1. Introduction

The damming of watercourses leads to the interception and subsequent deposition of transported solid particles, resulting from the phenomenon of bank and bottom erosion, due to the reduced kinetic energy of the water current [

1,

2,

3,

4,

5,

6]. This dynamic results in the accumulation of millions of cubic meters of sediment within the reservoir, generating a dead volume that reduces the available water storage capacity and makes the reservoir capacity non-renewable [

7,

8,

9,

10,

11]. The need to dredge the accumulated sediment, however, is at odds with effective sediment management, partly due to the introduction of various regulations that have complicated the usual practices of dumping at sea or depositing it on land without a comprehensive characterisation plan [

12].

Dredging activities, in fact, have a high environmental and economic cost, also by virtue of the handling, transport, and possible treatment procedures and the possible final destination of the sediments, currently represented by the landfill [

13]. These activities generate large quantities of sediments, characterised by a high-water content, great compressibility due to the organic matter content and the presence of salts and contaminants (especially sulphur, iron, and soluble manganese compounds), which can be extremely toxic to plants and cause a significant environmental impact [

14,

15]. For this purpose, the identification of environmentally friendly alternatives is the subject of much research being conducted in Europe, aimed at diverting these materials from disposal, using treatments to improve the characteristics of dredged sediments [

16].

Thus, it becomes a priority to invest in the valorisation of sediments to be transformed into a profitable local resource, with a view to the core principles of the circular economy, to reduce environmental, economic, and social impacts [

17,

18,

19,

20]. The possibility of reusing sediments has been discussed for some time, with several proposals all aiming to identify reuses that are valuable alternatives to disposal. In this regard, the results of various studies conducted on the characterisation of sediments, taken from different parts of the world, showed that they are suitable for replacing part or all the aggregates in concrete mixes [

21,

22,

23,

24,

25]. In addition, this reuse proposal not only produces environmental benefits related to the non-disposal of large volumes of dredged sediment, but also reduces the high consumption of non-renewable resources and CO

2 emissions related to the production of cement mixes. It is estimated that for every tonne of Portland cement produced, approximately 1 tonne of carbon dioxide is created, so intervening in the building industry is of considerable interest in combating global warming [

26].

Numerous research studies have been conducted on the reuse of sediments in mortar, primarily focusing on the reuse of treated sediments. In the examined studies, dredged materials were dewatered in the laboratory by using energy-intensive oven or air drying to dry the small volumes of sediment. Also, the processes they propose are often characterised by increasing costs due to the incorporation of additives (special cement, lime, geopolymers…), so that sediment-based mortar obtained from these studies is not such a sustainable material [

27,

28,

29,

30,

31,

32,

33]. In any case, treatments to which sediments are submitted successfully transform them into secondary raw materials suitable for reuse in the fabrication of a wide range of materials, such as ceramics, supplementary cementitious materials, fill materials, paving blocks, partition blocks, ready-mixed concrete, and foamed concrete [

34].

This research presents the results of activities on sediment samples from two southern Italian reservoirs, Camastra and San Giuliano, with a view to assessing the possibility of reusing them in cement matrices. Based on the results of the granulometric characterisation, it emerged that the upstream areas of the reservoirs present a sediment in which the clay component prevails, in contrast to the downstream areas, which are mostly characterised by a sandy component. Therefore, it was decided to label the sediment of the upstream areas the characteristics of a clayey material; instead, the sediment of the downstream areas was assumed to be sandy material. Starting from this assumption, various types of mortar were proposed, in which the aggregate was completely replaced by sandy valley material in varying quantities, and, in others, clay material was also used, in constant quantities, in place of a part of the binder. The sediments used were not pre-treated, but were reused as they were, providing not only an environmental benefit, but also economic sustainability. The proposed types of mortar were subjected to various tests, the results of which were compared with each other, to be able to make evaluations and understand the possibilities of using these materials in the building industry [

35].

2. Materials and Methods

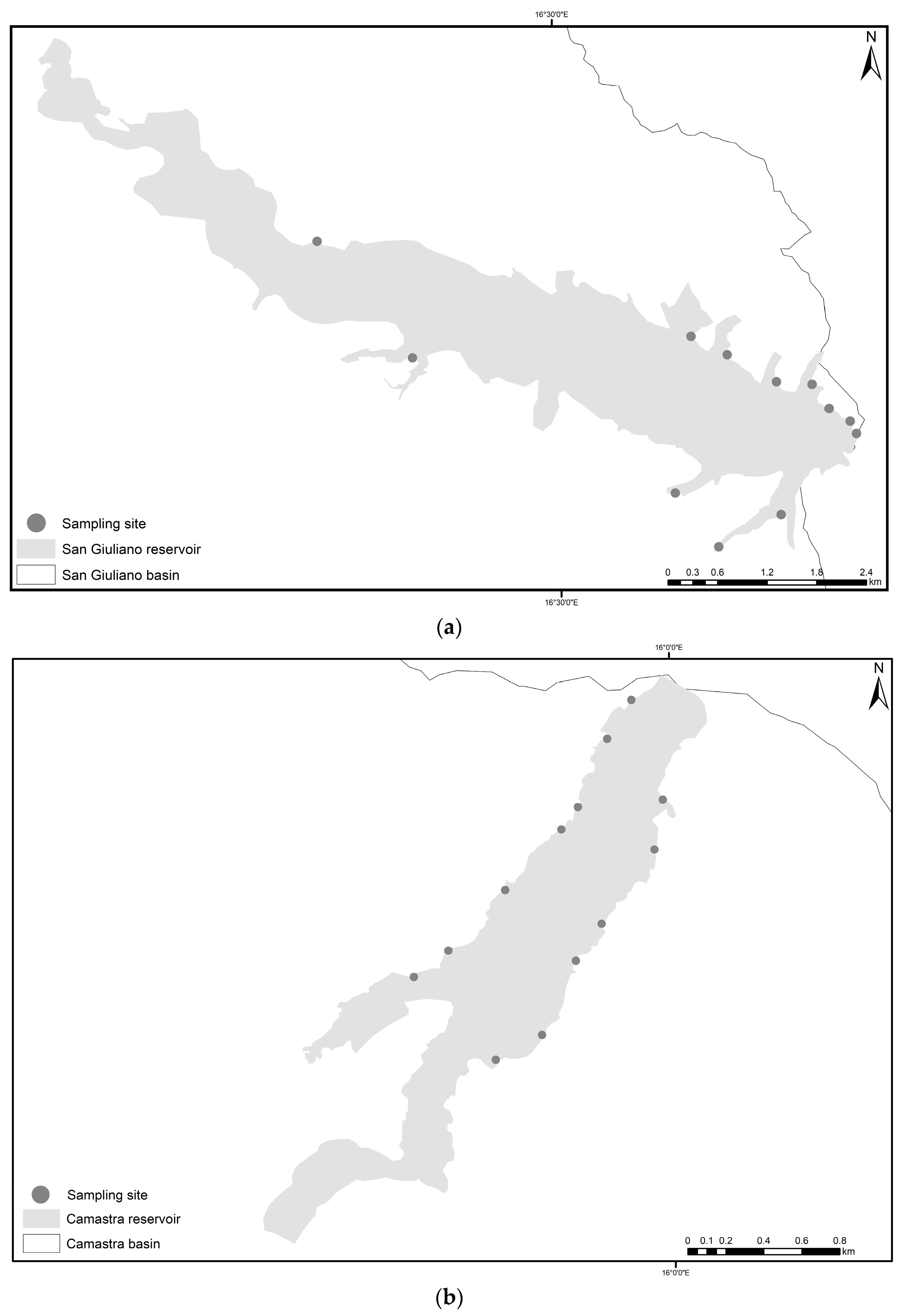

The cement mortar was prepared with the sediments sampled from the Camastra and San Giuliano reservoirs and characterised by complete substitution, at different quantities, of the fine aggregate and, for some of them, also by partial substitution, at a constant quantity, of part of the hydraulic binder. Sampling stations are shown in

Figure 1a,b.

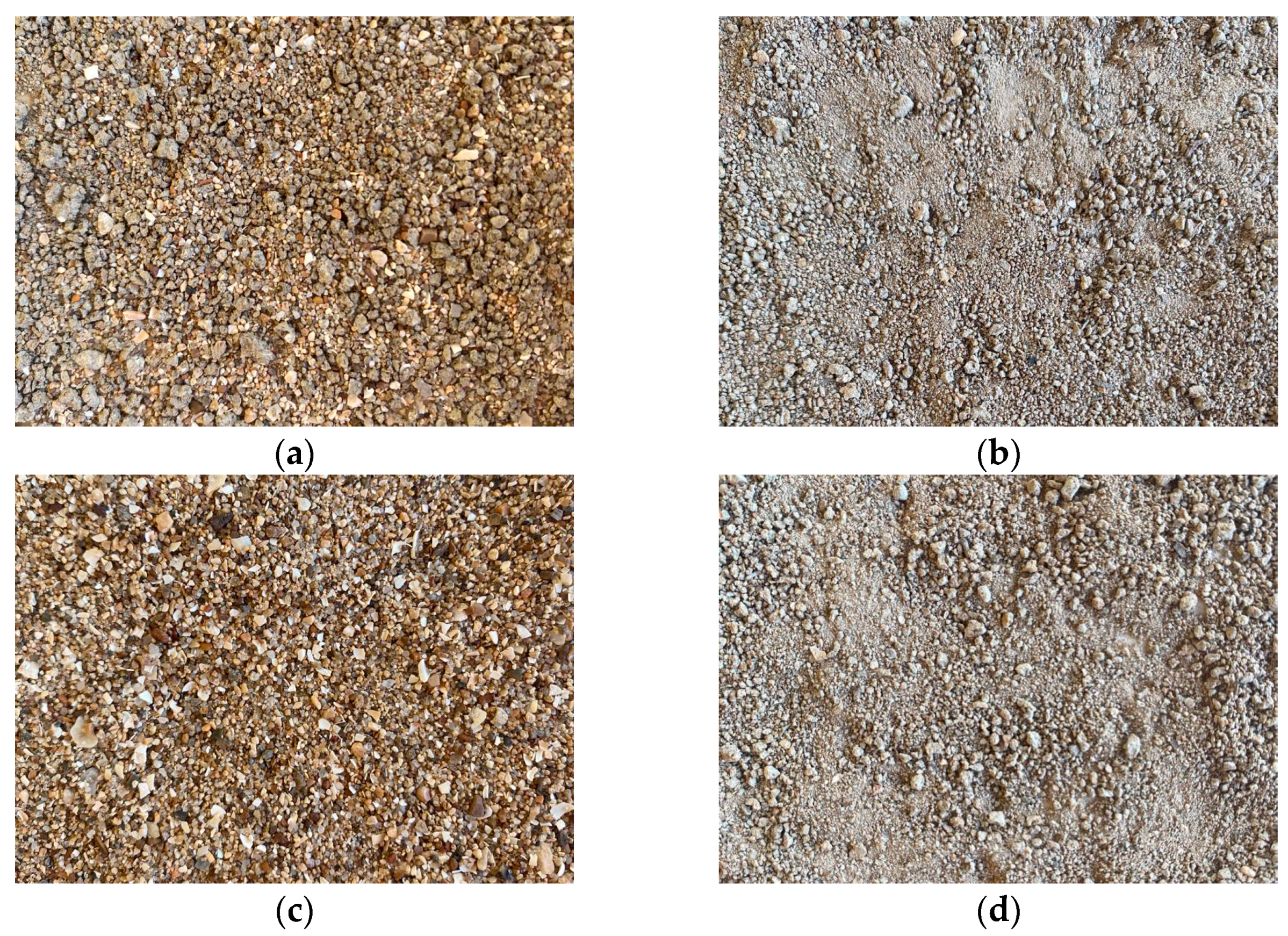

Sediments dredged from both reservoirs, depicted in

Figure 2, were grouped depending on their origin from upstream or downstream areas. These groups were named C_D (Camastra downstream), C_U (Camastra upstream), SG_D (San Giuliano downstream), and SG_U (San Giuliano upstream).

The upstream and downstream samples from both the Camastra and San Giuliano reservoirs were then delivered to the M2C laboratory located near the University of Caen Normandy, in order to determine their physiochemical characteristics, the concentration of heavy metals in them, and their chemical properties, according to the French standard NF EN ISO 11885, 2009. The results of these investigations are presented in

Table 1,

Table 2 and

Table 3, respectively.

Due to a similar particle size distribution, the material from the sampling points in the upstream areas was mixed to obtain samples used for the preparation of the mortar as a partial replacement of the binder; similarly, the material located at the stations in the downstream areas was combined to totally replace the sandy aggregate and be used as sandy material.

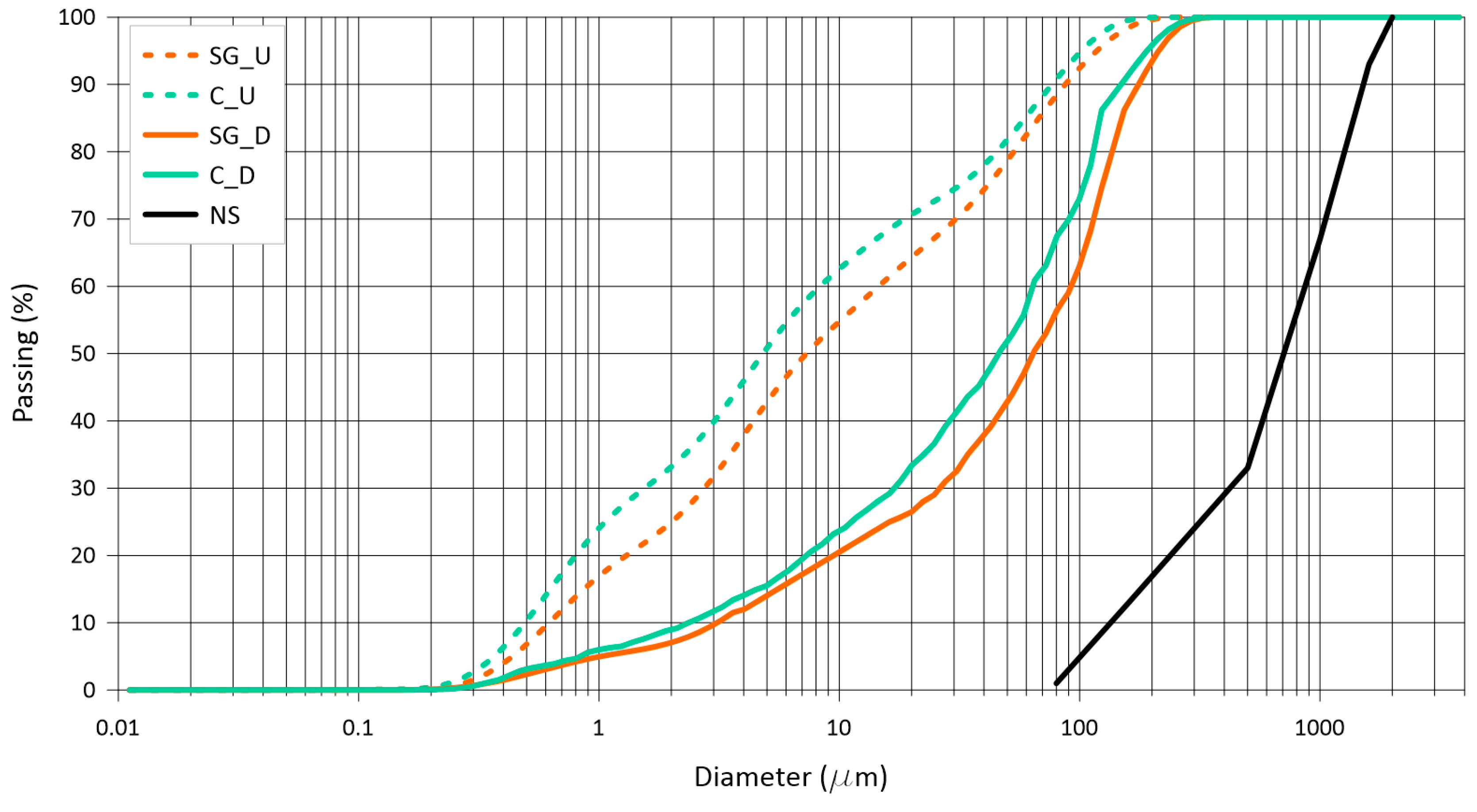

Figure 3 shows the grain size distribution of the sediments, divided between those collected in the upstream area and those sampled in the downstream part of the two investigated reservoirs, related to that of the normalised sand. The diagram highlights that the upstream sediment of both reservoirs has a predominantly clayey matrix, while the downstream material has a markedly sandy composition, approximately 53% for the San Giuliano sediment and 45% for the Camastra sediment. In addition, when comparing with normalised sand, it can be seen that the latter is well graded, as opposed to the sediments in both reservoirs, which are poorly graded because they cross multiple particle size fractions.

Cement CEM II A-LL 42.5 R (Buzzi Unicem, Barletta, Italy) was used as a binder [

36].

Normalised sand (~1700 kg/m

3, 0.08–2 mm, Société Nouvelle du Littoral, Leucate, France) was used to prepare the control mortar [

37].

The sediment from the two reservoirs was subjected to moisture content determination to identify the correct water proportion in relation to cement. Accordingly, 50 g of sediment of the two types was placed in the oven at 50 °C for each of the two lakes to make the procedure suitable for implementation in a production process.

The mortar was prepared with sediments extracted from the two lakes, varying the amount of aggregate (sandy material: C_s1, C_s2, C_s3, C_s5, SG_s1, SG_s2, SG_s3, SG_s4, and SG_s5 samples, where C and SG are used for Camastra and San Giuliano lakes, respectively, and s for sandy material). In the other mortar, there was also the addition of clay as partial replacement of the binder (sandy and clayey material: C_s1&c, C_s2&c, C_s3&c, C_s5&c, C_s6&c, SG_s3&c, SG_s4&c, SG_s5&c, SG_s6&c, and SG_s7&c samples, where C and SG for Camastra and San Giuliano reservoirs, respectively, and s&c for sandy and clayey materials).

Table 4 and

Table 5 show the samples, prepared with one part by mass of cement and half part of water, according to the European Standard [

37] and using the same water/cement ratio of 0.50 as the normalised mortar, which constitutes the control sample, prepared with three parts by mass of normalised sand.

Sand and cement in the mortar were substituted by sandy and clayey materials, respectively, according to mass proportions. Starting from the composition of the mortar prepared with the sediments sampled at the two reservoirs, the percentage of sandy material (aggregate ratio

) contained in them, relative to the sum of the masses of the specimen elements, was determined according to Equations (1) and (2). Equation (2) was used for the test specimens in which part of the binder was replaced with upstream clay material.

where s

m is the mass of the sandy material, c is the mass of the cement, c

m is the mass of the clayey material, and w is the mass of the water.

The consistency of the cement composites in the fresh state was determined through the flow test [

38] for the 19 specimens and the normalised mortar. The percentage increase in diameter was determined using Equation (3):

where D

m is the mean flowing diameter over two orthogonal diameters, and D is the base diameter of the truncated cone ring.

For mechanical strength determination, prismatic specimens of dimensions 40 mm × 40 mm × 160 mm were prepared. After 28 days of air curing at ambient temperature, the 19 specimens and the normalised mortar were subjected to flexural and compressive tests (MATEST, Milan, Italy) at a rate of load increase of 50 ± 10 N/s and 2400 ± 200 N/s, respectively until failure [

38].

The arrangement and grain size of the aggregates in the composites were investigated with a Premier series dyno-lite portable optical microscope, for the 19 specimens and the normalised mortar.

In addition, scanning electron microscopy made it possible to observe the microstructure of the composites [

39]. For this purpose, JEOL’s JSM-IT100 (Croissy-sur-Seine, France) series SEM was used for two specimens and the normalised mortar (manufacturer: JEOL; city and country: Croissy-sur-Seine, France).

To analyse the possible contaminant release, a leaching test was carried out, according to the standards in

Table 6, for each of the parameters investigated, with reference to four specimens (one with only sandy material from the San Giuliano reservoir, one with sandy and clay material from the San Giuliano reservoir, one with only sandy material from the Camastra reservoir, and one with sandy and clay material from the Camastra reservoir).

3. Results

This section provides a concise and precise description of the experimental results, their interpretation and the experimental conclusions that can be drawn.

3.1. Data Focus

Table 1 highlights that the organic matter in the upstream areas is greater than that in the downstream, approximately 10% in the case of the Camastra and about 50% for the San Giuliano reservoir. Overall, the presence of organic matter is almost marginal within the dredged sediment, whatever the origin area, supporting the hypothesis of reuse in the mortar mix design. This is because the presence of significant organic matter is an undesirable component in a construction material, as it can cause problems in cement hydration and disturb its behaviour as a binder [

16].

Table 2 reports the analyses carried out to detect the concentration of heavy metals in sediments, compared with the Italian regulatory reference (columns A and B,

Table 1, Al- Annex 5, Part Four, Title V, Decree Law 152/06). The values obtained then showed that the sediments contain low concentrations of chromium (Cr), copper (Cu), nickel (Ni), lead (Pb), and zinc (Zn). On the contrary, slight excess quantities were recorded for arsenic (As) in the upstream sediments of the San Giuliano reservoir and for vanadium (V) in the upstream sediments of the Camastra reservoir. Those exceeding the threshold, however, refer only to the limit imposed by column A, while in relation to column B of the Italian Decree Law, the concentration of heavy metals in sediments is always well below the threshold. In general, components found in the XRF are mainly those linked to minerals of clay and sand (Si, Al, Fe), as highlighted by Weaver and Pollard [

40].

Table 3 shows the chemical properties of the investigated sediments. The oxides, except for aluminium, iron, and potassium, all have concentrations below unity, indicating a low content of these in the sediment. The main oxides (Al

2O

3, SiO

2 and Fe

2O

3) contained in sediments come from the particles of which they are composed, such as sands and clays [

40]. The average percentages are 4.85%, 5.4%, and 26%, respectively, for the oxides Al

2O

3, SiO

2, and Fe

2O

3, but the presence of calcium oxide CaO with an average rate of 21.3% is interesting in terms of cement reactions. The CaO percentage for the San Giuliano sediment is much higher, varying from 19.1% (upstream) to 36.4% (downstream), which is related to the strengths obtained.

Table 4 and

Table 5 show the data concerning the composition of the mortar produced and analysed, distinguishing between that obtained with sediments from the Camastra reservoir and that prepared with sediments taken from the San Giuliano reservoir.

With the same composition, the mortar made with the San Giuliano sediments was denser than that prepared with the Camastra sediments. With similar reasoning, it was found that, within the same reservoir, the substitution of part of the binder with the upstream clay material resulted in a slight reduction in weight per unit volume, with the same sand content.

However, comparing all density data with the reference, the values obtained by replacing the aggregate with the downstream sediment (assumed to be sand) were lower for all types of mortar. The difference in density is more pronounced when using sediment from the Camastra reservoir than when using sediment from the San Giuliano reservoir.

3.2. Workability Tests

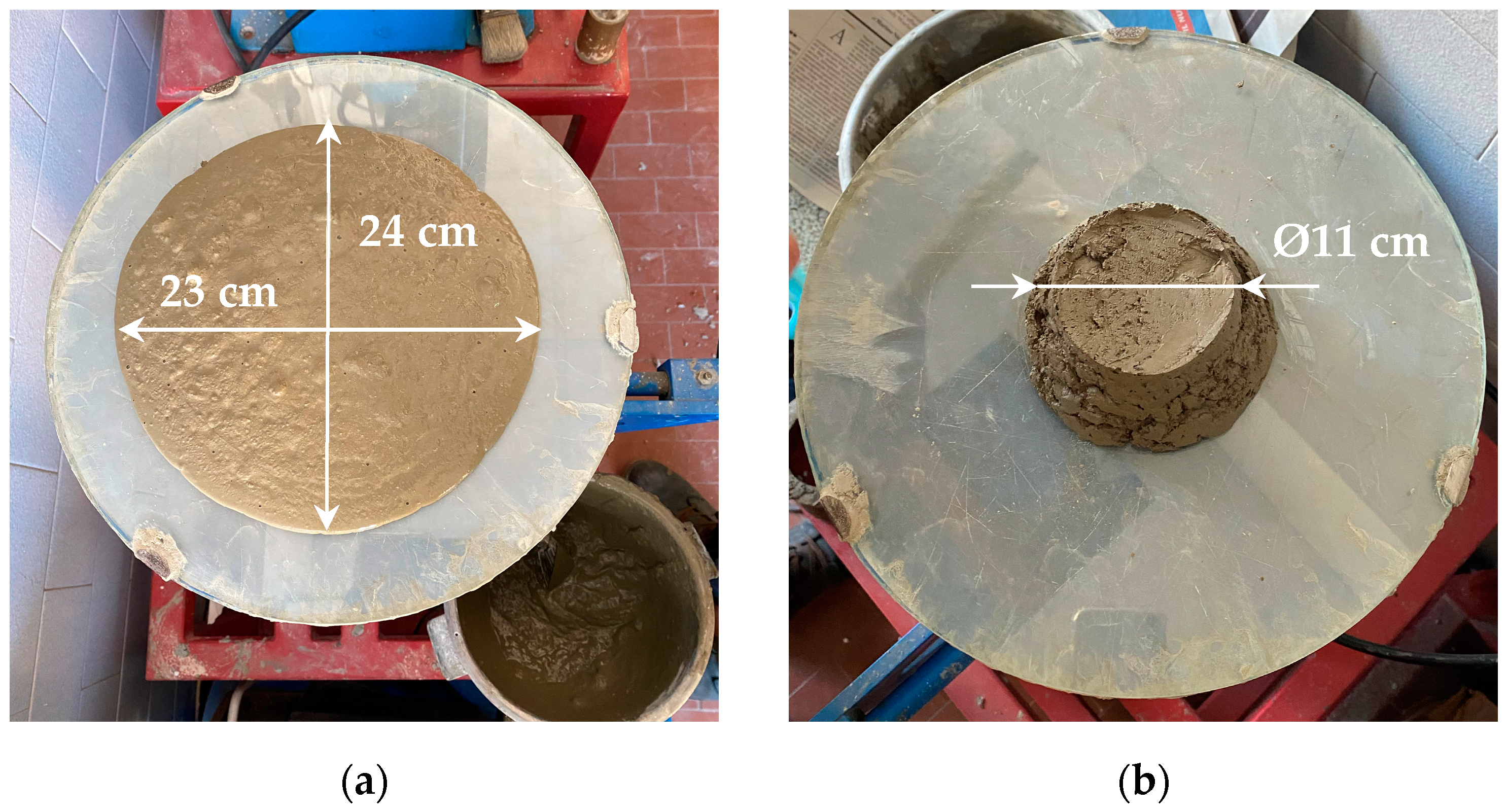

The flow test was intended to verify the deformation behaviour of the proposed mortar using the flow table (

Figure 4). The flow values of the tested samples (Equation (3)) were then compared to those obtained for the normalised mortar (Equation (4)).

The consistency of the mortar was variable depending on its composition. In some cases, optimal flow was witnessed; instead, for other specimens where the application of the shakes had no noticeable effect, the specimens did not show significant flow.

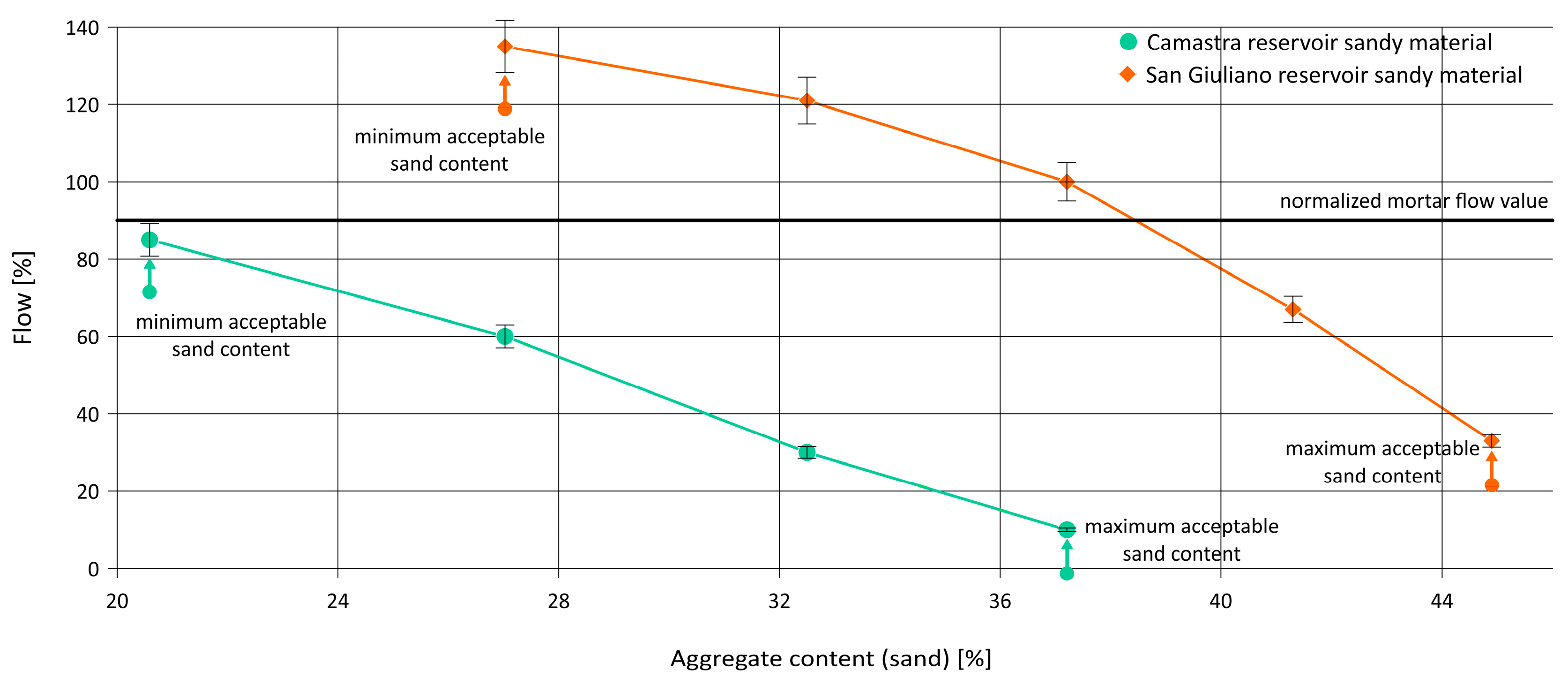

Figure 5 shows the comparison of flow trends for mortar obtained by replacing the aggregate with downstream sand, i.e., sandy material.

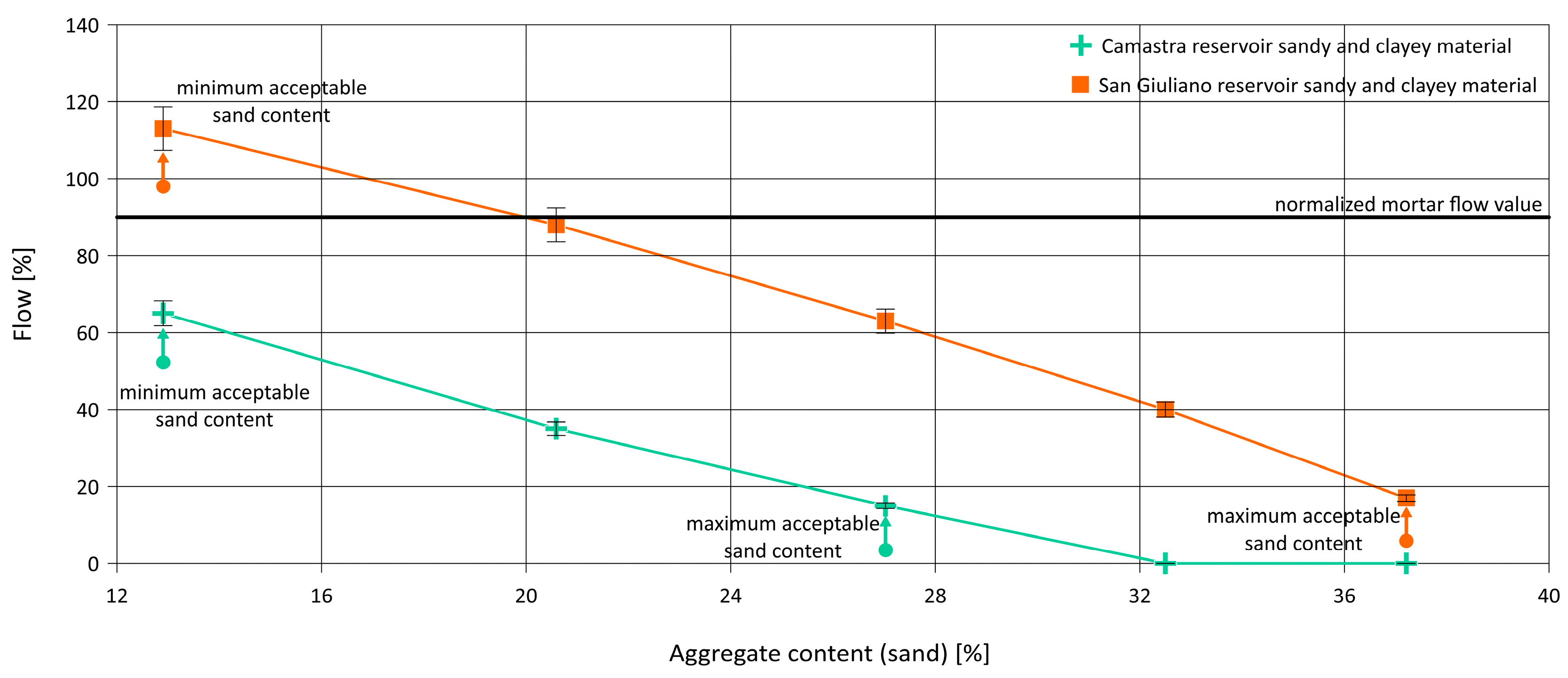

Figure 6 shows the same comparison, in particular mortar that was also obtained by partially replacing the binder with upstream clayey material. For both graphs, a better flow is shown for the specimens made with the sediment from the San Giuliano reservoir, on the contrary, the mortar made with the sediments from the Camastra reservoir was less fluid. In addition, it can also be seen that, for both reservoirs, as the aggregate content (sand) increased, the flow tended to decrease, and the material was drier and stiffer. In comparison to normalised mortar, on the other hand, a better workability was found for the mixes prepared with sediment from the San Giuliano reservoir, which, at lower percentages of aggregate, were more fluid, with values close to 140% when 250 g of sand was used. On the contrary, mortar prepared with the sediment of the Camastra reservoir showed flow values always lower than the normalised mortar, fluctuating between 10% and 85% only if the aggregate was replaced and even lower if even part of the binder was replaced with the upstream clay material [

41].

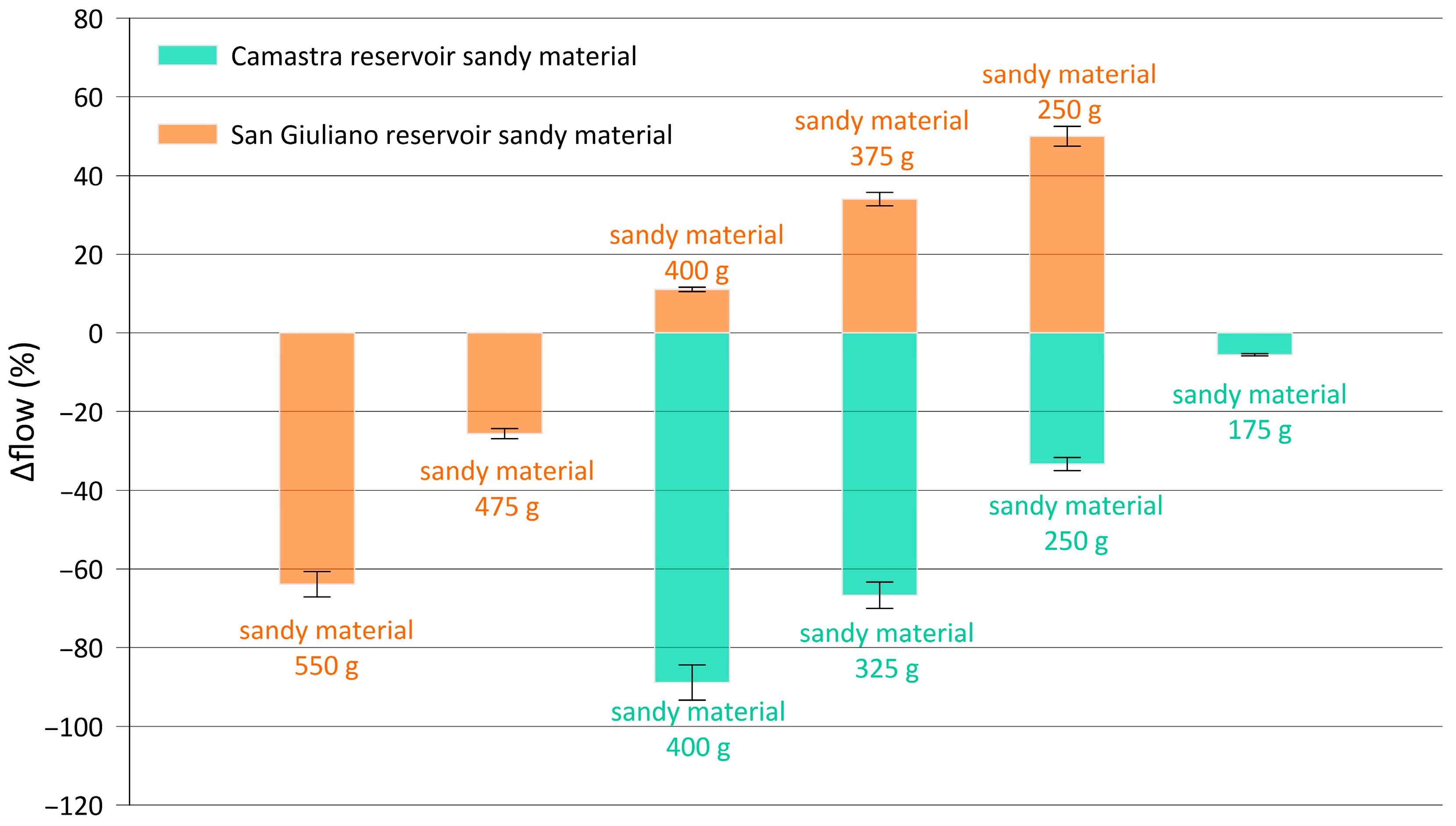

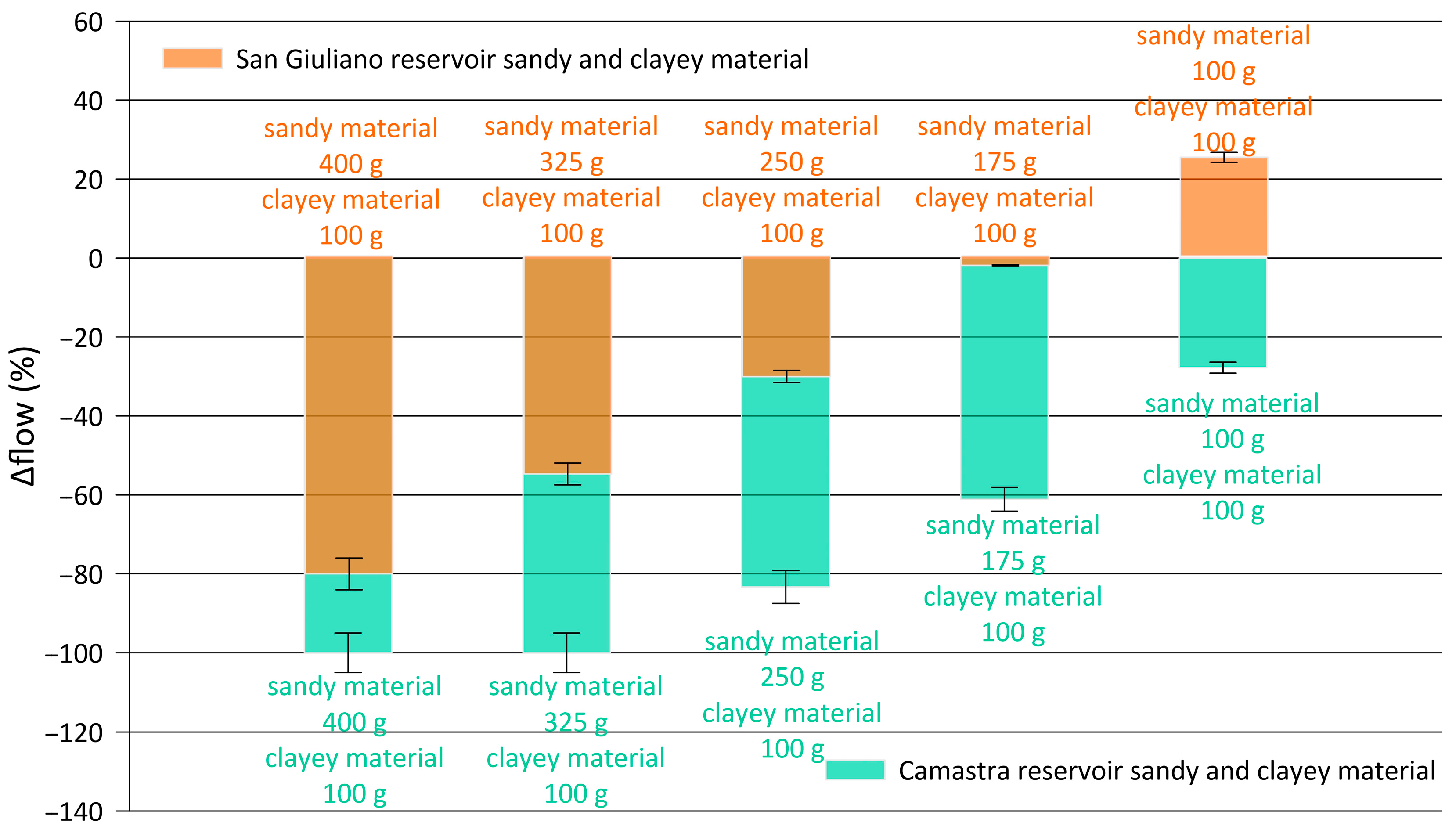

The ∆flow bar charts (

Figure 7 and

Figure 8) show the relationship between the flow of the proposed mixes and that of the normalised mortar. Furthermore, they also represent the comparison between the samples made with sediments from the two investigated reservoirs. Again, it is evident that the mortar made with the Camastra reservoir sediments shows a reduction in fluidity compared to the normalised mortar, ranging from around 5% in sample C_s5 to around 100% in samples C_s1&c and C_s2&c. Conversely, the mortar made with the sediments of the San Giuliano reservoir has, in some cases, a higher flow than the normalised mortar (SG_s3, SG_s4, SG_s5 and SG_s7&c), which was higher where the amount of sand used was lower. In other cases, there is less flow than the normalised mortar, varying between approx. 5% of specimen SG_s6&c and 80% of specimen SG_s3&c. In any case, the flow deviates more in the case of conglomerates made from the sediments of the Camastra reservoir, and, within the same reservoir, the deviation from normalised mortar was greater by replacing part of the binder with clay, increasing as the amount of sandy material used increased.

3.3. Mechanical Strength Performance

Figure 9 shows the specimens broken after failure during the application of a flexural load. The specimens break cleanly, resulting in a fragile fracture, due to the limit strength of the aggregates being reached, which is characterised by a lower mechanical strength than that which develops at the cement–aggregate interface. Also, the strength reduction occurs because of the presence of clay particles enveloping the aggregates and decreasing the binding.

In comparison with normalised mortar, on the other hand, there are no differences in the mode and type of failure, indicating similar mechanical behaviour.

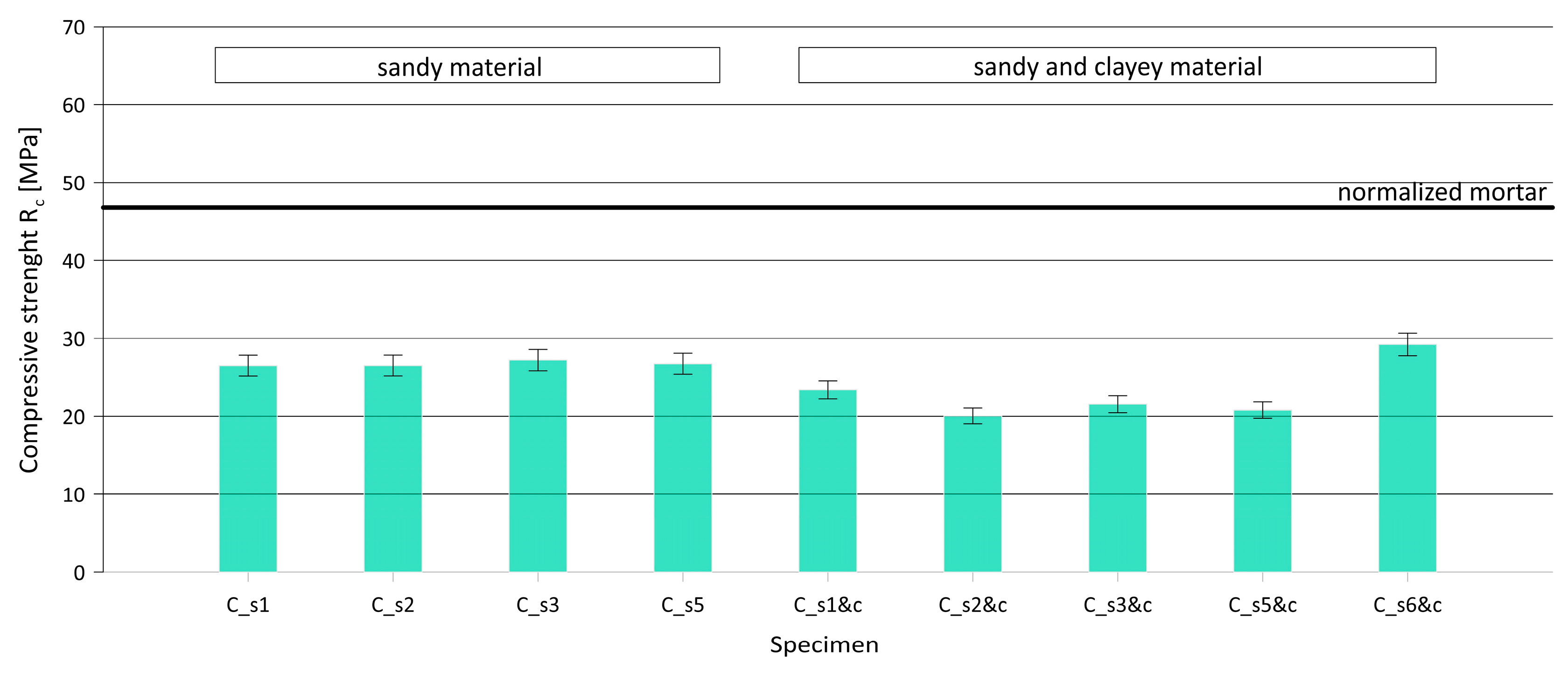

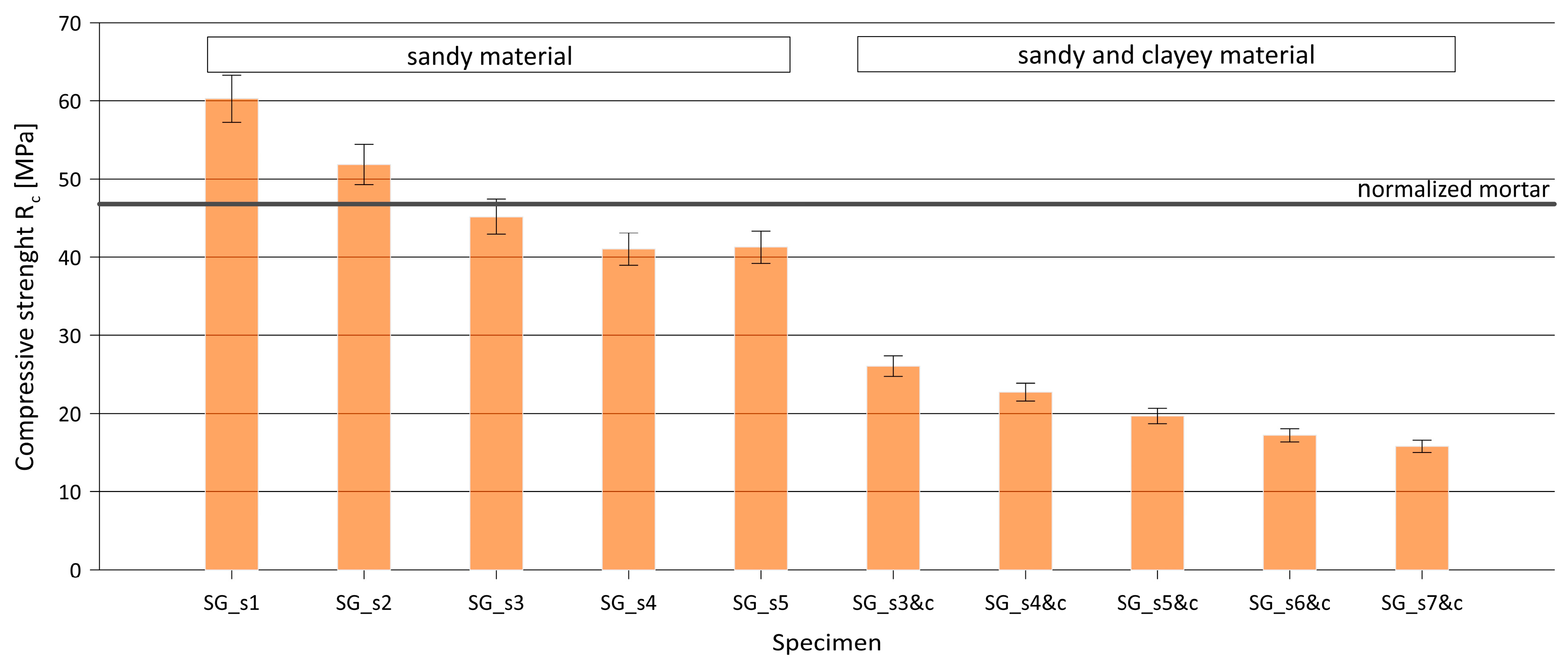

Subsequently, a compressive load was applied to the two semi-prisms obtained from the flexural tests, determining the limit load, beyond which the specimen reaches failure. The values were then represented in two diagrams (

Figure 9 and

Figure 10) showing the compressive strengths R

c in MPa (on Y-axis) for each specimen compared with the normalised mortar. The plots clearly show a substantial difference in mechanical strengths where the Camastra sediments were used instead of the San Giuliano sediments. In the former case, the compressive strength was lower than in the latter.

Furthermore, mortar made with Camastra reservoir sediments exhibited compressive strength R

c values that were approximately half that of normalised mortar and, in any case, all below 30 MPa (see

Figure 10). It is observed, however, that the specimen C_s6&c, prepared with the least amount of sandy material and substituting the upstream clay material for part of the binder, displays the highest compressive strength (29 MPa). Specimens made with only sandy material substituting show approximately the same compressive strength of 27 MPa, while those where a part of cement was replaced by clayey material have a compressive strength closer to 20 MPa (except specimen C_s6&c previously mentioned), about 25% less.

On the contrary, if mortar is produced with sediments coming from the San Giuliano reservoir, the mechanical strength values are clearly higher (even twice as high as those obtained for the Camastra, at the same sandy material amount), with a tendency to decrease when replacing part of the binder with clayey material (see

Figure 11). Test specimens SG_s1 (550 g of aggregate) and SG_s2 (475 g of sandy material) exhibit a compressive strength (60 MPa and 52 MPa, respectively) that was on average 15% higher than that of the normalised mortar (48 MPa), while the types of mortar named SG_s3 (400 g of sandy material), SG_s4 (325 g of sandy material), and SG_s5 (250 g of sandy material) show lower values of 46 MPa, 41 MPa, and 41 MPa, respectively. Specimens made by replacing a part of the binder show a compressive strength of about 20 MPa, which is 50% less than those obtained by replacing only the sandy material. According to the observations of Roziere et al. [

42], also in this case the average compressive strength of sediment-based specimens is comparable to that of the reference conglomerate.

The difference in mechanical strength found between normalised mortar and those prepared with dredged sediment may also be the result of the different grain size composition of the aggregates composing them. In fact, where the normalised sand is well graded, the sandy material used to replace it is characterised by the presence of silt and clay fractions (higher for the Camastra and lower for the San Giuliano), which affect the failure behaviour of the specimens.

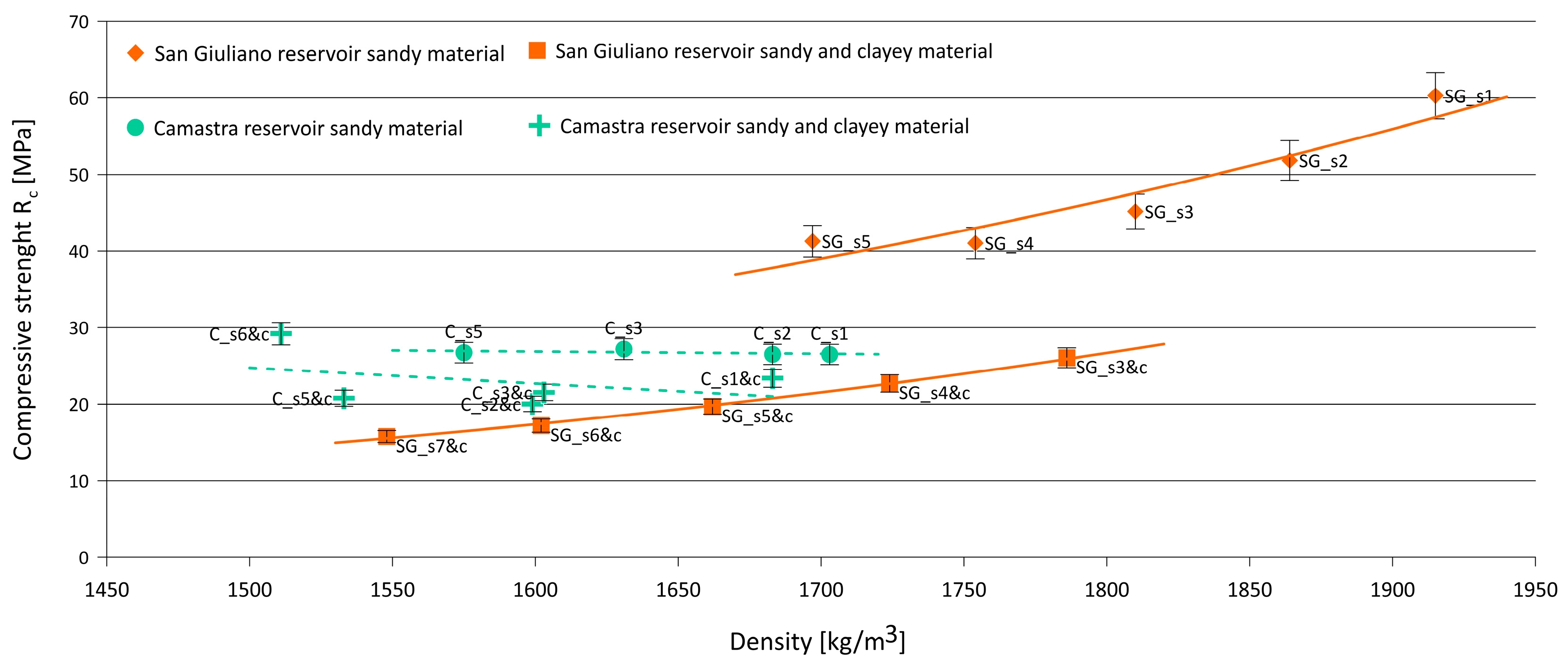

Figure 12 shows the relation between the compressive strength of the proposed types of mortar and their density. Data of the mortar prepared with the San Giuliano sediments are approximated by an exponential-type curve (continuous orange line), while data of the mortar prepared with the Camastra sediments are better approximated by a linear function (dashed green line).

Trends are significantly different from those containing sediments from the Camastra reservoir. For the latter, there is a reduction in compressive strength as the density increases, i.e., as the aggregate quantity increases, the compressive strength tends to decrease by about 30%. This result is similar to previous studies [

28,

43] on marine sediments. The studies demonstrate that mechanical strengths (including flexural strength) decrease as the amount of sediment used to replace normalised sand increases, with a tendentially linear decreasing trend. On the contrary, when mortar was prepared with sediments from the San Giuliano reservoir, compressive strengths were higher as the density increased, although there is a decrease in strength, with values between 15 MPa and 30 MPa, if a part of the binder was replaced with the clay material from the upstream areas. In other words, if the sediment of the San Giuliano reservoir is used, the higher content of sandy aggregate (SG_S1, 550 g of aggregate) corresponds to the higher values of density (1950 kg/m

3) and compressive strength (60 MPa), while both parameters decrease if the upstream clayey material is used, more significantly for compressive strength (about 33% less) and less clearly for density (about 5% less).

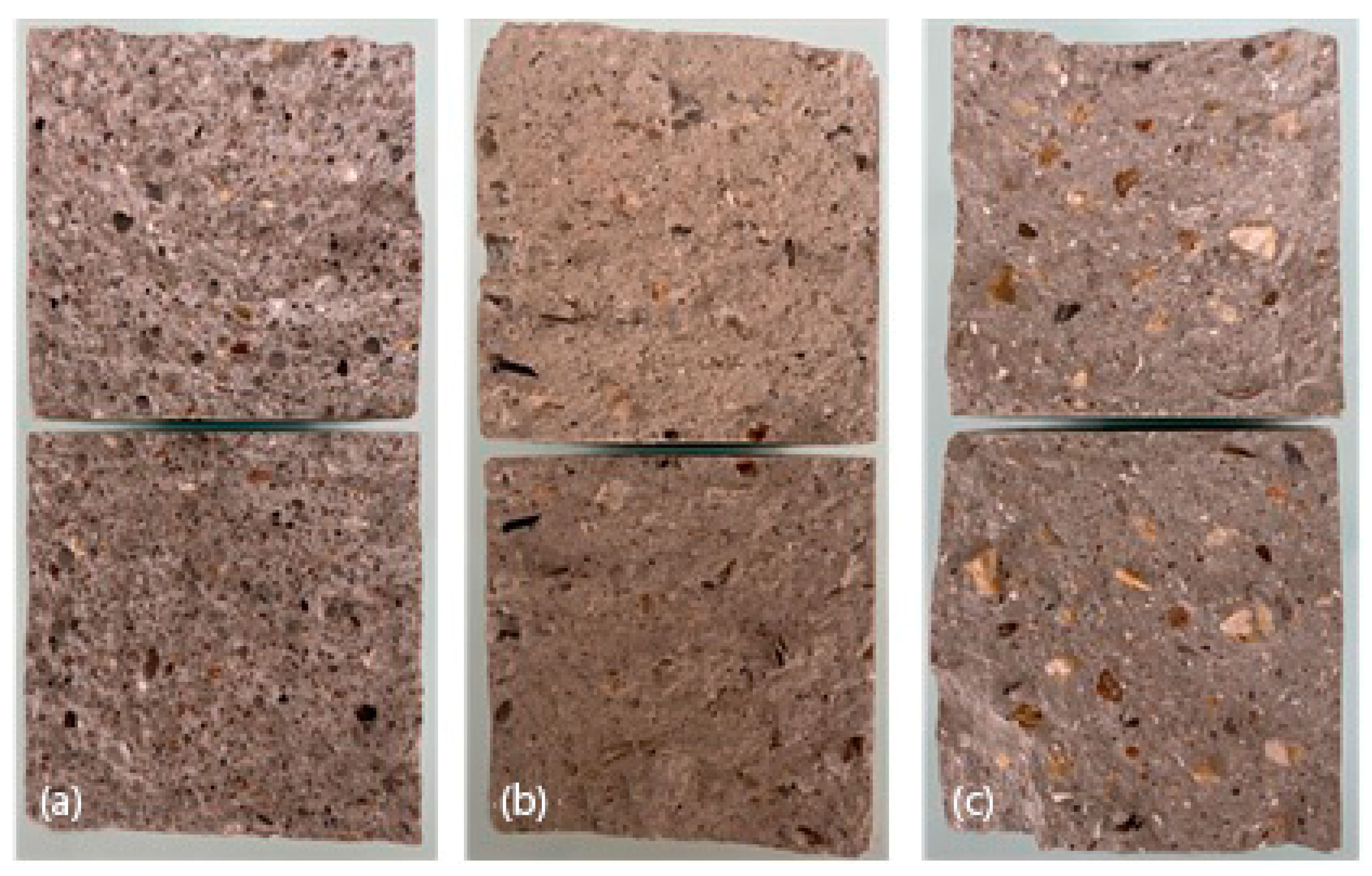

It is relevant to observe the differences in the aggregate from both reservoirs, in terms of shape and size, compared to normalised sand.

Figure 13 represents the view of the fracture sections for the normalised mortar and for two specimens with the same sand aggregate content (400 g). A careful visual assessment shows that, for the normalised mortar, the grains have a more regular shape, and the grain size spindle is more evident; in the C_s1 and SG_3 specimens, the sediment size is coarser, with a rough and angular shape. Moreover, a good distribution of the aggregate was observed.

3.4. Microstructural Analyses

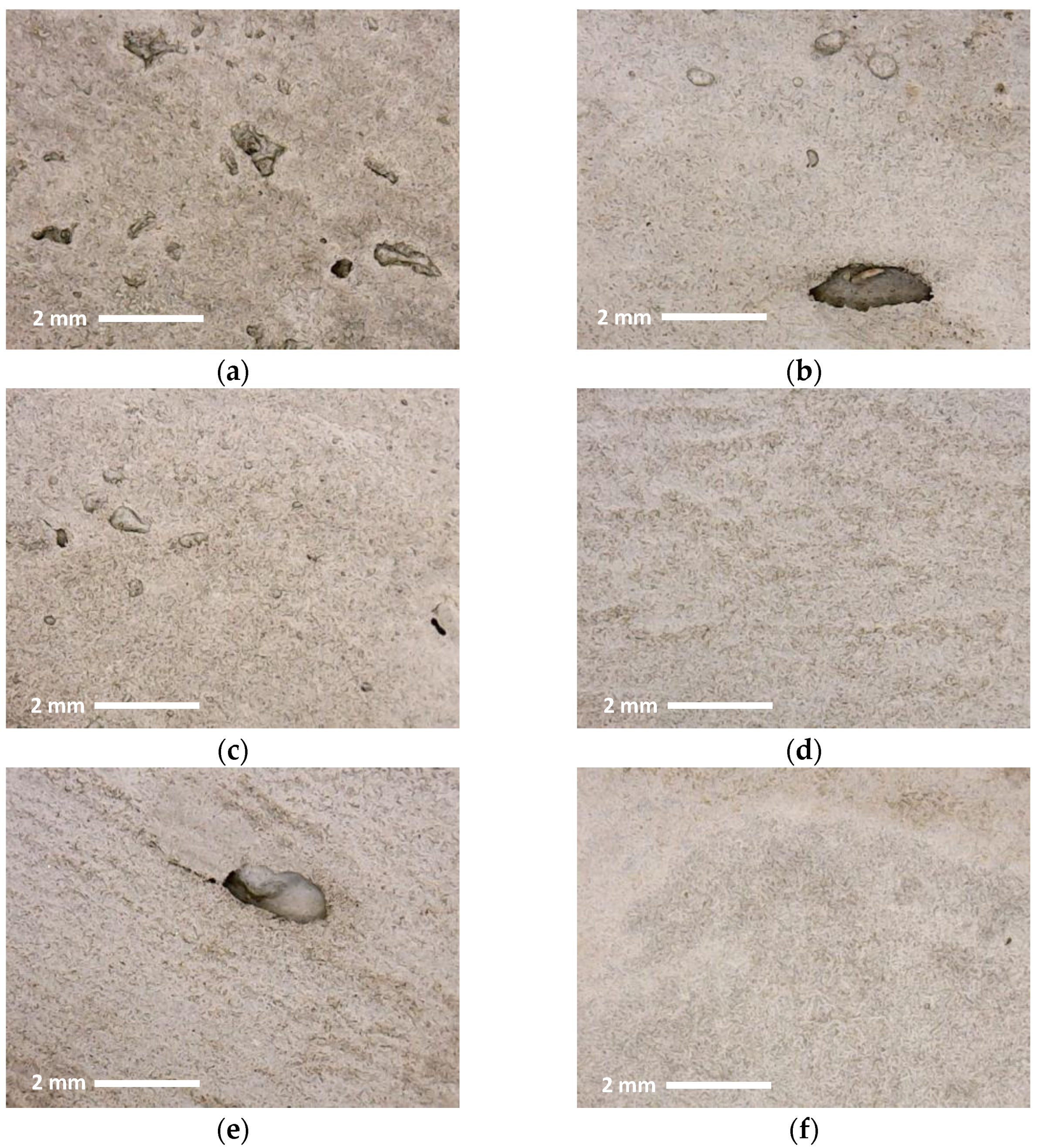

Using an optical microscope, it was possible to examine the test specimens in detail, both in their intact condition before the mechanical strength tests were carried out (

Figure 14a–f) and after breakage (

Figure 15a–c).

Figure 14 represents, for each of the two reservoirs, the specimens at the upper limit of workability ((a)—C_s1, (b)—SG_s1), in the intermediate situation ((c)—C_s2, (d)—SG_s4) and at the lower limit of workability ((e)—C_s5, (f)—SG_s5).

The specimen surface tends to be more irregular, approaching the limits of workability compared to specimens with a 250 g sand content (

Figure 14c,d). Mortar prepared with the San Giuliano reservoir sediment shows greater continuity and a smoother surface than that obtained using the sediment sampled at Camastra. In the latter case, in fact, a greater presence of voids is observed, which is even more significant, also in dimensional terms, the greater the amount of sand used.

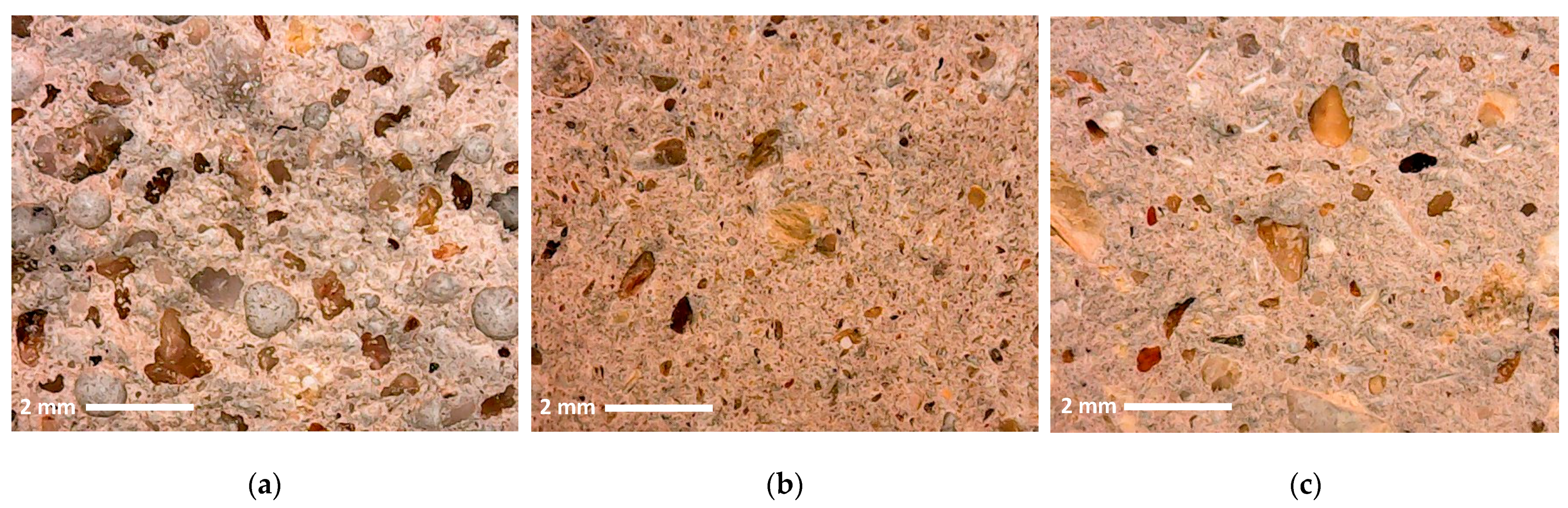

Figure 15 shows magnifications of the failure surfaces obtained using an optical microscope. It is noticeable that the grains that form the failure surface of the mortar prepared with sediment are different from that of the normalised mortar, both in terms of shape and spatial distribution. In fact, the normalised mortar appears to be characterised by grains with a more rounded shape than the mortar with the Camastra or San Giuliano sediments, which are characterised by greater angularity of the sandy aggregate. In addition, while the normalised mortar exhibits greater areal coverage by the sandy aggregate, with substantially larger size, the mortar prepared with the sediments is found to be characterised by a lower concentration of coarse grain on the surface, where the grains are smaller in size. Finally, operating the comparison between the mortar prepared with the sediments from the two reservoirs denotes that specimen C_s1 has a lower concentration of sandy aggregate on the failure surface, testifying to a more binder-like behaviour on the part of the Camastra sediment than that taken at the San Giuliano reservoir.

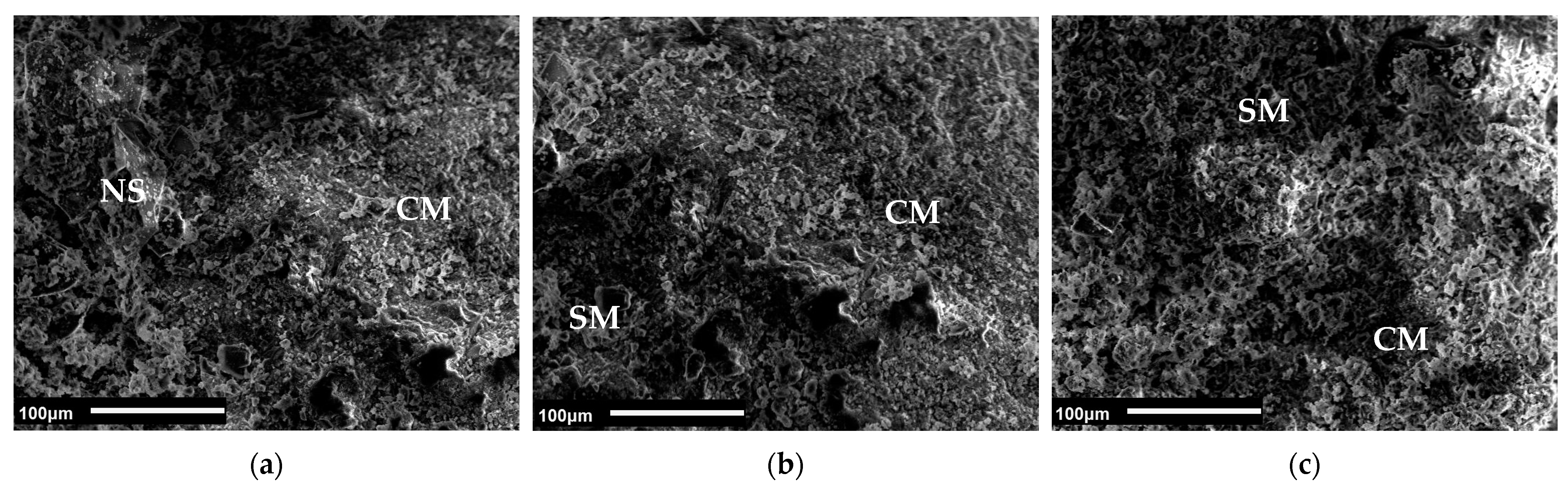

Figure 16 shows images obtained with a scanning electron microscope (SEM). On a microstructural level, there are no substantial differences in the comparison between the normalised mortar and the mortar obtained using the sampled sediments. In the latter case, it can be seen from the microscope images that the mortar is coarser-grained. In addition, the normalised mortar has more rounded grains than that made from dredged sediment, which has more angularity, as also highlighted previously. Microstructure observation using scanning electron microscopy highlights details of the materials. It can be observed that the specimens show a similar sand adhesion to the cement matrix, with no voids. The photo of specimen C_s1 shows a greater presence of cementitious matrix and a lower diffusion of sandy aggregate, in contrast to specimen SG_s3 for which a more balanced distribution between sandy material and cementitious matrix results. This confirms the output from the mechanical strength tests, which show a higher compressive strength for the SG_s3 specimen compared to the C_s1 specimen (and to all those made with the Camastra reservoir sediments) due to an increased presence of sandy material, responsible for mechanical strengths, compared to the cementitious matrix. In addition, the contents of

Figure 16 confirm the GSD curves (

Figure 3), i.e., a greater presence of clayey material for the Camastra downstream sediments, which show a more binder-like behaviour, than for the San Giuliano downstream sediments.

3.5. Contaminant Release

Sediments may be characterised by the presence of contaminants of organic and inorganic natures, by virtue of the activities that take place within the reservoir (assumed to be the closure section). Therefore, the possibility of their use in the preparation of mortar suitable for use in the construction industry cannot be separated from the verification that any leakage of pollutants from the mix is below the legal limit values. The outcome of tests performed in this regard may limit the fraction of lake sediment to be used instead of commonly used sand or in place of part of the binder, so that environmental compatibility is always ensured.

Table 7 and

Table 8 contain the results of the leaching test carried out for samples C_s1, C_s1&c, SG_s5, and SG_s3&c. The specimens identified were chosen as having the highest amount of aggregate within the workability range of each type of mortar proposed. The highest amount of reused sediment constitutes the most unfavourable condition.

Tables show that contaminants, for which the Italian regulations require testing for possible release into the atmosphere, are all below the limits, even substantially so [

44,

45]. The values identified because of the performed tests are, in fact, always far below the thresholds set by the regulations in question.

Consequently, as the four samples show no release of contaminants, the release of mobile substances in the solid matrices will also be below the legal limits for all other samples in which less sediment is reused.

4. Discussion

The tests performed allowed us to qualify the possibility of reusing the sediments dredged from the San Giuliano and Camastra reservoirs to prepare cement mortar in which a complete replacement of the aggregate and, in some cases, even a partial replacement of the binder was proposed. To assess whether these proposed types of mortar could be used instead of the commonly employed ones, a comparison was made with respect to the reference, represented by the normalised mortar. In defining the composition of the mixes, several tests were carried out, testing the different manufactured specimens, and evaluating mainly the characteristics of workability, mechanical strength, and contaminant release, which are the parameters that can fully characterise mortar.

The workability of mortar is a key characteristic for laying it, a function of the cohesion and adhesive power of the mixtures; a mortar type is considered workable if it can be laid down to a thickness of a few millimetres. As evident in

Figure 3 and

Figure 4, the range within which the consistency of the cement mortar obtained can be considered acceptable, i.e., an optimal range of workability, was identified in relation to the grain size characteristics of each reservoir. Attempt mortar was prepared with greater and lesser aggregate quantities than the identified workability limits, verifying that if the upper limit were to be exceeded, an excessively dry and stiff mix would be obtained due to greater quantities of aggregate. On the contrary, it also emerged that it is not convenient to go below the lower limit in terms of the percentage of downstream aggregate, both because few sediments would be reused (contrary to the aim of removing as much sediment as possible from the landfill), and because excessive fluidity would be observed, with possible shrinkage phenomena. Furthermore, in correspondence with the identified workability limits, microscope images of hardened paste are shown in

Figure 13, from which a loss of continuity is observed as one moves towards the extremes of workability. However, although showing some irregularities, the proposed types of mortar are all found to be reusable. The comparison with the normalised mortar shows that the mortar prepared with the Camastra sediments exhibits lower workability. In contrast, the mortar prepared with the San Giuliano sediments exhibits better workability than the normalised mortar, as the amount of sandy material used is reduced since the contribution of the aggregate is lessened.

Mechanical strength expresses the ability to handle applied stresses; mortar first reacts linearly, which is followed by a cracking regime that leads to the deterioration of mechanical properties as a result of excessive loading. Mechanical strength strongly depends on the amount of aggregate from which the mix is composed and on the differences in the grain size distribution of normalised mortar and that of the sediment from the San Giuliano and Camastra reservoirs. The greater the sandy aggregate, the higher the mechanical strength; on the contrary, there is a significant decrease in the strengths when partial replacement of the binder with the clay material was carried out (with the same amount of sandy material), as well as when the sandy material decreases. An analysis of the mechanical strengths reveals that the Camastra sediments produce mortar with a lower capacity to resist bending and compressive forces, i.e., the sediments were not suitable for use as aggregate. In fact, even the mortar with the highest cement–sediment ratio does not stand out in terms of compressive strength, but it is noticeable that all mixtures exhibit almost the same strength, reflecting a reduced aggregate effect from the sediment and a more pronounced behaviour as a binder. Of note is the specimen C_s6&c, characterised by the lowest amount of sandy material and the highest binder–aggregate ratio, which exhibits higher mechanical strength than the other specimens (with higher percentages of sandy material). This condition is related to the lower content of sandy material, so that more of the binding properties of the sediment are exhibited, and, due to more cohesion, higher compressive strength is recorded.

The use of sediment from the San Giuliano reservoir, on the other hand, results in mortar with higher mechanical strength values, which tends to decrease significantly when 100 g of cement was removed and replaced with the upstream, predominantly clayey, material. This is determined by the nature of the sediment itself, which consists mostly of aggregate, giving the mortar mechanical strength.

The release test allows for the estimation of the long-term potential emission of mobile compounds, particularly those that could represent a possible source of pollution to the environment or a hazard to human health. The test was carried out by placing the solid sample inside a solution. The eluate produced was chemically analysed to assess the release potential of the mobile substances contained in the initial sample. Specimen leaching tests show that the mortar specimens exhibit a high degree of environmental compatibility, due to a contaminant release in the atmosphere significantly lower than the limits set by Italian regulations (DM 186/2006; DL 121/2020). As already highlighted in the research works by Mesrar et al. and Bellara et al., respectively, for marine sediments in the port of Le Havre and for lake sediments in Algeria, the concentrations of heavy metals are in many cases below the detectable thresholds of the measuring devices and, for the values appreciable from the instruments adopted, not quantitatively relevant [

46,

47]. In addition, the results obtained from the leaching test are also in agreement with the findings of XRF spectrophotometry and depicted in

Table 2 and

Table 3, where the amounts of contaminants in the dredged sediments are low. Therefore, not only do the sediments as they are not exhibit contaminant content above regulatory limits, but neither does the proposed mortar, based on the dredged sediments, cause contaminant release into the atmosphere, positioning themselves as environmentally friendly.

5. Conclusions

In order to examine the possibility of reusing the sediments from the two reservoirs in southern Italy to make cement mortar, a series of laboratory tests were used to provide an analytical set of data to guide the judgement on the validity of the proposed reuse [

1,

48].

The proposed types of mortar exhibited good workability if they had an amount of aggregate contained within the identified limits, beyond which the mixtures were either not very fluid and therefore unsuitable for use or excessively fluid, with the risk of shrinkage phenomena. Flexural and compressive strengths were lower than those of the normalised mortar, with a more noticeable reduction being observed where partial replacement of the binder with the clay material was implemented. The results of the study make it possible to hypothesize a reuse that does not perform structural functions, also in terms of the output of the leaching tests. It emerges that the proposed mortar is environmentally compatible, since the values recorded for the heavy metals analysed are always below the thresholds set by current Italian legislation, taken as a reference.

Against this background, the proposed reuse of sediment is in line with the principles of the circular economy, as it ensures a reduction in raw material consumption and the recycling of a material that is currently labelled as waste. This helps to preserve non-renewable natural resources and reduce the carbon footprint associated with the production process of building mortar [

49]. Therefore, the reuse is sustainable, because, firstly, the dredged sediment is reused without any kind of treatment. Furthermore, the use of the sediment as aggregate ensures that virgin raw materials are not depleted, and finally, the reuse in mortar also allows for a reduction in the amount of water to be used in the mix, due to the water content of the sediment, which already constitutes a part of the water needed to prepare the mortar.

Nevertheless, scientific research should be expanded to identify conditions that also allow applications with structural functions. In the latter case, the sandy material constituting the fine aggregate should undergo a preliminary on-site washing treatment to remove the smaller parts. In fact, since the aggregate provides the conglomerate with mechanical strength, the removal of the smaller particles (silt-clay) would lead to an increase in mechanical strength, which would thus become comparable to that of traditional mortar, opening the possibility of reuse with structural functions of these materials.