2.1. Preliminary Processing of Measurement Results

While checking the necessary conditions (parallel and perpendicular characters) of the proper crane performance, there is a need to introduce the coordinates X, Y, and Z of the crane bridge controlled points. They can be obtained on the basis of measurements performed using a total station. Assuming the coordinates

of the geometrical center (centroid) of the instrument (the origin of the local coordinate system) based on the measured values the coordinates

of the bridge, points of the crane bridge at level 0 (measurement level) can be derived from the following relation:

where:

s is horizontal distance,

α is horizontal angle,

β is vertical angle,

is height of the instrument (total station), and

i is the number of controlled points.

The coordinates of the points corresponding to the structural elements of the crane bridge are determined in the local coordinate system of the total station with an arbitrarily oriented axis, OX, from which the horizontal angle

α is measured. This coordinate system can be considered as an external coordinate system. In order to carry out detailed theoretical and empirical analyses, it is necessary to determine an internal local coordinate system associated with the crane bridge. This procedure makes the analyses insensitive to measurement errors, including: centering errors and leveling errors of the instrument and signals; deviation of the angular and linear reference; and measurement errors of distances and angles (horizontal and vertical). Thus, the assumed internal, local coordinate system associated with the crane bridge produces a more accurate solution. Therefore, an isometric transformation of coordinates should be performed from the measurement level to the level of the object using two common points. Two common points should be chosen on the crane bridge, making it possible to perform an isometric transformation [

11].

The coordinates of Point 1 on the object are assumed to be , and it is assumed that the X axis in the internal coordinate system passes through points 1 and 2 (hence , coordinate ). While the coordinates of the common points are determined, it is necessary to perform isometric transformation of the remaining coordinates by means of formulas that are literature-based. The coordinates of points in the internal coordinate system should be complemented by their mean errors, which are determined subsequently.

The propagation law of cofactors is applied in the form

, where

is the transformation matrix,

is the matrix of cofactors of measurement results,

is the weight matrix, and

). While the mean error values (e.g., mentioned in the total station user manual) of measurements of horizontal angles

, vertical angles

, and distances

are known, the weight matrix

takes the form

Assuming that

the matrix of cofactors (approximations of variances)

for particular controlled points (

j) takes the form (not taking into account mean errors of the instrument position and mean error of the instrument height)

Equation (3) represents the most commonly used variant in practical applications, here, the measurements are made in a single instrument position (there is no need to set up the network). Selected elements of the matrix (3) will be used in further computational stages. The horizontal coordinates X, Y defined in the local system of the crane bridge are input data to assess the distance between the corners of the crane bridge.

These distances are involved in the equation:

and are further considered as pseudo-observations.

Expanding the Equation (4) in the Taylor series (limited to initial terms), we obtain the following functional model of corrections for pseudo-observation:

where:

are corrections for pseudo-observation (distances),

are distances calculated on the basis of approximate coordinates (pseudo-observations),

are theoretical distances (from the technical design),

are increments to approximate coordinates,

are numbers of controlled points,

is the next number of the distance, and

( are adjusted coordinates, are approximate coordinates).

Theoretical and empirical tests of the crane bridge should be carried out in the vertical plane too. Hence the equation of pseudo-observation (height) corrections takes the following form:

where

is the equation of correction to height,

are the points’ heights determined from measurements,

are the theoretical point heights (from technical design),

are the increments to approximate heights, and

( is adjusted height, is approximate height).

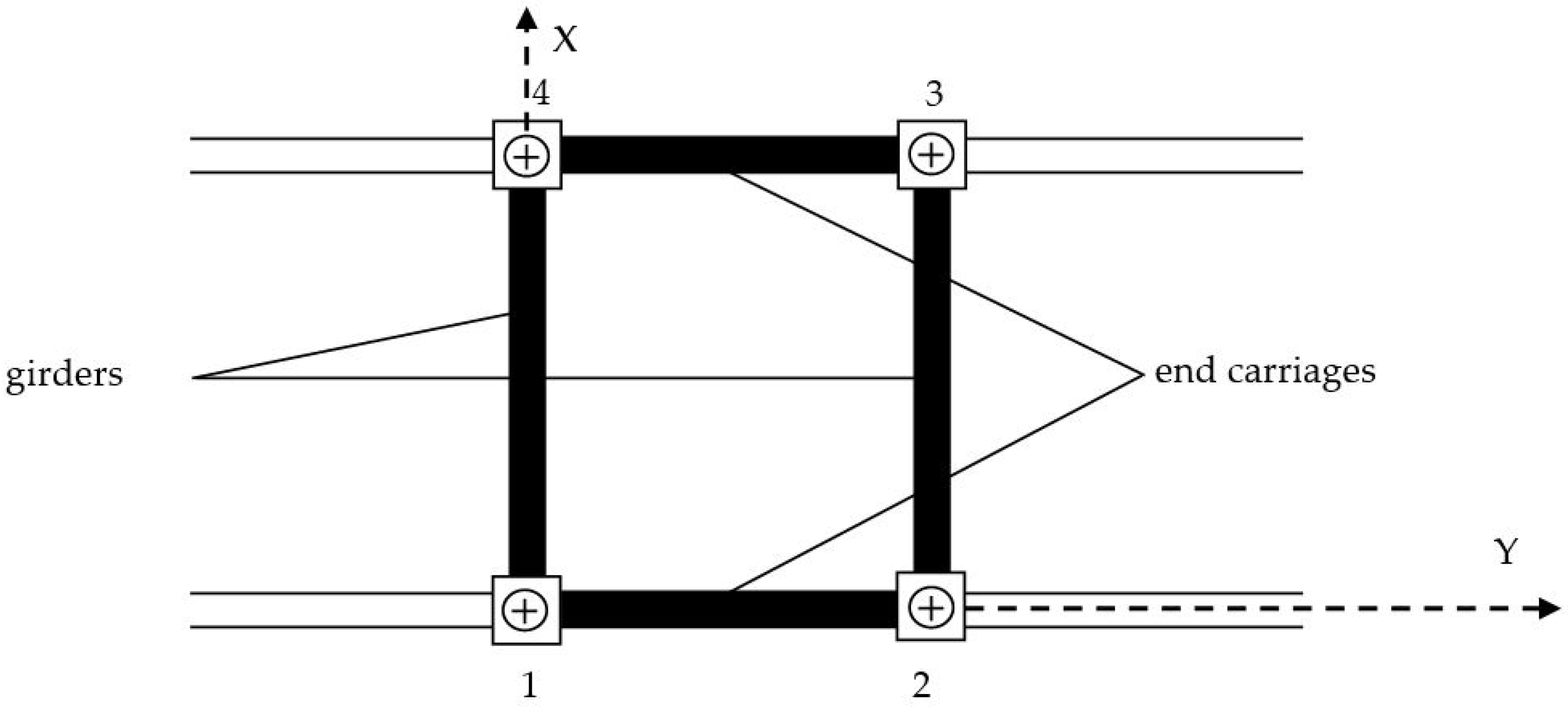

In order to provide proper work of the crane bridge, it is necessary to maintain perpendicularity of end carriages and girders, as well as parallel end carriages and girders (

Figure 1). Most cases described in the available literature have not taken this issue into account while performing various types of specialized analyses [

9,

12,

13].

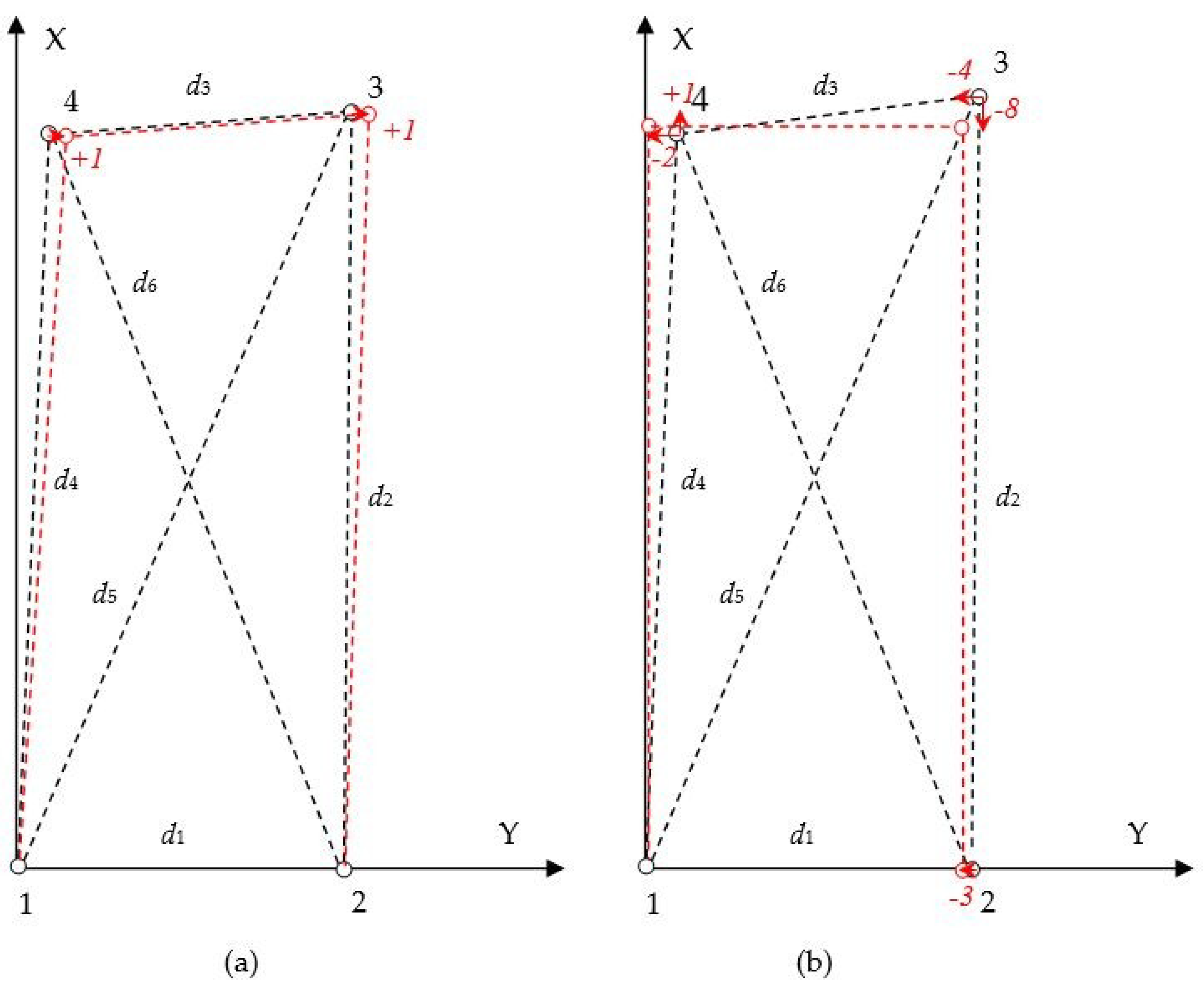

According to

Figure 2, the following conditions of parallel character have been adopted:

where:

are adjusted coordinates of controlled points located on the crane bridge.

The condition of perpendicularity between pairs of end carriages and girders should also be maintained, therefore:

For the conditions imposed on pseudo-observations, the height of controlled points can be presented in the form (all controlled points are located at the same height)

2.2. Adjustment of Observations Results

The system of correction equations presented earlier as relation (5) can be written in the following matrix Form (10):

where:

is the vector of correction to pseudo-distances,

is the vector of increments to approximate parameters (coordinates of points),

is the vector of deviations of theoretical lengths from the corresponding value of pseudo-observation (i is the number of pseudo-observations), and

is the known matrix of coefficients standing at the estimated parameters of the model.

Applying the least squares method [

14], specified in form of

, the estimator of the parameter vector

may be derived from the following equation:

The matrix of weights assigned to the appropriate pseudo-observations is marked as

, whereas the matrix

is a matrix of pseudo-observation cofactors in the form of

where the transformation matrix is

The matrix of cofactors:

was formed from the corresponding elements of the matrix

designated earlier by the Form (3).

In order to assess the accuracy of the adjustment results obtained from Equation (11), the covariance matrix of the parameter vector

is applied:

where

is a matrix of cofactors and

(

n is the number of pseudo-observations,

r is the number of parameters).

The accuracy analysis often employs the covariance matrix of corrections vector

:

Equation (11) is obtained by means of the traditional least squares method and it is impossible to apply here the conditions imposed on the estimated parameters. In order to take into account conditions of parallel and perpendicular characters, and the imposed height of the controlled points (Equations (7), (8), and (9)), the adjustment task must be solved by the parametric method with the conditions on estimated parameters. This method has already been used and described by the authors in the works [

1,

2,

3], and the broader theoretical considerations can be found in [

15,

16]. Only the main dependencies necessary to understand the presented solution will be presented below.

The parametric method with conditions corresponds to the following optimization task:

The first dependence Equation (17), which corresponds to the traditional least squares method, has been explained above. The second equation, , of Dependence (17) concerns the conditions imposed on the estimated parameters X. The elements of matrix B are the coefficients standing at the estimated parameters in Relations (7), (8), and (9). These coefficients may take the following values: −1, 0, and 1.

Vector is a vector of free terms in this equation.

In search of a solution to the optimization problem (17) by means of the least square method, the traditional method (e.g., [

16]) or a simplified method involving the acceptance for free terms (occurring in the conditional equations) with enormously high values of weights [

16] can be applied. The proposed solution method is based on the use of conditional equations, as additional equations of corrections, with very high values of weights, so that

. Hence it reads as follows:

The adoption of very high values of weights allows for the received correction values equal to zero within the limits of numerical calculations.

Taking these assumptions, the solution is simple enough to use the literature-bound parametric method [

16]. Thus, the system of correction equations takes the form

where

,

,

.

The adjustment criterion takes the following form:

where the weight matrix

is

.

In order to assess the accuracy of the obtained results, appropriate covariance matrixes are used as follows:

- (1)

The covariance matrix

of the parameter vector

,

where

is a matrix of cofactors.

- (2)

The covariance matrix

of the integrated corrections vector

,

where the covariance matrix

takes the form

and

(

n is the number of pseudo-observations,

m is the number of parameters).