Abstract

Soil is continuously excavated for development activities in urban and rural areas and treated as waste. This study investigates the characteristics of urban soils excavated from earthworks of buildings in the Brittany region of France for their perspective reuse in earthen construction materials to valorize soil waste and provide a sustainable building material locally. Excavated soil from earthwork activities was taken from the Brittany region of France from three different locations. Soil suitability for compressed earth blocks was investigated based on their granulometry, consistency limits, and mineralogy. Finally, compressed earth blocks with dimensions of 4 × 4 × 16 cm3 were manufactured with different formulations and compacted dynamically. Flexural and compressive strength tests were performed on bricks to observe their mechanical behavior. Grain size analysis of soil samples shows that the percentage of clay in the landfill stockpile of excavated soils varies between 13% and 16%, while at some local sites, the percentage of clay goes up to 57%. The grain size of soils varies from the recommended zone. The plasticity of soil samples ranges from 17.3% to 20.4%. The plasticity index and clay content of the soil show that these soils are inactive clays with a lesser possibility of swelling and shrinkage. Mineralogical analysis of soil shows the absence of water-sensitive clay minerals, while quartz, kaolinite, and illite are major minerals present in soils. Linear shrinkage in bricks ranges from 0.6% to 2.2% and is considerably higher for clayey soils. Mechanical testing of earth bricks shows that the compressive strength of earth blocks ranges from 0.92 MPa to 2.22 MPa while the flexural strength ranges from 0.25 to 0.74 MPa. A mixture of sandy and clayey soils shows good strength due to improved granulometry. Earth bricks with soils from some stockpiles, excavation sites, and soil mixture show compressive strength higher than 1 MPa, which is recommended strength by international standards, and offer the opportunity to produce sustainable building materials locally.

1. Introduction

Infrastructure and development work generate a considerable amount of excavated soil from different operations, such as the installation of pipelines, excavations of trenches and tunnels, roads, and infrastructure projects. Excavated soil is treated as waste and dumped into land sites. Nearly half of the landfill sites are occupied by excavated soil [1]. The construction and public work sector in France produce nearly 231 million tons of waste every year, mainly in the form of excavated soils and demolition material [2]. Nearly 45 million tons of are to be excavated from the Grand Paris Express project (Paris, France) alone [3] Excavated soil storage in stockpiles on land sites is costly. Furthermore, increasing distance from the storage site makes the operation uneconomical due to transportation costs [4].

Excavated soil reuse is complex due to its heterogeneous nature and because of the difficulty to treat all the soils with a similar approach due to variations in soil characteristics when compared with recycling inert waste from concrete, roads, bricks, etc. However, the treatment of soil can transform it into a valuable resource as the reuse of excavated soils provides an alternative to eliminate waste and valorize soil waste. Soil reuse with or without treatment [5,6] reduces the burden on nonrenewable resources by minimizing the use of quarry materials to meet the demands of the construction industry and preserve the natural resources, such as sand and rock [7]. Excavated soil can be used in different applications, such as landscaping, agronomy, backfilling of quarries, building materials [8], roads, embankments, dikes, etc., with some limitations and possibilities [9]. For recycling excavated soils, their physicochemical, mineralogical, microstructural, and hydromechanical characteristics and analysis of pollutants are necessary [6,10,11]. Organic matter, grain size distribution, carbonate content, Atterberg limits, permeability, mineralogy, pH, conductivity, and bearing capacity of soils are some important characteristics that play a key role in the reuse of soil in different applications, such as earth bricks, paving layers, backfill, landscaping, and drainage [12]. Contaminant analysis helps to know the presence of inorganic impurities, such as heavy metals (Ni, Zn, As, Hg, Cr, Cs, etc.), and organic impurities, such as polycyclic aromatic hydrocarbons (PAH), polychlorinated biphenyls (PCB), etc., as urban soil are sometimes polluted due to industrial activities in the proximity. Treatment of polluted soils based on their category (Category B and C) is necessary for their reuse [13].

The building sector is one of the most energy-consuming sectors in the world. In modern buildings, concrete and fired bricks are primary building materials. However, these materials consume a huge amount of energy and nonrenewable resources. Every year nearly 40 to 50 billion tons of sand is used in the construction industry. The use of fertile soil in fired bricks is also leading to the shortage of agricultural soil. Furthermore, cement is a key component of concrete and is responsible for 8% of global anthropogenic CO2 emissions [14]. The construction industry in France and Europe is a major contributor to the emission of greenhouse gases and the consumption of energy and natural resources. The building sector is responsible for 37.2% of global energy consumption worldwide and 44% of energy consumption in France, including residential building consumption [15]. Higher CO2 emissions, use of nonrenewable resources, and increasing costs of concrete and cement have increased the demand for sustainable building materials with a low carbon footprint to achieve carbon neutrality goals [10,16,17].

One of the possible recycling applications for excavated soils is earthen construction materials. Soil has been used as a building material for earthen construction for centuries across the globe. Advancement in construction technology has made it possible to valorize soil waste and manufacture environment-friendly earthen bricks for modern buildings. Recycling excavated soils and agro-industry waste in earth bricks has a real potential for decarbonization of the construction industry, preservation of natural resources, and cost-effective buildings [18]. However, the topsoil layer is usually rich in organic matter and unsuitable for earth bricks [19]. Earth bricks with excavated soils can be an ecological and economical product as the excavated soils are locally available in large quantities with minimum transportation and have the possibility of recyclability. The use of energy for the extraction of soil, transportation of material, and manufacturing of earth bricks is also very low due to the availability of soil locally [20].

Earth bricks are ecological and recyclable materials with a considerably lower thermal conductivity than traditional construction materials, such as concrete and fired bricks, which is important in order to minimize the energy consumption of buildings and for thermal comfort. In addition, earth bricks have good hygrothermal properties, which help to transfer moisture between earth brick walls and air to regulate humidity [16,21]. Different earthen construction materials, such as adobe bricks and rammed earth, and compressed earth blocks, are manufactured based on the characteristics of excavated material and local climatic conditions [22].

Earth bricks can be stabilized with the addition of binders (lime, cement, gypsum, geopolymers) to increase the strength of bricks and water resistance as earth bricks have low strength and are sensitive to water and weathering actions, such as rain, snow, etc. [20,23,24]. However, binders have a higher economic and environmental cost. Furthermore, stabilized earth blocks reversibility in the form of natural soil is not possible [25]. The addition of natural fibers is also helpful to increase the strength of bricks as fibers act as reinforcement, and their distribution parallel the axis of bricks significantly increases the tensile strength and transforms ductile behavior into brittle one by increasing the toughness of bricks [26]. Soil with suitable granulometry for bricks also minimizes the need for binders as natural binders, such as clay, are helpful to bind the soil particles and increase the strength of bricks [27]. Therefore, a certain amount of clay is essential to increase the strength of bricks. In the case of earth wall construction, the presence of sand, silt, clay, and gravel in soil samples is also important. Coarse soil particles having a diameter above 5 mm to 10 mm are not suitable for earth bricks as the compressive strength of earthen bricks decreases with the increasing size of coarse particles [28,29]. Furthermore, the compaction of earth blocks is helpful to increase the strength and durability of bricks. The compaction of earth blocks increases density and decreases their water absorption capacity by eliminating pores. Compaction of earth bricks can be achieved with static compaction, dynamic compaction, and vibrations [30]. The manufacturing and labor cost of small-scale blocks is considerably higher. The manufacturing cost further increases with the addition of a binder. However, the manufacturing and labor cost decreases with increasing block size and automation. Large-size compressed earth blocks stabilized with compaction can have a similar cost to concrete with a much lower carbon footprint. In addition, excavated soil dumping involves transportation and land costs. A substantial amount of soil is excavated every year in the Brittany region of France from earthworks in construction activities. Gendrot (public work company) excavates 200,000 m3 of soil and inert spoil in the Brittany region of France. France has planned an extended producer responsibility tax, which encourages the producer to look for recovery solutions to avoid this tax.

The objective of this study is to investigate the characteristics of excavated soils and examine the feasibility of the recovery of this material in compressed earth blocks for nonstructural building applications. Laboratory-scale earth blocks will be manufactured without the addition of a binder for the reversibility of soil.

2. Materials and Method

Inert soil samples are taken from the Brittany region around Rennes city. The soil samples selected are the most representative surface soils of the region. In terms of geology, the Rennes basin and the surrounding area are part of a vast plateau in central Brittany. Most of it is made up of schists. There are virtually no rock outcrops. These schists are more or less weathered to provide a clayey subsoil and are sometimes covered by aeolian silts or loess (west of Rennes). The overlying soils can be described as silty-clayey [31].

The soil was excavated after removing vegetative soil. Typically, the excavated soil comes from suburban areas and covers soils to an average depth of 1 m. The soil samples were taken from excavated soil deposits belonging to the Gendrot public works company but are representative of regularly stored soil from various regional construction projects. Sampling sites are Bourg de Compte (BDC) and Cesson Redwood (Cesson) storage site and the Calma earthwork site. Excavated soil from the BDC and Cesson sites is crushed and sieved into a fraction of 0/4 mm with a crush/sieve system. Soil excavation from a site is shown in Figure 1a. Figure 1b shows the crushing/sieving of soil, and Figure 1c shows the extracted soil stockpile.

Figure 1.

Soil excavation (a), crushing and sieving (b), stockage (c).

Physicochemical and mineralogical characteristics of excavated soils were determined to observe their suitability for earth bricks. These characteristics include granulometry, moisture content, particle density, Atterberg limits, methylene blue value, organic matter, carbonate content, and minerals such as quartz, kaolinite, calcite, etc. The grain size of soil samples is important for their reuse in earthen materials. Soil samples were passed through sieves of 2 mm, and the granulometry of soil samples was determined with laser granulometry by following French standards [32] to observe the percentage of clay, silt, and sand. Atterberg limits of soil are important for their reuse in building materials and road applications for molding and compaction of the soil. Liquidity limits of soils were determined with the Casagrande test, while plasticity of soil was observed by the failure of soil roll in accordance with the French standard [33]. Methylene blue value (MBV) was determined by the French standard [34] to observe the presence of clay and the behavior of soil. Organic matter in soil significantly influences its strength and approach to the treatment of soil. The organic matter of studied soils was determined by burning the soil at 550 °C in accordance with the French standard [35]. The particle density of soil samples was determined with a helium pycnometer, model AccuPyc 1330 [36]. The test was repeated 3 times on each soil sample to obtain an average value.

Proctor test was performed to observe the optimum moisture content and maximum dry density of soil as optimum moisture content of the soil is essential to achieve maximum densification of soil and increase its load-bearing capacity. Compaction of soil in building materials increases the compressive and tensile strength of building composites. The optimum moisture content of soil samples was determined with a modified Proctor test [37] by applying compaction energy of 600 kN.m/m3 to achieve the maximum dry density. XRD analyses were carried out to identify and determine the mineral phases. The analyses were performed by using a D8-Advance Bruker-AXS diffractometer with a Ni-filtered CuKα radiation at 40 kV and 40 mA. Quantitative phase analysis based on reference intensity ratio values was performed on randomly oriented soil powders with a step length of 0.5° and a scan speed of 0.014°/s over the range 3°–70°2θ for the whole soil composition. The uncertainty was estimated to be ±5%. The interpretations of the data obtained were performed using the DIFFRAC EVA v4.2 (©Bruker AXS) software.

2.1. Sample Preparation

Manufacturing of earth blocks includes mixing of soil, molding, compaction, and drying. Soil samples were dried in an oven at 50 °C for 24 h. Dried soil samples were crushed, ground, and passed through a 2 mm sieve for their reuse in compressed earth blocks. Earth blocks were manufactured with 5 different soil compositions to optimize the strength of bricks. The soil compositions studied are shown in Table 1.

Table 1.

Soil compositions used for manufacturing earth bricks.

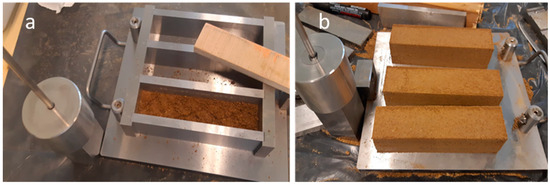

The soil mixture was prepared with the addition of optimum moisture content and molded into prismatic specimens of 4 × 4 × 16 cm3 for flexural and compressive strength tests based on French standards for mortars [38]. A total of 450 g of soil was mixed with optimum moisture content, which is commonly used to mix soils to achieve maximum densification through compaction [39,40]. Prismatic molds were oiled to decrease the adhesion of soil to molds. The soil mixture was filled into molds in two layers [41] and compacted with dynamic loading by applying Proctor normal energy of 600 kN.m/m3 with repeated strokes of falling mass. With dynamic compaction of bricks, it is easier to control compaction energy—it is one of the efficient techniques to remove the voids and increase the strength of bricks [42,43]. After compaction of the first layer of soil, groves were made on the first layer of soil to make it rough and increase bonding between the two layers. Strong bonding between layers increases the strength of earth bricks. The bonding of layers in the case of mortar specified in the standards is different from the cement paste which when poured in the mold is homogenized and has no problem with adhesion. Compaction tools and groves on the soil layer can be seen in Figure 2a. Excessive soil on the brick surface after compaction was trimmed to maintain a height of 4 cm. Compacted bricks were unmolded and dried at a low temperature in the oven at 40 °C to rest near the natural drying temperature. Demolded compressed earth blocks can be seen in Figure 2b.

Figure 2.

Manufacturing of compressed earth blocks.

2.2. Testing of Earth Bricks

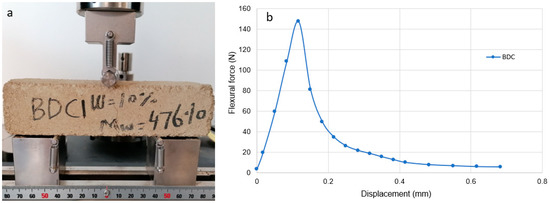

The mechanical behavior of earth blocks was investigated with flexural and compressive strength tests. The flexural strength of earth bricks (indirect tensile strength) was determined with a three-point bending test [44] using a Shimadzu AGS-X model machine with a 50 kN sensor at a displacement rate of 0.5 mm/min. Figure 3 shows the flexural strength testing of compressed earth blocks with the BDC soil sample along with the flexural load-deflection curve. The flexural load was applied perpendicular to the layer interface of earth bricks. During the flexural loading in Figure 3a, cracks started from the bottom of the brick and propagated slowly upward before failure. Figure 3b shows that unreinforced bricks do not support the load after failure as they have very little toughness.

Figure 3.

Flexural strength testing (a) and flexural load-deflection curve (b).

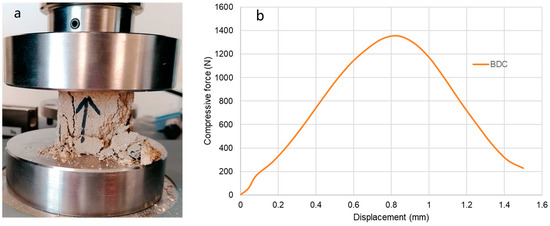

After the flexural strength test, two halves of BDC brick were cut into cubes of 4 × 4 × 4 cm3 with an electric cutter with a fine blade. Brick sections were cut into cubes contrary to the norm’s specifications due to compressive machine adaptability with cubic blocks. Cutting of bricks introduces the microcracks and readjustment of particles, which decreases the strength of bricks. However, compressive load-deflection graphs show no oscillation indicating that there was no significant cracking. The compressive strength of earth bricks was observed by applying compressive load at the top of cubic specimens. Compressive strength testing of the BDC brick cube can be seen in Figure 4a. Figure 4b shows the compressive load-deflection behavior of unreinforced compressed earth blocks.

Figure 4.

Compressive strength test (a) and compressive load-deflection curve.

3. Results and Discussion

3.1. Characteristics of Excavated Soils

The physicochemical and mineralogical characteristics of soil samples were determined by different tests. The results are summarized in Table 2.

Table 2.

Physicochemical characteristics of soil samples.

The grain size distribution of soils is shown in Table 3.

Table 3.

Grain size distribution of soil.

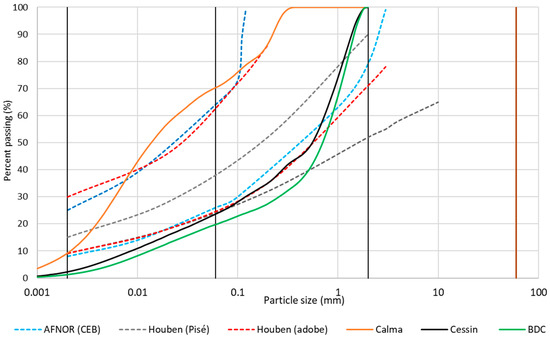

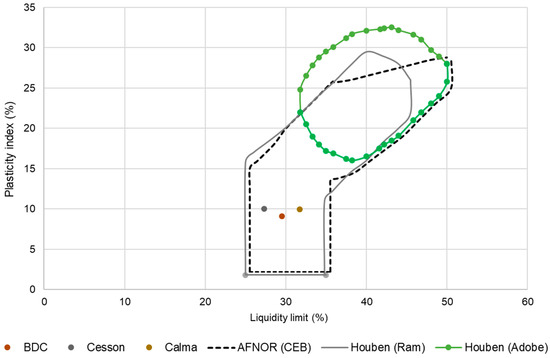

Granulometry of soil shows that BDC and Cesson soils have higher sand content while Calma soil has higher clay content. According to the USDA soil classification system [45], BDC and Cesson soils are sandy loam while Calma is clayey soil. The grading coefficient of Calma soils is between 1 and 3, which means that this soil is well graded while the other soils are poorly graded [46]. Soils with a higher percentage of fine particles usually have higher plasticity. Significant clay quantity is essential in bricks to ensure the plasticity and bonding of soil particles. However, excessive clay leads to shrinkage, cracks, and expansion of earth blocks in their interaction with water. The suitability of the Brittany region soils for earth bricks with granulometry in accordance with the French standard [47] and recommendations of Houben and Guillaud [48] is shown in Figure 5.

Figure 5.

Suitability of excavated soils for earth bricks based on granulometry.

It can be observed from Figure 5 that Cesson soils are close to the zones recommended for adobe bricks. Clay and silt content in Cesson soils is slightly lower than the recommended zone. BDC soils have significantly lower clay and silt content and higher sand content. A sufficient quantity of fine particles is necessary for the plasticity of soils for their reuse in earth bricks. On the other hand, Calma soils have a higher percentage of fine particles and tend to move away from the zones recommended for earthen construction. A higher percentage of fine particles leads to excessive shrinkage and cracking during the drying of bricks. Therefore, for balanced granulometry, a mixture of BDC and Cesson soil with Calma soils can be interesting and push the soil samples inside the zones recommended for earth bricks in Figure 5.

Liquidity and plasticity limits of soil are also helpful in the analysis of the soil suitability for earth bricks. Clayey soils have usually higher plasticity. The liquidity and plasticity s of soils in Table 2 are the highest for Calma soils, which are clayey. The plasticity of sandy soil (Cesson) is the lowest. For molding of bricks, such as adobe and cob, molding moisture content of soil used varies between the liquidity and plasticity limit of soil. Figure 6 defines the zones suitable for earth bricks based on their Atterberg limits.

Figure 6.

Soil suitability for bricks is based on consistency limits.

It can be seen in Figure 6 that BDC, Cesson, and Calma soils are within the zone recommended for compressed earth blocks and rammed earth. The plasticity index of BDC, Cesson, and Calma soil is lower than 12, which means that these soils are less plastic silts [49]. Table 3 shows that activity of clay is below 0.75, which means the soils are inactive clays with less swelling and shrinkage potential. XRD analysis of soils in Table 4 also confirms the absence of swelling clays in soil samples.

Table 4.

Mineral composition of soil samples.

BDC, Cesson, and Calma have organic matter, which is below 10, and according to French standards [50] these soils are classified as low organic soils. Cesson and Calma soils have a higher percentage of organic matter than BDC soil. Higher organic matter in the soil makes soil unsuitable for building applications, such as earth bricks, as higher organic matter influences the cohesion and molding of soil, decreases the strength of bricks, and leads to higher shrinkage and biodeterioration in bricks [27]. Higher organic soils require treatment with a binder, such as lime, cement, or geopolymers, to improve their mechanical properties [42].

Table 2 shows that the solid particle density of soil samples ranges from 2.6 to 2.7 g/cm3, which is within the common range of density of soils from 2.55 to 2.7 g/cm3. The density of soil is influenced by the presence of minerals in soils as the density of quartz is 2.65 g/cm3, feldspar 2.65 to 2.8, and micas 2.7 to 3.3 g/cm3 [51]. The optimum molding moisture content of Calma soils is the highest as this soil has a higher percentage of clay particles. The optimum moisture content of the soil is helpful to achieve maximum densification of soil samples through compaction. MBV value of Cesson and BDC soil samples shows that these soils are sandy silts and water-sensitive soils as their MBV value is below 1.5. Calma soil has an MBV value of 1.6, which is sandy-clayey soil with low plasticity [49]. Based on granulometry, plasticity index, and methylene blue value, soil samples were classified by the French standard [52]. Soil classification shows that BDC and Cesson soils are category B5 soils, which are silty sand soils while Calma soils are within the category of A1 soils, which are low plasticity soils [49].

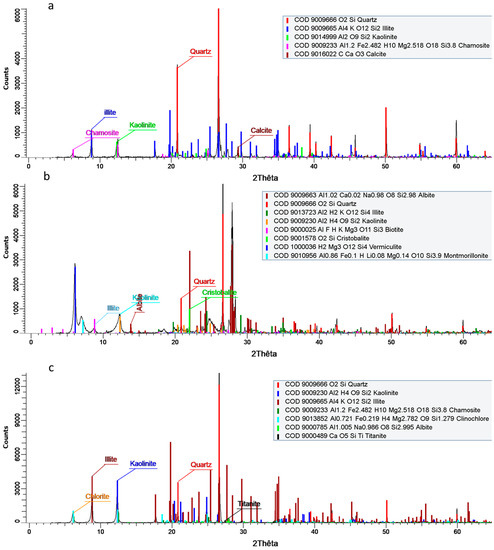

The mineralogy of soil samples was investigated with X-ray diffraction (XRD) analysis. The diffractogram of soil samples shows that silicate minerals are dominant in all soil samples, which include clay (illite, kaolinite), feldspar (albite), mica (biotite), quartz, and chlorites (chamosite, clinochlore). The presence of carbonates is low, as only BDC soils show the presence of calcite. XRD diffractogram of soil samples is shown in Figure 7.

Figure 7.

XRD pattern of BDC (a), Cesson (b), and Calma soils (c). Note: Ilt = illite, Ab = Albite, Bt = Biotite, Qz = Quartz, Chm = Chamosite, Cli = Clinochlore, Cal = Calcile.

XRD analysis helps to see the presence of different minerals in the soil. Different types of clay minerals help to assess the swelling and shrinkage potential of earth bricks. Furthermore, the presence of minerals, such as carbonates, is helpful to determine a suitable binder to stabilize the soil. The percentage of different minerals in soil samples is given in Table 4.

Calma soils have a high percentage of clay minerals. The clay and sand content of soils determined with laser granulometry and XRD are consistent. However, for BDC soils, sand content was overestimated by laser granulometry. Quantitative analysis with the XRD test provides a more comprehensive picture of soil mineralogy and the percentage of clay minerals. An important clay mineral identified in soil samples is illite along with chlorites (chamosite and clinochlore). Illite clay is good for shaping and drying bricks. Illite and chlorite clays demonstrate small volumetric changes in their interaction with water contrary to montmorillonite and smectite clays, which have very good cohesion and a tendency to swell during their interaction with water. Swelling and shrinkage of bricks on wetting and drying lead to crack growth, which is undesirable for construction materials [39,53]. Quartz (SiO2) and feldspar minerals are other major minerals in soil samples, and these are the most common mineral in the earth’s crust. The presence of calcite is negligible in Calma and Cesson soils while its percentage is 4.1% in BDC soils. Calcium carbonate acts as a cementing agent in soils by increasing their compressive and shear strength [54].

3.2. Characteristics of Earth Bricks

3.2.1. Physical Characteristics of Earth Bricks

Earth bricks were manufactured with dynamic compaction and dried in an oven at 40 °C. The drying of bricks lasted for 3 to 4 days. The dry density of earth bricks was measured with the ratio of mass and volume of bricks [55] and the linear shrinkage of earth bricks was measured by observing the shrinkage in bricks specimens during drying before mechanical testing. These characteristics of bricks are important for their reuse as construction material for earthen structures. The physical characteristics of compressed earth blocks are shown in Table 5.

Table 5.

Characteristics of earth bricks.

Table 5 shows that the density of earth bricks ranges from 1661 kg/m3 to 1718 kg/m3. Calma soils have the lowest density as they are clayey soil. Small pores in clayey particles contribute to the low density of clayey soil. Densification of soil by dynamic or energy-controlled compaction helps to obtain better material homogeneity. The procedure needs to be formalized and implemented in a production cycle. This procedure could be adapted to larger brick sizes or even metric-sized walls. The dry density of compressed earth blocks in the literature varies from 1500 to 2000 kg/m3 and is lower that than of concrete. The density of bricks is influenced by compaction, the addition of binder, and reinforcement of bricks with natural fibers as the addition of natural fibers decreases the density of bricks [56,57,58].

Linear shrinkage in Calma bricks is around 2.2%, which is considerably high. Sandy soils, such as Cesson, have low shrinkage. Higher clay content and molding moisture content of Calma soils are the reason behind higher shrinkage. Similar behavior was observed in the literature studies [59].

3.2.2. Flexural Strength of Earth Bricks

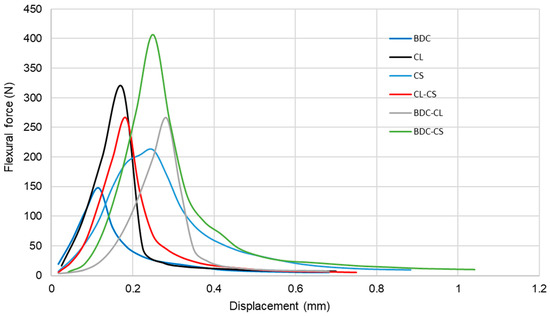

The flexural strength of earth bricks was determined with a 3-point bending test. The results relating to deflection under a vertical load (4 × 4 × 16 cm3 test) could be used to define the load-bearing capacity limitation as compressive testing. However, other tests, such as pushover tests, could be carried out on walls built with this type of bricks [60]. Flexural load-deflection curves of soil samples are shown in Figure 8.

Figure 8.

Flexural load-deflection curves of soil samples.

Figure 8 shows that the load-deflection behavior of all the soil samples is similar and nonlinear in the elastic zone. The behavior of earth bricks is brittle and after failure, loads drop to zero without significant brittleness. The flexural strength (indirect tensile strength) of earth bricks is shown in Table 6 and it ranges from 0.25 MPa to 0.74 MPa. The flexural strength of earth bricks is influenced by the nature of the soil, manufacturing method, compaction energy, use of natural fibers, and a stabilizing binder. Literature studies show that variation in the flexural strength of earth bricks usually ranges from 0.29 MPa to 2.26 MPa [61,62,63]. Table 6 shows that BDC soils have the lowest flexural strength while the mixture of BDC and Cesson soils and the Calma soils have the highest flexural strength. The flexural strength of BDC-CS soils is nearly 3 times higher than that of BDC soils. BDC soils have a higher percentage of clays, such as illite, which have low cohesion. A mixture of sandy soils (Cesson) with BDC and CL soils, which have a higher percentage of clay minerals, gives good compressive and flexural strength as the presence of both clay and sand is essential to increasing the strength of specimens. Higher sand content in bricks leads to brittleness while higher clay content results in higher plasticity and crack growth [64].

Table 6.

Compressive and flexural strength of earth bricks.

Furthermore, higher organic matter in Cesson soils is also reduced in the mixture as BDC soils have low organic matter. Higher strength of Calma soils is associated with a higher percentage of fine particles and clay minerals, which act as a binder. There is a lack of norms and standards for earth bricks and recommended tensile strength for unstabilized earth bricks varies from 0.12 MPa to 0.25 MPa in different norms [40,47,65]. BDC samples have considerably lower tensile strength, which is 0.25 MPa while Cesson and Calma soils have higher tensile strength that meets the strength requirement of earthen bricks. The bending stiffness of earth blocks was determined with flexural load-deflection curves. The results of bending stiffness are shown in Table 6. The rise in flexural load is similar for most of the bricks in Figure 8. Calma bricks have the highest bending stiffness as these bricks have higher flexural strength and bending stiffness usually increases with increasing flexural load.

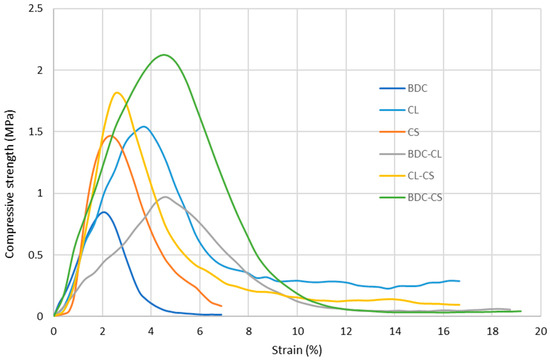

3.2.3. Compressive Strength of Earth Bricks

The compressive strength of earth bricks was determined on cubes of earth bricks with dimensions of 4 × 4 × 4 cm3 obtained after the flexural strength test. Compressive strength load-deflection curves are shown in Figure 9.

Figure 9.

Compressive load-deflection curves.

The compressive strength of earth blocks is shown in Table 6. The compressive strength of earth blocks ranges from 0.92 MPa to 2.22 MPa. The BDC-CS soil mixture has higher compressive and flexural strength as shown in Table 6. Mineralogy of BDC soils shows that BDC soil is mainly composed of clay mineral illite while CS is sandy soil. A mixture of BDC and CS soil improves soil granulometry, and bricks have good mechanical behavior with improved soil granulometry contrary to the soil mixture of BDC and CL soils, which are both rich in clay minerals and have low compressive strength. CS is sandy soil and exhibits good compressive and flexural strength. However, sandy soils have brittle behavior. Therefore, ideal soil should be a mixture of both fine and coarse particles [66]. Cesson and Calma soils have two times higher compressive strength than BDC soils. The compressive strength of compressed earth blocks recommended by the French standard is 1 MPa [47], while in some international standards, it ranges from 1 to 2 MPa [65,67,68]. Cesson, Calma, and a mixture of Cesson and BDC soils have a good compressive strength that satisfies the strength requirement according to French recommendations.

In French specifications for nonstructural applications, 1 MPa strength is the minimum threshold for compressed earth blocks as the earthen walls are often protected with stabilized earth plaster to protect them from rain and to overcome the durability issue. Stabilization of the earth with hydraulic binders and geopolymers increases the strength and durability of earth bricks. However, the reversibility of stabilized soils is not possible after the life cycle of the earthen structure.

The ratio of compressive and tensile strength (σc/σt) of earth bricks varies from 1.9 to 4 in Table 6, which is significantly lower than that of concrete (σc/σt = 10), which has significantly higher compressive strength and whose tensile strength is usually 10% of its compressive strength. The compressive strength requirement for earthen construction materials varies with applications and the applied load. Table 7 shows the strength requirement prescribed in some international standards for stabilized and nonstabilized earthen construction materials.

Table 7.

Recommended compressive strength for earthen construction materials.

4. Conclusions

In this study, physicochemical and mineralogical characteristics of excavated soils from the Brittany region of France were investigated for their reuse in raw earth blocks (CEB). The grain size distribution of studied soils differs from soil suitable for compressed earth blocks as laser granulometry of BDC and Cesson soils’ grain size shows that they have higher sand content while Calma soils have a higher percentage of clay particles (57%). Higher clay content causes shrinkage in bricks while higher sand content results in brittleness. Organic matter in soils ranges from 3% to 8.7%, which is low and suitable for earth bricks as high organic matter increases soil porosity and decreases the strength of bricks. Methylene blue values of soils range from 1.23 to 1.60 g/100 g, which are low values, and indicate that soils have low plasticity. Liquidity and plasticity limits of soil show that the soils are within the zone recommended for bricks. In addition, the activity of clay calculated with the plasticity index and clay content shows that the studied soils are inactive with less possibility of swelling and shrinkage, which is essential for earth bricks. Silicate minerals (quartz, feldspar) are major components of soil samples with illite and kaolinite as major clay minerals, which are dimensionally stable clays with low water sensitivity and suitable for earthen constructions.

Prismatic earth brick specimens were manufactured through dynamic compaction. Due to the lack of a definite standard for earth bricks, laboratory-scale prismatic specimens’ surface layers were scratched to improve bonding between layers. The density of manufactured compressed earth blocks varies from 1661 to 1718 kg/m3. Earth bricks with clayey soils (CL) have the lowest density and higher optimum moisture content. Linear shrinkage in bricks ranges from 0.6 to 2.2% and is the highest for clay soil (CL) due to a higher percentage of fine particles and molding moisture content.

For the compressive strength test, bricks were cut into cubes with a fine blade electric saw, which induced the microcracks in bricks and undermined the compressive strength of bricks. Flexural and compressive strength testing of bricks shows that a mixture of Cesson and BDC soils, Cesson, Calma, and a mixture of Cesson and Calma soil-based bricks have good compressive (2.22, 1.74, 1.71, and 1.6 MPa) and flexural strength (0.74, 0.43, 0.47, and 0.69 MPa). A mixture of sandy soils with soils having a higher percentage of clay minerals, including BDC and CL soils, shows good compressive and flexural strength due to improved granulometry of soil mixture. Most of the soil samples have compressive strength higher than 1 MPa and meet the compressive strength requirement of compressed earth blocks, except for BDC soil samples, and can be used for manufacturing earth blocks for walls and nonstructural applications. The flexural strength of all the soil samples is higher than 0.25 MPa and meets the strength requirement of compressed earth bricks in different standards. The bending stiffness of Calma soils is higher as these soils have higher flexural strength. The strength requirement of compressed earth blocks varies with application. For structural applications, the required compressive strength is around 5 MPa by some standards. The compressive strength of most of the studied soil samples is below 2 MPa except for a mixture of BDC and CS soil. The low strength of earth blocks is one of the main barriers to using these blocks for load-bearing structural walls. The durability of earthen blocks is also a problem as these blocks are often sensitive to water and show swelling and shrinkage when they interact with water.

The feasibility study on the design of earth blocks without the addition of stabilizers showed that the compressive strengths reached the threshold recommended by the French standard. However, given the variability of excavated soil, there is a risk that the resistance value will be lower than that required. To address this risk, controls on the disposal of excavated soil must be put in place to ensure geotechnical quality. Geotechnical monitoring must be carried out when the soil is deposited on site. In addition, compaction can also be improved, by developing mechanized compaction and kneading of the material. Further research work is recommended to study the durability of bricks and the variation in brick behavior with different soils.

Author Contributions

A.K., A.P. and A.M.; experimental work, M.H., E.C., N.L. and D.L.; analysis, M.H., A.K., H.Z. and D.L.; writing, M.H. and A.K.; supervision, A.K., A.M. and A.P.; review and editing, M.H.; A.K., H.Z. and D.L.; project administration, A.K., A.M. and A.P.; funding acquisition, A.K., A.M. and A.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been funded by the European Union project, NextGenerationEU under France Relance progam for the valorisation of inert excavated soils (VALODEB) with collaboration of Unilasalle Rennes and Gendrot TP.

Data Availability Statement

Data will be made available on request.

Acknowledgments

We are thankful to Jean Baptiste Besnier, Ivane Lelievre, Clarisse Roig, and Sébastien Potel for their technical assistance and cooperation to support the experimental work.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Huang, T.; Kou, S.; Liu, D.; Li, D.; Xing, F. Evaluation of the Techno-Economic Feasibility for Excavated Soil Recycling in Shenzhen, China. Sustainability 2022, 14, 3028. [Google Scholar] [CrossRef]

- FFB. Mieux Gérer les Déchets de Chantier du Bâtiment. Bâtir pour la Planète, 2021. Available online: http://www.dechets-chantier.ffbatiment.fr/ (accessed on 10 February 2023).

- Bastin, A. Vers une gestion circulaire des matières inertes issues de la démolition et des travaux publics en région parisienne: Une lecture croisant transition sociotechnique et approches territoriales. Flux-Cah. Sci. Int. Réseaux Territ. 2020, 116–117, 42–57. [Google Scholar] [CrossRef]

- Choi, H.; Park, M.-H.; Jeong, D.-M.; Kim, J.-H. Soil recycling among construction sites by optimizing schedule and costs for earthmoving. J. Asian Archit. Build. Eng. 2017, 16, 439–446. [Google Scholar] [CrossRef]

- Kuno, G.; Okamoto, S.; Shibata, Y. Recycling excavated soil to back-filling material with liquefied stabilized soil method. In Proceedings of the CIB World Building Congress, Gaevle, Sweden, 7–12 June 1998; 8p. [Google Scholar]

- Zihler, J.; Dettwiler, J.; Zäch, C. Reuse of Excavated Soils, Soil Excavation Guideline, Editor SAEFL-Swiss Agency for the Environment; Forests and Landscape: Zürich, Switzerland, 2001; 20p. [Google Scholar]

- Xu, J.; Xiong, W.; Guo, X.; Lai, T.; Liu, Y.; Ying, W. Properties of using excavated soil waste as fine and coarse aggregates in unfired clay bricks after dry-wet cycles. Case Stud. Constr. Mater. 2022, 17, e01471. [Google Scholar] [CrossRef]

- Scialpi, G.; Perrotti, D. The use of urban biowaste and excavated soil in the construction sector: A literature review. Waste Manag. Res. 2022, 40, 262–273. [Google Scholar] [CrossRef]

- Hale, S.E.; Roque, A.J.; Okkenhaug, G.; Sørmo, E.; Lenoir, T.; Carlsson, C.; Kupryianchyk, D.; Flyhammar, P.; Žlender, B. The reuse of excavated soils from construction and demolition projects: Limitations and possibilities. Sustainability 2021, 13, 6083. [Google Scholar] [CrossRef]

- Magnusson, S.; Lundberg, K.; Svedberg, B.; Knutsson, S. Sustainable management of excavated soil and rock in urban areas–A literature review. J. Clean. Prod. 2015, 93, 18–25. [Google Scholar] [CrossRef]

- Guo, Q.; Zhan, L.; Shen, Y.; Wu, L.; Chen, Y. Classification and quantification of excavated soil and construction sludge: A case study in Wenzhou, China. Front. Struct. Civ. Eng. 2022, 16, 202–213. [Google Scholar] [CrossRef]

- Kataguiri, K.; Boscov, M.E.G.; Teixeira, C.E.; Angulo, S.C. Characterization flowchart for assessing the potential reuse of excavation soils in Sao Paulo city. J. Clean. Prod. 2019, 240, 118215. [Google Scholar] [CrossRef]

- MTECT. Sites et Sols Pollués. Ministère de la Transition Ecologique et de la Cohesion des Territoires. 2022. Available online: https://www.ecologie.gouv.fr/sites-et-sols-pollues (accessed on 3 February 2023).

- Müller, N.; Harnisch, J. A Blueprint for a Climate Friendly Cement Industry; WWF International: New York, NY, USA, 2009. [Google Scholar]

- International Energy Agency. Final Energy Consumption in the Buildings Sector, 2021. 2022. Available online: https://www.iea.org/data-and-statistics/charts/final-energy-consumption-in-the-buildings-sector-202 (accessed on 3 February 2023).

- Cagnon, H.; Aubert, J.E.; Coutand, M.; Magniont, C. Hygrothermal properties of earth bricks. J. Energy Build. 2014, 80, 208–217. [Google Scholar] [CrossRef]

- MTECT. Stratégie Nationale Bas-Carbone. Ministère de la Transition Ecologique et de la Cohesion des Territoires. 2022. Available online: https://www.ecologie.gouv.fr/strategie-nationale-bas-carbone-snbc (accessed on 8 February 2023).

- Hussain, M.; Levacher, D.; Leblanc, N.; Zmamou, H.; Djeran-Maigre, I.; Razakamanantsoa, A.; Saouti, L. Reuse of harbour and river dredged sediments in adobe bricks. J. Clean. Mat. 2022, 3, 100046. [Google Scholar] [CrossRef]

- Little, B.; Morton, T. Building with Earth in Scotland: Innovative Design and Sustainability; Scottish Executive Central Research Unit: Edinburgh, UK, 2001. [Google Scholar]

- Gomes, M.I.; Faria, P.; Gonçalves, T.D. Earth-based mortars for repair and protection of rammed earth walls. Stabilization with mineral binders and fibers. J. Clean. Prod. 2018, 172, 2401–2414. [Google Scholar] [CrossRef]

- Alassaad, F.; Touati, K.; Levacher, D.; Sebaibi, N. Effect of latent heat storage on thermal comfort and energy consumption in lightweight earth-based housings. Build Environ. 2023, 229, 109915. [Google Scholar] [CrossRef]

- Shaaban, M. Sustainability of excavation soil and red brick waste in rammed earth. Civ. Eng. Archit. 2021, 9, 789–798. [Google Scholar] [CrossRef]

- Adam, E.A.; Agib, A.R.A. Compressed Stabilised Earth Block Manufacture in Sudan; UNESCO: Paris, France, 2001; Volume 1, Available online: https://unesdoc.unesco.org/ark:/48223/pf0000128236 (accessed on 15 February 2023).

- Siddiqua, S.; Barreto, P.N.M. Chemical stabilization of rammed earth using calcium carbide residue and fly ash. Constr. Build. Mater. 2018, 169, 364–371. [Google Scholar] [CrossRef]

- Raza, I.A.; Navdeep; Maaze, R.; Attri, G.K.; Shrivastava, S. Comparative life cycle assessment of recycled soil-stabilized bricks and traditional bricks. Mater. Today Proc. 2023, 80, 532–537. [Google Scholar] [CrossRef]

- Bui, H.; Sebaibi, N.; Boutouil, M.; Levacher, D. Determination and Review of Physical and Mechanical Properties of Raw and Treated Coconut Fibers for Their Recycling in Construction Materials. Fibers 2020, 8, 37. [Google Scholar] [CrossRef]

- Maniatidis, V.; Walker, P. A Review of Rammed Earth Construction. DTI Project Report, Developing Rammed Earth for UK Housing. 2003. Available online: https://researchportal.bath.ac.uk/en/publications/a-review-of-rammed-earth-construction (accessed on 2 February 2023).

- McHenry, P.G. Adobe and rammed earth buildings. In Design and Construction; A Wiley Interscience Publication: New York, NY, USA, 1984; ISBN 978-0471876779. [Google Scholar]

- Norton, J. Building with Earth. A Handbook, 2nd ed.; Intermediate Technology Publications: London, UK, 1997; ISBN 0946688338. [Google Scholar]

- Seifi, S.; Sebaibi, N.; Levacher, D.; Boutouil, M. Mechanical performance of a dry mortar without cement, based on paper fly ash and blast furnace slag. J. Build. Eng. 2018, 22, 113–121. [Google Scholar] [CrossRef]

- BRGM. Cartes Géologiques et Banque de Données du Sous-Sol. 2021. Available online: https://infoterre.brgm.fr (accessed on 18 July 2023).

- AFNOR NF X31-107; Qualité du Sol-Détermination de la Distribution Granulométrique des Particules du Sol-Méthode à la Pipette. AFNOR: Paris, France, 2003.

- AFNOR NF EN ISO 17892-12; Reconnaissance et Essais Géotechniques-Essais de Laboratoire Sur Les Sols-Partie 12: Détermination des Limites de Liquidité et de Plasticité. AFNOR: Paris, France, 2018.

- AFNOR NF P 94-068; Sols Reconnaissance et Essais-Mesure de la Capacité D’adsorption de Bleu de Méthylène D’un Sol ou D’un Matériau Rocheux-Détermination de la Valeur de Bleu de Méthylène D’un Sol ou D’un Matériau Rocheux Par L’essai à la Tache. AFNOR: Paris, France, 1998.

- AFNOR XP P 94-047; Sols: Reconnaissance et Essais. Détermination de la Teneur Pondérale en Matières Organiques D’un Matériau. AFNOR: Paris, France, 2007.

- DIN 51913:2013-05; Testing of Carbonaceous Materials-Determination of Density by Gas Pycnometer (Volumetric) Using Helium as the Measuring Gas-Solid Materials. German Technical Standard: Berlin, Germany, 2013.

- AFNOR NF P 94-093; Sols: Reconnaissance et Essais. Détermination des Références de Compactage D’un Matériau. AFNOR: Paris, France, 1999.

- AFNOR NF EN 1015-11; Méthodes D’essai des Mortiers Pour Maçonnerie—Partie 11: Détermination de la Résistance en Flexion et en Compression du Mortier Durci. AFNOR: Paris, France, 2019.

- Fgaier, F.; Lafhaj, Z.; Chapiseau, C.; Antczak, E. Effect of sorption capacity on thermo-mechanical properties of unfired clay bricks. J. Build. Eng. 2016, 6, 86–92. [Google Scholar] [CrossRef]

- NZS 4298; Materials and Workmanship for Erth Buildings, Building Code Compliance Document. New Zealand Standard on Earth Construction: Wellington, New Zealand, 1998; E2 (AS2). 91p. Available online: https://cobcode.s3.amazonaws.com/supporting-docs/NZS4298-1998-Materials_and_Workmanship_For_Earth_Buildings.pdf (accessed on 24 March 2023).

- AFNOR EN 196-1; Méthodes D’essais des Ciments—Partie 1: Détermination des Résistances. AFNOR: Paris, France, 2016.

- Hussain, M. Sustainable Reuse of Sediments in Bio-Based Materials-Application to Fluvial Sediments with Incorporation of Natural Fibers. Ph.D. Thesis, Université de Rouen, Mont-Saint-Aignan, France, 2022. [Google Scholar]

- Dormohamadi, M.; Rahimnia, R. Combined effect of compaction and clay content on the mechanical properties of adobe brick. Case Stud. Constr. Mater. 2020, 13, e00402. [Google Scholar] [CrossRef]

- ASTM C1557-03; Standard Test Methods for Tensile Strength and Young’s Modulus of Fibers. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004.

- USDA. Soil survey manual. In USDA Handbook; U.S. Department of Agriculture: Washington, DC, USA, 1951; 503p. [Google Scholar]

- Whitlow, R. Basic Soil Mechanics; Construction Press: London, UK, 1983. [Google Scholar]

- AFNOR XP P13-901; Compressed Earth Blocks for Walls and Partitions: Definitions–Specifications–Test Methods–Delivery Acceptance Conditions. AFNOR: Paris, France, 2001.

- Houben, H.; Guillaud, H. Earth Construction: A Comprehensive Guide; Intermediate Technology Publications: London, UK, 1994; ISBN 1-85339-193-X. [Google Scholar]

- GTR. Réalisation des remblais et des couches de forme. In Guide Technique Paris, 2nd ed.; LCPC, SETRA: Paris, France, 2000; 211p. [Google Scholar]

- AFNOR XP P 94-011 1999; Sols: Reconnaissance et essais—Description. Identification. Dénomination des Sols—Terminologie. Éléments de classification. AFNOR: Paris, France, 1992.

- Blake, G.R. Particle density. In Encyclopedia of Soil Science. Encyclopedia of Earth Sciences Series; Chesworth, W., Ed.; Springer: Dordrecht, The Netherlands, 2008. [Google Scholar] [CrossRef]

- AFNOR NF P 11-300; Earthworks Classification of Materials for Use in the Construction of Embankments and Capping Layers of Road Infrastructures. AFNOR: Paris, France, 1992.

- Velde, B. Clay minerals. In Terra Literature Review-An Overview of Research in Earthen Architecture Conservation; Avrami, E., Guillaud, H., Hardy, M., Eds.; The Getty Conservation Institute: Los Angeles, CA, USA, USA, 2008; p. 1e7. [Google Scholar]

- Fukue, M.; Nakamura, T.; Kato, Y. Cementation of soils due to calcium carbonate. Soils Found. 1999, 39, 55–264. [Google Scholar] [CrossRef] [PubMed]

- AFNOR EN 1015-10; Methods of Test for Mortar for Masonry. Part 10: Determination of Dry Bulk Density Harden Mortar for Masonry. AFNOR: Paris, France, 1999.

- Guettala, S.; Bachar, M.; Azzouz, L. Properties of the compressed-stabilized earth brick containing cork granules. J. Earth Sci. Clim. Chang. 2016, 7, 353. [Google Scholar] [CrossRef]

- Salih, M.M.; Osofero, A.I.; Imbabi, M.S. Critical review of recent development in fiber reinforced adobe bricks for sustainable construction. Front. Struct. Civ. Eng. 2020, 14, 839–854. [Google Scholar] [CrossRef]

- Turco, C.; Junior, A.P.; Teixeira, E.; Mateus, R. Authors closure to the Discussion of the Review article “Optimisation of Compressed earth blocks (CEBs) using natural origin materials: A systematic literature review”. Constr. Build. Mater. 2022, 325, 126888. [Google Scholar] [CrossRef]

- Koroneos, C.; Dompros, A. Environmental assessment of brick production in Greece. Build. Environ. 2007, 42, 2114–2123. [Google Scholar] [CrossRef]

- Djeran-Maigre, I.; Morsel, A.; Hussain, M.; Levacher, D.; Razakamanantsoa, A.; Delfosse, E. Behaviour of masonry lateral loaded walls made with sediment-based bricks from the Usumacinta River (Mexico). Clean. Eng. Technol. 2022, 11, 100587. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Antico, F.C.; Burbano-Garcia, C.; Concha-Riedel, J.; Norambuena-Contreras, J.; Concha, J.; Flores, E.I.S. Experimental evaluation of adobe mixtures reinforced with jute fibers. Constr. Build. Mater. 2021, 276, 122127. [Google Scholar] [CrossRef]

- Kumar, N.; Barbato, M. Effects of sugarcane bagasse fibers on the properties of compressed and stabilized earth blocks. Constr. Build. Mater. 2022, 315, 125552. [Google Scholar] [CrossRef]

- Khoudja, D.; Taallah, B.; Izemmouren, O.; Aggoun, O.; Herihiri, O.; Guettala, A. Mechanical and thermophysical properties of raw earth bricks incorporating date palm waste. Constr. Build. Mater. 2021, 270, 121824. [Google Scholar] [CrossRef]

- Nassar, S.; Saliba, J.; Saiyouri, N. Investigation of the possible valorization of dredged sediments in compressed earth blocks. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- NORMA E.080. Diseño y Construcción Con Tierra Reforzada. Ministerio de Vivienda, Construcción y Saneamiento. Anexo-Resolución Ministerial N◦ 121-2017-Vivienda. 2017. Available online: https://procurement-notices.undp.org/view_file.cfm?doc_id=109376 (accessed on 15 January 2023).

- Haurine, F. Caractérisation D’atterrissements D’argiles Récents Sur le Territoire Français, en Vue de Leur Valorisation Dans L’industrie des Matériaux de Construction en Terre Cuite. Sciences de la Terre. Ph.D. Thesis, Ecole Nationale Supérieure des Mines de Paris, Paris, France, 2015. [Google Scholar]

- NMAC, New Mexico Administrative Code (NMAC). New Mexico Earthen Building, 2009, Title 14, Chapter 7, Part 4; The Construction Industries Division of the Regulation and Licensing Department: Santa Fe, NM, USA, 2009.

- SAZS 724; Zimbabwe Standard. Rammed Earth Structures. Standards Association of Zimbabwe: Harare, Zimbabwe, 2001.

- Shrestha, H.D. CSEB Green buildings in Nepal. Standard Norms and Specification for CSEB Block; Government of Nepal, Ministry of Education: Kathmandu, Nepal, 2012.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).