1. Introduction

Due to the numerous problems associated with the construction of foundations over problematic soils (considering their high compressibility and volumetric change through swelling, as well as collapsibility potential, low shear strength, etc.), the necessity for soil stabilization and improvement in its geotechnical characteristics has arisen with a focus on the reuse of materials that are considered unsuitable for geotechnical construction purposes. Soil stabilization is generally very effective in cases with challenging soils in civil engineering construction projects, such as infrastructure, embankments, foundations, etc., providing adequate geotechnical properties to deficient natural soils. Soil stabilization can be achieved through the application of different cementitious, non-cementitious, and chemical binders, such as the increasingly widely employed lime and cement, leading to an increase in adverse environmental effects such as the emission of CO

2. For soil stabilization, the application of locally available waste materials, i.e., both natural and industrial secondary by-products, is of great interest in efforts to eliminate their deposition in landfills. Different waste materials, such as industrial by-products and natural pozzolans, are under continuous research as alternative low-carbonate material additives to the traditionally used Portland cement and hydraulic natural lime in geotechnical engineering projects. Examples of alternative materials are fly ash [

1,

2,

3], rice husk ash, silica fume, cement kiln dust (CKD) [

4], ground granulated blast furnace slag (GGBFS) [

5,

6], etc.

Numerous case studies on foundation problems on expansive soils have been reported worldwide [

7,

8,

9]. These soils tend to experience volumetric changes related to their composition of expansive clay minerals or water content variations that can result in either swelling or shrinkage. In general, water content changes originating from seasonal rainfall variations, local site leakages, etc., can cause significant hazards in geotechnical engineering projects. Expansive soils are traditionally stabilized using lime, which is an economically viable additive, although researchers have indicated its limitations in terms of the introduction of chemical additives such as NaCl, KCl, MgCl

2, CaCl

2, etc., which is considered economically unjustifiable [

10]. For this reason, alternative waste materials, such as industry by-products and natural pozzolans like fly ash [

10,

11,

12,

13,

14], bagasse ash [

15], CKD [

16,

17,

18,

19], GGBFS [

20], wood ash [

21], etc., are proposed for the stabilization of expansive soils.

In this study, the application of volcanic ash (VA) is considered, due to its increasing availability worldwide. In general, the application of VA as a natural material for soil stabilization has not yet gained extensive international acceptance, despite its wide availability. VA is part of the pyroclastic material group and is associated with volcanic activity. The magma from the interior of the Earth rises to the crust, where it seeks a way to the surface through fissures, ultimately rising and forming a chimney-shaped structure. Once such a chimney is active, it expels magma in the form of lava and a pyroclastic material, combined with gases. The ejected pyroclastic materials have different granulometries, varying between fine dust and metric fragments. VA comes from this material, with the characteristic that its particle grain size is less than 2 mm (sand size) [

22]. VA is very diverse in terms of its composition, because the magma from which it comes can be acidic magma or basic magma; therefore, characterization of pyroclastic material is necessary prior to its application. In general, over 0.84% of the world’s land surface is covered with VA deposits, making it an easily accessible material. An extensive review of its chemical and mineral composition, physical properties, different applications as a binder material, etc., was conducted in [

23].

The application of VA for soil stabilization has been performed by different authors, confirming its influence on the enhancement of different geotechnical parameters. The stabilization of clay material of both low (CL) and high (CH) plasticity was studied [

24] under different dosages and combinations of VA, cement, and natural lime, using uniaxial compressive tests (UCS) under different curing times, the CBR test, and durability tests to study the influence of water immersion. The stabilization of CL using different dosages and combinations of VA and CKD was attempted to determine its influence on UCS, CBR, and durability tests, as well as to study the influence of water immersion on UCS, water absorption by capillarity, and the linear shrinkage of specimens [

25]. The stabilization of CH with VA through the addition of lime for the enhancement in pozzolanic activity to study its influence on CBR was shown in [

26]. Sandy soil was stabilized using VA and GGBFS for the improvement of UCS in [

27]. CL stabilization using VA alkali activated by NaOH under different curing conditions to determine UCS was described in [

28]. CL stabilization using three different types of VA to define UCS under different curing conditions was described in [

29]. CL stabilized using a combination of VA and alkali-activated GGBS to study UCS under different curing times and durability tests (freezing–thawing (FT) and drying–wetting (DW)) was demonstrated in [

30]. CL stabilized using different dosages of VA alkali activated by NaOH to study its influence on UCS under different curing conditions and resistance parameters by direct shear tests was described in [

31].

In this study, VA, which is abundantly available after the Tajogaite volcano activity of 2021 at La Palma Island, Canary Island, Spain, was applied [

32]. The dispersal of VA during the eruption of Tajogaite in 2021 provided additional available material that could be recovered for different innovative applications, including geotechnical construction, thereby avoiding its deposition in landfills. This VA was previously studied to evaluate its environmental impact and its potential for reuse in the production of zeolitic material [

33], as an alkali-activated binder [

34], as a Portland cement constituent [

32,

35], and for the evaluation of its chemical, mineralogical, and geotechnical properties under static conditions [

36]

In this work, the stabilization of the natural clayey gypsum soil, containing the highly expansive clay mineral smectite, from the south-east region of Spain was studied. Its characteristics in a remolded state were compared to those obtained by the addition of different binders, such as VA, hydraulic natural lime, and ordinary Portland cement. The identification criteria for the swelling potential characterization comprised both indirect, physical and mineralogical properties, as well as direct properties, assessed by the measurement of free swelling in oedometer tests. Different criteria for expansive soil characterization are described in the literature, e.g., free swell, heave potential, degree of expansiveness, etc. [

7,

37,

38,

39]. The analysis of the resistance parameters by direct shear test was also performed on naturally remolded clay and soil mixture specimens that provided suitable reductions in the swelling potential.

2. Materials and Test Methods

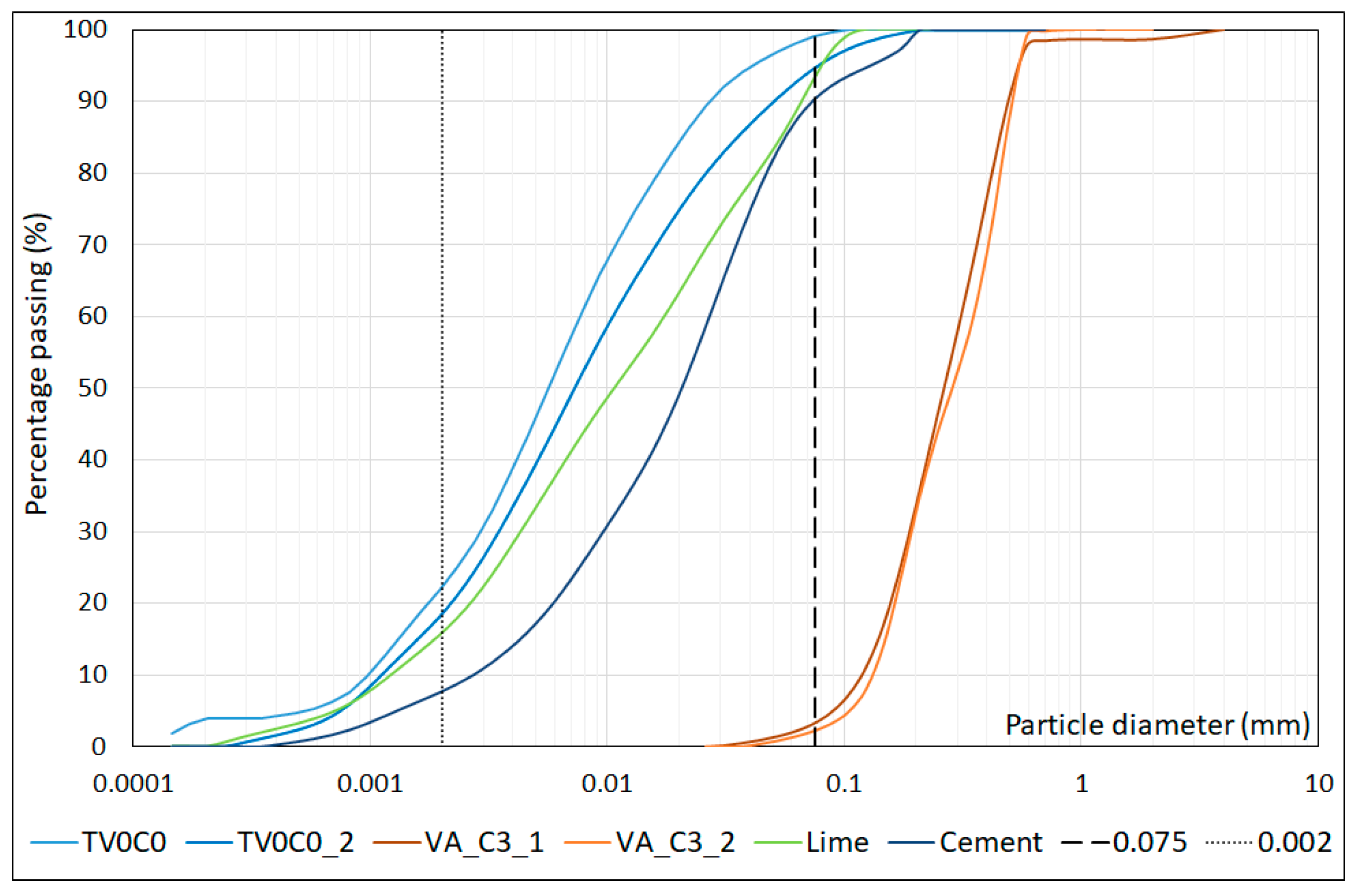

The soil used throughout this study was the clay of the Murcia (Spain) region, obtained from the excavation of a tunnel for road construction. This material was oven dried to establish its physical, chemical and geotechnical characteristics. The following tests were performed to define the natural clay material: mineralogical and chemical characterization by X-ray diffraction (XRD) [

40], X-ray fluorescence (XRF) [

41], Oriented Aggregates (AO) (see

Section 3.1); sieve and laser analysis to determine grain size distribution curve (as described in [

42,

43], see

Section 3.3); plasticity parameters (as described in [

44], see

Section 3.4); specific gravity test of soil solids (as described in [

45], see

Section 3.5); modified Proctor test for compaction analysis (as described in [

46], see

Section 3.6); consolidation test (as described in [

47], see

Section 3.7); and direct shear test (as described in [

48], see

Section 3.8).

The VA used in this study as a binder for the stabilization and improvement of the geotechnical properties of swelling clays was obtained from La Palma Island, Canary Islands, Spain, during the last days of the Tajogaite eruption in 2021 [

36]. In general, VA materials have lower reactivity than other mineral additives, such as fly ash, granulated blast furnace slag, metakaolin. Thus, VA is usually alkaline activated by the addition of NaOH or KOH, and additives such as GGBFS, burnt lime, metakaolin, kaolinite, etc. [

23]. In this case, the addition of lime was considered for activation, although other additives could have been applied as well.

Besides VA, the traditionally used lime and cement were also added as a binder to this natural clay to compare their effects. The lime used in this study was natural hydraulic lime, and the cement was commercial Portland cement; both were characterized by XRD and XRF (see

Section 3.1).

The performed tests on the studied raw materials and soil mixtures are summarized in

Table 1, as are the applied standards for each test. The characterization of the VA used in this study, denominated as VA-C3, is described in detail in [

36].

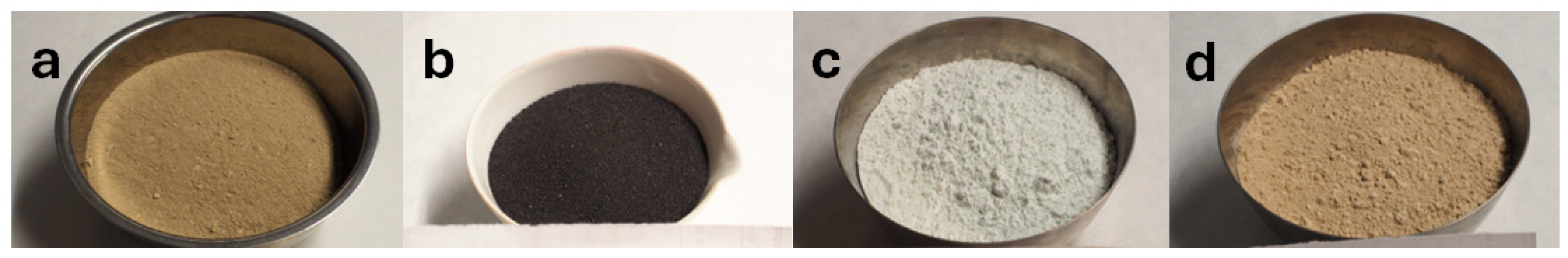

Table 2 summarizes the nomenclature of the samples used in the laboratory tests, that are further used throughout this paper due to its simplicity: T for soil, V for volcanic ash, C for lime, and CEM for cement. The percentage of additives indicated is with respect to the dry weight of the sample. It should be noted that the samples that contained VA (TV10C5, TV20C5, TV30C5) also had added lime (abbreviation C) to enhance the VA’s pozzolanic activity; in such cases, a small amount of lime was added, i.e., 5% C with respect to the dry VA weight as opposed to the total dry weight of the sample, such as for the samples that only contained lime (TV0C1, TV0C3, TV0C5) or cement (TV0CEM1, TV0CEM3). Images of the raw materials are shown in

Figure 1.

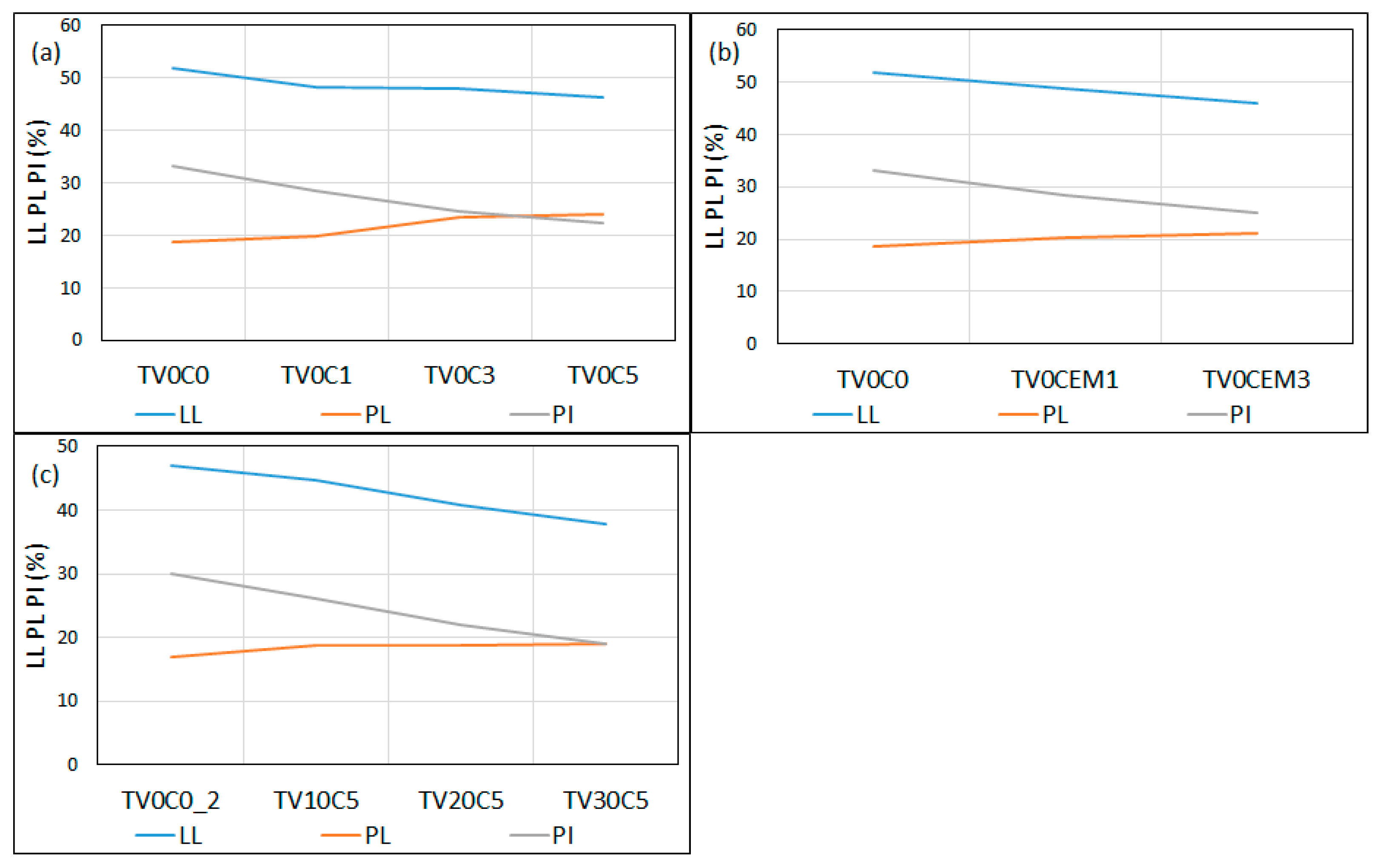

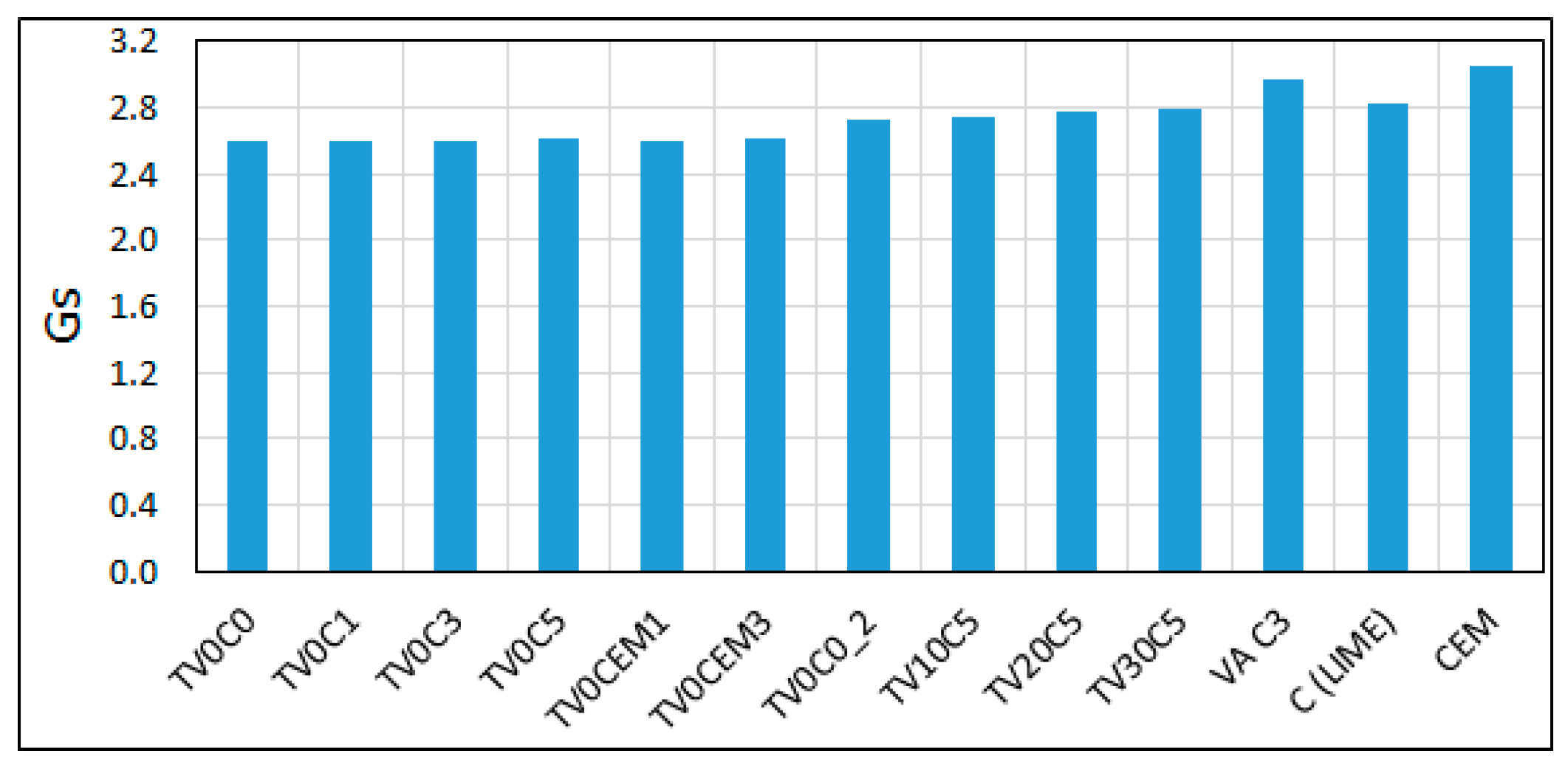

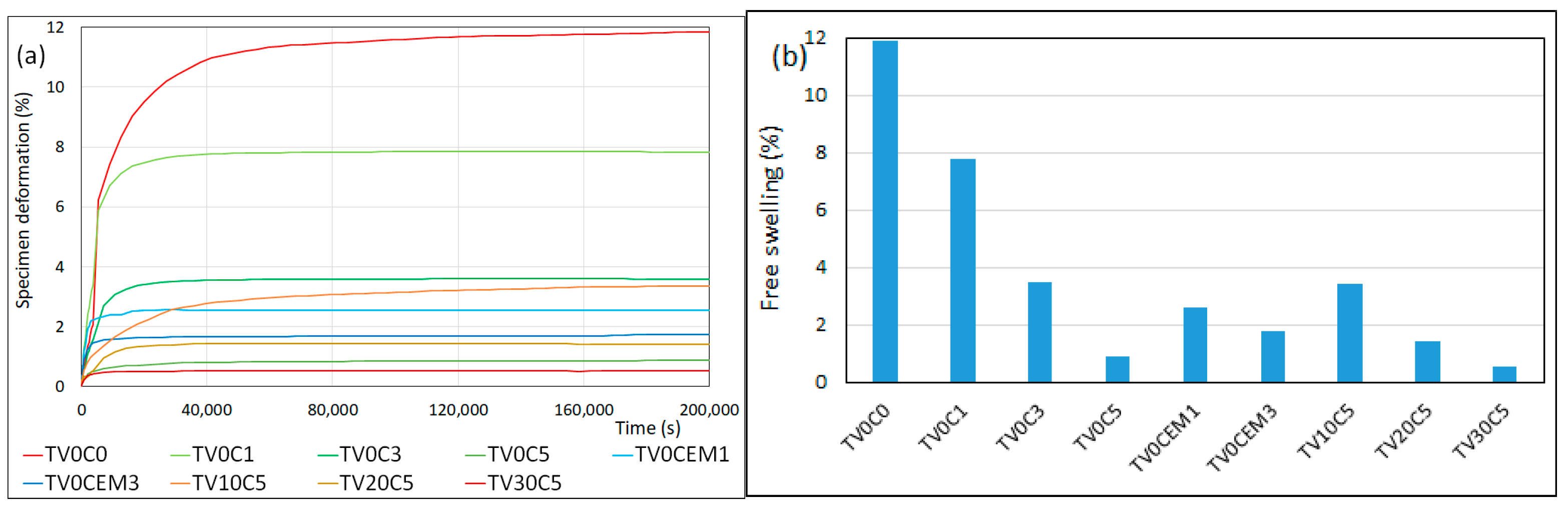

According to the Unified Soil Classification System [

49], the natural soil used in this study could be is classified as high plasticity clay (CH), according to plasticity parameters, i.e., for TV0C0 and TV0C0-2, the values obtained for the liquid limit (LL), plastic limit (PL), and plasticity index (PI), corresponded to 51 and 47%, 18%, and 33 and 29, respectively (see Figure 5). Once remolded, the natural clayey soil was classified as inadequate for further reuse in construction engineering according to the Spanish Standard PG-3 classification [

50] based on the following characteristics: free swelling up to 12%; gypsum content greater than 3%; approximately 95% of the material was silt/clay size; and the liquid limit (LL) and the plasticity index (PI) were >50% and >30, respectively. For these reasons, it was decided to stabilize it by the addition of different binders to improve its geotechnical characteristics for possible reuse. Additionally, according to the activity index (AI = PI/%clay) of TV0C0 as defined in [

51], i.e., ranging from 1.3 to 1.8, it was also defined as high expansive clayey soil being AI > 1.25.

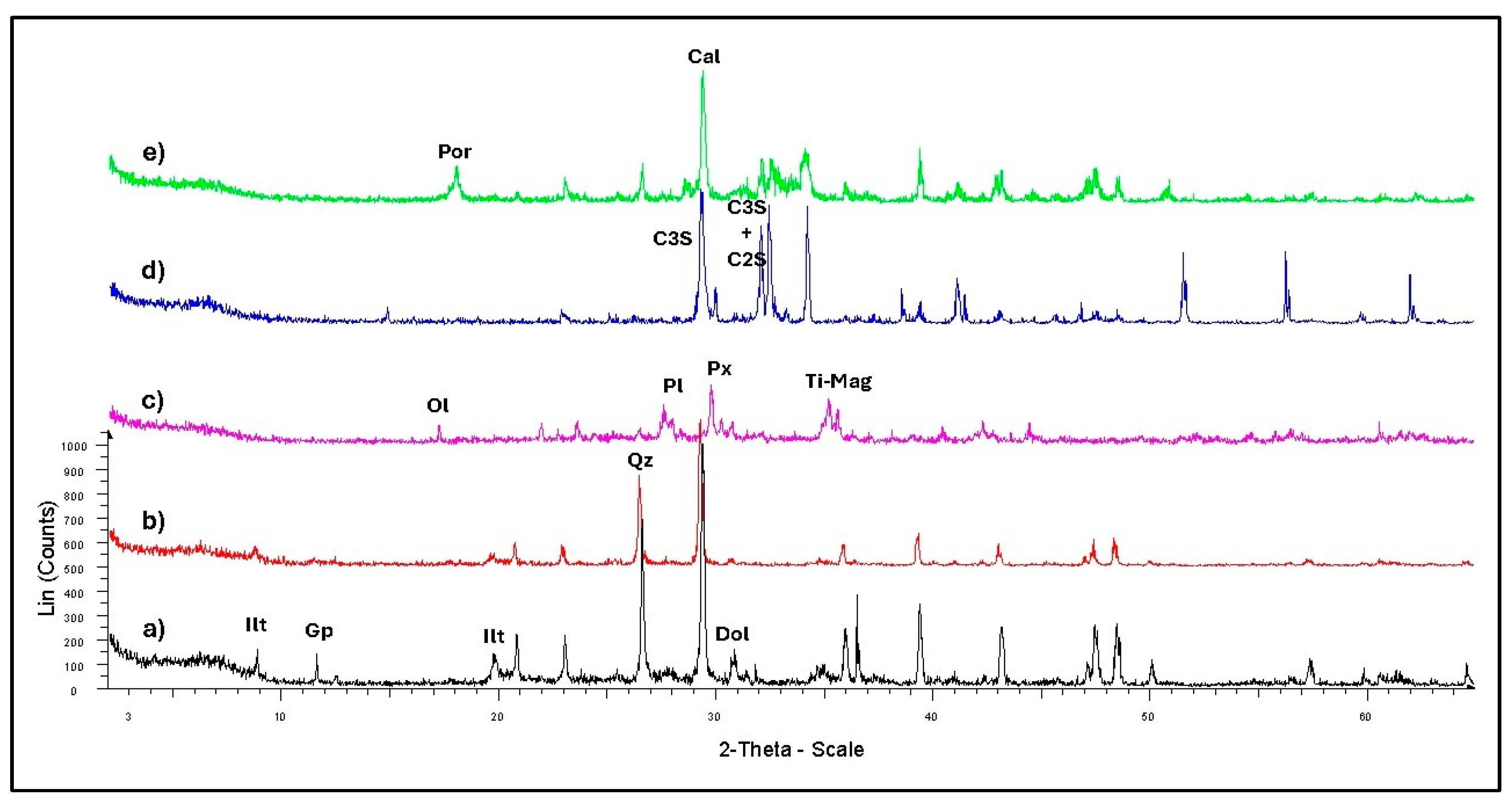

The mineralogical and chemical composition of the natural soil, VA, lime and cement were determined through X-ray diffraction (XRD) by the disoriented polycrystalline powder method and X-ray fluorescence (XRF), respectively. Diffractograms were obtained using a BRUKER D8 Advance diffractometer using CuKα radiation, in an angular range of 2θ from 10 to 60°, with a step size of 0.02° and a time per step of 1s. The diagrams were interpreted with the EVA DIFFRACplus 13.0 software by comparison with the PDF2 (Powder Diffraction File) database of the International Center for Diffraction Data. Chemical analyses were carried out using a BRUKER S2 Ranger for major and minor elements, expressed as % by weight (wt %) of oxides. “Loss On Ignition” (LOI) was previously determined for the fitting of the chemical analysis.

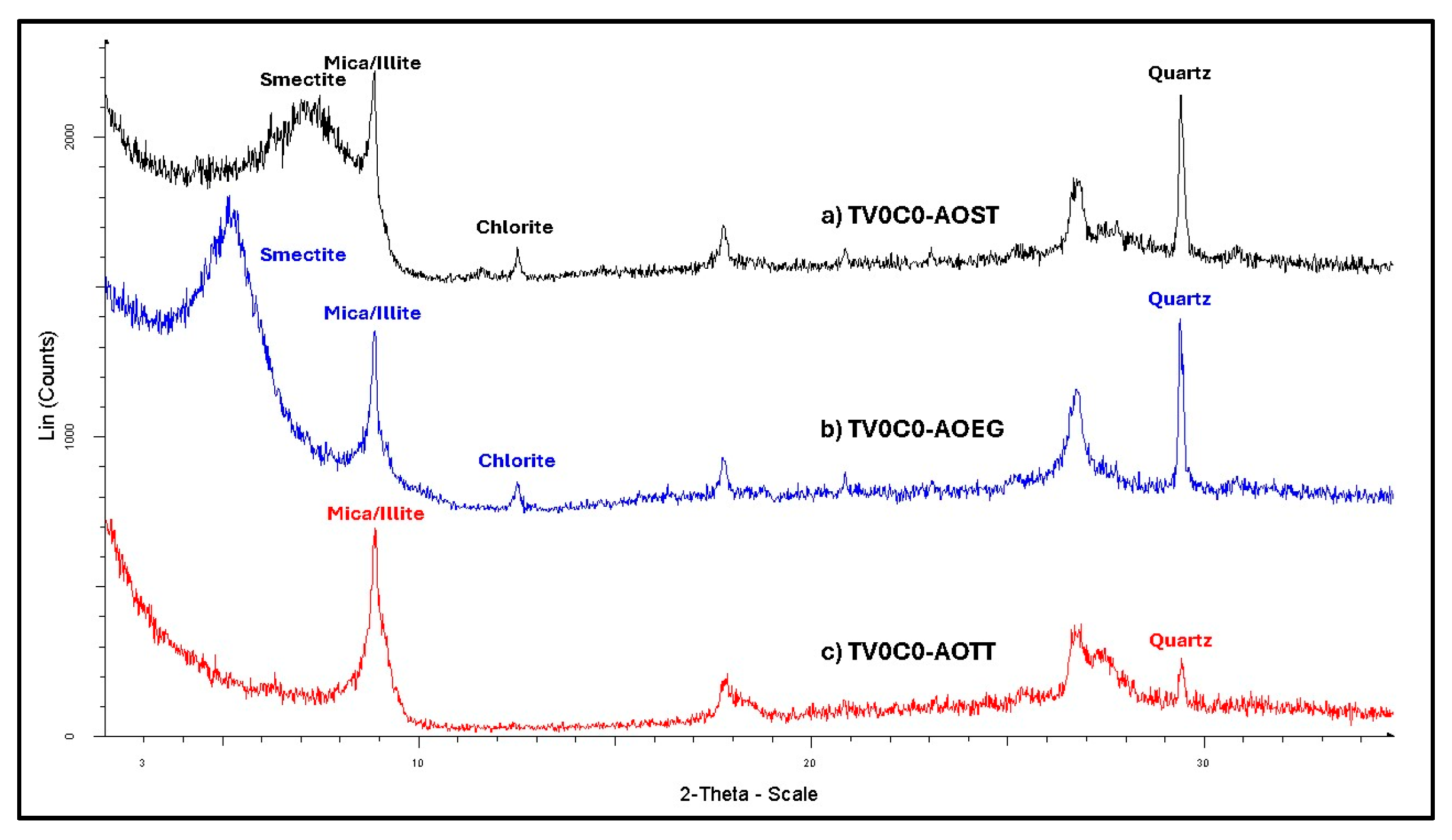

The XRD and XRF results are summarized in

Table 3 and Table 5. In the natural remolded clay sample (TV0C0), considering its high content of phyllosilicates in the crystalline phase (see

Table 3), the identification of these based on AO (oriented aggregates), using the method described in [

52], was necessary. The AO patterns are represented in Figure 3 and the quantification of clay minerals in

Table 4.

The soil mixture specimen preparation comprised thorough manual mixing of the dry materials, i.e., both soil and additives, until a uniform color was observed, before water addition and further mixing for 10 minutes [

53]. The soil mixtures were placed in plastic bags for the next 45 minutes as rest time prior to molding for tests, such as Atterberg limits, compaction, oedometer and direct shear tests.

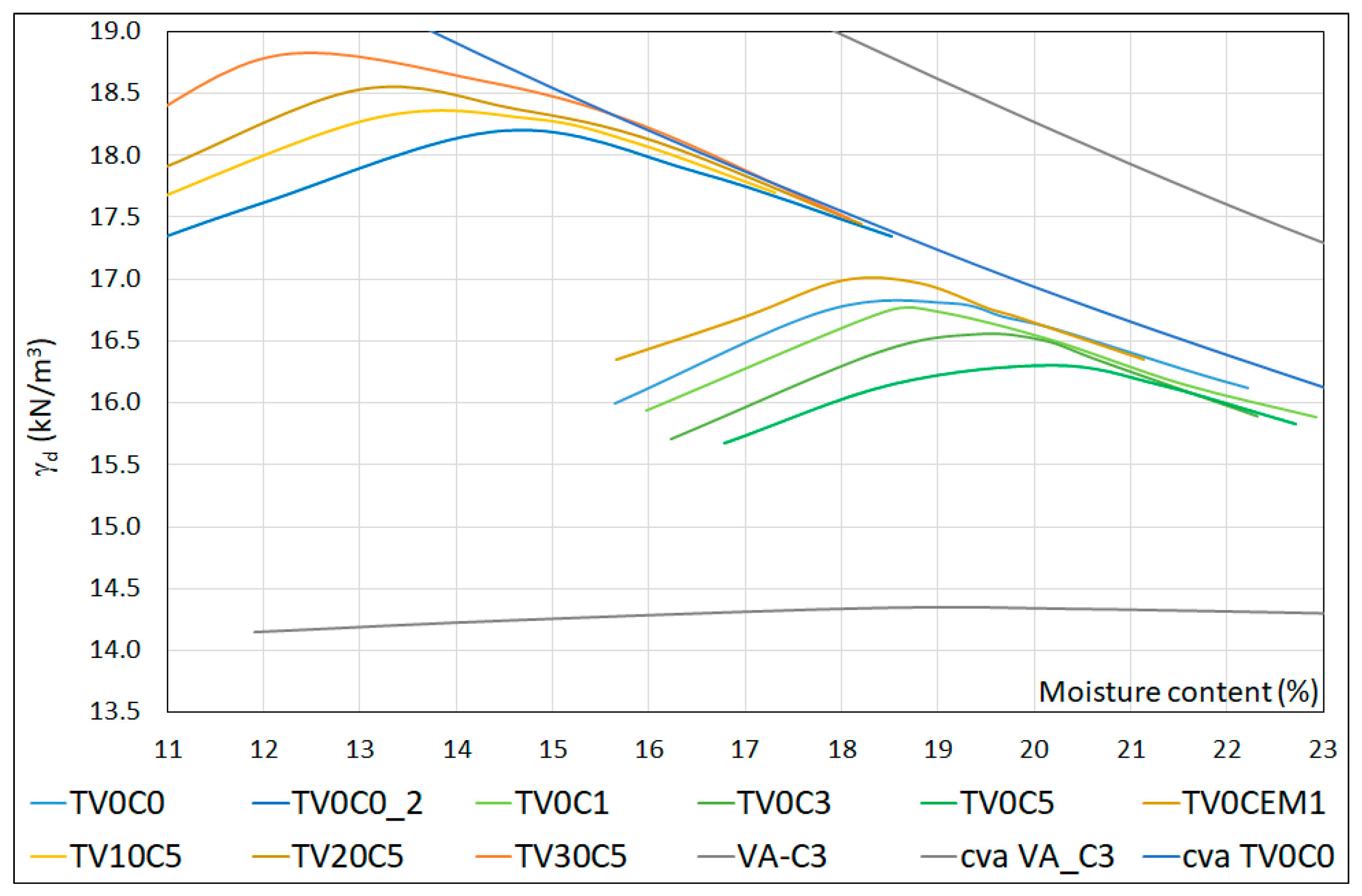

The compaction tests were performed under modified energy [

46] to determine the conditions of compaction regarding the optimum moisture content and dry specific unit weight of the naturally remolded clay and different mixtures of the natural clay with binders. For this test, a soil sample with a specific moisture content was compacted in five layers in a standard mold with a standard weight under modified effort. The test was repeated for different moisture contents for each soil mixture, to determine the correlation between unit dry weight and moisture content.

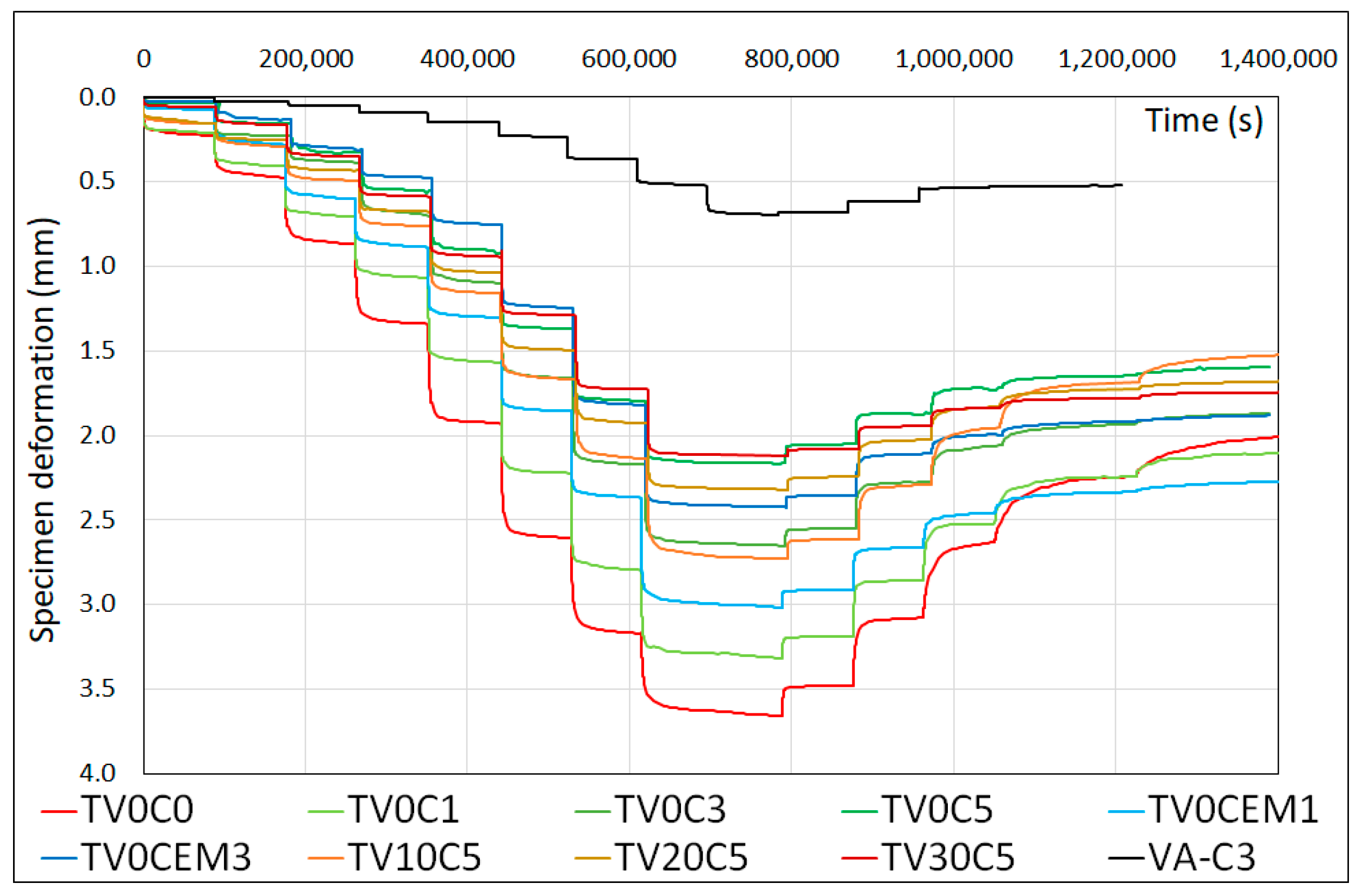

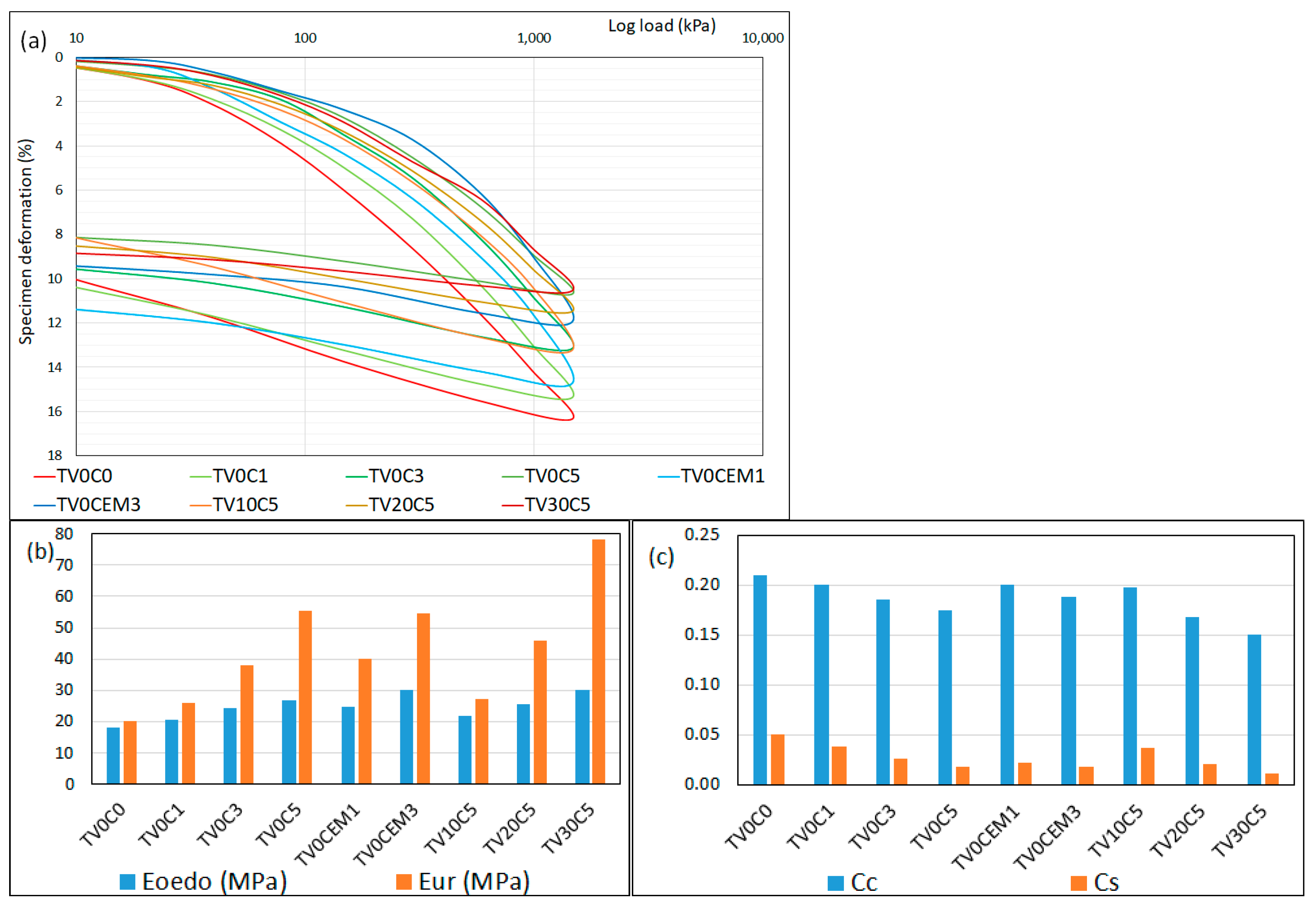

The oedometer tests were performed, using the method described in [

47], on the soil mixture specimens in a circular mold with a 70 mm internal diameter and 20 mm height. The soil mixture specimens for the oedometer analysis were compacted in the consolidometer ring in three layers under the same compaction energy as the one obtained in the compaction test on the natural remolded clay soil to obtain comparable values for the moisture content and specific unit dry weight for all samples. The specimens were installed between porous stones to permit drainage on both sides of the specimen, before being inundated with distilled water. The free swelling of all specimens was determined at the beginning of the test. Constant values were reached after approximately 3 days. After this, the conventional oedometer test was performed under gradual loading and unloading stages (loading steps under vertical compressive load at 20, 40, 80, 150, 300, 600, 1000, and 1500 kPa, and unloading steps at 600, 150, 40, 10 and 5 kPa). The loading stages were each maintained for 24 h, except the maximum loading and the final two unloading stages, which were maintained for 48 h. The free swelling, sample deformation, and deformational modulus were determined to compare the influence of different binders. A consolidation analysis of VA-C3 is presented in [

36], i.e., material poured in a dry state into a consolidometer ring mold through a funnel to simulate a loose state, before being inundated prior to the application of different constant vertical loads until consolidation concluded (considered load stages 10, 20, 40, 80, 150, 300, 600, 1000, and 1500 kPa every 24 h), and unloading, which took place in four stages (1000, 300, 40, and 10 kPa, every 24 h).

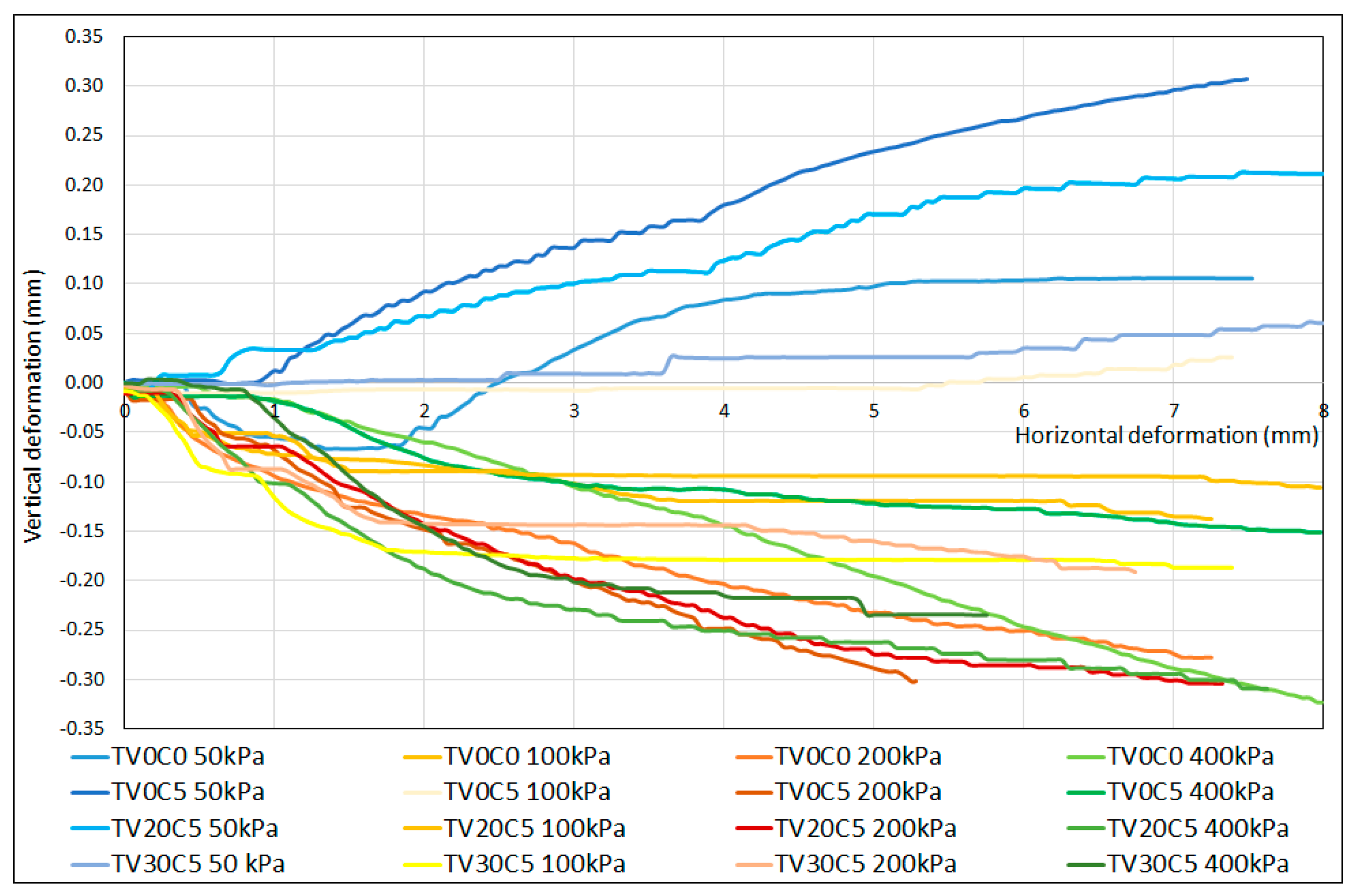

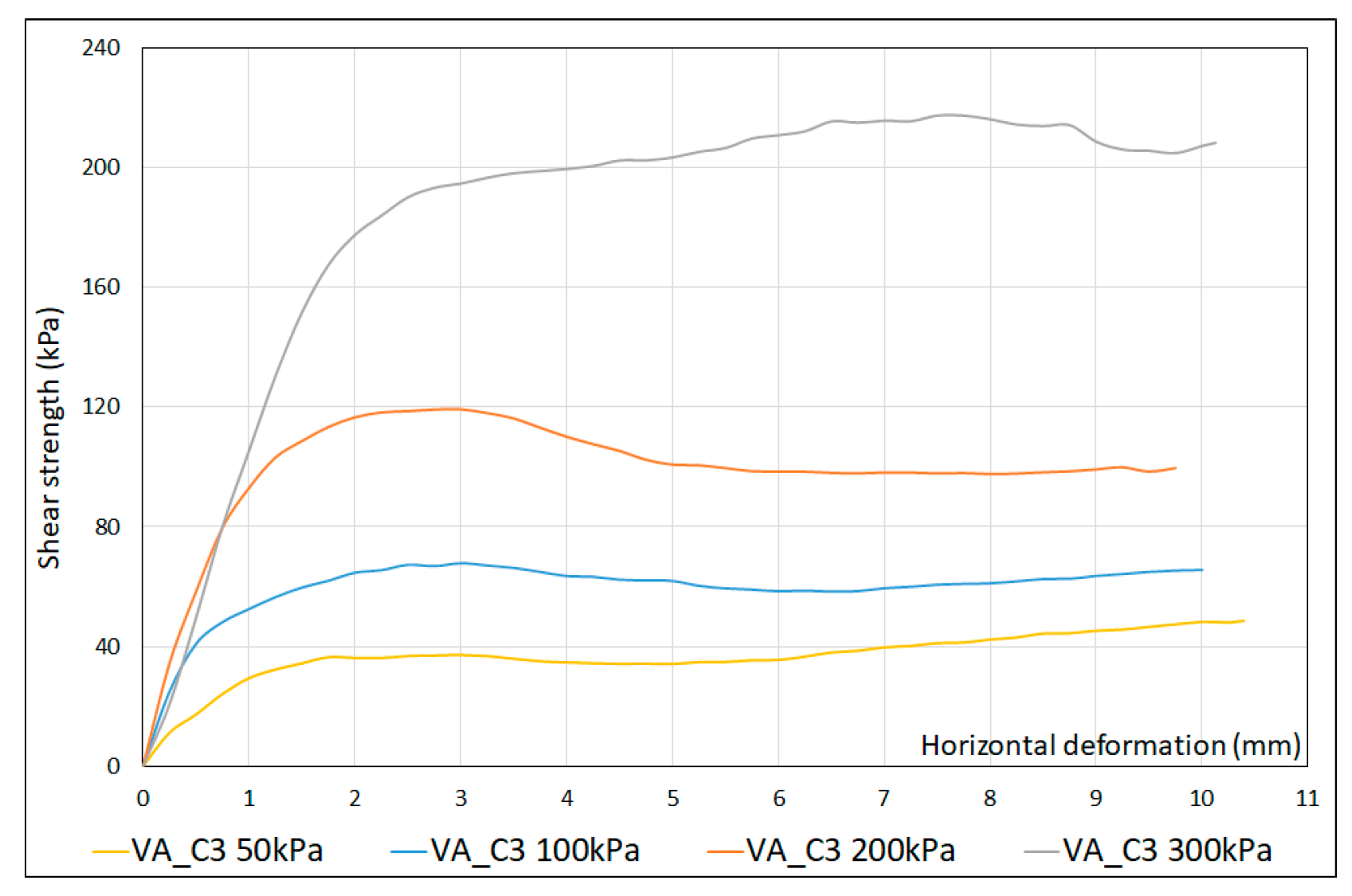

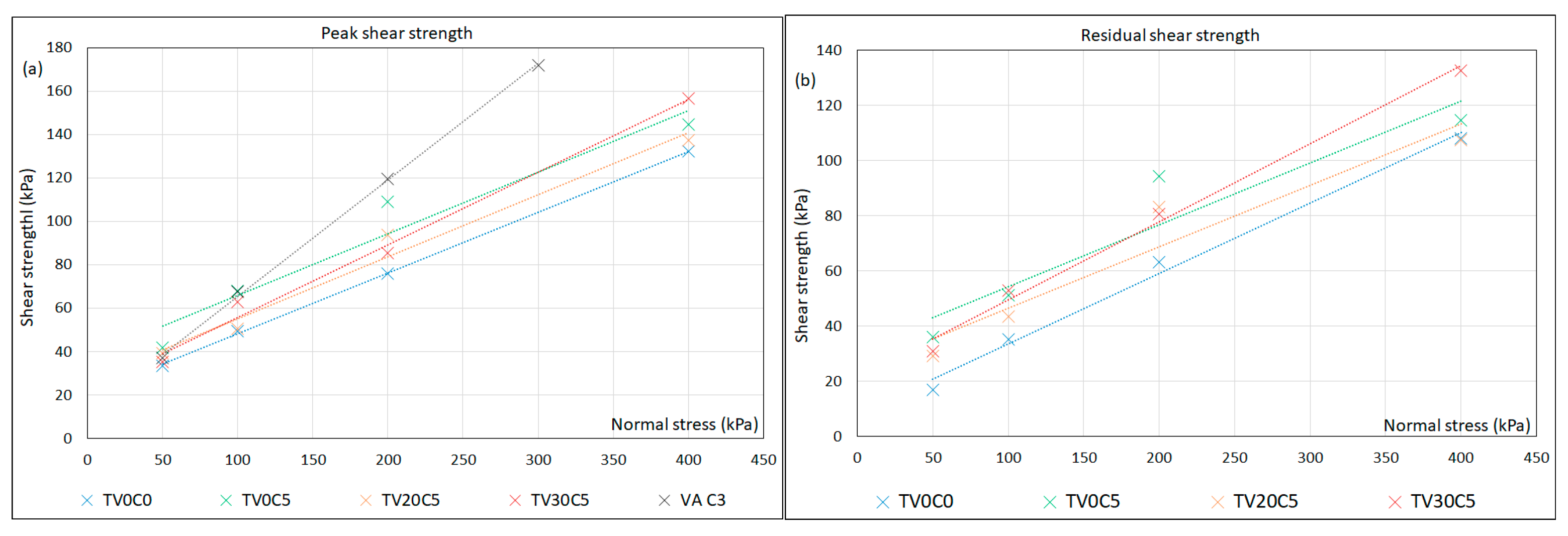

Direct shear tests were performed, using the method described in [

48], on the soil mixtures in circular shear boxes with 50 × 25 mm dimensions under four different vertical confinements, i.e., 50, 100, 200, and 400 kPa, while for VA-C3, a square mold of 60 × 60 mm was used with a vertical confinement of 50, 100, 200, and 300 kPa. The soil mixture specimens were compacted directly in the circular shear box in three layers under the same compaction energy as the one obtained in the compaction test on the natural remolded clay soil to obtain comparable values of moisture content and specific unit dry weight for all samples. The VA-C3 was poured into the square shear box through a funnel to simulate a dry loose state. The saturation and consolidation stages were maintained for all soil mixtures for 24 h, prior to the application of the failure stage. The shear rates applied during the failure stage were 0.003 mm/min and 0.03 mm/min for soil mixtures and VA-C3, respectively, considered as slow velocities in order to simulate consolidated drained conditions. The peak and residual shear strength parameters were determined, i.e., apparent cohesion (c) and friction angle (φ), using the Mohr-Coulomb criterion.

There were two base soils, that were similar in their chemical and mineralogical compositions. The samples of soil mixtures prepared for the Atterberg limits, specific gravity, and compaction tests with the addition of lime (TV0C1, TV0C3, TV0C5) and cement (TV0CEM1, TV0CEM3) were prepared with base soil sample TV0C0, while samples with VA-C3 (TV10C5, TV20C5, TV30C5) were prepared based on TV0C0-2. The specimens of different soil mixtures for the study by oedometer and direct shear tests are all prepared with the base soil TV0C0.

Throughout this report, the results of the laboratory tests corroborating the information cited above are presented. Additionally, the improvement of different geotechnical properties of the swelling clayey soil was effected by the addition of different binders in different proportions.