The Influence of Alteration of Aggregates on the Quality of the Concrete: A Case Study from Serpentinites and Andesites from Central Macedonia (North Greece)

Abstract

:1. Introduction

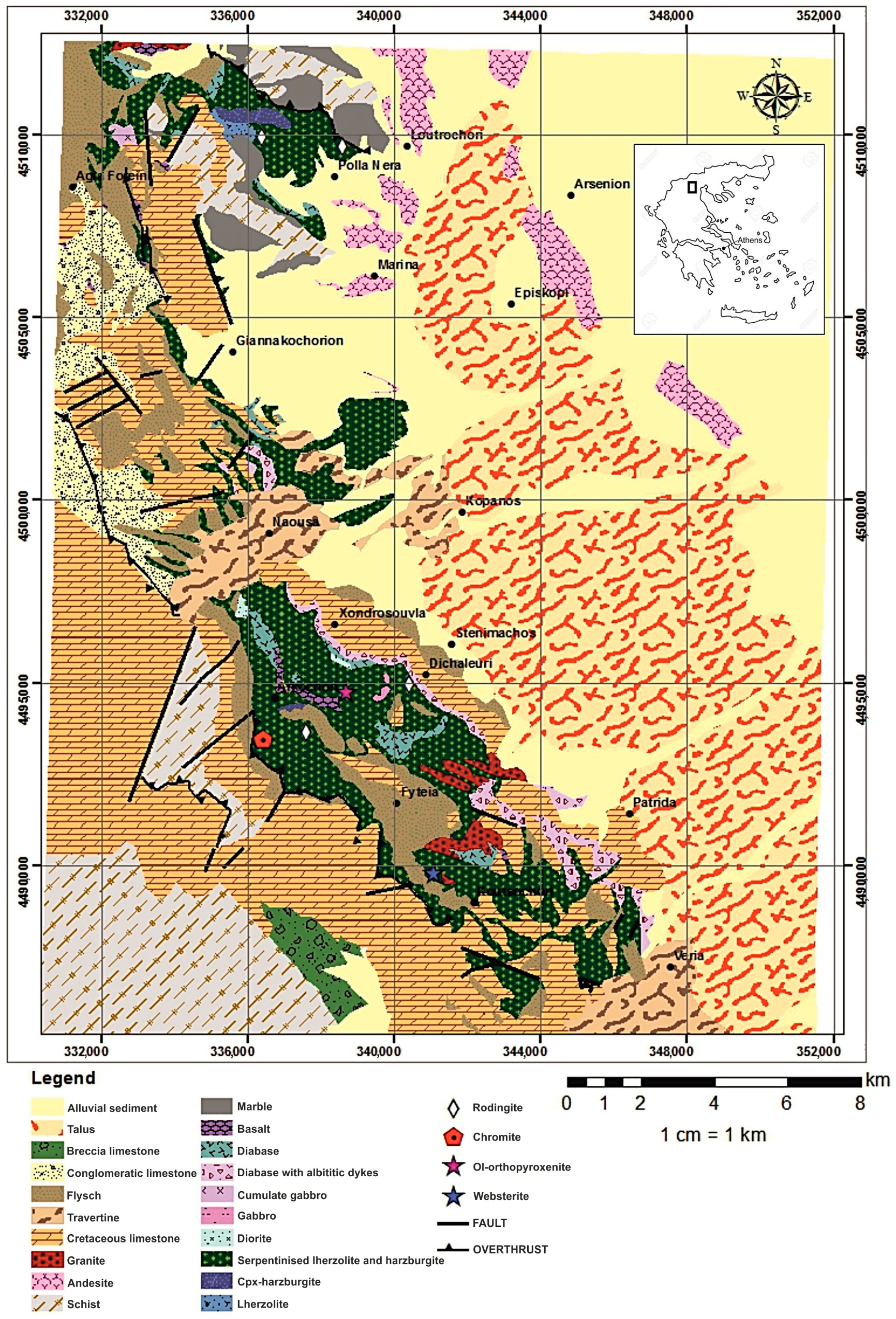

2. Geological Setting

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. Test Methods for Aggregates

3.2.2. Test Methods for Concrete

4. Test Results

4.1. Mechanical Properties of Aggregates

4.2. Petrographic Features of Aggregates

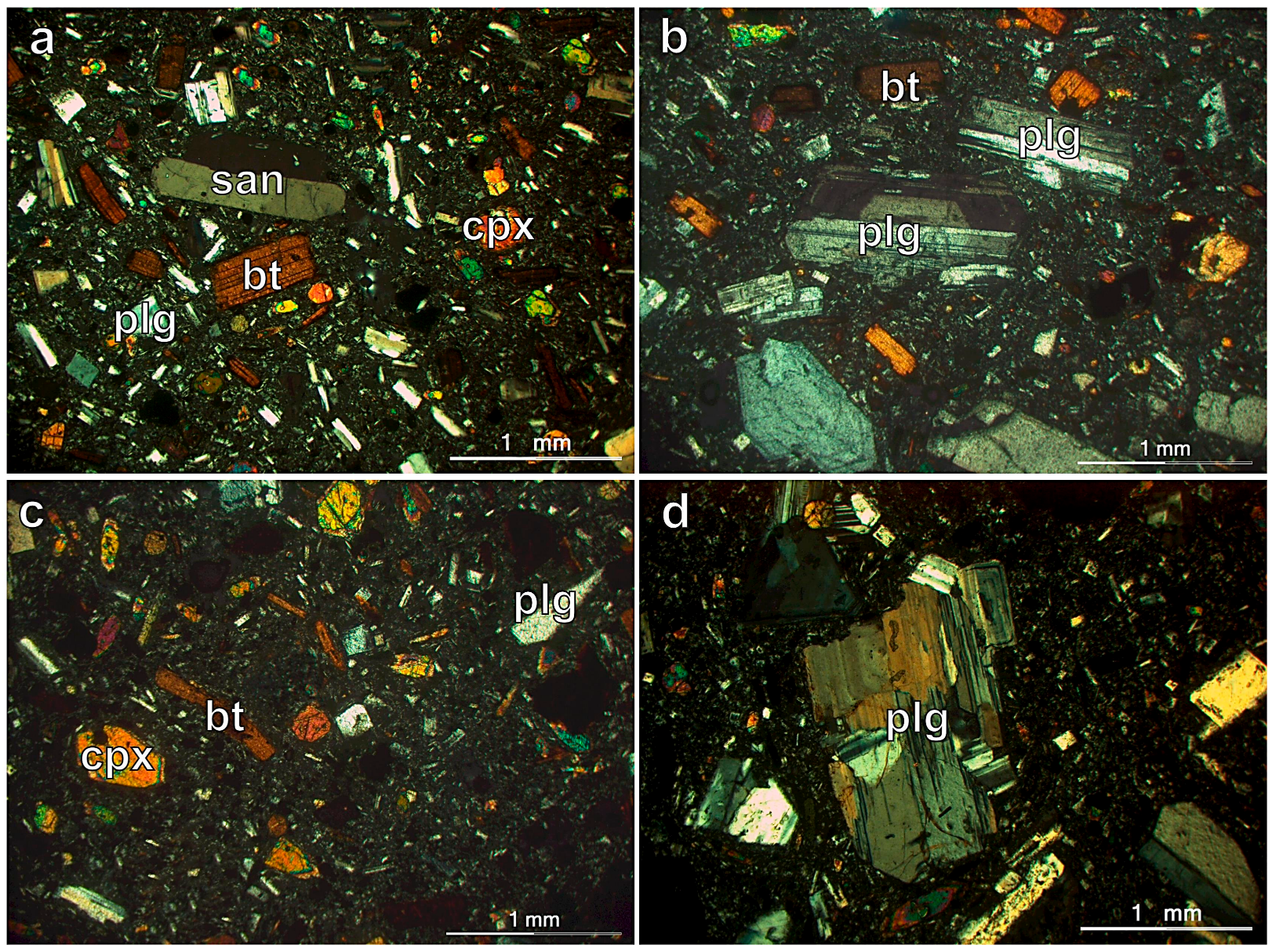

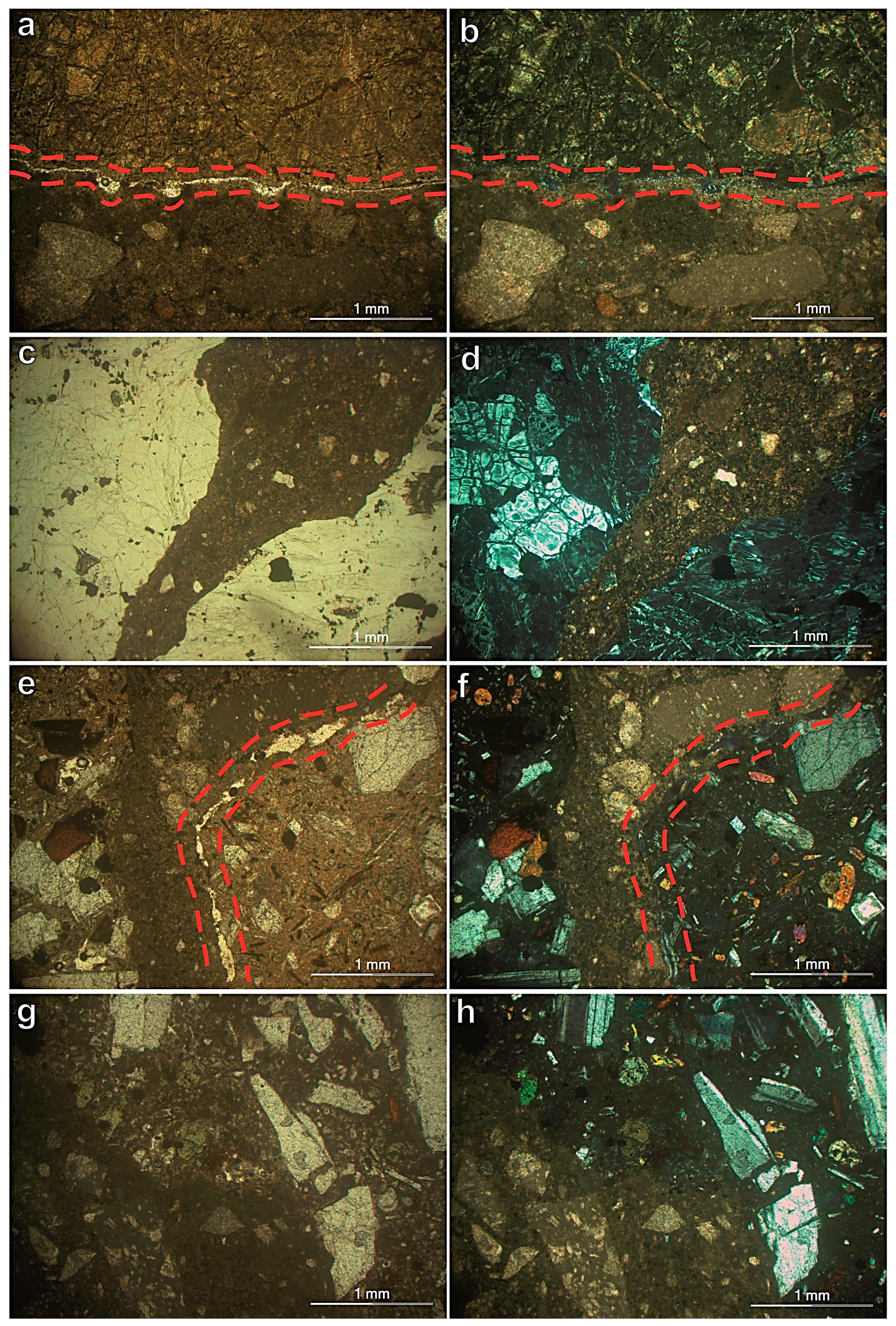

4.2.1. Serpentinites

4.2.2. Andesites

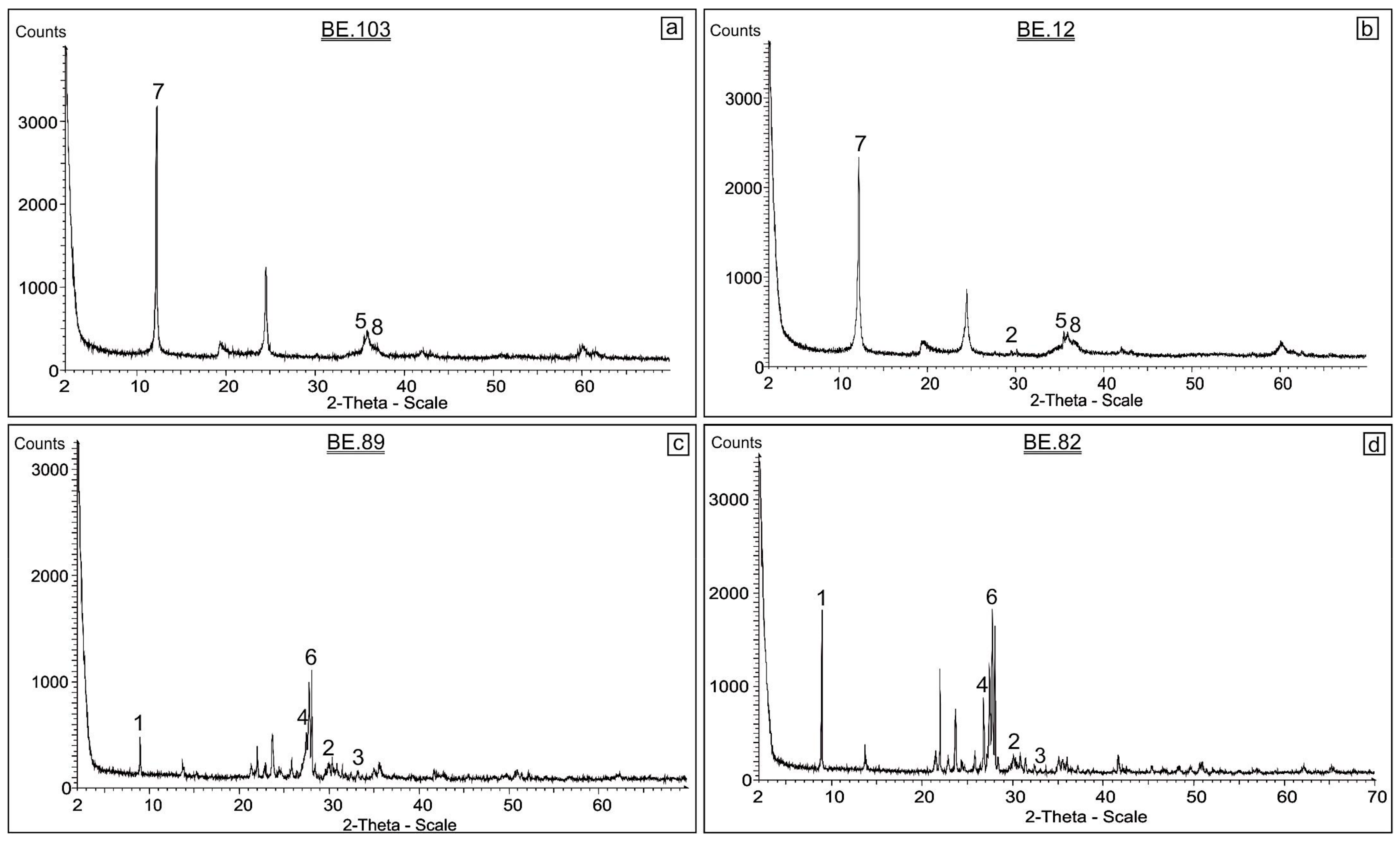

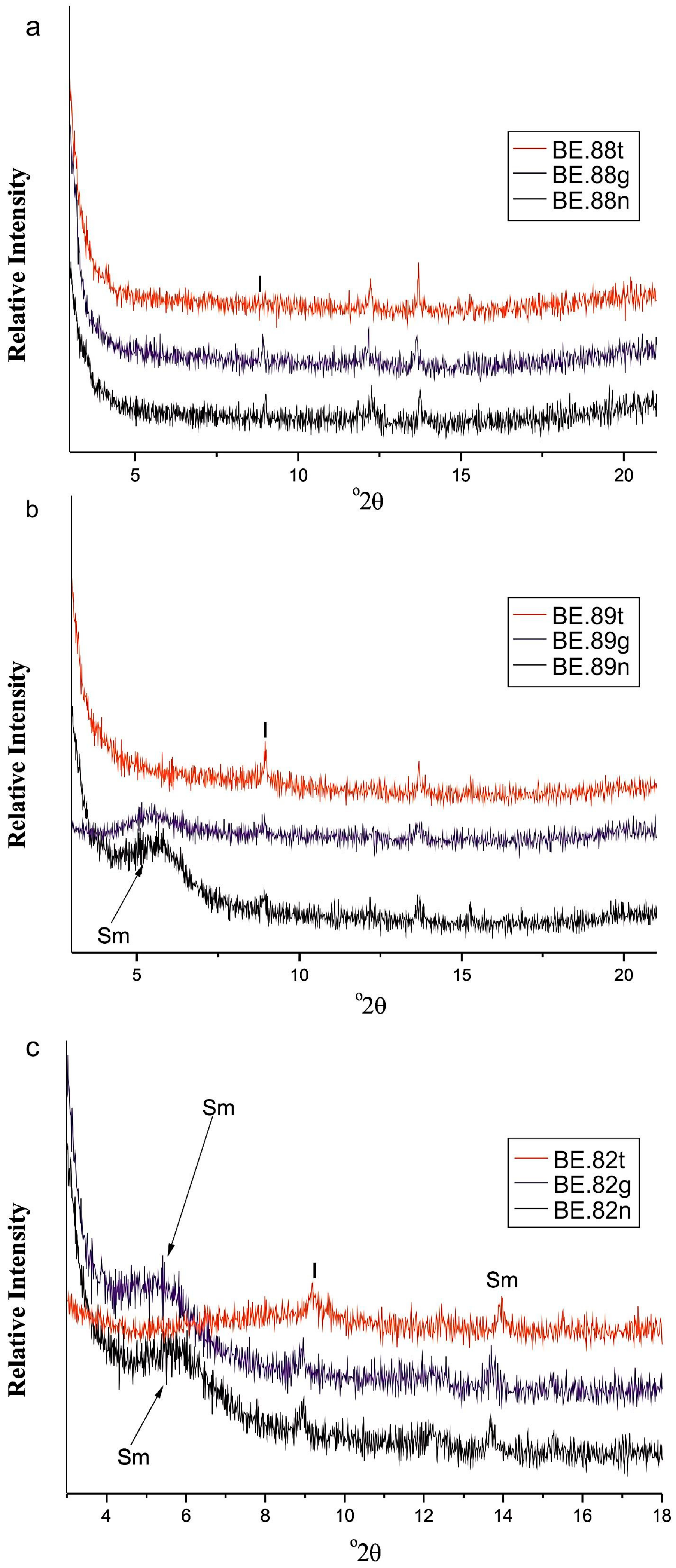

4.3. X-ray Diffractometry of Aggregates

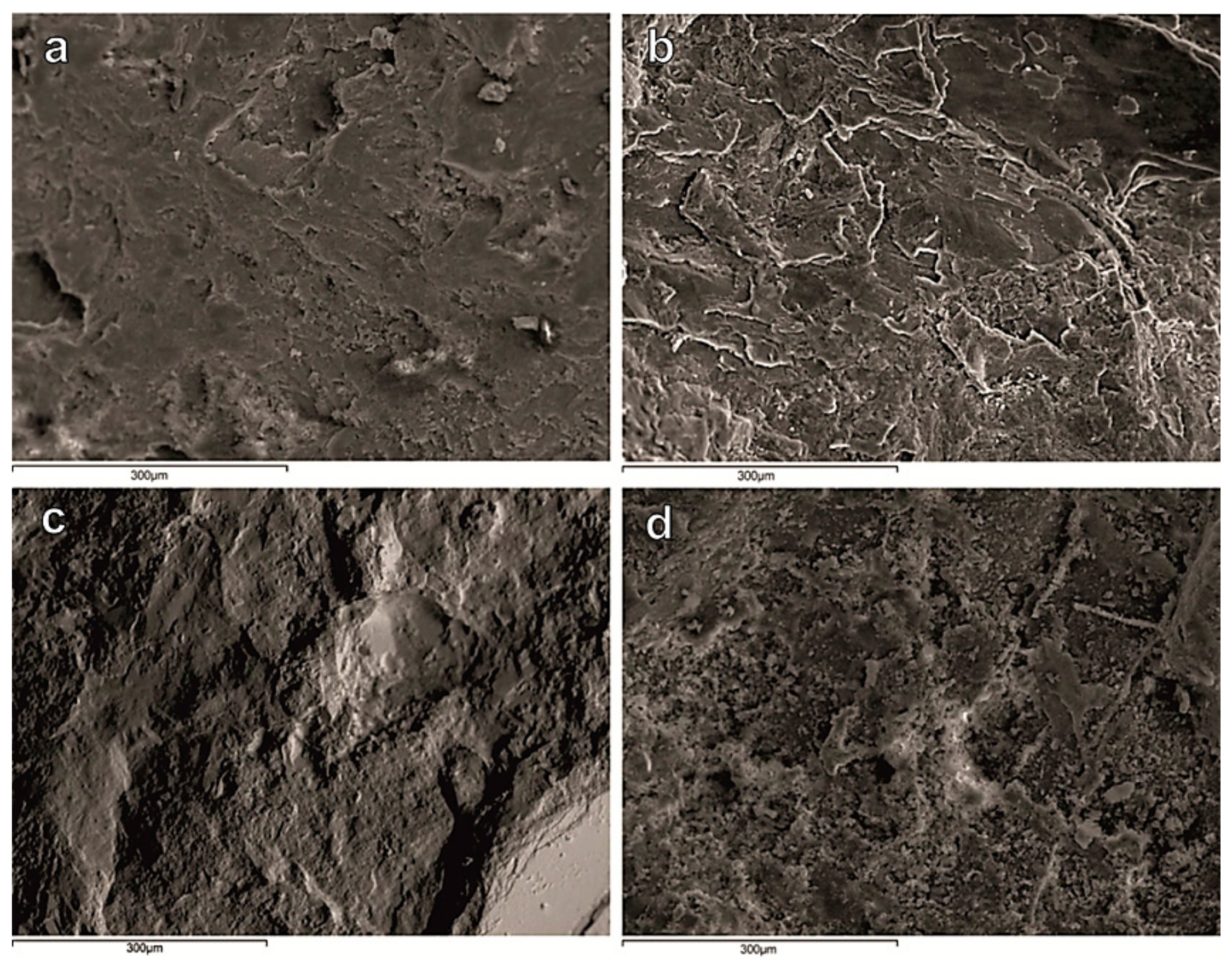

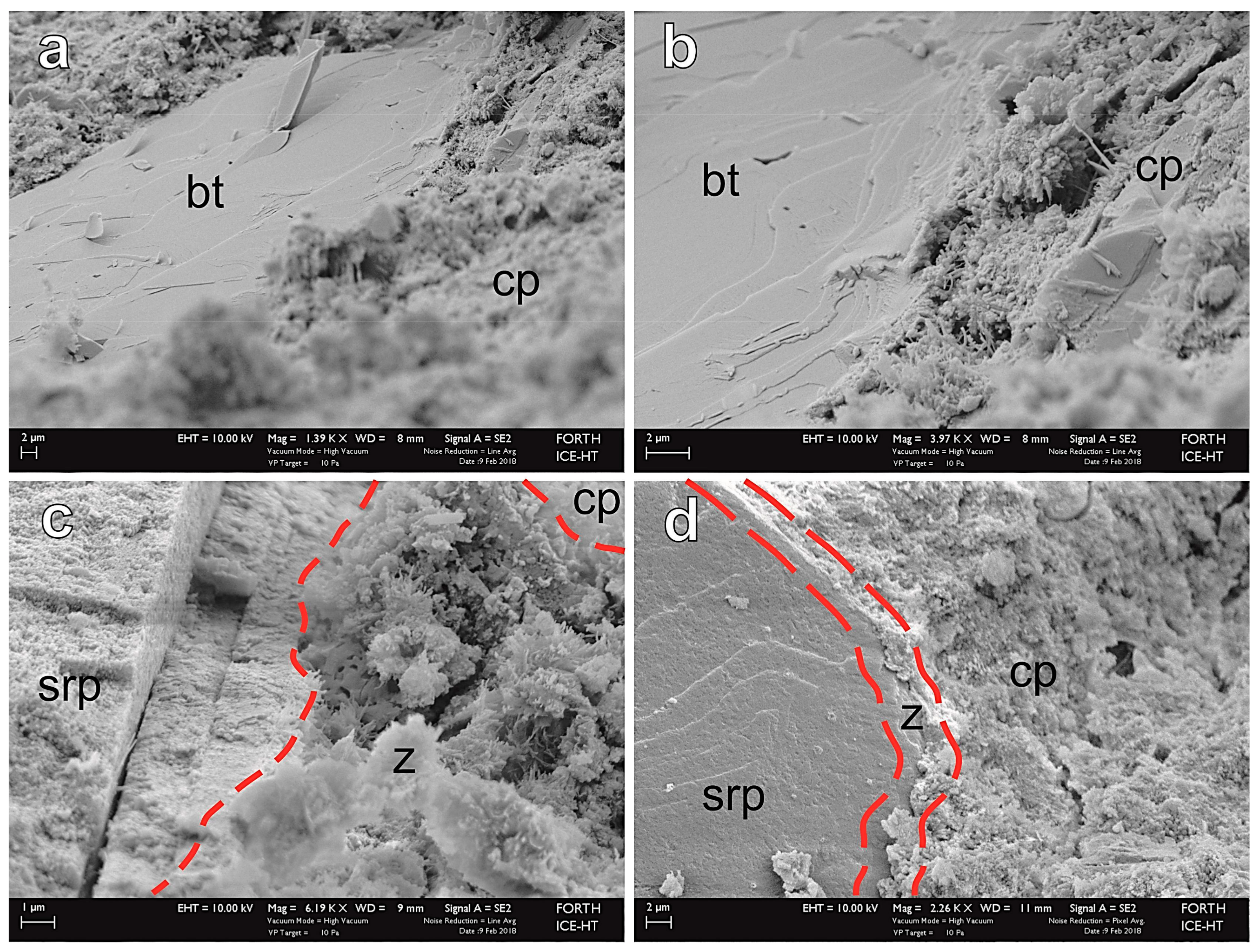

4.4. Surface Texture of Aggregates

4.5. Test Results for Concrete

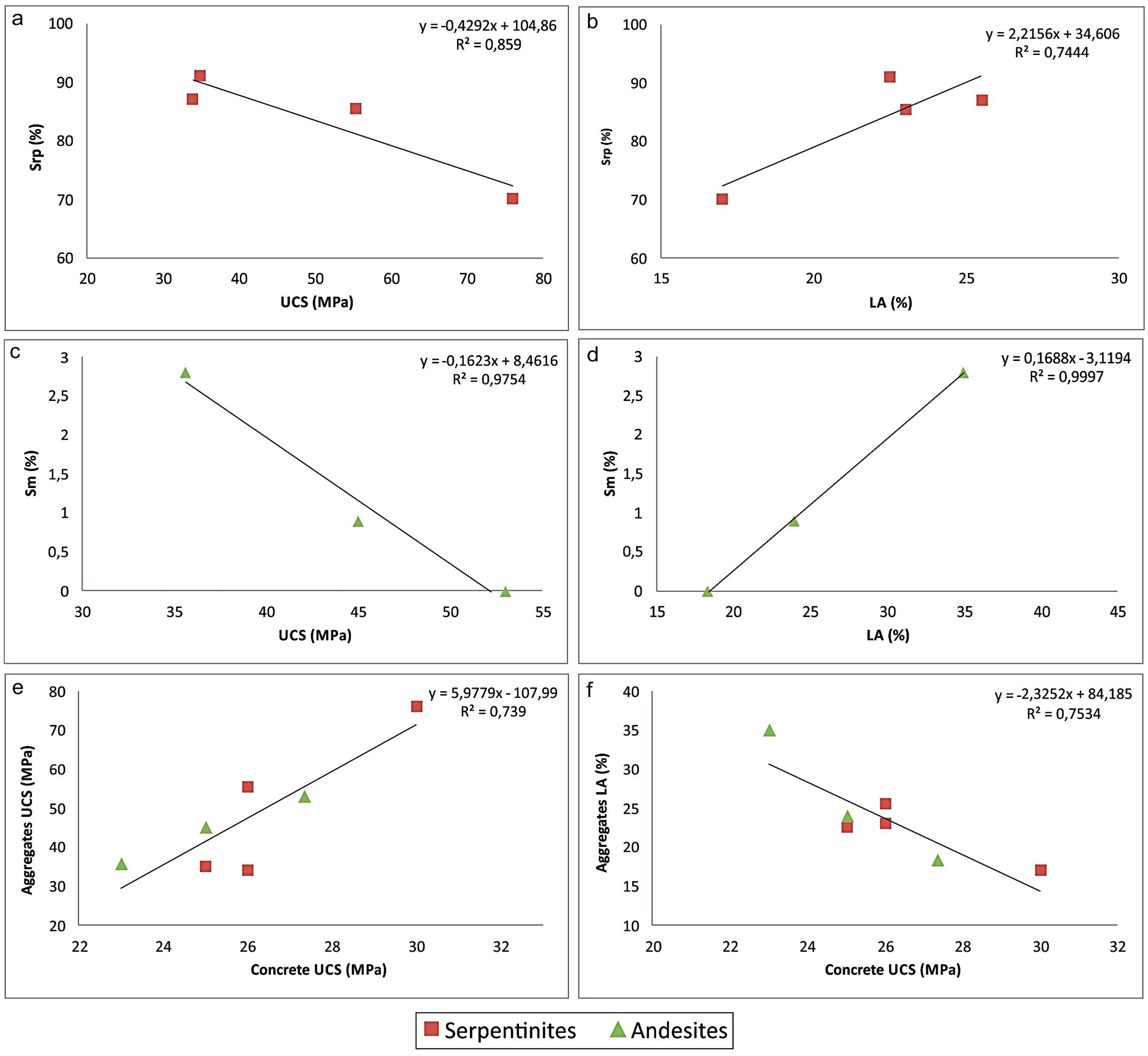

5. Discussion

5.1. The Influence of Serpentinisation in the Performance of the Serpentinites

5.2. The Influence of Smectites in the Performance of Andesites

5.3. Impact of the Secondary Phases on the Concrete Quality

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jackson, N. Civil Engineering Materials; Macmillan Press Ltd.: London, UK, 1981. [Google Scholar]

- LaLonde, W.S.; Janes, M.F. Concrete Engineering Handbook; Library of Congress: New York, NY, USA, 1961. [Google Scholar]

- US Concrete Industry Report; Library of Congress: New York, NY, USA, 2001.

- Neville, A.M. Properties of Concrete, ELSB 5th ed.; Pearson Education Publishing Ltd.: London, UK, 2005. [Google Scholar]

- Taylor, G.D. Materials in Construction, 2nd ed.; Longman Group Ltd., Longman House: London, UK, 1994. [Google Scholar]

- Rajput, R.K. Engineering Materials, 3rd ed.; S. Chard & Company Ltd.: Ram Nagar, New Delhi, 2006. [Google Scholar]

- Gonilho Pereira, C.; Castro-Gomes, J.; Pereira de Oliveira, L. Influence of natural coarse aggregate size, mineralogy and water content on the permeability of structural concrete. Constr. Build. Mater. 2009, 23, 602–608. [Google Scholar] [CrossRef]

- Piasta, W.; Góra, J.; Turkiewicz, T. Properties and durability of coarse igneous rock aggregates and concretes. Constr. Build. Mater. 2016, 126, 119–129. [Google Scholar] [CrossRef]

- Yilmaz, M.; Tuğrul, A. The effects of different sandstone aggregates on concrete strength. Constr. Build. Mater. 2012, 35, 294–303. [Google Scholar] [CrossRef]

- Rigopoulos, I.; Tsikouras, B.; Pomonis, P.; Hatzipanagiotou, K. The influence of alteration on the engineering properties of dolerites: The example from the Pindos and Vourinos ophiolites (northern Greece). Int. J. Rock Mech. Min. Sci. 2010, 47, 69–80. [Google Scholar] [CrossRef]

- Petrounias, P.; Rogkala, A.; Kalpogiannaki, M.; Tsikouras, B.; Hatzipanagiotou, K. Comparative study of physico-mechanical properties of ultrabasic rocks (Veria-Naousa ophiolite) and andesites from central Macedonia (Greece). Bull. Geol. Soc. Gr. 2016, 50, 1989–1998. [Google Scholar]

- Giannakopoulou, P.P.; Tsikouras, B.; Hatzipanagiotou, K. The interdependence of mechanical properties of ultramafic rocks from Gerania ophiolitic complex. Bull. Geol. Soc. Gr. 2016, 50, 1829–1837. [Google Scholar]

- Yilmaz, N.G.; Goktan, R.M.; Kibici, Y. Relations between some quantitative petrographic characteristics and mechanical strength properties of granitic building stones. Int. J. Rock Mech. Min. Sci. 2011, 48, 506–513. [Google Scholar] [CrossRef]

- Diamantis, K.; Gartzos, E.; Migiros, G. Study on uniaxial compressive strength, point load strength index, dynamic and physical properties of serpentinites from Central Greece: Test results and empirical relations. Eng. Geol. 2009, 108, 199–207. [Google Scholar] [CrossRef]

- Rigopoulos, I.; Tsikouras, B.; Pomonis, P.; Hatzipanagiotou, K. The impact of petrographic characteristics on the engineering properties of ultrabasic rocks from northern and central Greece. Q. J. Eng. Geol. Hydrogeol. 2012, 45, 423–433. [Google Scholar] [CrossRef]

- Tiwari, B.; Ajmera, B. Consolidation and swelling behavior of major clay minerals and mixtures. Appl. Clay Sci. 2011, 54, 264–273. [Google Scholar] [CrossRef]

- Bish, D.L.; Howard, S.A. Quantitative phase analysis using the Rietveld Method. J. Appl. Cryst. 1988, 21, 86–91. [Google Scholar] [CrossRef]

- Bish, D.L.; Post, J.E. Quantitative mineralogical analysis using the Rietveld full pattern fitting method. Am. Mineral. 1993, 78, 932–940. [Google Scholar]

- McCusker, L.B.; Von Dreele, R.B.; Cox, D.E.; Louer, D.; Scardi, P. Rietveld refinement guidelines. J. Appl. Crystallogr. 1999, 32, 36–50. [Google Scholar] [CrossRef]

- Hillier, S. Accurate quantitative analysis of clay and other minerals in sandstones by XRD: Comparison of a Rietveld and a reference intensity ratio (RIR) method and the importance of sample preparation. Clay Miner. 2000, 35, 291–302. [Google Scholar] [CrossRef]

- Gualtieri, A.F. Accuracy of XRPD QPA using the combined Rietveld-RIR Method. J. Appl. Crystallogr. 2000, 33, 267–278. [Google Scholar] [CrossRef]

- Rogkala, A.; Petrounias, P.; Tsikouras, B.; Hatzipanagiotou, K. New occurrence of pyroxenites in the Veria-Naousa ophiolite (north Greece): Implications on their origin and petrogenetic evolution. Geosciences 2017, 7, 92. [Google Scholar] [CrossRef]

- Mercier, J.; Vergely, P.; Bebien, J. Les ophiolites helleniques “obductees” au Jurassique superieursont-elles les vestiges d’ un ocean tethysienou d’ une mermarginale perieuropeenne. C. R. Somm. Soc. Geol. France 1975, 17, 108–112. [Google Scholar]

- Economou, M. A short note on the evolution of the Vermion ophiolite complex (Macedonia-Greece). Ofioliti 1983, 8, 333–338. [Google Scholar]

- Michailidis, K.M. Zoned chromites with high Mn-contents in the Fe-Ni-Cr-laterite ore deposits from the Edessa area in Northern Greece. Miner. Deposita 1990, 25, 190–197. [Google Scholar] [CrossRef]

- Economou-Eliopoulos, M. Apatite and Mn. Zn. Co-enriched chromite in Ni-laterites of northern Greece and their genetic significance. J. Geochem. Explor. 2003, 80, 41–54. [Google Scholar] [CrossRef]

- Tsoupas, G.; Economou-Eliopoulos, M. High PGE contents and extremely abundant PGE-minerals hosted in chromitites from the Veria ophiolite complex. Northern Greece. Ore Geol. Rev. 2008, 33, 3–19. [Google Scholar] [CrossRef]

- Saccani, E.; Photiades, A.; Santato, A.; Zeda, O. New evidence for supra-subduction zone ophiolites in the Vardar zone of northern Greece: Implications for the tectonomagmatic evolution of the Vardar oceanic basin. Ofioliti 2008, 33, 65–85. [Google Scholar]

- Rogkala, A.; Petrounias, P.; Tsikouras, B.; Hatzipanagiotou, K. Petrogenetic significance of spinel from serpentinised peridotites from Veria-Naousa ophiolite. Bull. Geol. Soc. Gr. 2016, 50, 1999–2008. [Google Scholar]

- Eleftheriadis, G.; Castorina, F.; Soldatos, T.; Masi, U. Geochemical and Sr-Nd isotopic evidence for the genesis of the Late Cainozoic Almopia volcanic rocks (Central Macedonia, Greece). Mineral. Petrol. 2003, 78, 21–36. [Google Scholar] [CrossRef]

- Brunn, J.H. Geological Map of Greece, Veroia Sheet, 1:50.000; IGME: Athens, Greece, 1982. [Google Scholar]

- Part 1: Composition, Specifications and Conformity Criteria for Common Cements; EN 197-1; European Standard: Warsaw, Poland, 2011.

- Resistance to Abrasion of Small-Size Coarse Aggregate by Use of the Los Angeles Machine; ASTM C-131; American Society for Testing and Materials: Philadelphia, PA, USA, 1989.

- Standard Test Method for Unconfined Compressive Strength of Intact Rock Core Specimens; ASTM D 2938-95; American Society for Testing and Materials: West Conshohocken, PA, USA, 2002.

- Part 3: Procedure and Terminology for Simplified Petrographic Description; EN 932; European Standard: Warsaw, Poland, 1996.

- Methods for Sampling and Testing of Mineral Aggregates, Sands and Fillers, Part 1: Methods for Determination of Particle Size and Shape; British Standard Institution: London, UK, 1975.

- Standard for Selecting Proportions for Normal, Heavyweight and Mass Concrete; ACI-211.1-91; American Concrete Institute: Farmington Hills, MI, USA, 2002.

- Part 3: Testing Hardened Concrete. Compressive Strength of Test Specimens; BS EN 12390; British Standard: London, UK, 2009.

- Standard Practice for Petrographic Examination of Hardened Concrete; ASTM C856; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- Rigopoulos, I.; Tsikouras, B.; Pomonis, P.; Hatzipanagiotou, K. Determination of the interrelations between the engineering parameters of construction aggregates from ophiolite complexes of Greece using factor analysis. Constr. Build. Mater. 2013, 49, 747–757. [Google Scholar] [CrossRef]

- Barttli, B. The influence of geological factors on the mechanical properties of basic igneous rocks used as road surface aggregates. Eng. Geol. 1992, 33, 31–44. [Google Scholar] [CrossRef]

- Smith, M.R.; Collis, L. Aggregates: Sand, Gravel and Crushed Rock Aggregates for Construction Purposes; Spec. Publ. 17; The Geological Society: London, UK, 2001. [Google Scholar]

- Escartin, J.; Hirth, G.; Evans, B. Strength of slightly serpentinized peridotites: Implications for the tectonics of oceanic lithosphere. Geology 2001, 29, 1023–1026. [Google Scholar] [CrossRef]

- Frost, B.R.; Beard, J.S. On silica activity and serpentinization. J. Petrol. 2007, 48, 1351–1368. [Google Scholar] [CrossRef]

- Evans, B.W. Control of the products of serpentinization by the Fe2+Mg−1 exchange potential of olivine and orthopyroxene. J. Petrol. 2008, 49, 1873–1887. [Google Scholar] [CrossRef]

- Jöreskog, K.G.; Klovan, J.E.; Reyment, R.A. Geological Factor Analysis; Elsevier: Amsterdam, The Netherlands, 1976. [Google Scholar]

- Zoltai, T.; Stout, J.H. Mineralogy Concepts and Principles; Burgess Publishing Co.: Minneapolis, MN, USA, 1984. [Google Scholar]

- Taylor, R.K.; Smith, T.J. The engineering geology of clay minerals; swelling, shrinking and mudrock breakdown. Clay Miner. 1986, 21, 235–260. [Google Scholar] [CrossRef]

- Higgs, N.B. Preliminary studies of methylene blue adsorption as a method of evaluating degradable smectite-bearing concrete aggregate sands. Cem. Concr. Res. 1986, 16, 525–534. [Google Scholar] [CrossRef]

- Farrokhpay, S.; Ndlovu, B.; Bradshaw, D. Behaviour of swelling clays versus non-swelling clays in flotation. Miner. Eng. 2016, 96–97, 59–66. [Google Scholar] [CrossRef]

| Samples | Lithotypes | Uniaxial Compressive Strength of Rocks (UCS MPa) | Los Angeles (LA %) |

|---|---|---|---|

| ΒΕ.82 | Andesite | 35.62 | 35.00 |

| ΒΕ.88 | Andesite | 53.00 | 18.36 |

| BE.89 | Andesite | 45.00 | 23.98 |

| ΒΕ.01 | Serpentinite | 76.00 | 17.00 |

| ΒΕ.12 | Serpentinite | 55.40 | 23.00 |

| ΒΕ.103 | Serpentinite | 34.00 | 25.51 |

| ΒΕ.133 | Serpentinite | 35.00 | 22.50 |

| Samples | BE.82 | BE.88 | BE.89 | BE.01 | BE.12 | BE.103 | BE.133 |

|---|---|---|---|---|---|---|---|

| Spinel | - | - | - | 10.0 | 9.6 | 6.5 | 1.5 |

| Orthopyroxene | - | - | - | 8.0 | - | - | 3.6 |

| Clinopyroxene | 7.6 | 9.0 | 8.7 | 7.7 | - | 5.1 | 2.1 |

| Serpentine | - | - | - | 70.7 | 85.4 | 87.0 | 91.4 |

| Magnetite | - | - | - | 4.3 | 5.0 | 1.4 | 1.5 |

| Hematite | 2.0 | 0.6 | 1.0 | - | - | - | - |

| K-feldspar | 25.2 | 29.1 | 25.1 | - | - | - | - |

| Plagioclase | 52.8 | 45.8 | 55.1 | - | - | - | - |

| Biotite | 5.6 | 7.2 | 6.1 | - | - | - | - |

| Illite | 3.8 | 8.3 | 3.1 | - | - | - | - |

| Smectite | 2.8 | - | 0.9 | - | - | - | - |

| Sample No. | BE.82 | BE.88 | BE.89 | BE.01 | BE.12 | BE.103 | BE.133 |

|---|---|---|---|---|---|---|---|

| Aggregate type | Andesites | Serpentinites | |||||

| Concrete UCS (MPa) | 23.00 | 27.33 | 25.00 | 30.00 | 26.00 | 26.00 | 25.00 |

| Pair | T-Test | DF | P-Value | T-Table Values | Figure | |||

|---|---|---|---|---|---|---|---|---|

| α = 0.01 | α = 0.02 | α = 0.05 | α = 0.10 | |||||

| UCSaggregate - Serpentine | −2.360 | 3 | 0.10297 | 5.841 | 4.541 | 3.182 | 2.353 | 9a |

| LAaggregate - Serpentine | −19.790 | 3 | 0.00033 | 5.841 | 4.541 | 3.182 | 2.353 | 9b |

| UCSaggregate - Smectite | 7.417 | 2 | 0.01770 | 9.925 | 6.965 | 4.303 | 2.920 | 9c |

| LAaggregate - Smectite | 6.043 | 2 | 0.02631 | 9.925 | 6.965 | 4.303 | 2.920 | 9d |

| UCSconcrete - UCSaggregate | 4.282 | 6 | 0.00519 | 3.707 | 3.143 | 2.447 | 1.943 | 9e |

| UCSconcrete - LAaggregate | −0.819 | 6 | 0.44431 | 3.707 | 3.143 | 2.447 | 1.943 | 9f |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Stamatis, P.M.; Tsikouras, B.; Papoulis, D.; Lampropoulou, P.; Hatzipanagiotou, K. The Influence of Alteration of Aggregates on the Quality of the Concrete: A Case Study from Serpentinites and Andesites from Central Macedonia (North Greece). Geosciences 2018, 8, 115. https://doi.org/10.3390/geosciences8040115

Petrounias P, Giannakopoulou PP, Rogkala A, Stamatis PM, Tsikouras B, Papoulis D, Lampropoulou P, Hatzipanagiotou K. The Influence of Alteration of Aggregates on the Quality of the Concrete: A Case Study from Serpentinites and Andesites from Central Macedonia (North Greece). Geosciences. 2018; 8(4):115. https://doi.org/10.3390/geosciences8040115

Chicago/Turabian StylePetrounias, Petros, Panagiota P. Giannakopoulou, Aikaterini Rogkala, Panagiotis M. Stamatis, Basilios Tsikouras, Dimitrios Papoulis, Paraskevi Lampropoulou, and Konstantin Hatzipanagiotou. 2018. "The Influence of Alteration of Aggregates on the Quality of the Concrete: A Case Study from Serpentinites and Andesites from Central Macedonia (North Greece)" Geosciences 8, no. 4: 115. https://doi.org/10.3390/geosciences8040115

APA StylePetrounias, P., Giannakopoulou, P. P., Rogkala, A., Stamatis, P. M., Tsikouras, B., Papoulis, D., Lampropoulou, P., & Hatzipanagiotou, K. (2018). The Influence of Alteration of Aggregates on the Quality of the Concrete: A Case Study from Serpentinites and Andesites from Central Macedonia (North Greece). Geosciences, 8(4), 115. https://doi.org/10.3390/geosciences8040115