Abstract

The aim of the present note is to contribute to the search for sustainable binders to be used for soil stabilization purposes. Fly ash and quicklime are added to a clayey soil of low plasticity in different proportions; samples were prepared by wet mixing and Standard Proctor compaction of the soil–water–binder mixture. Permeability tests were carried out for the first 28 days of curing, varying the moulding water content of the investigated samples. Compressibility was evaluated through one-dimensional consolidation tests performed after 7 days of curing and shear strength was investigated at the same curing time. Reactions development was successfully monitored by measuring pH and small strain shear modulus by means of bender elements testing for the first 28 days of curing. Microstructural investigation through scanning electron microscope and Energy dispersive X-Ray Spectroscopy revealed the presence of pozzolanic products in the mixture, reflecting the reduction in compressibility and the improvement in the mechanical characteristics of the soil of concern, after the treatment. The addition of the combination of fly ash and quicklime allowed to enhance the draining capability of the mixtures, especially when the mixture is compacted at optimum water content.

1. Introduction

Among sustainable practices in Environmental Geotechnics, soil stabilization makes a major contribution since it allows for the reuse of excavated soil that, otherwise, should be disposed of and replaced by good quality soil from quarries. Besides the easily understandable environmental and economic advantage of stabilization practices, a supplement to sustainability would be added if residues/by-products (from industry or from agriculture) were used as stabilizers. In the present research work, the possibility to use fly ash (i.e., residue of thermal power plant) as a soil stabilizer is evaluated preparing soil-fly ash-lime mixtures with different binder proportions and performing geotechnical tests in order to assess soil reuse possibility in earthen structures.

The soil reuse objective can also be achieved using traditional stabilizers such as lime or cement. In this case, the positive outcomes of the treatment are ensured due to their well-known potentialities and to the gained knowledge about the achievable micro and macro modifications of soil properties (e.g., [1,2]). Accordingly, testing standards and construction procedures are easily available. On the other hand, production of traditional binders causes significant CO2 emission (approximately 1.281 ton of CO2/ton of lime and 1 ton of CO2/ton of cement—[3,4]) and extraction of raw material for their production results in dust emissions, alterations to landscape and possible changes in groundwater quality [5].

Using residues as binders for soil stabilization ensures a more environmental-friendly approach. Recent research applied to geomaterials focuses on soils, sediments or mine tailings treated with rice husk ash, mushroom waste, wet olive pomace, marble powder, ground granulated blast furnace slag, incinerator slag or fly ash e.g., [6,7]. All these residues are able to improve the soil mechanical characteristics but, in some cases, side effects compromised the improvement. In addition, the hydraulic and mechanical behaviour of soils treated with fly ash needs further investigation, given that standardized methodologies are not currently available and some properties, such as shear strength and permeability, are rarely addressed [8].

For stabilization purposes, fly ash can be used as such or after modification/activation, alone or in combination with other (sometimes traditional) binders. For instance, Fujikawa et al. [9] explored the possibility to recycle coal fly ash in mixed materials investigating the durability and leaching properties of fly ash–cement–water mixtures while Najafi et al. [10] synthesized clay–fly ash geopolymer from the mixtures in order to enhance the adsorption capacity (lead and zinc) of a clay.

The major producers of fly ash are India, China and USA, together producing more than 280 Million tons/year; Middle East Countries and Africa yearly produce 32 million tons of fly ash while European countries account for nearly 40 million tons/year; only 50% of fly ash worldwide production is currently reused [11]. Their disposal is a big matter of concern because their toxicity poses both environmental and sanitary issues. For all the previously discussed reasons, researchers must explore the viable ways to reuse fly ash and environmental geotechnics can contribute to this particular goal by studying the possibility to use fly ash in the soil stabilization process [12].

As widely known, fly ash is a pozzolanic precursor that should be activated in an alkaline environment in order to enhance its stabilization capability and, to this purpose, activators are usually sodium or potassium hydroxides [8,13]. When treating clayey soils, that are naturally rich in silica and alumina, also a calcium supplier is needed, especially when using class F fly ash [14,15]. Lime is a binder able to combine the function of activator and calcium supplier; therefore, it is one of the most viable options to help in fly ash stabilization of soils [16,17]; for this reason, lime was selected as an activator in the present research work.

The aim of the present note is to contribute to the findings about the use of fly ash in soil stabilization. In particular, experimental results on clayey soil–fly ash–lime mixtures are presented, focusing on hydraulic conductivity, compressibility and shear resistance, also discussing them in comparison with those obtained for the same soil treated either with traditional lime or with fly ash only. Also the timing of the stabilization process was investigated by monitoring pH and small strain stiffness of the mixture and commenting on the reaction products with the help of scanning electron microscopy.

2. Materials and Methods

2.1. Materials

The soil used in the experimental activity is a clayey soil of low plasticity (CL according to USCS), suitable for lime treatment with reference to its grain size distribution and plasticity index (e.g., UNI EN 14227-11 [18]). The characteristics of the soil are summarized in Table 1.

Table 1.

Characteristics of the tested soil.

The lime used is a fine calcic quicklime (QL) classified as CL80-Q dp (UNI EN 459-1 [20]), completely passing through the ASTM 200 sieve (75 μm sieve opening).

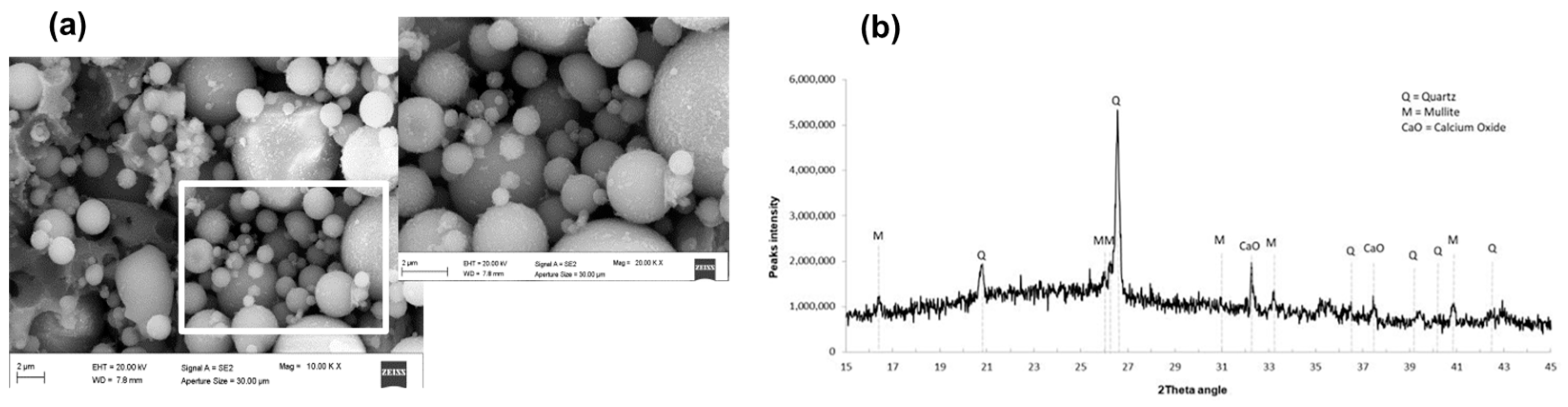

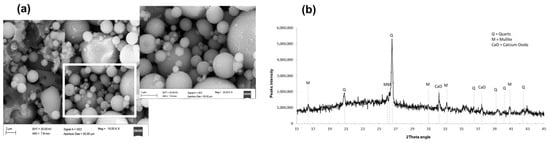

The Fly Ash (FA) is a high pozzolanic fly ash (supplied by General Admixtures SpA). Its unit weight is 2200 kg/m3. Microstructural and chemical investigation was performed on the FA by means of SEM observations and Energy Dispersive X-Ray Spectroscopy, EDS (FESEMSUPRA40–ZEISS), after air dewatering of samples and their gilding (by an Emitech K550 sputter coater). SEM images at several magnification levels are displayed in Figure 1. As is common for this material [21], EDS highlighted the presence of 45% Silicon, 23% Aluminum, 10% Iron, 10% Calcium, 4% Potassium and 7% other components (% by weight, excluding Oxygen). The diameter of observed spherical particles composing FA is mainly within the interval 0.35–61 μm (data retrieved by analysing more than 30 SEM measurements).

Figure 1.

Fly ash: (a) SEM images (10 kX and 20 kX) and (b) X-Ray diffraction spectrum.

The X-Ray diffraction spectrum of FA (Philips diffractometer, PW1730 X-ray generator, PW 1050/70 goniometer and CuK radiation) is displayed in Figure 1: the mineralogical composition includes quartz (SiO2), calcium oxide (CaO) and mullite (Al4.56Si1.44O9.72) as main crystalline components.

2.2. Methods

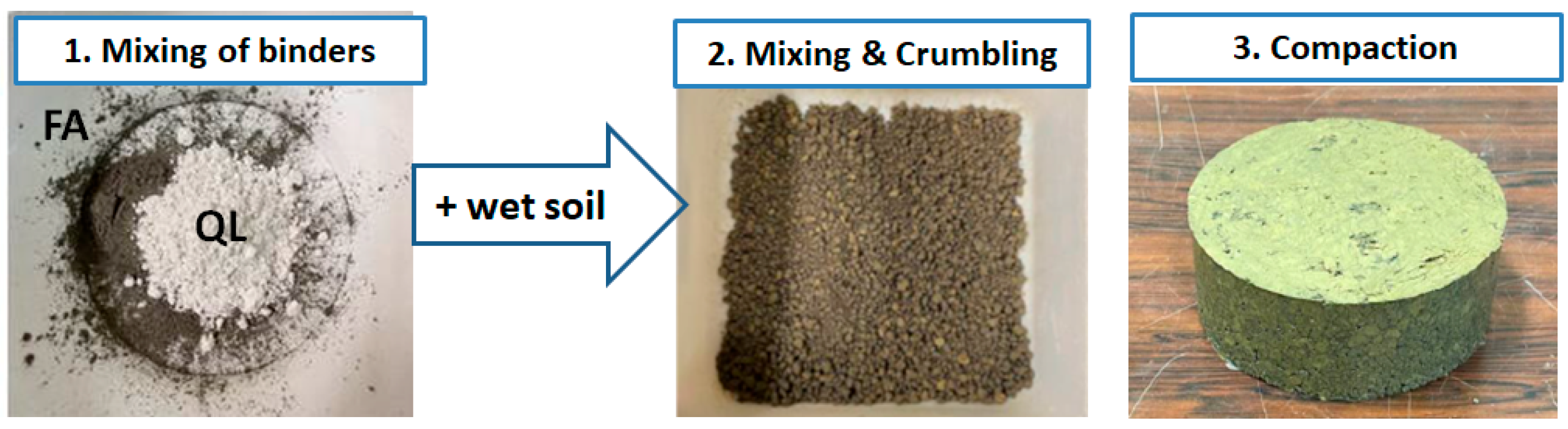

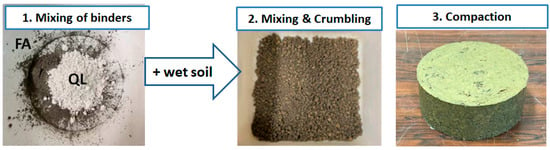

All the samples were prepared by crumbling the air dried soil (to 2 mm in size), adding the amount of water necessary to reach the desired moisture content (determined according to ASTM D2216-19 [22]), then mixing binders and soil at the wet state (as usually performed in the field [23]) until a uniform distribution was achieved. When using the combination of lime and fly ash, the binders were mixed together in the dry state before being added to the wet soil. The wet soil–binder mixture was compacted soon after the mixing, according to the Standard Proctor procedure (ASTM D698-12 [24]). A visualization of the sample preparation is reported in Figure 2.

Figure 2.

Scheme of the sequence for sample preparation when using the combination of lime and fly ash.

The samples were then cured in sealed plastic containers at the controlled temperature of 20 ± 1 °C. The curing temperature is an important factor to be taken into account, especially when lime is included in the mixture, because it has the capability to accelerate the pozzolanic reaction to a significant extent [25,26]. In particular, Al-Mukhtar et al. found that an increase in curing temperature from 20 °C to 50 °C is able to multiply the rate of pozzolanic reaction by a factor of 6 [27,28]. On the contrary, humidity is not controlled during the curing because adding lime to a clayey soil typically reduces the susceptibility to swelling and shrinkage e.g., [29].

The experimental program is summarized in Table 2; the amount of binders in the mixture is expressed as weight of binder by dry weight of soil; details on each type of test are given in the following.

Table 2.

Experimental test program (mixture proportions, compaction water contents, type of tests and investigated curing times).

Mixtures are prepared by adding a total amount of 4% of binder by dry weight of soil, given that the initial consumption of lime (ICL value-ASTM C977-18 [19]) determined for the soil of concern was 2% (Table 1). In particular, the ICL value represents the amount of lime needed in a soil–lime system to complete the short term reactions and to trigger the pozzolanic reactions; therefore, a higher percentage is usually needed for the full development of cementation reactions.

Thus, in order to,

- Evaluate the possibility of adding a sustainable binder, such as fly ash, in the mixture;

- Compare the improvements that can be achieved with those mixtures prepared with a traditional binder, i.e., lime;

The total amount of binders for the present research work was fixed at 4% for all the tested mixtures.

When working with pozzolanic by-products, there is often the need to activate them by creating a high alkaline environment (e.g., [30]) that fosters the dissolution of silicates and aluminates from the pozzolanic precursor in the pore water. In the present case, quicklime is selected as the activator of the fly ash (precursor) because once quicklime is put in contact with the wet soil, it immediately turns into calcium hydroxide, a strong base that completely dissociates in Ca++ and OH− in the pore water, creating a beneficial alkaline environment, capable to also last in the long term [2]. Also, other hydroxides can be used for the same purpose, like potassium or sodium hydroxide, but, by selecting lime, the calcium ions coming from lime dissociation are also expected to directly react with silicates and aluminates coming both from the ash and from the clay fraction of the soil, adding to the stabilization purpose.

Given the previous considerations, the composition of the tested mixtures is listed in the following:

- soil+4% of quicklime (soil+4%QL);

- soil+4% of fly ash (soil+4%FA);

- soil+2% of fly ash + 2% of quicklime (soil+2%FA+2%QL).

Permeability tests (k test in Table 2-ASTM D5084-10 [31]) were carried out in flexible walls permeameters at 35 kPa of effective confining stress with tap water as permeant fluid. The tests on the treated specimens were carried out for at least 28 days of curing. One-dimensional incremental load consolidation tests (IL oedometric test in Table 2-ASTM D2435-11 [32]) were performed on the specimens compacted at optimum water contents, after 7 days of curing.

Consolidated drained triaxial compression tests (TX test in Table 2-ASTM D7181-11 [33]) and direct shear tests (DS test in Table 2-ASTM D3080-98 [34]) were carried out on specimens obtained by trimming the samples compacted at optimum water content. Shear strength parameters were derived by Mohr–Coulomb peak failure envelopes in drained conditions; these conditions were ensured by applying a low relative horizontal displacement rate (0.0024 mm/min) in the direct shear tests and an axial deformation rate of 0.011%/min in the triaxial tests. The range of effective confining isotropic pressure in the triaxial tests, as well as the vertical effective pressure in the direct shear tests, was 50–250 kPa.

In order to monitor reactions development, both pH measurements of soil–fly-ash–lime slurry and Bender Elements (BE) test on compacted sample (optimum conditions) were carried out.

The slurry was prepared by mixing the two binders (2% by weight each) and then adding them to 20 g of dried soil, then 100 mL of distilled water was added, the slurry was thoroughly mixed for the first hour and then pH was daily measured until 28 days of curing.

The BE Test (ASTM D8295-19 [35]) was carried out in unconfined conditions. The test setup included a function generator (Aim TTI TG5011A) for the input signal (sine pulse, 10 Vpp amplitude), a pair of piezo ceramic sensors (Bender Elements, BE), a wooden sample holder and a digital oscilloscope (Picoscope 6, Pico Technology LTD, Eaton Socon – St. Neots, UK) to receive the signal. The shear wave travel times were computed by a time domain method (Peak-to-peak); signals of several frequencies were applied, ranging from 0.5 kHz to 50 kHz. The first measurement was performed two hours after mixing and compaction of the soil–lime sample and the measurements were repeated on the same sample at increasing curing times across the first 28 days of curing.

Microstructural investigation of treated and untreated samples was performed by FESEMSUPRA40–ZEISS and TESCAN VEGA3 scanning electron microscopes. Treated samples compacted at optimum water content (soil+4%FA and soil+2%FA+2%QL) were observed at the end of the permeability test, after 24 h of air dewatering and subsequent gilding (using the same equipment described in Section 2.1).

3. Results and Discussion

3.1. Compaction Characteristics

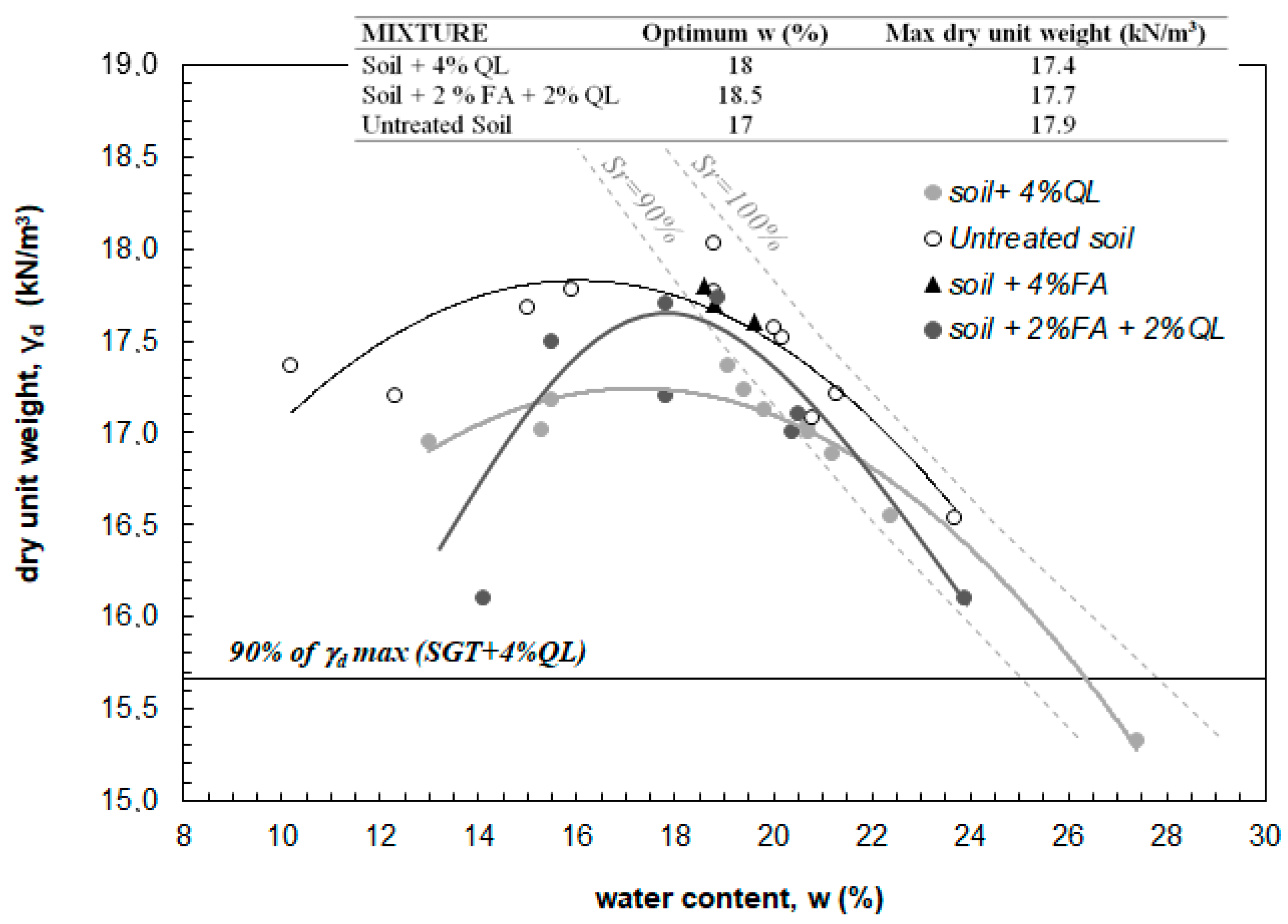

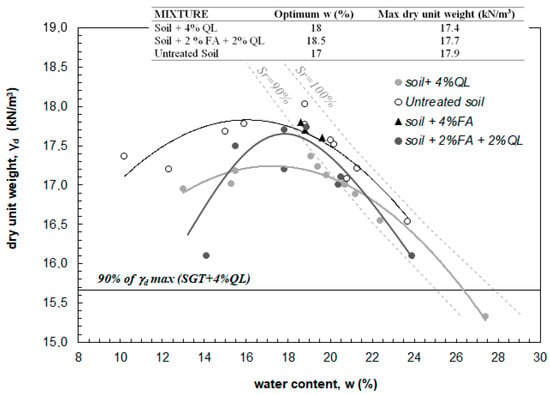

Compaction curves are shown in Figure 3. For both the mixtures of soil+4%QL and soil+2%FA+2%QL, an increase in the optimum water content is observed if compared with the untreated compacted soil. With reference to the maximum dry unit weight, a very slight decrease can be noticed when the combination of binders is added to the soil, while for the soil treated with 4%QL, the maximum dry unit weight was lower than that of the untreated soil.

Figure 3.

Compaction curves of the studied mixtures and of the untreated soil.

The typical flattening of the Proctor curve [36] can be observed for the quicklime treatment but is not noticed for the combined treatment, indirectly showing different effects in modifying the soil fabric after mixing and compaction. Indeed, the flattening of the compaction curve is one of the most interesting effects of soil stabilization because it represents the possibility to obtain high values of dry unit weight (next to the maximum) with a wide range of water contents, thus highlighting a lower dependence of the mechanical characteristics (usually associated to the dry unit weight) on the compaction water content. In order to quantify modifications of the Proctor curve as a result of the treatment, it is possible to calculate a shape factor, F, that takes into account each of the three previously described effects (on the optimum water content, on the dry unit weight, and on the flattening; details and discussion about the factor F can be found in [36]). In particular, the higher the factor, the more significant are the modifications brought about by the binder; in the present study, F = 7 for the 4% lime stabilized soil and F = 4.1 for the soil stabilized with both fly ash and lime. In the former case, the contribution from the flattening sub-factor (Fflat = 5) is higher than in the latter (Fflat = 2.2).

In addition, after mixing with binders, there is a systematic reduction in the water content for all the tested mixtures; in particular, for the soil+2%FA+2%QL mixture, the reduction is on average equal to 2.2 percent points while, for the soil+4%QL mixture, it is equal to 3.6 percent points; this greater reduction is surely related to the higher amount of quicklime in the latter mixture which is, at least, twice that of the combined treatment. Quicklime, undergoing to exothermic hydration mechanism, is capable to reduce the water content to a greater extent (i.e., contribution of evaporation) if its amount in the mixture is doubled.

3.2. Hydraulic Conductivity

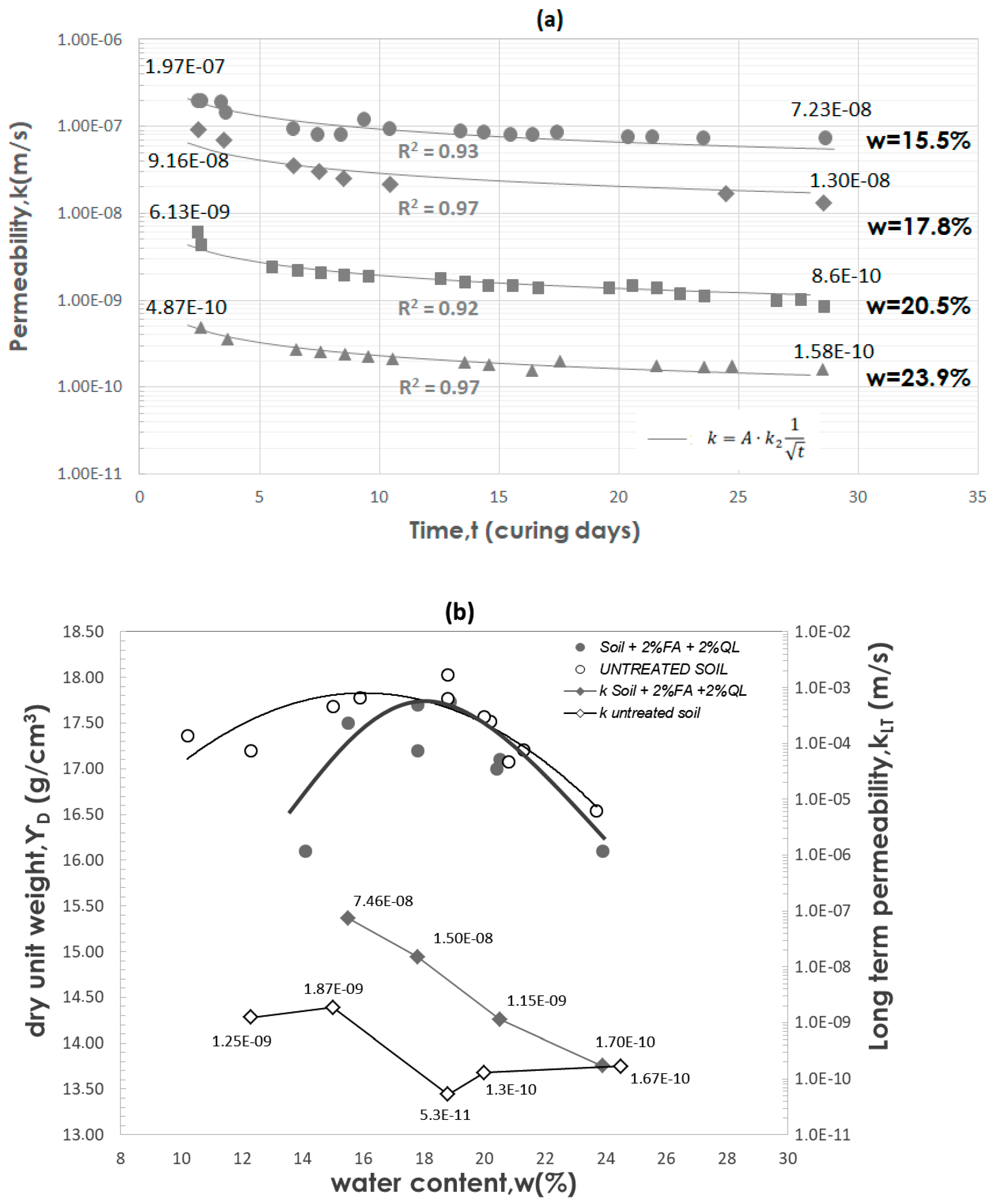

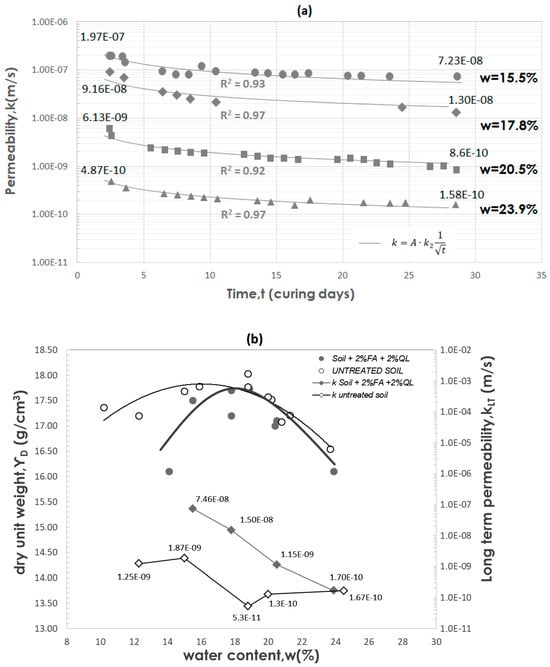

Hydraulic conductivity of the soil+2%FA+2%QL mixture was studied by varying the compaction water contents (Table 2). This factor has a well-known capability to affect permeability of compacted soils or mixtures (e.g., [37,38]). In the present research work, the investigated range of water content is from 15% to 25%. In Figure 4a the trend of permeability values of the mixtures prepared with the combination of the two binders, measured starting from 2 until 28 days of curing, is displayed. Whatever the water content, it is possible to observe a systematic reduction in permeability, k, with curing time, the reduction is within one order of magnitude. In particular:

Figure 4.

Hydraulic conductivity of the soil+2%FA+2%QL mixture varying the water content, w: (a) trend of k with curing time; (b) comparison of long term k values, kLT, with those of the untreated compacted soil, varying the compaction w.

- For the two samples of mixture compacted near optimum (w = 17.8% and w = 20.5%), the long-term permeability is about seven times lower than the initial one (i.e., at 2 days of curing);

- For the sample compacted in dry condition (w = 15.5%), the permeability is more than halved after 28 days of curing;

- For the sample compacted in wet conditions (w = 23.9%), hydraulic conductivity three times lower than the initial one is registered at the end of the test.

The reduction trend is well fitted (R2 = 0.92–0.97, solid lines in Figure 4a) by the power law:

where t is the time variable, k2 is the value of permeability measured at 2 days of curing and A is a numeric coefficient that depends on compaction water content, w. In particular, A = 1 if |w − wopt| ≤ 2, i.e., near optimum conditions and A = 1.5 if |w − wopt| > 2, i.e., dry or wet of optimum conditions. All the permeability values tend to stabilize after the first 20 days of curing.

This decrease in the long term is due to the growth of amorphous pozzolanic products capable of partially filling the inter-aggregate porosity resulting after the flocculation stage, due to the dissociation of the calcium hydroxide and to the subsequent cation exchange reaction (e.g., [1,26]).

By comparing the long term permeability coefficient, kLT, of the soil+2%FA+2%QL mixtures with those measured for the untreated samples, compacted at different w, (Figure 4b) it is possible to state that the addition of the binders causes a general increase in the hydraulic conductivity, especially at optimum compaction conditions (three order of magnitude difference), while the presence of the binders is not affecting permeability values when approaching wet conditions. As for untreated compacted clayey soils [38], the permeability coefficient strongly decreases when increasing the moulding water content. In particular, for the treated soil, a reduction of more than two order of magnitude occurs, shifting from dry to wet conditions, compromising the draining capability of the mixture at high compaction water contents.

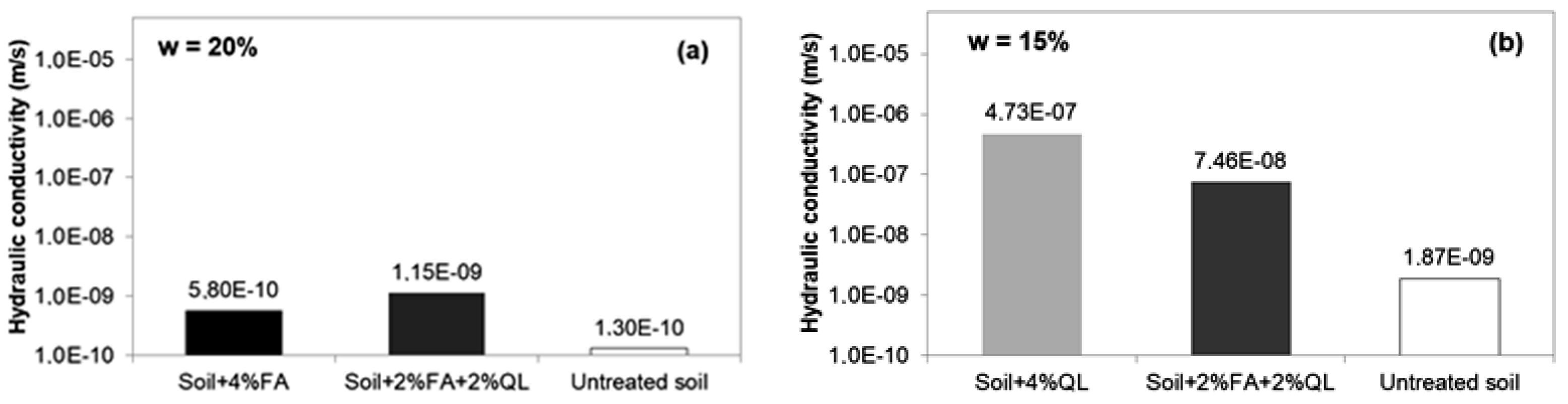

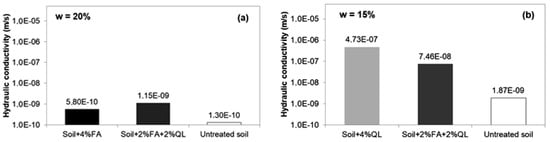

In Figure 5, long term hydraulic conductivity values are displayed in order to compare the effect of different types of binders, with water content being equal. In Figure 5a, the comparison between the treatment with 4%FA and 2%FA+2%QL is displayed: an increase in k is obtained with both of the mixtures but it is more significant when lime is included in the mixture design. Referring to dry conditions (Figure 5b), the treatment with 2% FA+2%QL increases the hydraulic conductivity of the soil to a lesser extent if compared to the 4%QL treatment, that is capable to cause a rise in k values of more than two orders of magnitude. These findings provide further evidence that cation exchange reactions triggered by lime and the consequent aggregation of clayey particles surely plays a key role in increasing k values and, therefore, using lime as an activator of fly ash (instead of other hydroxides) helps to increase draining capability of the earthworks of concern, if desired.

Figure 5.

Long term hydraulic conductivity of the soil+2%FA+2%QL mixture compared with other mixtures, with water content being equal: (a) comparison with soil+4%FA; (b) comparison with soil+4%QL.

As previously said, few results are available in the literature about the permeability of alkali-activated fly ash treatment of soils [8]. Some authors compared the effect on permeability of these amended soils with that of lightweight cement stabilized soil and found, as in the present work, the same typical behaviour of lime stabilized soil: permeability increased and it is 10 times higher than that obtained with cement treatment [39]. Galupino and Dungca [40] studied the hydraulic conductivity of a silty sand treated with different amount of rich calcium fly ash (without activation) and it turned out that permeability is increased within the same order of magnitude when the amount of added fly ash is increased, similarly to the findings of the present work.

3.3. Compressibility

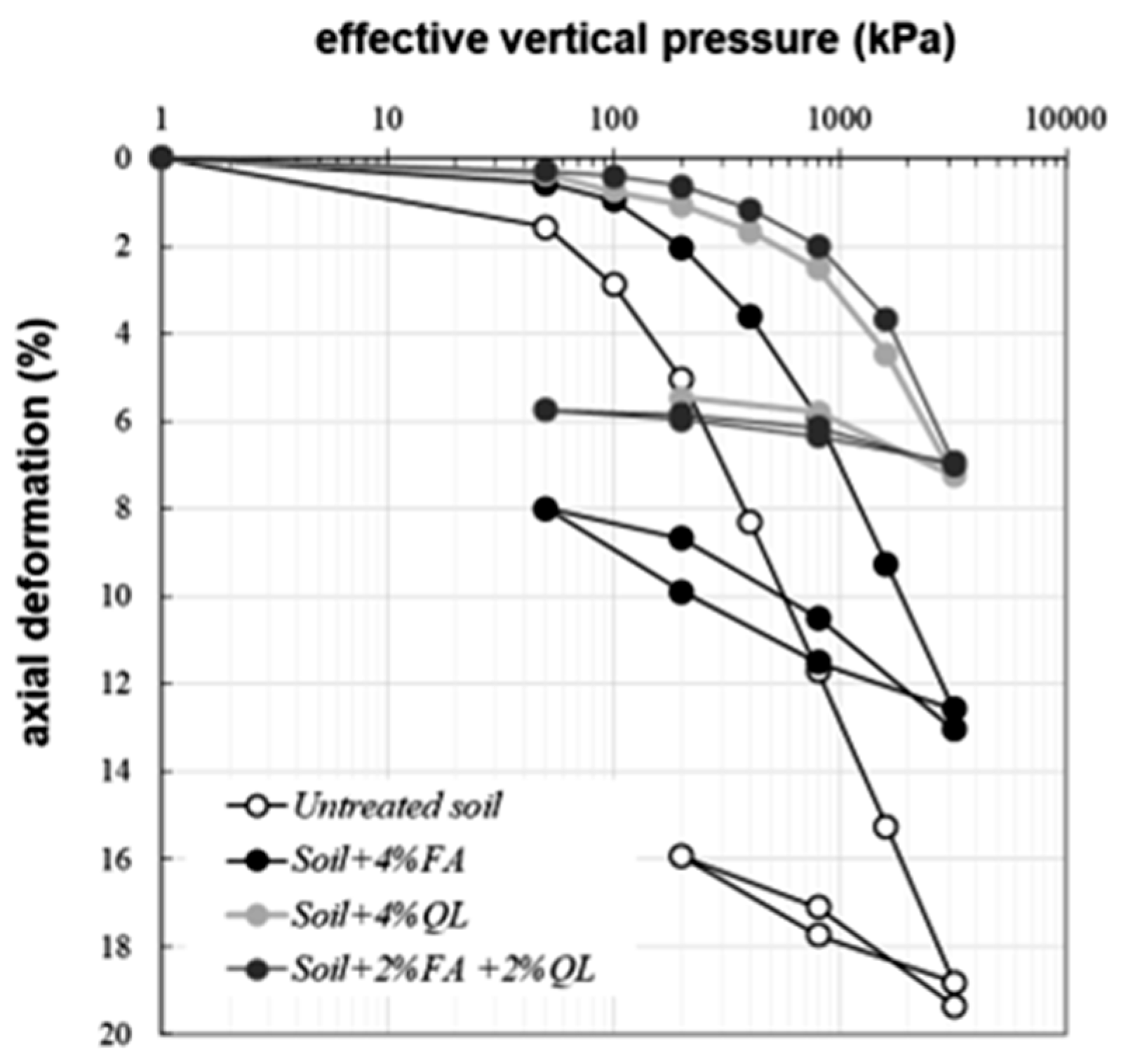

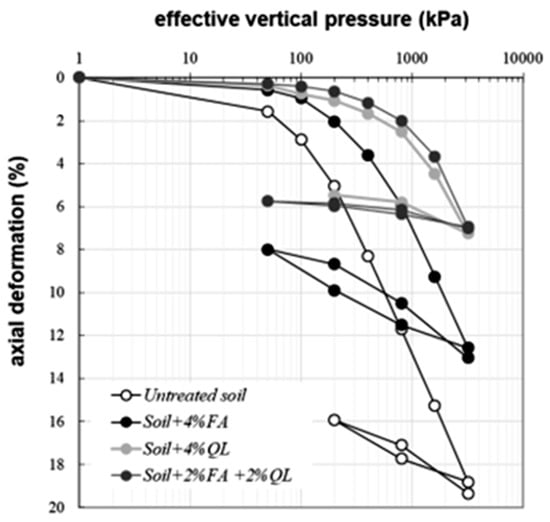

One-dimensional incremental load consolidation tests were carried out after 7 days of curing, applying vertical effective stresses ranging from 50 to 3200 kPa, water content being equal (approximately w = 19%). The compressibility curves are displayed in Figure 6.

Figure 6.

Compressibility curves for the tested mixtures and for the untreated soil, compacted at the corresponding optimum water content.

Compressibility was significantly reduced after treatment, irrespective of the type of binder added. In particular, in the range of 50–100 kPa, the axial deformation is very similar among the investigated mixtures. When approaching higher pressures (until 3200 kPa), the addition of fly ash only is not as effective as the other mixtures in reducing the deformability: this is surely due to the fact that the FA treatment develops cementitious products to a greater extent if alkali activated with hydroxides, acting as strong bases in the soil–binders–water system [30]. Indeed, the combination of FA and QL gave very similar results to those obtained with 4%QL.

Referring to the unloading phase, the swelling for the specimen treated with 4%FA (4.5% of axial deformation) is more than three times higher than that occurring for the specimen treated with the combination 2%FA+2%QL (1.3%). The slope of the unloading-reloading branch for the untreated soil is similar to that of the soil treated with 4%FA, while when lime is present in the mixture, the unloading branch has a very modest slope. This can be well explained by the decrease in the affinity for water caused by the short-term reactions (i.e., cation exchange and subsequent flocculation/aggregation of clay particles due to the reduced double layer thickness) that typically occur between lime and the clay fraction of soil. This finding corroborates the appropriateness of the selection of lime as an activator of the FA in soil stabilization applications instead of other types of hydroxides.

Previous studies found that the compressibility of compacted fly ash–bentonite mixtures decreased significantly after treatment [41]; beside this, historical results showed that low-level additions of lime to the fly ash before compaction accentuate age-hardening limiting of long-term field settlements of earth fills [42]. Mir and Sridharan [43] examined several percentages of fly ash mixed with black cotton soil: compacted samples were cured for 7 and 28 days and tested at 50–800 kPa for consolidation: the findings showed that the compressibility and swelling potential of mixed soils are significantly reduced.

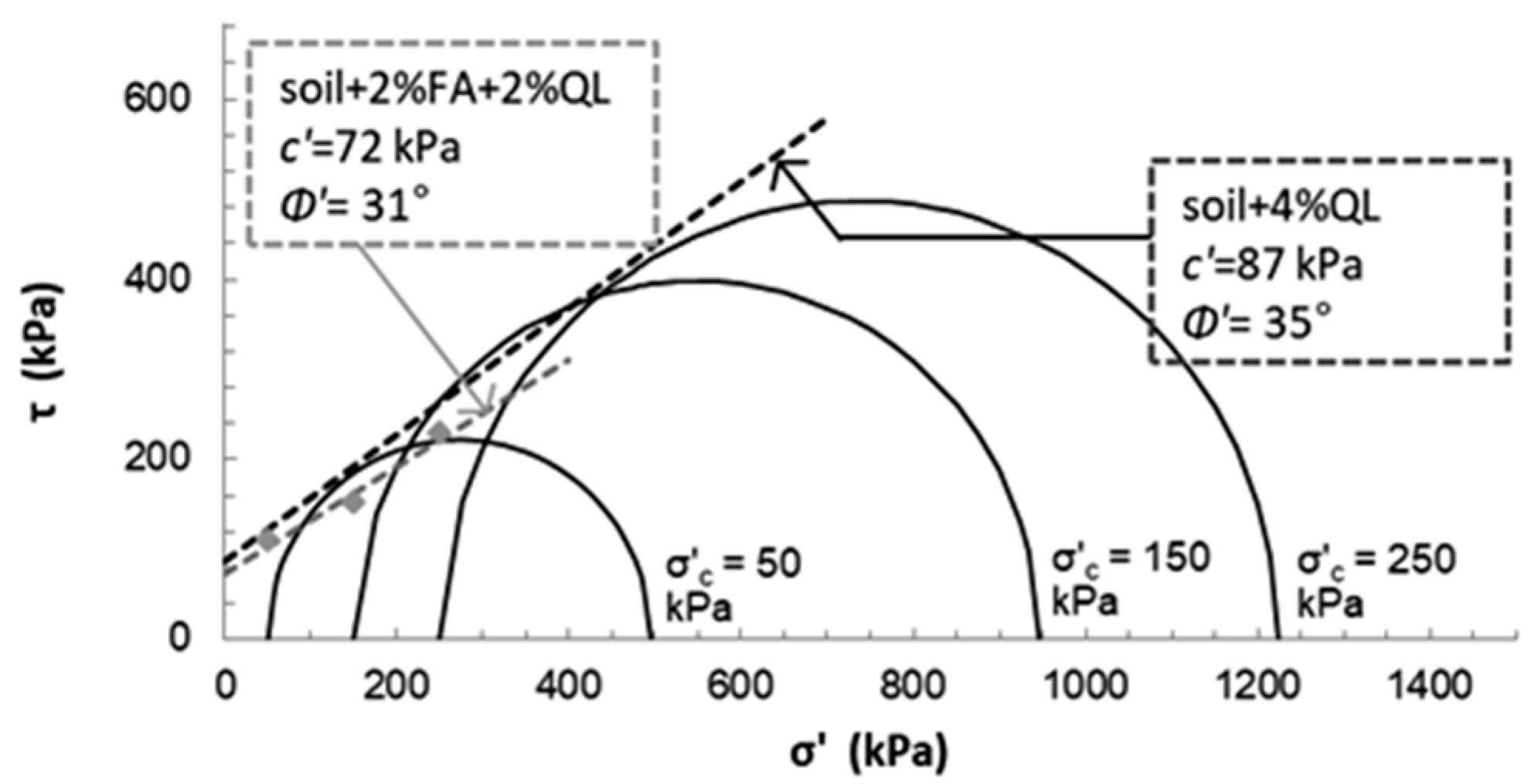

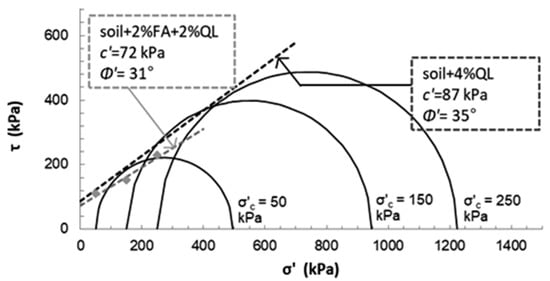

3.4. Shear Strength

The cementation products resulting from the pozzolanic reactions are usually expected to improve the strength of treated soils. In this case, a direct shear test carried out at 7 days of curing on specimens from a compacted sample of soil+2%FA+2%QL showed a peak failure envelope in the Mohr plane (Figure 7) characterized by 72 kPa of cohesion and a shear resistance angle equal to 31° (range of applied effective stress 50–250 kPa). Results of a triaxial compression test carried out on the compacted mixture of soil +4% QL at the same curing time and water content (see Table 2), highlighted a cohesion value of 87 kPa and a peak angle of 35°. Given the peculiar difference in the two different types of tests (triaxial apparatus allows more controlled test conditions), it is possible to state that results obtained for the two mixtures are similar and, therefore, the sustainable use of activated FA+QL instead of the use of QL only is a promising alternative also for improving mechanical behaviour of soils.

Figure 7.

Peak failure envelopes obtained for soil of concern treated with 2%FA+2%QL or with 4%QL.

Unfortunately, the shear strength of soil stabilized with an alkali-activated pozzolanic precursor is rarely addressed but it can be stated that strength properties generally improve after treatment [8]. Researchers found that the compressive strength of soil treated with class F fly ash activated with lime reached more than 1 MPa after 7 days of curing [44] and that of a sulphate-rich soil treated with a combination of fly ash, lime, and sodium silicate is equal to 6 MPa at 30 days of curing [45].

Consoli et al. [46] found an increase in both cohesion and shear resistance angle when treating a sandy soil with FA and lime.

3.5. Monitoring of Reactions Development

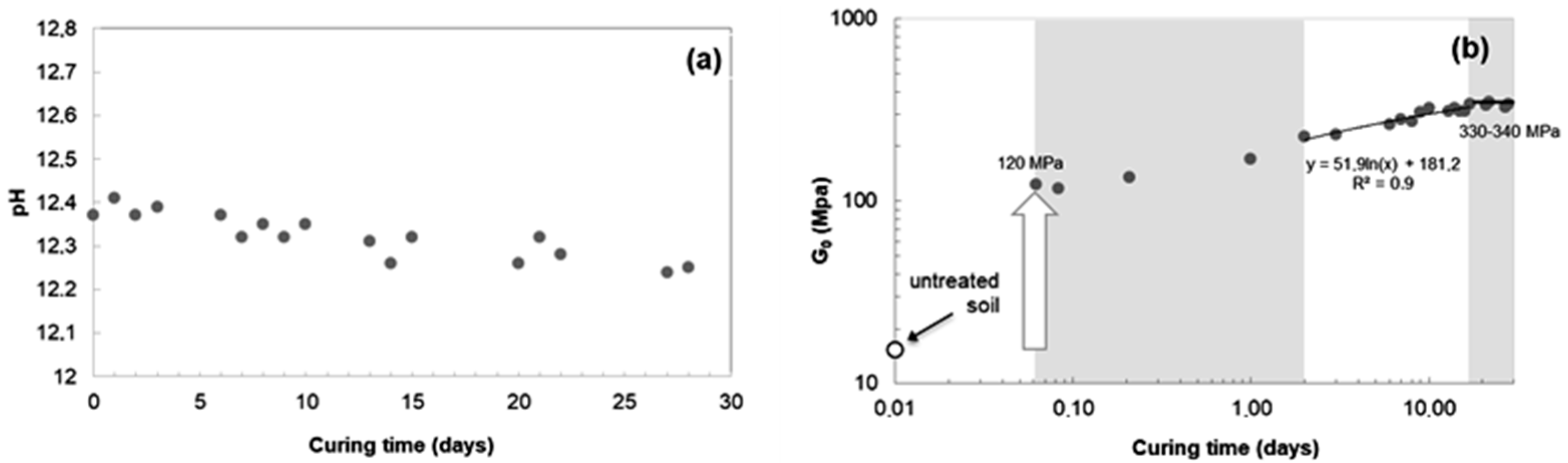

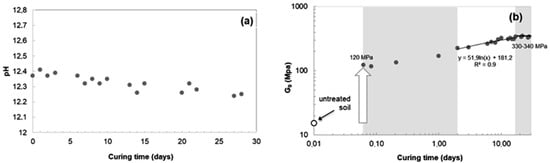

Both pH measurements and BE testing have proved effective in mapping typical stabilization reactions progress over time (e.g., [2,47,48,49]). For the studied mixture, pH was measured until 28 days of curing and BE testing was periodically repeated for the same time span (Figure 8).

Figure 8.

Monitoring of reactions development over time until 28 days of curing. (a) pH values. (b) Small strain shear modulus.

pH values are those typical of soil–lime mixture (Figure 8a), starting from 12.4 after 1 h and slightly but progressively reducing over time after the first 3 days; the global reduction in the long term is due to the development of pozzolanic reactions in which two hydroxyl groups are linked by each calcium ion (supplied by FA or QL) reacting with silica or alumina (from FA or from the clay fraction of the soil). The reduction extent is within 12.4 and 12.2, ensuring, in the investigated time span, the needed alkaline environment to optimize the stabilization capability of FA. pH measured for a mixture of soil, water and 4% of FA showed values reducing from 10 to 8.8 during the same curing period.

Referring to the small strain shear modulus, G0, the value measured for the compacted untreated soil (15.3 MPa) is considered as the initial value. Among the applied frequencies (0.5 kHz to 50 kHz) 40 kHz is the frequency of the transmitted wave that resulted well readable across all the investigated curing period, corresponding to values from two to nine of the ratio between the tip to tip distance and the wavelength, that is the range ensuring a negligible disturbance due to the near field effect (e.g., [50,51]).

As observable by Figure 8b (log-scale), G0 is subjected to a sharp increase, reaching 120 MPa after 2 h since mixing and compaction, then it progressively increased during the first 2 days, reaching 171 MPa after 24 h and 226 MPa after 48 h. From 2 days onwards, results showed a slower but continuous increase in G0, well described by a logarithmic law, until attaining values between 330–340 MPa after 17 days. From 17 to 28 days G0 values remained steady.

The immediate G0 increase can be due to the induced desaturation due to the hydration of calcium oxide (supplied by lime and present also in the FA, Figure 1b) while the significant increase in the first two days corresponds to the rearrangement of clay particles in an aggregated/flocculated structure, mainly due to the presence of lime. Cementation reactions further improve the stiffness over time until 17 days. This trend corroborates the findings in permeability values that increase due to the addition of the binders, decrease during the first 20 days and remain almost steady thereafter (see k trends in Figure 4a). Also, the improvement in compressibility and the good shear strength parameters measured after 7 days of curing fit the timing of reactions described by pH and G0 variations well. The timing of reactions development and the modification of the soil structure is similar to that of soils stabilized by traditional binders (lime or cement), as reported by many researchers (e.g., [52,53]).

3.6. Microstructure

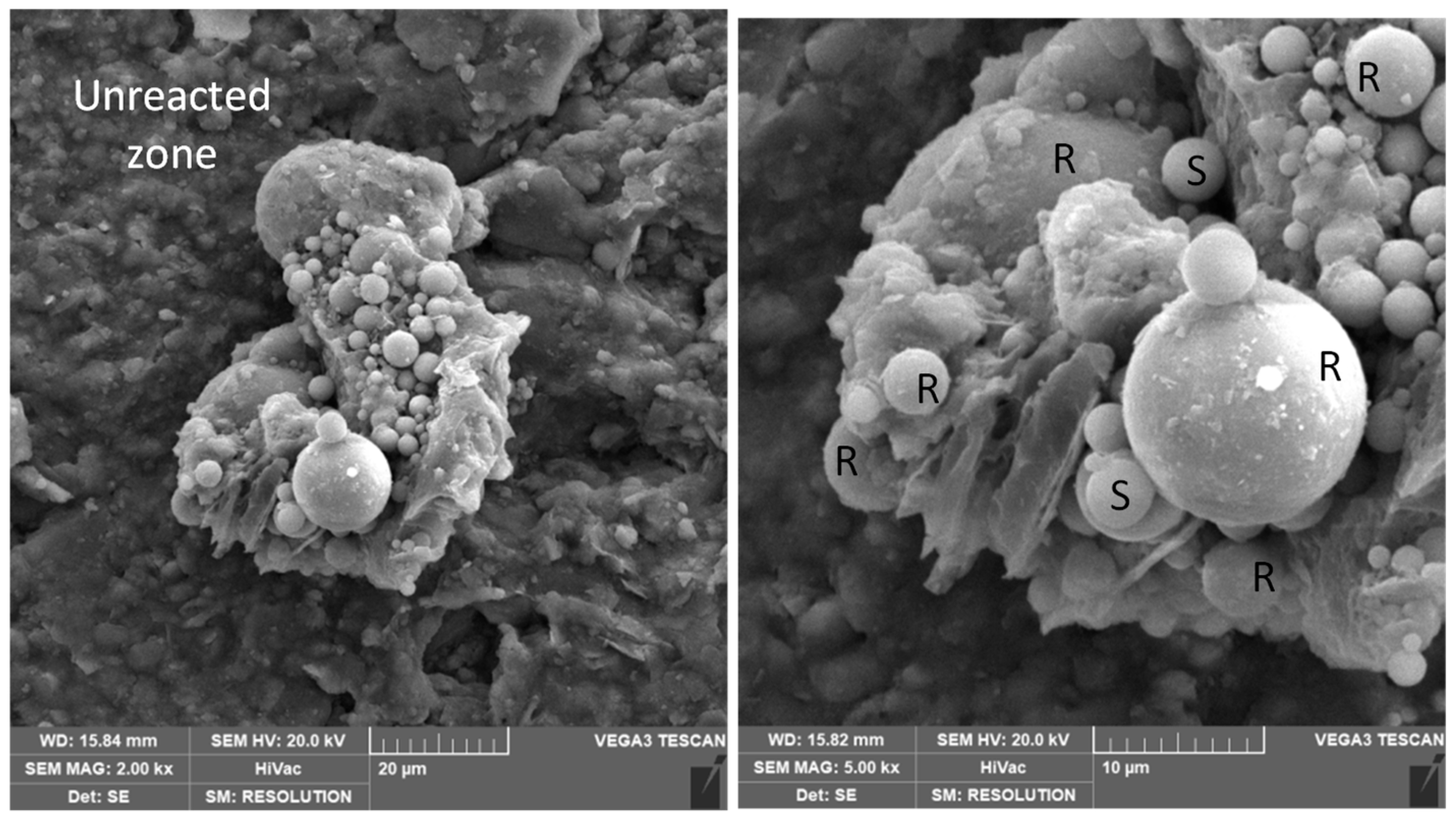

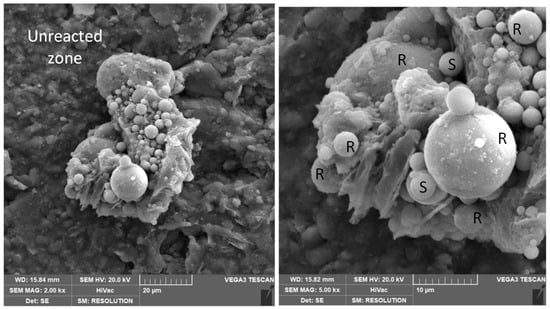

Samples treated with 4% of FA and samples treated with 2%FA+2%QL were observed at SEM and analysed through EDS after the end of the permeability tests.

Unreacted spherical particles constituting FA (Figure 1a) appear with a smooth surface, on the contrary, the rough surface of particles, once reacted, indicates that chemical reactions took place with amorphous pozzolanic products coating FA grains [54,55].

Referring to the sample treated with FA only (Figure 9), round particles with smooth surface (S) as well as some with a rough surface (R) are detected across the observed sample, proving that in this sample, pozzolanic reactions developed to a limited extent, giving rise to a not uniform distribution of reaction products. Anyway, unreacted FA particles, given their silt-size dimension, contribute to the variation of the soil fabric by increasing the packing effect, acting as a filler. Also, unreacted zones (Figure 9), with a fabric similar to that of the untreated soil (Figure 10), are detected.

Figure 9.

SEM images of the soil treated with 4%FA at two magnification levels (2000× and 5000×).

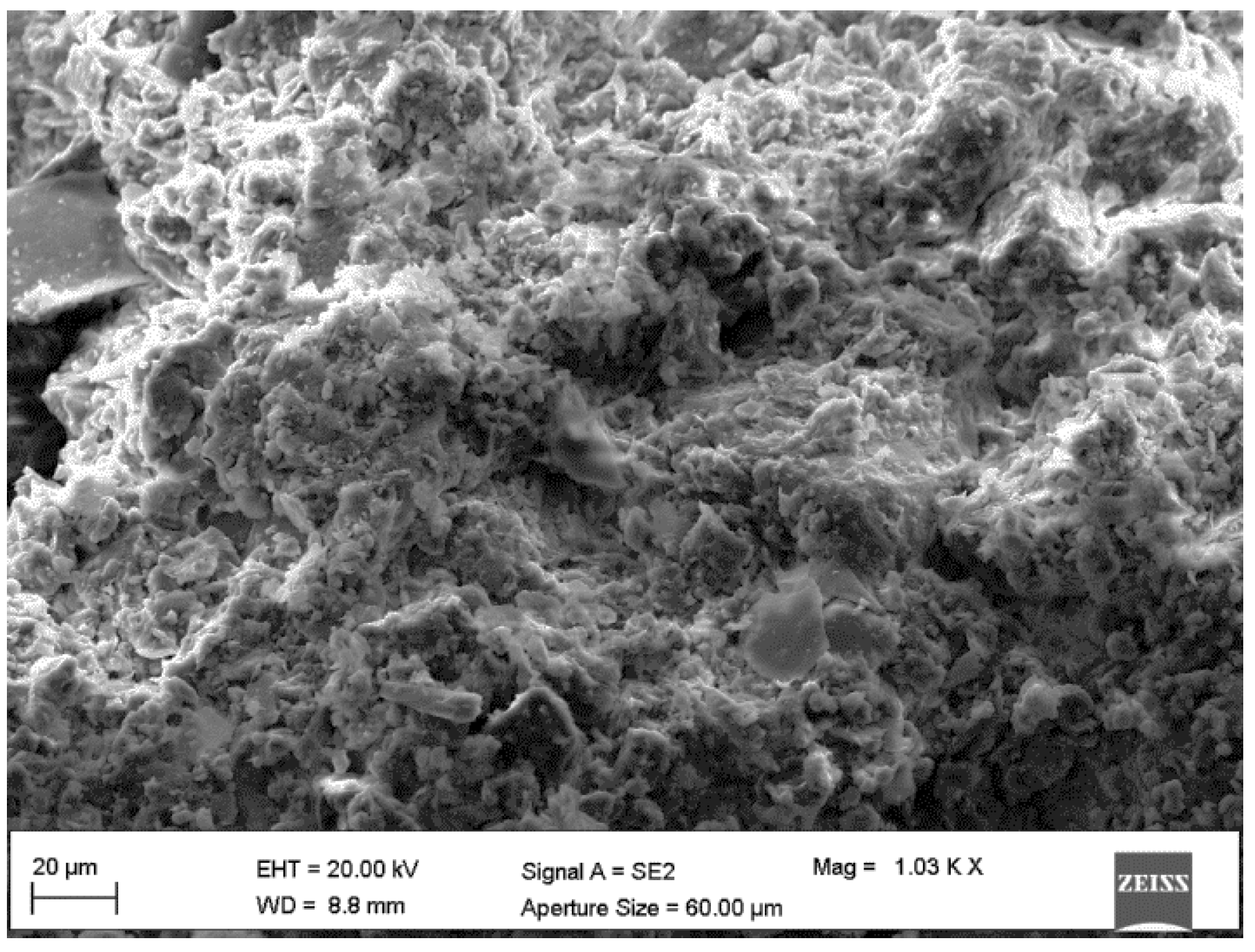

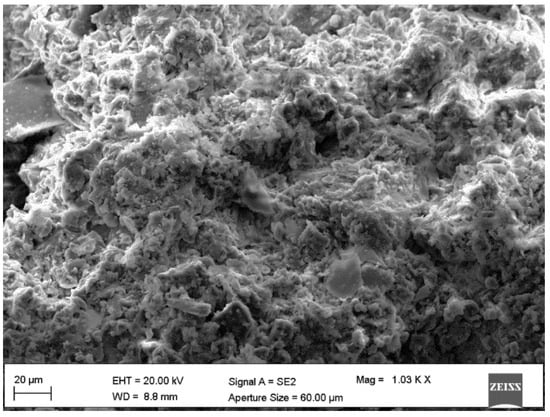

Figure 10.

SEM image of the untreated soil.

The observed morphology matches with that found by Wang et al. [56] for a soil treated with only FA after 14 days of curing and by Cristelo et al. [57] in the first 7 days: they observed a small amount of gel attached to the fly ash surface or forming a fibrous filling in the pore space.

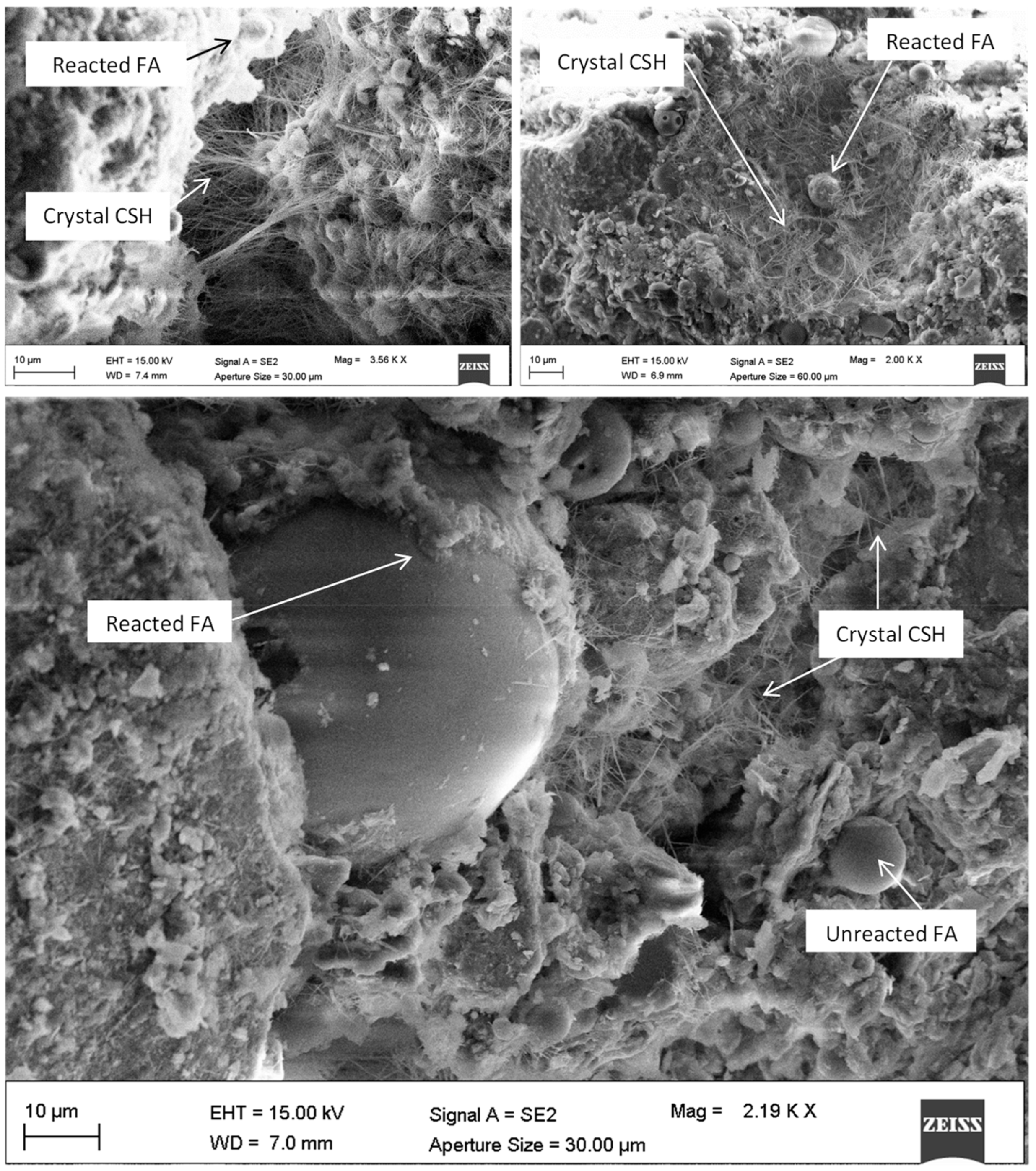

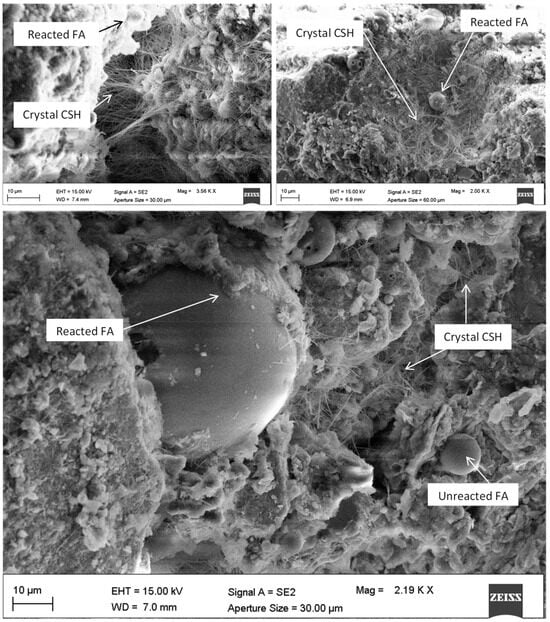

Observing the sample treated with the combination of the two binders (2%FA+2%QL) in Figure 11, it is possible to notice the presence of pozzolanic products occurring twofold: rough spherical reacted particles of FA spreading around the soil grains and needle-like structures, corresponding to C-S-H in crystalline form, typically deriving from the reactions between calcium from lime and the silicates available in the clay fraction of the soil.

Figure 11.

SEM images of the soil treated with 2%FA+2%QL.

Crystal compounds are spread all across the sample, coating, in some zones, the FA particles. Needle like crystal structures reach more than 10 μm in length and are able to physically connect the pore walls from side to side, helping the amorphous products, originating mainly from the FA, in binding the soil grains, thus contributing to improve the mechanical performance of the mixture since the beginning of the reactions and in the long term.

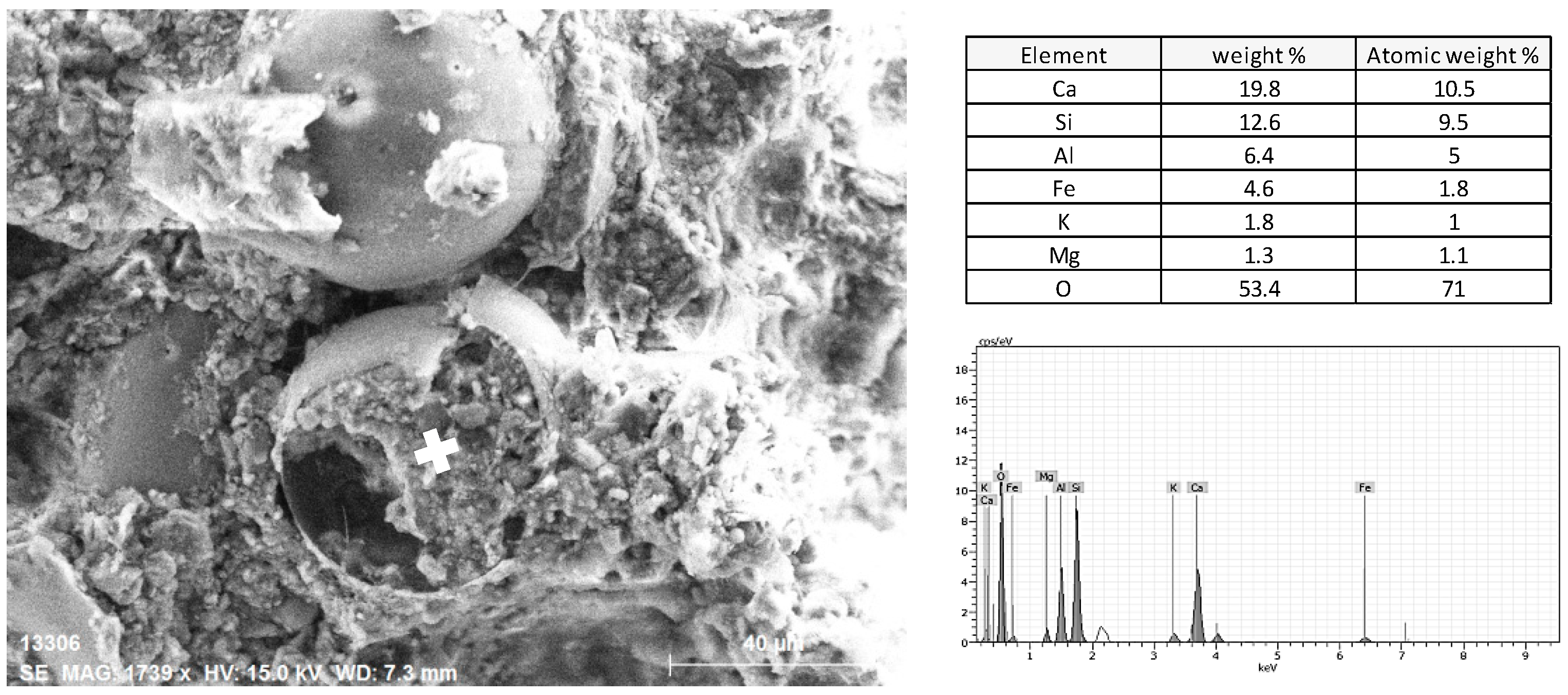

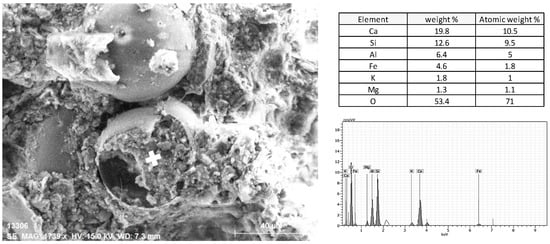

EDS performed on the pozzolanic products in a reacted plerosphere highlights the predominant presence of silicon and calcium (Figure 12). The ratio of the atomic weight between the two amounts Ca/Si can be evaluated for some considerations about the type of CSH, in fact, a Ca/Si ratio below one suggests the presence of amorphous CSH (I), derived from silica-rich pozzolanic dissolution. For EDS data in Figure 12, the ratio Ca/Si is equal to 1.1, suggesting the presence of semi-crystalline or poorly ordered CSH in the spot zone of the performed EDS. The same ratio, computed for EDS on needle-like crystal structures, returns a value of 2.8, far higher than 1 [58].

Figure 12.

EDS performed on pozzolanic products.

4. Conclusions

The present paper investigates the use of fly ash as a binder for the stabilization of a clayey soil by either using it alone (added in 4% by dry weight of soil) or once activated with calcium hydroxide coming from quicklime (2% fly ash + 2% quicklime). The experimental results obtained for the studied compacted mixtures, also compared with the traditional lime stabilization using 4% quicklime, allow to draw the conclusions reported in the following.

The combined use of fly ash and quicklime:

- Allowed to increase the hydraulic conductivity of the soil of concern, especially in the optimum compaction conditions, also if a limited reduction occurred in the long term due to the formation of gel form pozzolanic products; compaction water content significantly affected permeability values;

- Was capable of reducing the compressibility similar to the traditional lime treatment and significantly limited the swelling of the soil when unloaded;

- Is a promising option for the improvement of the mechanical characteristics of the soil, such as the shear strength; also, further investigation is needed to confirm this finding, considering different compaction water contents and also investigating compressive strength properties.

In addition:

- pH and small strain shear modulus measurements are useful to monitor reaction development in the soil–binder–water system because they reflect the improvement of the geotechnical properties and the related timing;

- Modifications in the microstructure observed by SEM help in corroborating the findings of geotechnical tests given that reaction products, both from fly ash and lime, are easily detectable.

The present work offers a contribution to the search for sustainable soil stabilization options by replacing half of the binder amount with a by-product, i.e., fly ash. The activation of the pozzolanic precursor with quicklime adds to the stabilization purpose because, different from other hydroxides, lime is not only capable of creating the needed alkaline environment but also participated in the beneficial flocculation and cementation reactions. Future developments include additional testing of both shear and compressive strength, varying the compaction water content, and considering different curing times.

Author Contributions

Conceptualization, M.D.S.; methodology, M.D.S. and E.F.; validation, E.F. and F.M.; formal analysis, M.D.S. and M.K.K.; investigation, M.K.K. and L.C.; data curation, M.D.S.; writing—original draft preparation, M.D.S.; writing—review and editing, M.K.K., E.F., and F.M.; supervision, M.D.S.; project administration, M.D.S.; funding acquisition, M.D.S. All authors have read and agreed to the published version of the manuscript.

Funding

Project funded under the National Recovery and Resilience Plan (NRRP), Mission 4 Component C2 Investment 1.1-Call for tender No. 104 of 2 February 2022 of Italian Ministry of University and Research funded by the European Union–NextGenerationEU. Award Number: Project code: 2022EFFE52, Concession Decree No. 961 of 30 June 2023 adopted by the Italian Ministry of University and Research. CUP: I53D23001710006. Project title: INnovative and Sustainable Stabilization Processes Involving REcycleD SOils and Used materiaLS–INSSPIRED SOULS.

Data Availability Statement

Data is contained within the article: The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors thank the Italian Ministry of University and Research and the European Union–NextGenerationEU for the funding of the research project and Eng. M. Del Cane for his valuable cooperation in the experimental laboratory activities.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Correction Statement

This article has been republished with a minor correction to the Data Availability Statement. This change does not affect the scientific content of the article.

Abbreviations

The following abbreviations are used in this manuscript:

| FA | Fly Ash |

| QL | Quicklime |

| ICL | Initial Consumption of Lime |

| k | Permeability |

| IL | Incremental Load |

| BE | Bender Elements |

| DS | Direct Shear |

| TX | Triaxial |

| F | Shape Factor for Compaction Curve |

| Fflat | Flattening Sub-Factor |

| γd,max | Dry Unit Weight |

| w | Water Content |

| wopt | Optimum Water Content |

| k2 | Permeability Measured at 2 Days of Curing |

| kLT | Long Term Permeability |

| τ | Shear Stress |

| σ | Normal Stress |

| c’ | Cohesion |

| ϕ’ | Shear Resistance Angle |

| G0 | Small Strain Shear Modulus |

| CSH | Calcium Silicate Hydrates |

References

- Beetham, P.; Dijkstra, T.; Dixon, N.; Fleming, P.; Hutchinson, R.; Bateman, J. Lime stabilisation for earthworks: A UK perspective. Proc. Ins. Civ. Eng.—Ground Improv. 2014, 168, 81–95. [Google Scholar] [CrossRef]

- Di Sante, M.; Fratalocchi, E.; Mazzieri, F.; Pasqualini, E. Time of reaction in a lime treated clayey soil and influence of curing conditions on its microstructure and behaviour. Appl. Clay Sci. 2014, 99, 100–109. [Google Scholar] [CrossRef]

- McCaffrey, R. Climate change and the cement industry. Glob. Cem. Lime Mag. 2002, 15, 1–19. [Google Scholar]

- Forster, A.M.; Válek, J.; Hughes, J.; Pilcher, N. Lime binders for the repair of historic buildings: Considerations for CO2 abatement. J. Clean. Prod. 2020, 252, 119802. [Google Scholar] [CrossRef]

- Ganapathi, H.; Phukan, M. Environmental hazards of limestone mining and adaptive practices for environment management plan. In Environmental Processes and Management: Tools and Practices; Springer: Cham, Switzerland, 2020; pp. 121–134. [Google Scholar]

- Devi, K.; Chhachhia, A.; Kumar, A. Soil Improvement using waste materials: A review. J. Build. Mat. Sci. 2020, 2, 11–17. [Google Scholar] [CrossRef]

- Jing, X.; Wu, S.; Qin, J.; Li, X.; Liu, X.; Zhang, Y.; Mao, J.; Nie, W. Multiscale mechanical characterizations of ultrafine tailings mixed with incineration slag. Front. Earth Sci. 2023, 11, 1123529. [Google Scholar] [CrossRef]

- Huang, J.; Kogbara, R.B.; Hariharan, N.; Masad, E.A.; Little, D.N. A state-of-the-art review of polymers used in soil stabilization. Constr. Build. Mater. 2021, 305, 124685. [Google Scholar] [CrossRef]

- Fujikawa, T.; Sato, K.; Koga, C. Long-term durability and environmental safety of slurry type of coal ash mixed material. Environ. Geotech. 2023, 10, 102–111. [Google Scholar] [CrossRef]

- Najafi, E.K.; Arabani, M.; Jamshidi Chenari, R. Clay–fly ash geopolymer characterisation and application for the removal of lead and zinc. Environ. Geotech. 2021, 10, 32–43. [Google Scholar] [CrossRef]

- Gollakota, A.R.K.; Volli, V.; Shu, C.M. Progressive utilisation prospects of coal fly ash: A review. Sci. Total Environ. 2019, 672, 951–989. [Google Scholar] [CrossRef]

- Noaman, M.F.; Khan, M.A.; Ali, K.; Hassan, A. A review on the effect of fly ash on the geotechnical properties and stability of soil. Clean. Mater. 2022, 6, 100151. [Google Scholar] [CrossRef]

- Khadka, S.D.; Jayawickrama, P.W.; Senadheera, S. Strength and shrink/swell behavior of highly plastic clay treated with geopolymer. Transp. Res. Rec. 2018, 2672, 174–184. [Google Scholar] [CrossRef]

- Palomo, A.; Krivenko, P.; Garcia-Lodeiro, I.; Kavalerova, E.; Maltseva, O.; Fernández-Jiménez, A. A review on alkaline activation: New analytical perspectives. Mater. Constr. 2014, 64, e022. [Google Scholar] [CrossRef]

- Kampala, A.; Horpibulsuk, S. Engineering properties of silty clay stabilized with calcium carbide residue. J. Mater. Civ. Eng. 2013, 25, 632–644. [Google Scholar] [CrossRef]

- Mashifana, T.P.; Okonta, F.N.; Ntuli, F. Geotechnical Properties and Microstructure of lime-fly ash-phosphogypsum-stabilized soil. Adv. Civ. Eng. 2018, 2018, 3640868. [Google Scholar] [CrossRef]

- Islam, M.S.; Islam, T.; Khatun, N. Permeability Alteration of Low Plastic Clay and Poorly Graded Sand Using Lime and Fly Ash. Indian Geotech. J. 2021, 51, 967–978. [Google Scholar] [CrossRef]

- UNI EN 14227-11; Miscele Legate con Leganti Idraulici–Specifiche—Parte 11: Terra Trattata Con Calce. Ente Italiano di Normazione: Rome, Italy, 2006.

- ASTM C977-18; Standard Specification for Quicklime and Hydrated Lime for Soil Stabilization. ASTM International: West Conshohocken, PA, USA, 2018.

- UNI EN 459-1; Calci da Costruzione—Parte 1: Definizioni, Specifiche e Criteri di Conformità. Ente Italiano di Normazione: Rome, Italy, 2015.

- Dwivedi, A.; Jain, M.K. Fly ash—Waste management and overview: A Review. Rec. Res. Sci. Tech. 2014, 6, 30–35. [Google Scholar]

- ASTM D2216-19; Standard Test Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass. ASTM International: West Conshohocken, PA, USA, 2019.

- Fratalocchi, E.; Bellezza, I.; Di Sante, M.; Pasqualini, E. Mix-design, construction and controls of lime stabilized embankments. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering, Alexandria, Egypt, 5–9 October 2009; Volume 3, pp. 2248–2251. [Google Scholar]

- ASTM D698-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM International: West Conshohocken, PA, USA, 2012; (updated 2021).

- Anday, M.C. Curing Lime Stabilized Soils; Highway Research Record National Research Council: Washington, DC, USA, 1963; pp. 13–26. [Google Scholar]

- Wild, S.; Arabi, M.; Rowlands, G.O. Relation between pore size distribution, permeability and cementitious gel formation in cured clay-lime systems. Mat. Sci. Technol. 1987, 3, 1005–1011. [Google Scholar] [CrossRef]

- Al-Mukhtar, M.; Lasledj, A.; Alcover, J.F. Behaviour and mineralogy changes in lime treated expansive soil at 20 °C. Appl. Clay Sci. 2010, 50, 191–198. [Google Scholar] [CrossRef]

- Al-Mukhtar, M.; Lasledj, A.; Alcover, J.F. Behaviour and mineralogy changes in lime treated expansive soil at 50 °C. Appl. Clay Sci. 2010, 50, 199–203. [Google Scholar] [CrossRef]

- Toohey, N.M.; Mooney, M.A.; Bearce, R.G. Stress-Strain-Strength Behavior of Lime-Stabilized Soils during Accelerated Curing. J. Mat. Civ. Eng. 2012, 25, 1880–1886. [Google Scholar] [CrossRef]

- Costa, L.T.; Vitale, E.; Cappelletti, P.; Graziano, S.F.; Rispoli, C.; Russo, G. Alkaline activation of volcanic ash as binder for soil improvement. In Proceedings of the 8th Italian Conference of Researchers in Geotechnical Engineering, Turin, Italy, 4–6 July 2023; Springer: Cham, Switzerland, 2023; pp. 792–799. [Google Scholar]

- ASTM D5084-10; Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D2435M-11; Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM D7181-11; Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM D3080-98; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 1998.

- ASTM D8295-19; Standard Test Method for Determination of Shear Wave Velocity and Initial Shear Modulus in Soil Specimens Using Bender Elements. ASTM International: West Conshohocken, PA, USA, 2019.

- Di Sante, M. On the Compaction Characteristics of Soil-Lime Mixtures. Geotech. Geol. Eng. 2020, 38, 2335–2344. [Google Scholar] [CrossRef]

- Di Sante, M.; Fratalocchi, E.; Mazzieri, F. Effects of Variation in Compaction Water Content on Geotechnical Properties of Lime-treated Clayey Soil. Procedia Eng. 2016, 158, 63–68. [Google Scholar] [CrossRef]

- Daniel, D.E.; Benson, C.H. Water content—Density criteria for compacted soil liners. J. Geotech. Eng. 1991, 116, 1811–1831. [Google Scholar] [CrossRef]

- Du, Y.J.; Yu, B.W.; Liu, K.; Jiang, N.J.; Liu, M.D. Physical, hydraulic, and mechanical properties of clayey soil stabilized by lightweight alkali-activated slag geopolymer. J. Mater. Civ. Eng. 2017, 29, 04016217-1–04016217-10. [Google Scholar] [CrossRef]

- Galupino, E.J.G.; Dungca, J.R. Permeability characteristics of soil-fly ash mix. ARPN J. Eng. Appl. Sci. 2015, 10, 6440–6447. [Google Scholar]

- Wasil, M. Compressibility of Fly Ash and Fly Ash-Bentonite Mixtures. Balt. J. Road Bridge Eng. 2022, 17, 21–43. [Google Scholar] [CrossRef]

- Gray, D.H.; Lin, Y.K. Engineering Properties of Compacted Fly Ash. J. Soil. Mech. Found. Div. 1972, 98, 361–380. [Google Scholar] [CrossRef]

- Mir, B.A.; Sridharan, A. Volume change behavior of clayey soil-fly ash mixtures. Int. J. Geotech. Eng. 2014, 8, 72–83. [Google Scholar] [CrossRef]

- Rivera, J.F.; Ororbio, A.; Cristelo, N.; Mejia de Gutierres, R. Fly-ash based geopolymers as A4 type soil stabilizer. Transp. Geotech. 2020, 25, 100409. [Google Scholar] [CrossRef]

- Lv, Q.; Jiang, B.; Ma, B.; Zhao, B.; Huo, Z. A study on the effect of the salt content on the solidification of sulphate saline soil solidified with an alkali-activated geopolymer. Constr. Build. Mater. 2018, 176, 68–74. [Google Scholar] [CrossRef]

- Consoli, N.C.; Prietto, P.D.M.; Carraro, J.A.H.; Heineck, K.S. Behavior of compacted soil-fly ash-carbide lime mixtures. J. Geotech. Geoenviron. Eng. 2001, 127, 774–782. [Google Scholar] [CrossRef]

- Di Sante, M.; Bernardo, D.; Bellezza, I.; Fratalocchi, E.; Mazzieri, F. Linking small-strain stiffness to development of chemical reactions in lime-treated soils. Transp. Geotech. 2022, 34, 100742. [Google Scholar] [CrossRef]

- Rao, S.M.; Shivananda, P. Role of curing temperature in progress of lime–soil reactions. Geotech. Geol. Eng. 2005, 23, 79–85. [Google Scholar] [CrossRef]

- Consoli, N.C.; Fonseca, A.V.D.; Silva, S.R.; Cruz, R.C.; Fonini, A. Parameters controlling stiffness and strength of artificially cemented soils. Geotechnique 2012, 62, 177–183. [Google Scholar] [CrossRef]

- Arroyo, M.; Muir Wood, D.; Greening, P.D. Source near-field effects and pulse tests in soil samples. Géotechnique 2003, 53, 337–345. [Google Scholar] [CrossRef]

- Arulnathan, R.; Boulanger, R.W.; Riemer, M.F. Analysis of bender element tests. ASTM Geotech. Test. J. 1998, 21, 120–131. [Google Scholar] [CrossRef]

- Tang, A.M.; Vu, M.N.; Cui, Y.J. Effects of the maximum soil aggregates size and cyclic wetting-drying on the stiffness of a lime-treated clayey soil. Géotechnique 2011, 61, 421–429. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, Y.J.; Benahmed, N.; Tang, A.M.; Duc, M. Changes of small strain shear modulus and suction for a lime-treated silt during curing. Géotechnique 2020, 70, 276–280. [Google Scholar] [CrossRef]

- Fraay, A.L.A.; Bijen, J.M.; de Haan, Y.N. The reaction of fly Ash in concrete. A critical Examination. Cem. Concr. Res. 1989, 19, 235–246. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on microstructure of blended cement paste. Constr. Build. Mater. 2007, 21, 1534–1541. [Google Scholar] [CrossRef]

- Wang, H.; Liu, T.; Yan, C.; Wang, J. Expansive Soil Stabilization Using Alkali-Activated Fly Ash. Processes 2023, 11, 1550. [Google Scholar] [CrossRef]

- Cristelo, N.; Glendinning, S.; Miranda, T.; Oliveira, D.; Silva, R. Soil stabilization using alkaline activation of fly ash for self-compacting rammed earth construction. Construct. Build. Mater. 2012, 36, 727–735. [Google Scholar] [CrossRef]

- Richardson, I.G. The calcium silicate hydrates. Cem. Concr. Res. 2008, 38, 137–158. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).