1. Introduction

Ground penetrating radar (GPR) is a non-destructive testing method that provides a continuous evaluation of pavement using electromagnetic waves [

1,

2]. The successful use of GPR for pavement assessments in addition to surface layer asphalt density [

3,

4,

5,

6] includes asphalt and base layer depth profiling [

7], pavement material assessment [

8], and detection of standing water or drainage issues [

9]. The degree of asphalt concrete (AC) pavement compaction is a critical factor affecting both the air void content in roadway structures and the proper functioning of pavements [

10,

11,

12,

13,

14]. Estimates show that each 1 percent increase in air void content above 7 percent air voids results in approximately 10% loss in pavement life [

10,

11].

Despite the importance of air void content, the state-of-the-practice compaction evaluation is both destructive and point source-based, with quality control and quality assurance (QA/QC) assessments based on significantly less than 1% of the placed pavement. To address this limitation, ground penetrating radar (GPR) has been used for decades to measure the surface dielectric constant (also referred to as the dielectric) of asphalt pavement using non-contact horn antennas typically mounted on vehicles [

15], or other innovative methods including step-frequency and array-based systems [

16,

17,

18,

19]. Since the measured dielectric constant is a function of all the components in the asphalt mixture (i.e., aggregates, binder, and additives), the measured dielectric requires unique calibration factors for each specific mix-design to be converted to actual air void content. This dielectric-based compaction assessment assumes that changes in dielectric caused by mix variability are negligible compared to changes in air voids. Studies have shown this is generally a reasonable assumption [

4,

5,

6]. Other factors like water content and pavement temperature have been considered. While the current field core calibration is based on measurements up to 200 degrees Fahrenheit, the proposed study relies on measurements conducted at room temperature. A laboratory study conducted by Iowa State suggests this discrepancy in temperature will not be a significant factor. The study showed that the permittivity (dielectric), measured in the temperature range of 80 to 200 degrees Fahrenheit using high-frequency impulses (10 GHz), was almost independent of temperature [

20]. The dielectric constant measurement methods used in this study do not separate the effects of moisture in the analysis. Therefore, the presence of water should increase the measured dielectric and skew the predicted air void content lower. In this study, the asphalt specimen air void measurements were made using a vacuum sealing method [

21] to keep the specimen dry prior to dielectric testing. Water is also present immediately after the final roller compactor is applied on the pavement. However, since the pavement is typically 180 degrees Fahrenheit (82 degrees Celsius), the water evaporates quickly. Therefore, care was taken to ensure water had evaporated from the pavement surface prior to conducting field testing, following protocol similar to previous studies [

22,

23].

More recently, smaller-size dipole-type antennas have been used to measure the dielectric of asphalt mixture to a higher degree of accuracy [

22]. These antennas have been used in a non-contact manner, similar to the afore-mentioned horn antennas, to provide a continuous and comprehensive statistics-based evaluation of compaction quality as it relates to various construction activities and mix design strategies [

23]. As mentioned above, in order to determine the asphalt pavement compaction density in the field with GPR, a relationship between the dielectric constant and air void content of the mixture needs to be established to convert measured dielectric constants to in-place pavement density. However, calibration of the dielectric to asphalt air void content has relied on destructive coring of the as built pavement to calibrate to each mix. This destructive and labor-intensive calibration method must be repeated each time a significant change in mix design occurs. Mechanistic mix-modeling approaches have been proposed [

5,

6], but they use input values such as aggregate and binder dielectric constant that are not readily measured [

8]. Al-Qadi et. al. [

8] demonstrated that the dielectric of the binder and aggregate components can be obtained by back calculation from density and dielectric constant data. However, this approach also relies on core-drilling for accurate dielectric to air void conversion. Further, proper calibration should include air void content on the extreme values, which are not always feasible to identify and collect in the field, and require sophisticated models to add stability for extrapolating outside of the bounds of collected data [

23]. While field core-based dielectric to air void content conversion has been shown to be achievable, the destructive and labor-intensive nature have created a barrier to widespread implementation, especially in environments like Texas and Minnesota where source aggregates are not constant [

22,

23].

To address these issues, a novel method based on the use of asphalt mixture specimens manufactured using the superpave gyratory compactor (SGC) is proposed. Compacted asphalt specimens representing a range of air void contents observable in the field are then used to calibrate the dielectric constant to the specific production mix without the need for field cores. These 6-inch cylindrical samples are referred to as “asphalt specimens” or “specimens” herein. The GPR equipment that allows for input of the calibration curve to directly output density is referred to as the density profiling system (DPS) herein. The gyratory compactors used to fabricate the specimens are readily available, since the asphalt paving industry relies on them as part of typical asphalt mix design QA/QC procedures [

24]. The proposed procedure is also suitable for mix design sensitivity analysis that may be used to determine the necessity and frequency of field core validations and recalibrations. An additional advantage of using the asphalt specimen-based calibration is that agencies typically have test summary sheets of production mixes with standard reporting mechanisms for any changes to the mix that are tracked during a project [

24]. These reporting mechanisms could provide agencies with the necessary input to trigger recalibration, which would be useful for development of dielectric–mix sensitivity-based implementation specifications.

Since the Fresnel zone of the GPR antennas exceeds the diameter of the specimens used for calibration, it was found to be inaccurate to make measurements at the field recommended heights of 6 to 12 in. (15–30 cm). The measurements were affected by surface edge diffractions. Reducing the antenna to a height with an acceptable Fresnel zone (smaller than the specimen diameter) is not feasible, since the timing of the reflected signal from the asphalt specimen is within the range of the direct coupling noise of the system and multiple reflections between the surface and the antenna. Dielectric constant measurements of small asphalt specimens (6 in. diameter) can only be accurately measured using waveguide methods [

25] or microwave free-space methods [

26] that are impractical outside of laboratory conditions, require additional measurement equipment that may not represent the frequency characteristics of the field equipment, and require samples of known and regular dimensions that are not easily produced with typical asphalt production mix. The other option, increasing the diameter of the specimen used for calibration, is equally impractical since the SGC is the most widely used compactor for the fabrication of asphalt samples and it is limited to a maximum diameter of 6 in. Considering these limitations, the proposed method only requires the existing field dielectric constant measuring and asphalt specimen fabrication equipment, but addresses the small specimen issue by introducing spacer material with a known dielectric constant [

27,

28]. This material is shown to sufficiently slow down the wave, and to increase the time gap between the direct coupling and the asphalt specimen response without having to raise the antenna.

The proposed method does not require field cores, which damage the in-place pavement, to develop the calibration curve. The method is amenable to implementation in that the material is readily available, and equipment used to create the asphalt specimens is already part of the QC/QA process. The current testing and reporting of production mix characteristics can be used for similar reporting of mix changes that need to be tracked for routine DPS implementation. Thus, the proposed method is a modification of the field air launched method that resolves the aforementioned limitations, and allows for fully non-invasive conversion of asphalt dielectric to density without requiring any additional equipment or drastically changing the QA/QC reporting mechanisms.

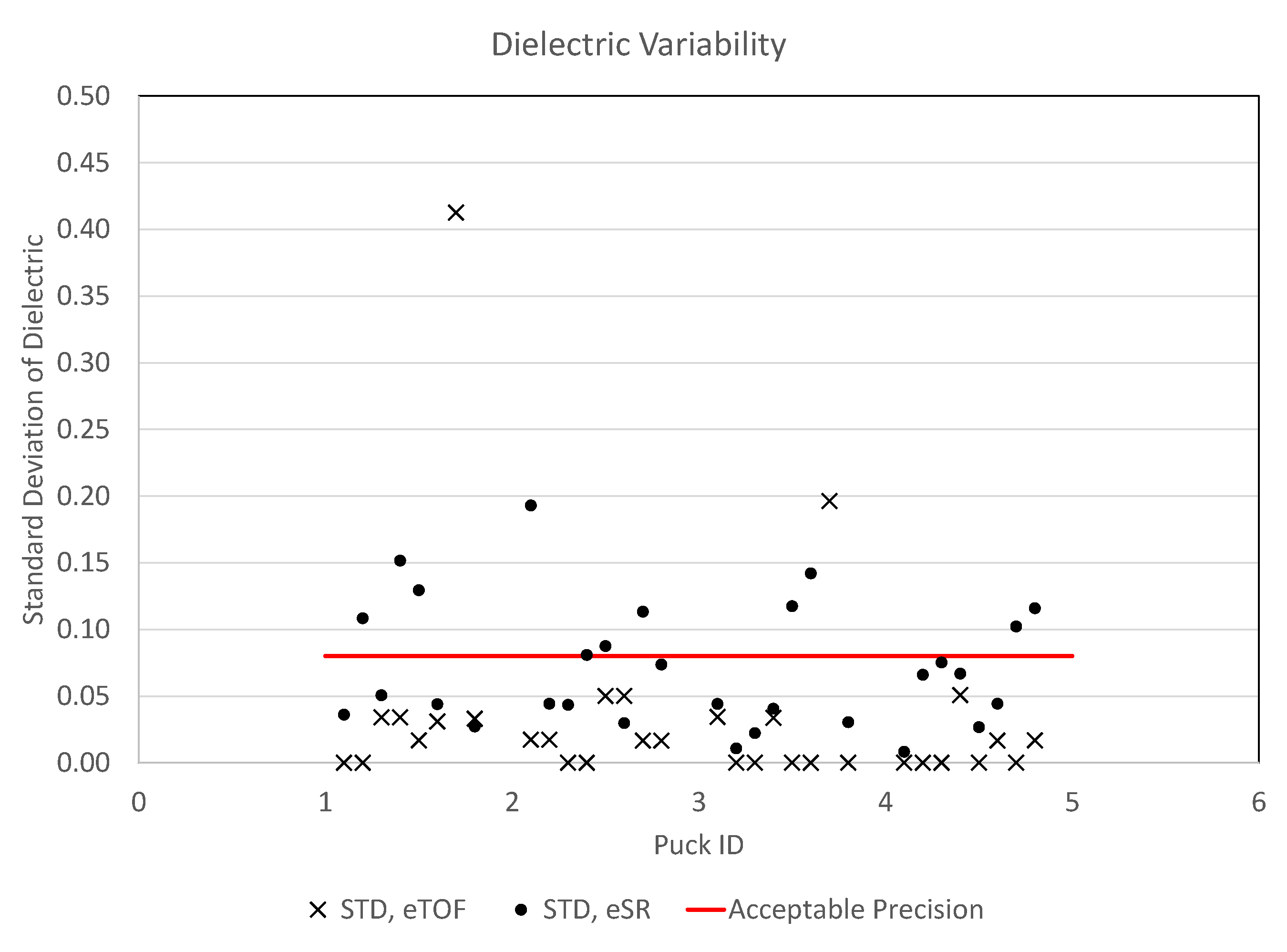

2. Materials and Methods

Two basic procedures are required for the coreless calibration method including (1) the fabrication of asphalt specimens with a range of air void contents and (2) testing each asphalt specimen to calculate the dielectric constant. The former follows AASHTO T312 that is widely used by the pavement industry [

24]. By following the AASHTO T312 procedure, a certified lab technician can fabricate asphalt specimens with targeted air void contents spanning the range of asphalt compaction air voids observable in the field. Testing of these standard specimens involves an innovative testing technique and associated calculation methodologies that are the subject of this paper. Two calculation methodologies are discussed. One is called surface reflection (SR) method, which is based on measured surface reflection amplitude from one asphalt specimen surface; the other one is called time-of-flight (TOF) method, which is based on measured travel times from the top and bottom of the asphalt specimen. The procedure for estimation of both surface reflection and time-of-flight based dielectric (TOF dielectric) measurements of the asphalt specimen using the Delrin® spacer are given in

Section 2.2 and

Section 2.3, respectively. The problem, Fresnel zone-related edge effects versus signal isolation, is introduced in the antenna characteristics section.

2.1. Antenna Characteristics

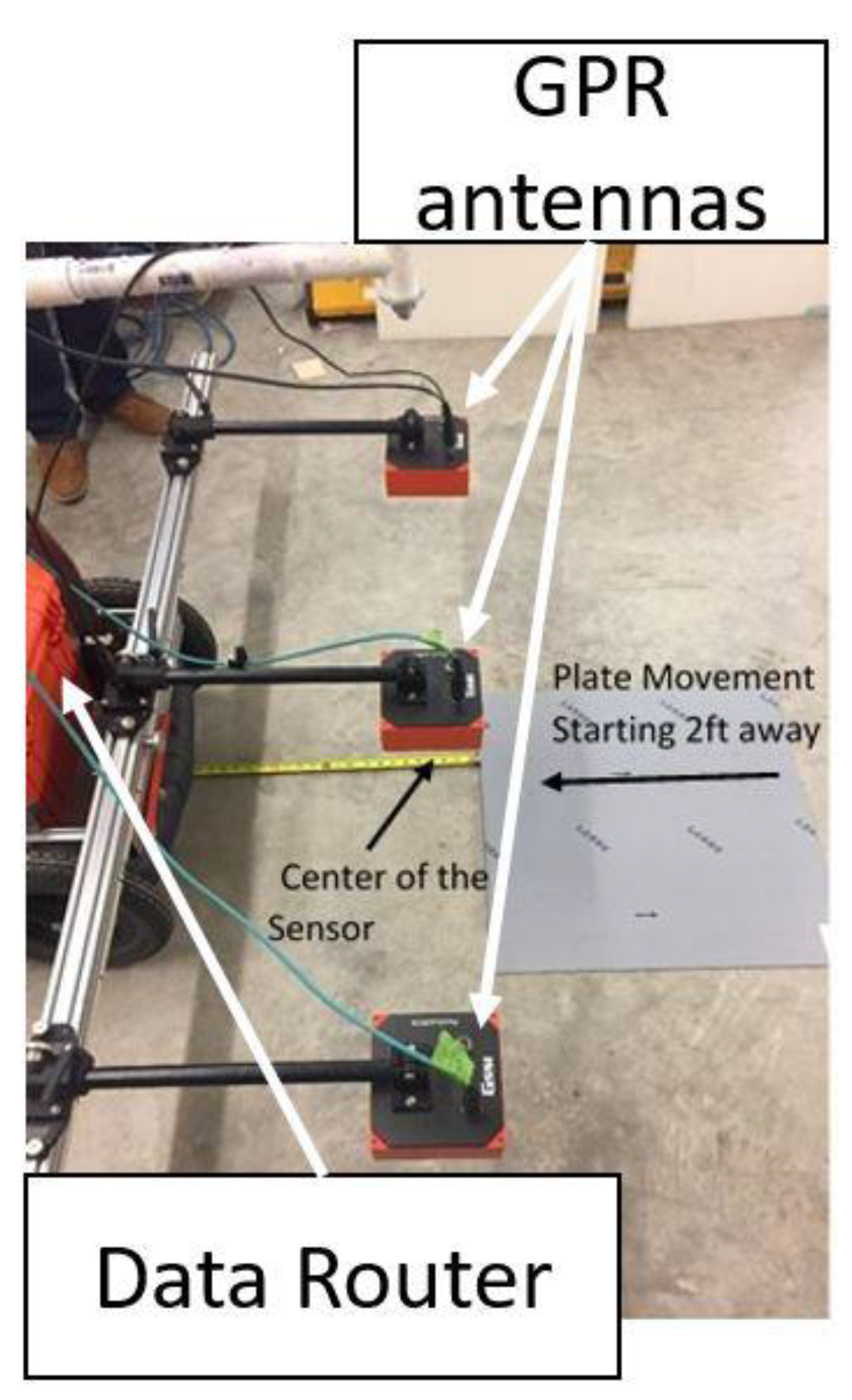

When measuring the dielectric constant of a specimen, a typical GPR waveform contains a direct wave from transmitter to receiver (direct coupling). In both of the proposed methods, sufficient isolation between direct coupling and the reflection from the surface of the asphalt specimen must be achieved. A 12 in. (30 cm) height above the pavement surface is recommended by the manufacturer during field survey measurements for sufficient isolation from direct coupling interference (see

Figure 1). At this height, the ground footprint area (first Fresnel zone) of the GPR waveform can be estimated using Fr ~ 0.5 c (t/f)

1/2, where Fr is the first Fresnel zone radius of the footprint, c is speed of light, t is two-way travel time, and f is antenna frequency [

29].

The estimated Fr is 3.8 in. (9.7 cm) at an antenna height of 12 in. (30 cm), while the radius of a gyratory specimen is typically 3 in (7.6 cm). This means that the area of a gyratory specimen (a reflector) is less than the area bordered by the circular zone with the radius (Fr). Since most reflected waveform energy comes from this zone, the measured reflected signal from gyratory specimens is affected by the geometry of the specimen (edge of the specimen) and does not accurately reflect material dielectric constant. Therefore, the recommended testing arrangement cannot be effectively employed when testing gyratory compacted asphalt specimens.

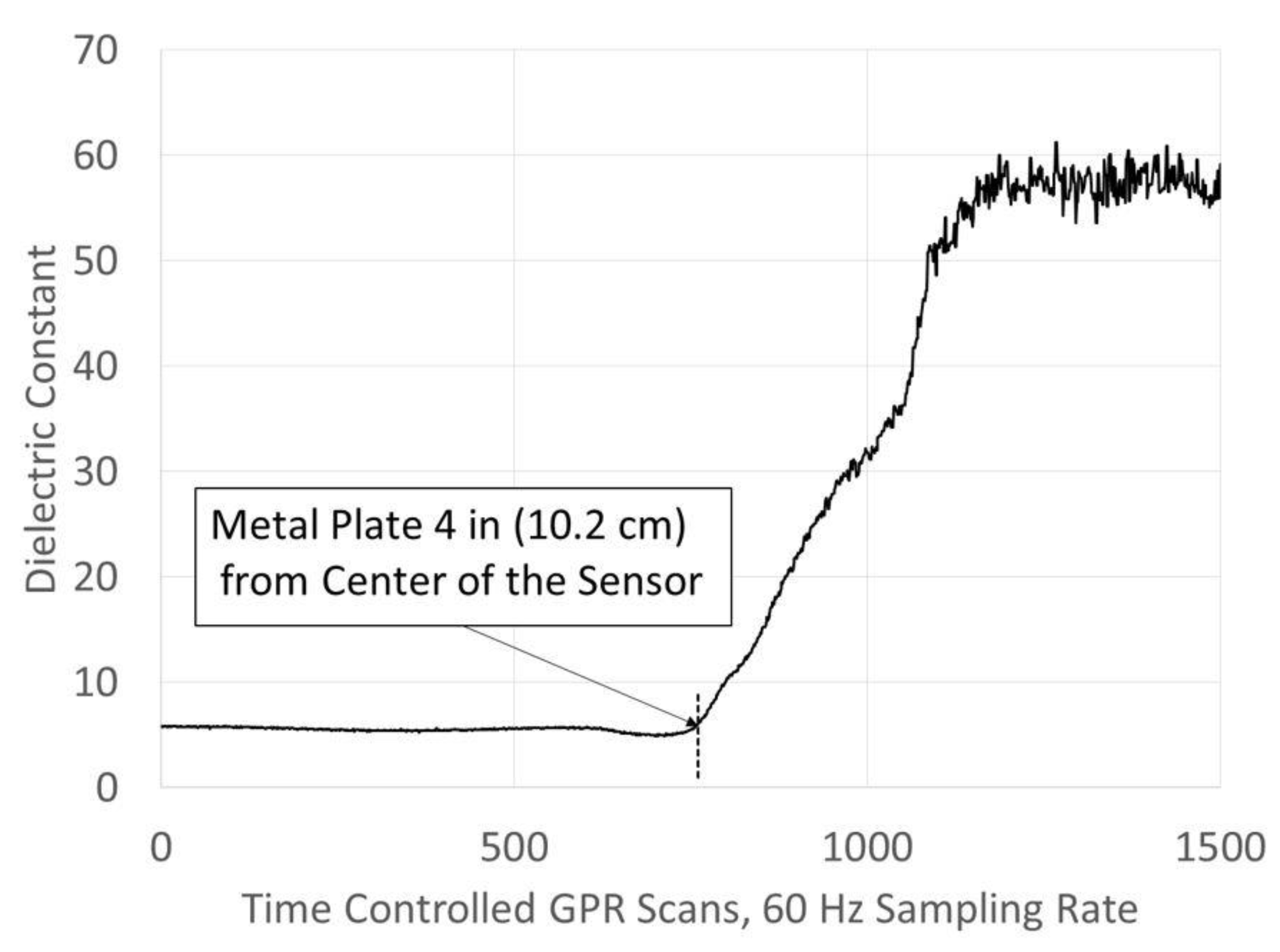

An experiment was carried out to verify the theoretical antenna footprint area, where a metal plate was placed initially approximately 2 ft (60 cm) away from an antenna at the standard 12 in. (30 cm) height (see

Figure 2). The plate was gradually moved toward the center of the antenna while monitoring the dielectric constant output. It was noticed that the output dielectric constant suddenly increased when the edge of the metal plate was approximately 4in. (10 cm) away from the center of the antenna, which indicates that the antenna detected the metal plate at this radius (see

Figure 3). The approximate 4 in. (10 cm) distance was determined by measuring the distance with a tape measure at the location corresponding to the dielectric magnitude at scan 780 where the increase in amplitude occurred. This measured distance of 4 in. (10 cm) between the edge of the metal plate and the center of the antenna was in agreement with the calculated Fresnel zone radius of 3.8 in. (9.7 cm).

As discussed above, the direct coupling may affect the specimen top surface reflection if the antenna does not have enough height above the surface. Ideally, this direct coupling effect should be able to be eliminated from the waveforms of the specimen measurements by subtracting the GPR waveform from air measurement that only contains the direct coupling and antenna characteristics. However, it has been noticed that direct coupling does not always occur at the same location relative to the time axis on the GPR waveform. In other words, the amplitudes of the direct coupling from different air measurements do not occur at the same time (they show variation on the time axis). This phenomenon makes the subtraction difficult and incomplete. To characterize the noise that cannot be accounted for solely by subtracting the mean direct coupling, 1000 “air-scans” were collected and analyzed by looking at 2 standard deviations from the mean at each sample location. The air scans are conducted by ensuring there is nothing but air within 18 in. (46 cm) of the antenna during data collection. In this arrangement, any recorded signal is not a result of any physical material but rather of interference intrinsic to the antenna that should be filtered (e.g., multiple reflections within the measurement equipment, direct coupling, etc.). To evaluate the response accurately within the direct coupling zone, the signal (mean response) was plotted along with the noise (represented by the 2 standard deviations from the mean) of the 1000 responses at each sample (see

Figure 4). It can be observed that significant variability is observed earlier in time, during the direct coupling response, especially at locations between local maxima and minima where the slope of the signal is highest. This variability affects the precision of the asphalt specimen response, thus creating a need to separate the asphalt specimen response in time, away from the direct coupling. Analysis of the asphalt specimen response within the direct coupling time window can thus alter the reflection amplitude (which affects the surface reflection (SR) method) and shift the apparent arrival time (which affects the time-of-flight (TOF) method). The air launched method used in the field cannot be applied to asphalt specimens, since the asphalt specimen response at an antenna height that accounts for the antenna footprint is not sufficiently separated in time from the direct coupling noise shown in

Figure 4.

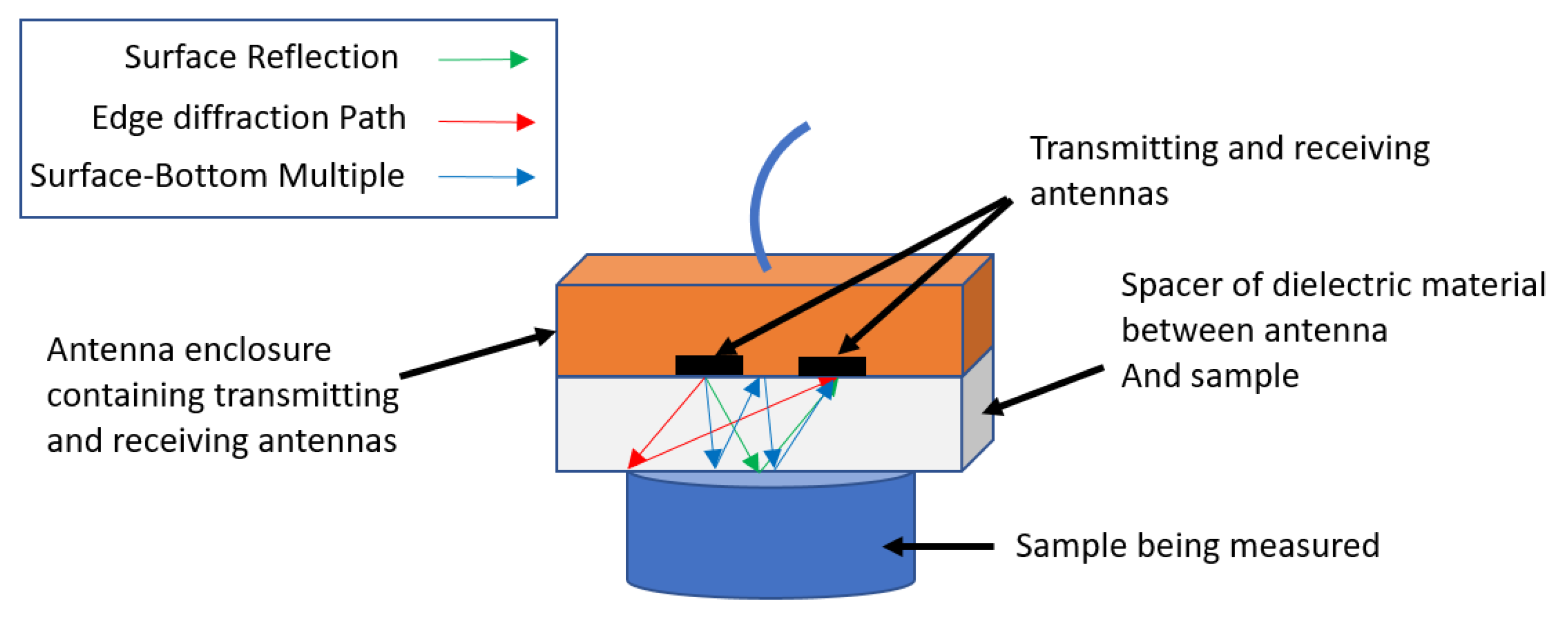

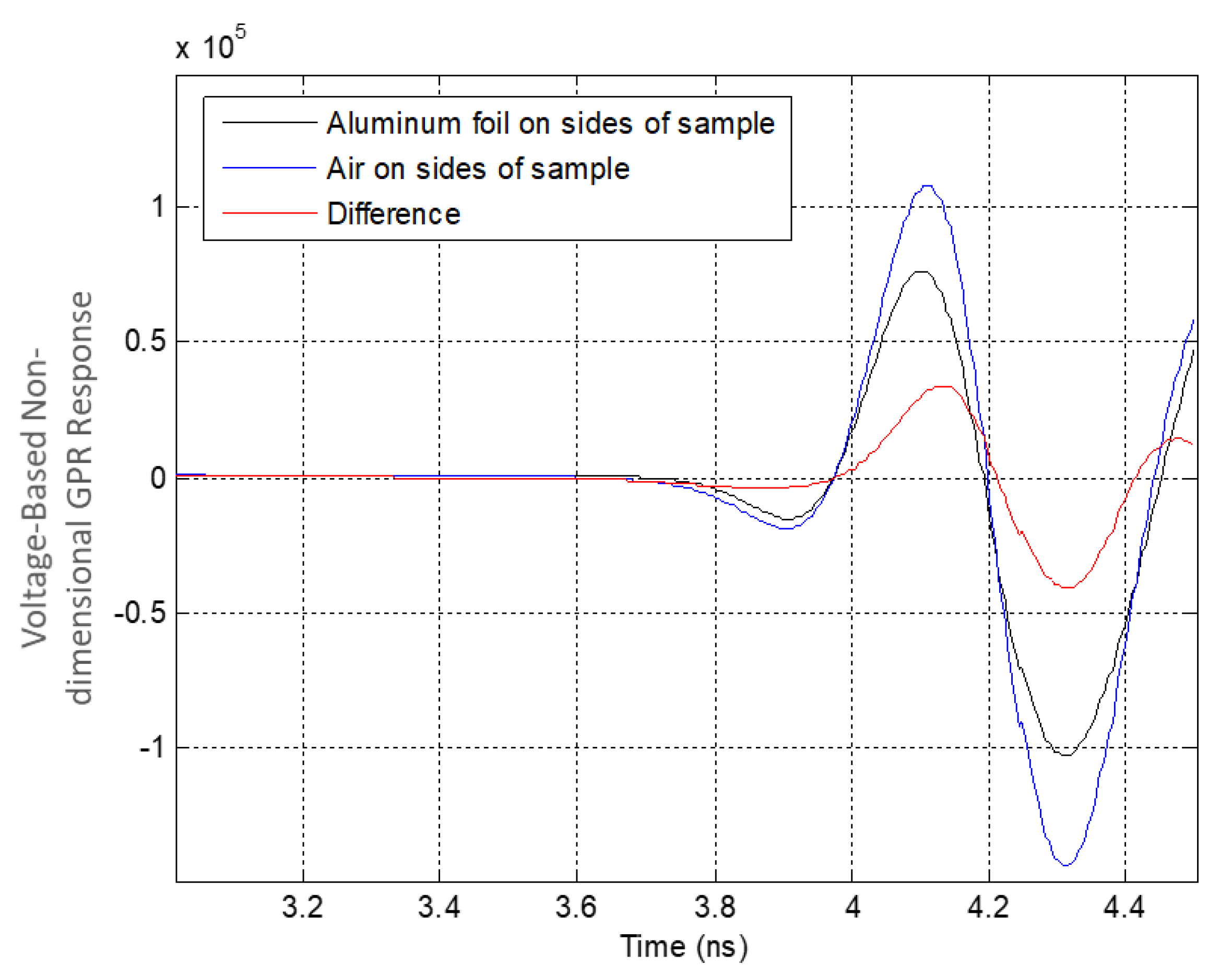

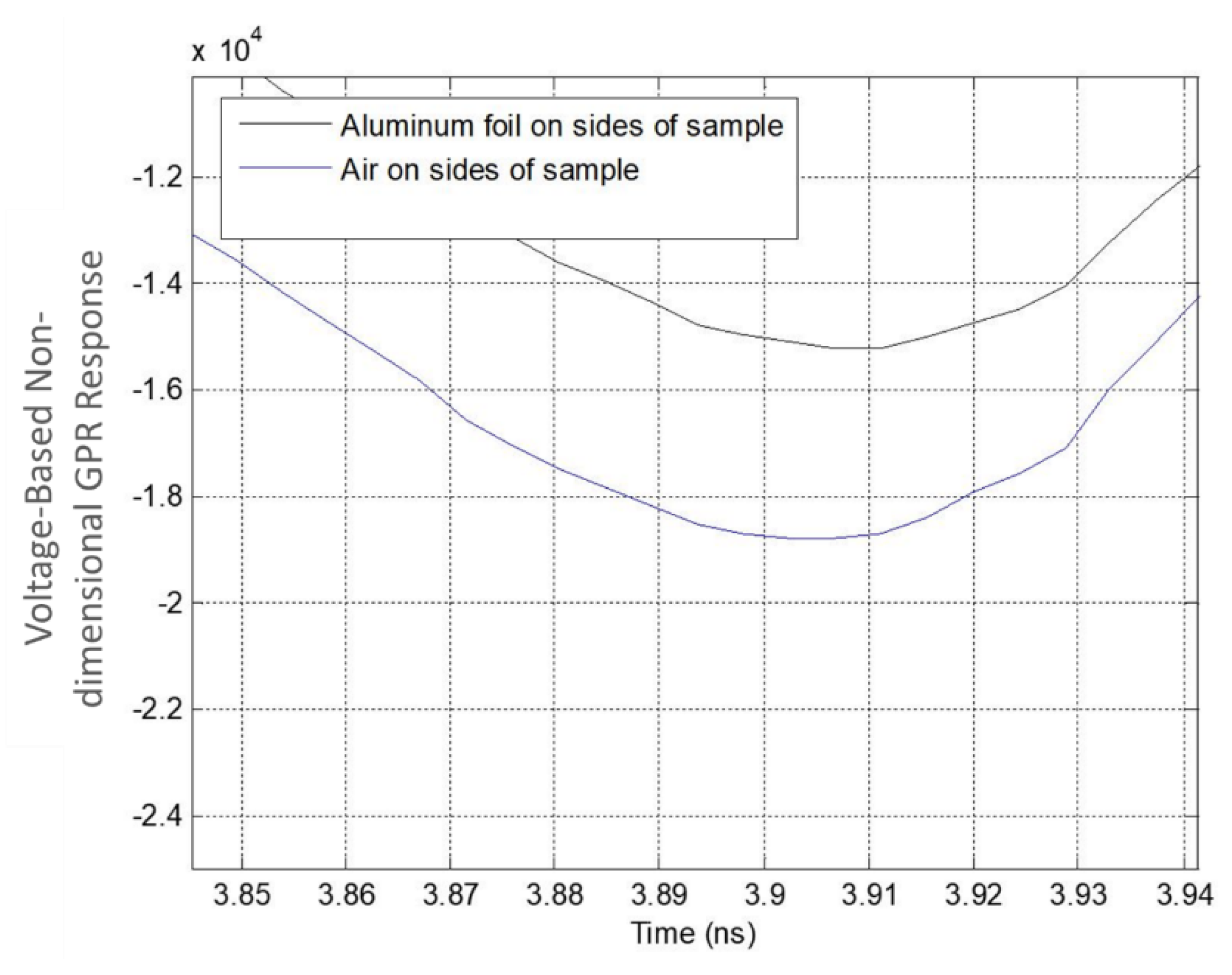

The basic concept, to overcome Fresnel zone height requirements and the corresponding direct coupling interference characterized above, involves replacing the air medium with a known dielectric medium that reduces the pulse velocity such that the asphalt specimen reflection occurs after the direct coupling noise. A solid spacer medium, such as the acetal homopolymer plastic (Delrin®), can be used since the asphalt sample can be measured in a stationary location, unlike continuous coverage field measurements.

2.2. Approach 1: Dielectric Obtained from the Surface Reflection

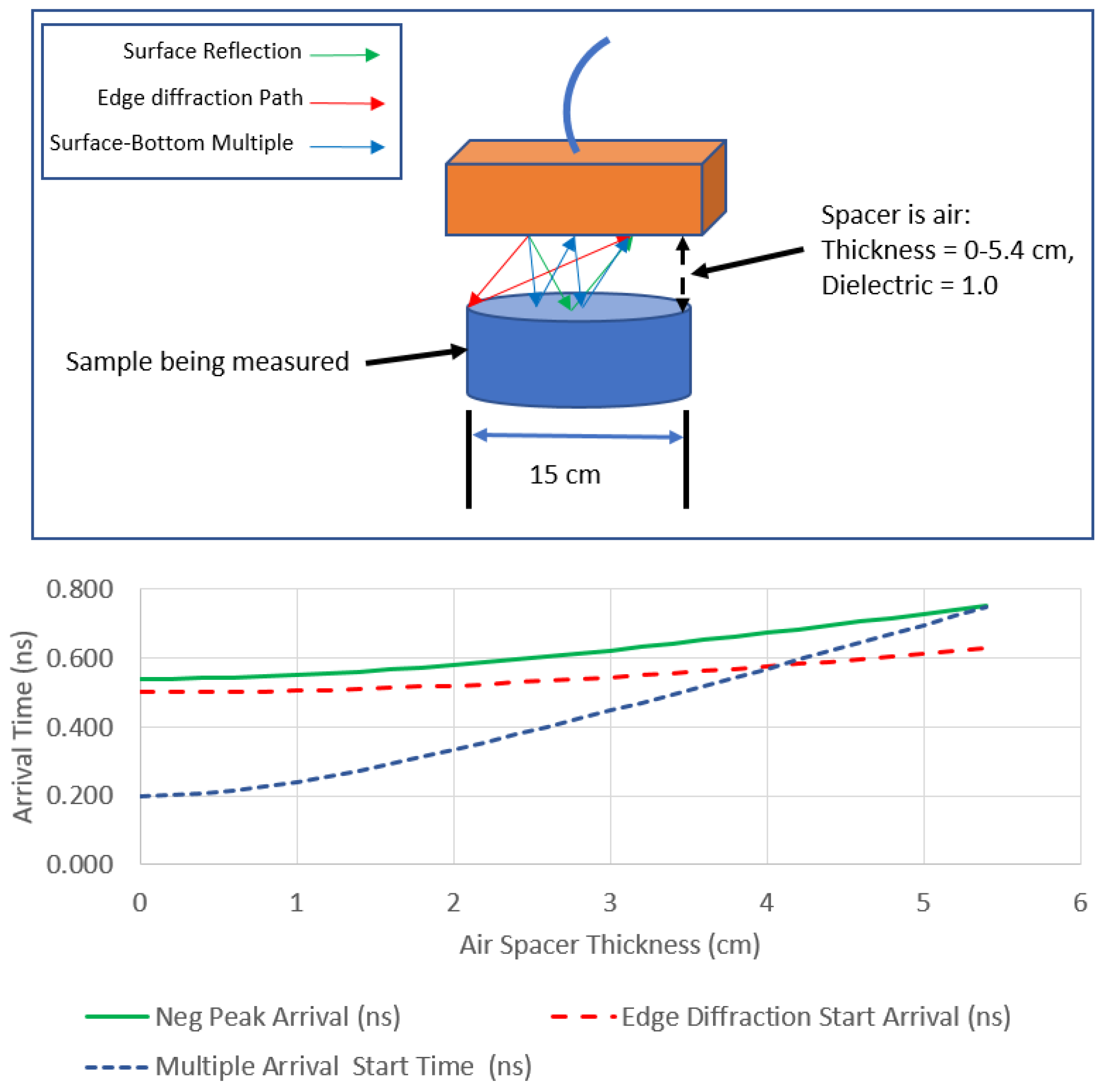

Using the proposed spacer method as the model, the secondary effects caused by the limited dimensions of the 6 in. (15 cm) asphalt specimen are discussed with respect to the surface reflection dielectric (SR dielectric) by evaluating the edge diffraction path in comparison to the surface reflection.

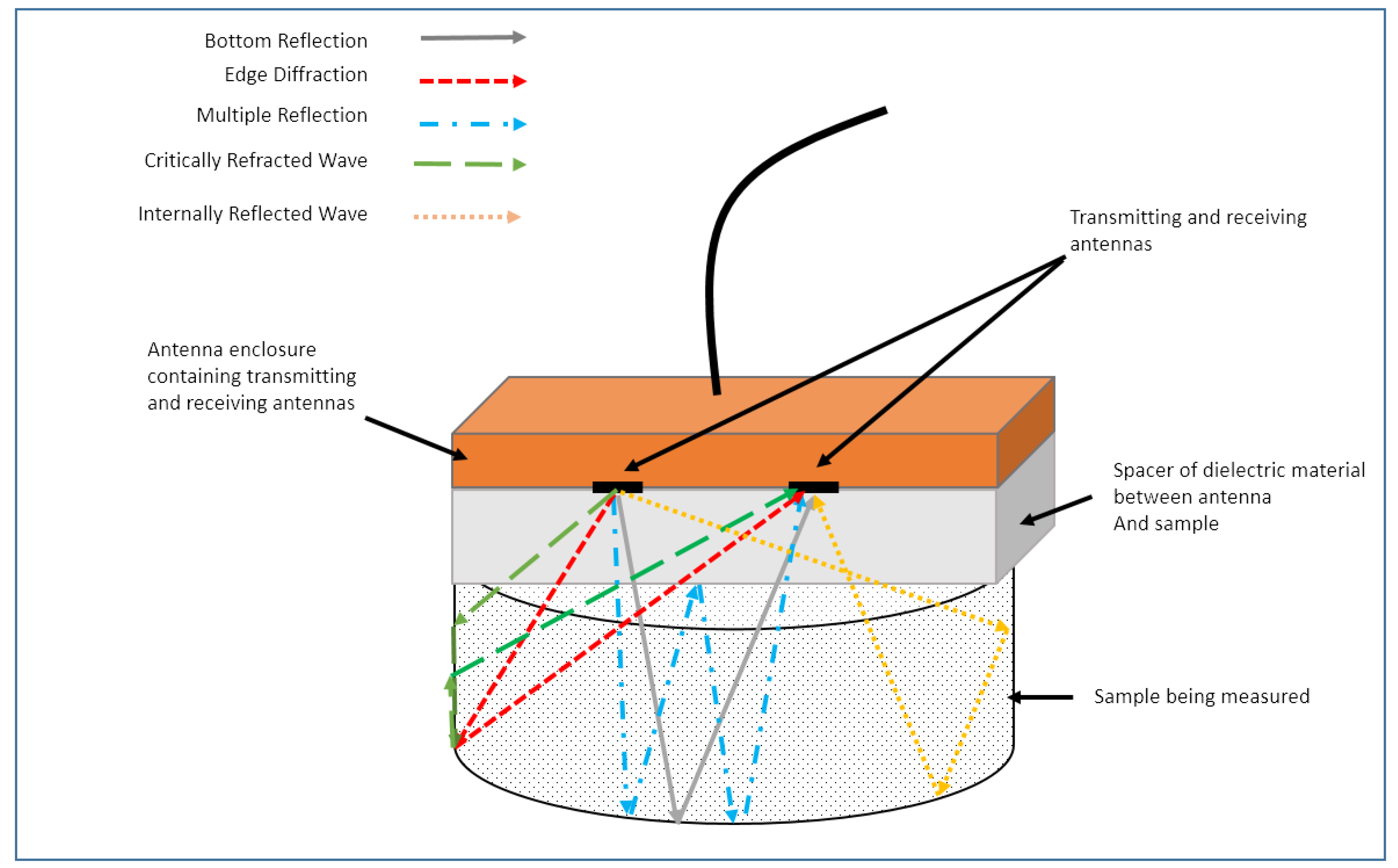

Figure 5 shows the ray paths associated with the different reflections and diffractions.

The surface reflection dielectric constant calculation (SR dielectric) is the closer analog to the field testing procedure of the two proposed dielectric calculation methods. This method is also the more straight-forward process to calculate the dielectric from the isolated surface reflection amplitude. It is possible to calculate the arrival times of the different reflections and diffractions and assess if there is a certain combination of spacer dielectric and thickness that provides a time window that ensures the reflection from the surface precedes the arrival of other reflected and diffracted energy given the following known information:

- 1.

Spacing between the transmitting and receiving antennas;

- 2.

Radiated pulse length;

- 3.

Thickness of spacer material;

- 4.

Dielectric of spacer material; and

- 5.

Diameter of core or asphalt specimen being measured.

The method assumes the following:

- 6.

Fresnel’s plane wave propagation equations can be used to approximate the reflection amplitude from the surface;

- 7.

The dielectric of the sample being tested is assumed to be relatively homogeneous across the surface of the material. This assumption might not be valid for asphalt samples containing large aggregate or samples containing a non-uniform aggregate distribution.

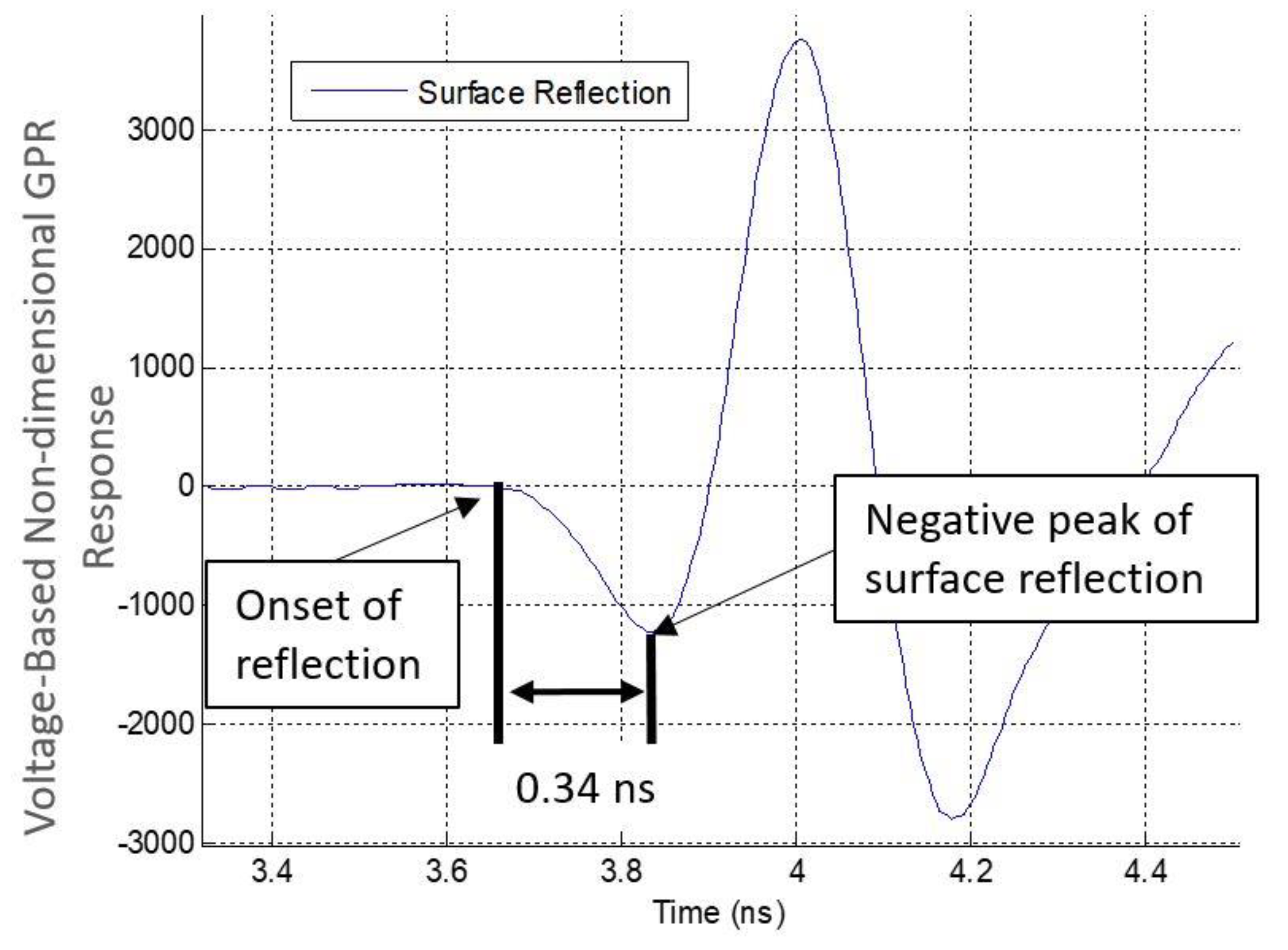

The separation distance between the transmitting and receiving parts of the antenna used in the study—a GSSI Model 42600 antenna—is 2.4 in. (6 cm). The functional separation of the antenna was determined experimentally to be 1.7 in. (4.4 cm) using one-way and two-way travel time calculations in a known-thickness, high-density polyethylene (HDPE) material with a known 2.3 frequency independent dielectric. The necessity for experimentally determined separation is caused by the impulse not exhibiting perfect point source behavior. The portion of the pulse length of interest is the time from the onset of the reflection pulse to its negative peak amplitude. The negative peak amplitude was chosen, since it occurs earlier in time and thus has less likelihood of being affected by the reflected waves from the asphalt specimen edge occurring later in time.

Figure 6 shows an isolated reflection pulse and the time length of interest, which is approximately 0.34 nanoseconds.

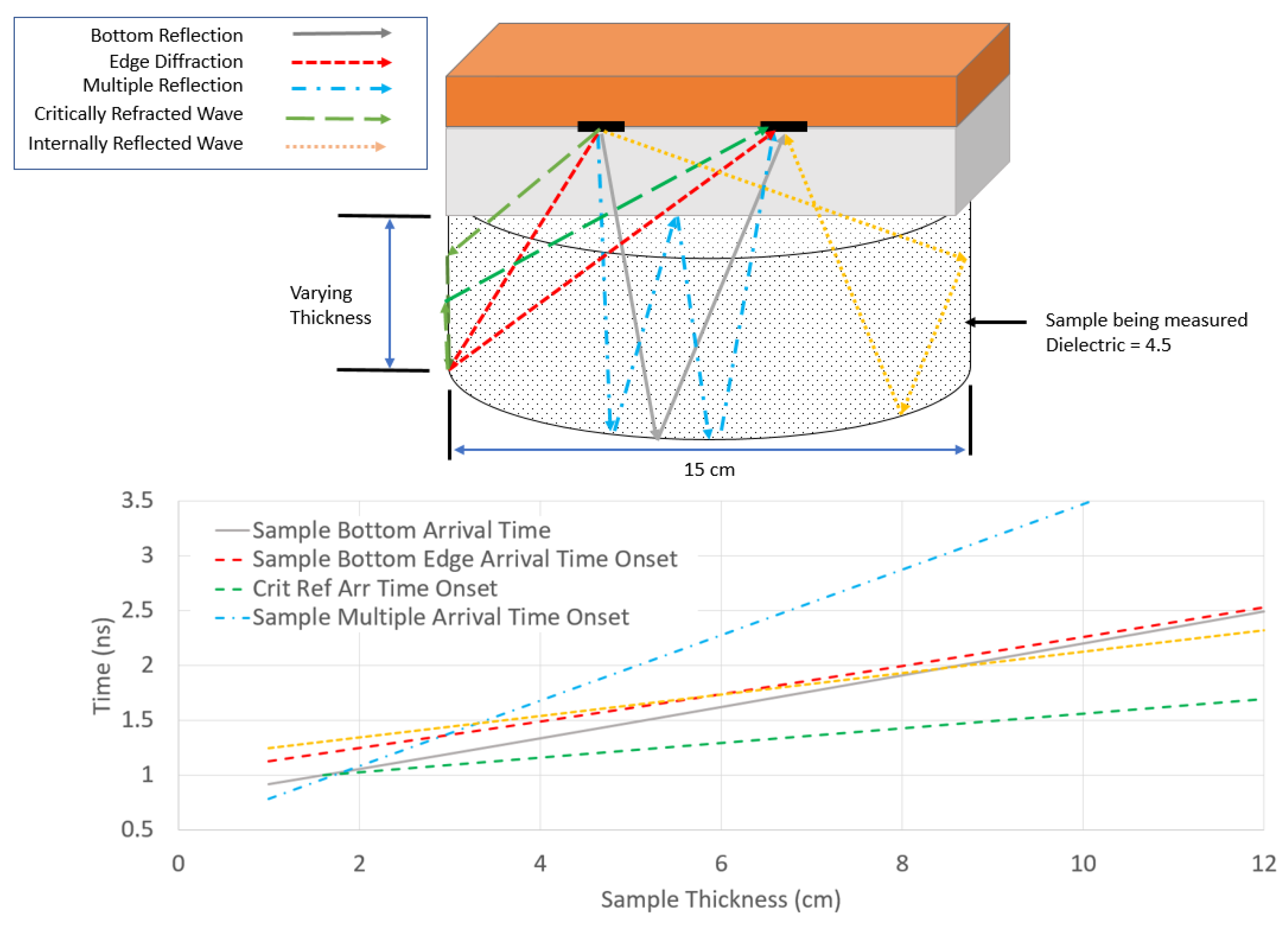

Using the known antenna-related parameters and a fixed diameter of 6 in. (15 cm) for the material to be measured, the arrival times of each reflection and diffraction can be calculated and plotted. For example,

Figure 7 shows the arrival times of the reflections and diffractions for an air spacer between the antenna and the sample. It is shown that for an air spacer thickness up to 2.1 in (5.4 cm), the negative peak of the surface reflection arrives later than the beginning of both the surface multiple and the edge diffraction.

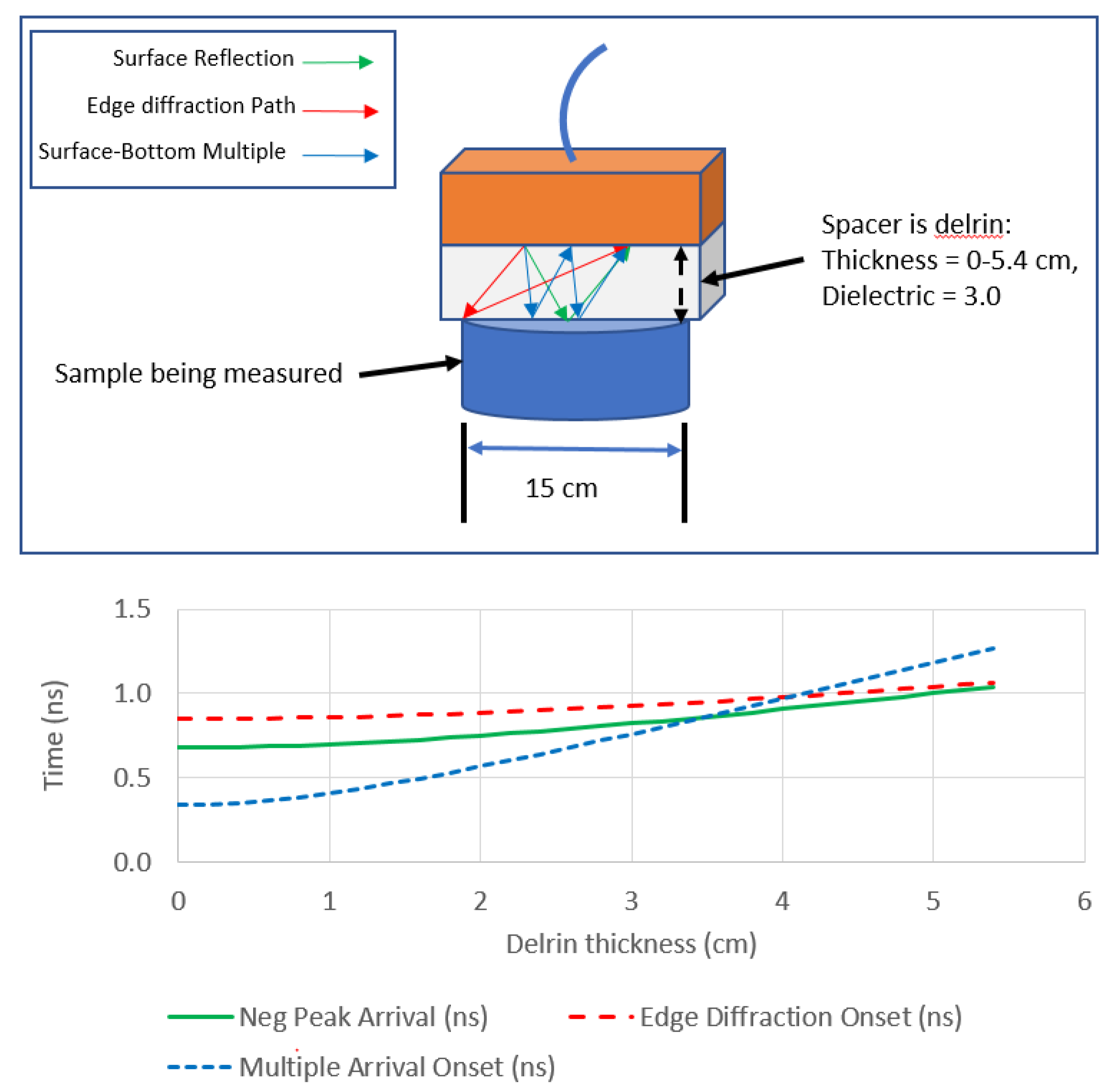

Analysis of the calculated arrival times of the different ray paths for spacers was conducted to determine the appropriate dimensions and dielectric constant of the spacer. Delrin® samples were selected as plastic with a comparatively high dielectric constant (Dielectric = 2.88) that is available in 6 in. by 6 in. (15.2 cm × 15.2 cm) sheets with various nominal thicknesses. Travel times of the first negative peak are plotted in

Figure 8, along with multiple arrival and edge diffraction start times to characterize isolation of the negative peak. It can be observed that within a thickness range of 1.4 in. to 2 in. (3.8 cm to 5.1 cm), the negative peak arrival occurs prior to the edge diffraction and surface-bottom multiple. Based on this analysis, Delrin® spacers with 1.5 in. (3.8 cm) thickness were selected for use in this study. Since the overlap in arrival between the signal of interest (surface reflection) and the multiple arrival onset occurs at a lower thickness—1.4 in. (3.5 cm)—the Delrin spacer isolates the negative peak from interference.

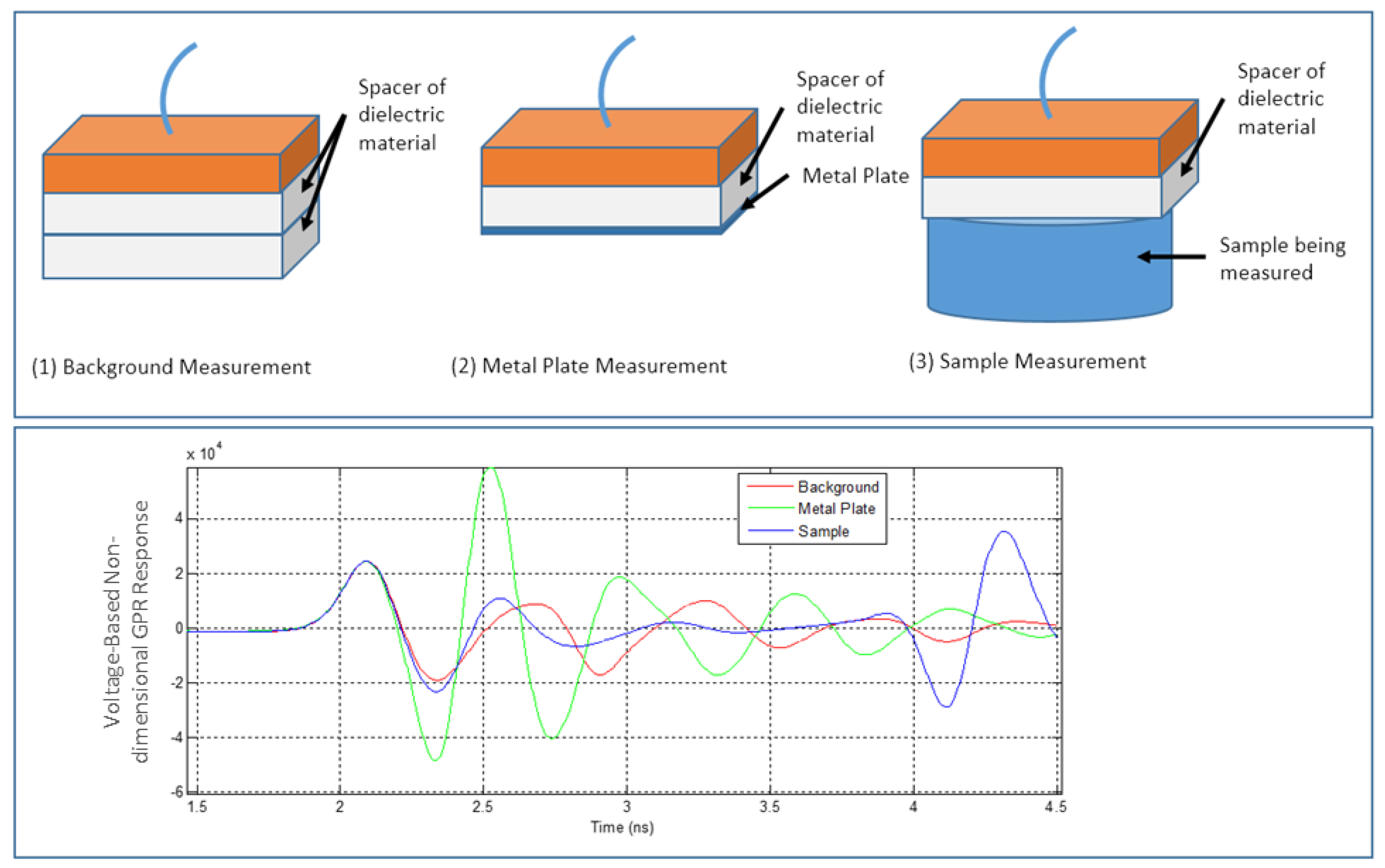

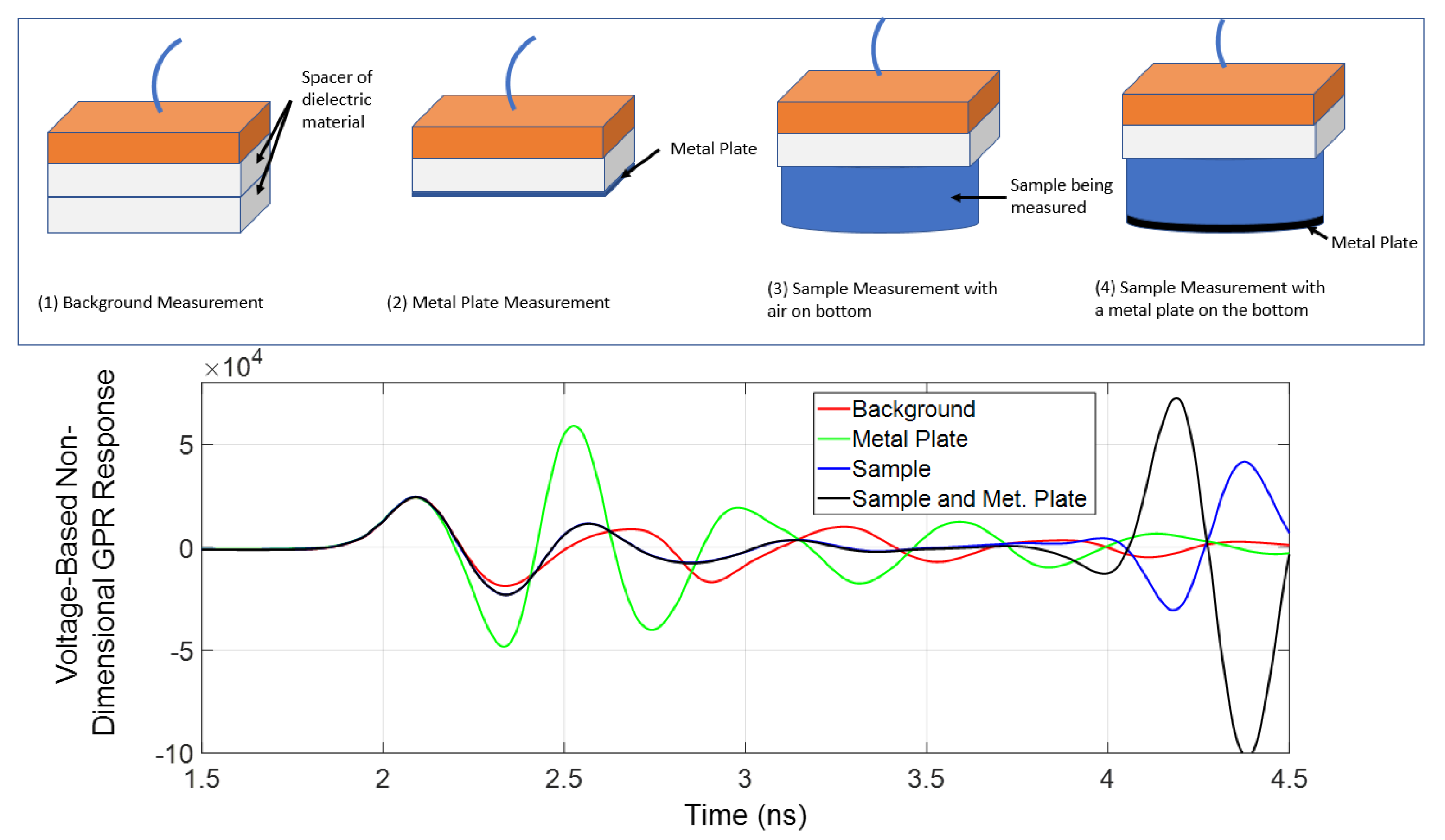

The surface reflection from the sample being measured is typically superimposed on clutter arising from various reflections and diffractions near to and inside the antenna enclosure. This clutter needs to be removed in order to isolate the amplitude of the surface reflection. For air-launched field tests, this is accomplished by averaging and subtracting multiple scans with only air within the time range of analysis. For the proposed Delrin

®-launched test, this is accomplished by adding Delrin

® to make a background measurement where Delrin

® is the only material within the time range of analysis. A second measurement is performed with a metal plate placed underneath the spacer, analogous to the metal plate amplitude calculation in the air launched method [

23]. The final measurement is made with the asphalt sample placed underneath the spacer.

Figure 9 shows the set-up for the three measurements and the corresponding scans.

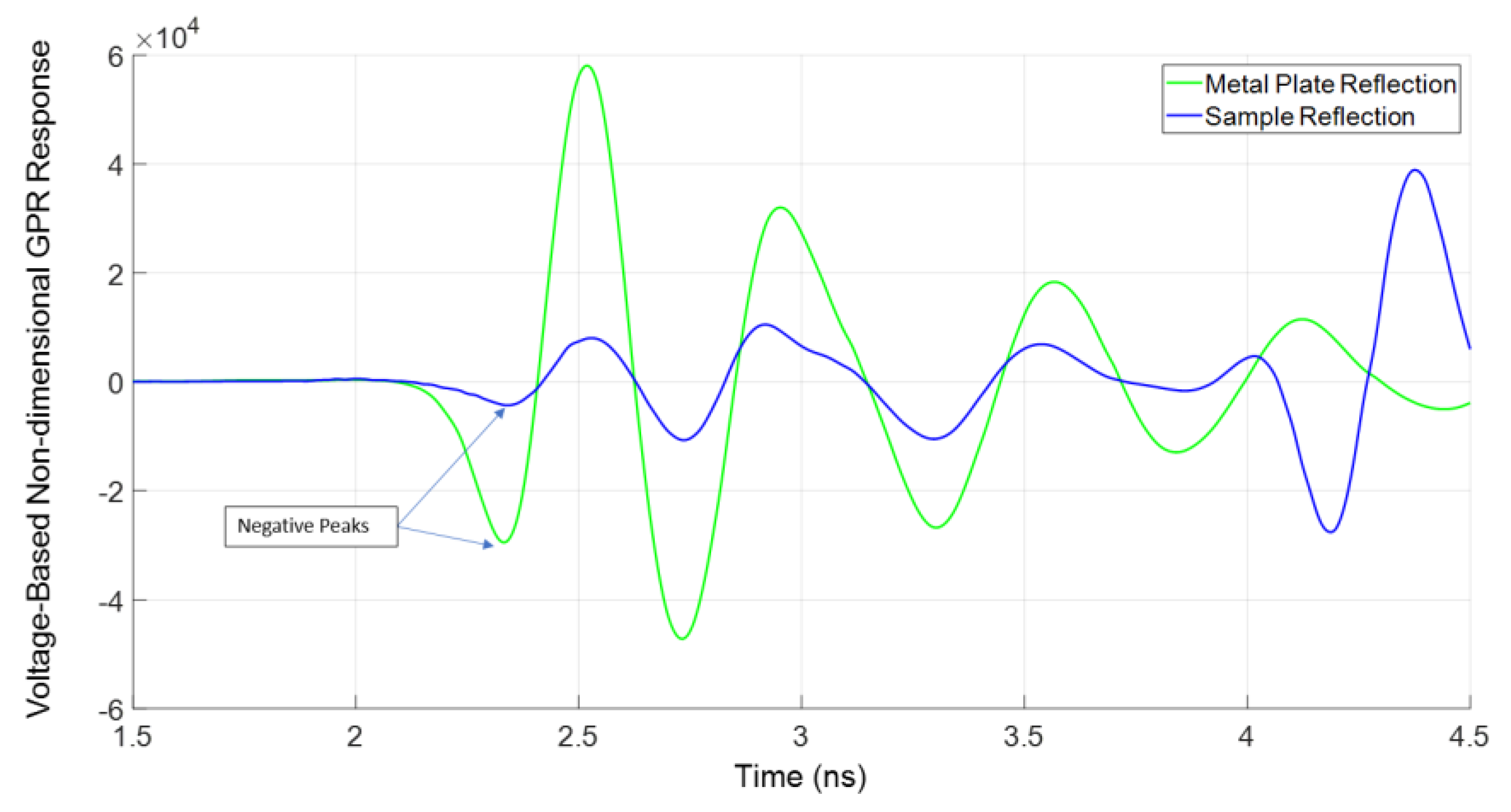

The averaged background measurement is subtracted from the metal plate and asphalt specimen measurements to isolate the reflections from the two different surfaces.

Figure 10 shows the isolated reflections following background subtraction. The points of interest in these measurements are the amplitudes of the negative peaks.

The surface dielectric is obtained using the reflection coefficient as an input into Fresnel’s equations. The reflection coefficient (

) is calculated taking the ratio of the peak-to-peak amplitude of the asphalt specimen reflection to the amplitude of the metal plate reflection, as shown in Equation (1):

Where:

= reflection coefficient at the interface between the spacer and the sample;

Asn = negative peak amplitude of sample reflection;

Amn = negative peak amplitude of metal plate reflection.

Fresnel’s plane wave equations are used for transverse electric field polarization. Equation (2) shows this equation solved for the dielectric of the lower medium, , which in this case would be the dielectric of the sample being tested.

Where:

= reflection coefficient at the interface between the spacer and the sample;

= dielectric of the sample being measured;

= dielectric of the spacer between the sample and the bottom of the antenna; and

= angle of incidence, which is calculated from the known separation distance between the transmitting and receiving antennas and the thickness of the spacer.

2.3. Approach 2: Dielectric Obtained from Two-Way Travel Time and Known Thickness (TOF Dielectric)

Within the framework of the asphalt specimen measurements, the time-of-flight (TOF) dielectric calculation is the more robust of the two proposed dielectric calculation methods in that the evaluation is based on wave propagation through the entire depth of the evaluated asphalt specimen rather than surface only. The method is therefore less sensitive to local inhomogeneity since the response is averaged over a longer distance within the specimen, but it requires precise input of dimensions and involves more calculations to obtain the dielectric. This robustness makes it attractive for asphalt specimen dielectric measurements, but the requirement of known dimensions makes the approach inapplicable for field dielectric measurement since the thickness of the pavement is not known

a priori. However, the resulting dielectric measured by the TOF method and the SR method is theoretically identical. A two-way travel time measurement obtained from energy propagating through the sample is achievable for a 6 in. (15 cm) diameter sample. For an asphalt specimen, the different propagation paths impacting the energy arriving at the receiving antenna are shown in

Figure 11.

The travel times of the different ray paths can be calculated versus the arrival time of the portion of the reflection of interest from the bottom of the sample being measured. Noting that the surface reflection contains a negative peak preceding the positive peak and arriving just 0.34 ns following the onset of the reflection (see

Figure 6), the arrival time of this peak can also be used as the bottom reflection arrival time indicator. Choosing the initial negative peak as the common indicator of arrival (for both top and bottom TOF) is advantageous to the positive peak in that it occurs earlier in time, which is easier to isolate from subsequent reflection and diffraction arrivals. The tradeoff in using the negative peak is that it is lower in magnitude than the following positive peak. Unlike the SR method, this can be addressed by using a metal plate to amplify the signal magnitude since the TOF-dielectric method requires only the indicator of arrival, not amplitude.

In

Figure 12, the arrival times of the peaks of the bottom reflection are plotted versus the calculated onsets of the reflections and diffractions involving the bottom of a 6 in. (15 cm) diameter sample. Close examination of

Figure 12 shows that, at an asphalt specimen thickness range between 0.8 in. to 3.1 in. (2 cm to 8 cm), the negative peak arrival time is only preceded by the critically refracted path. For samples with a thickness less than 0.8 in (2 cm), the negative peak arrival time is preceded by the onset of the multiple reflection within the sample. At sample thicknesses greater than 3.1 in. (8 cm), the onset of the internally-reflected path precedes the negative peak from the bottom reflection.

It is assumed that the interferences of the other travel paths are considered negligible, or removable in the analysis. It is also assumed that the increase in signal-to-noise ratio in the TOF-dielectric method by using a metal plate reflector nullifies any apparent shift in the arrival indicator that otherwise may have been significant in an asphalt to air reflection. These assumptions and their robustness were tested versus field data in repeat measurements and assessment of variable air void content asphalt specimens (discussed in the following sections). Additionally, the significance of the internally reflected wave is evaluated with a controlled laboratory experiment with 4.5 in. (11.4 cm) as well as comparison to field measurements and subsequent core ground truth for asphalt specimens with target thicknesses of 3.75 in (9.5 cm). Four measurements, shown in

Figure 13, are required for the TOF dielectric measurement. The corresponding scans of data from each measurement are shown in the bottom portion of

Figure 13. Steps to remove the clutter in the scans arriving from other reflections and diffractions are also required and given herein.

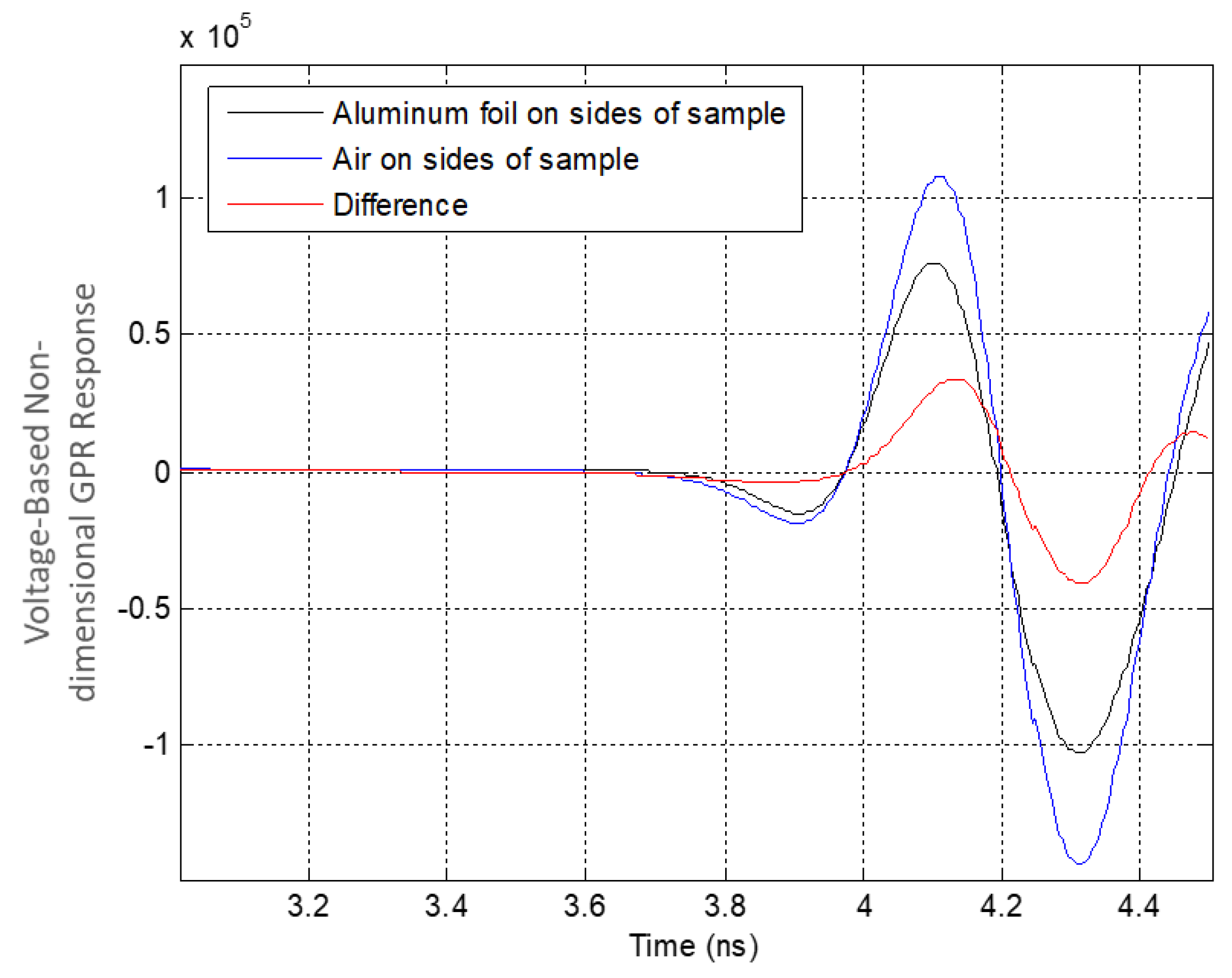

The subtraction of the second measurement, with a metal plate on the bottom, from the first measurement, which was made with a second spacer, provides an isolated reflection from the bottom of the spacer. The subtraction of the third measurement from the fourth measurement provides an isolated reflection from the bottom of the sample. The two isolated reflections are shown in

Figure 14. The first-arriving negative peaks of these reflections are used for the calculation of the arrival time difference. As a side note, it is interesting to observe that following the negative peak arrival, the positive peak of the reflection difference from the bottom of the sample is much larger than the positive peak of the metal plate reflection from the spacer bottom. The constructive interference of the different propagation paths shown in

Figure 14 contribute to the observed amplitude.

Given the known separation distance between the transmitting and receiving antennas, the dielectric of the spacer, the thickness of the spacer, and the thickness of the sample being tested, it is possible to calculate the dielectric of the sample using the measured travel time shown in

Figure 14. This requires accommodating for the angles of refraction at the interface between the spacer and the sample. The resulting equation is a 4th order polynomial that was used to generate look-up tables for arrival times versus dielectric that were then compared to corresponding arrival times calculated using straight ray-paths. Differences between the calculated dielectrics for typical asphalt specimen dielectrics and thicknesses were in the order of 0.01 or less. For context, a change in dielectric of 0.01 corresponds to a change in air void content of less than 0.2% for the air void content versus dielectric curves generated in this study. This discrepancy is considered to be acceptable for the purpose of measuring asphalt specimen samples, since it is well within the uncertainty of the air void content measurement. Consequently, the straight ray-path calculation method is described below.

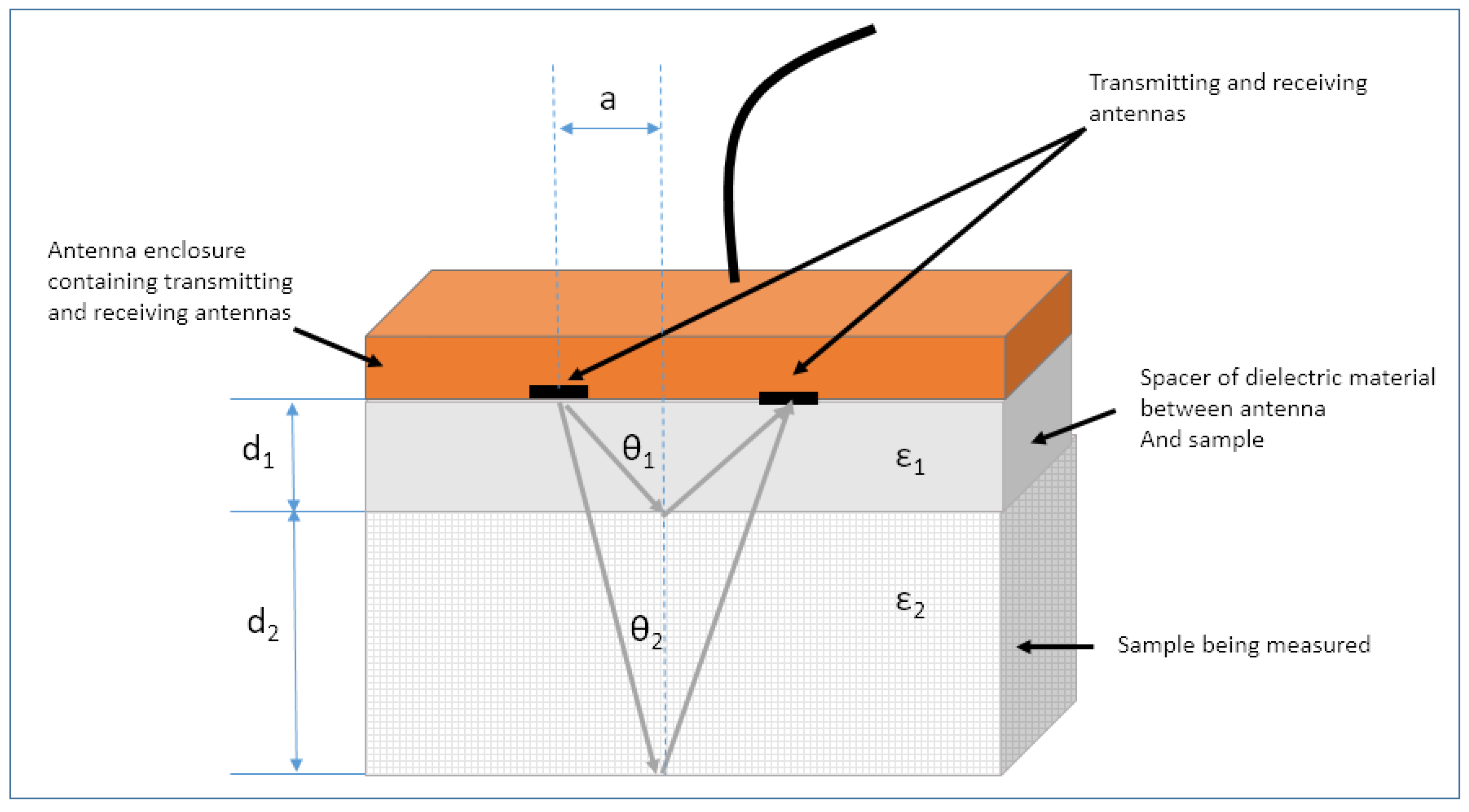

The geometry used in the calculation of the TOF dielectric is shown in

Figure 15 along with the known parameters. Knowing the travel time obtained from

Figure 14, the dielectric (ε

2) can be determined using Equations (3) through (7). The travel time of the path associated with the reflection from the top and bottom of the spacer is calculated in Equations (5) and (6). Substitution of the known parameters from Equations (3) to (6) permits the calculation of the dielectric of the sample. The method is extendable to more dielectric layers to accommodate items such as the thickness of the antenna enclosure. For the antenna used in this study, a 0.1 in. (0.3 cm) layer with 2.77 dielectric was added to the analysis to accommodate the known geometry and properties of the enclosure. The enclosure portion should be fixed to match the specific antenna used in the test, while the equations given in this study are generalized in that different spacer and asphalt specimen combinations can be experimented with based on the objective.

θ1 = incident angle of reflection from bottom of spacer;

θ2 = incident angle of reflection from bottom sample;

a = ½ separation distance between transmit and receive antennas;

d1 = thickness of spacer;

d2= thickness of sample;

t1 = travel time of negative peak of reflection from bottom of spacer;

ε1 = dielectric of spacer;

c = speed of light in air (30 cm/nanosecond);

t2 = travel time of negative peak of reflection from bottom of sample;

ε2 = dielectric of sample; and

tmeas = measured travel time difference between the bottom of the sample and the bottom of the spacer.

There are a number of assumptions inherent to the application of the TOF dielectric method including the following:

The interference associated with the internal reflection and critically-refracted paths arriving at the same time as the negative peak of the bottom reflection is negligible;

Far field conditions prevail in terms of the wavefront radiated from the transmitting antenna. In other words, the intensity of the radiate energy in different directions varies only by distance.

The energy arriving at the receive antenna can be approximated as a plane wave.