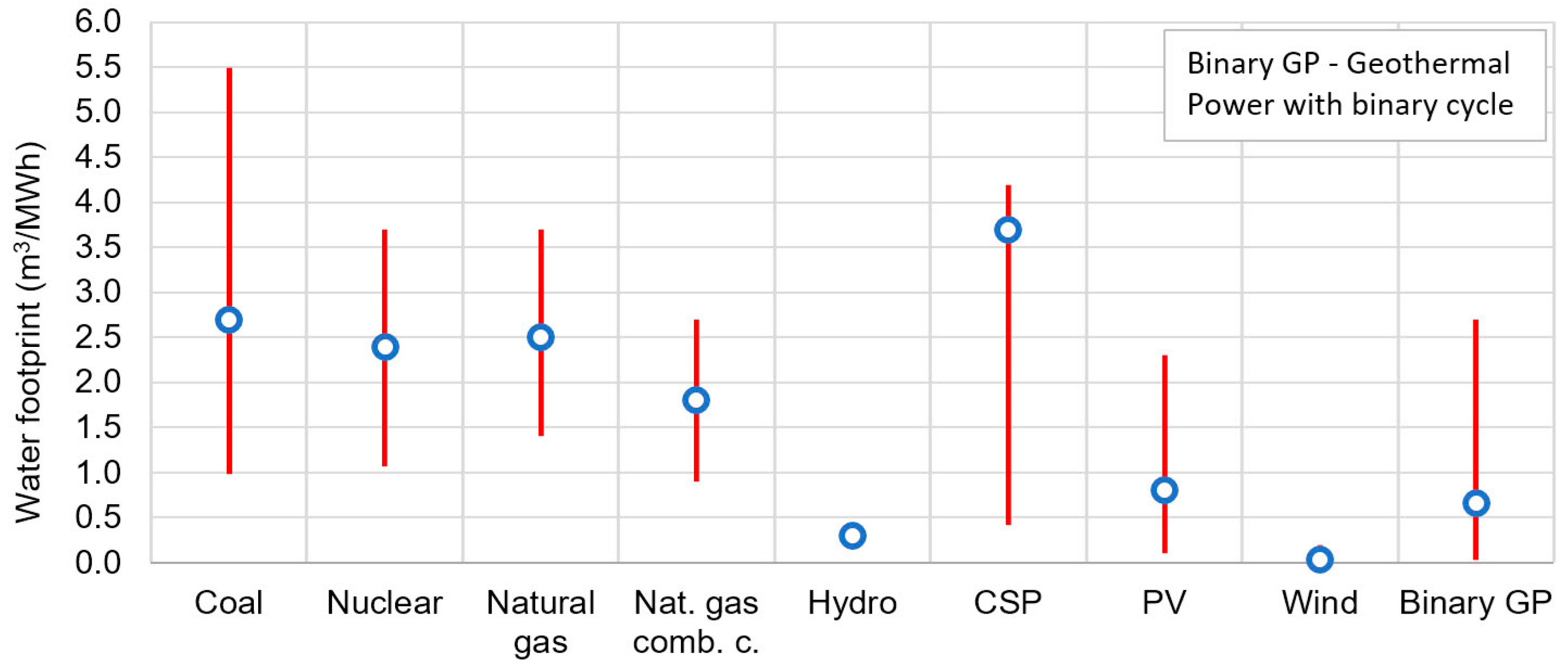

3.2. Water Footprint

3.3. Impact on Humans

3.3.1. Impact on Human Health

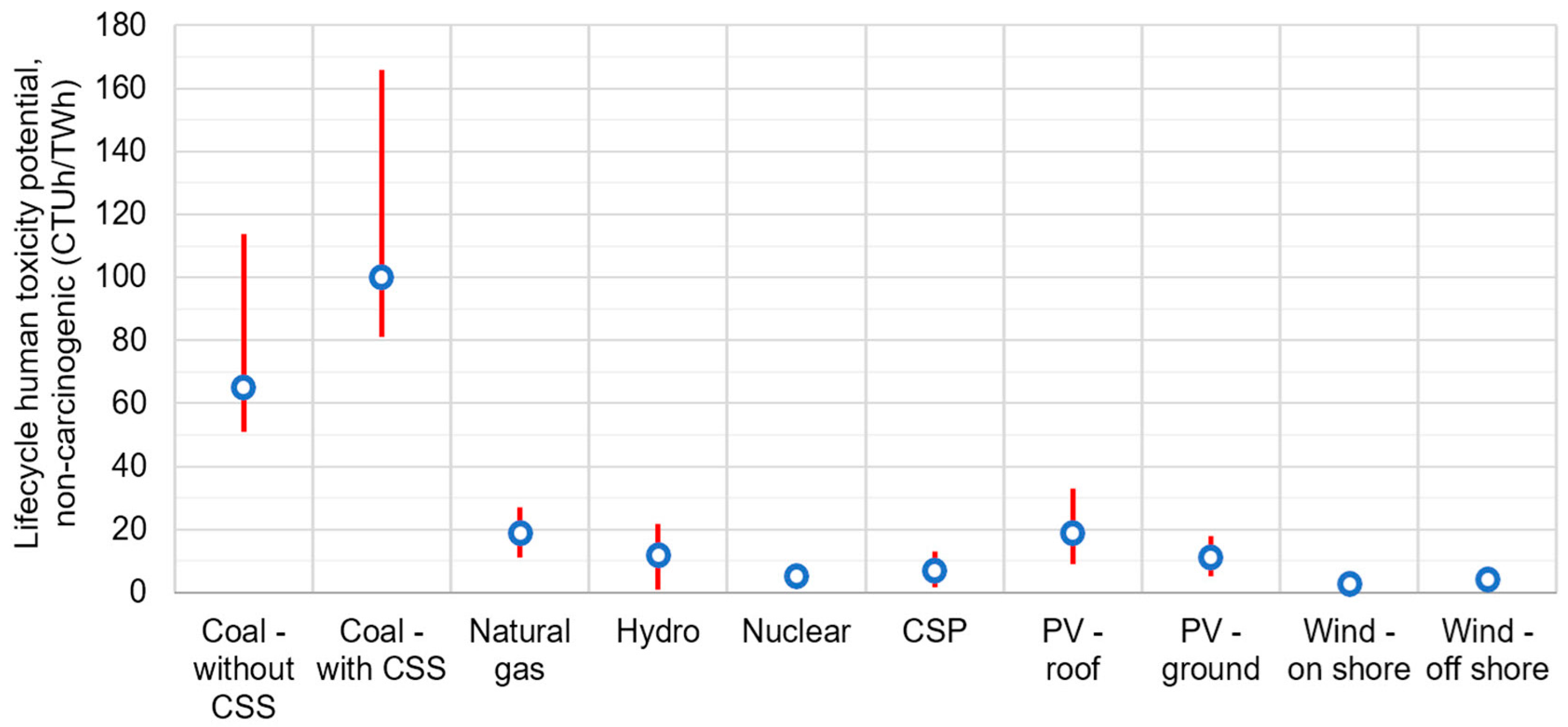

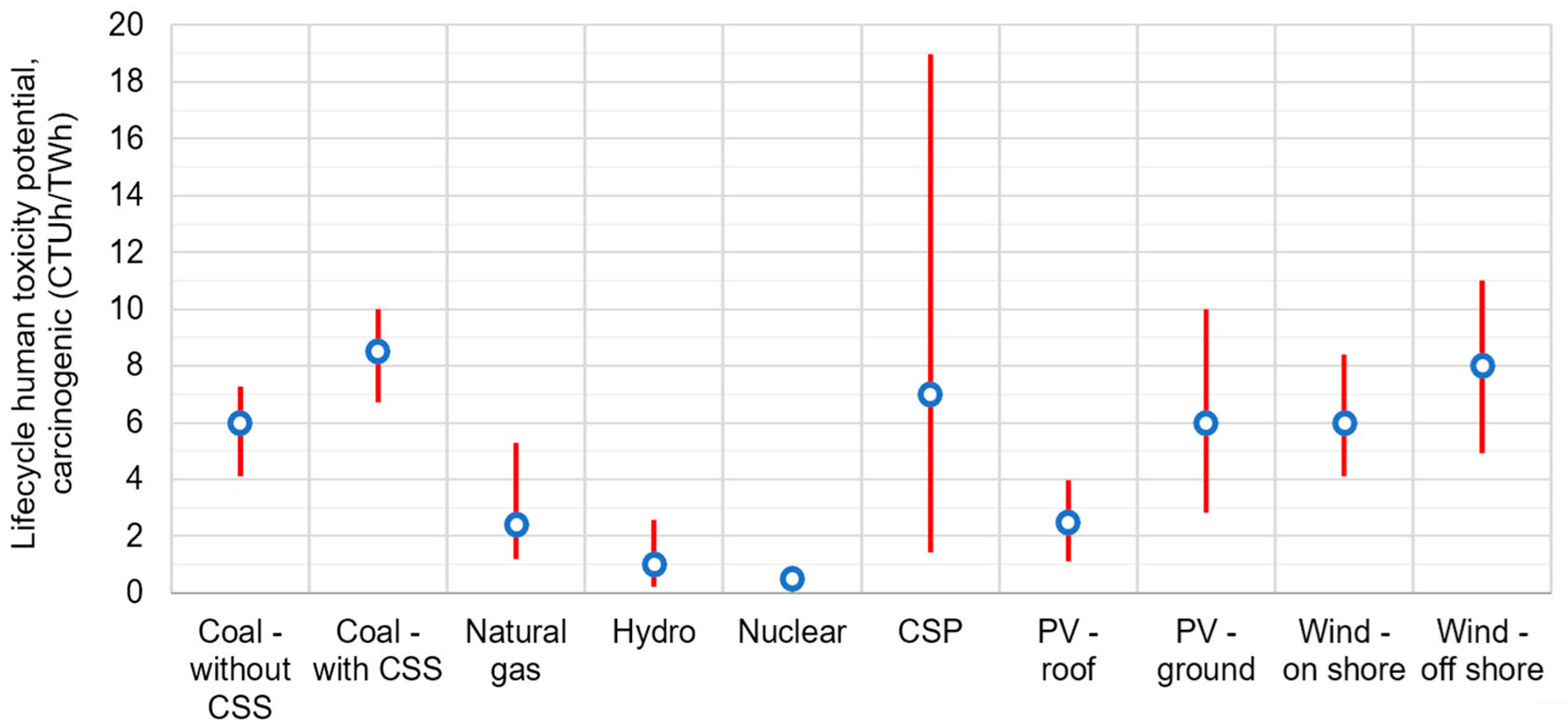

Toxicity

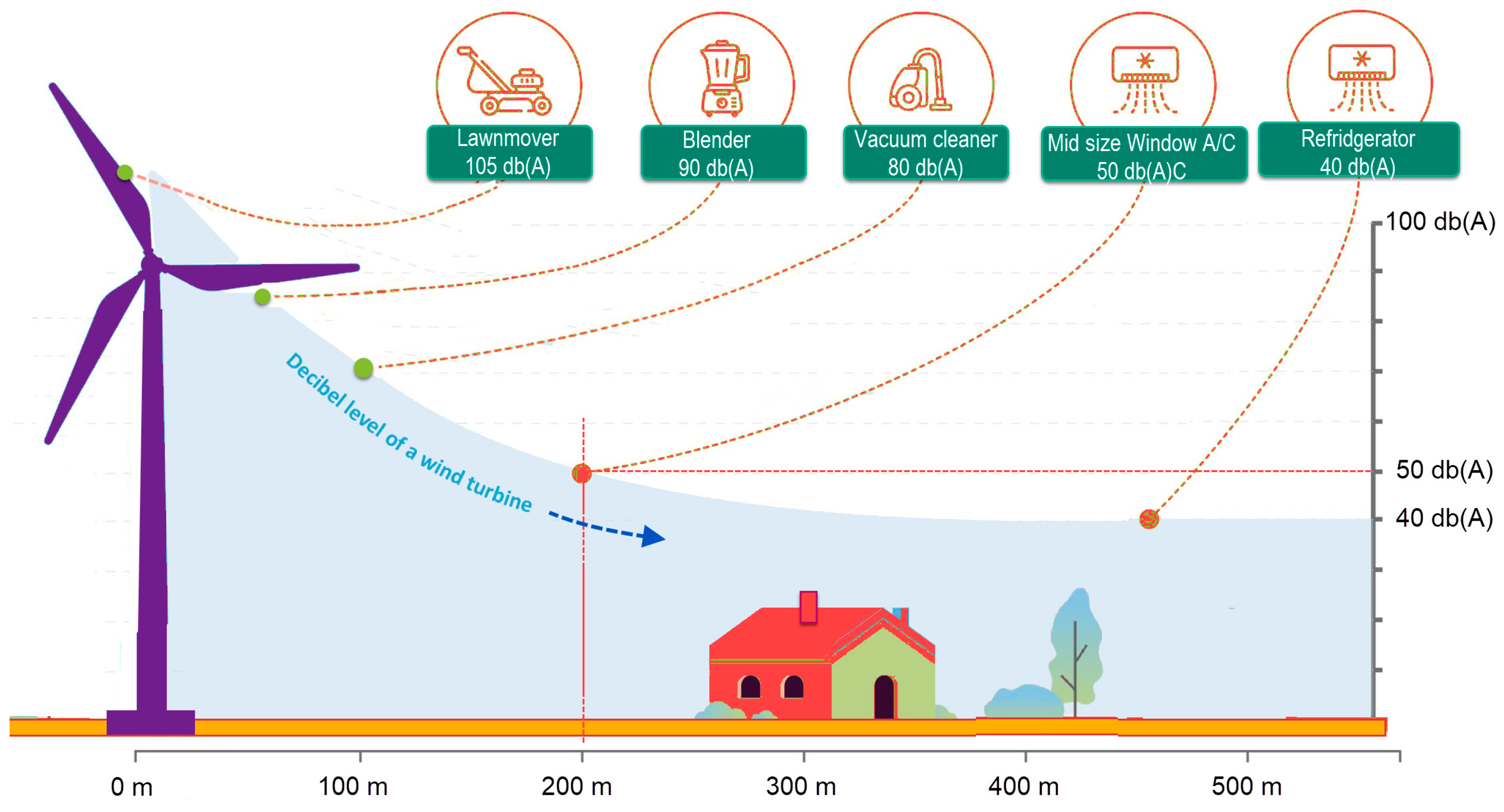

Noise

- ANSI S12.9-2005/Part 4—Quantities and procedures for describing and measuring sound in the environment—Part 4: Noise assessment and prediction of long-term community response [59];

- ISO 1996-1:2016—Acoustics—Description, measurement and assessment of noise in the environment Part 1: Basic quantities and assessment procedures [60];

- IEC 61400-11:2012—Wind turbines—Part 11: Acoustic noise measurement techniques [61];

- NZS6808:2010—Acoustics—Wind power plant noise [62].

Effect of Shadow Flicker

- The presence of covers such as vegetation, terrain and buildings. Shielding between the turbine and the wind farm reduces or eliminates SF;

- The standard approach is not to erect any objects within a distance of ten rotor diameters, as this is the limit within which significant shadow flicker effects can occur;

- For new buildings to be constructed, windows should be aligned to minimise the effects of SF.

Danger of Ice Flying off the Blades

Danger of Blade Parts Flying Off

3.3.2. Impact on Radio Waves and Air Traffic

- Formation of radar shadows behind wind turbines, which can result in lower targets being poorly recognised or not recognised at all. The relatively high frequencies used by the radar are attenuated when the signal passes through the wind farm, i.e., they shorten the range of the radar.

- Reflection of the radar beams from the wind turbines can lead to false radar targets (false echoes).

3.4. Impact on the Ecological System

3.4.1. Land Footprint

3.4.2. Habitat Destruction

3.4.3. Collision with a Wind Farm

3.4.4. Noise

Onshore Wind Farm Noise

- Be viewed as a direct danger, which would lead to an increase in predatory behavior at the expense of foraging or the departure of the afflicted region, which would result in the loss of habitat [120];

- Distract attention during foraging and reduce foraging efficiency [117];

- Influence the reproductive process. Taubmann et al. [123] reported that noise disturbs grouse up to a distance of 865 m. Increasing turbine noise, turbine visibility, and turbine shadow during the breeding season reduced the likelihood of selecting a breeding site.

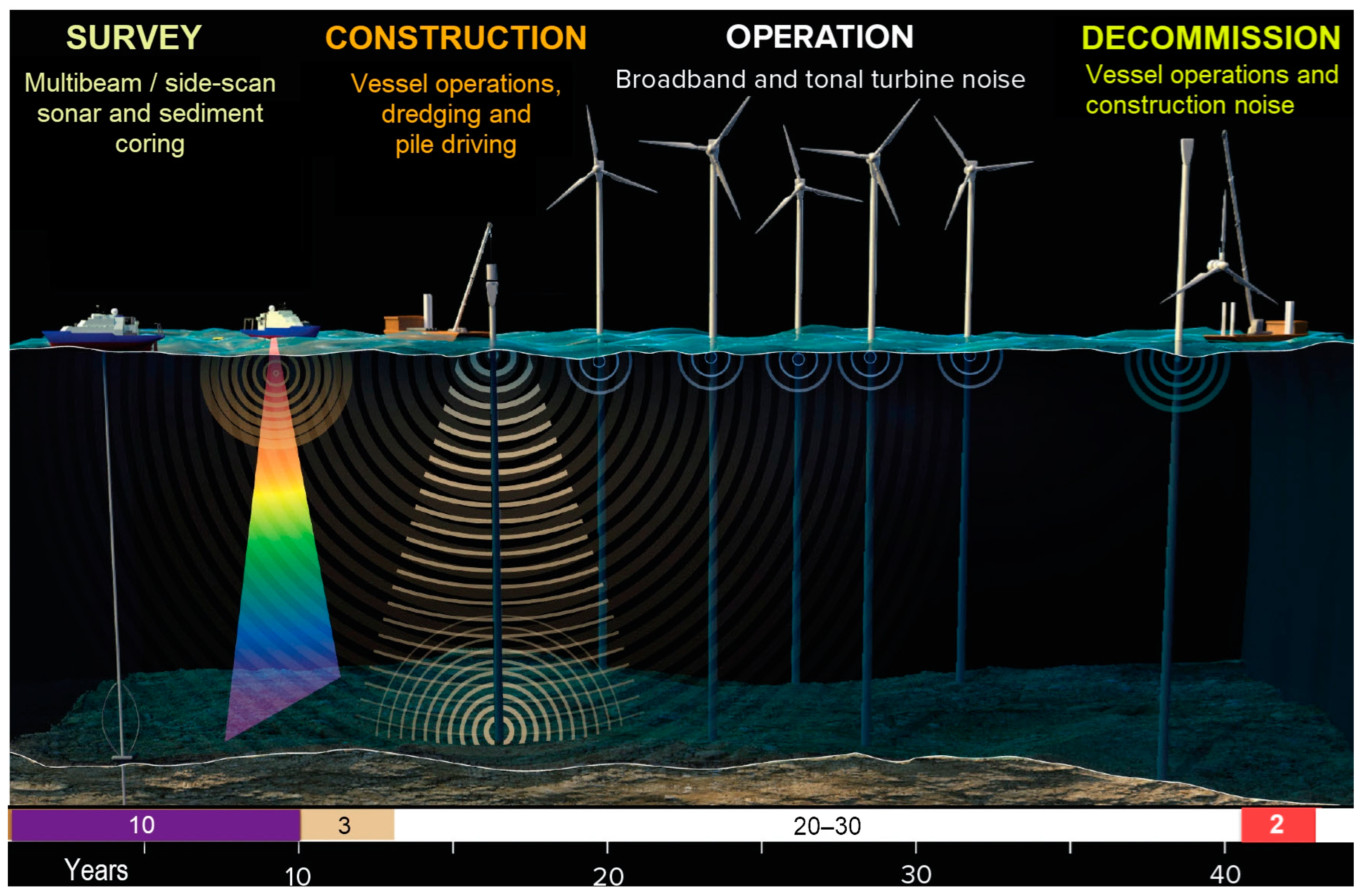

Offshore Wind Farm Noise

- Research and site investigation;

- Construction work;

- Operations;

- Decommissioning.

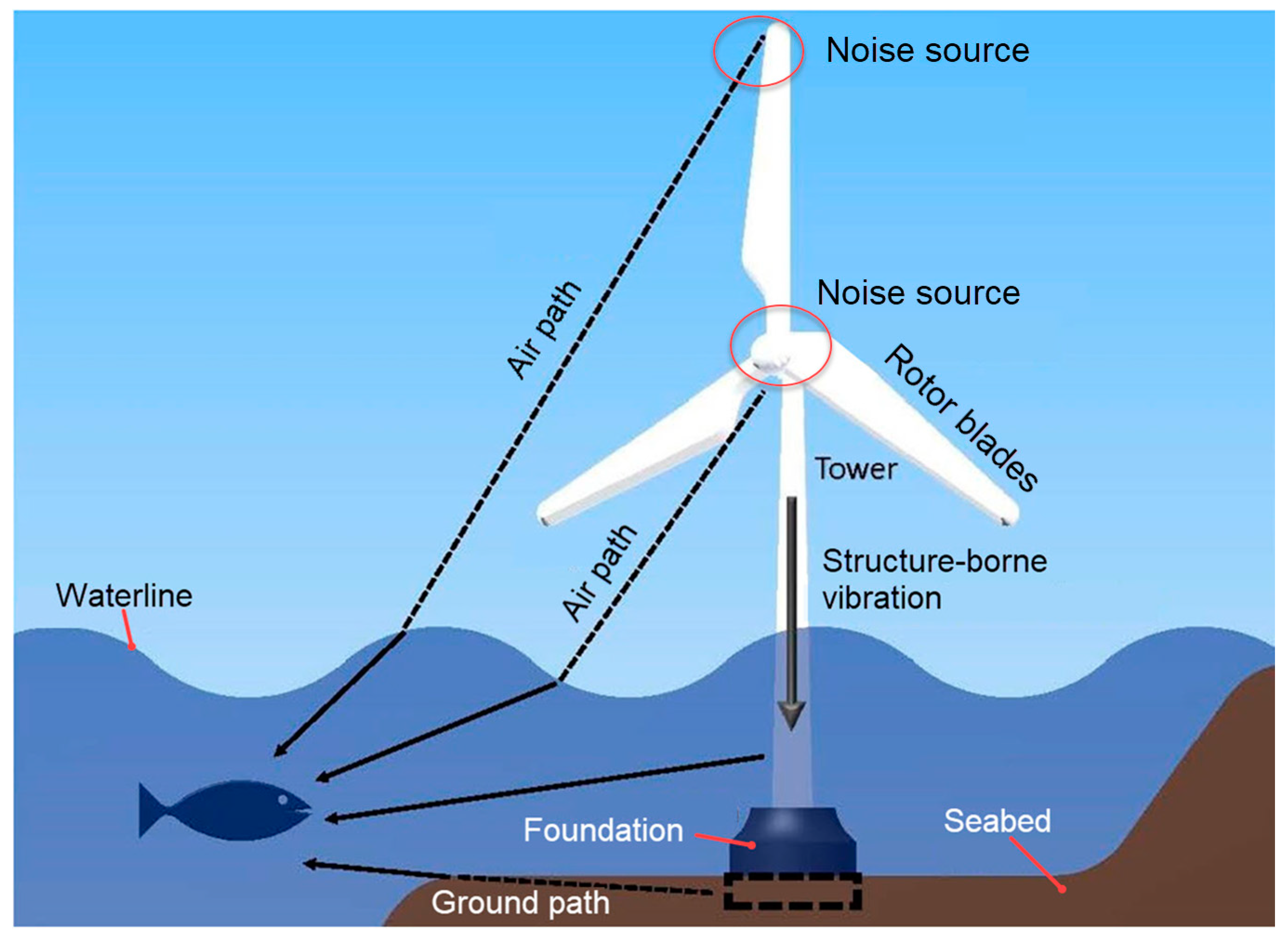

- The rotor blades generate aerodynamic noise that travels through the air and can pass through the air into the water.

- The airborne noise is generated by vibrations in the turbine support (tower), the nacelle and the rotor blades, so some of this noise hits the air-water interface.

- The foundation of the structure is in contact with the seabed and the vibrations of the structure create waves that can propagate along the seabed. These waves transmit the sound that propagates upwards in the water.

- The structural vibrations are loaded to the lower part of the tower and hit the interface between the turbine and the water. The majority of underwater noise comes from this route.

3.4.5. Influence of the Electromagnetic Field of Cables in the Sea

3.4.6. The Effects of Vibrations from Wind Turbines on the Ecological System

3.5. Impact on the Environment in the “End-of-Life” Phase

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rogelj, J.; Shindell, D.; Jiang, K.; Fifita, S.; Foster, P.; Ginzburg, V.; Handa, C.; Kheshgi, H.; Kobayashi, S.; Kriegler, E.; et al. Mitigation Pathways Compatible with 1.5 °C in the Context of Sustainable Development. In Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C Above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change; Masson-Delmotte, V., Zhai, P., Pörtner, H.-O., Roberts, D., Skea, J., Shukla, P.R., Pirani, A., Moufouma-Okia, W., Péan, C., Pidcock, R., et al., Eds.; IPCC/WMO: Geneva, Switzerland, 2018; pp. 93–174. [Google Scholar]

- Dammeier, L.C.; Loriaux, J.M.; Steinmann, Z.J.N.; Smits, D.A.; Wijnant, I.L.; van den Hurk, B.; Huijbregts, M.A.J. Space, Time, and Size Dependencies of Greenhouse Gas Payback Times of Wind Turbines in Northwestern Europe. Environ. Sci. Technol. 2019, 53, 9289–9297. [Google Scholar] [CrossRef] [PubMed]

- Andersen, H.; Martin Smith, H.; Nielsen, A.; Rahbek Nielsen, T.; Rodriguez Diez, J.; Venderby, C.; Pearce, A.; Alsbjerg, T. Vestas Sustainability Report 2023; Vestas: Aarhus, Denmark, 2024; p. 73. [Google Scholar]

- Bošnjaković, M.; Katinić, M.; Santa, R.; Marić, D. Wind Turbine Technology Trends. Appl. Sci. 2022, 12, 8653. [Google Scholar] [CrossRef]

- United Nations Economic Commission for Europe (UNECE). Carbon Neutrality in the UNECE Region: Integrated Life-Cycle Assessment of Electricity Sources; United Nations Economic Commission for Europe (UNECE): New York, NY, USA, 2022; p. 108. [Google Scholar]

- Li, L.; Ma, W.; Duan, X.; Wang, S.; Wang, Q.; Gu, H.; Wang, J. Effects of Wind Farm Construction on Soil Nutrients and Vegetation: A Case Study of Linxiang Wind Farm in Hunan Province. Sustainability 2024, 16, 6350. [Google Scholar] [CrossRef]

- Ze, J.; Xiuchun, Y.; Ang, C.; Dong, Y.; Min, Z.; Lunda, W. Localized Eco-Climatic Impacts of Onshore Wind Farms: A Review. J. Resour. Ecol. 2024, 15, 151–160. [Google Scholar] [CrossRef]

- Bennun, L.; van Bochove, J.; Ng, C.; Fletcher, C.; Wilson, D.; Phair, N.; Carbone, G. Biodiversity Impacts Associated to Onshore Wind Power Projects, 2021st ed.; Hunziker, D., Ed.; IUCN: Gland, Switzerland; The Biodiversity Consultancy: Cambridge, UK; Gland, Switzerland, 2021; ISBN 978-2-8317-2101-9. (PDF). [Google Scholar]

- Science X Studying the Impact of Wind Farms on Animal Species and the Ecology of the North Sea. Available online: https://phys.org/news/2023-01-impact-farms-animal-species-ecology.html (accessed on 24 July 2024).

- Liu, B.; Ma, X.; Guo, J.; Li, H.; Jin, S.; Ma, Y.; Gong, W. Estimating Hub-Height Wind Speed Based on a Machine Learning Algorithm: Implications for Wind Energy Assessment. Atmos. Chem. Phys. 2023, 23, 3181–3193. [Google Scholar] [CrossRef]

- Caduff, M.; Huijbregts, M.A.J.; Althaus, H.-J.; Koehler, A.; Hellweg, S. Wind Power Electricity: The Bigger the Turbine, The Greener the Electricity? Environ. Sci. Technol. 2012, 46, 4725–4733. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- C(2021) 9332 Final; Commission Recommendation on the Use of EF Methods. EU Commission: Brussels, Belgium, 2021; pp. 1–23.

- Sala, S.; Reale, F.; Cristóbal-García, J.; Marelli, L.; Rana, P. Life Cycle Assessment for the Impact Assessment of Policies. Life Thinking and Assessment in the European Policies and for Evaluating Policy Options. Jt. Res. Cent. 2016, 53. [Google Scholar] [CrossRef]

- Mello, G.; Ferreira Dias, M.; Robaina, M. Wind Farms Life Cycle Assessment Review: CO2 Emissions and Climate Change. Energy Rep. 2020, 6, 214–219. [Google Scholar] [CrossRef]

- Bošnjaković, M.; Tadijanović, V. Environment Impact of a Concentrated Solar Power Plant. Teh. Glas. 2019, 13, 68–74. [Google Scholar] [CrossRef]

- Bošnjaković, M.; Santa, R.; Crnac, Z.; Bošnjaković, T. Environmental Impact of PV Power Systems. Sustainability 2023, 15, 11888. [Google Scholar] [CrossRef]

- Isabella Pimentel Pincelli, J.H.; Brent, A. Developing Onshore Wind Farms in Aotearoa New Zealand: Carbon and Energy Footprints. J. R. Soc. N. Z. 2024, 1–23. [Google Scholar] [CrossRef]

- Oebels, K.B.; Pacca, S. Life Cycle Assessment of an Onshore Wind Farm Located at the Northeastern Coast of Brazil. Renew. Energy 2013, 53, 60–70. [Google Scholar] [CrossRef]

- Khaiyum, M.Z.; Sarker, S.; Kabir, G. Evaluation of Carbon Emission Factors in the Cement Industry: An Emerging Economy Context. Sustainability 2023, 15, 5407. [Google Scholar] [CrossRef]

- Belaïd, F. How Does Concrete and Cement Industry Transformation Contribute to Mitigating Climate Change Challenges? Resour. Conserv. Recycl. Adv. 2022, 15, 200084. [Google Scholar] [CrossRef]

- Eberle, A.; Cooperman, A.; Walzberg, J.; Hettinger, D.; Tusing, R.F.; Berry, D.; Inman, D.; Sirnivas, S.; Marquis, M.; Ennis, B.; et al. Materials Used in U.S. Wind Energy Technologies: Quantities and Availability for Two Future Scenarios; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2023. [Google Scholar]

- Khalil, E.A.; AbouZeid, M.N. Computation of the Environmental Performance of Ready-Mix Concrete for Reducing CO2 Emissions: A Case Study in Egypt. Energy Rep. 2023, 9, 144–148. [Google Scholar] [CrossRef]

- Li, X.; Hao, H.; Wang, H.; Zhang, L.; Guo, Y.; Lian, J.; Du, Y.; Wang, X.; Zeng, C. Design and Analysis of a New Prefabricated Foundation for Onshore Wind Turbines. Buildings 2024, 14, 193. [Google Scholar] [CrossRef]

- Knight, K.A.; Cunningham, P.R.; Miller, S.A. Optimizing Supplementary Cementitious Material Replacement to Minimize the Environmental Impacts of Concrete. Cem. Concr. Compos. 2023, 139, 105049. [Google Scholar] [CrossRef]

- Sustainability Performance of the Steel Industry 2004–2022; Worldsteel: Brussels, Belgium, 2023; pp. 1–9.

- Morini, A.A.; Ribeiro, M.J.; Hotza, D. Carbon Footprint and Embodied Energy of a Wind Turbine Blade—A Case Study. Int. J. Life Cycle Assess. 2021, 26, 1177–1187. [Google Scholar] [CrossRef]

- Liu, P.; Barlow, C.Y. The Environmental Impact of Wind Turbine Blades. IOP Conf. Ser. Mater. Sci. Eng. 2016, 139, 12032. [Google Scholar] [CrossRef]

- Yang, J.; Meng, F.; Zhang, L.; McKechnie, J.; Chang, Y.; Ma, B.; Hao, Y.; Li, X.; Pender, K.; Yang, L.; et al. Solutions for Recycling Emerging Wind Turbine Blade Waste in China Are Not yet Effective. Commun. Earth Environ. 2023, 4, 466. [Google Scholar] [CrossRef]

- OECD. Water Security for Better Lives; OECD Studies on Water: Paris, France, 2013; p. 173. [Google Scholar]

- Mekonnen, M.M.; Gerbens-Leenes, P.W.; Hoekstra, A.Y. The Consumptive Water Footprint of Electricity and Heat: A Global Assessment. Environ. Sci. Water Res. Technol. 2015, 1, 285–297. [Google Scholar] [CrossRef]

- Vanham, D.; Medarac, H.; Schyns, J.F.; Hogeboom, R.J.; Magagna, D. The Consumptive Water Footprint of the European Union Energy Sector. Environ. Res. Lett. 2019, 14, 104016. [Google Scholar] [CrossRef]

- Jin, Y.; Behrens, P.; Tukker, A.; Scherer, L. Water Use of Electricity Technologies: A Global Meta-Analysis. Renew. Sustain. Energy Rev. 2019, 115, 109391. [Google Scholar] [CrossRef]

- Saidur, R.; Rahim, N.A.; Islam, M.R.; Solangi, K.H. Environmental Impact of Wind Energy. Renew. Sustain. Energy Rev. 2011, 15, 2423–2430. [Google Scholar] [CrossRef]

- Jia, X.; Klemeš, J.J.; Tan, R.R. Overview of Water Use in Renewable Electricity Generation. Chem. Eng. Trans. 2021, 89, 403–408, SE-Research Articles. [Google Scholar] [CrossRef]

- Koulouri, A.; Moccia, J. Saving Water with Wind Energy; The European Wind Energy Association: Etterbeek, Brussels, 2014; p. 20. [Google Scholar]

- Abbasi, M.; Monazzam, M.R.; Ebrahimi, M.H.; Zakerian, S.A.; Dehghan, S.F.; Akbarzadeh, A. Assessment of Noise Effects of Wind Turbine on the General Health of Staff at Wind Farm of Manjil, Iran. J. Low Freq. Noise, Vib. Act. Control 2016, 35, 91–98. [Google Scholar] [CrossRef]

- SYED, Z. An Israeli Wind Project Draws Scrutiny on Turbines and People’s Health. Available online: https://www.popsci.com/environment/wind-turbines-effects-health/ (accessed on 23 July 2024).

- Schmidt, J.H.; Klokker, M. Health Effects Related to Wind Turbine Noise Exposure: A Systematic Review. PLoS ONE 2014, 9, e114183. [Google Scholar] [CrossRef]

- Erhart, S.; Erhart, K. Environmental Ranking of European Industrial Facilities by Toxicity and Global Warming Potentials. Sci. Rep. 2023, 13, 1772. [Google Scholar] [CrossRef]

- Papai, S.; De Bruyn, S.; Juijn, D.; De Vries, J. The Value of Human Toxicity; CE Delft: Delft, the Netherlands, 2021; p. 119. [Google Scholar]

- Wang, S. Near-Zero Air Pollutant Emission Technologies and Applications for Clean Coal-Fired Power. Engineering 2020, 6, 1408–1422. [Google Scholar] [CrossRef]

- Deshmukh, S.; Bhattacharya, S.; Jain, A.; Paul, A.R. Wind Turbine Noise and Its Mitigation Techniques: A Review. Energy Procedia 2019, 160, 633–640. [Google Scholar] [CrossRef]

- Martens, S.; Bohne, T.; Rolfes, R. Measuring and Analysing the Sound Propagation of Wind Turbines. In Proceedings of the 8th International Conference on Wind Turbine Noise, Lisbon, Portugal, 12–14 June 2019; p. 16. [Google Scholar]

- Hansen, C.; Hansen, K. Recent Advances in Wind Turbine Noise Research. Acoustics 2020, 2, 171–206. [Google Scholar] [CrossRef]

- Zhu, W.J.; Shen, W.Z.; Sørensen, J.N. Low-Noise Airfoil and Wind Turbine Design. In Wind Turbines; Aissaoui, A.G., Tahour, A., Eds.; IntechOpen: Rijeka, Croatia, 2016. [Google Scholar]

- Mathew, J.; Singh, A.; Madsen, J.; León, C.A. Serration Design Methodology for Wind Turbine Noise Reduction. J. Phys. Conf. Ser. 2016, 753, 22019. [Google Scholar] [CrossRef]

- Herr, M. Experimental Study on Noise Reduction through Trailing Edge Brushes. In New Results in Numerical and Experimental Fluid Mechanics V; Rath, H.-J., Holze, C., Heinemann, H.-J., Henke, R., Hönlinger, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 365–372. [Google Scholar]

- Geyer, T.F.; Schneehagen, E.W.; Herold, G.; Zang, T.; Moreau, D.J. Reduction of Rotor Aerodynamic Noise Using Porous Blade Tips. In Proceedings of the Fortschritte der Akustik—DAGA 2024, Hannover, Germany, 18–21 March 2024. [Google Scholar]

- Paruchuri, C.; Joseph, P.; Ayton, L.J. On the Superior Performance of Leading Edge Slits over Serrations for the Reduction of Aerofoil Interaction Noise. In Proceedings of the 2018 AIAA/CEAS Aeroacoustics Conference, Atlanta, Georgia, 25-29 June 2018. [Google Scholar]

- Masud, M.H.; Naim-Ul-Hasan; Arefin, A.M.E.; Joardder, M.U.H. Design Modification of Airfoil by Integrating Sinusoidal Leading Edge and Dimpled Surface. AIP Conf. Proc. 2017, 1851, 20048. [Google Scholar] [CrossRef]

- Gang, L.; Zhengtao, Z.; Pingguo, Z. Numerical Study on Noise Reduction of Wind Turbine Blade Vortex Generator. IOP Conf. Ser. Earth Environ. Sci. 2019, 358, 022026. [Google Scholar] [CrossRef]

- Arnold, B.; Lutz, T.; Krämer, E. Design of a Boundary-Layer Suction System for Turbulent Trailing-Edge Noise Reduction of Wind Turbines. Renew. Energy 2018, 123, 249–262. [Google Scholar] [CrossRef]

- Evans, T.; Cooper, J. Influence of Wind Direction on Noise Emission and Propagation from Wind Turbines. In Proceedings of the Acoustics 2012 Fremantle: Acoustics, Development and the Environment, Fremantle, Australia, 21–23 November 2012; Australian Acoustical Society: Fremantle, Australia, 2012; p. 5. [Google Scholar]

- Josimović, B.; Bezbradica, L.; Manić, B.; Srnić, D.; Srebrić, N. Cumulative Impact of Wind Farm Noise. Appl. Sci. 2023, 13, 8792. [Google Scholar] [CrossRef]

- Chiu, C.-H.; Lung, S.-C.C.; Chen, N.; Hwang, J.-S.; Tsou, M.-C.M. Effects of Low-Frequency Noise from Wind Turbines on Heart Rate Variability in Healthy Individuals. Sci. Rep. 2021, 11, 17817. [Google Scholar] [CrossRef]

- Thorsson, P.; Persson Waye, K.; Smith, M.; Ögren, M.; Pedersen, E.; Forssén, J. Low-Frequency Outdoor–Indoor Noise Level Difference for Wind Turbine Assessment. J. Acoust. Soc. Am. 2018, 143, EL206–EL211. [Google Scholar] [CrossRef]

- Wind Turbine Noise and Health Study: Summary of Results. Available online: https://www.canada.ca/en/health-canada/services/health-risks-safety/radiation/everyday-things-emit-radiation/wind-turbine-noise/wind-turbine-noise-health-study-summary-results.html (accessed on 28 July 2024).

- ANSI S12.9-Part 4-2005; Quantities And Procedures For Description And Measurement Of Environmental Sound—Part 4: Noise Assessment And Prediction Of Long-Term Community Response. Standards Secretariat Acoustical Society of America: New York, NY, USA, 2005.

- ISO 1996-1:2016; Acoustics–Description, Measurement and Assessment of Environmental Noise Part 1: Basic Quantities and Assessment Procedures. ISO: Geneva, Switzerland, 2016; p. 47.

- IEC 61400-11:2012; Wind Turbines—Part 11: Acoustic Noise Measurement Techniques. International Electrotechnical Commission: Singapore, 2012; p. 58.

- NZS 6808:2010; Acoustics—Wind Farm Noise. New Zealand High Commission: Singapore, 2010; p. 48.

- Nieuwenhuizen, E.; Köhl, M. Differences in Noise Regulations for Wind Turbines in Four European Countries. In Proceedings of the EuroNoise 2015, Maastricht, The Netherlands, 31 May–3 June 2015; pp. 333–338. [Google Scholar]

- Koppen, E.; Gunuru, M.; Chester, A. International Legislation and Regulations for Wind Turbine Shadow Flicker Impact. In Proceedings of the 7th International Conference on Wind Turbine Noise, Rotterdam, The Netherlands, 2–5 May 2017. [Google Scholar]

- Lindvall, T.; Radford, E.P. Measurement of Annoyance Due to Exposure to Environmental Factors: The Fourth Karolinska Institute Symposium on Environmental Health. Environ. Res. 1973, 6, 1–36. [Google Scholar] [CrossRef]

- Haac, R.; Darlow, R.; Kaliski, K.; Rand, J.; Hoen, B. In the Shadow of Wind Energy: Predicting Community Exposure and Annoyance to Wind Turbine Shadow Flicker in the United States. Energy Res. Soc. Sci. 2022, 87, 102471. [Google Scholar] [CrossRef]

- Voicescu, S.A.; Michaud, D.S.; Feder, K.; Marro, L.; Than, J.; Guay, M.; Denning, A.; Bower, T.; van den Berg, F.; Broner, N.; et al. Estimating Annoyance to Calculated Wind Turbine Shadow Flicker Is Improved When Variables Associated with Wind Turbine Noise Exposure Are Considered. J. Acoust. Soc. Am. 2016, 139, 1480–1492. [Google Scholar] [CrossRef] [PubMed]

- Godreau, C.; Paquet, Y.; Froidevaux, P.; Krenn, A.; Wickman, H. IEA Wind TCP Task 19 Technical Report Ice Detection Guidelines for Wind Energy Applications; IEA Wind: Paris, France, 2021. [Google Scholar]

- Summary of Wind Turbine Accident Data to 30 June 2024. Available online: https://scotlandagainstspin.org/turbine-accident-statistics/ (accessed on 12 August 2024).

- Madi, E.; Pope, K.; Huang, W.; Iqbal, T. A Review of Integrating Ice Detection and Mitigation for Wind Turbine Blades. Renew. Sustain. Energy Rev. 2019, 103, 269–281. [Google Scholar] [CrossRef]

- Rekuviene, R.; Saeidiharzand, S.; Mažeika, L.; Samaitis, V.; Jankauskas, A.; Sadaghiani, A.K.; Gharib, G.; Muganlı, Z.; Koşar, A. A Review on Passive and Active Anti-Icing and de-Icing Technologies. Appl. Therm. Eng. 2024, 250, 123474. [Google Scholar] [CrossRef]

- Chatterjee, J.; Alvela Nieto, M.T.; Gelbhardt, H.; Dethlefs, N.; Ohlendorf, J.-H.; Greulich, A.; Thoben, K.-D. Domain-Invariant Icing Detection on Wind Turbine Rotor Blades with Generative Artificial Intelligence for Deep Transfer Learning. Environ. Data Sci. 2023, 2, e12. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr. Root Causes and Mechanisms of Failure of Wind Turbine Blades: Overview. Materials 2022, 15, 2959. [Google Scholar] [CrossRef]

- Sarlak, H.; Sørensen, J.N. Analysis of Throw Distances of Detached Objects from Horizontal-Axis Wind Turbines. Wind Energy 2016, 19, 151–166. [Google Scholar] [CrossRef]

- Asian, S.; Ertek, G.; Haksoz, C.; Pakter, S.; Ulun, S. Wind Turbine Accidents: A Data Mining Study. IEEE Syst. J. 2017, 11, 1567–1578. [Google Scholar] [CrossRef]

- Auld, T.; McHenry, M.P.; Whale, J. Options to Mitigate Utility-Scale Wind Turbine Impacts on Defence Capability, Air Supremacy, and Missile Detection. Renew. Energy 2014, 63, 255–262. [Google Scholar] [CrossRef][Green Version]

- TRAFICOM. The Impact of Wind Farms on Radio Systems and the Reduction of Adverse Effects. Available online: https://www.traficom.fi/sites/default/files/media/file/Tuulivoimala_taajuusliite_EN.pdf (accessed on 24 July 2024).

- ATDI. Managing the Impact of Wind Farms on Military Communication Systems. Available online: https://atdi.com/military-wind-farm-mitigation-strategies/ (accessed on 24 July 2024).

- Angulo, I.; de la Vega, D.; Cascón, I.; Cañizo, J.; Wu, Y.; Guerra, D.; Angueira, P. Impact Analysis of Wind Farms on Telecommunication Services. Renew. Sustain. Energy Rev. 2014, 32, 84–99. [Google Scholar] [CrossRef]

- Helldin, J.O.; Jung, J.; Kindberg, J.; Lindberg, N.; Neumann, W.; Olsson, M.; Skarin, A.; Widemo, F. Effects of Wind Power on Terrestrial Mammals—A Synthesis; Swedish Environmental Protection Agency: Stockholm, Sweden, 2012. [Google Scholar]

- Watson, S.C.L.; Somerfield, P.J.; Lemasson, A.J.; Knights, A.M.; Edwards-Jones, A.; Nunes, J.; Pascoe, C.; McNeill, C.L.; Schratzberger, M.; Thompson, M.S.A.; et al. The Global Impact of Offshore Wind Farms on Ecosystem Services. Ocean Coast. Manag. 2024, 249, 107023. [Google Scholar] [CrossRef]

- Ivanov, E.; Capet, A.; De Borger, E.; Degraer, S.; Delhez, E.J.M.; Soetaert, K.; Vanaverbeke, J.; Grégoire, M. Offshore Wind Farm Footprint on Organic and Mineral Particle Flux to the Bottom. Front. Mar. Sci. 2021, 8, 631799. [Google Scholar] [CrossRef]

- Gartman, V.; Bulling, L.; Dahmen, M.; Geißler, G.; Köppel, J. Mitigation Measures for Wildlife in Wind Energy Development, Consolidating the State of Knowledge—Part 1: Planning and Siting, Construction. J. Environ. Assess. Policy Manag. 2016, 18, 1650013. [Google Scholar] [CrossRef]

- Denholm, P.; Hand, M.; Jackson, M.; Ong, S. Land-Use Requirements of Modern Wind Power Plants in the United States; National Renewable Energy Laboratory: Golden, CO, USA, 2009. [Google Scholar]

- Harrison-Atlas, D.; Lopez, A.; Lantz, E. Dynamic Land Use Implications of Rapidly Expanding and Evolving Wind Power Deployment. Environ. Res. Lett. 2022, 17, 044064. [Google Scholar] [CrossRef]

- Costanzo, G.; Brindley, G. Wind Energy in Europe—2023 Statistics and the Outlook for 2024–2030; WindEurope: Brussels, Belgium, 2024. [Google Scholar]

- IRENA. Future of Wind: Deployment, Investment, Technology, Grid Integration and Socio-Economic Aspects; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019; ISBN 9789292601553. [Google Scholar]

- Plumb, R.T.; Lautenbach, J.M.; Robinson, S.G.; Haukos, D.A.; Winder, V.L.; Hagen, C.A.; Sullins, D.S.; Pitman, J.C.; Dahlgren, D.K. Lesser Prairie-Chicken Space Use in Relation to Anthropogenic Structures. J. Wildl. Manage. 2019, 83, 216–230. [Google Scholar] [CrossRef]

- Pearce-Higgins, J.W.; Stephen, L.; Douse, A.; Langston, R.H.W. Greater Impacts of Wind Farms on Bird Populations during Construction than Subsequent Operation: Results of a Multi-Site and Multi-Species Analysis. J. Appl. Ecol. 2012, 49, 386–394. [Google Scholar] [CrossRef]

- Kiesecker, J.; Baruch-Mordo, S.; Kennedy, C.M.; Oakleaf, J.R.; Baccini, A.; Griscom, B.W. Hitting the Target but Missing the Mark: Unintended Environmental Consequences of the Paris Climate Agreement. Front. Environ. Sci. 2019, 7, 151. [Google Scholar] [CrossRef]

- Tolvanen, A.; Routavaara, H.; Jokikokko, M.; Rana, P. How Far Are Birds, Bats, and Terrestrial Mammals Displaced from Onshore Wind Power Development?—A Systematic Review. Biol. Conserv. 2023, 288, 110382. [Google Scholar] [CrossRef]

- Pasanen-Mortensen, M.; Elmhagen, B. Land Cover Effects on Mesopredator Abundance in the Presence and Absence of Apex Predators. Acta Oecologica 2015, 67, 40–48. [Google Scholar] [CrossRef]

- Hradsky, B.A.; Robley, A.; Alexander, R.; Ritchie, E.G.; York, A.; Di Stefano, J. Human-Modified Habitats Facilitate Forest-Dwelling Populations of an Invasive Predator, Vulpes Vulpes. Sci. Rep. 2017, 7, 12291. [Google Scholar] [CrossRef]

- Coppes, J.; Ehrlacher, J.; Thiel, D.; Suchant, R.; Braunisch, V. Outdoor Recreation Causes Effective Habitat Reduction in Capercaillie Tetrao Urogallus: A Major Threat for Geographically Restricted Populations. J. Avian Biol. 2017, 48, 1583–1594. [Google Scholar] [CrossRef]

- Braunisch, V.; Coppes, J.; Bächle, S.; Suchant, R. Underpinning the Precautionary Principle with Evidence: A Spatial Concept for Guiding Wind Power Development in Endangered Species’ Habitats. J. Nat. Conserv. 2015, 24, 31–40. [Google Scholar] [CrossRef]

- Foo, C.F.; Bennett, V.J.; Hale, A.M.; Korstian, J.M.; Schildt, A.J.; Williams, D.A. Increasing Evidence That Bats Actively Forage at Wind Turbines. PeerJ 2017, 5, e3985. [Google Scholar] [CrossRef]

- Rollins, K.E.; Meyerholz, D.K.; Johnson, G.D.; Capparella, A.P.; Loew, S.S. A Forensic Investigation Into the Etiology of Bat Mortality at a Wind Farm: Barotrauma or Traumatic Injury? Vet. Pathol. 2012, 49, 362–371. [Google Scholar] [CrossRef]

- HORN, J.W.; ARNETT, E.B.; KUNZ, T.H. Behavioral Responses of Bats to Operating Wind Turbines. J. Wildl. Manag. 2008, 72, 123–132. [Google Scholar] [CrossRef]

- Erickson, W.P.; Wolfe, M.M.; Bay, K.J.; Johnson, D.H.; Gehring, J.L. A Comprehensive Analysis of Small-Passerine Fatalities from Collision with Turbines at Wind Energy Facilities. PLoS ONE 2014, 9, e107491. [Google Scholar] [CrossRef]

- Thaxter, C.B.; Buchanan, G.M.; Carr, J.; Butchart, S.H.M.; Newbold, T.; Green, R.E.; Tobias, J.A.; Foden, W.B.; O’Brien, S.; Pearce-Higgins, J.W. Bird and Bat Species’ Global Vulnerability to Collision Mortality at Wind Farms Revealed through a Trait-Based Assessment. Proc. R. Soc. B Biol. Sci. 2017, 284, 20170829. [Google Scholar] [CrossRef]

- Barclay, R.M.R.; Baerwald, E.F.; Gruver, J.C. Variation in Bat and Bird Fatalities at Wind Energy Facilities: Assessing the Effects of Rotor Size and Tower Height. Can. J. Zool. 2007, 85, 381–387. [Google Scholar] [CrossRef]

- Sovacool, B.K. The Avian Benefits of Wind Energy: A 2009 Update. Renew. Energy 2013, 49, 19–24. [Google Scholar] [CrossRef]

- Voigt, C.C.; Straka, T.M.; Fritze, M. Producing Wind Energy at the Cost of Biodiversity: A Stakeholder View on a Green-Green Dilemma. J. Renew. Sustain. Energy 2019, 11, 63303. [Google Scholar] [CrossRef]

- May, R.; Nygård, T.; Falkdalen, U.; Åström, J.; Hamre, Ø.; Stokke, B.G. Paint It Black: Efficacy of Increased Wind Turbine Rotor Blade Visibility to Reduce Avian Fatalities. Ecol. Evol. 2020, 10, 8927–8935. [Google Scholar] [CrossRef] [PubMed]

- Tomé, R.; Canário, F.; Leitão, A.H.; Pires, N.; Repas, M. Radar Assisted Shutdown on Demand Ensures Zero Soaring Bird Mortality at a Wind Farm Located in a Migratory Flyway. In Wind Energy and Wildlife Interactions: Presentations from the CWW2015 Conference; Köppel, J., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 119–133. ISBN 978-3-319-51272-3. [Google Scholar]

- Weaver, S.P.; Hein, C.D.; Simpson, T.R.; Evans, J.W.; Castro-Arellano, I. Ultrasonic Acoustic Deterrents Significantly Reduce Bat Fatalities at Wind Turbines. Glob. Ecol. Conserv. 2020, 24, e01099. [Google Scholar] [CrossRef]

- Hayes, M.A.; Hooton, L.A.; Gilland, K.L.; Grandgent, C.; Smith, R.L.; Lindsay, S.R.; Collins, J.D.; Schumacher, S.M.; Rabie, P.A.; Gruver, J.C.; et al. A Smart Curtailment Approach for Reducing Bat Fatalities and Curtailment Time at Wind Energy Facilities. Ecol. Appl. 2019, 29, e01881. [Google Scholar] [CrossRef]

- Rabie, P.A.; Welch-Acosta, B.; Nasman, K.; Schumacher, S.; Schueller, S.; Gruver, J. Efficacy and Cost of Acoustic-Informed and Wind Speed-Only Turbine Curtailment to Reduce Bat Fatalities at a Wind Energy Facility in Wisconsin. PLoS ONE 2022, 17, e266500. [Google Scholar] [CrossRef]

- Pescador, M.; Gómez Ramírez, J.I.; Peris, S.J. Effectiveness of a Mitigation Measure for the Lesser Kestrel (Falco Naumanni) in Wind Farms in Spain. J. Environ. Manag. 2019, 231, 919–925. [Google Scholar] [CrossRef]

- Martin, G.R.; Banks, A.N. Marine Birds: Vision-Based Wind Turbine Collision Mitigation. Glob. Ecol. Conserv. 2023, 42, e02386. [Google Scholar] [CrossRef]

- Thaxter, C.B.; Ross-Smith, V.H.; Bouten, W.; Clark, N.A.; Conway, G.J.; Masden, E.A.; Clewley, G.D.; Barber, L.J.; Burton, N.H.K. Avian Vulnerability to Wind Farm Collision through the Year: Insights from Lesser Black-Backed Gulls (Larus Fuscus) Tracked from Multiple Breeding Colonies. J. Appl. Ecol. 2019, 56, 2410–2422. [Google Scholar] [CrossRef]

- Vasilakis, D.P.; Whitfield, D.P.; Schindler, S.; Poirazidis, K.S.; Kati, V. Reconciling Endangered Species Conservation with Wind Farm Development: Cinereous Vultures (Aegypius monachus) in South-Eastern Europe. Biol. Conserv. 2016, 196, 10–17. [Google Scholar] [CrossRef]

- Warwick-Evans, V.; Atkinson, P.W.; Walkington, I.; Green, J.A. Predicting the Impacts of Wind Farms on Seabirds: An Individual-Based Model. J. Appl. Ecol. 2018, 55, 503–515. [Google Scholar] [CrossRef]

- Gauld, J.G.; Silva, J.P.; Atkinson, P.W.; Record, P.; Acácio, M.; Arkumarev, V.; Blas, J.; Bouten, W.; Burton, N.; Catry, I.; et al. Hotspots in the Grid: Avian Sensitivity and Vulnerability to Collision Risk from Energy Infrastructure Interactions in Europe and North Africa. J. Appl. Ecol. 2022, 59, 1496–1512. [Google Scholar] [CrossRef]

- Duerr, A.E.; Parsons, A.E.; Nagy, L.R.; Kuehn, M.J.; Bloom, P.H. Effectiveness of an Artificial Intelligence-Based System to Curtail Wind Turbines to Reduce Eagle Collisions. PLoS ONE 2023, 18, e278754. [Google Scholar] [CrossRef] [PubMed]

- Francis, C.D.; Barber, J.R. A Framework for Understanding Noise Impacts on Wildlife: An Urgent Conservation Priority. Front. Ecol. Environ. 2013, 11, 305–313. [Google Scholar] [CrossRef]

- Dominoni, D.M.; Halfwerk, W.; Baird, E.; Buxton, R.T.; Fernández-Juricic, E.; Fristrup, K.M.; McKenna, M.F.; Mennitt, D.J.; Perkin, E.K.; Seymoure, B.M.; et al. Why Conservation Biology Can Benefit from Sensory Ecology. Nat. Ecol. Evol. 2020, 4, 502–511. [Google Scholar] [CrossRef] [PubMed]

- Kleist, N.J.; Guralnick, R.P.; Cruz, A.; Lowry, C.A.; Francis, C.D. Chronic Anthropogenic Noise Disrupts Glucocorticoid Signaling and Has Multiple Effects on Fitness in an Avian Community. Proc. Natl. Acad. Sci. USA 2018, 115, E648–E657. [Google Scholar] [CrossRef]

- Teff-Seker, Y.; Berger-Tal, O.; Lehnardt, Y.; Teschner, N. Noise Pollution from Wind Turbines and Its Effects on Wildlife: A Cross-National Analysis of Current Policies and Planning Regulations. Renew. Sustain. Energy Rev. 2022, 168, 112801. [Google Scholar] [CrossRef]

- Ware, H.E.; McClure, C.J.W.; Carlisle, J.D.; Barber, J.R.; Daily, G.C. A Phantom Road Experiment Reveals Traffic Noise Is an Invisible Source of Habitat Degradation. Proc. Natl. Acad. Sci. USA 2015, 112, 12105–12109. [Google Scholar] [CrossRef]

- Slabbekoorn, H.; Peet, M. Birds Sing at a Higher Pitch in Urban Noise. Nature 2003, 424, 267. [Google Scholar] [CrossRef]

- Rosa, P.; Koper, N. Integrating Multiple Disciplines to Understand Effects of Anthropogenic Noise on Animal Communication. Ecosphere 2018, 9, e02127. [Google Scholar] [CrossRef]

- Taubmann, J.; Kämmerle, J.-L.; Andrén, H.; Braunisch, V.; Storch, I.; Fiedler, W.; Suchant, R.; Coppes, J. Wind Energy Facilities Affect Resource Selection of Capercaillie Tetrao Urogallus. Wildlife Biol. 2021, 2021, 1–13. [Google Scholar] [CrossRef]

- Mooney, A.; Andersson, M.H.; Stanley, J. Acoustic Impacts of Offshore Wind Energy on Fishery Resources. Oceanography 2020, 33, 82–95. [Google Scholar] [CrossRef]

- Engås, A.; Løkkeborg, S.; Ona, E.; Soldal, A. V Effects of Seismic Shooting on Local Abundance and Catch Rates of Cod ((Gadus morhua) and Haddock) (Melanogrammus aeglefinus). Can. J. Fish. Aquat. Sci. 1996, 53, 2238–2249. [Google Scholar] [CrossRef]

- Slotte, A.; Hansen, K.; Dalen, J.; Ona, E. Acoustic Mapping of Pelagic Fish Distribution and Abundance in Relation to a Seismic Shooting Area off the Norwegian West Coast. Fish. Res. 2004, 67, 143–150. [Google Scholar] [CrossRef]

- van Geel, N.C.F.; Benjamins, S.; Marmo, B.; Nabe-Nielsen, J.; Wittich, A.; Risch, D.; Jameson, D.; Todd, V.L.G.; Todd, I.B.; Cox, S.E.; et al. Spatial Impact of Wind Farm Construction on Harbor Porpoise Detectability. In The Effects of Noise on Aquatic Life: Principles and Practical Considerations; Popper, A.N., Sisneros, J., Hawkins, A.D., Thomsen, F., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 1–24. ISBN 978-3-031-10417-6. [Google Scholar]

- Peng, Y.; Jarquin Laguna, A.; Tsouvalas, A. A Multi-Physics Approach for Modelling Noise Mitigation Using an Air-Bubble Curtain in Impact Pile Driving. Front. Mar. Sci. 2023, 10, 1134776. [Google Scholar] [CrossRef]

- Dähne, M.; Tougaard, J.; Carstensen, J.; Rose, A.; Nabe-Nielsen, J. Bubble Curtains Attenuate Noise from Offshore Wind Farm Construction and Reduce Temporary Habitat Loss for Harbour Porpoises. Mar. Ecol. Prog. Ser. 2017, 580, 221–237. [Google Scholar] [CrossRef]

- Nehls, G.; Rose, A.; Diederichs, A.; Bellmann, M.; Pehlke, H. Noise Mitigation During Pile Driving Efficiently Reduces Disturbance of Marine Mammals. In The Effects of Noise on Aquatic Life II; Popper, A.N., Hawkins, A., Eds.; Springer: New York, NY, USA, 2016; pp. 755–762. [Google Scholar]

- Popper, A.N.; Hastings, M.C. The Effects of Anthropogenic Sources of Sound on Fishes. J. Fish Biol. 2009, 75, 455–489. [Google Scholar] [CrossRef]

- Casper, B.M.; Halvorsen, M.B.; Matthews, F.; Carlson, T.J.; Popper, A.N. Recovery of Barotrauma Injuries Resulting from Exposure to Pile Driving Sound in Two Sizes of Hybrid Striped Bass. PLoS ONE 2013, 8, e73844. [Google Scholar] [CrossRef]

- Debusschere, E.; Hostens, K.; Adriaens, D.; Ampe, B.; Botteldooren, D.; De Boeck, G.; De Muynck, A.; Sinha, A.K.; Vandendriessche, S.; Van Hoorebeke, L.; et al. Acoustic Stress Responses in Juvenile Sea Bass Dicentrarchus Labrax Induced by Offshore Pile Driving. Environ. Pollut. 2016, 208, 747–757. [Google Scholar] [CrossRef]

- Sigray, P.; Andersson, M.H. Particle Motion Measured at an Operational Wind Turbine in Relation to Hearing Sensitivity in Fish. J. Acoust. Soc. Am. 2011, 130, 200–207. [Google Scholar] [CrossRef]

- Tougaard, J.; Hermannsen, L.; Madsen, P.T. How Loud Is the Underwater Noise from Operating Offshore Wind Turbines? J. Acoust. Soc. Am. 2020, 148, 2885–2893. [Google Scholar] [CrossRef]

- Hermans, A.; Winter, H.V.; Gill, A.B.; Murk, A.J. Do Electromagnetic Fields from Subsea Power Cables Effect Benthic Elasmobranch Behaviour? A Risk-Based Approach for the Dutch Continental Shelf. Environ. Pollut. 2024, 346, 123570. [Google Scholar] [CrossRef]

- Velilla, E.; Collinson, E.; Bellato, L.; Berg, M.P.; Halfwerk, W. Vibrational Noise from Wind Energy-Turbines Negatively Impacts Earthworm Abundance. Oikos 2021, 130, 844–849. [Google Scholar] [CrossRef]

- Sowmiya, S. Mitigation of Underwater Vibration Due to Offshore Wind Turbines. Int. J. Eng. Res. Technol. 2018, 6, 6. [Google Scholar]

- Moné, C.; Hand, M.; Bolinger, M.; Rand, J.; Heimiller, D.; Ho, J. 2015 Cost of Wind Energy Review; NREL: Oak Ridge, TN, USA, 2017. [Google Scholar]

- Majewski, P.; Florin, N.; Jit, J.; Stewart, R.A. End-of-Life Policy Considerations for Wind Turbine Blades. Renew. Sustain. Energy Rev. 2022, 164, 112538. [Google Scholar] [CrossRef]

- Delaney, E.L.; Leahy, P.G.; McKinley, J.M.; Gentry, T.R.; Nagle, A.J.; Elberling, J.; Bank, L.C. Sustainability Implications of Current Approaches to End-of-Life of Wind Turbine Blades—A Review. Sustainability 2023, 15, 2557. [Google Scholar] [CrossRef]

- Spini, F.; Bettini, P. End-of-Life Wind Turbine Blades: Review on Recycling Strategies. Compos. Part B Eng. 2024, 275, 111290. [Google Scholar] [CrossRef]

- Liu, P.; Barlow, C.Y. Wind Turbine Blade Waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef]

- Jensen, J.P.; Skelton, K. Wind Turbine Blade Recycling: Experiences, Challenges and Possibilities in a Circular Economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

| Type of Transport | Energy (GJ) | CO2 (t) |

|---|---|---|

| Transportation via road 200 km | 2.94 | 0.21 |

| Transportation via road 2593 km | 38.17 | 2.71 |

| Sea transport 600 nautical miles | 1.78 | 0.13 |

| Sea transport 13,471 nautical miles | 39.92 | 2.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bošnjaković, M.; Hrkać, F.; Stoić, M.; Hradovi, I. Environmental Impact of Wind Farms. Environments 2024, 11, 257. https://doi.org/10.3390/environments11110257

Bošnjaković M, Hrkać F, Stoić M, Hradovi I. Environmental Impact of Wind Farms. Environments. 2024; 11(11):257. https://doi.org/10.3390/environments11110257

Chicago/Turabian StyleBošnjaković, Mladen, Filip Hrkać, Marija Stoić, and Ivan Hradovi. 2024. "Environmental Impact of Wind Farms" Environments 11, no. 11: 257. https://doi.org/10.3390/environments11110257

APA StyleBošnjaković, M., Hrkać, F., Stoić, M., & Hradovi, I. (2024). Environmental Impact of Wind Farms. Environments, 11(11), 257. https://doi.org/10.3390/environments11110257